The Effect of Sensor Integration on the Load Carrying Capacity of Gears

Abstract

1. Introduction

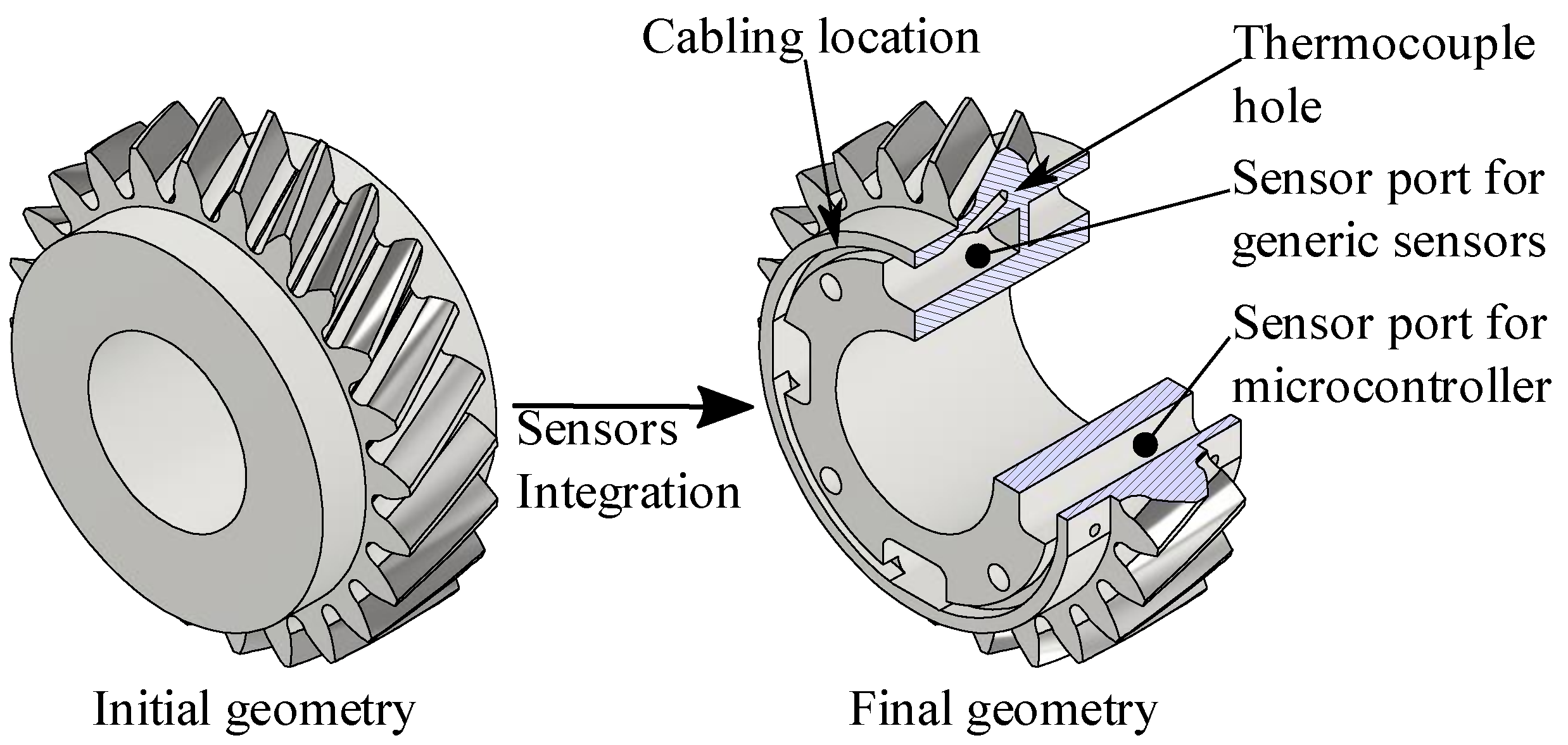

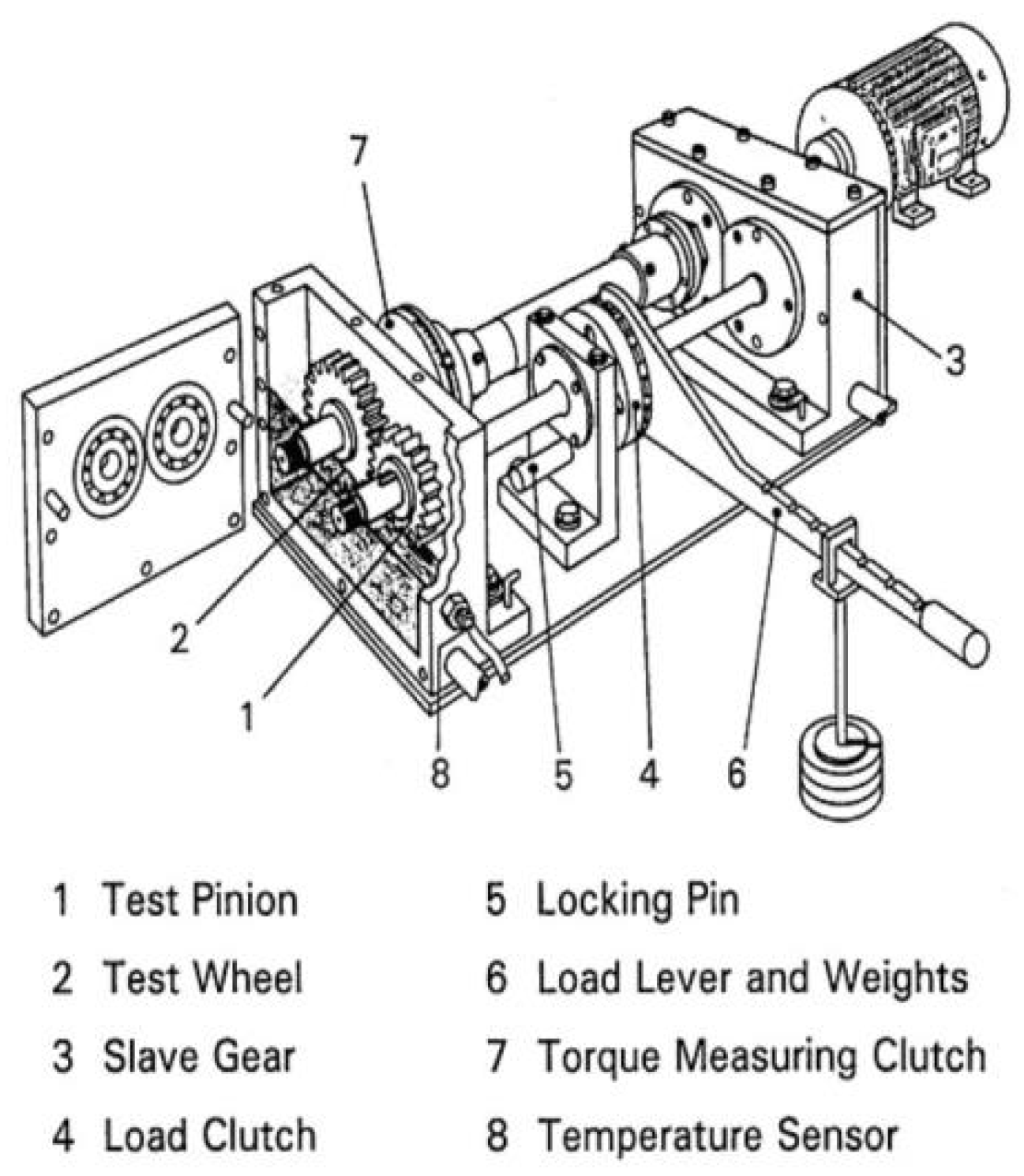

2. Definition of the Components

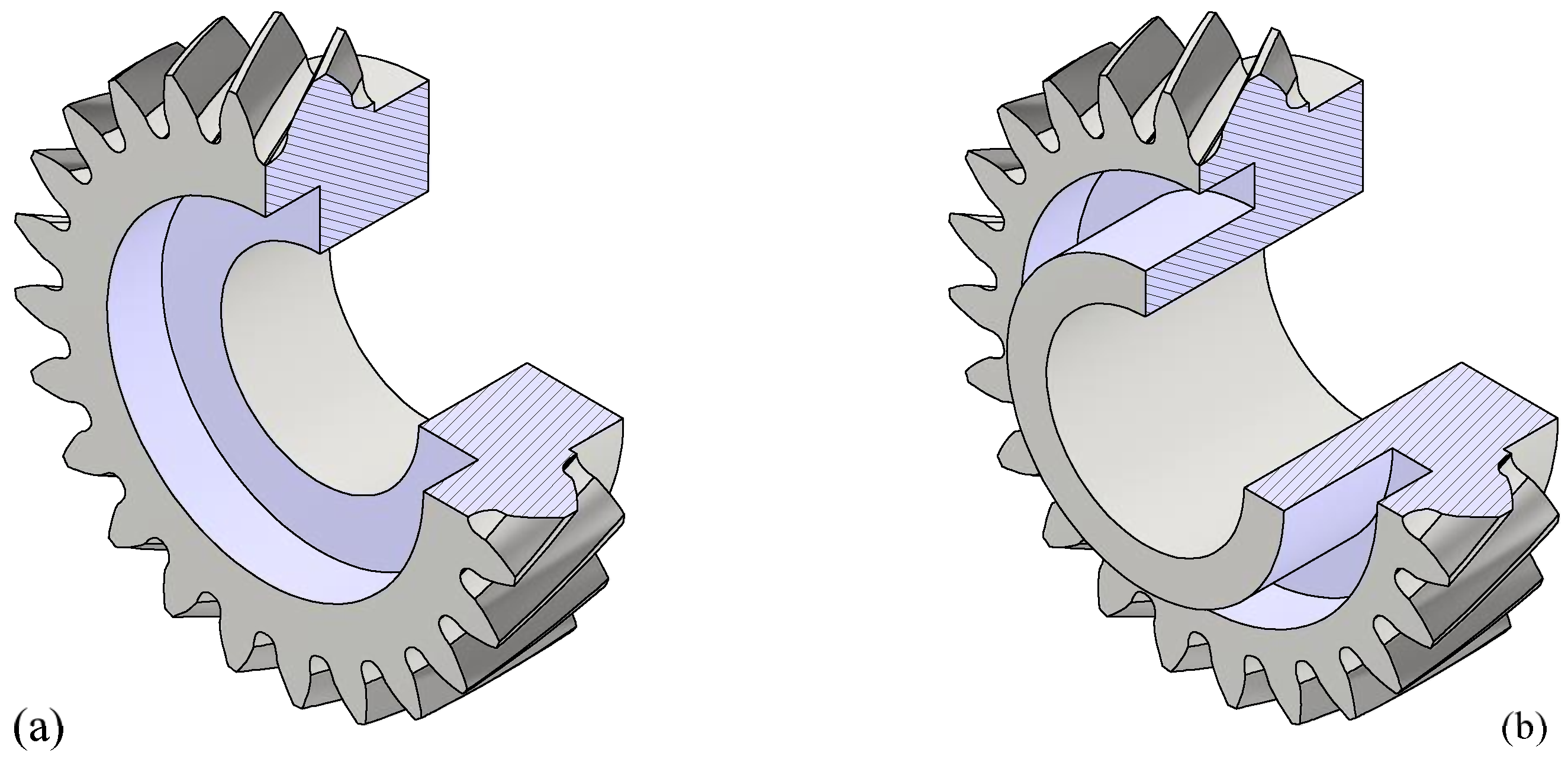

3. Definition of the Gear Body Shape

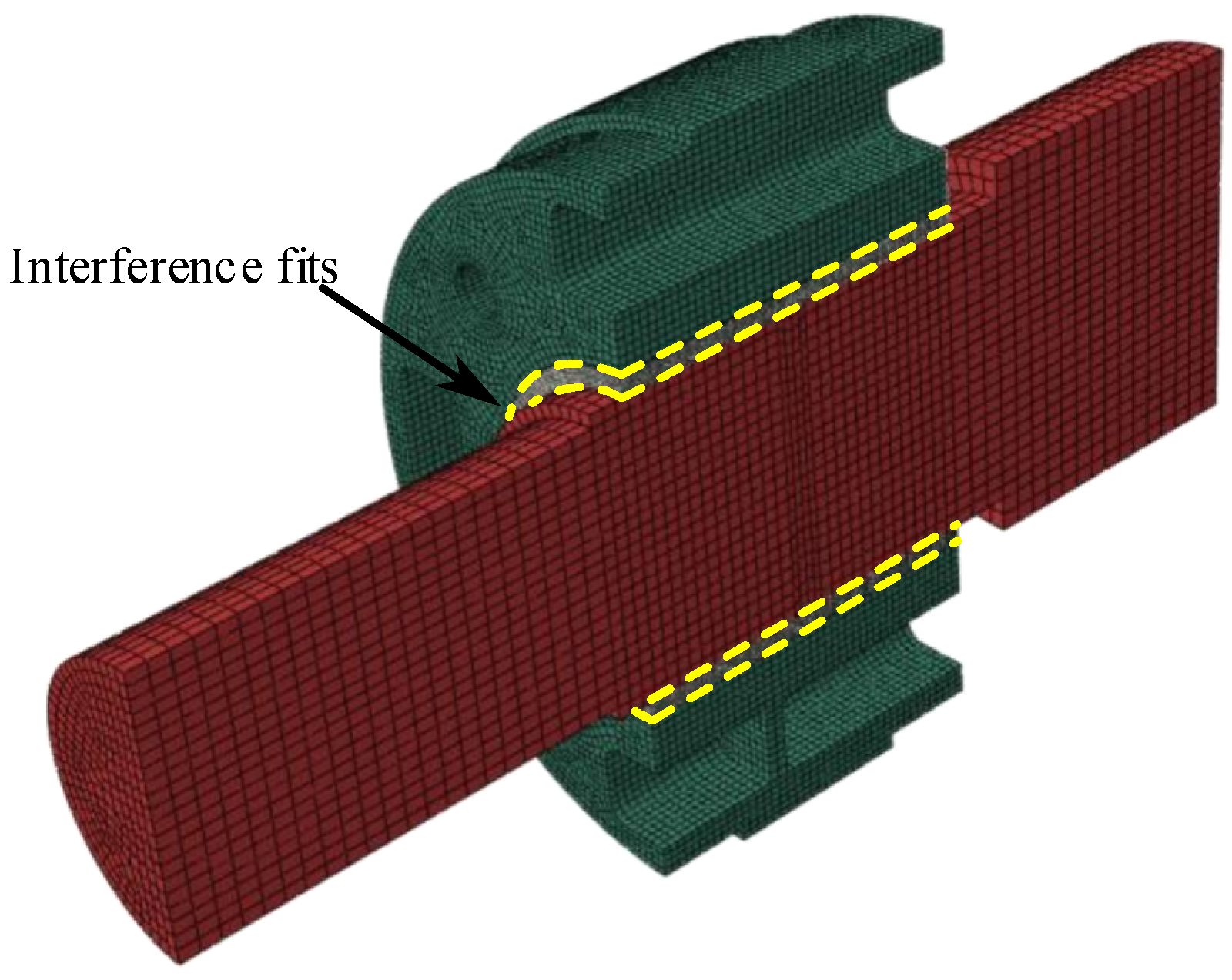

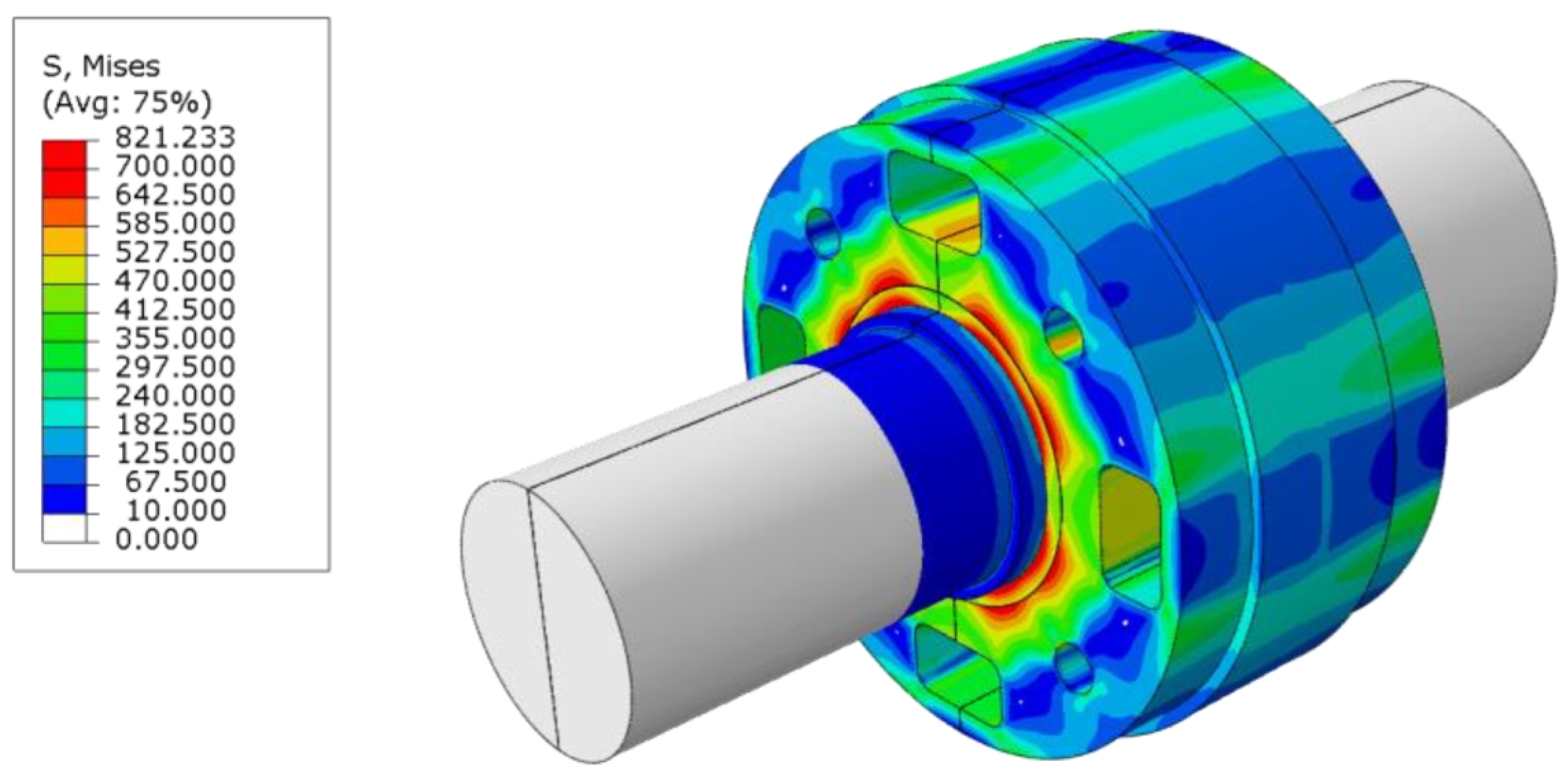

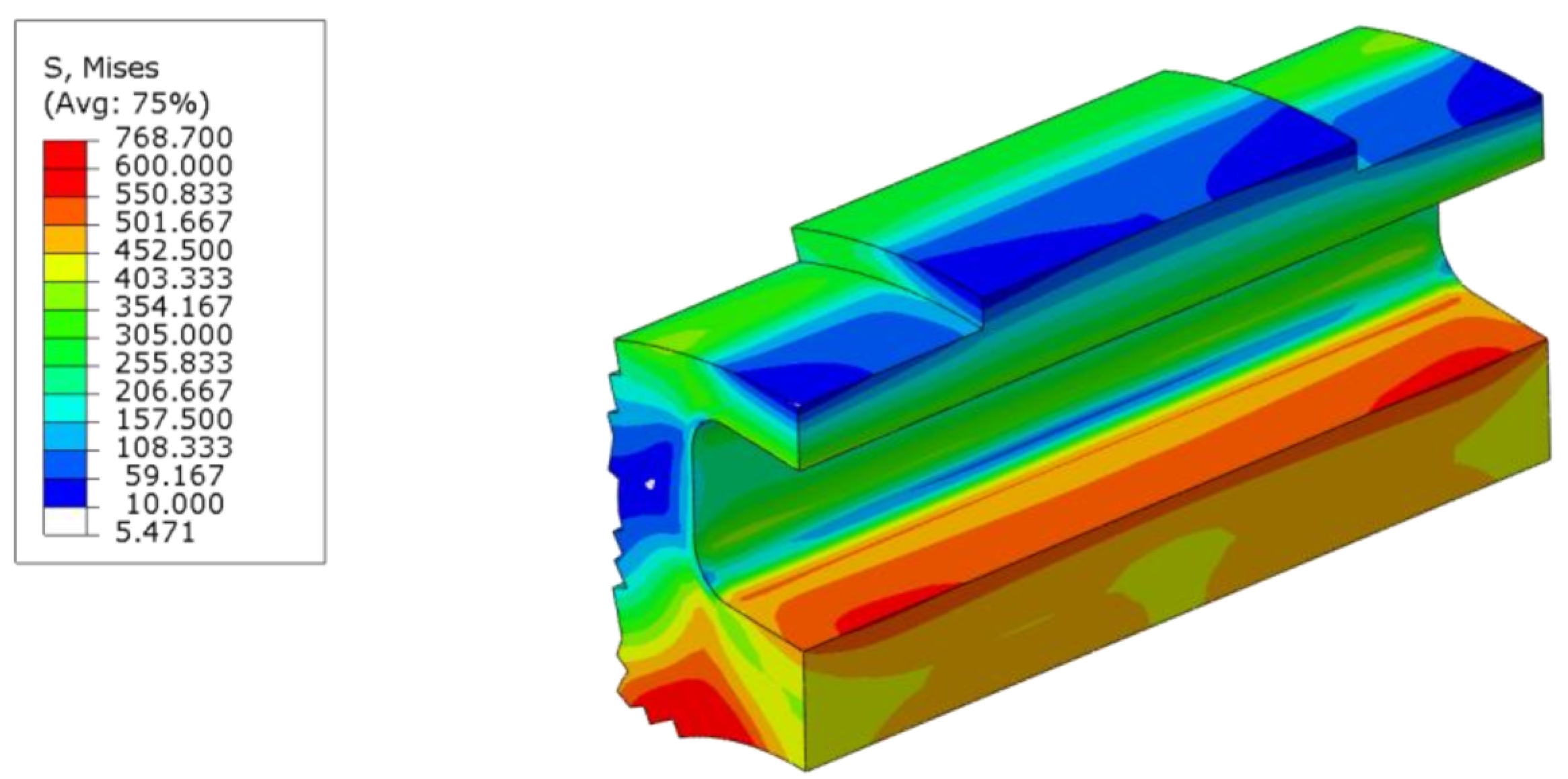

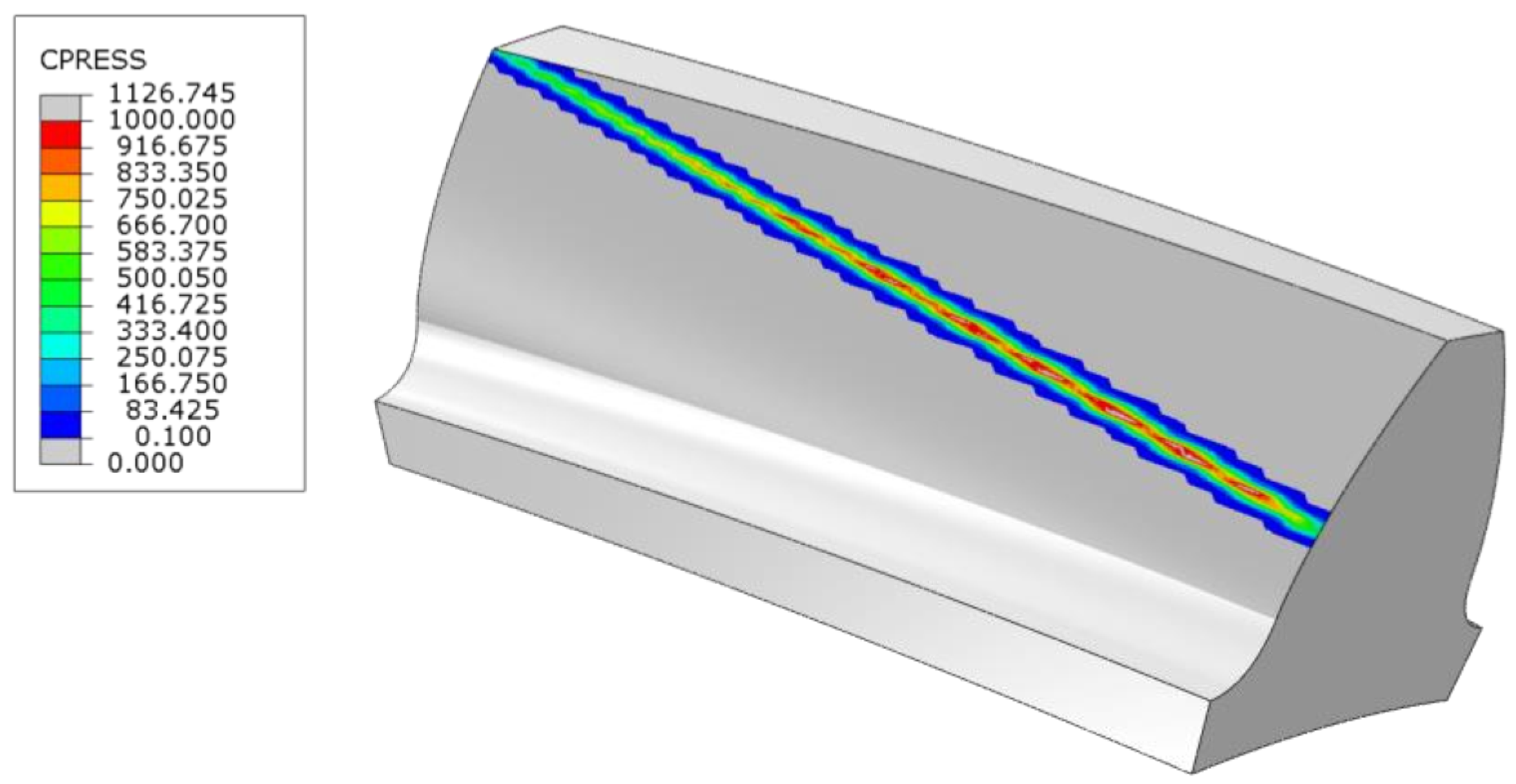

4. Evaluation of the Sensor Port Effect on the Interference Fit

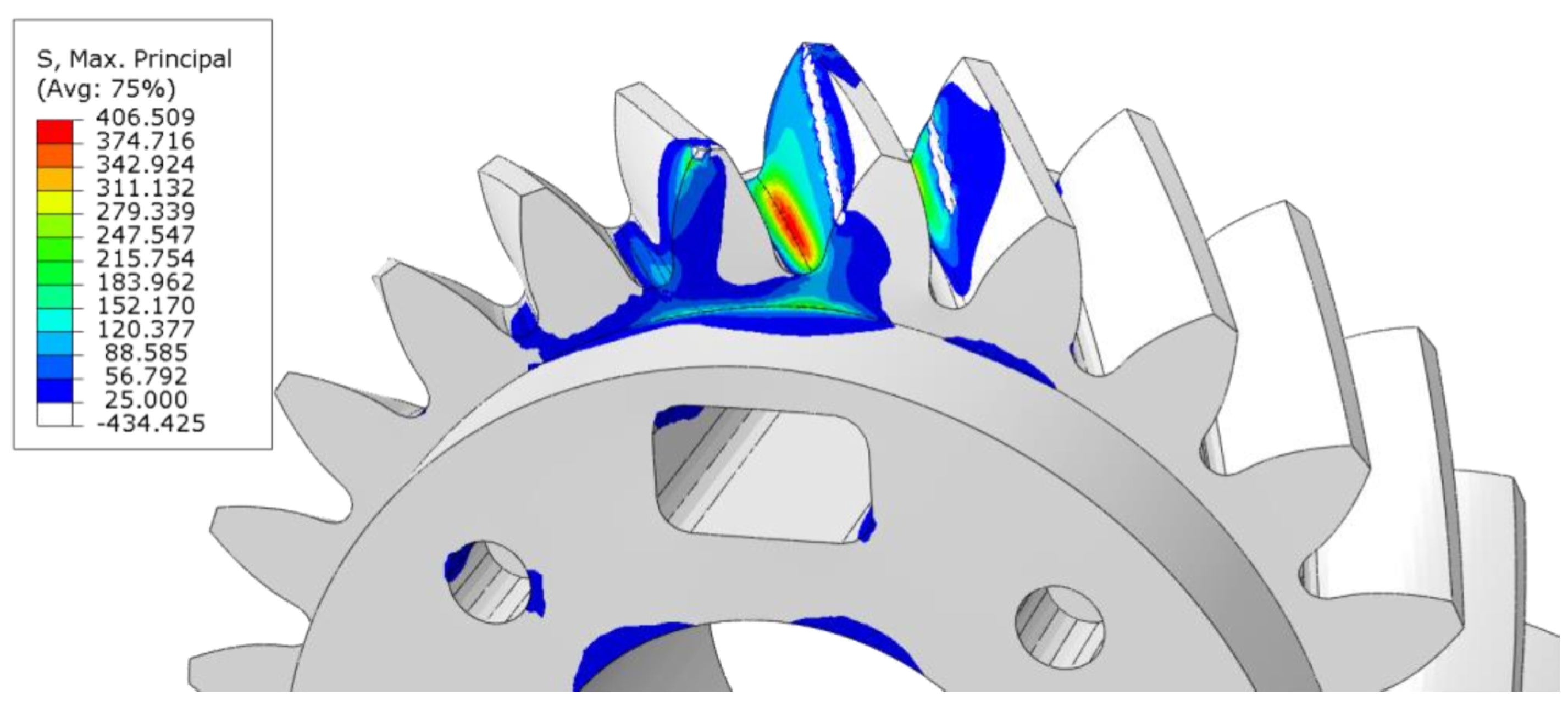

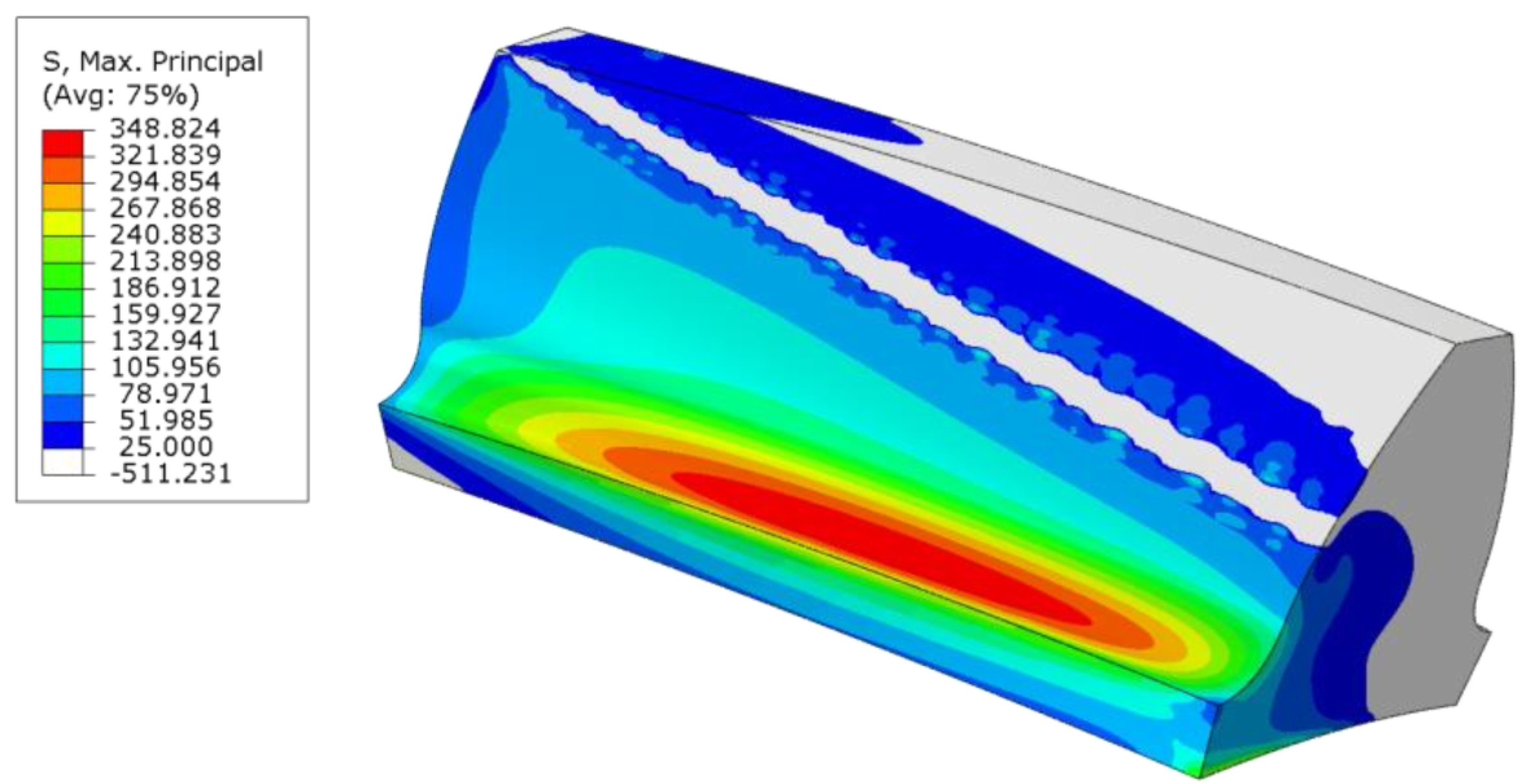

5. Evaluation of the Sensor Port Effect on the Tooth Root Stress

6. Results and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- De Solla Price, D. Gears from the Greeks. The Antikythera Mechanism: A Calendar Computer from ca. 80 B. C. Trans. Am. Philos. Soc. 1974, 64, 1. [Google Scholar] [CrossRef]

- Litvin, F.L. Development of Gear Technology and Theory of Gearing; National Aeronautics and Space Administration, Lewis Research Center: Cleveland, OH, USA, 1997; Volume 1406.

- Reti, L. Leonardo on Bearings and Gears. Sci. Am. 1971, 224, 100–111. [Google Scholar] [CrossRef]

- Ziegler, L.; Gonzalez, E.; Rubert, T.; Smolka, U.; Melero, J.J. Lifetime Extension of Onshore Wind Turbines: A Review Covering Germany, Spain, Denmark, and the UK. Renew. Sustain. Energy Rev. 2018, 82, 1261–1271. [Google Scholar] [CrossRef]

- Farrar, C.R.; Worden, K. An Introduction to Structural Health Monitoring. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2006, 365, 303–315. [Google Scholar] [CrossRef] [PubMed]

- Sait, A.S.; Sharaf-Eldeen, Y.I. A Review of Gearbox Condition Monitoring Based on Vibration Analysis Techniques Diagnostics and Prognostics. In Rotating Machinery, Structural Health Monitoring, Shock and Vibration, Volume 5; Conference Proceedings of the Society for Experimental Mechanics Series; Springer: New York, NY, USA, 2011; Volume 5, pp. 307–324. [Google Scholar] [CrossRef]

- Wang, T.; Han, Q.; Chu, F.; Feng, Z. Vibration Based Condition Monitoring and Fault Diagnosis of Wind Turbine Planetary Gearbox: A Review. Mech. Syst. Signal Process. 2019, 126, 662–685. [Google Scholar] [CrossRef]

- Nie, M.; Wang, L. Review of Condition Monitoring and Fault Diagnosis Technologies for Wind Turbine Gearbox. Procedia CIRP 2013, 11, 287–290. [Google Scholar] [CrossRef]

- Salameh, J.P.; Cauet, S.; Etien, E.; Sakout, A.; Rambault, L. Gearbox Condition Monitoring in Wind Turbines: A Review. Mech. Syst. Signal Process. 2018, 111, 251–264. [Google Scholar] [CrossRef]

- Sendlbeck, S.; Fimpel, A.; Siewerin, B.; Otto, M.; Stahl, K. Condition Monitoring of Slow-Speed Gear Wear Using a Transmission Error-Based Approach with Automated Feature Selection. Int. J. Progn. Health Manag. 2021, 12. [Google Scholar] [CrossRef]

- Concli, F.; Pierri, L.; Sbarufatti, C. A Model-Based SHM Strategy for Gears—Development of a Hybrid FEM-Analytical Approach to Investigate the Effects of Surface Fatigue on the Vibrational Spectra of a Back-to-Back Test Rig. Appl. Sci. 2021, 11, 2026. [Google Scholar] [CrossRef]

- Fromberger, M.L.; Kohn, B.; Utakapan, T.; Otto, M.; Stahl, K. Condition Monitoring by Position Encoders. In Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference Proceedings, Hamburg, Germanny, 21–24 August 2016; Institute of Noise Control Engineering: Reston, VA, USA, 2016; Volume 253, pp. 7451–7459. [Google Scholar]

- Feng, K.; Borghesani, P.; Smith, W.A.; Randall, R.B.; Chin, Z.Y.; Ren, J.; Peng, Z. Vibration-Based Updating of Wear Prediction for Spur Gears. Wear 2019, 426–427, 1410–1415. [Google Scholar] [CrossRef]

- Sendlbeck, S.; Otto, M.; Stahl, K. A Gear Damage Estimation and Propagation Approach by Combining Simulated and Measured Transmission Error Data. In Proceedings of the International Conference on Advanced Vehicle Powertrains 2021, Beijing, China, 2–4 September 2021. [Google Scholar]

- Fromberger, M.; Sendlbeck, S.; Rothemund, M.; Götz, J.; Otto, M.; Stahl, K. Comparing Data Sources for Condition Monitoring Suitability. Forsch. Ingenieurwes. 2019, 83, 521–527. [Google Scholar] [CrossRef]

- Sendlbeck, S.; Fromberger, M.; Otto, M.; Stahl, K. Vibration-Based Gear Condition Monitoring Using an Improved Section-Specific Approach without the Need of Historic Reference Data. In Proceedings of the 27th International Congress on Sound and Vibration (ICSV2021), Online, 11–16 July 2021. [Google Scholar]

- Fromberger, M.; Weinberger, U.; Kohn, B. Evaluating Signal Processing Methods for Use in Gearbox Condition Monitoring. In Proceedings of the 24th international congress on sound and vibration, London, UK, 23–27 July 2017. [Google Scholar]

- Sensorintegrierende Maschinenelemente—Wegbereiter Der Flächendeckenden Digitalisierung. Available online: https://www.spp2305.de/ (accessed on 7 August 2022).

- Holm-Hansen, B.T.; Gao, R.X. Time-Scale Analysis Adapted for Bearing Diagnostics. In Proceedings of the SPIE 3833, Intelligent Systems in Design and Manufacturing II, Boston, MA, USA, 20 August 1999; Volume 3833. [Google Scholar]

- Holm-Hansen, B.T.; Gao, R.X. Monitoring of Loading Status Inside Rolling Element Bearings Through Electromechanical Sensor Integration. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), Dallas, TX, USA, 16–21 November 1997; pp. 329–335. [Google Scholar] [CrossRef]

- Holm-Hansen, B.T.; Gao, R.X. Multiple Defect Analysis of a Sensor Integrated Ball Bearing. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), Anaheim, CA, USA, 15–20 November 1998; pp. 9–14. [Google Scholar] [CrossRef]

- Holm-Hansen, B.T.; Gao, R.X. Smart Bearing Utilizing Embedded Sensors: Design Considerations. In Proceedings of the Smart Structures and Materials 1997: Smart Structures and Integrated Systems, San Diego, CA, USA, 3–6 March 1997; Volume 3041, pp. 602–610. [Google Scholar] [CrossRef]

- Holm-Hansen, B.T.; Gao, R.X. Integrated Microsensor Module for a Smart Bearing with On-Line Fault Detection Capabilities. In Proceedings of the Conference Record—IEEE Instrumentation and Measurement Technology Conference, Ottawa, ON, Canada, 19–21 May 1997; Volume 2, pp. 1160–1163. [Google Scholar] [CrossRef]

- Holm-Hansen, B.T.; Gao, R.X. Vibration Analysis of a Sensor-Integrated Ball Bearing. J. Vib. Acoust. 2000, 122, 384–392. [Google Scholar] [CrossRef]

- Holm-Hansen, B.T.; Gao, R.X. Structural Design and Analysis for a Sensor-Integrated Ball Bearing. Finite Elem. Anal. Des. 2000, 34, 257–270. [Google Scholar] [CrossRef]

- Gao, R.X.; Holm-Hansen, B.T.; Wang, C. Design of a Mechatronic Bearing through Sensor Integration. In Proceedings of the SPIE 3518, Sensors and Controls for Intelligent Machining, Agile Manufacturing, and Mechatronics, Boston, MA USA, 17 December 1998; Volume 3518. [Google Scholar]

- Holm-Hansen, B.T.; Gao, R.X.; Zhang, L. Customized Wavelet for Bearing Defect Detection. J. Dyn. Syst. Meas. Control 2004, 126, 740–745. [Google Scholar] [CrossRef]

- Schirra, T.; Martin, G.; Vogel, S.; Kirchner, E. Ball Bearings as Sensors for Systematical Combination of Load and Failure Monitoring. In Proceedings of the International Design Conference, Dubrovnik, Croatia, 21–24 May 2018; Volume 6, pp. 3011–3022. [Google Scholar] [CrossRef]

- Schirra, T.; Martin, G.; Kirchner, E. Design of and with Sensing Macine Elements—Using the Example of a Sensing Rolling Bearing. Proc. Des. Soc. 2021, 1, 1063–1072. [Google Scholar] [CrossRef]

- Vogel, S.; Martin, G.; Schirra, T.; Kirchner, E. Robust Design for Mechatronic Machine Elements—How Robust Design Enables the Application of Mechatronic Shaft-Hub Connection. In Proceedings of the International Design Conference, Dubrovnik, Croatia, 21–24 May 2018; Volume 6, pp. 3033–3040. [Google Scholar] [CrossRef]

- Groche, P.; Brenneis, M. Manufacturing and Use of Novel Sensoric Fasteners for Monitoring Forming Processes. Measurement 2014, 53, 136–144. [Google Scholar] [CrossRef]

- Gräbner, D.; Dödtmann, S.; Dumstorff, G.; Lucklum, F. 3-D-Printed Smart Screw: Functionalization during Additive Fabrication. J. Sens. Sens. Syst. 2018, 7, 143–151. [Google Scholar] [CrossRef]

- Möhring, H.C.; Bertram, O. Integrated Autonomous Monitoring of Ball Screw Drives. CIRP Ann. 2012, 61, 355–358. [Google Scholar] [CrossRef]

- Biehl, S.; Staufenbiel, S.; Recknagel, S.; Denkena, B.; Bertram, O. Thin film sensors for condition monitoring in ball screw drives. In Proceedings of the 1st Joint International Symposium on System-Integrated Intelligence, Hannover, Germany, 28–29 June 2012; pp. 27–29. [Google Scholar]

- Biehl, S.; Staufenbiel, S.; Hauschild, F.; Albert, A. Novel Measurement and Monitoring System for Forming Processes Based on Piezoresistive Thin Film Systems. Microsyst. Technol. 2010, 16, 879–883. [Google Scholar] [CrossRef]

- Peters, J.; Ott, L.; Gwosch, T.; Matthiesen, S. Requirements for Sensor Integrating Machine Elements: A Review of Wear and Vibration Characteristics of Gears. Sens. Integr. Gears 2020. [Google Scholar] [CrossRef]

- Peters, J.; Ott, L.; Dörr, M.; Gwosch, T.; Matthiesen, S. Design of Sensor Integrating Gears: Methodical Development, Integration and Verification of an in-Situ MEMS Sensor System. Procedia CIRP 2021, 100, 672–677. [Google Scholar] [CrossRef]

- Peters, J.; Ott, L.; Dörr, M.; Gwosch, T.; Matthiesen, S. Sensor-Integrating Gears: Wear Detection by in-Situ MEMS Acceleration Sensors. Forsch. Ingenieurwes. 2022, 86, 421–432. [Google Scholar] [CrossRef]

- Sridhar, V.; Chana, K. Development of a Novel Sensor for Gear Teeth Wear and Damage Detection. Int. J. Progn. Health Manag. 2021, 12. [Google Scholar] [CrossRef]

- Binder, M.; Stapff, V.; Heinig, A.; Schmitt, M.; Seidel, C.; Reinhart, G. Additive Manufacturing of a Passive, Sensor-Monitored 16MnCr5 Steel Gear Incorporating a Wireless Signal Transmission System. Procedia CIRP 2022, 107, 505–510. [Google Scholar] [CrossRef]

- Schmitt, M.; Kamps, T.; Siglmüller, F.; Winkler, J.; Schlick, G.; Seidel, C.; Tobie, T.; Stahl, K.; Reinhart, G. Laser-Based Powder Bed Fusion of 16MnCr5 and Resulting Material Properties. Addit. Manuf. 2020, 35, 101372. [Google Scholar] [CrossRef]

- Bonaiti, L.; Concli, F.; Gorla, C.; Rosa, F. Bending Fatigue Behaviour of 17-4 PH Gears Produced via Selective Laser Melting. Procedia Struct. Integr. 2019, 24, 764–774. [Google Scholar] [CrossRef]

- Concli, F.; Bonaiti, L.; Gerosa, R.; Cortese, L.; Nalli, F.; Rosa, F.; Gorla, C. Bending Fatigue Behavior of 17-4 PH Gears Produced by Additive Manufacturing. Appl. Sci. 2021, 11, 3019. [Google Scholar] [CrossRef]

- Kadach, D. FVA-Heft Nr. 1205 Einfluss Der Lastverteilung Auf Die Grübchentragfähigkeit von Einsatzgehärteten Stirnrädern; Forschungsvereinigung Antriebstechnik e.V. (FVA): Frankfurt, Germany, 2017. [Google Scholar]

- Kadach, D. FVA-Heft Nr. 1164—Einfluss von Stillstandsmarkierungen Auf Die Flankentragfähigkeit von Zahnrädern; Forschungsvereinigung Antriebstechnik e.V. (FVA): Frankfurt, Germany, 2015. [Google Scholar]

- Kadach, D.; Tobie, T.; Stahl, K. Fretting Lines on Gears—Systematic Investigations on the Formation Conditions and Mechanisms. In Proceedings of the JSME international conference on motion and power transmissions, Kyoto, Japan, 28 February–3 March 2017; Volume 2017, pp. 4–5. [Google Scholar] [CrossRef]

- Kadach, D.; Matt, P.; Tobie, T.; Stahl, K. Influences of the Facing Edge Condition on the Flank Load Carrying Capacity of Helical Gears. In Proceedings of the ASME 2015 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 2–5 August 2015. [Google Scholar] [CrossRef]

- Kadach, D. Stillstandsmarkierungen an Zahnrädern Und Deren Auswirkungen Auf Die Flankentragfähigkeit. Ph.D. Thesis, Technische Universität München, München, Germany, 2015. [Google Scholar]

- ISO 14635-1; Gears—FZG Test Procedures—Part 1: FZG Test Method A/8,3/90 for Relative Scuffing Load-Carrying Capacity of Oils. International Organization for Standardization: Geneva, Switzerland, 2006.

- Hoehn, B.-R.; Oster, P.; Tobie, T. Test Methods for Gear Lubricants. Michaelis Metode Ispitivanja. Goriva Maz. 2008, 47, 129–152. [Google Scholar]

- ISO 6336-1: 2006; Calculation of Load Capacity of Spur and Helical Gears—Part 1: Basic Principles, Introduction and General Influence Factors. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 6336-2:2019; Calculation of Load Capacity of Spur and Helical Gears—Part 2: Calculation of Surface Durability (Pitting). International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 6336-3:2019; Calculation of Load Capacity of Spur and Helical Gears—Part 3: Calculation of Tooth Bending Strength. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 6336-5:2019; Calculation of Load Capacity of Spur and Helical Gears—Part 5: Strength and Quality of Materials. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 6336-6:2019; Calculation of Load Capacity of Spur and Helical Gears—Part 6: Calculation of Service Life under Variable Load. International Organization for Standardization: Geneva, Switzerland, 2019.

- Götz, J.; Sepp, S.; Otto, M.; Stahl, K. Low Excitation Spur Gears with Variable Tip Diameter. In INTER-NOISE and NOISE-CON Congress and Conference Proceedings; Institute of Noise Control Engineering: Washington, DC, USA, 2021; Volume 263, pp. 1275–1285. [Google Scholar]

- Utakapan, T.; Kohn, B.; Fromberger, M.; Otto, M.; Stahl, K. Evaluation of Gear Noise Behaviour with Application Force Level: Conference Proceedings. Forsch. Ingenieurwes. 2017, 81, 59–64. [Google Scholar] [CrossRef]

- Enthoven, J.C.; Cann, P.M.; Spikes, H.A. Temperature and Scuffing. Tribol. Trans. 1993, 36, 258–266. [Google Scholar] [CrossRef]

- Bowman, W.F.; Stachowiak, G.W. A Review of Scuffing Models. Tribol. Lett. 1996, 2, 113–131. [Google Scholar] [CrossRef]

- Niemann, G.; Winter, H.; Höhn, B.-R.; Stahl, K. Maschinenelemente 1. In Maschinenelemente 1; Springer: Berlin, Germany, 2019. [Google Scholar] [CrossRef]

- Bibel, G.D.; Reddy, S.K.; Savage, M.; Handschuh, R.F. Effects of Rim Thickness on Spur Gear Bending Stress. J. Mech. Des. 1994, 116, 1157–1162. [Google Scholar] [CrossRef]

- Marunić, G. Effects of Rim and Web Thickness on Gear Tooth Root, Rim and Web Stresses. Key Eng. Mater. 2008, 385–387, 117–120. [Google Scholar] [CrossRef]

- Oda, S.; Nagamura, K.; Aoki, K. Stress Analysis of Thin Rim Spur Gears by Finite Element Method. Bull. JSME 1981, 24, 1273–1280. [Google Scholar] [CrossRef]

- Li, S. Deformation and Bending Stress Analysis of a Three-Dimensional, Thin-Rimmed Gear. J. Mech. Des. 2002, 124, 129–135. [Google Scholar] [CrossRef]

- Conrado, E.; Davoli, P. The “True” Bending Stress in Spur Gears. Gear Technol. 2007, 8, 52–57. [Google Scholar]

- Kawalec, A.; Wiktor, J. Tooth-Root Stress Calculation of Internal Spur Gears. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2004, 218, 1153–1166. [Google Scholar] [CrossRef]

- Politis, D.J.; Politis, N.J.; Lin, J. Review of Recent Developments in Manufacturing Lightweight Multi-Metal Gears. Prod. Eng. 2021, 15, 235–262. [Google Scholar] [CrossRef]

- Ramadani, R.; Pal, S.; Kegl, M.; Predan, J.; Drstvenšek, I.; Pehan, S.; Belšak, A. Topology Optimization and Additive Manufacturing in Producing Lightweight and Low Vibration Gear Body. Int. J. Adv. Manuf. Technol. 2021, 113, 3389–3399. [Google Scholar] [CrossRef]

- Mura, A.; Curà, F.; Pasculli, L. Optimisation Methodology for Lightweight Gears to Be Produced by Additive Manufacturing Techniques. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2017, 232, 3512–3523. [Google Scholar] [CrossRef]

- Truman, C.E.; Booker, J.D. Analysis of a Shrink-Fit Failure on a Gear Hub/Shaft Assembly. Eng. Fail. Anal. 2007, 14, 557–572. [Google Scholar] [CrossRef]

- Strozzi, A.; Baldini, A.; Giacopini, M.; Bertocchi, E.; Bertocchi, L. Achievement of a Uniform Contact Pressure in a Shaft–Hub Press-Fit. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2012, 227, 405–419. [Google Scholar] [CrossRef]

- Leonhardt, C.; Otto, M.; Stahl, K. Potential of Lightweight Construction and Component Properties of Joined Spur Gears. In Dritev-Getriebe in Fahrzeugen; VDI Wissensforum GmbH: Dusseldorf, Germany, 2019. [Google Scholar]

- Chu, S.J.; Jeong, T.K.; Jung, E.H. Effect of Radial Interference on Torque Capacity of Press- and Shrink-Fit Gears. Int. J. Automot. Technol. 2016, 17, 763–768. [Google Scholar] [CrossRef]

- Bae, J.H.; Kim, J.S.; Hwang, B.C.; Bae, W.B.; Kim, M.S.; Kim, C. Prediction of the Dimensional Deformation of the Addendum and Dedendum after the Warm Shrink Fitting Process Using a Correction Coefficient. Int. J. Automot. Technol. 2012, 13, 285–291. [Google Scholar] [CrossRef]

- Leonhardt, C. FVA 797—Einfluss von Querpressverbänden Auf Die Zahnfußtragfähigkeit Außenverzahnter Stirnradverzahnungen; Forschungsvereinigung Antriebstechnik e.V. (FVA): Frankfurt, Germany, 2021. [Google Scholar]

- Güven, F. Effect of Design Parameters on Stresses Occurring at the Tooth Root in a Spur Gear Pressed on a Shaft. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2021, 235, 1164–1174. [Google Scholar] [CrossRef]

- Gorla, C.; Rosa, F.; Conrado, E.; Tesfahunegn, Y.A. Combined Effects of Lead Crowning and Assembly Deviations on Meshing Characteristics of Helical Gears. Int. J. Appl. Eng. Res. 2016, 11, 11681–11694. [Google Scholar]

- Bonaiti, L.; Bayoumi, A.B.M.; Concli, F.; Rosa, F.; Gorla, C. Gear Root Bending Strength: A Comparison between Single Tooth Bending Fatigue Tests and Meshing Gears. J. Mech. Des. Trans. ASME 2021, 143, 103402. [Google Scholar] [CrossRef]

- Broßmann, U. Über Den Einfluß Der Zahnfußausrundung Und Des Schrägungswinkels Auf Beanspruchung Und Festigkeit Schrägverzahnter Stirnräder. Ph.D. Thesis, Technische Universität München, München, Germany, 1979. [Google Scholar]

- Papadopoulos, I.V.; Davoli, P.; Gorla, C.; Filippini, M.; Bernasconi, A. A Comparative Study of Multiaxial High-Cycle Fatigue Criteria for Metals. Int. J. Fatigue 1997, 19, 219–235. [Google Scholar] [CrossRef]

” symbol rep-resent an encastre while the “

” symbol rep-resent an encastre while the “ ” one represent a locating-type constraint.

” one represent a locating-type constraint.

” symbol rep-resent an encastre while the “

” symbol rep-resent an encastre while the “ ” one represent a locating-type constraint.

” one represent a locating-type constraint.

| Name | Symbol | Pinion | Wheel | U.M. |

|---|---|---|---|---|

| Number of teeth | z | 22 | 24 | - |

| Normal modulus | 4.25 | Mm | ||

| Normal pressure angle | 20 | ° | ||

| Helix angle | 29 | ° | ||

| Profile shift coefficient | 0.100 | 0.077 | - | |

| Centre distance | 112.5 | Mm | ||

| Tip diameter | 117.70 | 127.30 | Mm | |

| Addendum factor of the basic rack | 1.55 | - | ||

| Tooth root radius factor | 0.25 | - | ||

| Facewidth | 27.6 | Mm | ||

| Torque | 1000 | Nm | ||

| Rotational velocity | 3000 | Rpm | ||

| Working hours | 2000 | H | ||

| Contact stress | 1528 | 1527 | MPa | |

| Pitting stress limit | 1536 | MPa | ||

| Safety factor, pitting | 1.01 | 1.01 | - | |

| Nominal tooth root stress | 432 | 433 | MPa | |

| Allowable stress number for bending | 950 | MPa | ||

| Safety factor, tooth root bending fatigue | 2.10 | 2.09 | - | |

| T | ||||||||

|---|---|---|---|---|---|---|---|---|

| mm | mm | Nm | MPa | MPa | MPa | MPa | - | |

| Baseline | 50 | 55 | 1000 | 4.63 | 1.372 | 48.3 | 220 | 4.56 |

| Modified | 186 | 3.85 |

[MPa] | [MPa] | ||

|---|---|---|---|

| Original Geometry | Main model | 396 | 337 |

| Sub model | 336 | 290 | |

| Modified Geometry | Main model | 407 | 353 |

| Sub model | 349 | 302 | |

| Modified Geometry with thermocouple hole | Main model | 440 | 380 |

| Without Interference Fit | With Interference Fit | ||

|---|---|---|---|

| Modified Geometry | Main model | 1.05 | 1.12 |

| Sub model | 1.04 | 1.12 | |

| Modified Geometry with thermocouple hole | Main model | 1.13 | 1.22 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bonaiti, L.; Knoll, E.; Otto, M.; Gorla, C.; Stahl, K. The Effect of Sensor Integration on the Load Carrying Capacity of Gears. Machines 2022, 10, 888. https://doi.org/10.3390/machines10100888

Bonaiti L, Knoll E, Otto M, Gorla C, Stahl K. The Effect of Sensor Integration on the Load Carrying Capacity of Gears. Machines. 2022; 10(10):888. https://doi.org/10.3390/machines10100888

Chicago/Turabian StyleBonaiti, Luca, Erich Knoll, Michael Otto, Carlo Gorla, and Karsten Stahl. 2022. "The Effect of Sensor Integration on the Load Carrying Capacity of Gears" Machines 10, no. 10: 888. https://doi.org/10.3390/machines10100888

APA StyleBonaiti, L., Knoll, E., Otto, M., Gorla, C., & Stahl, K. (2022). The Effect of Sensor Integration on the Load Carrying Capacity of Gears. Machines, 10(10), 888. https://doi.org/10.3390/machines10100888