Kinematic Analysis of V-Belt CVT for Efficient System Development in Motorcycle Applications

Abstract

:1. Introduction

- The continuous variation of the speed ratio allows the engine working at a nearly constant speed to optimize the endothermic engine efficiency;

- This kind of transmission is an automatic one, thus simplifying the driving so that even non-expert two-wheeled drivers can use these vehicles easily;

- The constructive simplicity of the transmission makes it cost-effective for production and maintenance;

- The lightweight and the high efficiency (near 80% at the full operating speed [10]) of transmission positively affect the fuel consumption;

- The transmission can absorb sudden change in the torque (it works as a flexible coupling joint).

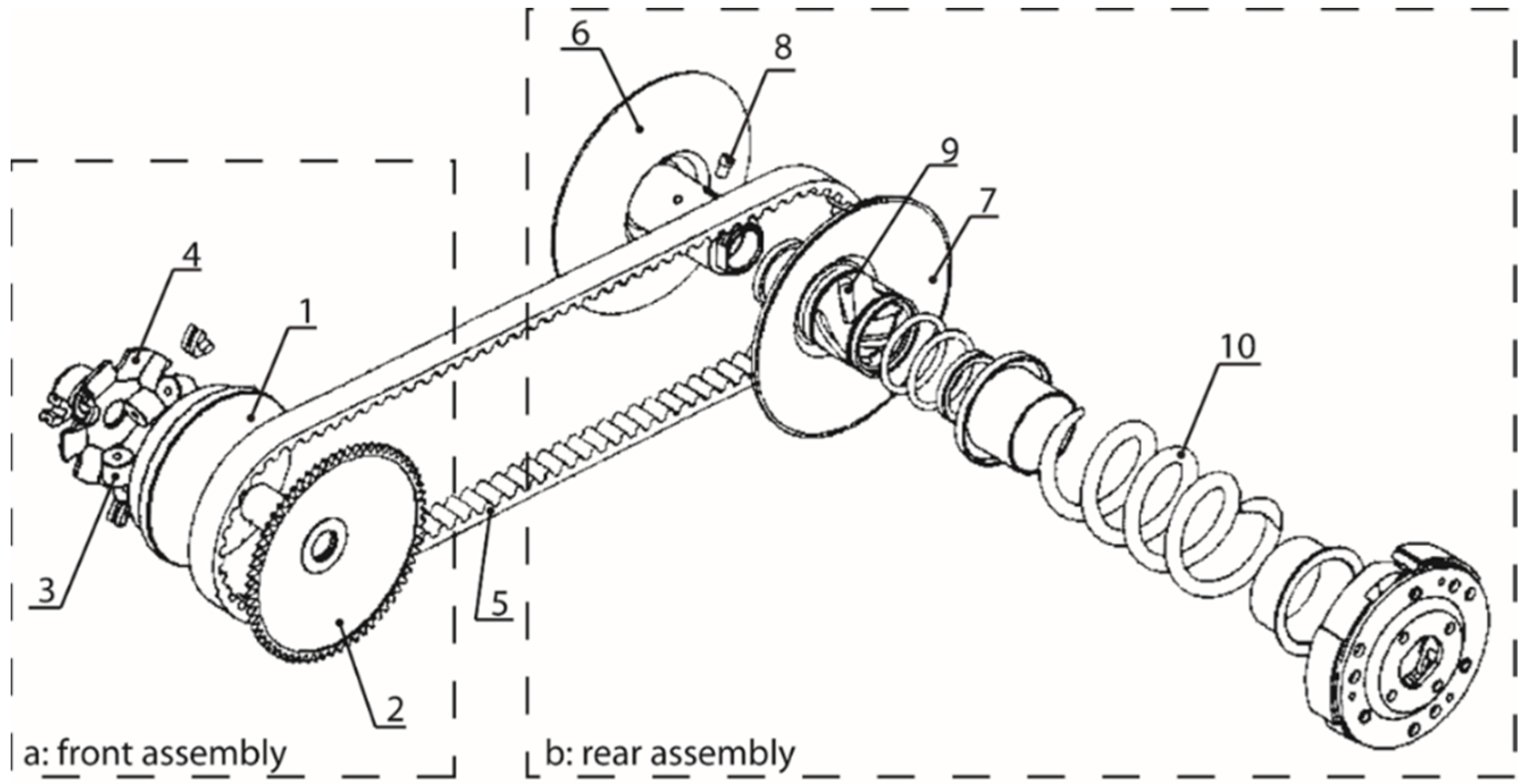

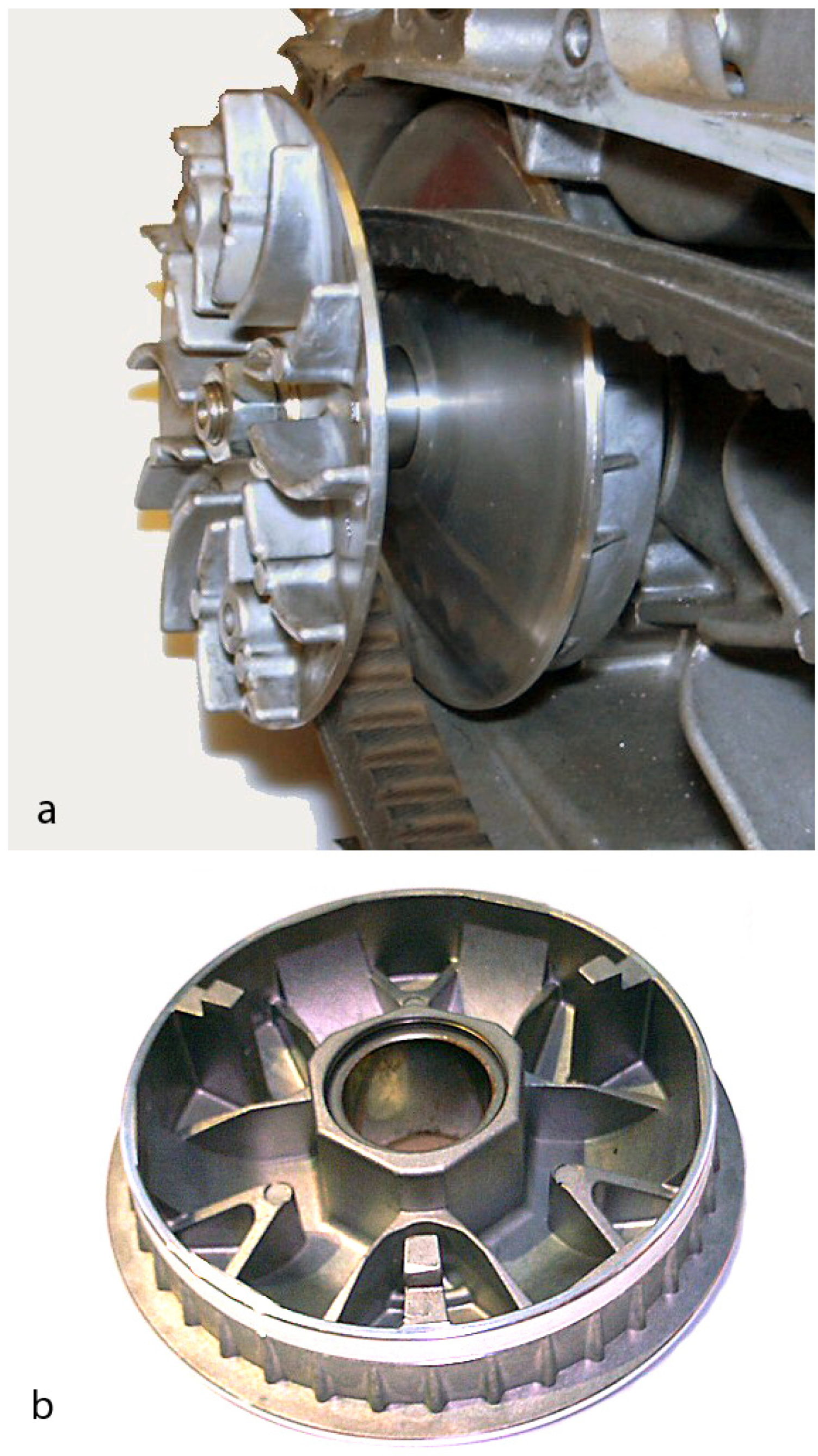

2. Materials and Methods

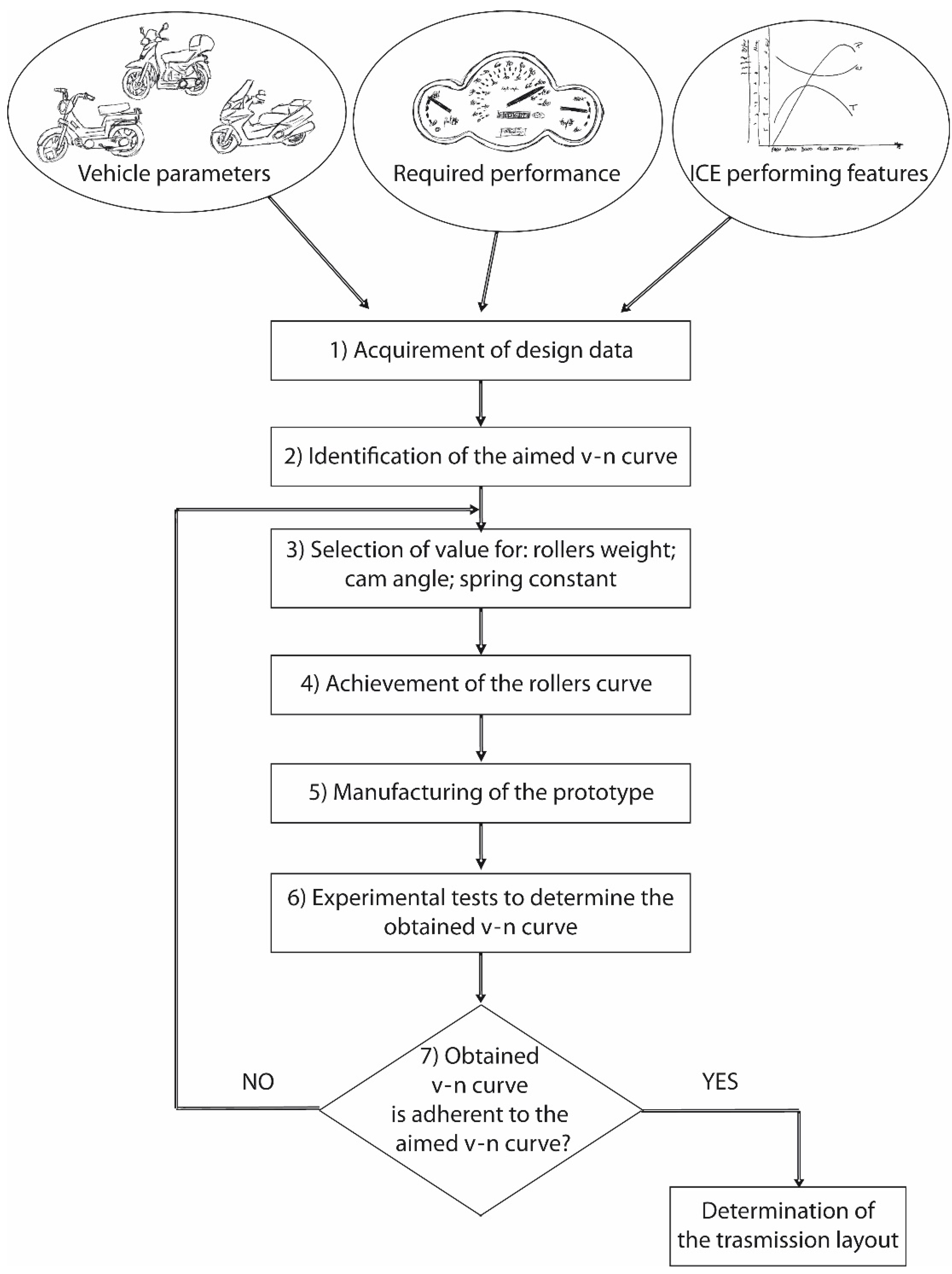

2.1. Analysis of Typical CVT Design Procedure

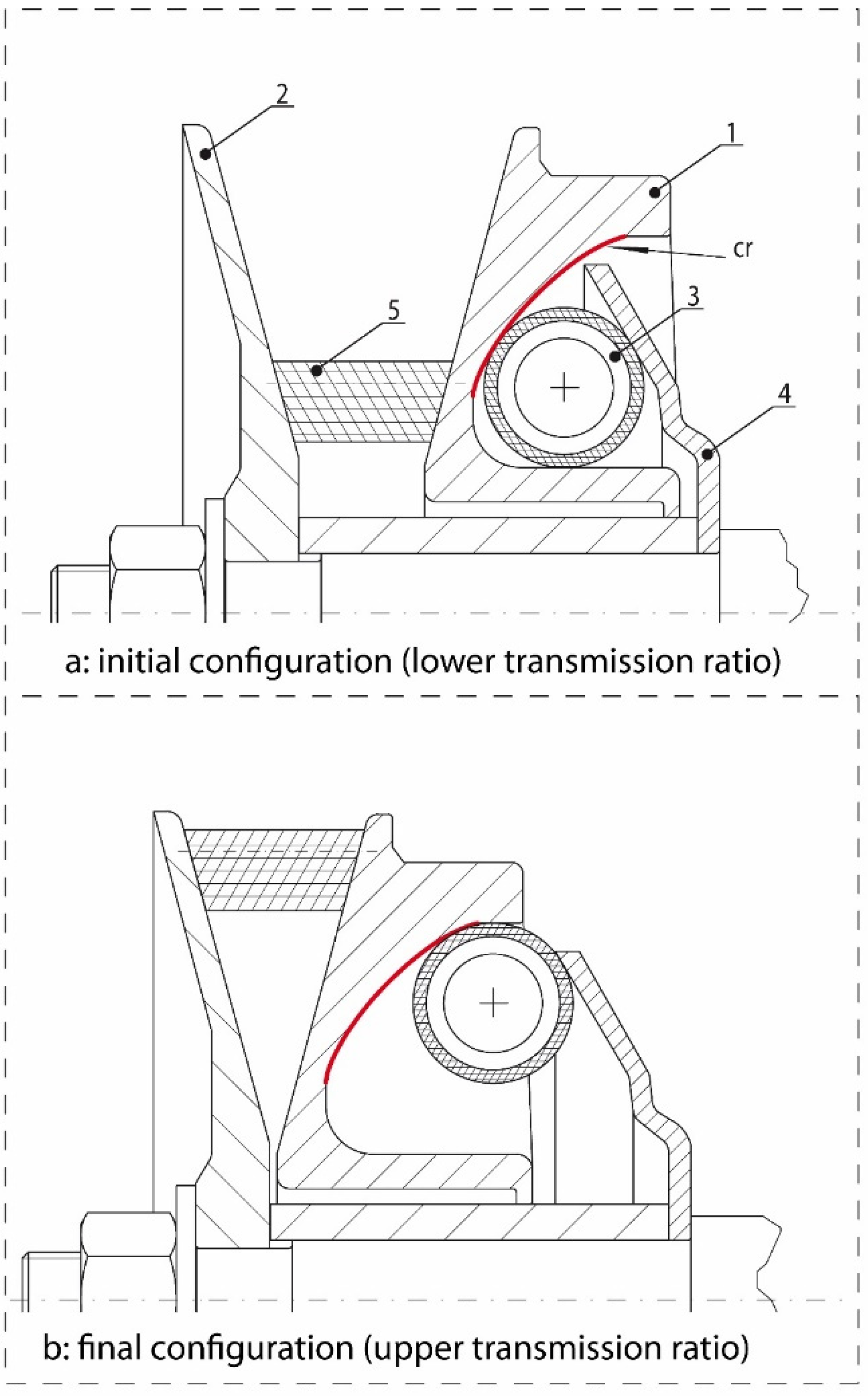

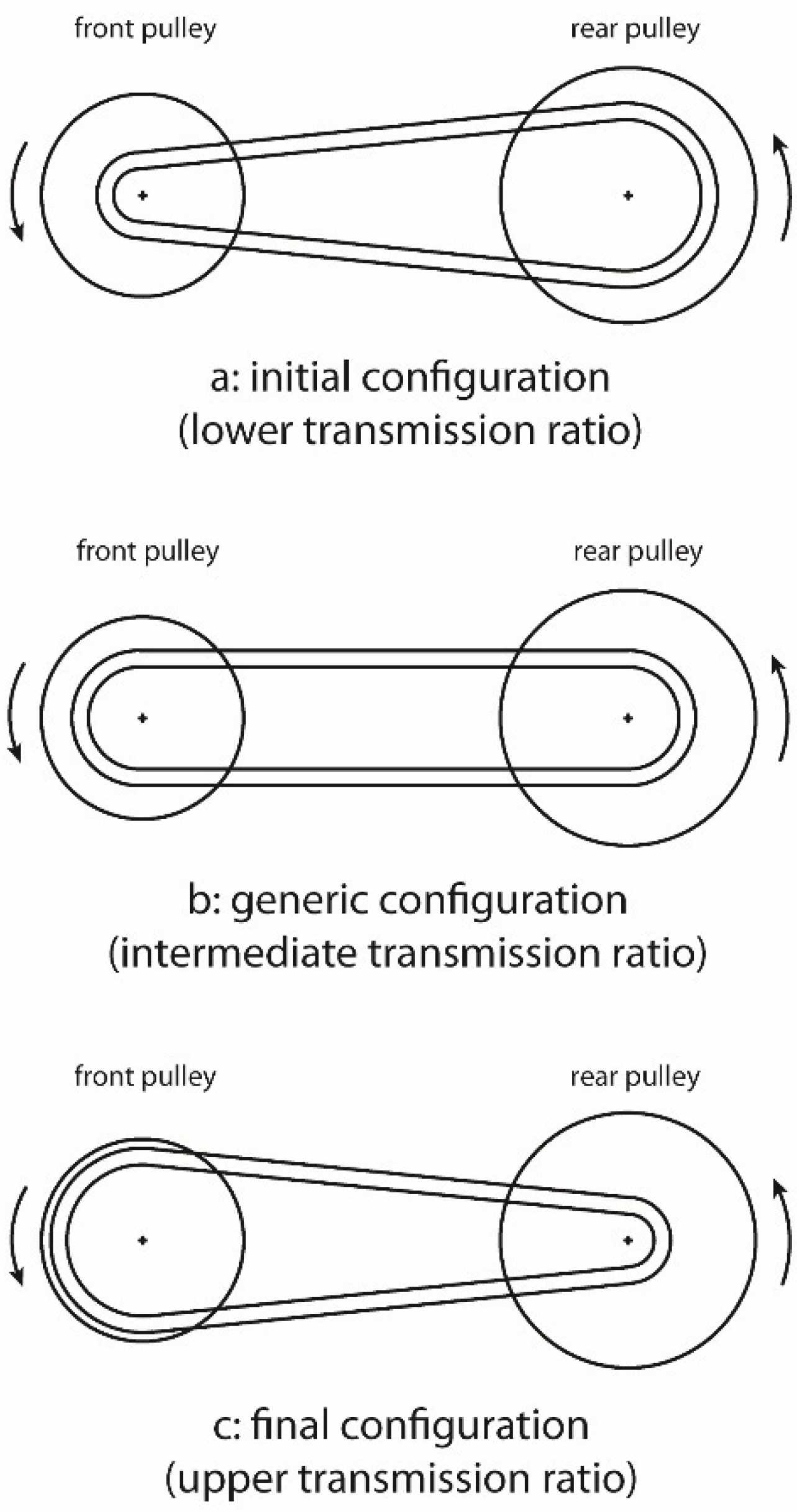

- The pitch diameter in the transmission’s initial setup is the smaller the belt can occupy on the front pulley. This condition corresponds to the lower transmission ratio reachable.

- The engine speed increases and the centrifugal force acting on the rollers is enough to move the half pulley along its axis; the belt reaches a pitch diameter on the front pulley depending on the vehicle’s operating condition. This configuration is the work area of continuous transmission ratio variation from the lower to the upper.

- The upper ratio is reached, the belt is on the bigger pitch diameter on the front pulley and any other movement is impossible for the half front pulley.

- Acquirement of design data: required performances; internal combustion engine (ICE) performing features, vehicle parameters;

- Identification of the target v-n curve;

- Selection of values for rollers weight, cam angle, spring constant;

- Use of the mathematical model for the design of the curved ramp of the rollers;

- Manufacturing of the prototype;

- Experimental test of the obtained v-n curve.

2.2. Critical Issue of the Current Design Approach

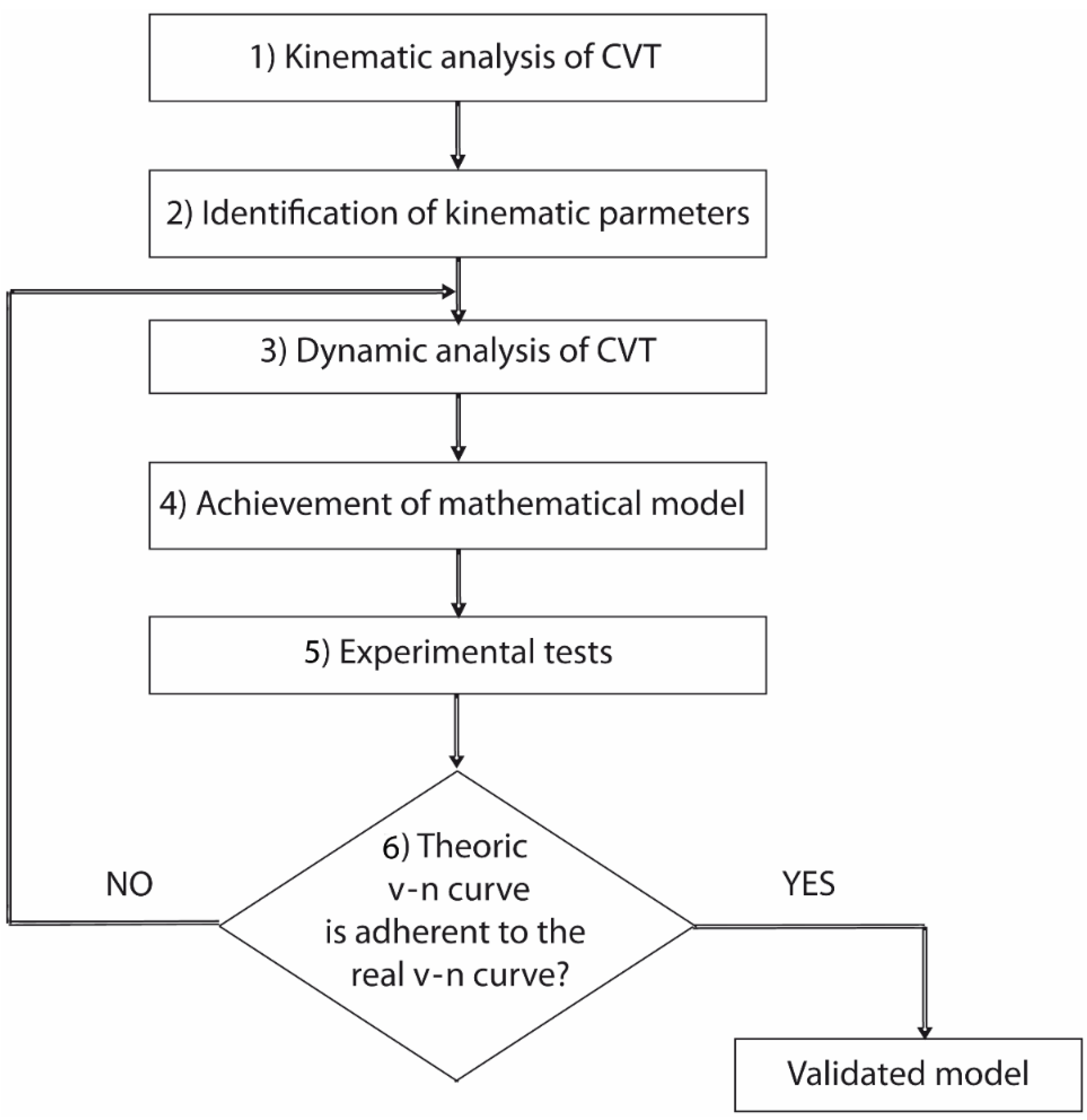

2.3. Development of an Efficient and Accurate Mathematical Model

3. Kinematic Analysis of the CVT Transmission

3.1. Identification of Design Parameters

- Center distance (I);

- Driver pulley rotational speed;

- Driven pulley rotational speed;

- Transmission ratio;

- Driver pulley pitch diameter;

- Driven pulley pitch diameter;

- Belt wrap angle on the pulleys;

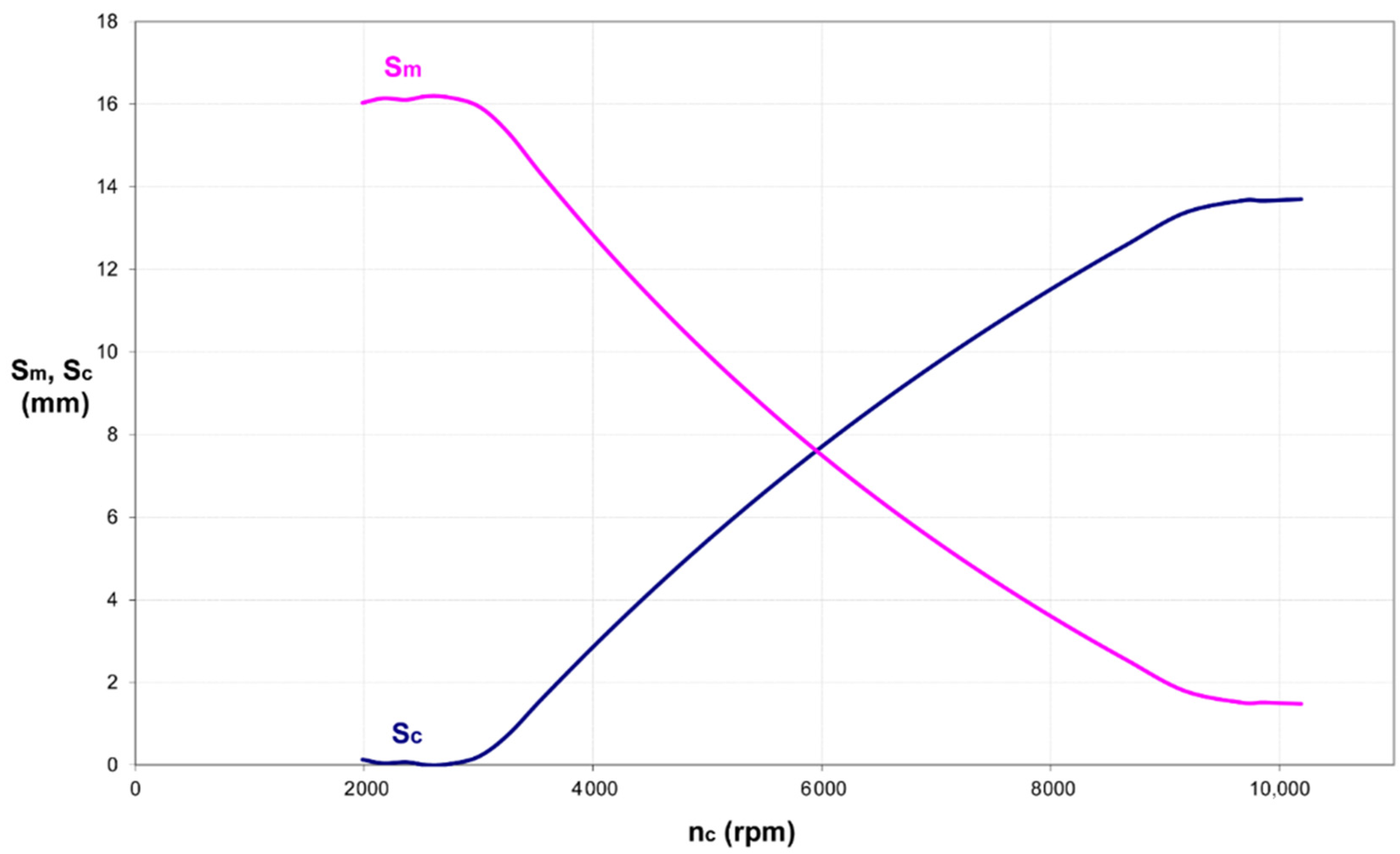

- Axial displacement of the driver half-pulley;

- Axial displacement of the driven half-pulley;

- Rollers curved ramps; and

- Correlation between rollers’ and belt’s position as a function of the engine’s rotation speed.

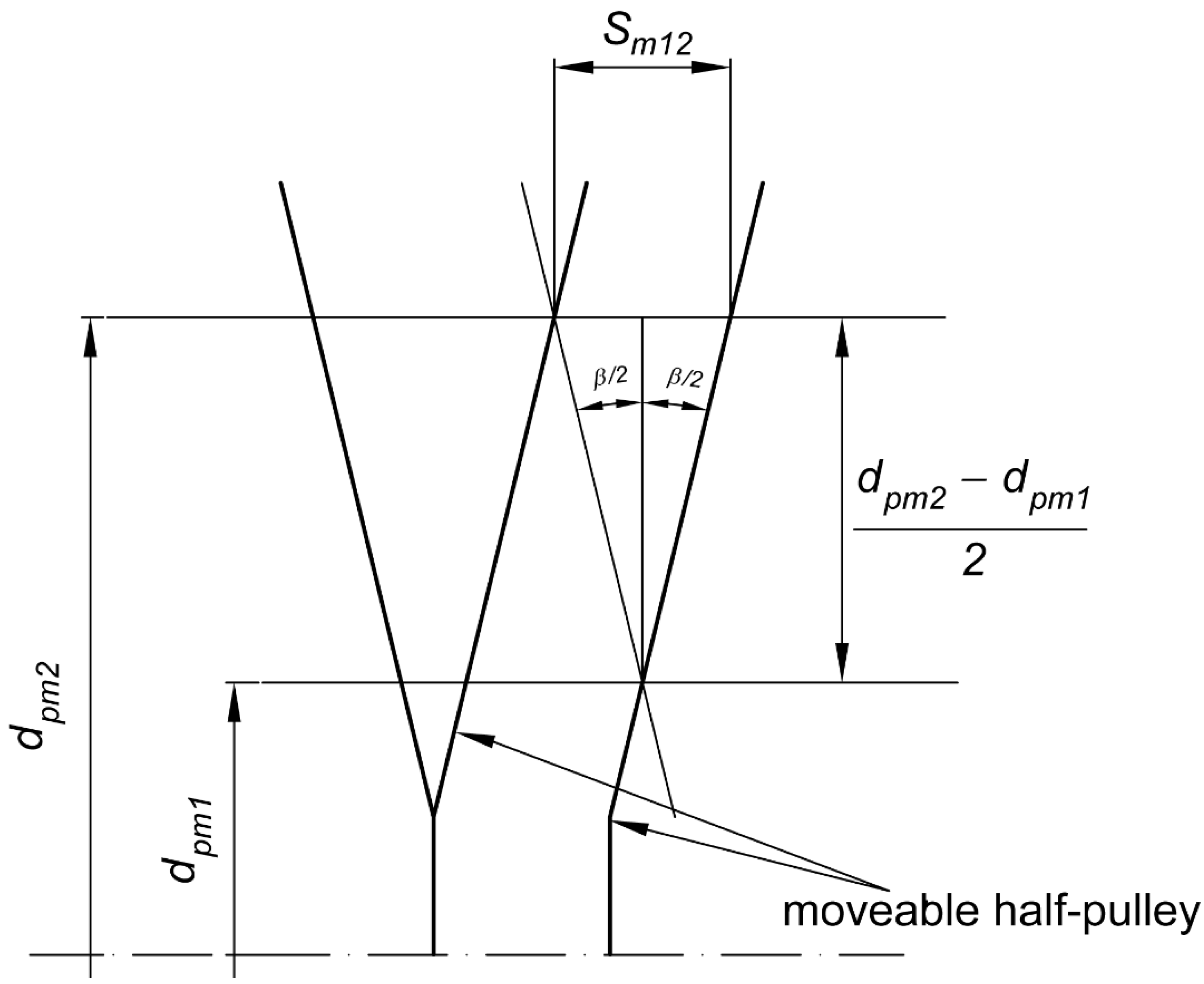

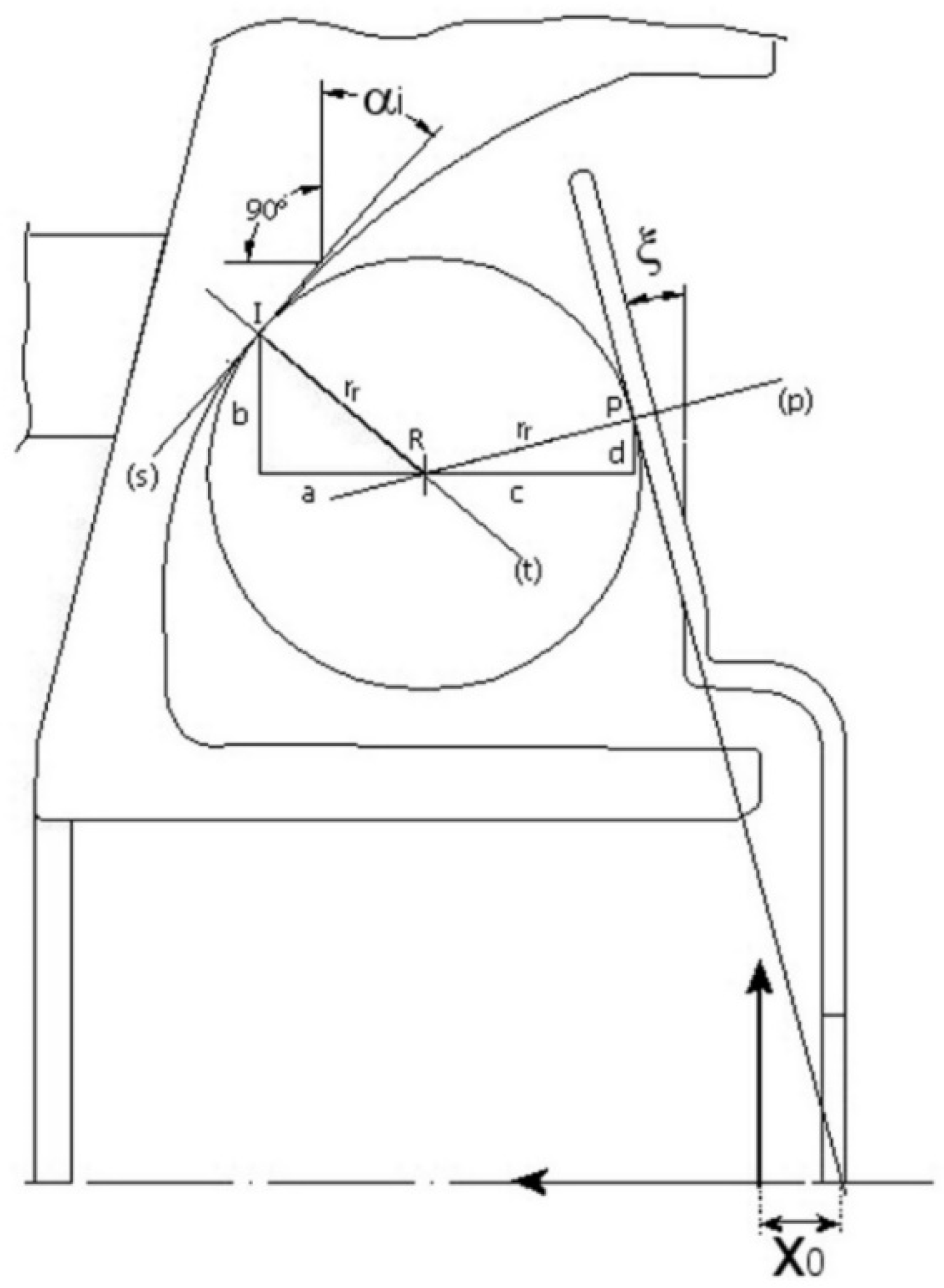

3.2. Half-Pulley’s Axial Displacement Calculation

3.3. Kinematic Analysis of the Transmission

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, R.; Wei, D.; Han, F.; Lu, Y.; Fang, J.; Liu, Y.; Wang, J. The effect of traffic density on smog pollution: Evidence from Chinese cities. Technol. Forecast. Soc. Chang. 2019, 144, 421–427. [Google Scholar] [CrossRef]

- Rakowska, A.; Wong, K.C.; Townsend, T.; Chan, K.L.; Westerdahl, D.; Ng, S.; Močnik, G.; Drinovec, L.; Ning, Z. Impact of Traffic Volume and Composition on the Air Quality and Pedestrian Exposure in Urban Street Canyon. Atmos. Environ. 2014, 98, 260–270. [Google Scholar] [CrossRef]

- Liberto, C.; Valenti, G.; Orchi, S.; Lelli, M.; Nigro, M.; Ferrara, M. The Impact of Electric Mobility Scenarios in Large Urban Areas: The Rome Case Study. IEEE Trans. Intell. Transp. Syst. 2018, 19, 3540–3549. [Google Scholar] [CrossRef]

- Murena, F.; Prati, M.V.; Costagliola, M.A. Real driving emissions of a scooter and a passenger car in Naples city. Transp. Res. Part D Transp. Environ. 2019, 73, 46–55. [Google Scholar] [CrossRef]

- Adak, P.; Sahu, R.; Elumalai, S.P. Development of emission factors for motorcycles and shared auto-rickshaws using real-world driving cycle for a typical Indian city. Sci. Total Environ. 2016, 544, 299–308. [Google Scholar] [CrossRef] [PubMed]

- Piantini, S.; Giorgetti, A.; Baldanzini, N.; Monti, C.; Pierini, M. Design of a Motorcycle Steering Damper for a Safer Ride. Machines 2020, 8, 24. [Google Scholar] [CrossRef]

- Mannini, L.; Cipriani, E.; Crisalli, U.; Gemma, A. FCD data for on-street parking search time estimation. IET Intell. Transp. Syst. 2018, 12, 664–672. [Google Scholar] [CrossRef]

- Hoang, P.H.; Zhao, S.; Houn, S.E. Motorcycle Drivers’ Parking Lot Choice Behaviors in Developing Countries: Analysis to Identify Influence Factors. Sustainability 2019, 11, 2463. [Google Scholar] [CrossRef] [Green Version]

- Pérez-Fernández, O.; García-Palomares, J.C. Parking Places to Moped-Style Scooter Sharing Services Using GIS Location-Allocation Models and GPS Data. ISPRS Int. J. Geo-Inf. 2021, 10, 230. [Google Scholar] [CrossRef]

- Chen, T.F.; Lee, D.W.; Sung, C.K.L. An experimental study on transmission efficiency of a rubber V-belt CVT. Mech. Mach. Theory 1998, 33, 351–363. [Google Scholar] [CrossRef]

- Grzegozek, W.; Dobaj, K.; Kot, A. Experimental Verification and Comparison of the Rubber V- Belt Continuously Variable Transmission Models. IOP Conf. Ser. Mater. Sci. Eng. 2016, 148, 012005. [Google Scholar] [CrossRef] [Green Version]

- Arango, I.; Muñoz Alzate, S. Numerical Design Method for CVT Supported in Standard Variable Speed Rubber V-Belts. Appl. Sci. 2020, 10, 6238. [Google Scholar] [CrossRef]

- Grzegozek, W.; Kot, A. The experimental analysis of the slip in the rubber belt CVT. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2016; Volume 148. [Google Scholar]

- Singh, T.; Nair, S.A. Mathematical Review and Comparison of Continuously Variable Transmissions. In Proceedings of the SAE Passenger Car Conference and Exposition, Dearborn, MI, USA, 1–4 September 1992. [Google Scholar]

- Gerbert, G.B. Force and Slip Behaviour in V-belt Drives. Acta Politech. Scand. Mech. Eng. Ser. 1972, 67, 1–101. [Google Scholar]

- Ashok, B.; Denis Ashok, S.; Ramesh Kumar, C. A Review on Control System Architecture of a SI Engine Management System. Annu. Rev. Control. 2016, 41, 94–118. [Google Scholar] [CrossRef]

- Dittrich, O. Theorie des Umschlingungstriebes Mit Keilförmigen Reibscheibenflanken. Ph.D. Thesis, Technische Hochschule, Karlsruhe, Germany, 1953. [Google Scholar]

- Gerbert, G. Belt slip—A unified approach. ASME J. Mech. Des. 1996, 118, 432–438. [Google Scholar] [CrossRef]

- Kim, K.; Kim, H. Axial Forces of a V-Belt CVT. KSME J. 1989, 3, 56–61. [Google Scholar] [CrossRef]

- Cammalleri, M. A new approach to the design of speed-torque-controlled Rubber V-belt Variator. Inst. Mech. Eng. Part D J. Automob. Eng. 2005, 219, 1413–1427. [Google Scholar] [CrossRef]

- Julió, G.; Plante, J.S. An experimentally-validated model of rubber-belt CVT mechanics. Mech. Mach. Theory 2011, 46, 1037–1053. [Google Scholar] [CrossRef]

- Ranogajec, V.; Ivanović, V.; Deur, J.; Tseng, H.E. Optimization-based Assessment of Automatic Transmission Double-transition Shift Controls. Control. Eng. Pract. 2018, 76, 155–166. [Google Scholar] [CrossRef]

- Kahlbau, S.; Bestle, D. Optimal Shift Control for Automatic Transmission. Mech. Based Des. Struct. Mach. 2013, 41, 259–273. [Google Scholar] [CrossRef]

- Ceccanti, F.; Giorgetti, A.; Cavallini, C.; Arcidiacono, G.; Citti, P. Comparative evaluation of fuzzy axiomatic design and IAMS comprehensive VIKOR approaches for material selection in mechanical design. Int. J. Eng. Res. Technol. 2020, 13, 80–87. [Google Scholar] [CrossRef]

- Giorgetti, A.; Girgenti, A.; Citti, P.; Delogu, M. A Novel Approach for Axiomatic-Based Design for the Environment. Axiomatic Design in Large Systems: Complex Products, Buildings and Manufacturing Systems; Springer: Cham, Switzerland, 2016; pp. 131–148. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

La Battaglia, V.; Giorgetti, A.; Marini, S.; Arcidiacono, G.; Citti, P. Kinematic Analysis of V-Belt CVT for Efficient System Development in Motorcycle Applications. Machines 2022, 10, 16. https://doi.org/10.3390/machines10010016

La Battaglia V, Giorgetti A, Marini S, Arcidiacono G, Citti P. Kinematic Analysis of V-Belt CVT for Efficient System Development in Motorcycle Applications. Machines. 2022; 10(1):16. https://doi.org/10.3390/machines10010016

Chicago/Turabian StyleLa Battaglia, Vincenzo, Alessandro Giorgetti, Stefano Marini, Gabriele Arcidiacono, and Paolo Citti. 2022. "Kinematic Analysis of V-Belt CVT for Efficient System Development in Motorcycle Applications" Machines 10, no. 1: 16. https://doi.org/10.3390/machines10010016

APA StyleLa Battaglia, V., Giorgetti, A., Marini, S., Arcidiacono, G., & Citti, P. (2022). Kinematic Analysis of V-Belt CVT for Efficient System Development in Motorcycle Applications. Machines, 10(1), 16. https://doi.org/10.3390/machines10010016