Actuators and Sensors for Application in Agricultural Robots: A Review

Abstract

1. Introduction

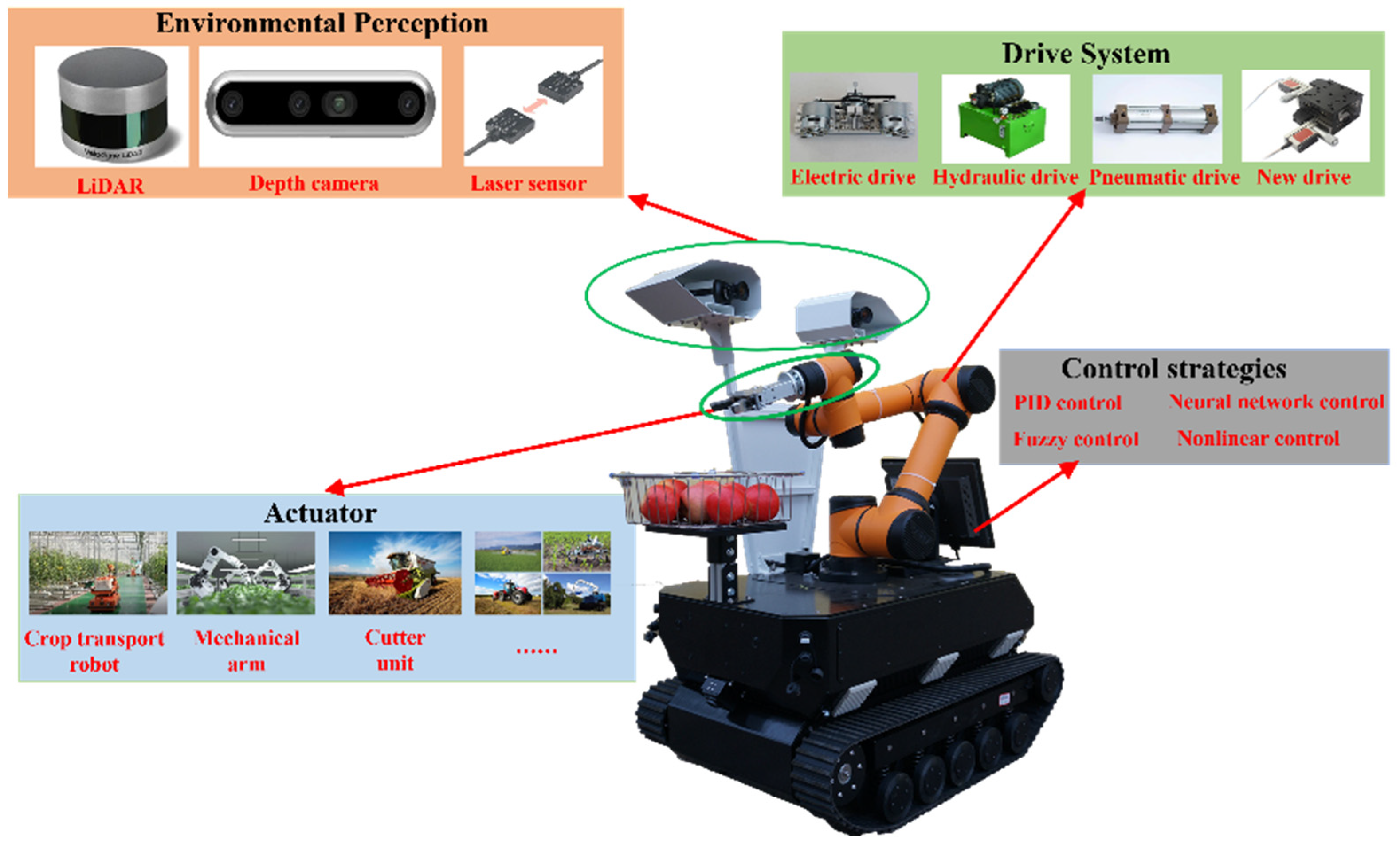

2. Executive Components

2.1. Drive System

2.1.1. Electrical Transmission Systems

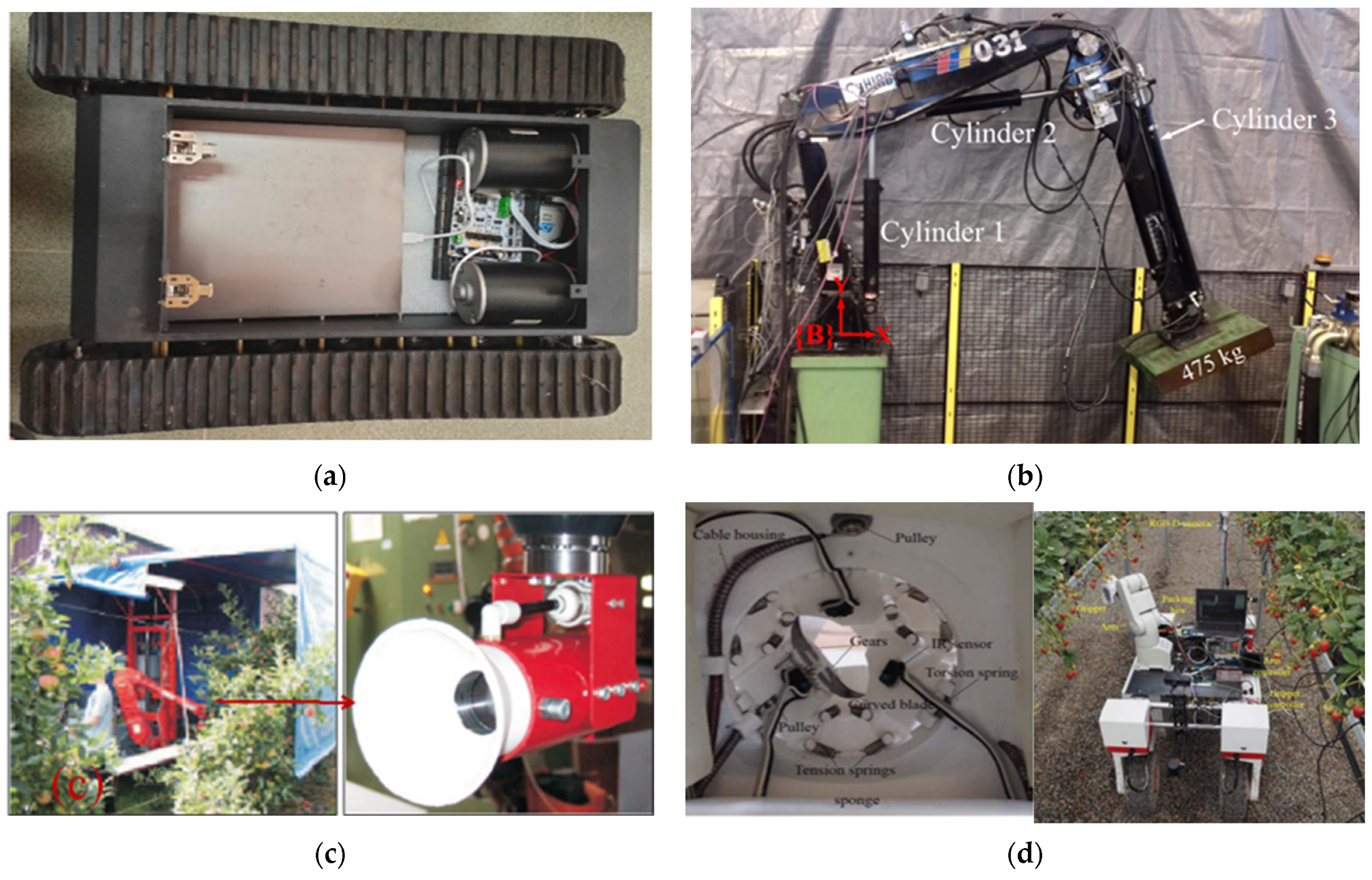

2.1.2. Hydraulic Drive Systems

2.1.3. Pneumatic Actuator

2.1.4. New Driving Device

2.2. Control Strategy

| Control Strategy | Advantage | Disadvantage | Application Situation |

|---|---|---|---|

| Proportional, integral, differential (PID) control method | Simple to use, flexible, and easy to adjust | The adjustment accuracy is not high, and not precise enough |  a: Automatica-following agricultural robots [79] |

| Fuzzy control method | Strong robustness and fault tolerance | Lack of systematicness, low control precision and dynamic quality |  b: Autonomous mobile agricultural robot [80] |

| Sliding mode control method | Fast response, excellent tracking, strong robustness against external disturbances and parametric uncertainties | The discontinuous switching characteristics can cause chattering in the system. |  c: Self-propelled crawler plant protection robot [56] |

2.2.1. PID Control

2.2.2. Fuzzy Control

2.2.3. Nonlinear Control

3. Application Scenarios in Agriculture

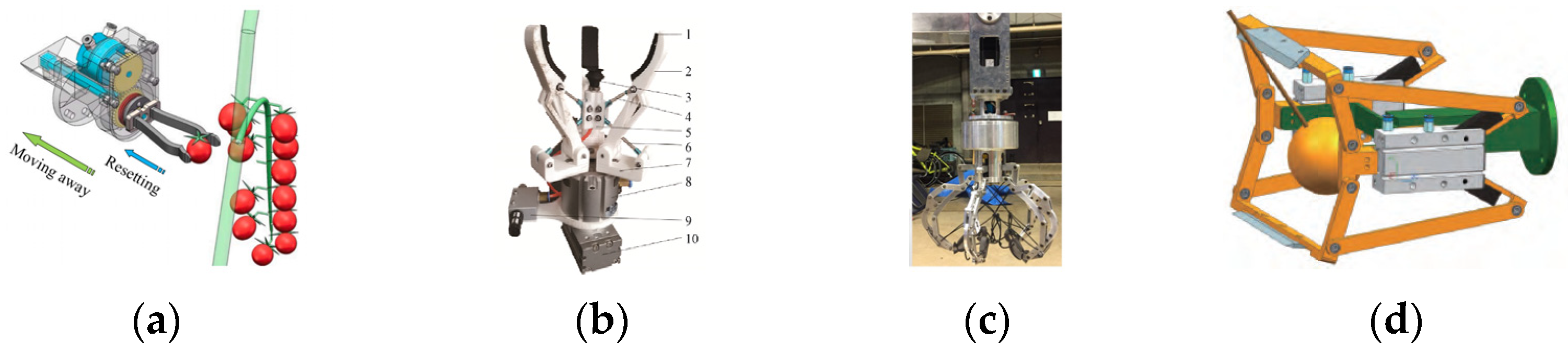

3.1. End-Effector Applications in Agricultural Robots

3.1.1. Clamping Mechanism

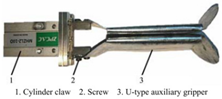

3.1.2. Cut-Off Mechanism

3.1.3. Absorption Mechanism

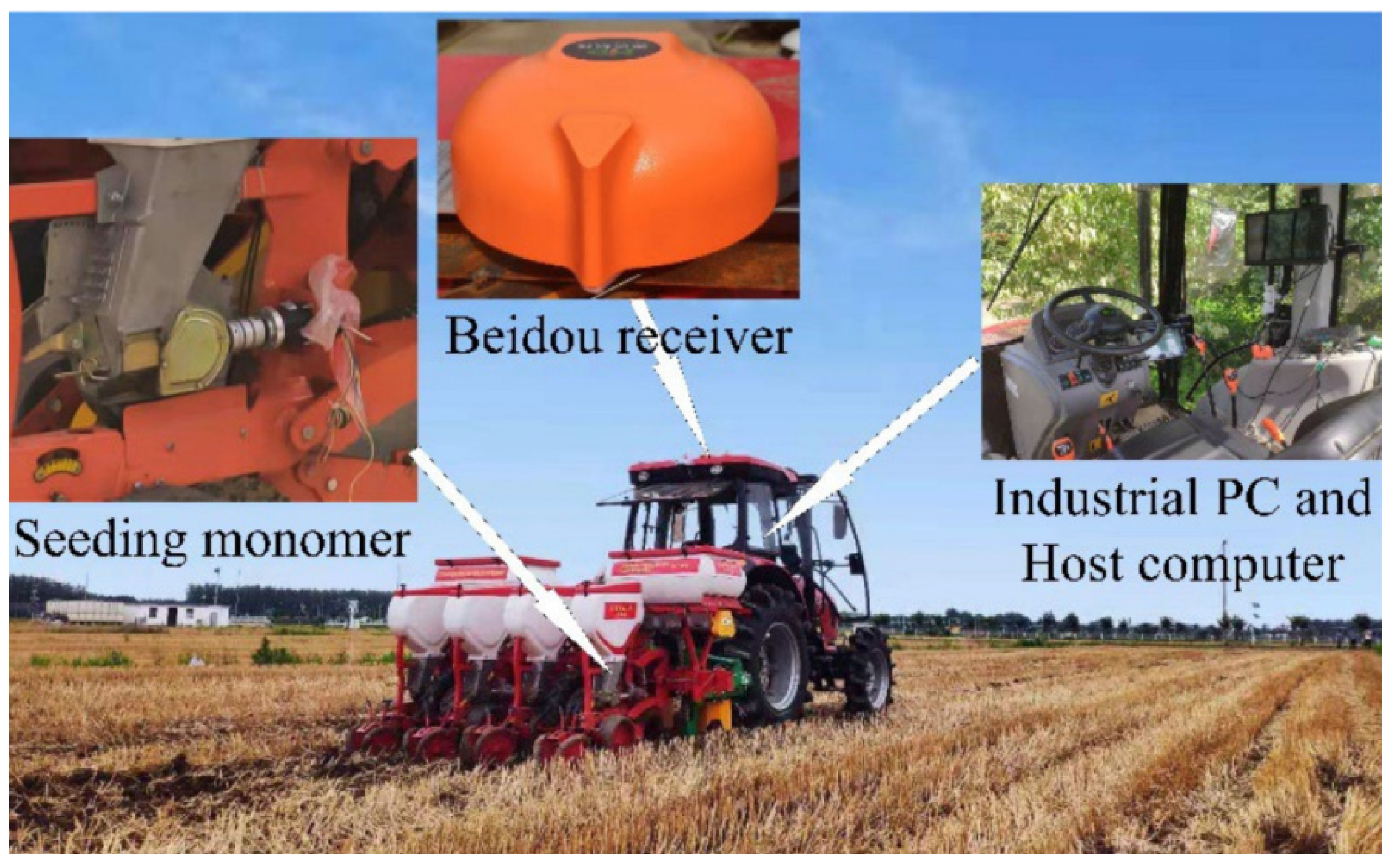

3.1.4. Press-In Mechanism

3.1.5. Other Mechanisms for End-Effectors

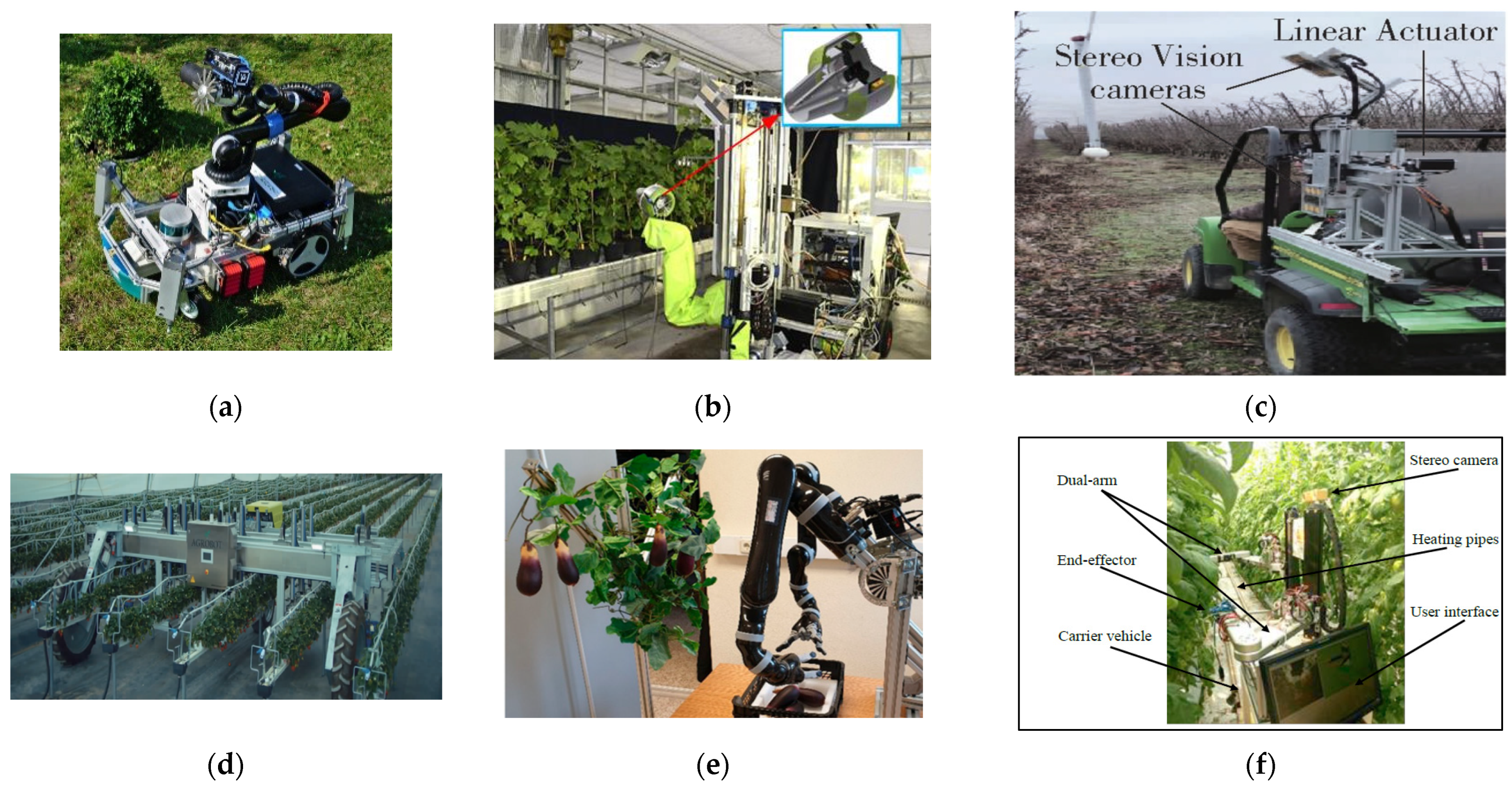

3.2. Robot Arms Applied in Agricultural Robots

4. Assistive Technologies and Systems

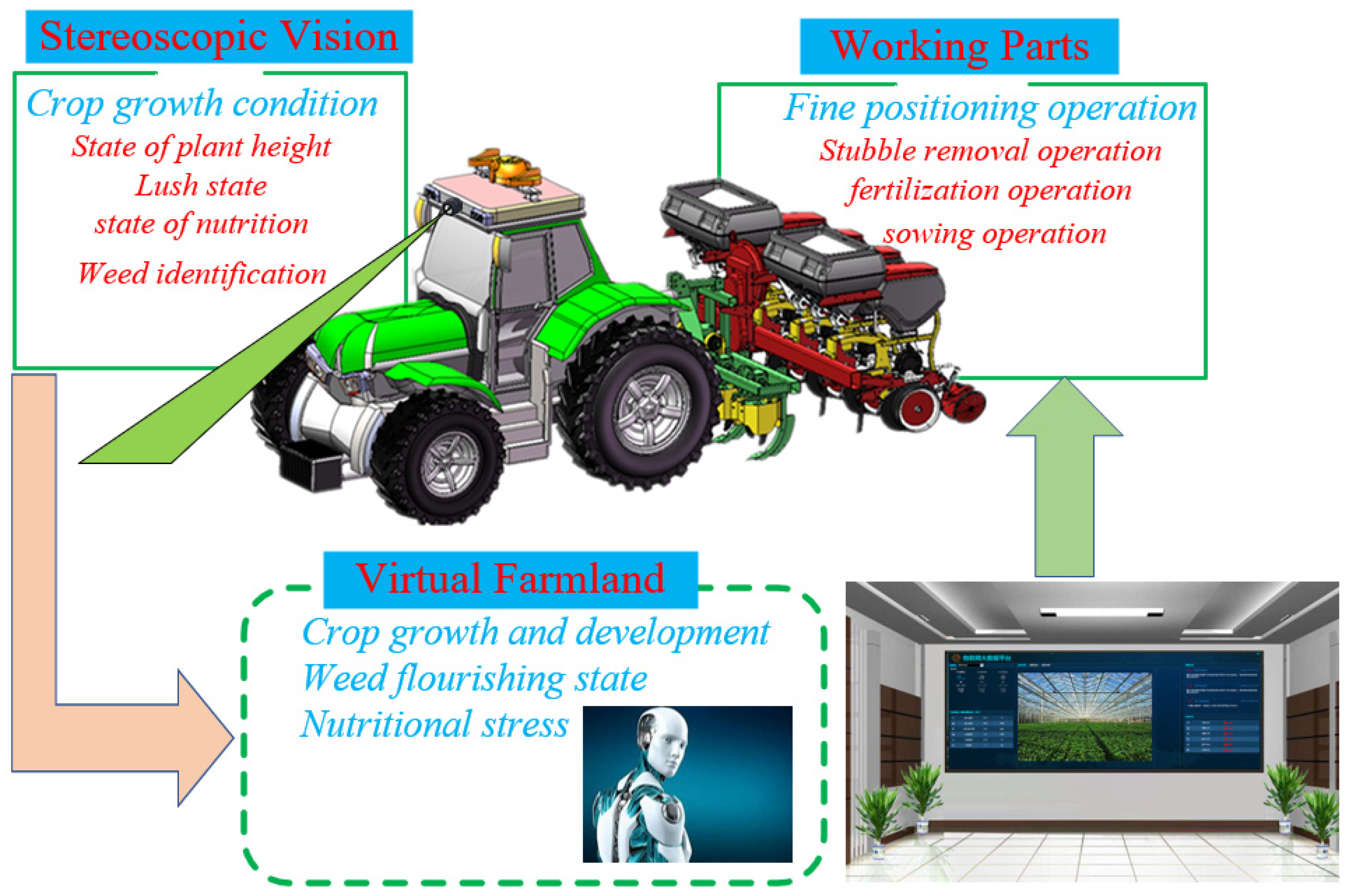

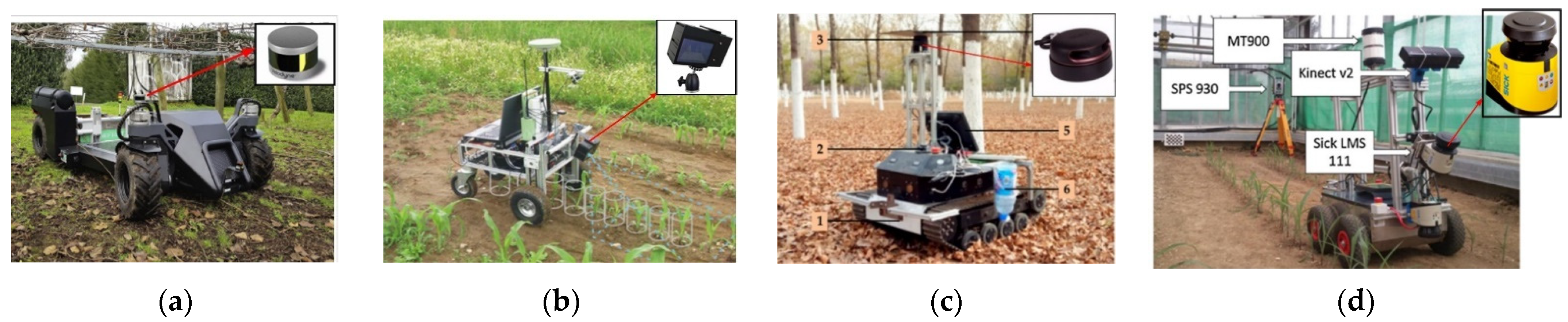

4.1. Environmental Perception

4.1.1. Cameras

Monocular Camera

Binocular Camera

Depth Camera

4.1.2. Radar

4.2. Information Fusion

5. Discussion

6. Conclusion and Outlook

6.1. Conclusion and Challenges

- (1)

- The combination of agricultural machinery and agronomy is not common.

- (2)

- The development situation is positive, but the technology is lacking.

- (3)

- More variety, but insufficient design and optimization.

6.2. Outlook

- (1)

- Increase scalability and versatility.

- (2)

- Coordination of overall operation

- (3)

- Standardization of agricultural production

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.B.; Li, P.; Zhao, S.L.; Lv, Z.M.; Du, F.; An, Y.J. An Adaptive Vision Navigation Algorithm in Agricultural IoT System for Smart Agricultural Robots. CMC Comput. Mater. Continua 2021, 66, 1043–1056. [Google Scholar] [CrossRef]

- Kumar, K.N.; Pillai, A.V.; Narayanan, M.K.B. Smart agriculture using IoT. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Yi, X.W.; Yingkuan, W.; Yang, Z.Q. Review of smart robots for fruit and vegetable picking in agriculture. Int. J. Agric. Biol. Eng. 2021, 14, 33–54. [Google Scholar]

- Chebrolu, N.; Lottes, P.; Schaefer, A.; Winterhalter, W.; Burgard, W.; Stachniss, C. Agricultural robot dataset for plant classification, localization and mapping on sugar beet fields. Int. J. Robot. Res. 2017, 36, 1045–1052. [Google Scholar] [CrossRef]

- Bechar, A.; Vigneault, C. Agricultural robots for field operations: Concepts and components. Biosyst. Eng. 2016, 149, 94–111. [Google Scholar] [CrossRef]

- Bechar, A.; Vigneault, C. Agricultural robots for field operations. Part 2: Operations and systems. Biosyst. Eng. 2017, 153, 110–128. [Google Scholar] [CrossRef]

- Azmi, H.N.; Hajjaj, S.S.H.; Gsangaya, K.R.; Sultan, M.T.H.; Mail, M.F.; Hua, L.S. Design and fabrication of an agricultural robot for crop seeding. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Xiang, Y.; Noguchi, N. Development and evaluation of a general-purpose electric off-road robot based on agricultural navigation. Int. J. Agric. Biol. Eng. 2014, 7, 14–21. [Google Scholar]

- Moysiadis, V.; Tsolakis, N.; Katikaridis, D.; Sørensen, C.G.; Pearson, S.; Bochtis, D. Mobile Robotics in Agricultural Operations: A Narrative Review on Planning Aspects. Appl. Sci. 2020, 10, 3453. [Google Scholar] [CrossRef]

- Zhang, Z.Z.; Kayacan, E.; Thompson, B.; Chowdhary, G. High precision control and deep learning-based corn stand counting algorithms for agricultural robot. Auton. Robot. 2020, 44, 1289–1302. [Google Scholar] [CrossRef]

- Choi, K.H.; Han, S.K.; Han, S.H.; Park, K.-H.; Kim, K.-S.; Kim, S. Morphology-based guidance line extraction for an autonomous weeding robot in paddy fields. Comput. Electron. Agric. 2015, 113, 266–274. [Google Scholar] [CrossRef]

- Feng, L.; Chen, S.; Zhang, C.; Zhang, Y.; He, Y. A comprehensive review on recent applications of unmanned aerial vehicle remote sensing with various sensors for high-throughput plant phenotyping. Comput. Electron. Agric. 2021, 182, 106033. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, B.; Zhou, J.; Wang, K. Real-time 3D unstructured environment reconstruction utilizing VR and Kinect-based immersive teleoperation for agricultural field robots. Comput. Electron. Agric. 2020, 175, 105579. [Google Scholar] [CrossRef]

- Fernandez, B.; Herrera, P.J.; Cerrada, J.A. A Simplified Optimal Path Following Controller for an Agricultural Skid-Steering Robot. IEEE Access 2019, 7, 95932–95940. [Google Scholar] [CrossRef]

- Roshanianfard, A.; Noguchi, N.; Okamoto, H.; Ishii, K. A review of autonomous agricultural vehicles (The experience of Hokkaido University). J. Terramechanics 2020, 91, 155–183. [Google Scholar] [CrossRef]

- Tabile, R.A.; Godoy, E.P.; Pereira, R.R.D.; Tangerino, G.T.; Porto, A.J.V.; Inamasu, R.Y. Design and Development of the Architecture of an Agricultural Mobile Robot. Eng. Agric. 2011, 31, 130–142. [Google Scholar] [CrossRef]

- Adamides, G.; Katsanos, C.; Constantinou, I.; Christou, G.; Xenos, M.; Hadzilacos, T.; Edan, Y. Design and development of a semi-autonomous agricultural vineyard sprayer: Human-robot interaction aspects. J. Field Robot. 2017, 34, 1407–1426. [Google Scholar] [CrossRef]

- Birrell, S.; Hughes, J.; Cai, J.Y.; Iida, F. A field-tested robotic harvesting system for iceberg lettuce. J. Field Robot. 2020, 37, 225–245. [Google Scholar] [CrossRef] [PubMed]

- Libran-Embid, F.; Klaus, F.; Tscharntke, T.; Grass, I. Unmanned aerial vehicles for biodiversity-friendly agricultural landscapes—A systematic review. Sci. Total Environ. 2020, 732, 139204. [Google Scholar] [CrossRef] [PubMed]

- Ghafar, A.S.A.; Hajjaj, S.S.H.; Gsangaya, K.R.; Sultan, M.T.H.; Mail, M.F.; Hua, L.S. Design and development of a robot for spraying fertilizers and pesticides for agriculture. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Kumar, P.; Ashok, G. Design and fabrication of smart seed sowing robot. Mater. Today Proc. 2021, 39, 354–358. [Google Scholar] [CrossRef]

- Kim, W.-S.; Lee, D.-H.; Kim, Y.-J.; Kim, T.; Lee, W.-S.; Choi, C.-H. Stereo-vision-based crop height estimation for agricultural robots. Comput. Electron. Agric. 2021, 181, 105937. [Google Scholar] [CrossRef]

- Arbo, M.H.; Utstumo, T.; Brekke, E.; Gravdahl, J.T. Unscented Multi-point Smoother for Fusion of Delayed Displacement Measurements: Application to Agricultural Robots. Model. Identif. Control. 2017, 38, 1–9. [Google Scholar] [CrossRef]

- Huang, C.-H.; Chen, P.-J.; Lin, Y.-J.; Chen, B.-W.; Zheng, J.-X. A robot-based intelligent management design for agricultural cyber-physical systems. Comput. Electron. Agric. 2021, 181, 105967. [Google Scholar] [CrossRef]

- Aravind, K.R.; Raja, P.; Perez-Ruiz, M. Task-based agricultural mobile robots in arable farming: A review. Span. J. Agric. Res. 2017, 15, e02R01. [Google Scholar] [CrossRef]

- Pierzchala, M.; Giguere, P.; Astrup, R. Mapping forests using an unmanned ground vehicle with 3D LiDAR and graph-SLAM. Comput. Electron. Agric. 2018, 145, 217–225. [Google Scholar] [CrossRef]

- Li, S.; Hao, G. Current Trends and Prospects in Compliant Continuum Robots: A Survey. Actuators 2021, 10, 145. [Google Scholar] [CrossRef]

- Rahok, S.A.; Ozaki, K. Application of Localization Based on the DC Magnetic Field that Occurs in the Environment on Wheel-Type Mobile Agricultural Robots. Adv. Robot. 2011, 25, 923–939. [Google Scholar] [CrossRef]

- Sebastian, B.; Ben-Tzvi, P. Physics Based Path Planning for Autonomous Tracked Vehicle in Challenging Terrain. J. Intell. Robot. Syst. 2018, 95, 511–526. [Google Scholar] [CrossRef]

- Gai, J.; Xiang, L.; Tang, L. Using a depth camera for crop row detection and mapping for under-canopy navigation of agricultural robotic vehicle. Comput. Electron. Agric. 2021, 188, 106301. [Google Scholar] [CrossRef]

- Eizicovits, D.; van Tuijl, B.; Berman, S.; Edan, Y. Integration of perception capabilities in gripper design using graspability maps. Biosyst. Eng. 2016, 146, 98–113. [Google Scholar] [CrossRef]

- Furukawa, S.; Wakimoto, S.; Kanda, T.; Hagihara, H. A Soft Master-Slave Robot Mimicking Octopus Arm Structure Using Thin Artificial Muscles and Wire Encoders. Actuators 2019, 8, 40. [Google Scholar] [CrossRef]

- Tsolakis, N.; Bechtsis, D.; Bochtis, D. AgROS: A Robot Operating System Based Emulation Tool for Agricultural Robotics. Agronomy 2019, 9, 403. [Google Scholar] [CrossRef]

- Xiong, Y.; Ge, Y.; Grimstad, L.; From, P.J. An autonomous strawberry-harvesting robot: Design, development, integration, and field evaluation. J. Field Robot. 2019, 37, 202–224. [Google Scholar] [CrossRef]

- Gorjian, S.; Ebadi, H.; Trommsdorff, M.; Sharon, H.; Demant, M.; Schindele, S. The advent of modern solar-powered electric agricultural machinery: A solution for sustainable farm operations. J. Clean. Prod. 2021, 292, 126030. [Google Scholar] [CrossRef]

- Hou, Z.; Li, Z.; Fadiji, T.; Fu, J. Soft grasping mechanism of human fingers for tomato-picking bionic robots. Comput. Electron. Agric. 2021, 182, 106010. [Google Scholar] [CrossRef]

- Zhang, B.; Xie, Y.; Zhou, J.; Wang, K.; Zhang, Z. State-of-the-art robotic grippers, grasping and control strategies, as well as their applications in agricultural robots: A review. Comput. Electron. Agric. 2020, 177, 105694. [Google Scholar] [CrossRef]

- Luo, K.; Wu, Z.; Cao, C.; Qin, K.; Zhang, X.; An, M. Biomechanical Characterization of Bionic Mechanical Harvesting of Tea Buds. Agriculture 2022, 12, 1361. [Google Scholar] [CrossRef]

- Valente, D.S.M.; Momin, A.; Grift, T.; Hansen, A. Accuracy and precision evaluation of two low-cost RTK global navigation satellite systems. Comput. Electron. Agric. 2020, 168, 105142. [Google Scholar] [CrossRef]

- Xue, J.; Zhang, L.; Grift, T.E. Variable field-of-view machine vision based row guidance of an agricultural robot. Comput. Electron. Agric. 2012, 84, 85–91. [Google Scholar] [CrossRef]

- Hiremath, S.A.; van der Heijden, G.W.A.M.; van Evert, F.K.; Stein, A.; ter Braak, C.J.F. Laser range finder model for autonomous navigation of a robot in a maize field using a particle filter. Comput. Electron. Agric. 2014, 100, 41–50. [Google Scholar] [CrossRef]

- Lammie, C.; Olsen, A.; Carrick, T.; Azghadi, M.R. Low-Power and High-Speed Deep FPGA Inference Engines for Weed Classification at the Edge. IEEE Access 2019, 7, 51171–51184. [Google Scholar] [CrossRef]

- Guzman, L.E.S.; Acevedo, M.L.R.; Guevara, A.R. Weed-removal system based on artificial vision and movement planning by A* and RRT techniques. Acta Sci.-Agron. 2019, 41, e42687. [Google Scholar] [CrossRef]

- Esposito, M.; Crimaldi, M.; Cirillo, V.; Sarghini, F.; Maggio, A. Drone and sensor technology for sustainable weed management: A review. Chem. Biol. Technol. Agric. 2021, 8, 18. [Google Scholar] [CrossRef]

- Hossain, M.Z.; Komatsuzaki, M. Weed Management and Economic Analysis of a Robotic Lawnmower: A Case Study in a Japanese Pear Orchard. Agriculture 2021, 11, 113. [Google Scholar] [CrossRef]

- Wu, X.; Aravecchia, S.; Lottes, P.; Stachniss, C.; Pradalier, C. Robotic weed control using automated weed and crop classification. J. Field Robot. 2020, 37, 322–340. [Google Scholar] [CrossRef]

- Mirbod, O.; Choi, D.; Thomas, R.; He, L. Overcurrent-driven LEDs for consistent image colour and brightness in agricultural machine vision applications. Comput. Electron. Agric. 2021, 187, 106266. [Google Scholar] [CrossRef]

- Nehme, H.; Aubry, C.; Solatges, T.; Savatier, X.; Rossi, R.; Boutteau, R. LiDAR-based Structure Tracking for Agricultural Robots: Application to Autonomous Navigation in Vineyards. J. Intell. Robot. Syst. 2021, 103, 61. [Google Scholar] [CrossRef]

- Navas, E.; Fernandez, R.; Sepulveda, D.; Armada, M.; Gonzalez-de-Santos, P. Soft Grippers for Automatic Crop Harvesting: A Review. Sensors 2021, 21, 2689. [Google Scholar] [CrossRef]

- Chen, J.; Qiang, H.; Wu, J.; Xu, G.; Wang, Z. Navigation path extraction for greenhouse cucumber-picking robots using the prediction-point Hough transform. Comput. Electron. Agric. 2021, 180, 105911. [Google Scholar] [CrossRef]

- Koivumäki, J.; Zhu, W.-H.; Mattila, J. Energy-efficient and high-precision control of hydraulic robots. Control. Eng. Pract. 2019, 85, 176–193. [Google Scholar] [CrossRef]

- Zhang, Z.; Igathinathane, C.; Li, J.; Cen, H.; Lu, Y.; Flores, P. Technology progress in mechanical harvest of fresh market apples. Comput. Electron. Agric. 2020, 175, 105606. [Google Scholar] [CrossRef]

- Xiong, Y.; Peng, C.; Grimstad, L.; From, P.J.; Isler, V. Development and field evaluation of a strawberry harvesting robot with a cable-driven gripper. Comput. Electron. Agric. 2019, 157, 392–402. [Google Scholar] [CrossRef]

- Tu, X.; Gai, J.; Tang, L. Robust navigation control of a 4WD/4WS agricultural robotic vehicle. Comput. Electron. Agric. 2019, 164, 104892. [Google Scholar] [CrossRef]

- Zhou, X.; Zhou, J. Data-Driven Driving State Control for Unmanned Agricultural Logistics Vehicle. IEEE Access 2020, 8, 65530–65543. [Google Scholar] [CrossRef]

- Li, Z.; Chen, L.; Zheng, Q.; Dou, X.; Yang, L. Control of a path following caterpillar robot based on a sliding mode variable structure algorithm. Biosyst. Eng. 2019, 186, 293–306. [Google Scholar] [CrossRef]

- Chen, L.; Wang, P.; Zhang, P.; Zheng, Q.; He, J.; Wang, Q. Performance analysis and test of a maize inter-row self-propelled thermal fogger chassis. Int. J. Agric. Biol. Eng. 2018, 11, 100–107. [Google Scholar] [CrossRef]

- Zhang, C.; Yong, L.; Chen, Y.; Zhang, S.; Ge, L.; Wang, S.; Li, W. A Rubber-Tapping Robot Forest Navigation and Information Collection System Based on 2D LiDAR and a Gyroscope. Sensors 2019, 19, 2136. [Google Scholar] [CrossRef]

- Jones, M.H.; Bell, J.; Dredge, D.; Seabright, M.; Scarfe, A.; Duke, M.; MacDonald, B. Design and testing of a heavy-duty platform for autonomous navigation in kiwifruit orchards. Biosyst. Eng. 2019, 187, 129–146. [Google Scholar] [CrossRef]

- Guevara, J.; Gene-Mola, J.; Gregorio, E.; Torres-Torriti, M.; Reina, G.; Cheein, F.A.A. Comparison of 3D scan matching techniques for autonomous robot navigation in urban and agricultural environments. J. Appl. Remote Sens. 2021, 15, 024508. [Google Scholar] [CrossRef]

- Shao, Y.; Han, X.; Xuan, G.; Liu, Y.; Gao, C.; Wang, G.; Hu, Z. Development of a multi-adaptive feeding device for automated plug seedling transplanter. Int. J. Agric. Biol. Eng. 2021, 14, 91–96. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Dai, D.; Wang, X.; Wang, S. Review of electro-hydraulic hitch system control method of automated tractors. Int. J. Agric. Biol. Eng. 2021, 14, 1–11. [Google Scholar] [CrossRef]

- Li, J.; Li, S.; Zhang, Y.; Liu, M.; Gao, Z. Development and test of hydraulic driven remote transporter. Int. J. Agric. Biol. Eng. 2021, 14, 72–80. [Google Scholar] [CrossRef]

- Roshanianfard, A.; Noguchi, N.; Kamata, T. Design and performance of a robotic arm for farm use. Int. J. Agric. Biol. Eng. 2019, 12, 146–158. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, G.; Chen, Z.; Wen, X.; Cheng, S.; Ma, Q.; Qi, J.; Zhou, Y.; Chen, L. An independent steering driving system to realize headland turning of unmanned tractors. Comput. Electron. Agric. 2022, 201, 107278. [Google Scholar] [CrossRef]

- Zhang, Z.; Jia, X.; Yang, T.; Gu, Y.; Wang, W.; Chen, L. Multi-objective optimization of lubricant volume in an ELSD considering thermal effects. Int. J. Therm. Sci. 2021, 164, 106884. [Google Scholar] [CrossRef]

- Chen, Z.; Yang, M.; Li, Y.; Yang, L. Design and experiment of tomato picking end-effector based on non-destructive pneumatic clamping control. Trans. CSAE 2021, 37, 27–35. [Google Scholar]

- Amritanandamayi, D.M.; Udupa, G.; Sreedharan, P. A novel underactuated multi-fingered soft robotic hand for prosthetic application. Robot. Auton. Syst. 2018, 100, 267–277. [Google Scholar] [CrossRef]

- Jiang, Z.; Hu, Y.; Jiang, H.; Tong, J. Design and force analysis of end-effector for plug seedling transplanter. PLoS ONE 2017, 12, e0180229. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Zhang, F.; Zhang, J.; Yuan, T.; Yin, J.; Guo, H.; Yang, C. Development and evaluation of a pneumatic finger-like end-effector for cherry tomato harvesting robot in greenhouse. Comput. Electron. Agric. 2022, 197, 106879. [Google Scholar] [CrossRef]

- Liu, Y.; Zhong, Y.; Wang, C. Recent advances in self-actuation and self-sensing materials: State of the art and future perspectives. Talanta 2020, 212, 120808. [Google Scholar] [CrossRef]

- Naoshi, K.; Mitsuji, K.; Noboru, N. Agricultural Robotics (I) Fundamentals and Theory; Qiao, J.; Chen, B., Translators; China Agricultural University Press: Beijing, China, 2009. [Google Scholar]

- Tawk, C.; Gillett, A.; in het Panhuis, M.; Spinks, G.M.; Alici, G. A 3D-Printed Omni-Purpose Soft Gripper. IEEE Trans. Robot. 2019, 35, 1268–1275. [Google Scholar] [CrossRef]

- Elmoughni, H.M.; Yilmaz, A.F.; Ozlem, K.; Khalilbayli, F.; Cappello, L.; Atalay, A.T.; Ince, G.; Atalay, O. Machine-Knitted Seamless Pneumatic Actuators for Soft Robotics: Design, Fabrication, and Characterization. Actuators 2021, 10, 94. [Google Scholar] [CrossRef]

- Rovira-Mas, F.; Saiz-Rubio, V.; Cuenca-Cuenca, A. Augmented Perception for Agricultural Robots Navigation. IEEE Sens. J. 2021, 21, 11712–11727. [Google Scholar] [CrossRef]

- Martin, P. A Future-Focused View of the Regulation of Rural Technology. Agronomy 2021, 11, 1153. [Google Scholar] [CrossRef]

- Sun, Y.N.; Pan, Z.Q. RBF network based motion trajectory optimization for robot used in agricultural activities. Emir. J. Food Agric. 2018, 30, 883–892. [Google Scholar] [CrossRef]

- Zhang, T.; Huang, Z.; You, W.; Lin, J.; Tang, X.; Huang, H. An Autonomous Fruit and Vegetable Harvester with a Low-Cost Gripper Using a 3D Sensor. Sensors 2019, 20, 93. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Ahamed, T.; Zhang, Y.; Gao, P.; Takigawa, T. Vision-Based Leader Vehicle Trajectory Tracking for Multiple Agricultural Vehicles. Sensors 2016, 16, 578. [Google Scholar] [CrossRef]

- Bengochea-Guevara, J.M.; Conesa-Munoz, J.; Andujar, D.; Ribeiro, A. Merge Fuzzy Visual Servoing and GPS-Based Planning to Obtain a Proper Navigation Behavior for a Small Crop-Inspection Robot. Sensors 2016, 16, 276. [Google Scholar] [CrossRef]

- Wang, H.; Liu, L.; He, P.; Yu, M.; Do, M.T.; Kong, H.; Man, Z. Robust adaptive position control of automotive electronic throttle valve using PID-type sliding mode technique. Nonlinear Dyn. 2016, 85, 1331–1344. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, H.; He, S.; Zheng, J.; Ping, Z.; Shao, K.; Cao, Z.; Man, Z. Adaptive Tracking Control of an Electronic Throttle Valve Based on Recursive Terminal Sliding Mode. IEEE Trans. Veh. Technol. 2021, 70, 251–262. [Google Scholar] [CrossRef]

- Jia, W.K.; Tian, Y.Y.; Duan, H.C.; Luo, R.; Lian, J.; Ruan, C.Z.; Zhao, D.A.; Li, C.J. Autonomous navigation control based on improved adaptive filtering for agricultural robot. Int. J. Adv. Robot. Syst. 2020, 17. [Google Scholar] [CrossRef]

- Mousakazemi, S.; Ayoobian, N.; Ansarifar, G.R. Control of the reactor core power in PWR using optimized PID controller with the real-coded GA. Ann. Nucl. Energy 2018, 118, 107–121. [Google Scholar] [CrossRef]

- Wang, H.; Noguchi, N. Adaptive turning control for an agricultural robot tractor. Int. J. Agric. Biol. Eng. 2018, 11, 113–119. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, H. An adaptive fuzzy hierarchical control for maintaining solar greenhouse temperature. Comput. Electron. Agric. 2018, 155, 251–256. [Google Scholar] [CrossRef]

- Zavlangas, P.G.; Tzafestas, S.G. Motion control for mobile robot obstacle avoidance and navigation: A fuzzy logic-based approach. Syst. Anal. Model. Simul. 2003, 43, 1625–1637. [Google Scholar] [CrossRef]

- Pradhan, S.K.; Parhi, D.R.; Panda, A.K. Motion control and navigation of multiple mobile robots for obstacle avoidance and target seeking: A rule-based neuro-fuzzy technique. J. Syst. Control. Eng. 2009, 223, 275–288. [Google Scholar] [CrossRef]

- Malavazi, F.B.P.; Guyonneau, R.; Fasquel, J.B.; Lagrange, S.; Mercier, F. LiDAR-only based navigation algorithm for an autonomous agricultural robot. Comput. Electron. Agric. 2018, 154, 71–79. [Google Scholar] [CrossRef]

- Essen, H.A.V.; Nijmeijer, H. Non-linear model predictive control for constrained mobile robots. In Proceedings of the 2001 European Control Conference (ECC), Porto, Portugal, 4–7 September 2001. [Google Scholar]

- Kraus, T.; Ferreau, H.J.; Kayacan, E.; Ramon, H.; De Baerdemaeker, J.; Diehl, M.; Saeys, W. Moving horizon estimation and nonlinear model predictive control for autonomous agricultural vehicles. Comput. Electron. Agric. 2013, 98, 25–33. [Google Scholar] [CrossRef]

- Tian, Z.; Gao, X.; Guo, P. Network Teleoperation Robot System Control Based on Fuzzy Sliding Mode. J. Adv. Comput. Intell. Intell. Inform. 2016, 20, 828–835. [Google Scholar] [CrossRef]

- Chowdhary, G.; Gazzola, M.; Krishnan, G.; Soman, C.; Lovell, S. Soft Robotics as an Enabling Technology for Agroforestry Practice and Research. Sustainability 2019, 11, 6751. [Google Scholar] [CrossRef]

- Birglen, L.; Schlicht, T. A statistical review of industrial robotic grippers. Robot. Comput. Integr. Manuf. 2018, 49, 88–97. [Google Scholar] [CrossRef]

- Williams, H.A.M.; Jones, M.H.; Nejati, M.; Seabright, M.J.; Bell, J.; Penhall, N.D.; Barnett, J.J.; Duke, M.D.; Scarfe, A.J.; Ahn, H.S.; et al. Robotic kiwifruit harvesting using machine vision, convolutional neural networks, and robotic arms. Biosyst. Eng. 2019, 181, 140–156. [Google Scholar] [CrossRef]

- Mu, L.; Cui, G.; Liu, Y.; Cui, Y.; Fu, L.; Gejima, Y. Design and simulation of an integrated end-effector for picking kiwifruit by robot. Inf. Process. Agric. 2020, 7, 58–71. [Google Scholar] [CrossRef]

- Davidson, J.R.; Hohimer, C.J.; Mo, C.; Karkee, M. Dual Robot Coordination for Apple Harvesting. In Proceedings of the 2017 ASABE Annual International Meeting, Spokane, WA, USA, 16–19 July 2017. [Google Scholar] [CrossRef]

- Ling, X.; Zhao, Y.; Gong, L.; Liu, C.; Wang, T. Dual-arm cooperation and implementing for robotic harvesting tomato using binocular vision. Robot. Auton. Syst. 2019, 114, 134–143. [Google Scholar] [CrossRef]

- Sepulveda, D.; Fernandez, R.; Navas, E.; Armada, M.; Gonzalez-De-Santos, P. Robotic Aubergine Harvesting Using Dual-Arm Manipulation. IEEE Access 2020, 8, 121889–121904. [Google Scholar] [CrossRef]

- Zhang, B.; Zhou, J.; Meng, Y.; Zhang, N.; Gu, B.; Yan, Z.; Idris, S.I. Comparative study of mechanical damage caused by a two-finger tomato gripper with different robotic grasping patterns for harvesting robots. Biosyst. Eng. 2018, 171, 245–257. [Google Scholar] [CrossRef]

- Russo, M.; Ceccarelli, M.; Corves, B.; Hüsing, M.; Lorenz, M.; Cafolla, D.; Carbone, G. Design and test of a gripper prototype for horticulture products. Robot. Comput. Integr. Manuf. 2017, 44, 266–275. [Google Scholar] [CrossRef]

- Zhang, K.; Lammers, K.; Chu, P.; Li, Z.; Lu, R. System design and control of an apple harvesting robot. Mechatronics 2021, 79, 102644. [Google Scholar] [CrossRef]

- Quan, L.; Jiang, W.; Li, H.; Li, H.; Wang, Q.; Chen, L. Intelligent intra-row robotic weeding system combining deep learning technology with a targeted weeding mode. Biosyst. Eng. 2022, 216, 13–31. [Google Scholar] [CrossRef]

- Li, B.; Gu, S.; Chu, Q.; Yang, Y.; Xie, Z.; Fan, K.; Liu, X. Development of transplanting manipulator for hydroponic leafy vegetables. Int. J. Agric. Biol. Eng. 2019, 12, 38–44. [Google Scholar] [CrossRef]

- Tian, G.; Zhou, J.; Gu, B. Slipping detection and control in gripping fruits and vegetables for agricultural robot. Int. J. Agric. Biol. Eng. 2018, 11, 29–34. [Google Scholar] [CrossRef]

- Roshanianfard, A.; Noguchi, N. Pumpkin harvesting robotic end-effector. Comput. Electron. Agric. 2020, 174, 105503. [Google Scholar] [CrossRef]

- Kurpaska, S.; Sobol, Z.; Pedryc, N.; Hebda, T.; Nawara, P. Analysis of the Pneumatic System Parameters of the Suction Cup Integrated with the Head for Harvesting Strawberry Fruit. Sensors 2020, 20, 4389. [Google Scholar] [CrossRef]

- Lehnert, C.; McCool, C.; Sa, I.; Perez, T. Performance improvements of a sweet pepper harvesting robot in protected cropping environments. J. Field Robot. 2020, 37, 1197–1223. [Google Scholar] [CrossRef]

- Kurpaska, S.; Bielecki, A.; Sobol, Z.; Bielecka, M.; Habrat, M.; Smigielski, P. The Concept of the Constructional Solution of the Working Section of a Robot for Harvesting Strawberries. Sensors 2021, 21, 3933. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, Y.; Yue, X.; Zhang, G.; Wen, X.; Ma, B.; Xu, L.; Chen, L. Real-time detection of crop rows in maize fields based on autonomous extraction of ROI. Expert Syst. Appl. 2022, 213, 118826. [Google Scholar] [CrossRef]

- Bao, X.; Niu, Y.; Li, Y.; Mao, J.; Li, S.; Ma, X.; Yin, Q.; Chen, B. Design and Kinematic Analysis of Cable-Driven Target Spray Robot for Citrus Orchards. Appl. Sci. 2022, 12, 9379. [Google Scholar] [CrossRef]

- Pérez-Ruíz, M.; Slaughter, D.C.; Fathallah, F.A.; Gliever, C.J.; Miller, B.J. Co-robotic intra-row weed control system. Biosyst. Eng. 2014, 126, 45–55. [Google Scholar] [CrossRef]

- Langsenkamp, F.; Sellmann, F.; Kohlbrecher, M.; Kielhorn, A.; Trautz, D. Tube Stamp for mechanical intra-row individual Plant Weed Control. In Proceedings of the 18 th World Congress of CIGR, Beijing, China, 16–19 September 2014. [Google Scholar]

- Yang, C.; Wu, Z.; Guo, Y. Structural design of a milking robot. Agric. Mech. Res. 2018, 40, 6. [Google Scholar]

- Liu, X.; Li, B.; Chang, J.; Zhang, G.; Wang, C. Design and analysis of double manipulator structure of medlar picking robot. High Tech Commun. 2019, 29, 175–182. [Google Scholar]

- van Marrewijk, B.M.; Vroegindeweij, B.A.; Gené-Mola, J.; Mencarelli, A.; Hemming, J.; Mayer, N.; Wenger, M.; Kootstra, G. Evaluation of a boxwood topiary trimming robot. Biosyst. Eng. 2022, 214, 11–27. [Google Scholar] [CrossRef]

- Mohamed, A.; Shaw-Sutton, J.; Green, B.M.; Andrews, W.; Stoelen, M.F. Soft manipulator robot for selective tomato harvesting. In Proceedings of the 12th European Conference on Precision Agriculture, Montpellier, France, 8–11 July 2019. [Google Scholar]

- Wang, C.; Zou, X.; Tang, Y.; Luo, L.; Feng, W. Localisation of litchi in an unstructured environment using binocular stereo vision. Biosyst. Eng. 2016, 145, 39–51. [Google Scholar] [CrossRef]

- Oberti, R.; Marchi, M.; Tirelli, P.; Calcante, A.; Iriti, M.; Tona, E.; Hočevar, M.; Baur, J.; Pfaff, J.; Schütz, C.; et al. Selective spraying of grapevines for disease control using a modular agricultural robot. Biosyst. Eng. 2016, 146, 203–215. [Google Scholar] [CrossRef]

- You, A.; Grimm, C.; Silwal, A.; Davidson, J.R. Semantics-guided skeletonization of upright fruiting offshoot trees for robotic pruning. Comput. Electron. Agric. 2022, 192, 106622. [Google Scholar] [CrossRef]

- Gonzalez-de-Santos, P.; Fernandez, R.; Sepulveda, D.; Navas, E.; Emmi, L.; Armada, M. Field Robots for Intelligent Farms-Inhering Features from Industry. Agronomy 2020, 10, 1638. [Google Scholar] [CrossRef]

- Zhao, Y.; Liang, G.; Liu, C.; Huang, Y. Dual-arm Robot Design and Testing for Harvesting Tomato in Greenhouse. IFAC PapersOnLine 2016, 49, 161–165. [Google Scholar] [CrossRef]

- Trinidad, J.B. Machine for Automatically Harvesting Fruits Cultivated in Rows. U.S. Patent Application No. 15/366,091, 7 June 2018. [Google Scholar]

- Jin, Y.; Liu, J.; Xu, Z.; Yuan, S.; Li, P.; Wang, J. Development status and trend of agricultural robot technology. Int. J. Agric. Biol. Eng. 2021, 14, 1–19. [Google Scholar] [CrossRef]

- Zion, B.; Mann, M.; Levin, D.; Shilo, A.; Rubinstein, D.; Shmulevich, I. Harvest-order planning for a multiarm robotic harvester. Comput. Electron. Agric. 2014, 103, 75–81. [Google Scholar] [CrossRef]

- Longo, D.; Muscato, G. Design and Simulation of Two Robotic Systems for Automatic Artichoke Harvesting. Robotics 2013, 2, 217–230. [Google Scholar] [CrossRef]

- Ye, H.; Huang, W.; Huang, S.; Cui, B.; Dong, Y.; Guo, A.; Ren, Y.; Jin, Y. Recognition of Banana Fusarium Wilt Based on UAV Remote Sensing. Remote Sens. 2020, 12, 938. [Google Scholar] [CrossRef]

- Zhang, X.; Han, L.; Dong, Y.; Shi, Y.; Huang, W.; Han, L.; Gonzalez-Moreno, P.; Ma, H.; Ye, H.; Sobeih, T. A Deep Learning-Based Approach for Automated Yellow Rust Disease Detection from High-Resolution Hyperspectral UAV Images. Remote Sens. 2019, 11, 1554. [Google Scholar] [CrossRef]

- Anagnostis, A.; Benos, L.; Tsaopoulos, D.; Tagarakis, A.; Tsolakis, N.; Bochtis, D. Human Activity Recognition through Recurrent Neural Networks for Human-Robot Interaction in Agriculture. Appl. Sci. 2021, 11, 2188. [Google Scholar] [CrossRef]

- Wang, W.; Song, J.; Zhou, G.; Quan, L.; Zhang, C.; Chen, L. Development and Numerical Simulation of a Precision Strip-Hole Layered Fertilization Subsoiler While Sowing Maize. Agriculture 2022, 12, 938. [Google Scholar] [CrossRef]

- Huynh, T.; Tran, M.-T.; Lee, D.-H.; Chakir, S.; Kim, Y.-B. A Study on Vision-Based Backstepping Control for a Target Tracking System. Actuators 2021, 10, 105. [Google Scholar] [CrossRef]

- Kragh, M.; Underwood, J. Multimodal obstacle detection in unstructured environments with conditional random fields. J. Field Robot. 2020, 37, 53–72. [Google Scholar] [CrossRef]

- Lee, B.; Kam, D.; Min, B.; Hwa, J.; Oh, S. A Vision Servo System for Automated Harvest of Sweet Pepper in Korean Greenhouse Environment. Appl. Sci. 2019, 9, 2395. [Google Scholar] [CrossRef]

- Li, Y.; Huang, D.; Qi, J.; Chen, S.; Sun, H.; Liu, H.; Jia, H. Feature Point Registration Model of Farmland Surface and Its Application Based on a Monocular Camera. Sensors 2020, 20, 3799. [Google Scholar] [CrossRef]

- Chen, Y.; Hou, C.; Tang, Y.; Zhuang, J.; Lin, J.; He, Y.; Guo, Q.; Zhong, Z.; Lei, H.; Luo, S. Citrus Tree Segmentation from UAV Images Based on Monocular Machine Vision in a Natural Orchard Environment. Sensors 2019, 19, 5558. [Google Scholar] [CrossRef]

- Zhou, C.; Ye, H.; Hu, J.; Shi, X.; Hua, S.; Yue, J.; Xu, Z.; Yang, G. Automated Counting of Rice Panicle by Applying Deep Learning Model to Images from Unmanned Aerial Vehicle Platform. Sensors 2019, 19, 3106. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, Y.; Zhang, B.; Wen, X.; Yue, X.; Chen, L. Autonomous detection of crop rows based on adaptive multi-ROI in maize fields. Int. J. Agric. Biol. Eng. 2021, 14, 217–225. [Google Scholar] [CrossRef]

- Lyu, H.-K.; Yun, S.; Choi, B. Machine Learning Feature Extraction Based on Binary Pixel Quantification Using Low-Resolution Images for Application of Unmanned Ground Vehicles in Apple Orchards. Agronomy 2020, 10, 1926. [Google Scholar] [CrossRef]

- Cubero, S.; Marco-Noales, E.; Aleixos, N.; Barbe, S.; Blasco, J. RobHortic: A Field Robot to Detect Pests and Diseases in Horticultural Crops by Proximal Sensing. Agriculture 2020, 10, 276. [Google Scholar] [CrossRef]

- Lei, X.; Ouyang, H.; Xu, L. Mature pomegranate recognition methods in natural environments using machine vision. Cienc. Rural 2019, 49, e20190298. [Google Scholar] [CrossRef]

- Zhou, K.; Meng, Z.; He, M.; Hou, J.; Li, T. Design and Test of a Sorting Device Based on Machine Vision. IEEE Access 2020, 8, 27178–27187. [Google Scholar] [CrossRef]

- Adhikari, S.P.; Kim, G.; Kim, H. Deep Neural Network-Based System for Autonomous Navigation in Paddy Field. IEEE Access 2020, 8, 71272–71278. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, Y.; Zhu, Z.; Li, Z.; Du, Y.; Mao, E. Tractor path tracking control based on binocular vision. Inf. Process. Agric. 2018, 5, 422–432. [Google Scholar] [CrossRef]

- Yin, W.; Wen, H.; Ning, Z.; Ye, J.; Dong, Z.; Luo, L. Fruit Detection and Pose Estimation for Grape Cluster-Harvesting Robot Using Binocular Imagery Based on Deep Neural Networks. Front. Robot. AI 2021, 8, 626989. [Google Scholar] [CrossRef]

- Xiang, R.; Jiang, H.; Ying, Y. Recognition of clustered tomatoes based on binocular stereo vision. Comput. Electron. Agric. 2014, 106, 75–90. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Vandevoorde, K.; Wouters, N.; Kayacan, E.; De Baerdemaeker, J.G.; Saeys, W. Detection of red and bicoloured apples on tree with an RGB-D camera. Biosyst. Eng. 2016, 146, 33–44. [Google Scholar] [CrossRef]

- Gu, Y.; Li, Z.; Zhang, Z.; Li, J.; Chen, L. Path Tracking Control of Field Information-Collecting Robot Based on Improved Convolutional Neural Network Algorithm. Sensors 2020, 20, 797. [Google Scholar] [CrossRef]

- Quan, L.; Li, H.; Li, H.; Jiang, W.; Lou, Z.; Chen, L. Two-Stream Dense Feature Fusion Network Based on RGB-D Data for the Real-Time Prediction of Weed Aboveground Fresh Weight in a Field Environment. Remote Sens. 2021, 13, 2288. [Google Scholar] [CrossRef]

- Wang, T.; Chen, B.; Zhang, Z.; Li, H.; Zhang, M. Applications of machine vision in agricultural robot navigation: A review. Comput. Electron. Agric. 2022, 198, 107085. [Google Scholar] [CrossRef]

- Lin, G.; Tang, Y.; Zou, X.; Xiong, J.; Li, J. Guava Detection and Pose Estimation Using a Low-Cost RGB-D Sensor in the Field. Sensors 2019, 19, 428. [Google Scholar] [CrossRef] [PubMed]

- Weiss, U.; Biber, P. Plant detection and mapping for agricultural robots using a 3D LIDAR sensor. Robot. Auton. Syst. 2011, 59, 265–273. [Google Scholar] [CrossRef]

- Reiser, D.; Vazquez-Arellano, M.; Paraforos, D.S.; Garrido-Izard, M.; Griepentrog, H.W. Iterative individual plant clustering in maize with assembled 2D LiDAR data. Comput. Ind. 2018, 99, 42–52. [Google Scholar] [CrossRef]

- Bietresato, M.; Carabin, G.; Vidoni, R.; Gasparetto, A.; Mazzetto, F. Evaluation of a LiDAR-based 3D-stereoscopic vision system for crop-monitoring applications. Comput. Electron. Agric. 2016, 124, 1–13. [Google Scholar] [CrossRef]

- Siebers, M.H.; Edwards, E.J.; Jimenez-Berni, J.A.; Thomas, M.R.; Salim, M.; Walker, R.R. Fast Phenomics in Vineyards: Development of GRover, the Grapevine Rover, and LiDAR for Assessing Grapevine Traits in the Field. Sensors 2018, 18, 2924. [Google Scholar] [CrossRef] [PubMed]

- Iqbal, J.; Xu, R.; Halloran, H.; Li, C. Development of a Multi-Purpose Autonomous Differential Drive Mobile Robot for Plant Phenotyping and Soil Sensing. Electronics 2020, 9, 1550. [Google Scholar] [CrossRef]

- Underwood, J.P.; Jagbrant, G.; Nieto, J.I.; Sukkarieh, S. Lidar-Based Tree Recognition and Platform Localization in Orchards. J. Field Robot. 2015, 32, 1056–1074. [Google Scholar] [CrossRef]

- Liu, L.; Mei, T.; Niu, R.; Wang, J.; Liu, Y.; Chu, S. RBF-Based Monocular Vision Navigation for Small Vehicles in Narrow Space below Maize Canopy. Appl. Sci. 2016, 6, 182. [Google Scholar] [CrossRef]

- Martelloni, L.; Fontanelli, M.; Pieri, S.; Frasconi, C.; Caturegli, L.; Gaetani, M.; Grossi, N.; Magni, S.; Pirchio, M.; Raffaelli, M.; et al. Assessment of the Cutting Performance of a Robot Mower Using Custom Built Software. Agronomy 2019, 9, 230. [Google Scholar] [CrossRef]

- Lou, Z.; Quan, L.; Sun, D.; Li, H.; Xia, F. Hyperspectral remote sensing to assess weed competitiveness in maize farmland ecosystems. Sci. Total Environ. 2022, 844, 157071. [Google Scholar] [CrossRef] [PubMed]

- Wei, C.; Li, H.; Shi, J.; Zhao, G.; Feng, H.; Quan, L. Row anchor selection classification method for early-stage crop row-following. Comput. Electron. Agric. 2022, 192, 106577. [Google Scholar] [CrossRef]

- Mao, W.J.; Liu, Z.J.; Liu, H.; Yang, F.Z.; Wang, M.R. Research Progress on Synergistic Technologies of Agricultural Multi-Robots. Appl. Sci. 2021, 11, 1448. [Google Scholar] [CrossRef]

- Ge, Y.; Xiong, Y.; Tenorio, G.L.; From, P.J. Fruit Localization and Environment Perception for Strawberry Harvesting Robots. IEEE Access 2019, 7, 147642–147652. [Google Scholar] [CrossRef]

- Guillet, A.; Lenain, R.; Thuilot, B.; Rousseau, V. Formation Control of Agricultural Mobile Robots: A Bidirectional Weighted Constraints Approach. J. Field Robot. 2017, 34, 1260–1274. [Google Scholar] [CrossRef]

- Fromm, M.; Schubert, M.; Castilla, G.; Linke, J.; McDermid, G. Automated Detection of Conifer Seedlings in Drone Imagery Using Convolutional Neural Networks. Remote Sens. 2019, 11, 2585. [Google Scholar] [CrossRef]

- Luo, Y.; Li, J.; Yu, C.; Xu, B.; Li, Y.; Hsu, L.-T.; El-Sheimy, N. Research on Time-Correlated Errors Using Allan Variance in a Kalman Filter Applicable to Vector-Tracking-Based GNSS Software-Defined Receiver for Autonomous Ground Vehicle Navigation. Remote Sens. 2019, 11, 1026. [Google Scholar] [CrossRef]

- Li, J.; Tang, Y.; Zou, X.; Lin, G.; Wang, H. Detection of Fruit-Bearing Branches and Localization of Litchi Clusters for Vision-Based Harvesting Robots. IEEE Access 2020, 8, 117746–117758. [Google Scholar] [CrossRef]

- Du, J.; Lu, X.; Fan, J.; Qin, Y.; Yang, X.; Guo, X. Image-Based High-Throughput Detection and Phenotype Evaluation Method for Multiple Lettuce Varieties. Front. Plant Sci. 2020, 11, 563386. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Wu, K.; Zhang, Y.; Wang, M.; Zhang, C.; Chen, L. The Development of an Electric-Driven Control System for a High-Speed Precision Planter Based on the Double Closed-Loop Fuzzy PID Algorithm. Agronomy 2022, 12, 945. [Google Scholar] [CrossRef]

- Jun, J.; Kim, J.; Seol, J.; Kim, J.; Son, H.I. Towards an Efficient Tomato Harvesting Robot: 3D Perception, Manipulation, and End-Effector. IEEE Access 2021, 9, 17631–17640. [Google Scholar] [CrossRef]

- Yuan, J. Research Progress Analysis of Robotics Selective Harvesting Technologies. Trans. Chin. Soc. Agric. Mach. 2020, 51, 1–17. [Google Scholar]

- Wu, D.; Zhao, E.; Fang, D.; Jiang, S.; Wu, C.; Wang, W.; Wang, R. Determination of Vibration Picking Parameters of Camellia oleifera Fruit Based on Acceleration and Strain Response of Branches. Agriculture 2022, 12, 1222. [Google Scholar] [CrossRef]

- Liu, L.; Bi, Q.; Zhang, Q.; Tang, J.; Bi, D.; Chen, L. Evaluation Method of Soil Surface Roughness after Ditching Operation Based on Wavelet Transform. Actuators 2022, 11, 87. [Google Scholar] [CrossRef]

- Aghi, D.; Mazzia, V.; Chiaberge, M. Local Motion Planner for Autonomous Navigation in Vineyards with a RGB-D Camera-Based Algorithm and Deep Learning Synergy. Machines 2020, 8, 27. [Google Scholar] [CrossRef]

| Actuator | Mobile Platform | Detection Sensor | Job Object | Degree of Freedom | Schematic Diagram | References |

|---|---|---|---|---|---|---|

| Grippers | / | A pair of color cameras | Kiwifruit | 4-bar linkage |  | [95] |

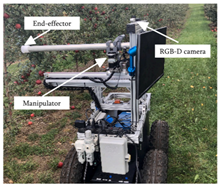

| Self-designed gripper | 4-wheel electric vehicle | Kinect | Kiwifruit | UR5 6-DoF jointed |  | [96] |

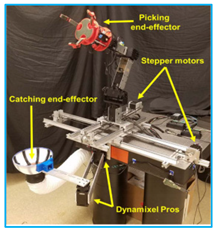

| Three-finger piking, catching | / | / | Apple | 6-DOF jointed arm + x − y displacement (picking), 2-DOF planer jointed (catching) |  | [97] |

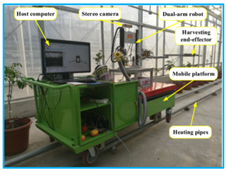

| Saw cutting type, suction type | Railed mobile platform | Bumblebee2 stereo camera | Tomato | 3-DOF SCARA-like |  | [98] |

| Kinova Gripper KG-3 | / | RGB camera 3D depth camera | Aubergine | Kinova MICOTM 6-DoF jointed |  | [99] |

| Object | Drive System | End-Effector | Appearance Example | Reference |

|---|---|---|---|---|

| Tomato | Electric | Clamping mechanism |  | [101] |

| Flowers | Electric | Cut-off mechanism |  | [78] |

| Apple | Pneumatic | Absorption mechanism |  | [102] |

| Plug seedling | Pneumatic | Press-in mechanism |  | [61] |

| Weeding | Electric | Disc weeding knife |  | [103] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, D.; Chen, L.; Liu, L.; Chen, L.; Wang, H. Actuators and Sensors for Application in Agricultural Robots: A Review. Machines 2022, 10, 913. https://doi.org/10.3390/machines10100913

Xie D, Chen L, Liu L, Chen L, Wang H. Actuators and Sensors for Application in Agricultural Robots: A Review. Machines. 2022; 10(10):913. https://doi.org/10.3390/machines10100913

Chicago/Turabian StyleXie, Dongbo, Liang Chen, Lichao Liu, Liqing Chen, and Hai Wang. 2022. "Actuators and Sensors for Application in Agricultural Robots: A Review" Machines 10, no. 10: 913. https://doi.org/10.3390/machines10100913

APA StyleXie, D., Chen, L., Liu, L., Chen, L., & Wang, H. (2022). Actuators and Sensors for Application in Agricultural Robots: A Review. Machines, 10(10), 913. https://doi.org/10.3390/machines10100913