Analysis, Design and Experimental Research of a Novel Bilateral Patient Transfer Robot

Abstract

1. Introduction

- (1)

- Integrated patient transfer robot:

- (2)

- Split patient transfer robot:

- (3)

- Humanoid patient transfer robot:

2. Analysis of the Working Principle for the Patient Transfer Robot

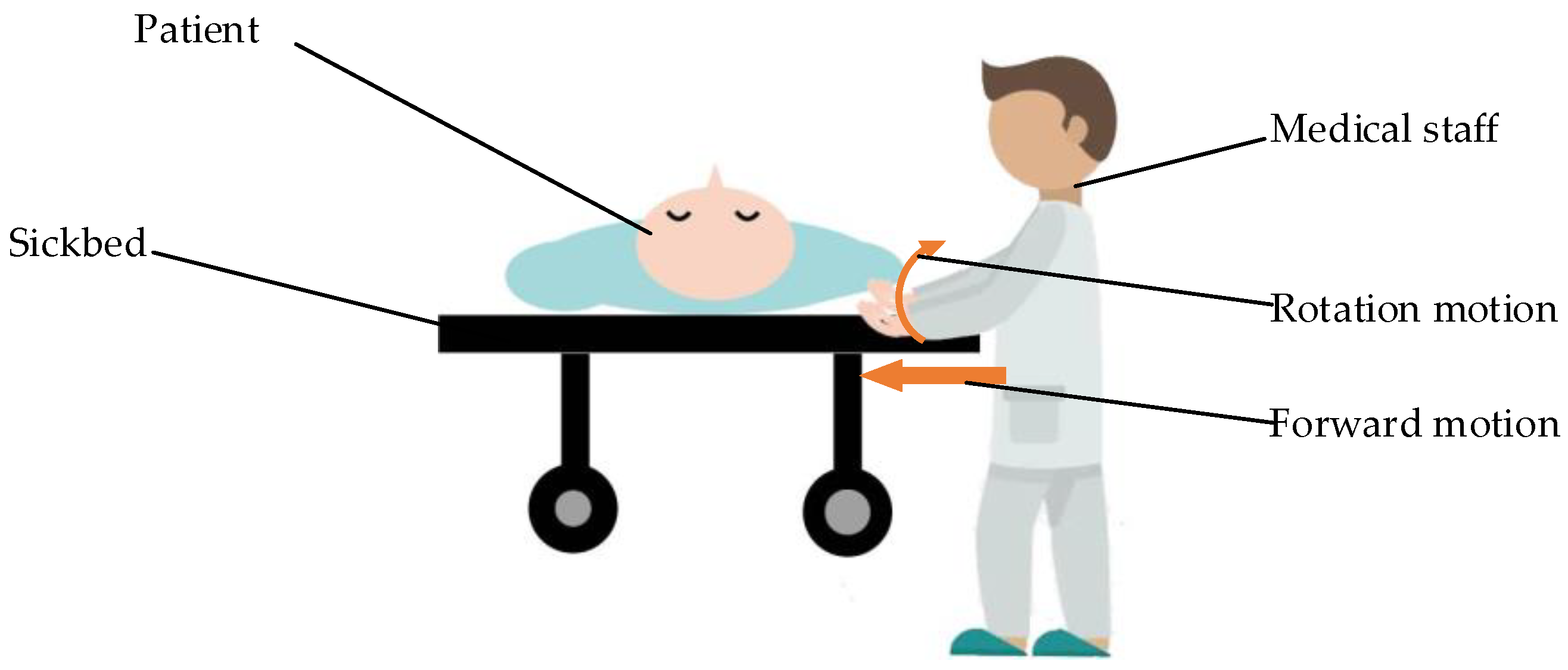

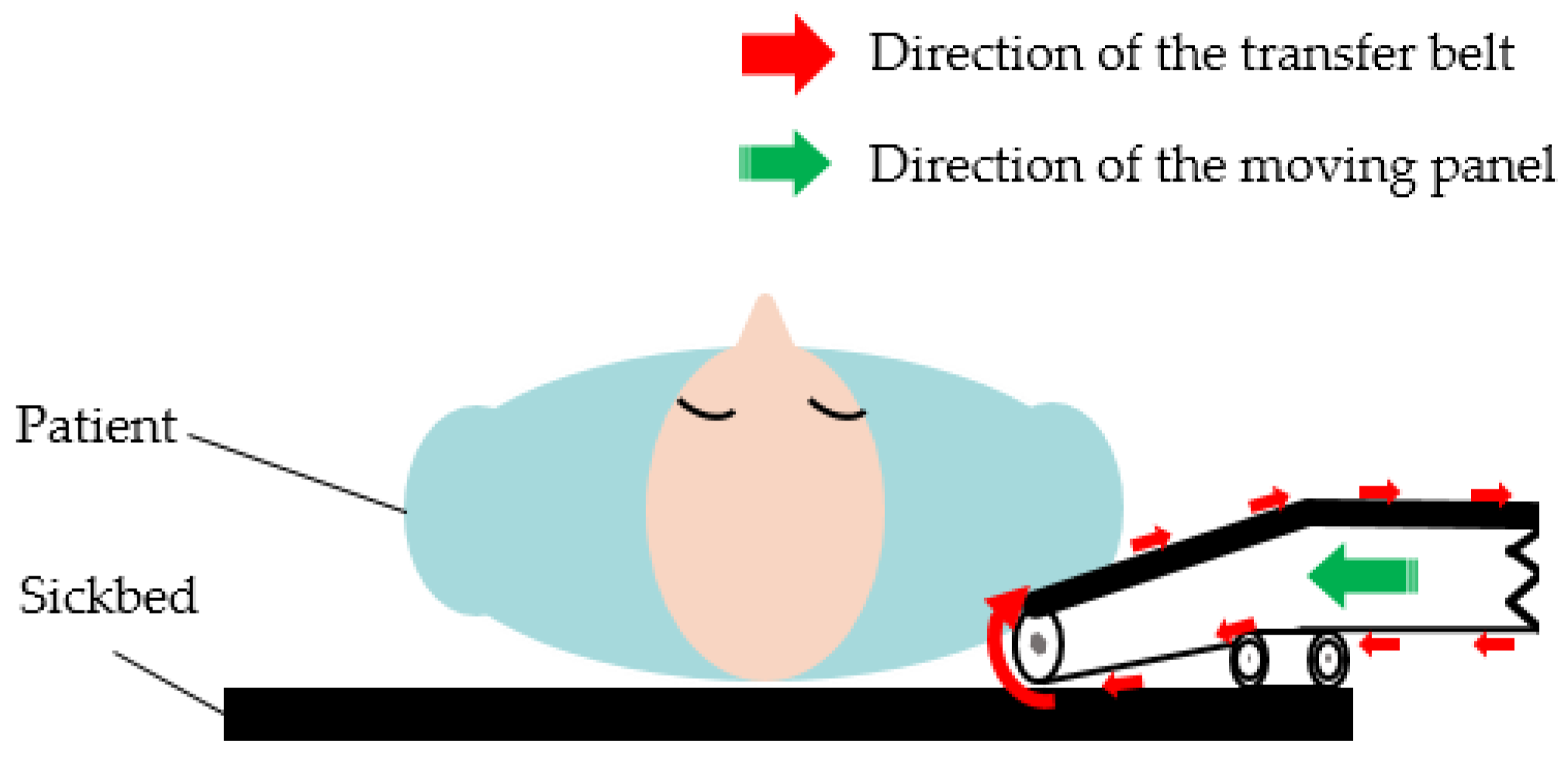

2.1. Analysis of the Working Principle for the Bilateral Movement in Patient Transfer

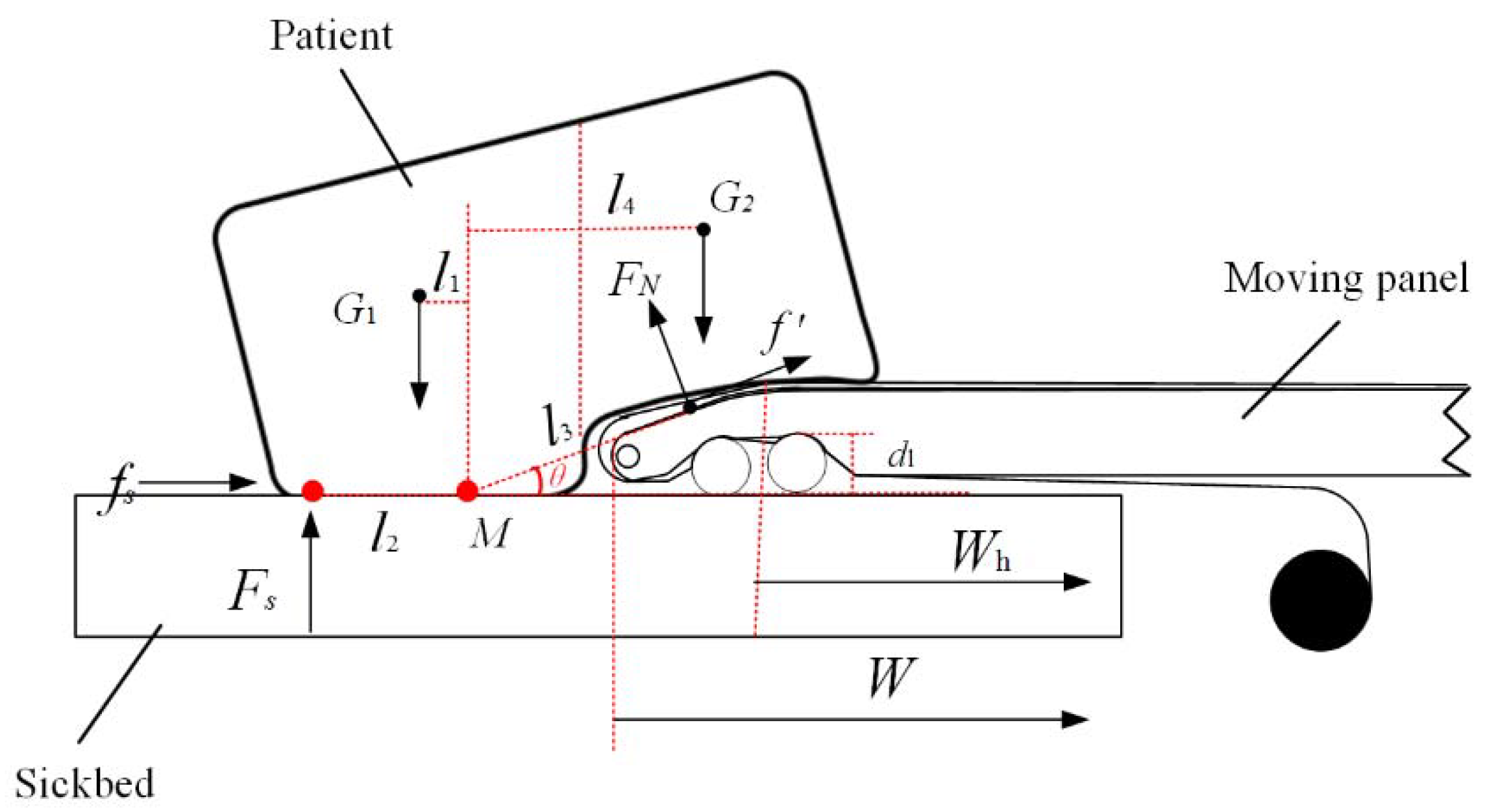

2.2. Force Analysis and Optimation of the Patient Transfer Robot

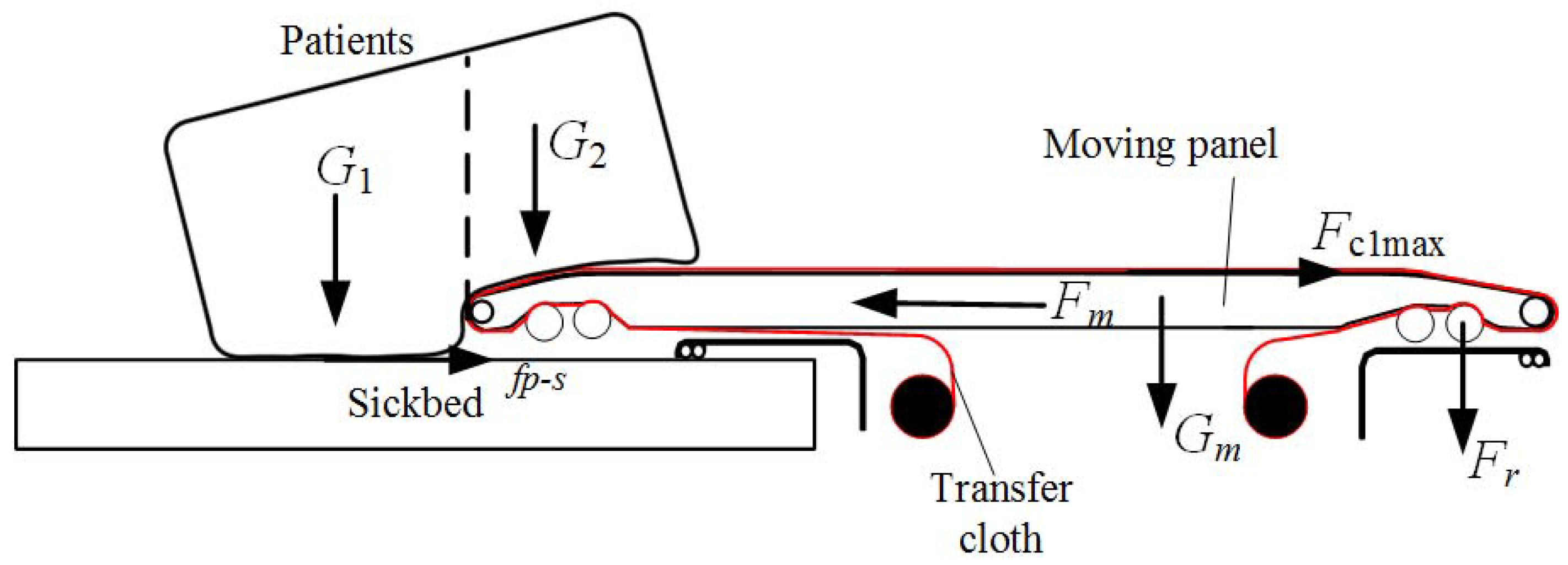

2.3. Driving Force Analysis of the Moving Panel

2.3.1. Analysis Force of the Transfer Belt

2.3.2. Analysis Force of the Moving Panel

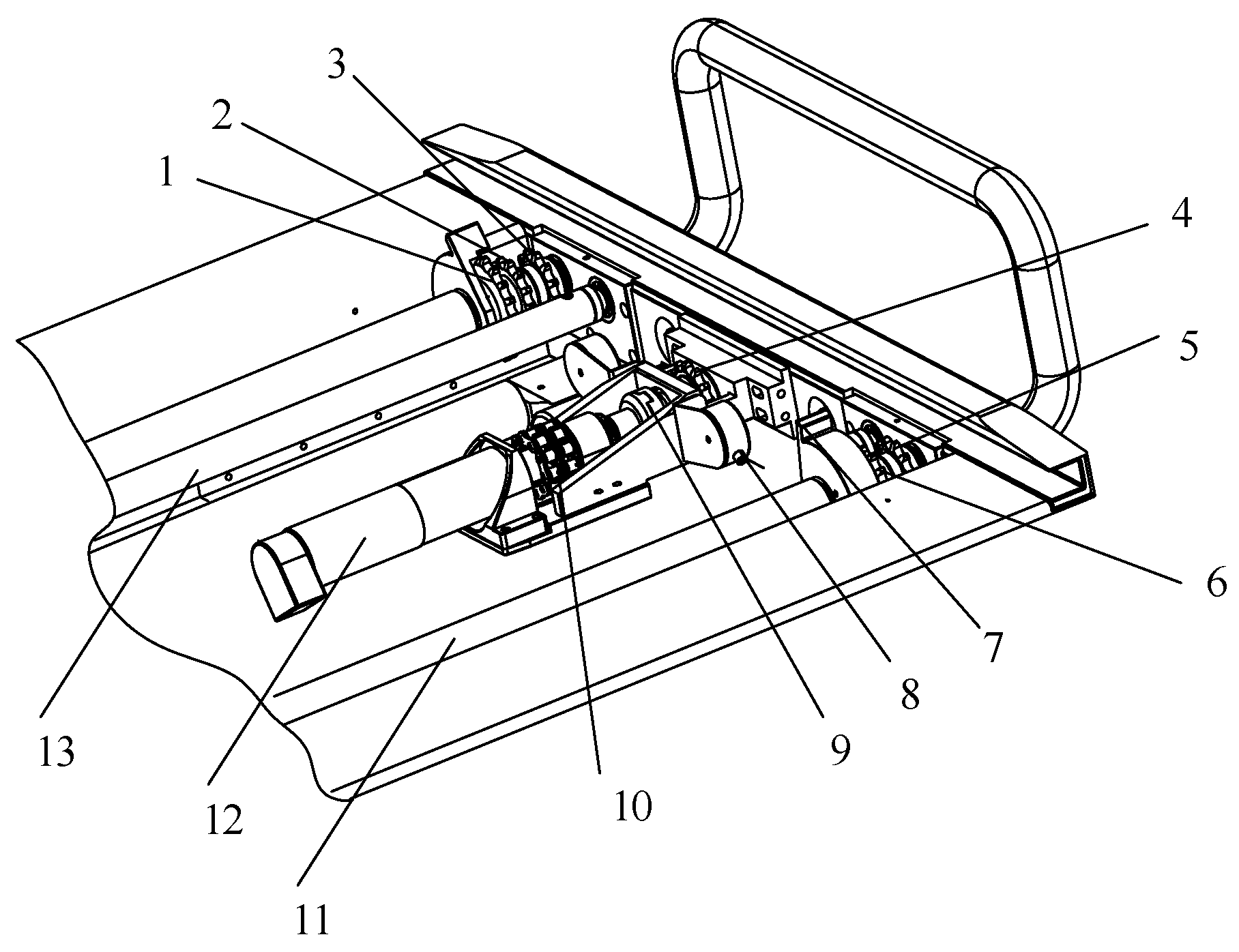

3. Mechanical Structure Design of the Patient Transfer Robot

3.1. The Structural Design of the Patient Transfer Part

3.1.1. The Structural Design of the Transverse Driving Part

3.1.2. The Structural Design of the Back-Lifting Part

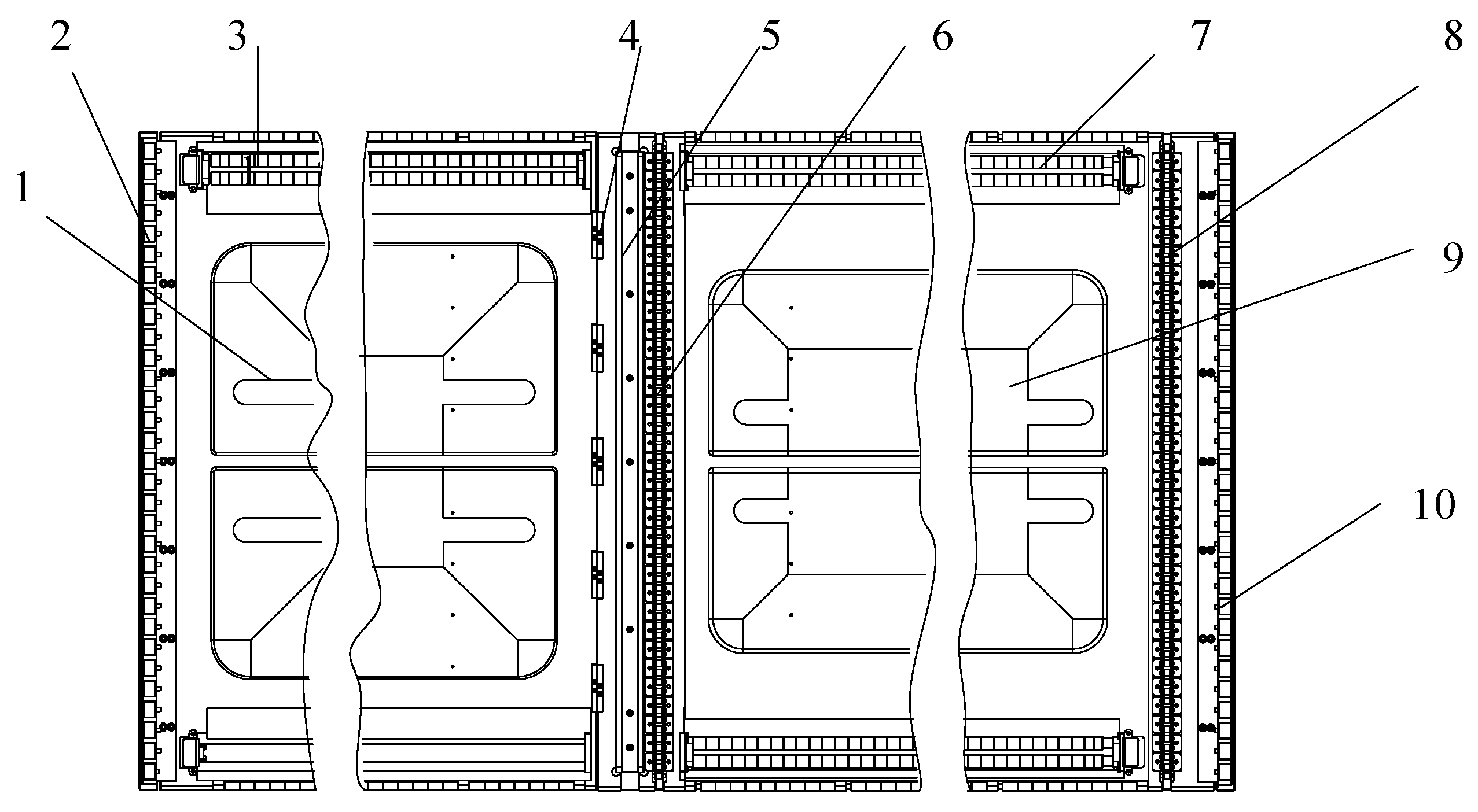

3.1.3. The Structural Design of the Moving Panel

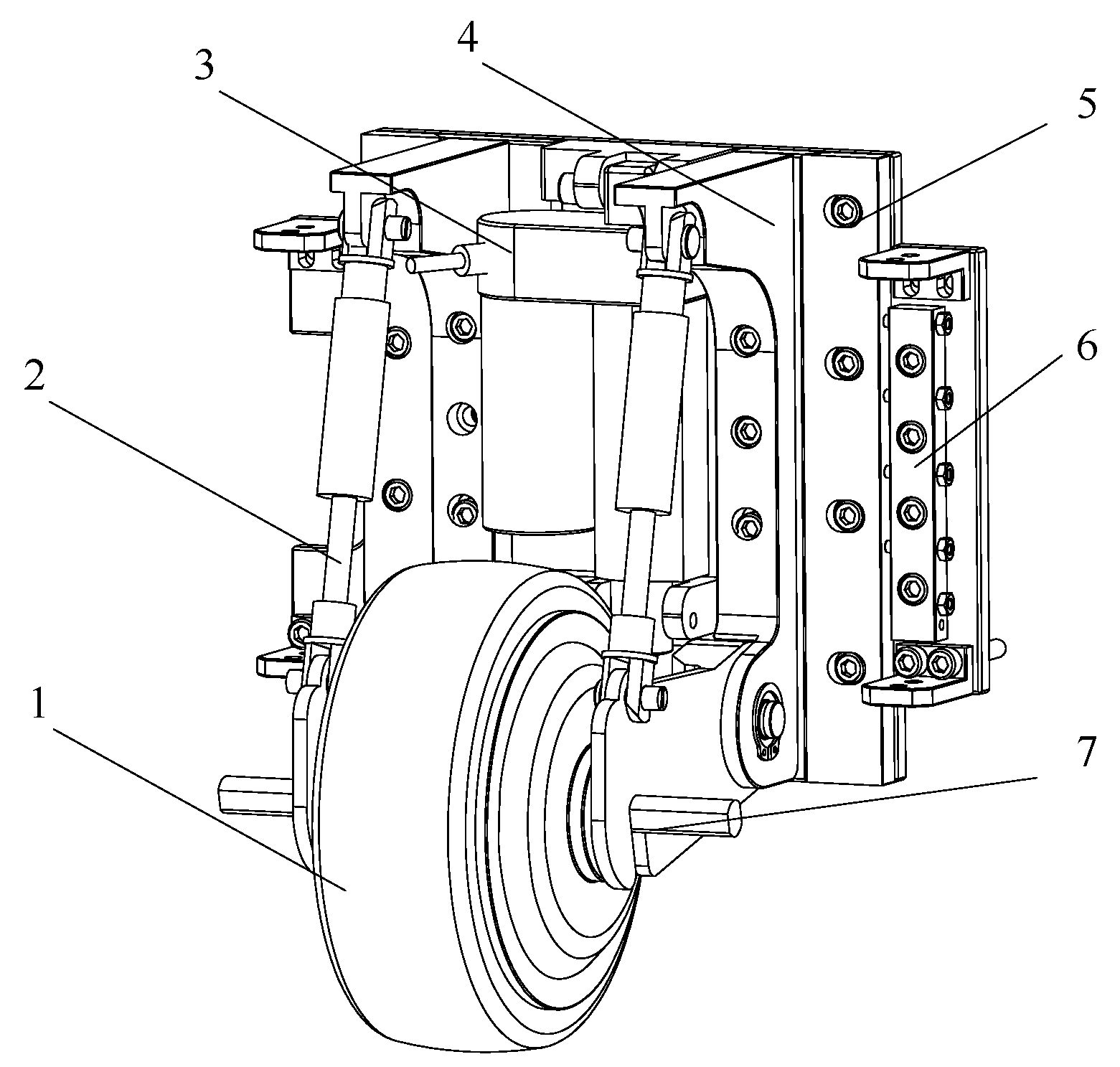

3.2. The Structural Design of the Moving Part

3.2.1. The Structural Design of the Lifting Part

3.2.2. The Structural Design of the Power-Assisted Moving Part

4. Control System Design of the Patient Transfer Robot

5. Preliminary Tests of the Patient Transfer Robot

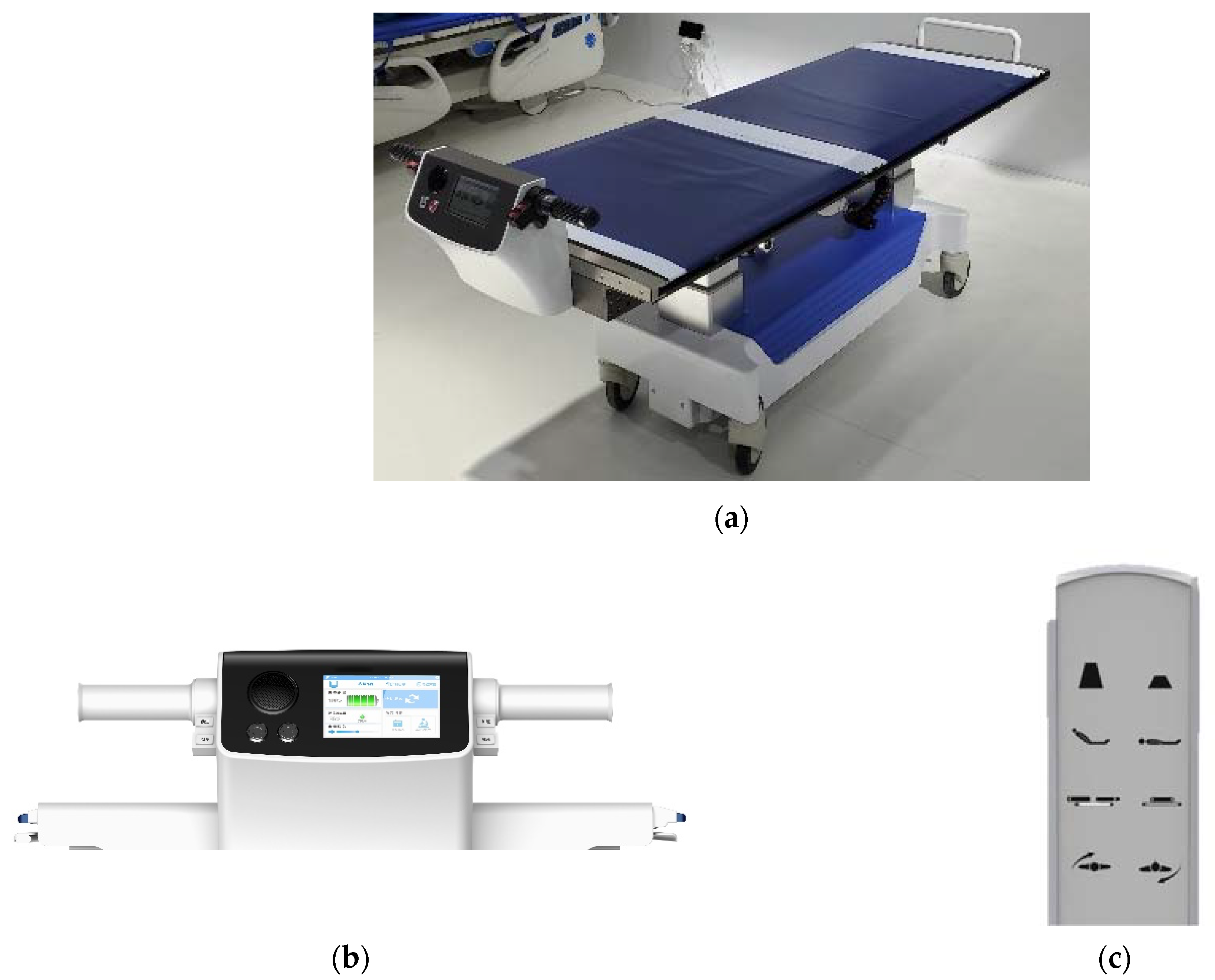

5.1. Prototype of the Patient Transfer Robot

5.2. Test for the Effect of Insertion Angle on Patient Comfort

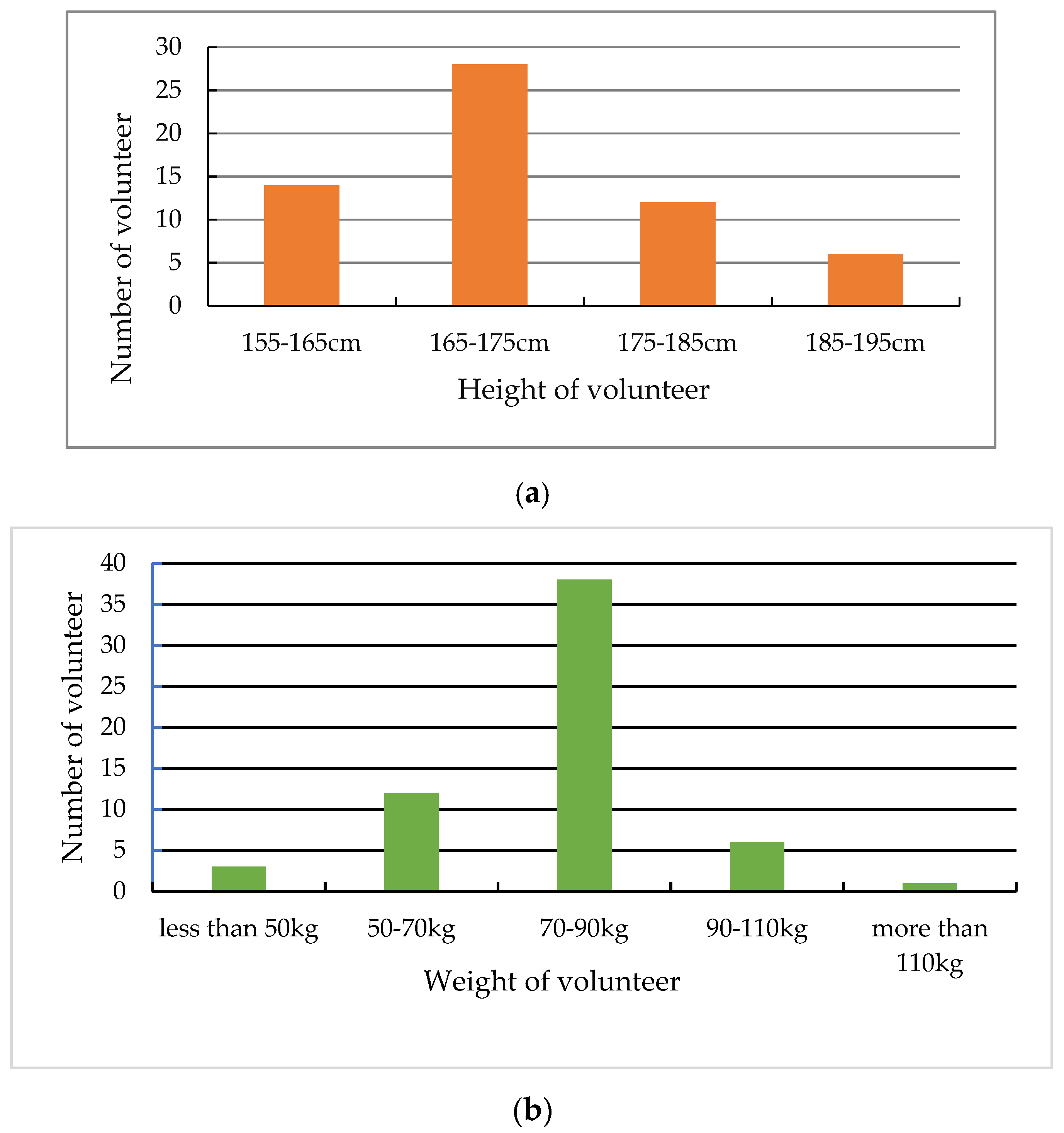

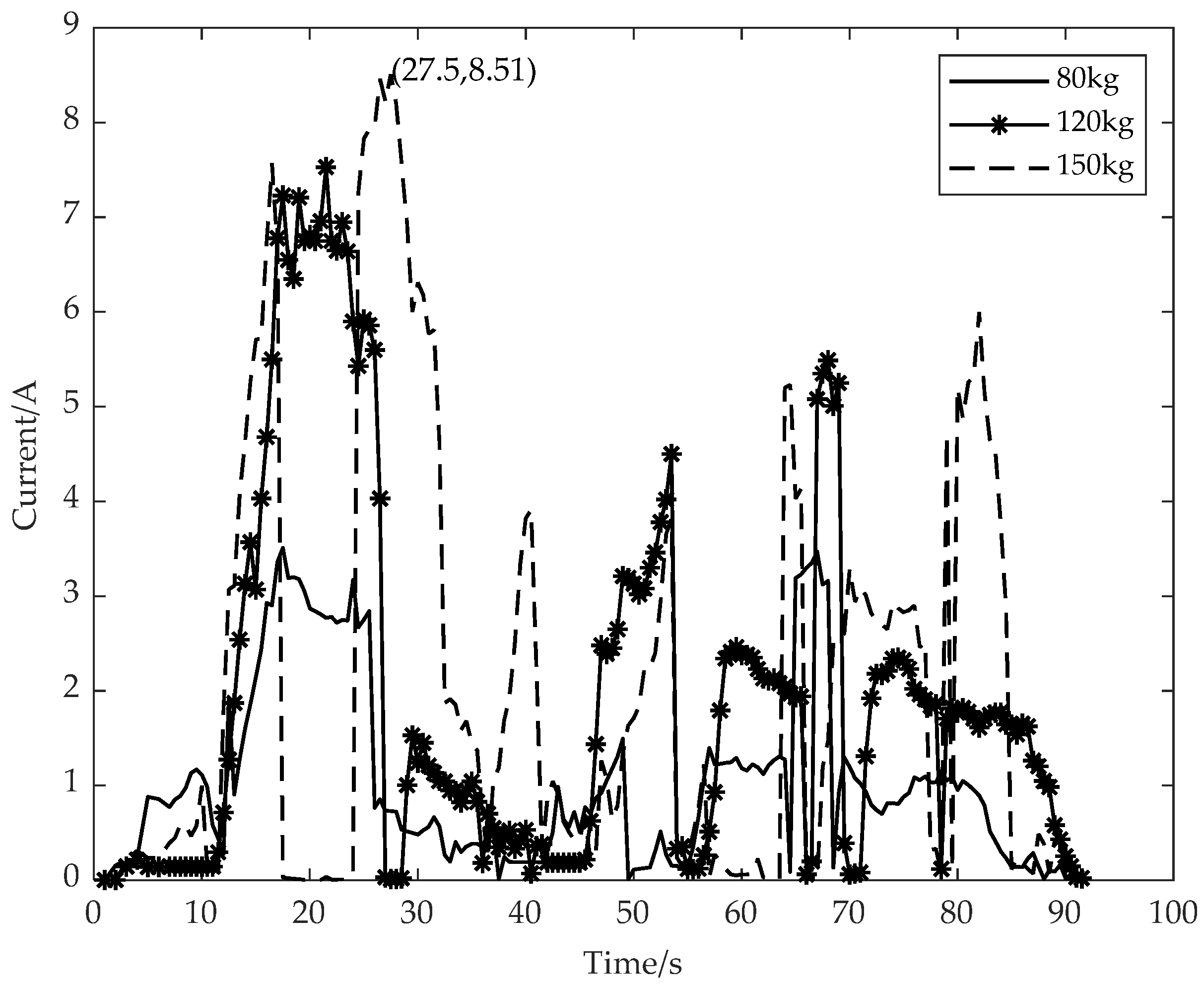

5.3. Test for the Carryring-Capacity of the Patient Transfer Robot

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Andersen, L.; Burdorf, A.; Fallentin, N.; Persson, R.; Jakobsen, M.D.; Mortensen, O.S.; Clausen, T.; Holtermann, A. Patient transfers and assistive devices: Prospective cohort study on the risk for occupational back injury among healthcare workers. Scand. J. Work Environ. Heath 2014, 40, 74–81. [Google Scholar] [CrossRef] [PubMed]

- Fan, Z.M.; Jamil, M.; Sadiq, M.T.; Huang, X.W. Exploiting multiple optimizers with transfer learning techniques for the identification of COVID-19 patients. J. Healthc. Eng. 2020, 2020, 8889412. [Google Scholar] [CrossRef] [PubMed]

- He, M.S.; Yao, Y.F.; Lin, C.; Zhong, M. Research progress and development trends of transfer nursing robot. Mach. Des. Manuf. 2020, 2020, 162–165,169. (In Chinese) [Google Scholar]

- Liu, C.H.; Fu, M.; Ding, J.; Yan, Y.J. Best Evidence Summary for In-hospital Transport of Critically III Patients. J. Nurs. 2020, 27, 33–38. (In Chinese) [Google Scholar]

- Gudrun, R.; Jill, M.; Lorelli, N.; Hayden, A.K.; Yokom, K.; Lang, E.S.; Lazarenko, G.C.; Joanna, A. Transition in care from EMS providers to emergency department nurses: A systematic review. Prehosp. Emerg. Care 2020, 24, 421–433. [Google Scholar]

- Sivakanthan, S.; Blaauw, E.; Greenhalgh, M.; Koontz, A.M.; Vegter, R.; Cooper, R.A. Person transfer assist systems: A literature review. Disabil. Rehabil. Assist. 2019, 6, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.F. Medical Electric Transfer Vehicle. C.N. Patent CN111631866A, 9 June 2020. (In Chinese). [Google Scholar]

- Mcnulty, C. Body Transfer System and Method. U.S. Patent 7748062, 6 July 2010. [Google Scholar]

- Shen, R.C.; Jiang, J.G.; Li, B.H.; Wang, Z.; Wu, Y.P.; Fang, R. Recent advances on patient transferring device. Recent Pat. Eng. 2017, 10, 198–208. [Google Scholar] [CrossRef]

- Wang, H.B.; Kasagami, F. A patient transfer apparatus between bed and stretcher. IEEE Trans. Syst. Man Cybern. Part B Cybern. 2008, 38, 60–67. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.B.; Fumio, K. Mechatronic design and application of a patient transfer apparatus. J. Mech. Eng. 2009, 45, 68–74. (In Chinese) [Google Scholar] [CrossRef]

- Shi, C.; Tang, S.H.; Duan, X.B.; Ning, B.; Chen, X.; Zhang, X. Development of a transfer arm of the robot for transferring the injuried. Bull. Acad. Mil. Med. Sci. 2010, 34, 55–57. (In Chinese) [Google Scholar]

- Tian, Y.; Wang, H.B.; Zhang, Y.S.; Su, B.W.; Wang, L.P.; Wang, X.S.; Sang, L.F.; Feng, Y.F.; Niu, J.Y. Design and evaluation of a novel person transfer assist system. IEEE Access 2021, 9, 14306–14318. [Google Scholar] [CrossRef]

- Sang, L.F.; Yamamura, M.; Dong, F.; Gan, Z.X.; Fu, J.Z.; Wang, H.B.; Tian, Y. Analysis, design, and experimental research of a novel wheelchair-stretcher assistive robot. Appl. Sci. 2020, 10, 264. [Google Scholar] [CrossRef]

- Tian, Y.; Wang, H.B.; Zhang, Y.S.; Su, B.; Du, J.Z.; Wang, X.C.; Feng, Y.F.; Cheng, B.; Niu, J.Y. Structural design and preliminary tests of a novel patient transfer apparatus for medical scenarios. J. Healthc. Eng. 2021, 2021, 2770846. [Google Scholar] [CrossRef] [PubMed]

- Mukai, T.; Onishi, M.; Odashima, T.; Hirano, S.; Luo, Z.W. Development of the tactile sensor system of a human-interactive robot “RI-MAN”. IEEE Trans. Robot. 2008, 24, 505–512. [Google Scholar] [CrossRef]

- Sato, S.; Guo, S.; Inada, S.; Muka, T. Design of transfer motion and verification experiment of care assistant robot RIBA-II. Trans. Jpn. Soc. Mech. Eng. 2012, 78, 1899–1912. [Google Scholar]

- Ding, J.; Lim, Y.; Solano, M.; Shadle, K.; ParChris, k.; Lin, C.; John, H. Giving patients a lift—The robotic nursing assistant (RoNA). In Proceedings of the 2014 IEEE International Conference on Technologies for Practical Robot Applications, Woburn, MA, USA, 14–15 April 2014; pp. 1–5. [Google Scholar]

- Liu, Y.; Chen, G.; Liu, J.; Guo, S.J. Biomimetic design of a chest carrying nursing-care robot for transfer task. In Proceedings of the 2018 IEEE International Conference on Robotics and Biomimetics, Kuala Lumpur, Malaysia, 12–15 December 2018; pp. 45–50. [Google Scholar]

- Liu, Y.X.; Guo, S.J.; Chen, G.L.; Liu, J.Y.; Gan, Z.X. Bionic motion planning and the analysis for human comfort of a piggyback nursing-care robot for transfer tasks. J. Mech. Eng. 2020, 56, 161–170. (In Chinese) [Google Scholar]

- Meng, Q.X.; Lai, X.Z.; Yan, Z.; Wang, Y.W.; Wu, M. Position control with zero residual vibration for two degrees-of-freedom flexible systems based on motion trajectory optimization. Inf. Sci. 2021, 575, 698–713. [Google Scholar] [CrossRef]

- Ding, Y.L. Ergonomics, 4th ed.; Beijing Institute of Technology Press: Beijing, China, 2011; pp. 35–155. [Google Scholar]

- GB Standards. GB 10000-1988: Chinese Adult Body Size; China Standards Press: Beijing, China, 1988; pp. 50–90. [Google Scholar]

- Zhou, M.Y. Ergonomics Application; Shanghai Jiao Tong University: Shanghai, China, 2012; pp. 129–179. [Google Scholar]

- Stark, M.; Zapf, A. Sample size calculation and re-estimation based on the prevalence in a single-arm confirmatory diagnostic accuracy study. Stat. Methods Med. Res. 2020, 29, 1–13. [Google Scholar] [CrossRef] [PubMed]

| State | Excellent | Good | Medium | Poor | Very Poor |

|---|---|---|---|---|---|

| Lifting and transfering | 32 | 18 | 8 | 2 | 0 |

| Placing and transfering | 28 | 24 | 6 | 2 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sang, L.; Wang, H.; Tian, Y. Analysis, Design and Experimental Research of a Novel Bilateral Patient Transfer Robot. Machines 2022, 10, 33. https://doi.org/10.3390/machines10010033

Sang L, Wang H, Tian Y. Analysis, Design and Experimental Research of a Novel Bilateral Patient Transfer Robot. Machines. 2022; 10(1):33. https://doi.org/10.3390/machines10010033

Chicago/Turabian StyleSang, Lingfeng, Hongbo Wang, and Yu Tian. 2022. "Analysis, Design and Experimental Research of a Novel Bilateral Patient Transfer Robot" Machines 10, no. 1: 33. https://doi.org/10.3390/machines10010033

APA StyleSang, L., Wang, H., & Tian, Y. (2022). Analysis, Design and Experimental Research of a Novel Bilateral Patient Transfer Robot. Machines, 10(1), 33. https://doi.org/10.3390/machines10010033