Zero-Defect Manufacturing and Automated Defect Detection Using Time of Flight Diffraction (TOFD) Images

Abstract

:1. Introduction

- Automated processing via image and signal-processing algorithms;

- Developing reliable and robust algorithms capable of producing results of different operating conditions and components that are characterized by having various shapes and sizes;

- Decision support regarding defect detection.

- The automatic processing systems that break through the limitations of the conventional processing and interpretation systems;

- Improving the efficiency of the inspection process;

- Enabling smart manufacturing through the automation of inspections and maintenance.

2. Literature Review

2.1. Related Works on TOFD

2.2. Automated Defect Detection

2.3. Applications in Manufacturing

2.4. Summary of the Literature Review

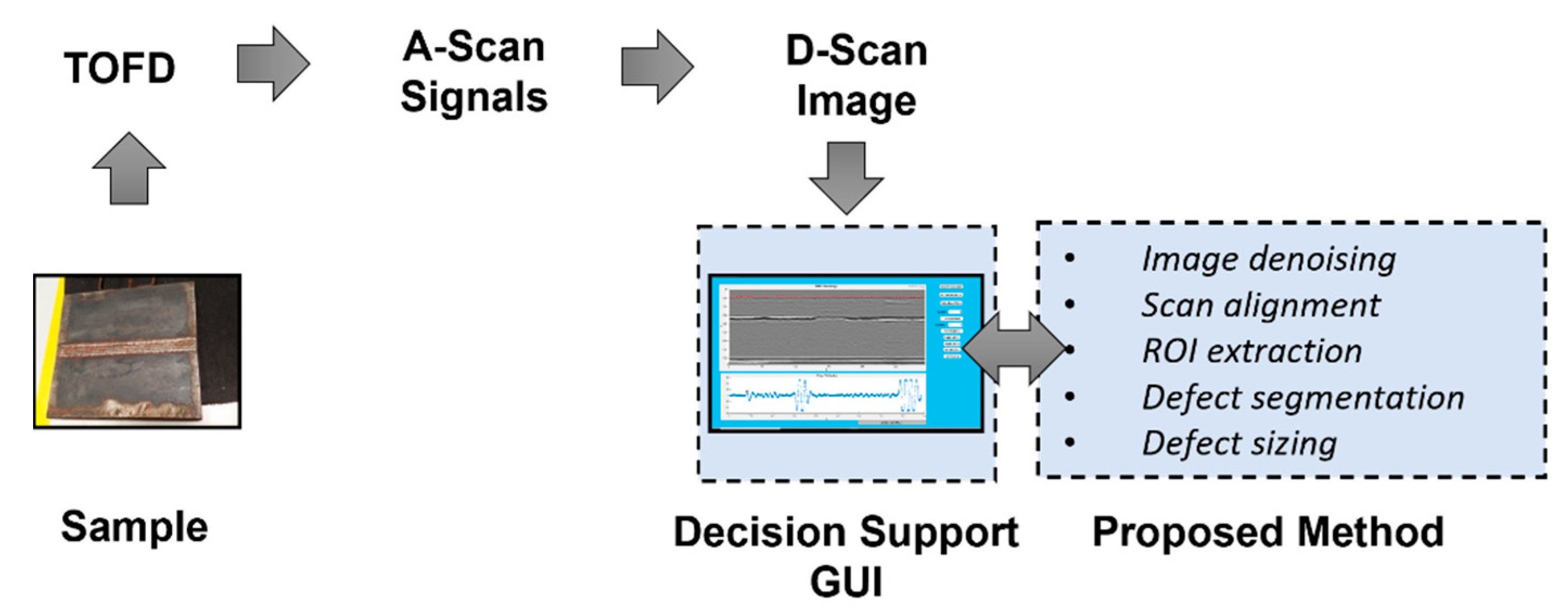

3. Preliminaries

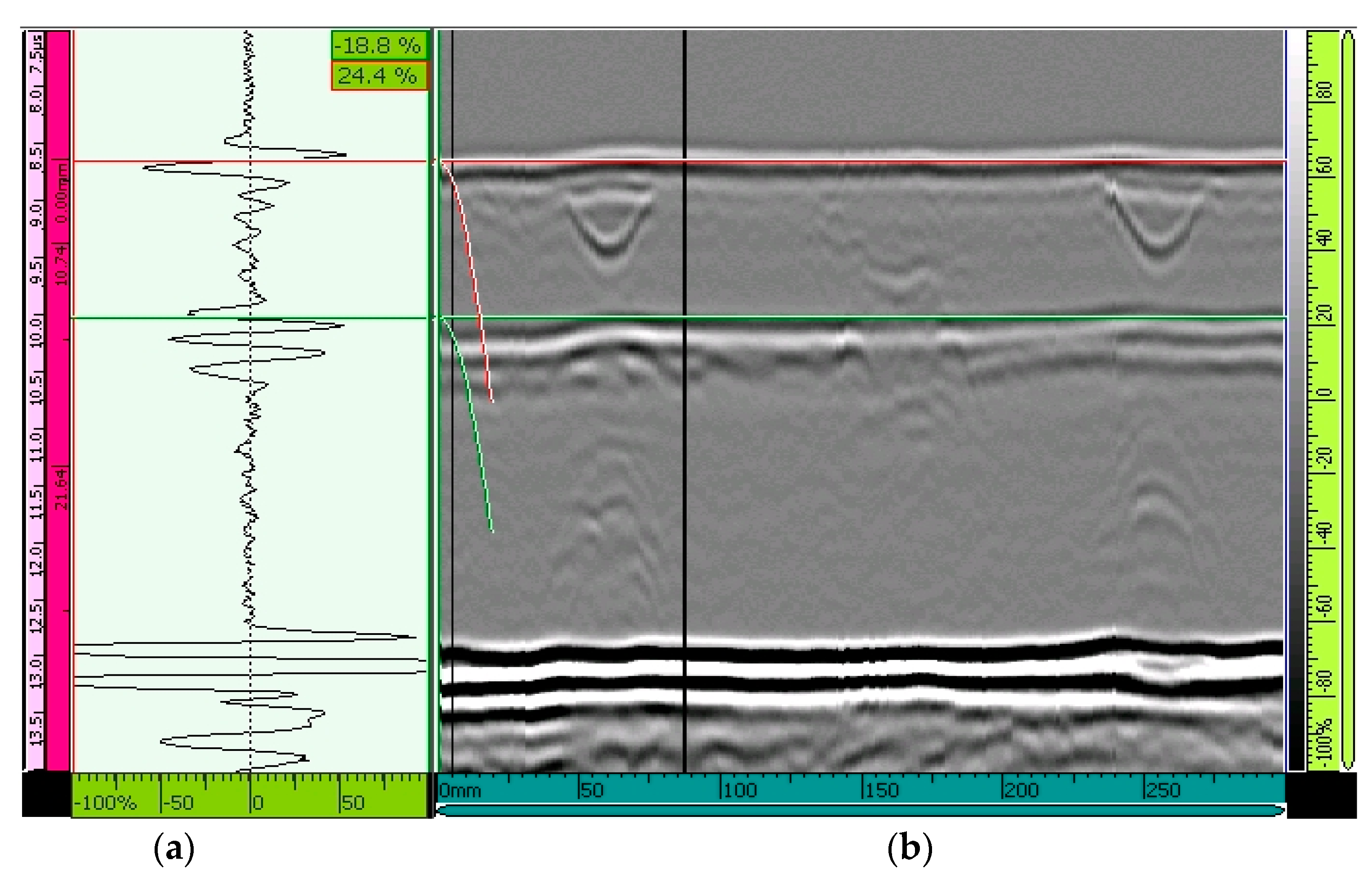

3.1. TOFD Setup

3.2. Image Denoising

3.3. Mean-Based Segmentation

3.4. One-Dimensional Extropy-Based Method

3.5. Two-Dimensional Entropy-Based Segmentation

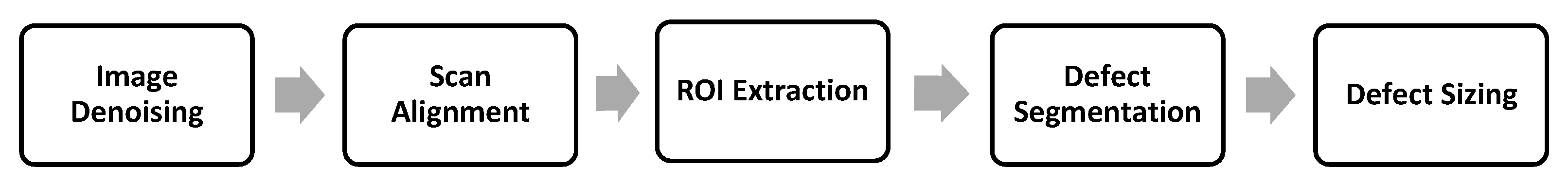

4. Research Methodology

4.1. Wavelet Transform Image Denoising

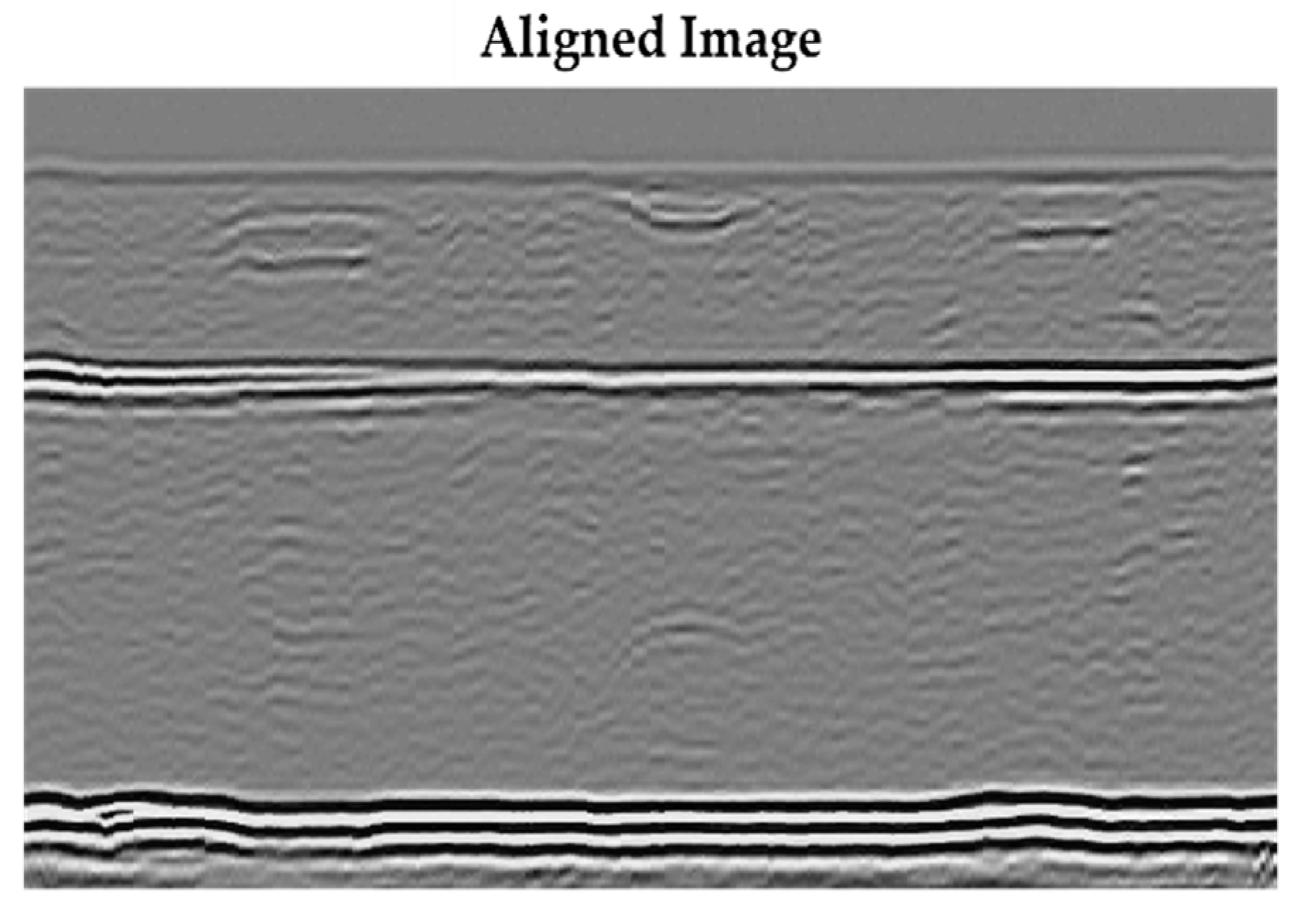

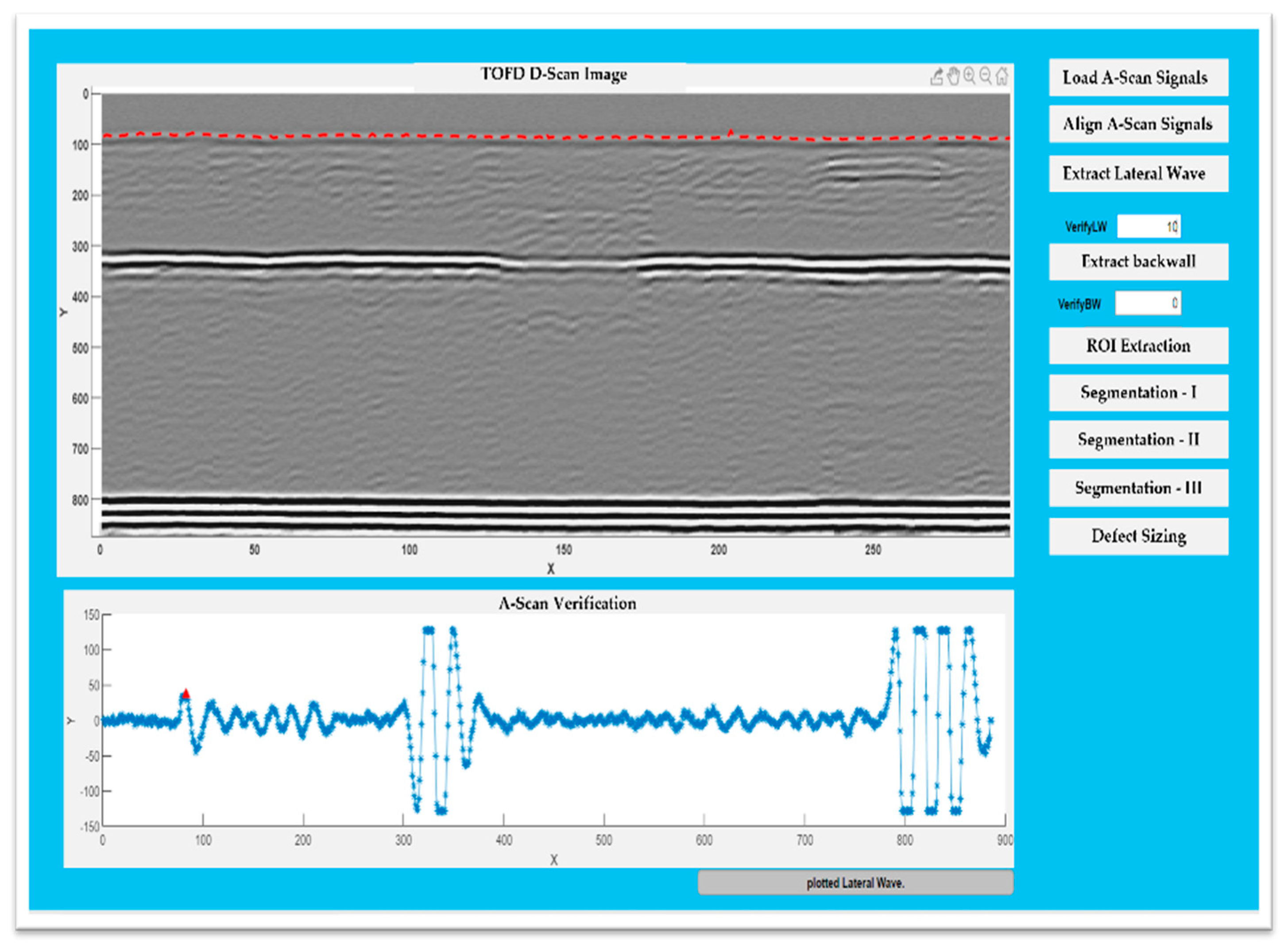

4.2. Scan Alignment

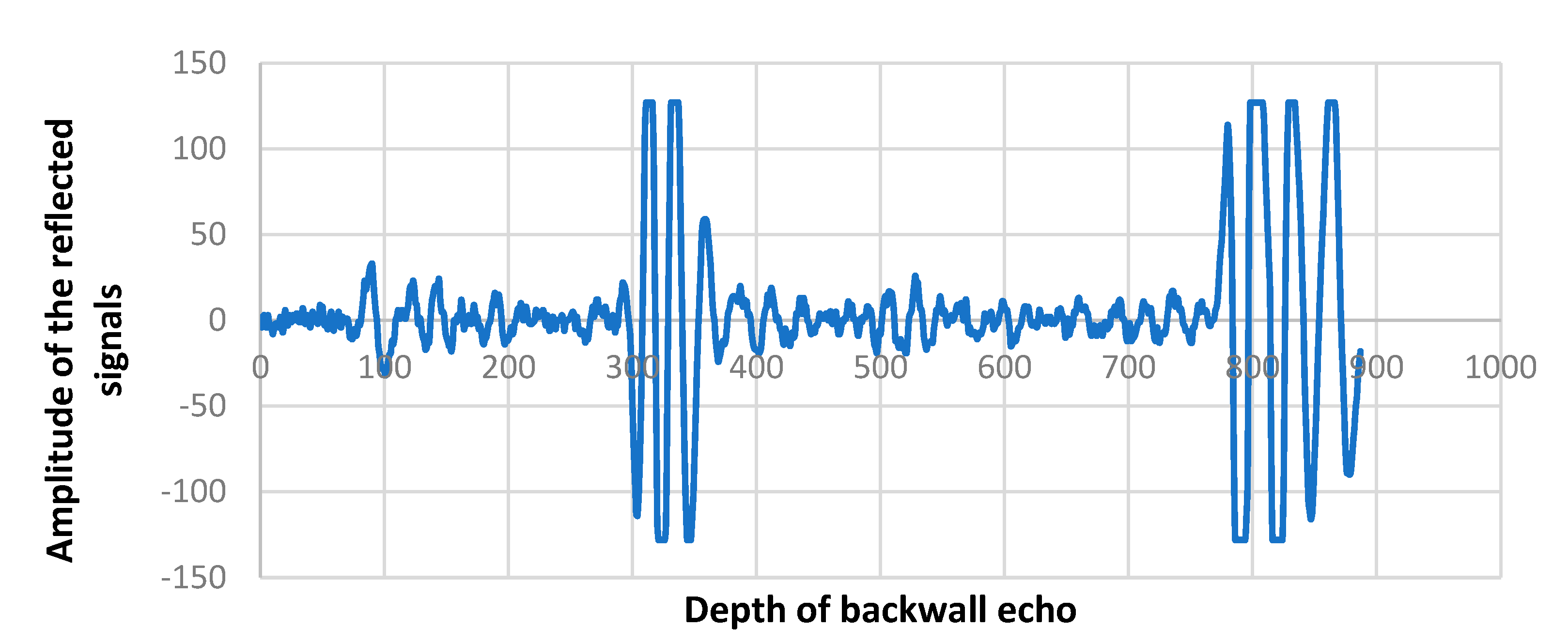

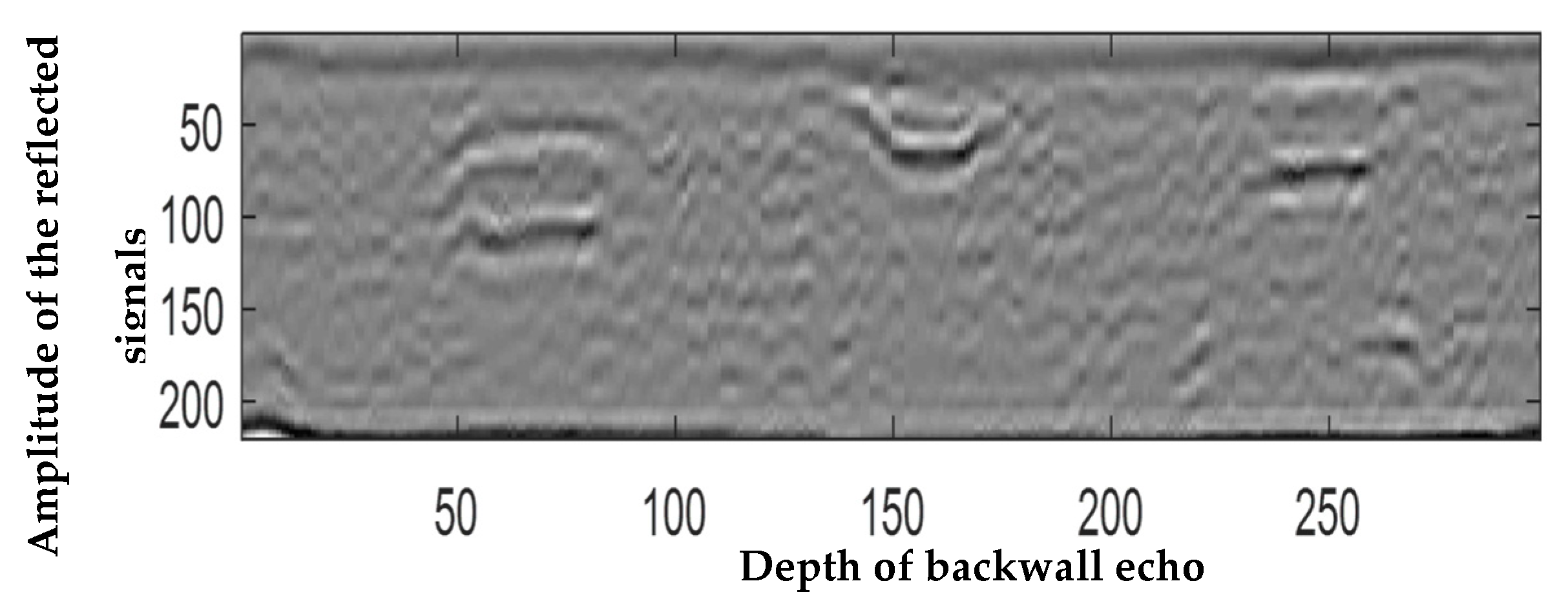

4.3. Region of Interest Extraction

- The first positive maximum of the signal is identified using a particular threshold and is marked as a lateral wave.

- The backwall echo has been identified using threshold and maximum amplitude information. The region between the latter and the backwall echo is marked as an area of interest for defect segmentation.

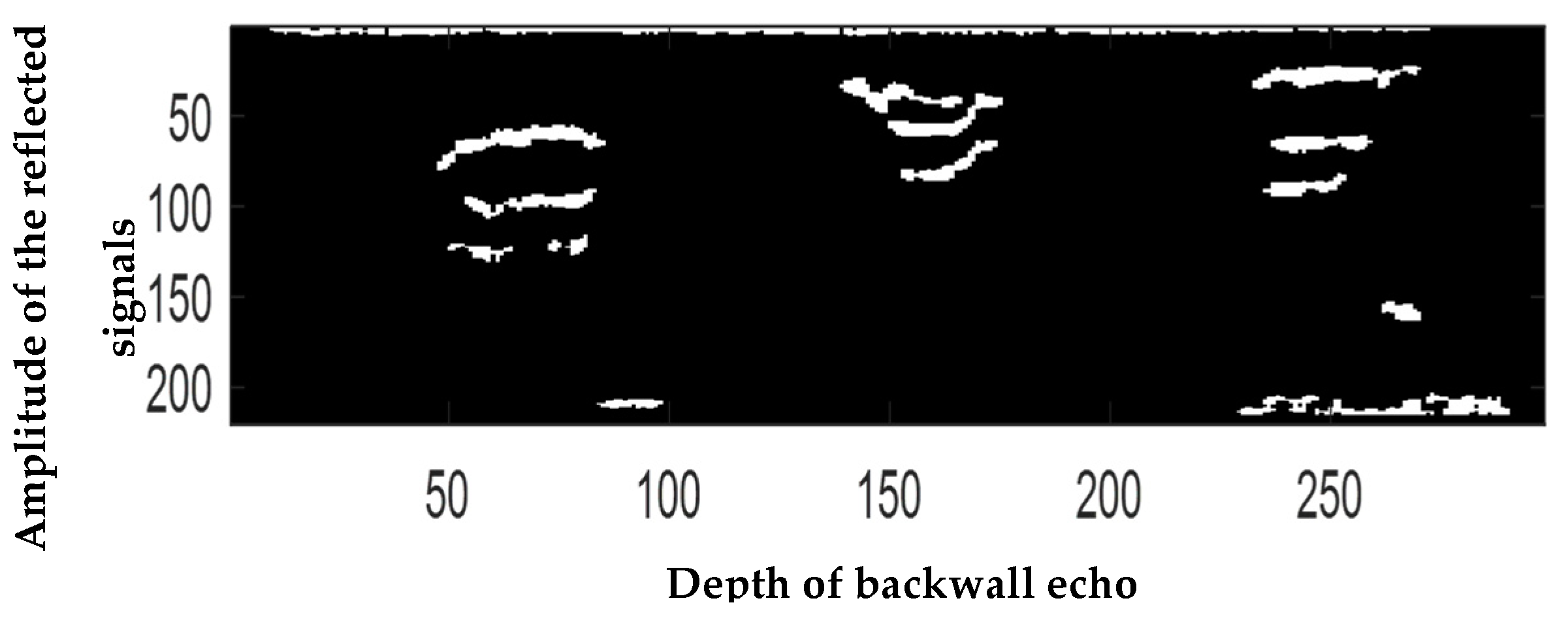

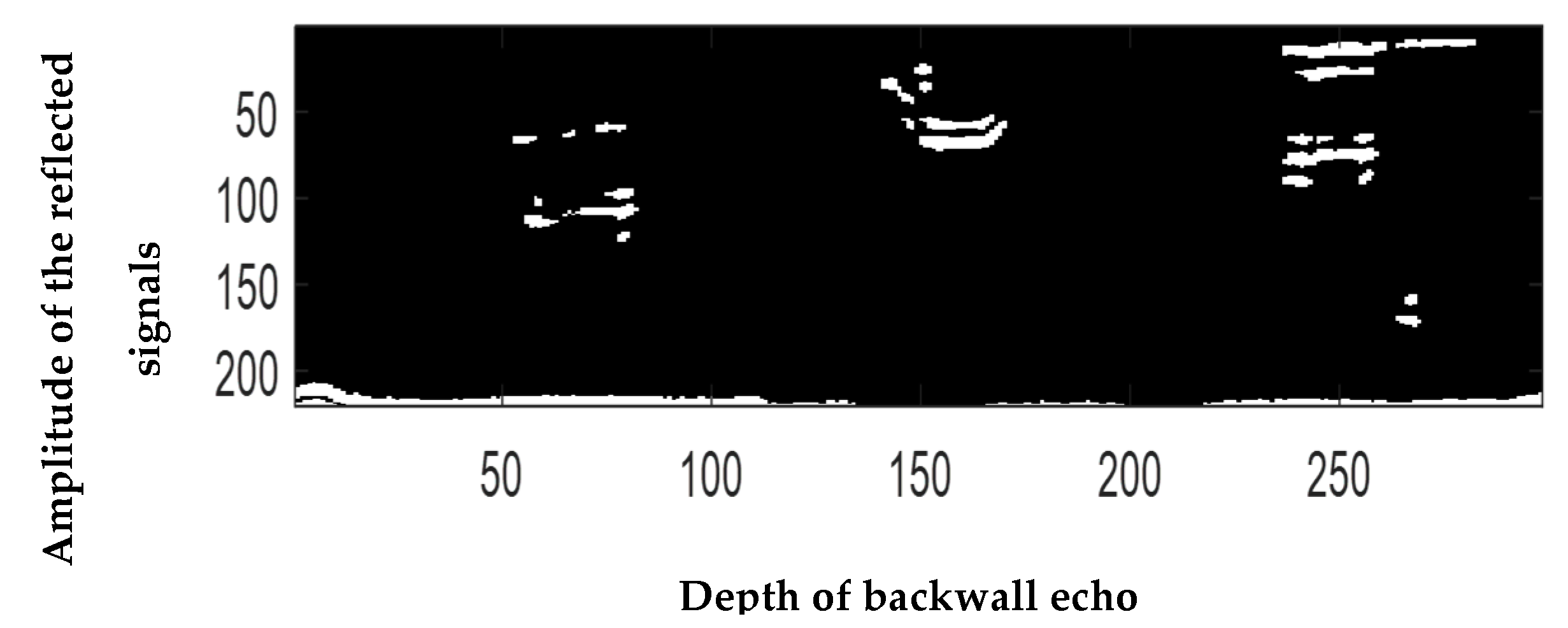

4.4. Defect Segmentation

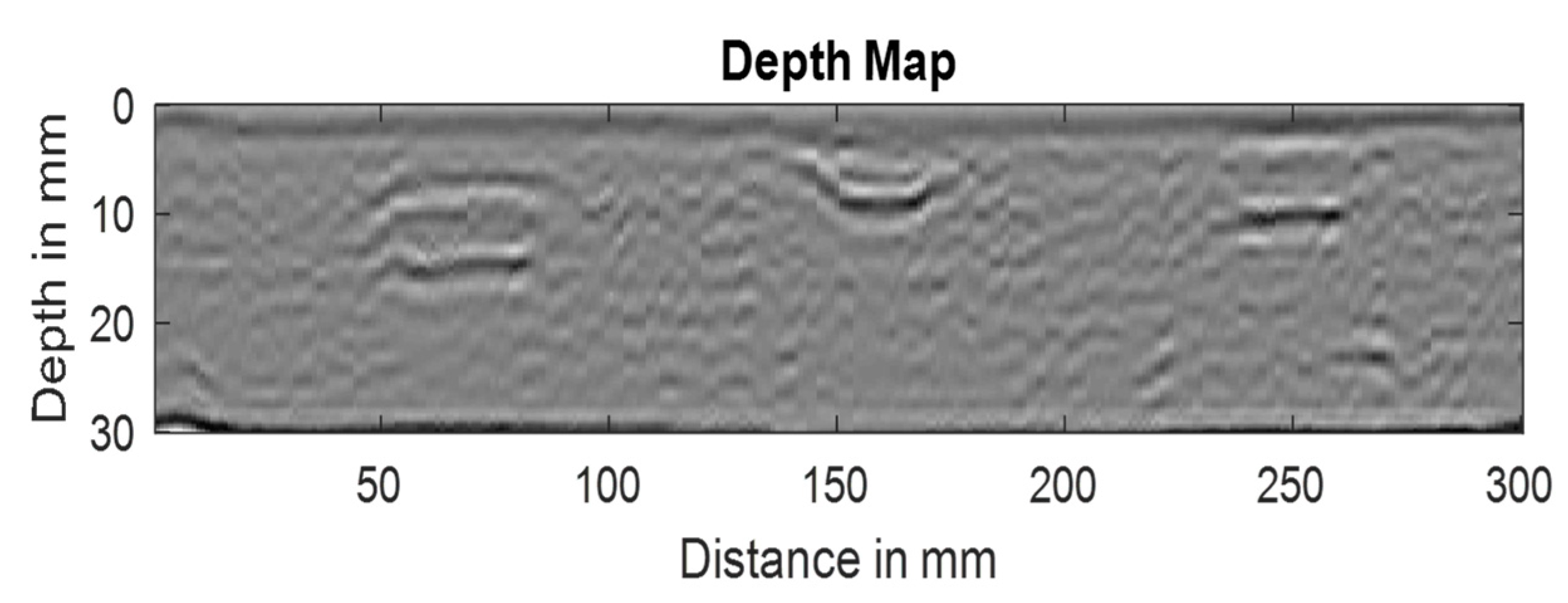

4.5. Defect Sizing

4.6. Example Calculation of Defect Size

4.7. Experimental Setup

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Omar, M. Nondestructive Tesitng Methods and New Applications; IntechOpen: London, UK, 2012. [Google Scholar] [CrossRef]

- Silk, M.G. Changes in ultrasonic defect location and sizing. NDT Int. 1987, 20, 9–14. [Google Scholar]

- Charlesworth, J.P.J.; Temple, A.G. Engineering Applications of Ultrasonic Time-of-Flight Diffraction; Research Studies Press Ltd.: Baldock, UK, 2001. [Google Scholar]

- Silk, M.G. The ultrasonic inspection of difficult materials. In Proceedings of the European Conference on NDT, London, UK, 13–17 September 1987; Pergamon Press: Oxford, UK, 1987. [Google Scholar]

- Manjula, K.; Vijayarekha, K.; Venkatraman, B.; Karthik, D. Ultrasonic Time of Flight Diffraction Technique for Weld Defects: A Review. Res. J. Appl. Sci. Eng. Technol. 2012, 4, 5525–5533. [Google Scholar]

- Silk, M.G. The Capabilities and Limitations of NDT. In Chapter Ultra Sonic Testing—Special Techniques; The British Institute of Non-Destructive Testing: Northampton, UK, 1988; Volume 1. [Google Scholar]

- Silk, M.G. Some modern non-destructive testing techniques and their application. Qual. Assur. 1978, 4, 92–97. [Google Scholar]

- Silk, M.G. Defect sizing using ultrasonic diffraction. Br. J. NDT 1979, 21, 12–15. [Google Scholar]

- Praveen, A.; Vijayarekha, K.; Abraham, S.T.; Venkatraman, B. Signal quality enhancement using higher order wavelets for ultrasonic TOFD signals from austenitic stainless-steel welds. Ultrasonics 2013, 53, 1288–1292. [Google Scholar] [CrossRef] [PubMed]

- Ying, W.; Xiao, G.; Jian, G.; Ze, W. Ultrasonic TOFD image registration algorithm of sub-pixel accuracy based on DFT. In IEEE Far East Forum on Non-Destructive Evaluation/Testing (FENDT); IEEE: Chengdu, China, 2014; pp. 84–88. [Google Scholar] [CrossRef]

- Jia, D.; Lin, L.; Xiao, G.; Jian, P.; Jin, L. Multiframe Ultrasonic TOFD Weld Inspection Imaging Based on Wavelet Transform and Image Registration. J. Sens. 2018, 2018, 9545832. [Google Scholar] [CrossRef]

- Lalithakumari, S.; Pandian, R. Discrete Wavelet Transform based Denoising of TOFD Signals of Austenitic Stainless-Steel Weld at Elevated Temperature. Russ. J. Nondestruct. Test. 2019, 55, 363–368. [Google Scholar] [CrossRef]

- Ahmed, K.; Redouane, D.; Abdessalem, B. Image processing and wavelets transform for sizing of weld defects using ultrasonic TOFD images. J. Acoust. Soc. Am. 2008, 123, 3083. [Google Scholar] [CrossRef]

- Chi, D.; Gang, T. Automatic defect detection in ultrasonic TOFD D-scan data using image processing methods. China Weld. (Engl. Ed.) 2015, 24, 56–61. [Google Scholar]

- Theresa Cenate, C.F.; Sheela Rani, B.; Sangeetha, B.N.; Venkatraman, B. Comparative Study of Diverse Techniques for Flaw Segmentation in TOFD Images of Austenitic Stainless Steel Weld. Indian J. Sci. Technol. 2015, 8, 1. [Google Scholar] [CrossRef]

- Al-Ataby, A.; Al-Nuaimy, W.; Brett, C.R.; Zahran, O. Automatic detection and classification of weld flaws in TOFD data using wavelet transform and support vector machines. Insight. Non. Destr. Test. Cond. Monit. 2010, 52, 597–602. [Google Scholar] [CrossRef]

- Lalithakumari, S.; Sheelarani, B.; Venkatraman, B. Classification of TOFD Signals by Artificial Neural Network. In Proceedings of the World Conference on Nondestructive Testing, Durban, South Africa, 16–20 April 2012. [Google Scholar]

- Zahran, O.; Al-Nuaimy, W. Utilising phase relationships for automatic weld flaw categorisation in time-of-flight diffraction images. In Proceedings of the International Conference on NDT, Turin, Italy, 20–25 March 2005. [Google Scholar]

- Al-Nuaimy, W.; Zahran, O. Automatic data processing and defect detection in time-of-flight diffraction images using statistical techniques. Insight. Non. Destr. Test. Cond. Monit. 2005, 47, 538–542. [Google Scholar]

- Cao, Y.; Zhu, H.; Yang, P. Ultrasonic Time of Flight Diffraction Defect Recognition Based on Edge Detection. In Proceedings of the International Conference on Biomedical Engineering and Computer Science, Wuhan, China, 23–25 April 2010; pp. 1–4. [Google Scholar] [CrossRef]

- Shan, M.; Liu, S. Defect depth automation measurement based on image processing for tofd parallel scanning. In Proceedings of the 10th World Congress on Intelligent Control and Automation, Beijing, China, 6–8 July 2012; pp. 4180–4183. [Google Scholar] [CrossRef]

- Wang, K.S. Towards zero-defect manufacturing (ZDM)—A data mining approach. Adv. Manuf. 2013, 1, 62–74. [Google Scholar] [CrossRef]

- Sophian, A. Non-destructive testing (NDT) in industry 4.0: A brief review. In Proceedings of the International Conference on Science and Technology(ICST), Oluvil, Sri Lanka, 3 July 2021; 2. [Google Scholar]

- Shaloo, M.; Schnall, M.; Klein, T.; Huber, N.; Reitinger, B. A Review of Non-Destructive Testing (NDT) Techniques for Defect Detection: Application to Fusion Welding and Future Wire Arc Additive Manufacturing Processes. Materials 2022, 15, 3697. [Google Scholar] [CrossRef] [PubMed]

- Javadi, Y.; Sweeney, N.E.; Mohseni, E.; MacLeod, C.N.; Lines, D.; Vasilev, M.; Qiu, Z.; Vithanage, R.K.W.; Mineo, C.; Stratoudaki, T.; et al. In-process calibration of a non-destructive testing system used for in-process inspection of multi-pass welding. Mater. Des. 2020, 195, 108981. [Google Scholar] [CrossRef]

- Gonzalez, R.C.; Woods, R.E. Digital Image Processing; Addison-Wesley: Boston, MA, USA, 1992. [Google Scholar]

- Zou, Y.; Zhang, J.; Upadhyay, M.; Sun, S.; Jiang, T. Automatic Image Thresholding Based on Shannon Entropy Difference and Dynamic Synergic Entropy. IEEE Access 2020, 8, 171218–171239. [Google Scholar] [CrossRef]

- Brink, A. Thresholding of digital images using two-dimensional entropies. Pattern Recognit. 1992, 25, 803–808. [Google Scholar] [CrossRef]

- de Albuquerque, M.P.; Esquef, I.F.; Gesualdi Mello, A.R. Image thresholding using Tsallis entropy. Pattern Recognit. Lett. 2004, 25, 1059–1065. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Subramaniam, S.; Kanfoud, J.; Gan, T.-H. Zero-Defect Manufacturing and Automated Defect Detection Using Time of Flight Diffraction (TOFD) Images. Machines 2022, 10, 839. https://doi.org/10.3390/machines10100839

Subramaniam S, Kanfoud J, Gan T-H. Zero-Defect Manufacturing and Automated Defect Detection Using Time of Flight Diffraction (TOFD) Images. Machines. 2022; 10(10):839. https://doi.org/10.3390/machines10100839

Chicago/Turabian StyleSubramaniam, Sulochana, Jamil Kanfoud, and Tat-Hean Gan. 2022. "Zero-Defect Manufacturing and Automated Defect Detection Using Time of Flight Diffraction (TOFD) Images" Machines 10, no. 10: 839. https://doi.org/10.3390/machines10100839

APA StyleSubramaniam, S., Kanfoud, J., & Gan, T.-H. (2022). Zero-Defect Manufacturing and Automated Defect Detection Using Time of Flight Diffraction (TOFD) Images. Machines, 10(10), 839. https://doi.org/10.3390/machines10100839