Study on Inflow Distortion Mechanism and Energy Characteristics in Bidirectional Axial Flow Pumping Station

Abstract

1. Introduction

2. Simulation Model

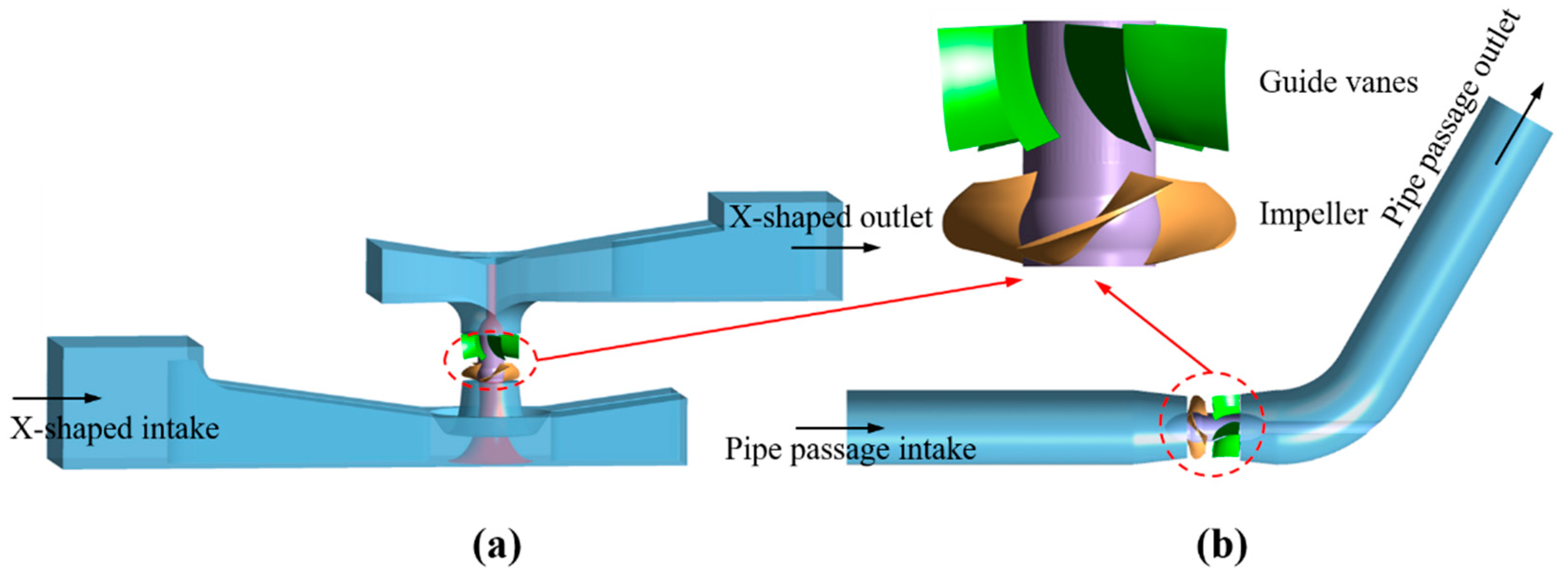

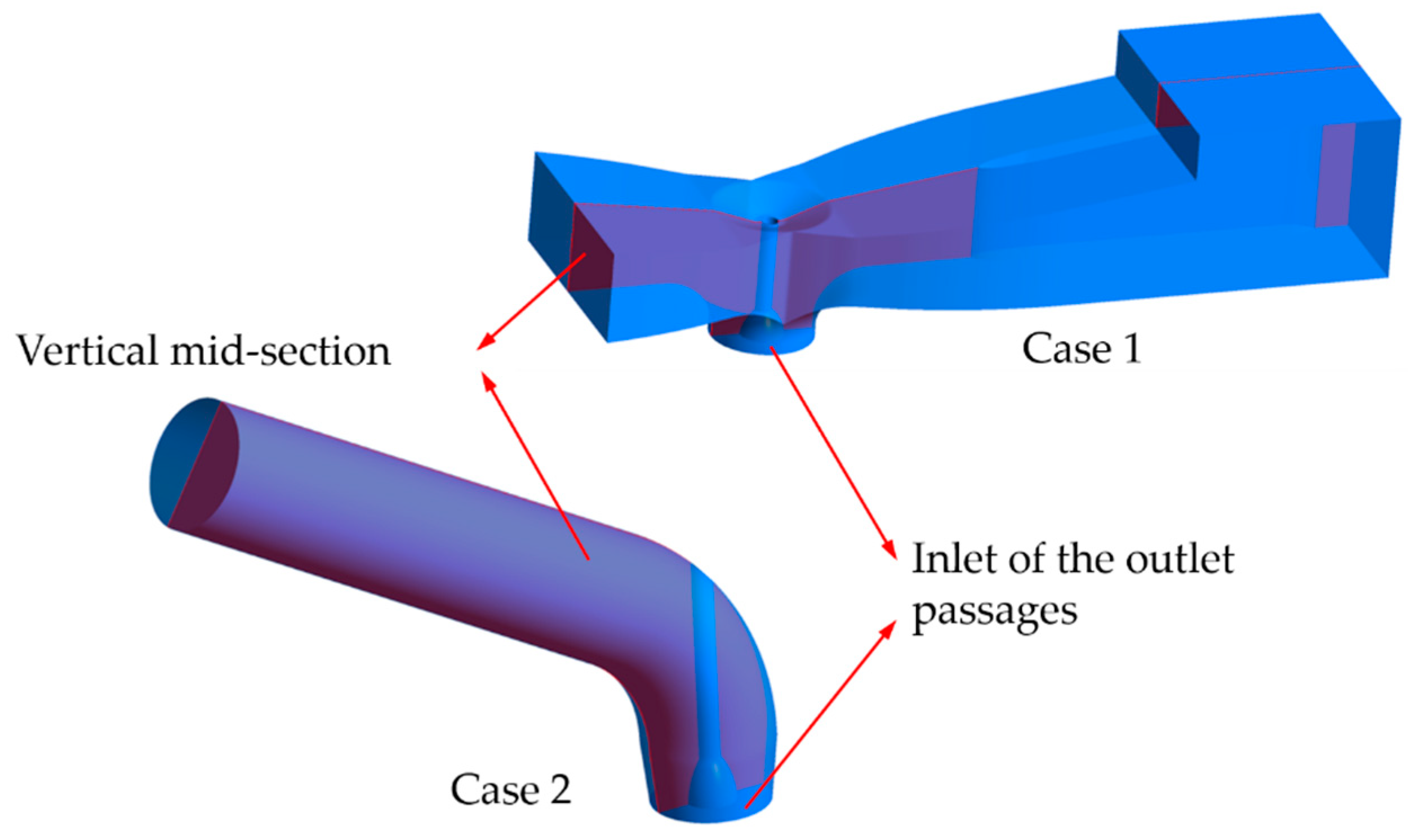

2.1. Pump Models with Bidirectional Passages and Pipe Passages

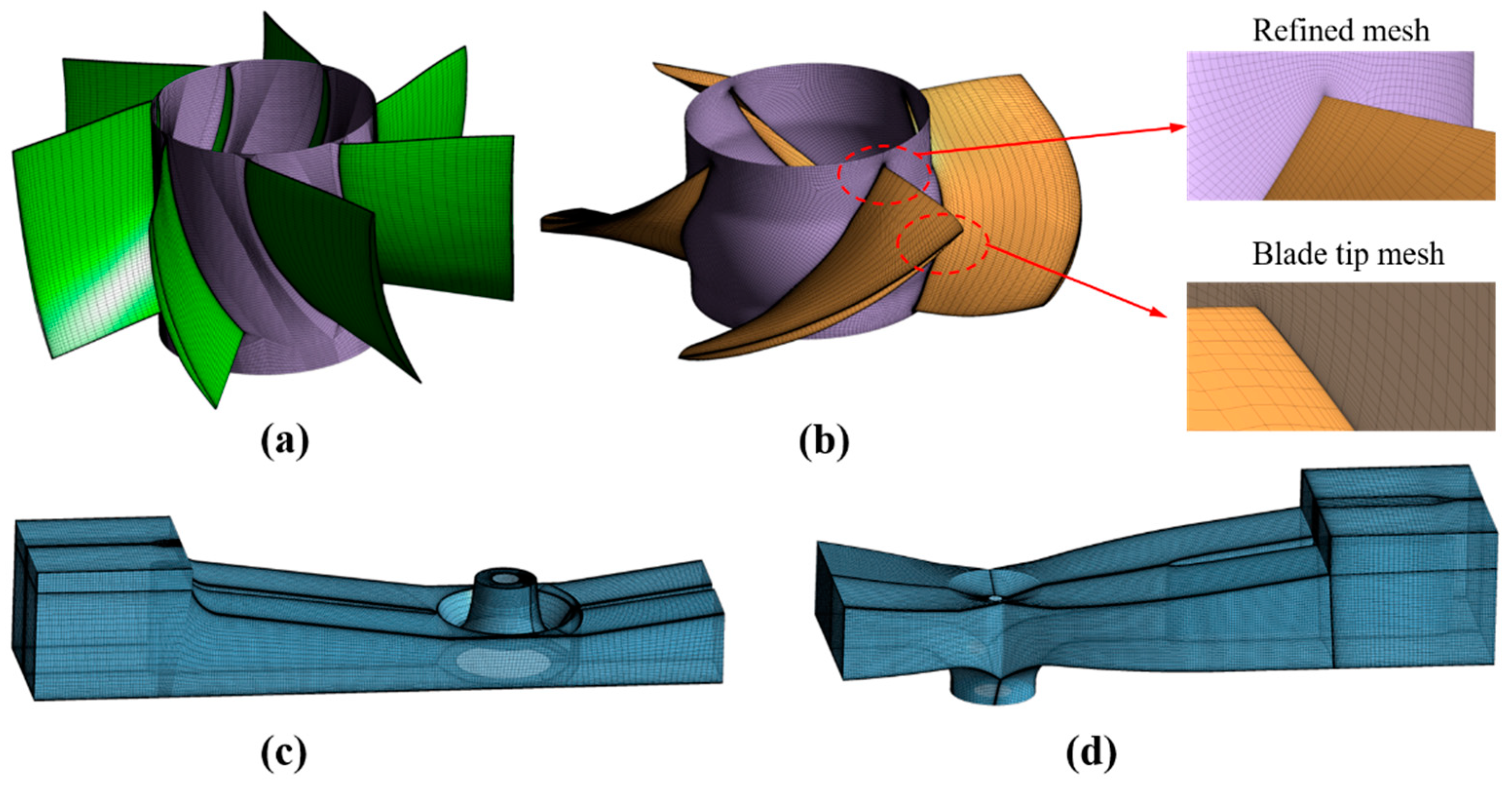

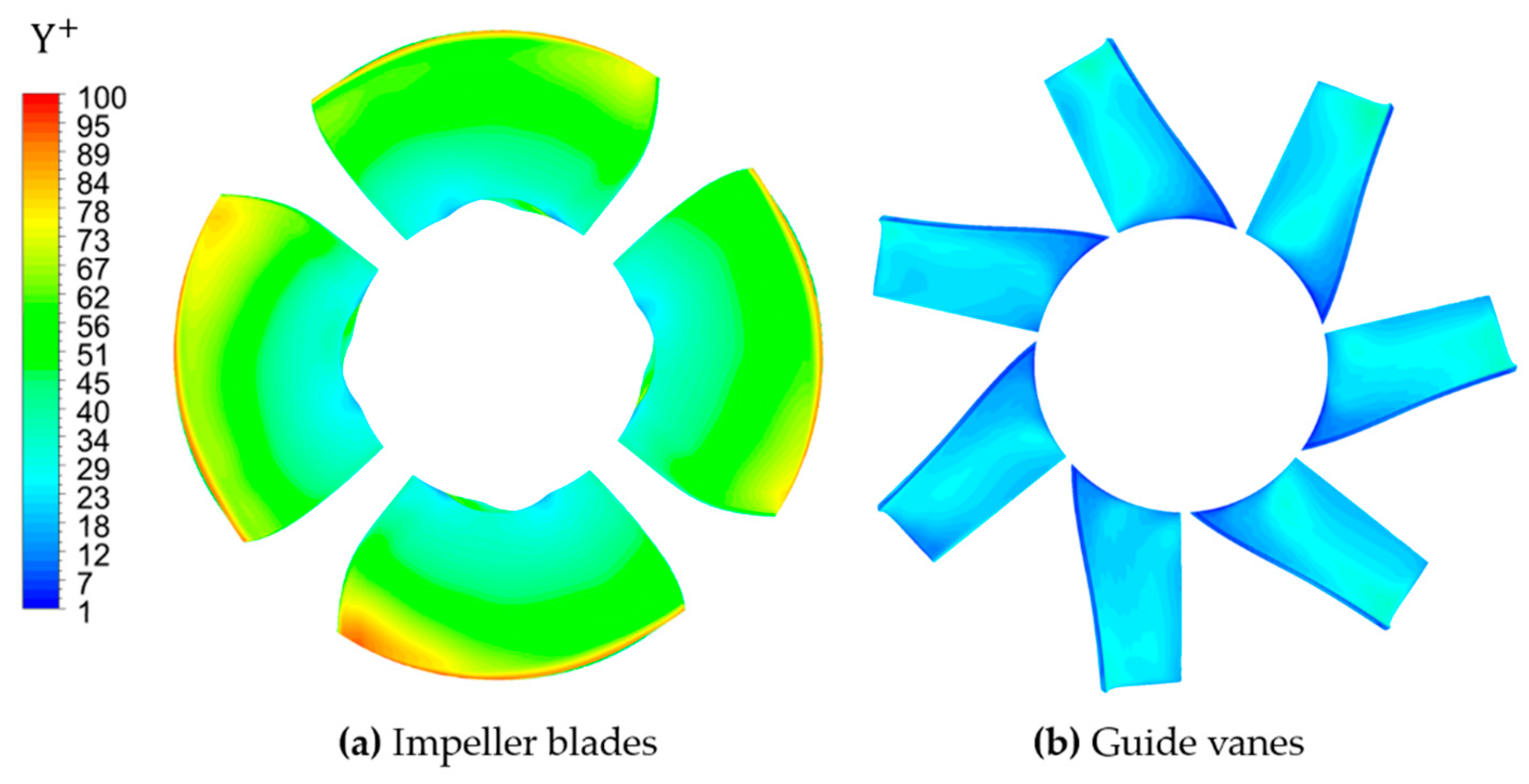

2.2. Mesh Generation

3. Numerical Simulation Method

3.1. Governing Equations and Boundary Conditions

3.2. Entropy Production Theory

4. Results and Discussions

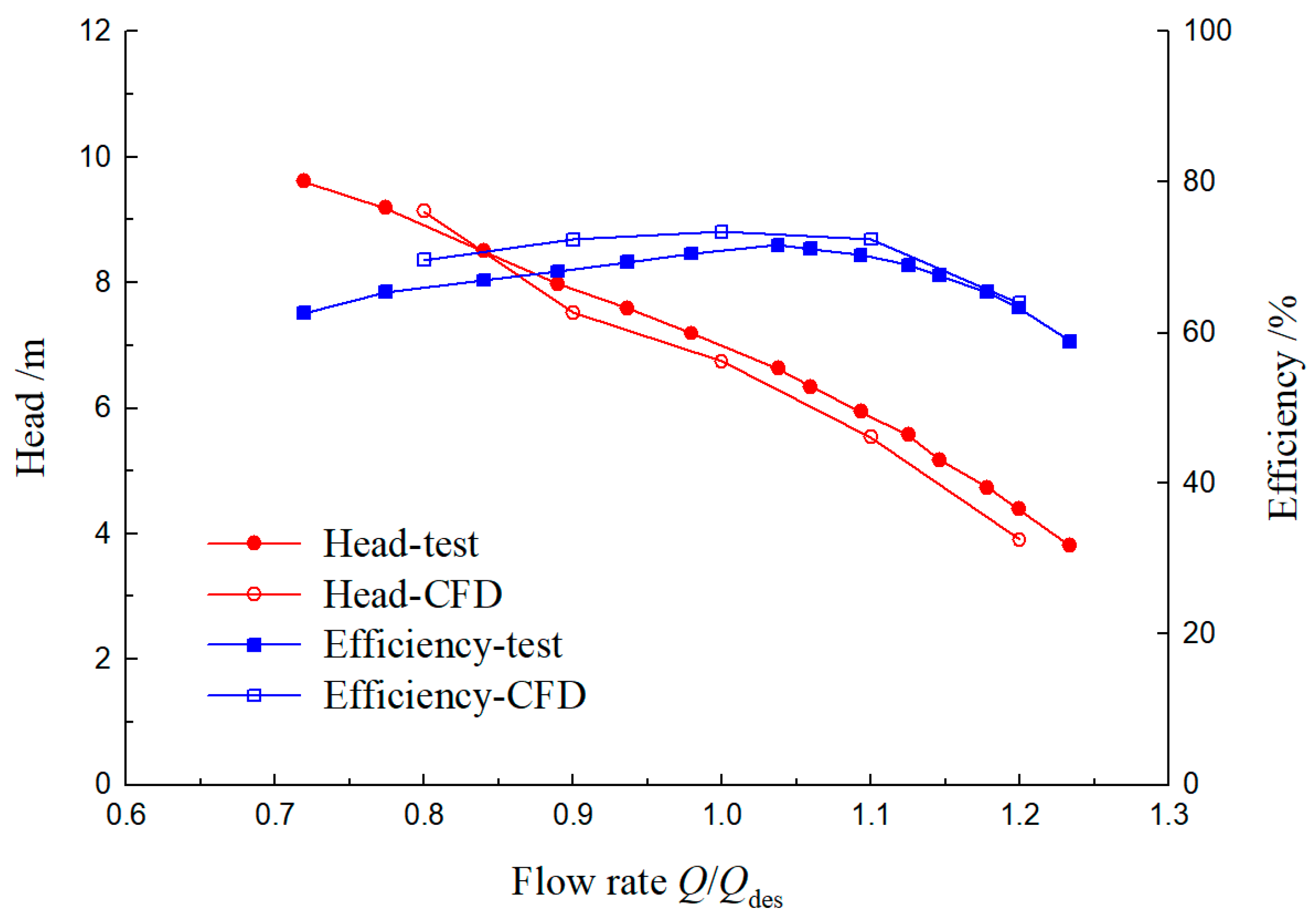

4.1. Pump Performance Verification

4.2. Energy Performance Comparison between the Uniform and Non-Uniform Inflow

4.3. Analysis of Total Entropy Production for Each Case with Different Flow Rates

4.4. Analysis of Total Entropy Production Rate for Each Case with Different Flow Rates

5. Conclusions

- (1)

- The non-uniform inflow in Case 1 plays an important role in the hydraulic performance compared with that in Case 2, and it leads to an obvious reduction in the head and efficiency, especially with a large flow rate of 1.2Qdes. The largest declines in head and efficiency are as high as 27% and 21%, respectively. In addition, for the uniform inflow with Case 2, the optimal efficiency point obviously shifts to the point with a larger flow rate.

- (2)

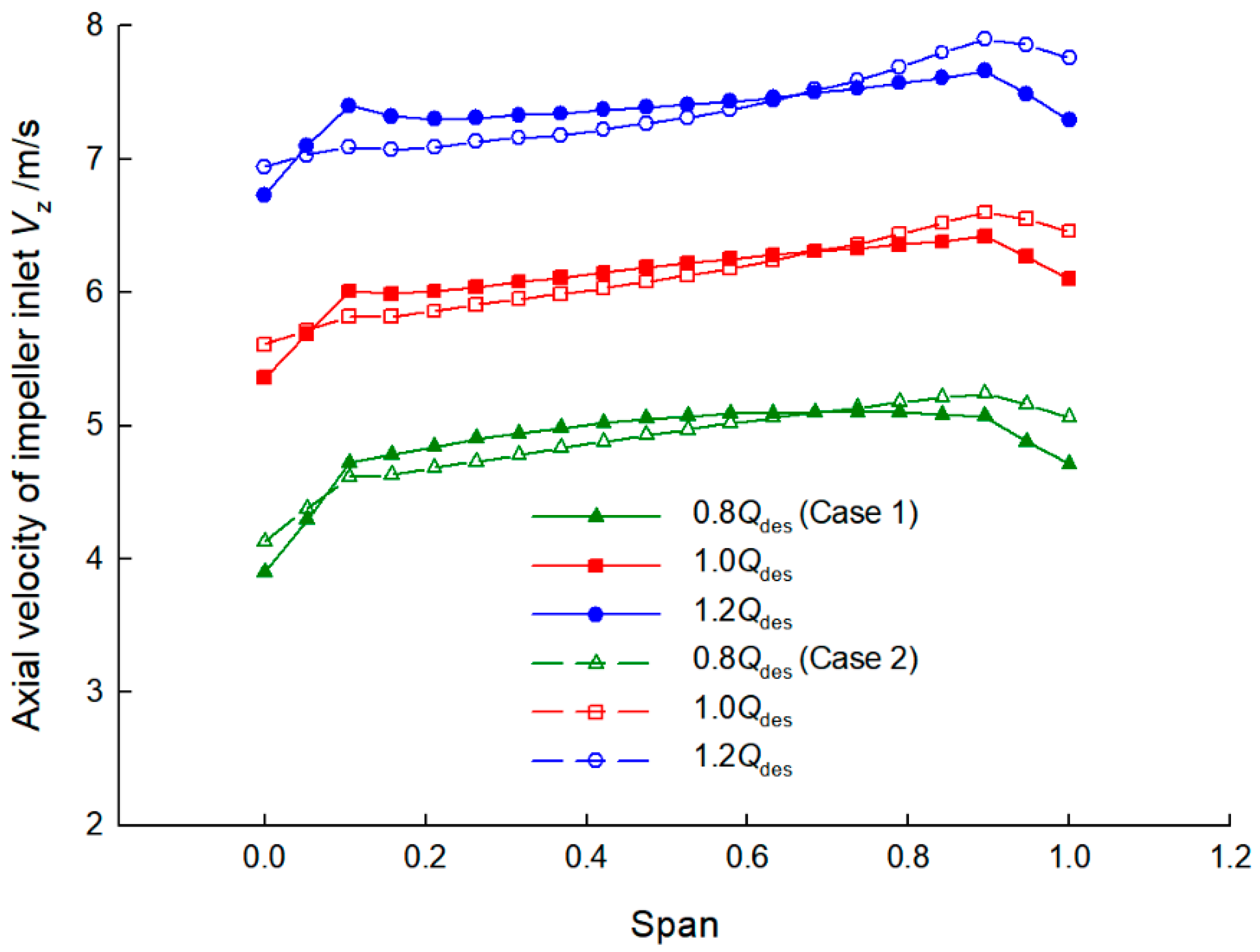

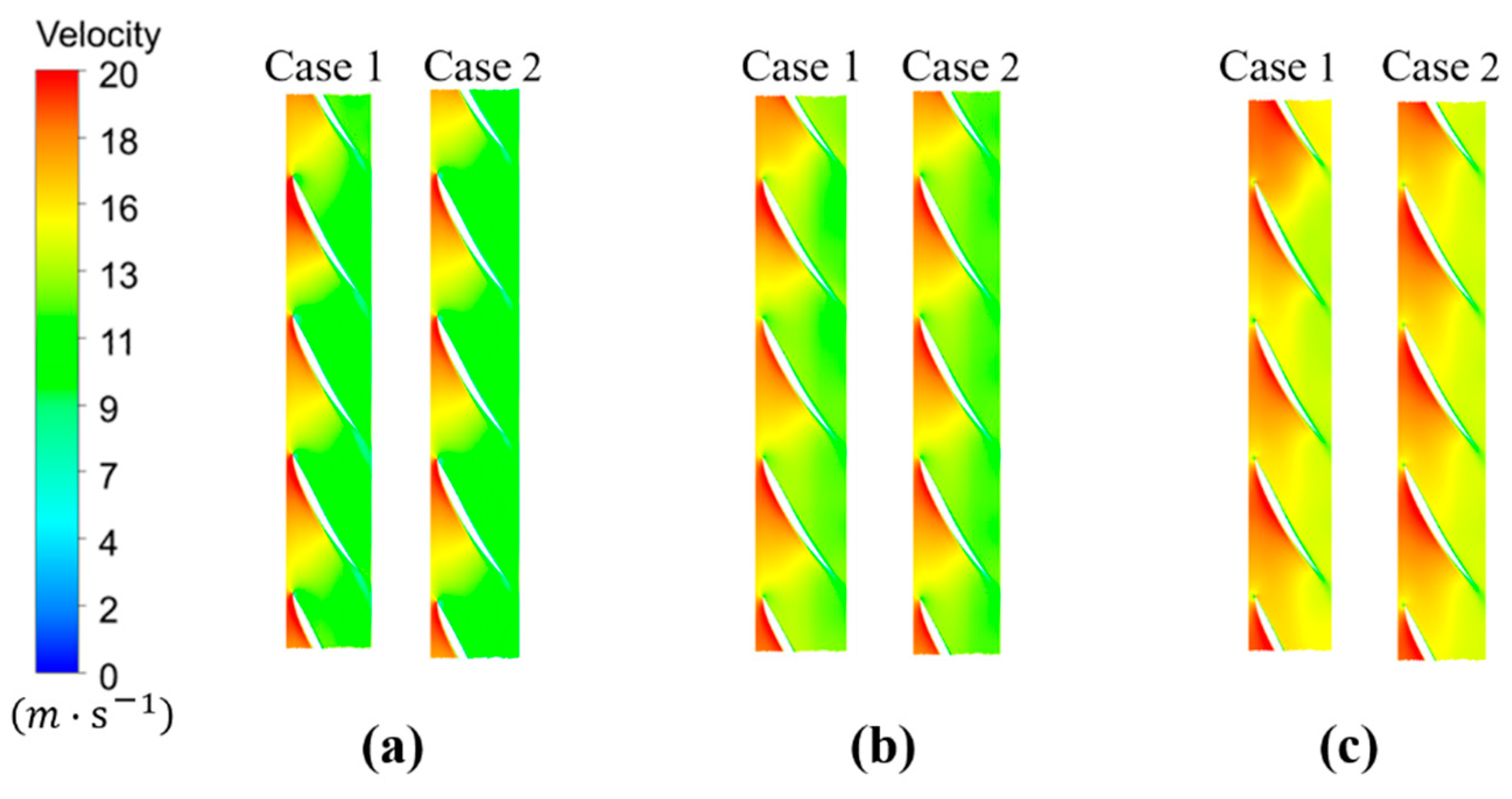

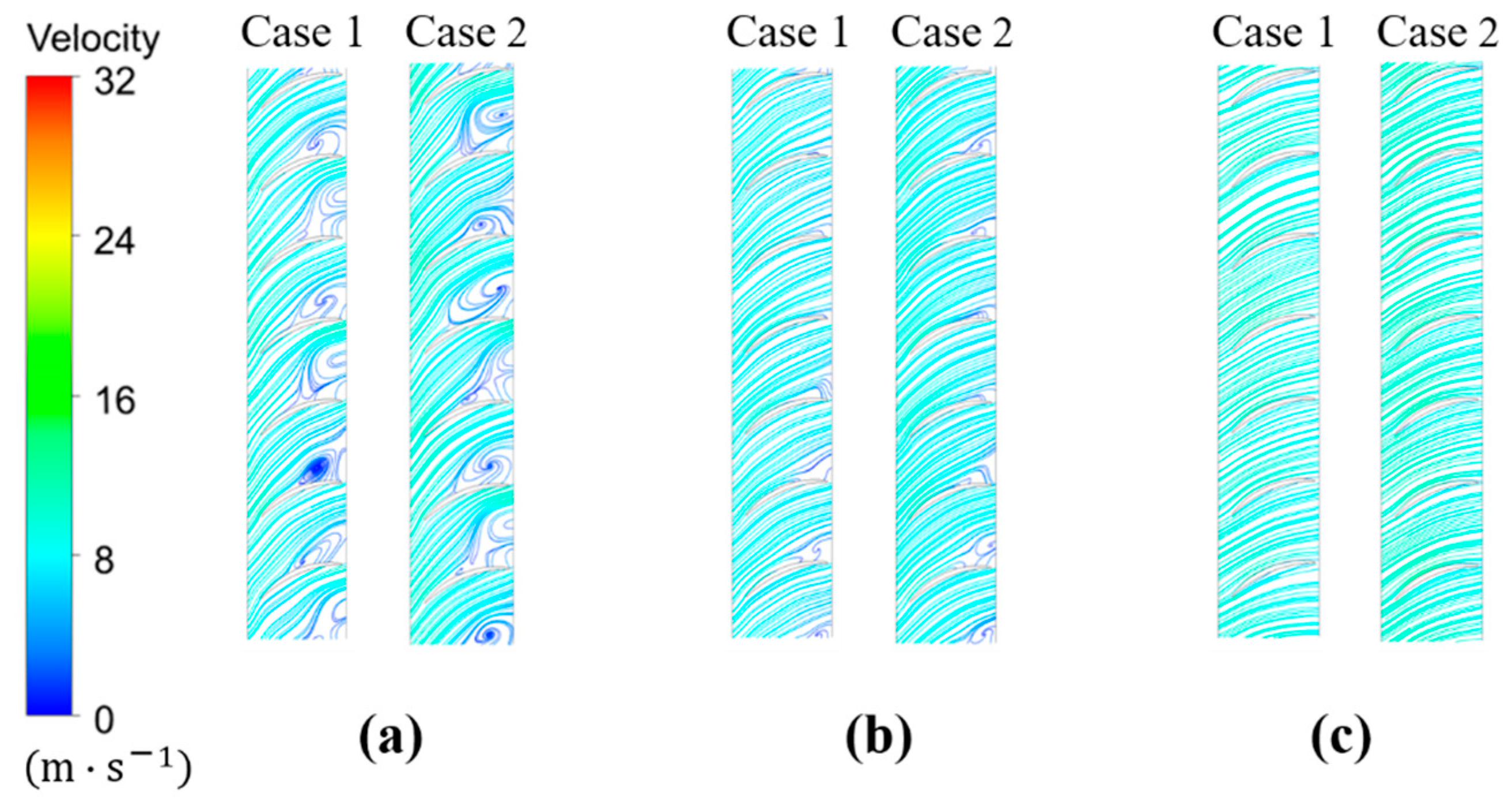

- By comparing the axial velocity of the impeller inlet between Cases 1 and 2, owing to the effects of wall viscous shear and the tip clearance, an increase in axial velocity near the hub and a reduction in axial velocity near the shroud can be observed, and with the presence of bidirectional passages in Case 1, the change in velocity in Case 2 with pipe passages appears more smoothly, which indicates the non-uniform inflow at the impeller inlet in Case 1.

- (3)

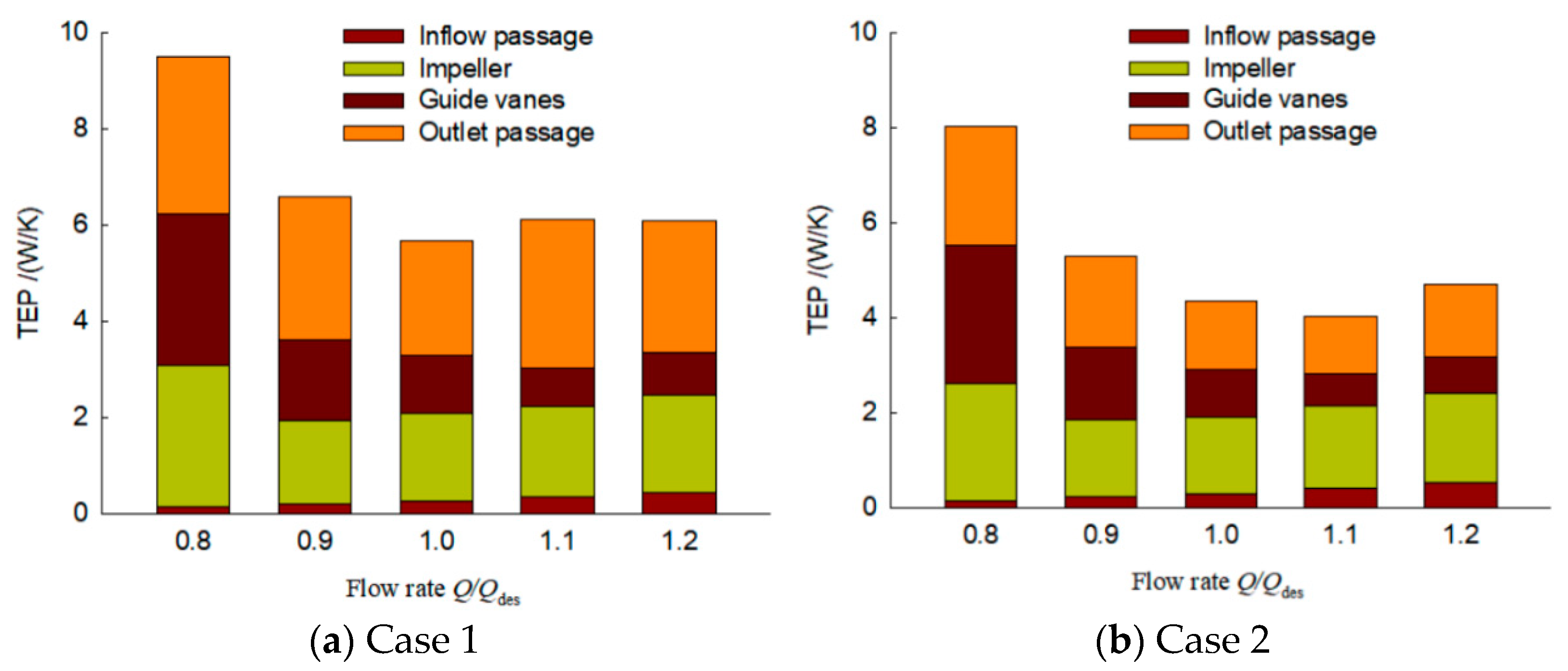

- In both cases, the TEP of the whole computational domain with design flow rate is clearly lower than that with off-design flow rate, and the TEP of the inflow passage of both cases occupies only 2~11%. In addition, the TEP of each component in Case 1 presents a higher value than that in Case 2, and the increase rates of TEP for the whole domain with flow rates of 0.8Qdes, 1.0Qdes, and 1.2Qdes are 18.68%, 30.50% and 29.67%, respectively.

- (4)

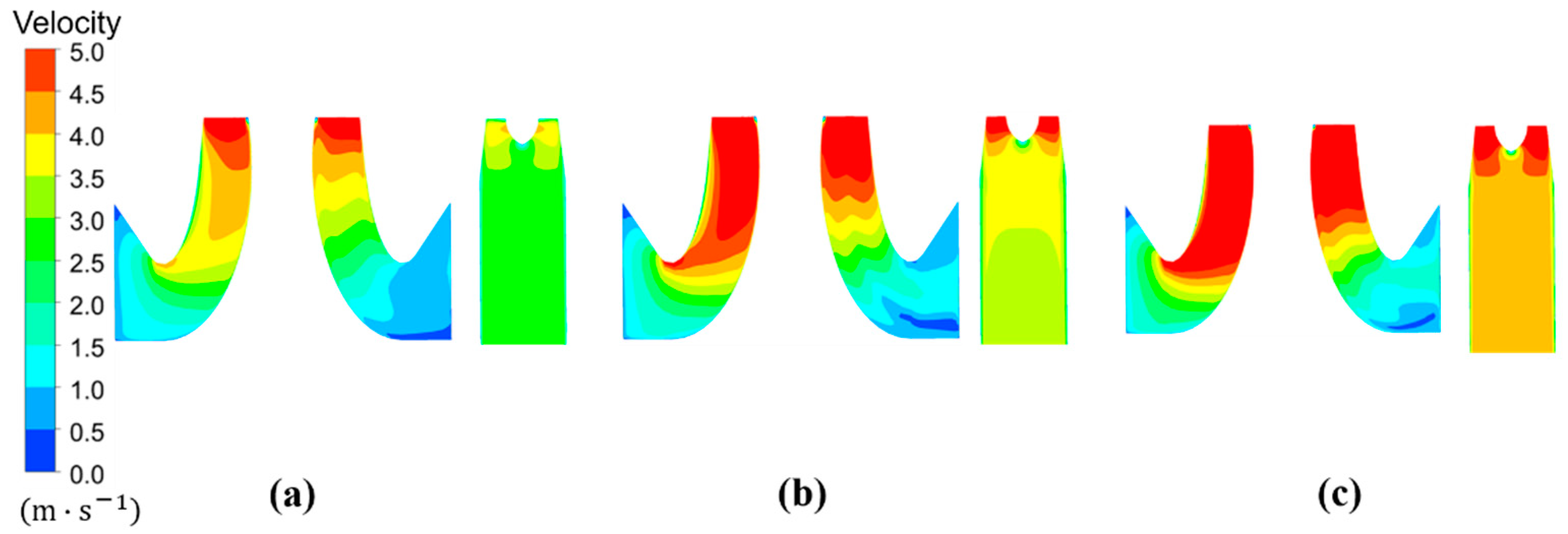

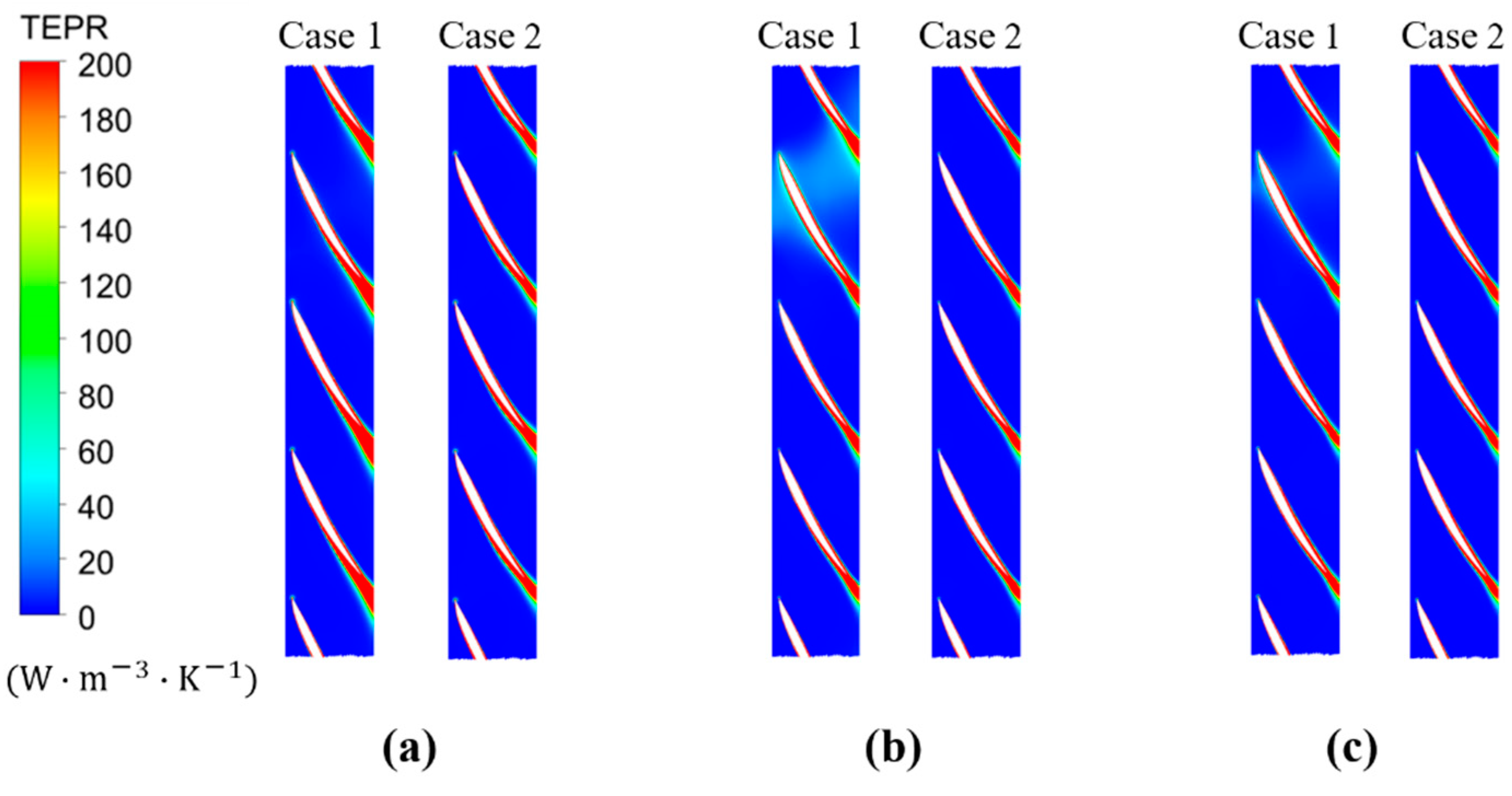

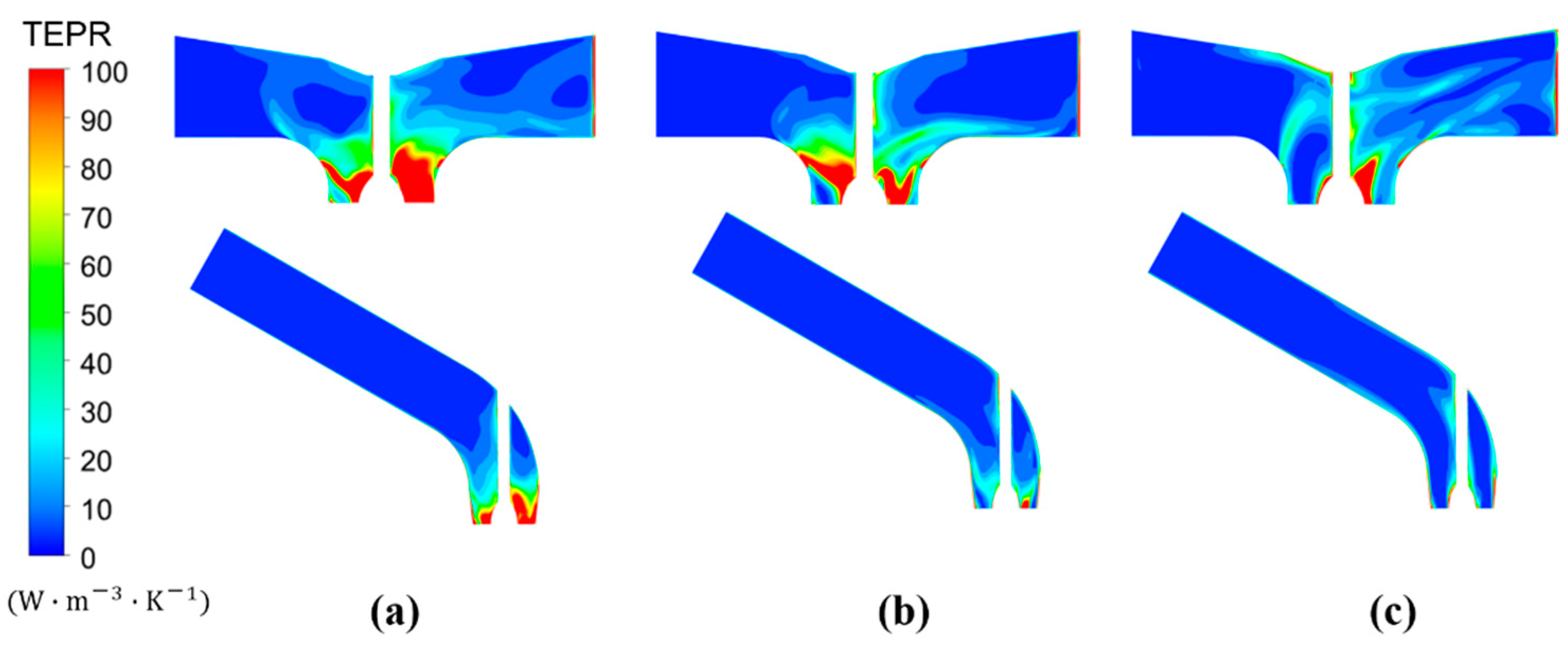

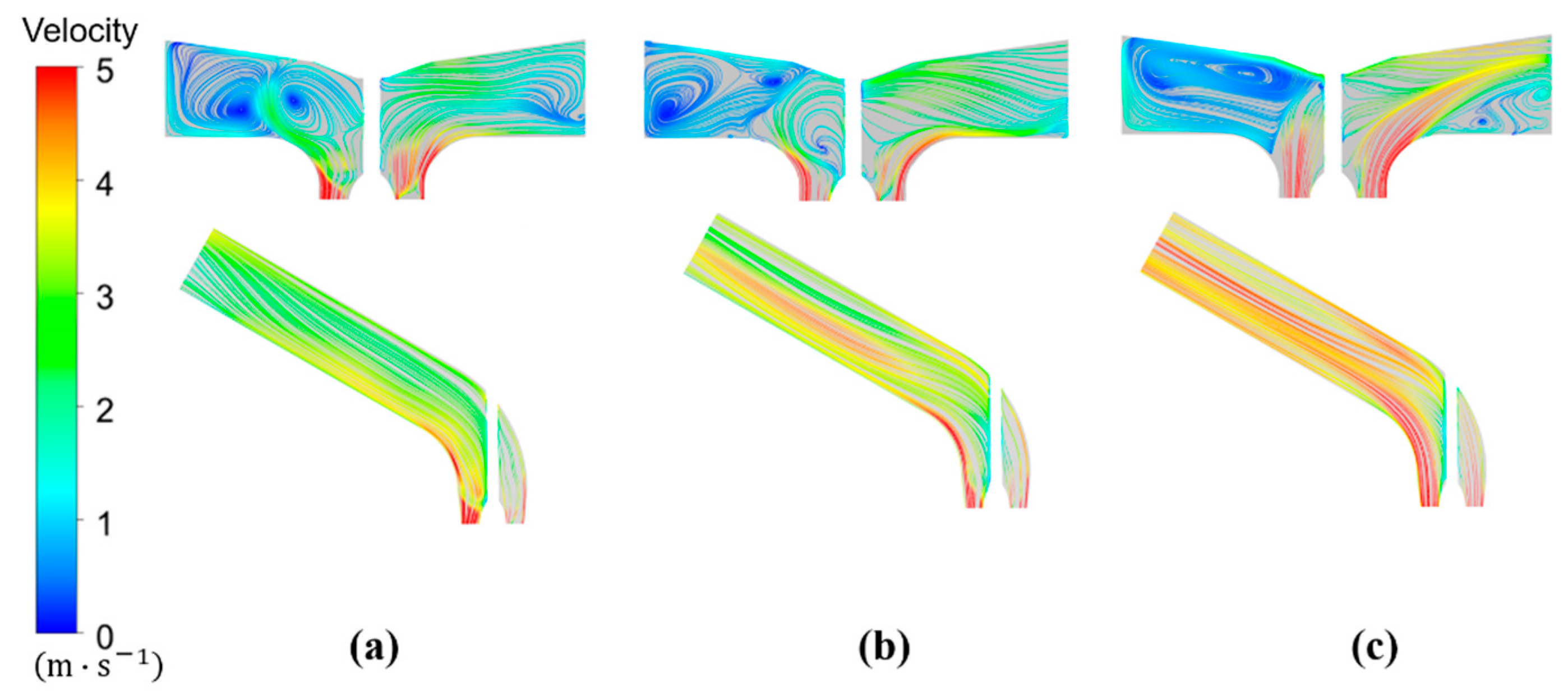

- The TEPR in each domain between Cases 1 and 2 was compared with the capture of the spatial distribution of energy loss caused by flow distortion. In the inlet passage, the high TEPR area is mainly located in the horn passage, which is far away from the inlet side, and it is distributed in the suction side of the impeller blades and guide vanes. In the outlet passage, a larger TEPR region in Case 1 mainly occurs near the inlet of the outlet passages due to the presence of flow separation.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Qdes (m3/s) | Design flow rate |

| (W) | Heat flux |

| t (s) | Time |

| T (K) | Temperature |

| S (J/(kg K)) | Specific entropy |

| (m/s) | Velocity in the x-direction of the Cartesian coordinate system |

| (m/s) | Velocity in the y-direction of the Cartesian coordinate system |

| (m/s) | Velocity in the z-direction of the Cartesian coordinate system |

| (W/(m3)) | Specific entropy production rate |

| (W/(m3)) | Entropy production rate induced by the time-averaged process |

| (W/(m3)) | Entropy production rate induced by the velocity fluctuation |

| (W/) | Total entropy production |

| CFD | Computational fluid dynamics |

| Span | Radial coefficient |

| R (mm) | Radius of the calculated circle |

| Rs (mm) | Shroud radius |

| Rh (mm) | Hub radius |

| Vz (m/s) | Axial velocity of impeller inlet |

| TEP | Total entropy production |

| TEPR | Total entropy production rate |

References

- Mao, Z.; Asai, Y.; Yamanoi, A.; Seki, Y.; Wiranata, A.; Minaminosono, A. Fluidic rolling robot using voltage-driven oscillating liquid. Smart Mater. Struct. 2022, 31, 105006. [Google Scholar] [CrossRef]

- Satoh, A.; Katoh, K. An Experimental Study for Clarifying the Mechanism of a Microjet in an Electro-Conjugate Fluid by the 2D PIV Analysis. In Proceedings of the International Conference of Fluid Power and Mechatronics, Beijing, China, 17–20 August 2011. [Google Scholar]

- Laser, D.J.; Santiago, J.G. A review of micropumps. J. Micromech. Microeng. 2004, 14, R35. [Google Scholar] [CrossRef]

- Meng, F.; Yuan, S.; Li, Y. Fluid-structure coupling analysis of impeller in unstable region for a reversible axial-flow pump device. Adv. Mech. Eng. 2018, 10, 1687814017751762. [Google Scholar] [CrossRef]

- Lei, X.; Tian, Y.; Zhang, Z.; Wang, L.; Xi, X.; Wang, H. Correction of pumping station parameters in a one-dimensional hydrodynamic model using the Ensemble Kalman filter. J. Hydrol. 2019, 568, 108–118. [Google Scholar] [CrossRef]

- Li, Y.; Lu, R.; Zhang, H.; Deng, F.; Yuan, J. Improvement of intake structures in a two-way pumping station with experimental analysis. Appl. Sci. 2020, 10, 6842. [Google Scholar] [CrossRef]

- Meng, F.; Qin, Z.; Li, Y.; Chen, J. Investigation of transient characteristics of a vertical axial-flow pump with non-uniform suction flow. Machines 2022, 10, 855. [Google Scholar] [CrossRef]

- Tang, F.; Yuan, J.; Zhou, J. Influence of water inlet channel on pump performance. Pump Technol. 1994, 20–21. [Google Scholar]

- Qiu, B.; Lin, H.; Huang, J.; Feng, X. Study on flow field in blade inlet of large vertical axial-flow pump and its influence on pump. J. Mech. Eng. 2005, 41, 28–34. [Google Scholar] [CrossRef]

- Cao, P.; Yin, G.; Wang, Y.; Li, G.; Wu, W. Numerical analysis of double tornado-type separation vortices in centrifugal pump. Trans. Chin. Soc. Agric. Mach. 2016, 47, 22–28. [Google Scholar]

- Van Esch, B.P.M. Performance and radial loading of a mixed-flow pump under non-uniform suction flow. J. Fluid. Eng. 2009, 131, 051101. [Google Scholar] [CrossRef]

- Lu, L.; Liu, C.; Chen, Y. Influence of inlet channel on hydraulic performance of axial flow pump. Pump Tech. 1997, 25–26, 39. [Google Scholar]

- Xu, Z.; Fan, Y.; Liu, S.; Wu, Y. 2D PIV experiments on non-uniform flow in a rectangular open model pump suction passage. In Proceedings of the ASME 2005 International Mechanical Engineering Congress and Exposition, Orlando, FL, USA, 5–11 November 2005. [Google Scholar]

- Wang, Y.; Wang, P.; Tan, X.; Xu, Z.; Ruan, X. Research on the non-uniform inflow characteristics of the canned nuclear coolant pump. Ann. Nucl. Energy 2018, 115, 423–429. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, P.; Yin, G.; Li, G. Flow feature and blade loading of a water-jet pump under non-uniform suction flow. J. Propuls. Technol. 2017, 38, 69–75. [Google Scholar]

- Jin, S.; Cao, P.; Wang, Y. Numerical analysis on velocity field of water- jet pump under non-uniform inflow. J. Drain. Irrig. Mach. Eng. 2016, 34, 115–121. [Google Scholar]

- Bulten, N.W.H. Numerical Analysis of a Waterjet Propulsion System; Technische Universiteit Eindhoven: Eindhoven, The Netherlands, 2006. [Google Scholar]

- Kock, F.; Herwig, H. Local entropy production in turbulent shear flows: A high-Reynolds number model with wall functions. Int. J. Heat Mass Transf. 2004, 47, 2205–2215. [Google Scholar] [CrossRef]

- Kock, F.; Herwig, H. Entropy production calculation for turbulent shear flows and their implementation in CFD codes. Int. J. Heat Fluid Flow 2005, 26, 672–680. [Google Scholar] [CrossRef]

- Herwig, H.; Kock, F. Direct and indirect methods of calculating entropy generation rates in turbulent convective heat transfer problems. Heat Mass Transf. 2007, 43, 207–215. [Google Scholar] [CrossRef]

- Ji, L.; Li, W.; Shi, W.; Chang, H.; Yang, Z.; Lund, H.; Kaiser, M.J. Energy characteristics of mixed-flow pump under different tip clearances based on entropy production analysis. Energy 2020, 199, 117447.1–117447.15. [Google Scholar] [CrossRef]

- Zhang, H.; Zang, J.; Zhang, D.; Shi, W.; Shen, J. Analysis of the formation mechanism of secondary tip leakage vortex (S-TLV) in an axial flow pump. Machines 2022, 10, 41. [Google Scholar] [CrossRef]

- Bejan, A. General criterion for rating heat-exchanger performance. Int. J. Heat Mass Transf. 1978, 21, 655–658. [Google Scholar] [CrossRef]

- Shen, S.; Qian, Z.; Ji, B. Numerical analysis of mechanical energy dissipation for an axial-flow pump based on entropy generation theory. Energies 2019, 12, 4162. [Google Scholar] [CrossRef]

- Böhle, M.; Fleder, A.; Mohr, M. Study of the losses in fluid machinery with the help of entropy. In Proceedings of the 16th International Symposium on Transport Phenomena and Dynamics of Rotating Machinery, Honolulu, HI, USA, 10–15 April 2016. [Google Scholar]

- Li, X.; Zhu, Z.; Li, Y.; Chen, X. Experimental and numerical investigations of head-flow curve instability of a single-stage centrifugal pump with volute casing. Proc. Inst. Mech. Eng. Part A-J. Power 2016, 230, 633–647. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, Y.; Zhu, G.; Li, Y.; Li, W.; Luo, X. Transition process characteristics of centrifugal pump with power-off based on entropy production theory. Trans. Chin. Soc. Agric. Eng. 2020, 36, 10–17. [Google Scholar]

- Zhang, D.; Wu, S.; Shi, W.; Pan, D.; Zhang, G. Application and experiment of different turbulence models for simulating tip leakage vortex in axial flow pump. Trans. Chin. Soc. Agric. Eng. 2013, 29, 46–53. [Google Scholar]

- Yang, X.; Yu, Y.; Dong, L.; Zhu, X. Study of improvement of flow pattern in side-inlet pumping station based on SST k-ω turbulence model. J. China Three Gorges Univ. (Nat. Sci.) 2018, 40, 1–4. [Google Scholar]

- Bejan, A. Entropy Production through Heat and Fluid Flow; John Wiley & Sons: New York, NY, USA, 1994. [Google Scholar]

| Parameter | Value | Unit |

|---|---|---|

| Design operation point | ||

| Design flow rate | 0.324 | m3/s |

| Design head | 6.75 | m |

| Rotation speed | 1409 | r/min |

| Specific speed | 699.03 | - |

| Impeller | ||

| Number of impeller blade | 4 | - |

| Impeller diameter | 300 | mm |

| Hub diameter | 145.71 | mm |

| Tip clearance | 0.2 | mm |

| Guide vanes | ||

| Number of guide vane blades | 7 | - |

| Inlet diameter | 292 | mm |

| Outlet diameter | 311 | mm |

| Hub diameter | 135.74 | mm |

| Flow Rate Q/Qdes | 0.8 | 0.9 | 1.0 | 1.1 | 1.2 |

|---|---|---|---|---|---|

| TEP of Case 1 (W/K) | 9.52 | 6.60 | 5.69 | 6.13 | 6.10 |

| TEP of Case 2 (W/K) | 8.02 | 5.31 | 4.36 | 4.03 | 4.71 |

| Increase rate (%) | 18.68 | 24.38 | 30.50 | 52.15 | 29.67 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Zhang, H.; Li, Y.; Meng, F.; Zheng, Y. Study on Inflow Distortion Mechanism and Energy Characteristics in Bidirectional Axial Flow Pumping Station. Machines 2022, 10, 1014. https://doi.org/10.3390/machines10111014

Chen J, Zhang H, Li Y, Meng F, Zheng Y. Study on Inflow Distortion Mechanism and Energy Characteristics in Bidirectional Axial Flow Pumping Station. Machines. 2022; 10(11):1014. https://doi.org/10.3390/machines10111014

Chicago/Turabian StyleChen, Jia, Huiyan Zhang, Yanjun Li, Fan Meng, and Yunhao Zheng. 2022. "Study on Inflow Distortion Mechanism and Energy Characteristics in Bidirectional Axial Flow Pumping Station" Machines 10, no. 11: 1014. https://doi.org/10.3390/machines10111014

APA StyleChen, J., Zhang, H., Li, Y., Meng, F., & Zheng, Y. (2022). Study on Inflow Distortion Mechanism and Energy Characteristics in Bidirectional Axial Flow Pumping Station. Machines, 10(11), 1014. https://doi.org/10.3390/machines10111014