Performance Evaluation of Shiryaev–Roberts and Cumulative Sum Schemes for Monitoring Shape and Scale Parameters in Gamma-Distributed Data Under Type I Censoring

Abstract

1. Introduction

2. Preamble and Existing Work

2.1. The Gamma Distribution and Censoring

2.2. The EWMA CEV and CM Charts with Deep Learning Method

3. The Proposed Control Charts

3.1. The CUSUM Control Chart

3.2. The SR Control Chart

4. Simulation Studies

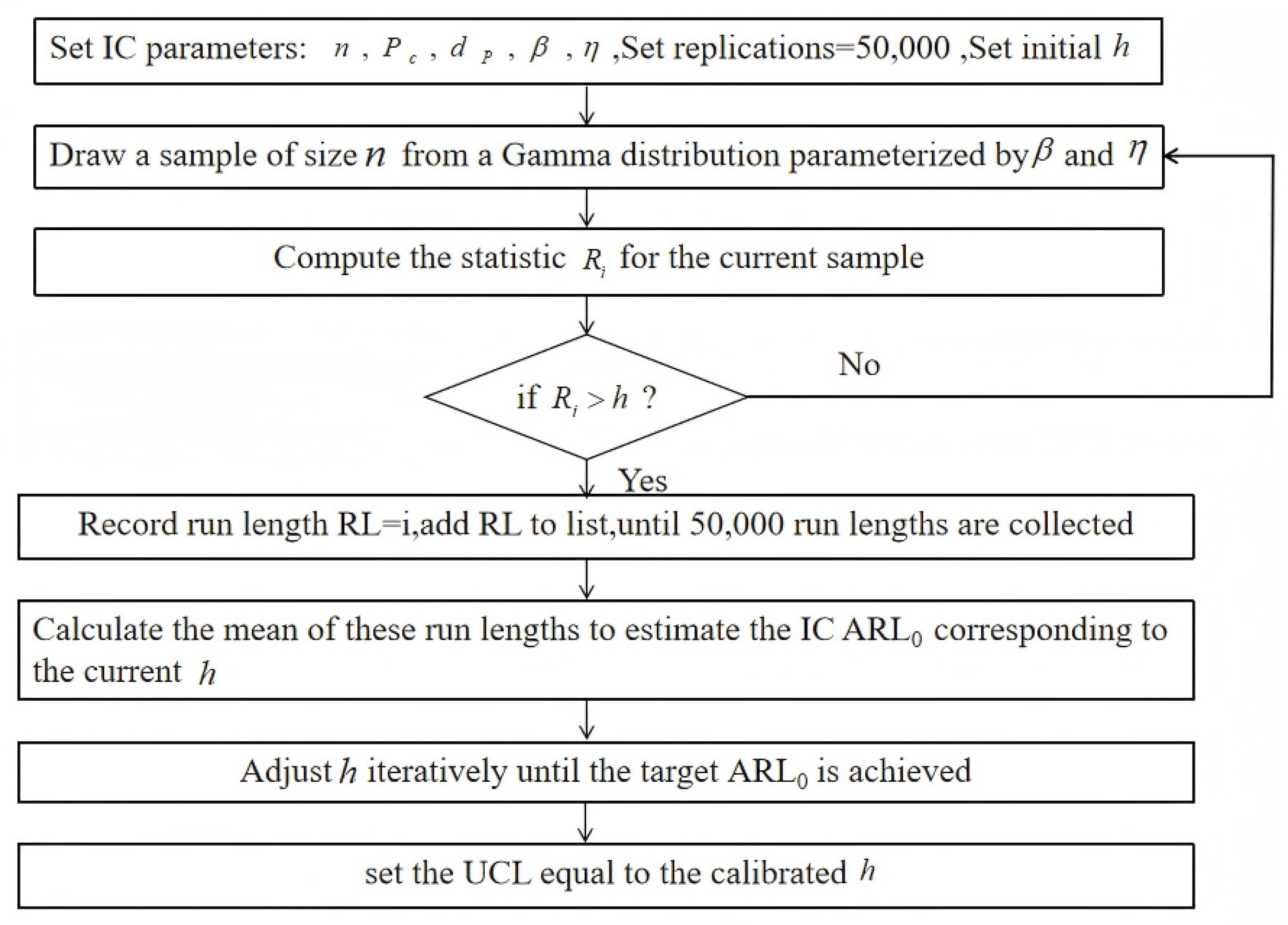

- Initialization:

- Set the process parameters for the IC state: sample size n, censoring rate , predetermined percent change , shape parameter , and scale parameter .

- Define the total number of simulation replications as 50,000.

- Initialize the upper control limit with a provisional value h.

- Data Generation:

- Draw a sample of size n from a Gamma distribution parameterized by and .

- Computation of the Statistic:

- Compute the statistic for the current sample.

- If , generate a new sample (return to Step 2).

- If , note the sample index at which this first OOC event is detected, and record it as the RL.

- Iteration and Calibration:

- Repeat Steps 2 and 3 until 50,000 run lengths are collected.

- Calculate the mean of these run lengths to estimate the IC corresponding to the current h.

- Adjust h iteratively until the target is achieved.

- Finally, set the UCL equal to the calibrated h.

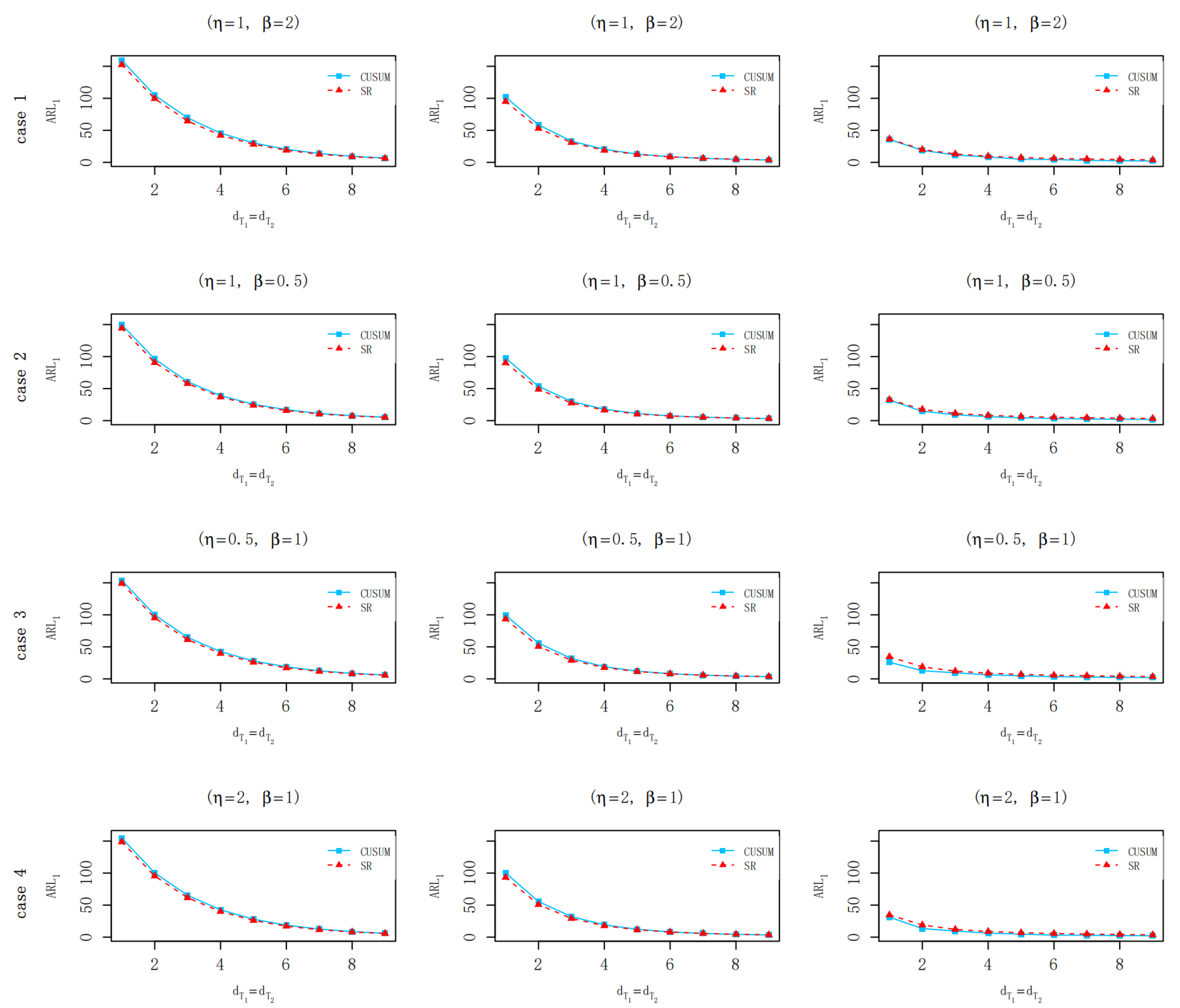

5. Comparison and Discussion with Existing Charts

6. Example

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shewhart, W.A. Economic Control of Quality of Manufactured Product; Macmillan and Co., Ltd.: New York, USA, 1931. [Google Scholar]

- Page, E. Continuous inspection schemes. Biometrika 1954, 41, 100–115. [Google Scholar] [CrossRef]

- Zhang, C.W.; Xie, M.; Liu, J.Y.; Goh, T.N. A control chart for the Gamma distribution as a model of time between events. Int. J. Prod. Res. 2007, 45, 5649–5666. [Google Scholar] [CrossRef]

- Alevizakos, V.; Koukouvinos, C. A double exponentially weighted moving average chart for time between events. Commun. Stat.-Simul. Comput. 2020, 49, 2765–2784. [Google Scholar] [CrossRef]

- Yang, J.; Yu, H.; Cheng, Y.; Xie, M. Design of Gamma Charts Based on Average Time to Signal. Qual. Reliab. Eng. Int. 2016, 32, 1041–1058. [Google Scholar] [CrossRef]

- Chakraborty, N.; Human, S.W.; Balakrishnan, N. A generally weighted moving average chart for time between events. Commun. Stat.-Simul. Comput. 2017, 46, 7790–7817. [Google Scholar] [CrossRef]

- Alevizakos, V.; Koukouvinos, C.; Lappa, A. Monitoring of time between events with a double generally weighted moving average control chart. Qual. Reliab. Eng. Int. 2019, 35, 685–710. [Google Scholar] [CrossRef]

- Shah, M.T.; Azam, M.; Aslam, M.; Sherazi, U. Time between events control charts for gamma distribution. Qual. Reliab. Eng. Int. 2021, 37, 785–803. [Google Scholar] [CrossRef]

- Alevizakos, V.; Chatterjee, K.; Koukouvinos, C. A triple exponentially weighted moving average control chart for monitoring time between events. Qual. Reliab. Eng. Int. 2021, 37, 1059–1079. [Google Scholar] [CrossRef]

- Lone, S.A.; Rasheed, Z.; Anwar, S.; Khan, M.; Anwar, S.M.; Shahab, S. Enhanced fault detection models with real-life applications. AIMS Math. 2023, 8, 19595–19636. [Google Scholar] [CrossRef]

- Steiner, S.H.; Mackay, R.J. Monitoring Processes with Highly Censored Data. J. Qual. Technol. 2000, 32, 199–208. [Google Scholar] [CrossRef]

- Dickinson, R.M.; Roberts, D.A.O.; Driscoll, A.R.; Woodall, W.H.; Vining, G.G. CUSUM Charts for Monitoring the Characteristic Life of Censored Weibull Lifetimes. J. Qual. Technol. 2014, 46, 340–358. [Google Scholar] [CrossRef]

- Choi, M.; Lee, J. A binomial CUSUM chart for monitoring type I right-censored Weibull lifetimes. Korean J. Appl. Stat. 2016, 29, 823–833. [Google Scholar] [CrossRef]

- Xu, S.; Jeske, D.R. Weighted EWMA charts for monitoring type I censored Weibull lifetimes. J. Qual. Technol. 2018, 50, 220–230. [Google Scholar] [CrossRef]

- Yu, D.; Jin, L.; Li, J.; Qin, X.; Zhu, Z.; Zhang, J. Monitoring the Weibull Scale Parameter Based on Type I Censored Data Using a Modified EWMA Control Chart. Axioms 2023, 12, 487. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, X.; Zhai, C.; Wang, J.; Ma, Y. Monitoring right censored Weibull distributed lifetime with weighted adaptive CUSUM charts based on dynamic probability limits. Expert Syst. Appl. 2025, 272, 126797. [Google Scholar] [CrossRef]

- Ali, S.; Shamim, R.; Shah, I.; Alrweili, H.; Marcon, G. Memory-type control charts for censored reliability data. Qual. Reliab. Eng. Int. 2023, 39, 2365–2384. [Google Scholar] [CrossRef]

- Lee, P.-H.; Liao, S.-L. Monitoring gamma type-I censored data using an exponentially weighted moving average control chart based on deep learning networks. Sci. Rep. 2024, 14, 6458. [Google Scholar] [CrossRef]

- Jiang, R.; Zhang, J.; Yu, Z. Adaptive EWMA control chart for monitoring two-parameter exponential distribution with type-II right censored data. J. Stat. Comput. Simul. 2024, 94, 787–819. [Google Scholar] [CrossRef]

- Nadi, A.A.; Afshari, R.; Gildeh, B.S. Control charts for monitoring relative risk rate in the presence of Weibull competing risks with censored and masked data. Qual. Technol. Quant. Manag. 2024, 21, 340–362. [Google Scholar] [CrossRef]

- Chaturvedi, A.; Joshi, N.; Bapat, S.R.; Nadarajah, S. Control Charts for the Percentiles of an Inverse Pareto Distribution Under Complete and Middle-Censored Data. Qual. Reliab. Eng. Int. 2025, 41, 1971–1984. [Google Scholar] [CrossRef]

- Shiryaev, A.N. The problem of the most rapid detection of a disturbance in a stationary process. Sov.-Math.-Dokl. 1961, 2, 795–799. [Google Scholar]

- Pollak, M.; Siegmund, D. Sequential Detection of a Change in a Normal Mean when the Initial Value is Unknown. Ann. Stat. 1991, 19, 394–416. [Google Scholar] [CrossRef]

- Kenett, R.S.; Pollak, M. Data-analytic aspects of the Shiryayev-Roberts control chart: Surveillance of a non-homogeneous Poisson process. J. Appl. Stat. 1996, 23, 125–138. [Google Scholar] [CrossRef]

- Srivastava, M.S.; Wu, Y. Comparison of EWMA, CUSUM and Shiryayev-Roberts Procedures for Detecting a Shift in the Mean. Ann. Stat. 1993, 21, 645–670. [Google Scholar] [CrossRef]

- Zhang, J.; Zou, C.; Wang, Z. A New Chart for Detecting the Process Mean and Variability. Commun. Stat.-Simul. Comput. 2011, 40, 728–743. [Google Scholar] [CrossRef]

- Zhang, J.; Zou, C.; Wang, Z. An adaptive Shiryaev-Roberts procedure for monitoring dispersion. Comput. Ind. Eng. 2011, 61, 1166–1172. [Google Scholar] [CrossRef]

- Moustakides, G.V.; Polunchenko, A.S.; Tartakovsky, A.G. Numerical Comparison of CUSUM and Shiryaev–Roberts Procedures for Detecting Changes in Distributions. Commun. Stat.-Theory Methods 2009, 38, 3225–3239. [Google Scholar] [CrossRef]

- Ottenstreuer, S. The Shiryaev–Roberts control chart for Markovian count time series. Qual. Reliab. Eng. Int. 2022, 38, 1207–1225. [Google Scholar] [CrossRef]

- Yu, D.; Mukherjee, A.; Li, J.; Jin, L.; Wen, K.; Zhang, J. Performance of the Shiryaev-Roberts-type scheme in comparison to the CUSUM and EWMA schemes in monitoring weibull scale parameter based on Type I censored data. Qual. Reliab. Eng. Int. 2022, 38, 3379–3403. [Google Scholar] [CrossRef]

- Meeker, W. Statistical Methods for Reliability Data; Wiley: New York, USA, 1998. [Google Scholar]

- Montgomery, D.C. Introduction to Statistical Quality Control; Wiley: Hoboken, NJ, USA, 2020. [Google Scholar]

- Zwetsloot, I.M.; Woodall, W.H. A Review of Some Sampling and Aggregation Strategies for Basic Statistical Process Monitoring. J. Qual. Technol. 2021, 53, 1–16. [Google Scholar] [CrossRef]

| SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | |

| h = 33.45 | h = 3.28 | h = 144.26 | h = 3.86 | h = 274.85 | h = 2.80 | h = 33.65 | h = 3.27 | h = 143.95 | h = 3.81 | h = 274.35 | h = 2.75 | |

| 370.99 | 369.82 | 370.08 | 370.75 | 370.27 | 369.28 | 370.61 | 369.99 | 370.65 | 370.46 | 369.39 | 371.00 | |

| 0.90 | 153.75 | 161.07 | 113.00 | 121.71 | 90.33 | 88.99 | 156.11 | 160.41 | 115.97 | 124.99 | 93.93 | 92.17 |

| 0.85 | 100.86 | 105.89 | 67.58 | 73.30 | 57.55 | 52.26 | 101.69 | 106.57 | 69.03 | 74.94 | 59.83 | 54.41 |

| 0.80 | 66.39 | 70.22 | 42.10 | 45.37 | 40.62 | 34.31 | 67.38 | 71.31 | 43.70 | 46.90 | 42.37 | 35.93 |

| 0.75 | 43.60 | 47.06 | 27.47 | 29.32 | 30.43 | 24.35 | 44.39 | 47.41 | 28.64 | 30.33 | 31.95 | 25.28 |

| 0.70 | 29.31 | 31.34 | 19.19 | 19.69 | 23.88 | 18.08 | 29.92 | 32.15 | 20.04 | 20.42 | 25.04 | 18.91 |

| 0.65 | 19.84 | 21.28 | 13.89 | 13.75 | 19.20 | 13.97 | 20.30 | 21.92 | 14.41 | 14.35 | 20.15 | 14.50 |

| 0.60 | 13.73 | 14.72 | 10.37 | 10.14 | 15.83 | 10.99 | 14.19 | 15.09 | 10.79 | 10.43 | 16.42 | 11.50 |

| 0.55 | 9.71 | 10.30 | 8.05 | 7.62 | 13.09 | 8.87 | 9.92 | 10.54 | 8.35 | 7.83 | 13.61 | 9.16 |

| 0.50 | 6.99 | 7.34 | 6.36 | 5.86 | 10.87 | 7.19 | 7.13 | 7.51 | 6.52 | 6.06 | 11.28 | 7.39 |

| SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | |

| h = 23.43 | h = 3.03 | h = 128.43 | h = 3.953 | h = 265.43 | h = 3.00 | h = 23.55 | h = 3.02 | h = 128.55 | h = 3.94 | h = 265.68 | h = 2.97 | |

| 370.43 | 370.91 | 370.68 | 370.72 | 370.89 | 370.96 | 370.24 | 370.97 | 370.64 | 369.98 | 370.62 | 370.55 | |

| 0.90 | 144.35 | 150.43 | 104.34 | 112.02 | 77.73 | 77.38 | 145.03 | 150.23 | 104.26 | 111.96 | 79.28 | 77.97 |

| 0.85 | 91.67 | 96.24 | 58.90 | 64.09 | 47.55 | 43.84 | 91.94 | 96.32 | 59.59 | 65.14 | 48.42 | 44.46 |

| 0.80 | 58.41 | 61.62 | 35.34 | 38.24 | 32.80 | 28.13 | 58.30 | 61.31 | 36.18 | 38.88 | 33.28 | 28.70 |

| 0.75 | 37.71 | 39.48 | 22.69 | 24.09 | 24.18 | 19.55 | 37.63 | 39.88 | 23.07 | 24.45 | 24.78 | 19.91 |

| 0.70 | 24.36 | 26.38 | 15.27 | 15.89 | 18.78 | 14.46 | 24.73 | 26.16 | 15.49 | 16.08 | 19.15 | 14.69 |

| 0.65 | 16.29 | 17.35 | 10.89 | 11.04 | 14.96 | 11.04 | 16.37 | 17.44 | 11.13 | 11.13 | 15.30 | 11.23 |

| 0.60 | 11.01 | 11.76 | 8.05 | 7.95 | 12.22 | 8.71 | 11.10 | 11.84 | 8.20 | 8.03 | 12.41 | 8.85 |

| 0.55 | 7.65 | 8.04 | 6.19 | 5.96 | 10.05 | 7.01 | 7.75 | 8.15 | 6.30 | 6.01 | 10.22 | 7.08 |

| 0.50 | 5.45 | 5.74 | 4.91 | 4.56 | 8.30 | 5.69 | 5.52 | 5.79 | 4.93 | 4.62 | 8.44 | 5.73 |

| SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | |

| h = 27.66 | h = 3.15 | h = 134.95 | h = 3.90 | h = 269.35 | h = 2.90 | h = 27.78 | h = 3.15 | h = 135.85 | h = 3.87 | h = 270.54 | h = 2.86 | |

| 369.77 | 370.32 | 370.81 | 370.98 | 370.67 | 369.87 | 370.75 | 370.82 | 369.87 | 370.93 | 370.17 | 370.50 | |

| 0.90 | 150.26 | 156.67 | 108.05 | 117.61 | 84.32 | 83.36 | 149.63 | 155.98 | 110.38 | 118.70 | 86.27 | 85.28 |

| 0.85 | 95.55 | 100.10 | 63.58 | 68.84 | 52.57 | 48.12 | 96.43 | 101.55 | 64.46 | 70.09 | 54.08 | 49.69 |

| 0.80 | 61.93 | 66.21 | 38.58 | 41.81 | 36.51 | 31.26 | 62.72 | 66.88 | 39.72 | 42.52 | 37.95 | 32.16 |

| 0.75 | 40.73 | 43.18 | 24.97 | 26.46 | 27.29 | 21.87 | 40.94 | 43.85 | 25.77 | 27.08 | 28.34 | 22.63 |

| 0.70 | 26.93 | 28.95 | 17.09 | 17.61 | 21.26 | 16.22 | 27.09 | 29.18 | 17.60 | 18.27 | 21.94 | 16.68 |

| 0.65 | 18.02 | 19.40 | 12.28 | 12.34 | 17.05 | 12.47 | 18.36 | 19.49 | 12.62 | 12.67 | 17.56 | 12.79 |

| 0.60 | 12.27 | 13.07 | 9.12 | 8.94 | 13.90 | 9.84 | 12.51 | 13.37 | 9.42 | 9.19 | 14.35 | 10.07 |

| 0.55 | 8.58 | 9.15 | 7.03 | 6.71 | 11.48 | 7.87 | 8.71 | 9.30 | 7.21 | 6.86 | 11.77 | 8.03 |

| 0.50 | 6.15 | 6.44 | 5.51 | 5.13 | 9.47 | 6.40 | 6.27 | 6.57 | 5.66 | 5.27 | 9.73 | 6.49 |

| SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | |

| h = 27.75 | h = 3.15 | h = 136.75 | h = 3.90 | h = 269.27 | h = 2.90 | h = 27.85 | h = 3.14 | h = 135.15 | h = 3.88 | h = 269.15 | h = 2.86 | |

| 369.63 | 369.52 | 370.88 | 370.86 | 369.67 | 370.25 | 370.26 | 369.31 | 370.83 | 369.76 | 370.36 | 370.68 | |

| 0.90 | 150.28 | 155.32 | 110.37 | 117.56 | 84.18 | 83.23 | 152.20 | 156.20 | 109.35 | 118.93 | 86.40 | 84.69 |

| 0.85 | 96.05 | 102.05 | 63.73 | 68.82 | 52.38 | 48.33 | 97.03 | 101.17 | 64.56 | 69.70 | 53.98 | 49.65 |

| 0.80 | 62.57 | 66.10 | 38.67 | 41.94 | 36.39 | 31.19 | 62.51 | 65.95 | 39.56 | 42.84 | 37.74 | 32.27 |

| 0.75 | 40.31 | 43.61 | 25.21 | 26.41 | 27.40 | 21.90 | 40.91 | 43.49 | 25.73 | 27.23 | 28.15 | 22.58 |

| 0.70 | 26.95 | 28.79 | 17.23 | 17.65 | 21.23 | 16.24 | 27.12 | 29.27 | 17.57 | 18.14 | 21.99 | 16.58 |

| 0.65 | 17.96 | 19.31 | 12.25 | 12.33 | 17.04 | 12.48 | 18.27 | 19.50 | 12.55 | 12.56 | 17.53 | 12.81 |

| 0.60 | 12.31 | 13.11 | 9.18 | 8.93 | 13.93 | 9.82 | 12.43 | 13.38 | 9.41 | 9.13 | 14.29 | 10.07 |

| 0.55 | 8.56 | 9.14 | 7.02 | 6.73 | 11.42 | 7.87 | 8.79 | 9.27 | 7.24 | 6.88 | 11.77 | 8.04 |

| 0.50 | 6.14 | 6.46 | 5.583 | 5.15 | 9.50 | 6.39 | 6.26 | 6.53 | 5.65 | 5.29 | 9.71 | 6.47 |

| SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | |

| h = 33.71 | h = 3.28 | h = 158.25 | h = 3.94 | h = 443.85 | h = 3.34 | h = 33.85 | h = 3.27 | h = 158.55 | h = 3.92 | h = 445.52 | h = 3.25 | |

| 370.37 | 369.95 | 369.98 | 370.86 | 369.16 | 369.53 | 369.21 | 369.02 | 370.21 | 369.12 | 369.37 | 371.98 | |

| 0.90 | 152.41 | 159.31 | 94.97 | 101.90 | 36.56 | 35.76 | 153.75 | 159.76 | 96.25 | 102.83 | 37.29 | 33.81 |

| 0.85 | 99.52 | 104.73 | 53.01 | 58.49 | 19.95 | 18.74 | 101.06 | 105.77 | 53.91 | 58.62 | 20.64 | 17.79 |

| 0.80 | 64.56 | 69.43 | 30.94 | 33.16 | 13.04 | 11.41 | 66.00 | 70.40 | 31.32 | 34.33 | 13.53 | 12.41 |

| 0.75 | 42.22 | 45.61 | 18.76 | 20.32 | 9.54 | 8.37 | 43.03 | 45.88 | 19.49 | 21.01 | 9.88 | 7.83 |

| 0.70 | 28.22 | 30.31 | 12.41 | 12.90 | 7.42 | 4.93 | 28.46 | 30.83 | 12.95 | 13.45 | 7.71 | 4.81 |

| 0.65 | 18.93 | 20.36 | 8.54 | 8.73 | 6.08 | 4.49 | 19.31 | 20.87 | 8.91 | 9.05 | 6.27 | 4.09 |

| 0.60 | 12.67 | 13.81 | 6.33 | 6.23 | 5.17 | 2.95 | 13.11 | 14.21 | 6.52 | 6.46 | 5.33 | 2.57 |

| 0.55 | 8.81 | 9.51 | 4.91 | 4.72 | 4.46 | 2.57 | 9.06 | 9.81 | 5.09 | 4.83 | 4.58 | 2.43 |

| 0.50 | 6.29 | 6.71 | 3.96 | 3.73 | 3.88 | 2.09 | 6.46 | 6.81 | 4.09 | 3.80 | 3.99 | 1.92 |

| SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | |

| h = 23.58 | h = 3.08 | h = 137.53 | h = 4.01 | h = 400.43 | h = 3.02 | h = 23.61 | h = 3.07 | h = 137.83 | h = 3.98 | h = 403.58 | h = 2.99 | |

| 370.92 | 370.92 | 370.00 | 370.73 | 369.40 | 370.95 | 369.47 | 370.98 | 370.63 | 369.99 | 369.71 | 370.53 | |

| 0.90 | 144.24 | 149.58 | 90.17 | 97.78 | 32.81 | 32.01 | 144.39 | 148.65 | 90.94 | 97.92 | 33.70 | 31.26 |

| 0.85 | 90.55 | 96.08 | 48.94 | 53.37 | 17.49 | 14.61 | 91.64 | 94.61 | 48.57 | 53.54 | 17.81 | 16.76 |

| 0.80 | 57.82 | 60.81 | 27.51 | 30.08 | 11.29 | 9.19 | 57.64 | 60.73 | 27.58 | 30.76 | 11.40 | 9.27 |

| 0.75 | 36.91 | 39.01 | 16.40 | 17.73 | 8.16 | 6.17 | 37.05 | 39.54 | 16.42 | 18.01 | 8.24 | 6.24 |

| 0.70 | 23.96 | 25.48 | 10.39 | 11.10 | 6.42 | 4.52 | 24.12 | 25.73 | 10.66 | 11.30 | 6.51 | 4.58 |

| 0.65 | 15.77 | 17.00 | 7.19 | 7.39 | 5.23 | 3.30 | 15.75 | 16.97 | 7.29 | 7.56 | 5.31 | 3.47 |

| 0.60 | 10.44 | 11.30 | 5.28 | 5.31 | 4.42 | 2.57 | 10.61 | 11.36 | 5.38 | 5.37 | 4.47 | 2.78 |

| 0.55 | 7.18 | 7.65 | 4.11 | 4.01 | 3.81 | 2.09 | 7.26 | 7.71 | 4.17 | 4.03 | 3.86 | 2.25 |

| 0.50 | 5.10 | 5.38 | 3.31 | 3.14 | 3.35 | 1.84 | 5.16 | 5.43 | 3.37 | 3.19 | 3.37 | 1.89 |

| SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | |

| h = 27.73 | h = 3.17 | h = 145.25 | h = 3.91 | h = 419.35 | h = 2.91 | h = 27.79 | h = 3.18 | h = 146.15 | h = 3.89 | h = 423.85 | h = 2.90 | |

| 369.71 | 370.33 | 370.53 | 370.97 | 369.77 | 369.85 | 370.64 | 370.83 | 369.07 | 370.91 | 369.10 | 370.48 | |

| 0.90 | 149.03 | 153.79 | 93.43 | 99.42 | 34.62 | 25.97 | 148.32 | 154.35 | 93.79 | 101.19 | 35.83 | 27.22 |

| 0.85 | 95.20 | 99.92 | 50.63 | 55.83 | 18.71 | 12.75 | 95.85 | 99.97 | 51.89 | 56.53 | 19.33 | 16.98 |

| 0.80 | 61.23 | 64.69 | 28.96 | 31.84 | 12.09 | 9.50 | 62.22 | 65.56 | 29.64 | 32.55 | 12.54 | 11.17 |

| 0.75 | 39.69 | 42.52 | 17.67 | 19.00 | 8.83 | 6.21 | 40.06 | 43.51 | 18.07 | 19.60 | 9.14 | 6.25 |

| 0.70 | 25.94 | 27.97 | 11.44 | 11.94 | 6.92 | 4.78 | 26.26 | 28.56 | 11.64 | 12.31 | 7.11 | 5.46 |

| 0.65 | 17.18 | 18.79 | 7.90 | 8.06 | 5.66 | 3.37 | 17.48 | 19.07 | 8.09 | 8.21 | 5.82 | 3.55 |

| 0.60 | 11.66 | 12.50 | 5.80 | 5.71 | 4.80 | 2.91 | 11.85 | 12.68 | 5.96 | 5.85 | 4.88 | 3.18 |

| 0.55 | 8.02 | 8.62 | 4.48 | 4.32 | 4.11 | 2.24 | 8.18 | 8.69 | 4.60 | 4.39 | 4.20 | 2.35 |

| 0.50 | 5.67 | 6.01 | 3.63 | 3.42 | 3.61 | 2.09 | 5.78 | 6.14 | 3.70 | 3.47 | 3.66 | 2.10 |

| SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | |

| h = 27.85 | h = 3.17 | h = 145.86 | h = 3.93 | h = 425.57 | h = 2.92 | h = 28.13 | h = 3.19 | h = 146.75 | h = 3.88 | h = 426.85 | h = 2.89 | |

| 370.29 | 370.02 | 369.88 | 370.83 | 369.44 | 370.15 | 370.51 | 370.21 | 370.08 | 370.14 | 370.32 | 369.98 | |

| 0.90 | 148.73 | 154.72 | 93.30 | 100.28 | 34.64 | 31.24 | 149.05 | 152.72 | 93.54 | 101.63 | 35.29 | 30.25 |

| 0.85 | 95.43 | 100.21 | 50.89 | 55.50 | 18.95 | 13.36 | 95.72 | 100.19 | 51.16 | 56.49 | 19.42 | 22.45 |

| 0.80 | 61.48 | 65.21 | 29.11 | 32.08 | 12.08 | 9.53 | 61.41 | 65.05 | 29.66 | 32.48 | 12.56 | 8.81 |

| 0.75 | 40.01 | 42.61 | 17.76 | 19.11 | 8.81 | 6.29 | 40.06 | 42.62 | 18.12 | 19.51 | 9.04 | 6.09 |

| 0.70 | 26.09 | 27.97 | 11.47 | 12.27 | 6.90 | 4.73 | 26.28 | 28.30 | 11.78 | 12.28 | 7.13 | 5.09 |

| 0.65 | 17.11 | 18.63 | 7.91 | 8.12 | 5.67 | 3.13 | 17.42 | 18.73 | 8.05 | 8.26 | 5.81 | 2.90 |

| 0.60 | 11.59 | 12.64 | 5.78 | 5.80 | 4.80 | 2.89 | 11.84 | 12.68 | 5.94 | 5.87 | 4.88 | 2.77 |

| 0.55 | 8.05 | 8.53 | 4.50 | 4.32 | 4.12 | 2.47 | 8.15 | 8.67 | 4.57 | 4.43 | 4.19 | 2.41 |

| 0.50 | 5.66 | 6.02 | 3.63 | 3.42 | 3.61 | 2.16 | 5.76 | 6.11 | 3.71 | 3.48 | 3.66 | 1.98 |

| SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | |

| h = 12.15 | h = 2.44 | h = 111.61 | h = 4.03 | h = 254.63 | h = 3.27 | h = 12.63 | h = 2.48 | h = 112.63 | h = 4.01 | h = 255.68 | h = 3.21 | |

| 370.87 | 370.83 | 370.96 | 370.46 | 370.52 | 370.56 | 370.50 | 370.52 | 370.73 | 370.23 | 370.21 | 370.20 | |

| 0.90 | 135.90 | 138.68 | 92.84 | 100.64 | 63.01 | 63.82 | 136.34 | 140.33 | 95.45 | 102.72 | 65.78 | 65.51 |

| 0.85 | 83.10 | 86.56 | 50.54 | 55.03 | 36.95 | 34.72 | 83.39 | 87.34 | 51.71 | 56.71 | 38.59 | 36.31 |

| 0.80 | 51.45 | 54.03 | 29.16 | 31.62 | 24.81 | 21.85 | 52.25 | 54.79 | 30.18 | 33.07 | 26.11 | 22.64 |

| 0.75 | 32.39 | 34.02 | 17.97 | 19.24 | 18.26 | 15.11 | 32.65 | 34.54 | 18.78 | 20.04 | 19.13 | 15.77 |

| 0.70 | 20.46 | 21.63 | 11.92 | 12.34 | 14.08 | 11.14 | 21.02 | 22.02 | 12.30 | 12.92 | 14.74 | 11.65 |

| 0.65 | 13.25 | 14.10 | 8.29 | 8.47 | 11.19 | 8.57 | 13.76 | 14.38 | 8.70 | 8.81 | 11.70 | 8.92 |

| 0.60 | 8.86 | 9.25 | 6.13 | 6.11 | 9.09 | 6.82 | 9.11 | 9.59 | 6.37 | 6.30 | 9.52 | 6.99 |

| 0.55 | 6.03 | 6.30 | 4.70 | 4.54 | 7.49 | 5.45 | 6.17 | 6.53 | 4.85 | 4.73 | 7.79 | 5.63 |

| 0.50 | 4.23 | 4.40 | 3.66 | 3.51 | 6.18 | 4.43 | 4.36 | 4.55 | 3.80 | 3.62 | 6.43 | 4.57 |

| SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | |

| h = 5.26 | h = 1.63 | h = 94.56 | h = 4.04 | h = 240.66 | h = 3.45 | h = 5.46 | h = 1.67 | h = 95.32 | h = 4.03 | h = 241.33 | h = 3.42 | |

| 370.46 | 369.66 | 370.16 | 370.52 | 370.46 | 370.43 | 370.54 | 369.84 | 370.26 | 370.13 | 370.14 | 370.26 | |

| 0.90 | 123.35 | 124.66 | 85.20 | 92.44 | 53.06 | 54.00 | 124.91 | 125.02 | 85.59 | 92.68 | 53.80 | 54.80 |

| 0.85 | 72.46 | 73.59 | 44.00 | 48.75 | 29.95 | 28.42 | 73.17 | 73.93 | 44.59 | 49.16 | 30.57 | 29.03 |

| 0.80 | 43.01 | 44.25 | 24.51 | 26.88 | 19.72 | 17.46 | 43.38 | 44.99 | 25.06 | 27.41 | 20.18 | 17.97 |

| 0.75 | 26.25 | 27.03 | 14.70 | 15.73 | 14.29 | 11.99 | 26.44 | 27.29 | 14.99 | 16.12 | 14.62 | 12.19 |

| 0.70 | 16.26 | 16.78 | 9.48 | 9.93 | 10.92 | 8.81 | 16.48 | 17.18 | 9.63 | 10.12 | 11.18 | 9.00 |

| 0.65 | 10.23 | 10.70 | 6.53 | 6.62 | 8.65 | 6.77 | 10.52 | 10.95 | 6.64 | 6.79 | 8.78 | 6.86 |

| 0.60 | 6.80 | 7.07 | 4.73 | 4.74 | 6.95 | 5.31 | 6.91 | 7.14 | 4.84 | 4.78 | 7.10 | 5.41 |

| 0.55 | 4.56 | 4.74 | 3.61 | 3.53 | 5.71 | 4.29 | 4.65 | 4.82 | 3.67 | 3.61 | 5.81 | 4.35 |

| 0.50 | 3.23 | 3.32 | 2.83 | 2.74 | 4.69 | 3.49 | 3.28 | 3.36 | 2.87 | 2.76 | 4.79 | 3.54 |

| SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | |

| h = 7.91 | h = 2.03 | h = 102.51 | h = 4.05 | h = 246.52 | h = 3.35 | h = 8.28 | h = 2.07 | h = 103.58 | h = 4.02 | h = 247.58 | h = 3.31 | |

| 369.97 | 370.87 | 370.68 | 370.10 | 370.67 | 369.77 | 370.87 | 369.13 | 370.08 | 370.60 | 370.03 | 369.89 | |

| 0.90 | 129.48 | 131.85 | 89.76 | 96.99 | 58.14 | 59.06 | 131.87 | 133.20 | 90.82 | 98.24 | 59.75 | 60.64 |

| 0.85 | 78.10 | 79.76 | 47.22 | 51.96 | 33.54 | 31.54 | 78.81 | 79.98 | 48.38 | 52.84 | 34.63 | 32.44 |

| 0.80 | 47.35 | 48.73 | 26.76 | 29.56 | 22.21 | 19.68 | 48.29 | 49.33 | 27.53 | 30.03 | 23.07 | 20.28 |

| 0.75 | 29.12 | 30.33 | 16.30 | 17.56 | 16.23 | 13.61 | 29.70 | 30.72 | 16.65 | 18.06 | 16.77 | 13.96 |

| 0.70 | 18.27 | 19.02 | 10.65 | 11.20 | 12.46 | 9.92 | 18.73 | 19.39 | 11.01 | 11.46 | 12.86 | 10.23 |

| 0.65 | 11.75 | 12.21 | 7.37 | 7.51 | 9.87 | 7.60 | 11.98 | 12.49 | 7.58 | 7.76 | 10.12 | 7.83 |

| 0.60 | 7.74 | 8.08 | 5.35 | 5.39 | 7.98 | 5.99 | 7.86 | 8.22 | 5.51 | 5.53 | 8.22 | 6.14 |

| 0.55 | 5.25 | 5.50 | 4.07 | 4.00 | 6.52 | 4.81 | 5.38 | 5.57 | 4.20 | 4.09 | 6.71 | 4.91 |

| 0.50 | 3.68 | 3.82 | 3.22 | 3.09 | 5.40 | 3.91 | 3.77 | 3.87 | 3.28 | 3.15 | 5.53 | 3.99 |

| SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | |

| h = 7.99 | h = 2.04 | h = 102.95 | h = 4.04 | h = 245.95 | h = 3.36 | h = 8.26 | h = 2.07 | h = 103.21 | h = 4.03 | h = 247.28 | h = 3.31 | |

| 369.84 | 370.53 | 370.09 | 370.89 | 370.20 | 370.00 | 370.05 | 369.57 | 370.82 | 370.53 | 370.84 | 370.02 | |

| 0.90 | 130.95 | 132.27 | 89.92 | 96.82 | 57.54 | 58.79 | 131.69 | 132.88 | 90.32 | 97.91 | 59.66 | 60.40 |

| 0.85 | 78.49 | 80.59 | 47.35 | 51.54 | 33.36 | 31.49 | 78.79 | 80.69 | 48.36 | 52.74 | 34.55 | 32.53 |

| 0.80 | 47.62 | 48.85 | 26.93 | 29.48 | 22.25 | 19.68 | 47.98 | 49.38 | 27.36 | 29.85 | 23.09 | 20.22 |

| 0.75 | 29.42 | 30.59 | 16.23 | 17.45 | 16.22 | 13.56 | 29.65 | 30.84 | 16.65 | 17.91 | 16.81 | 13.88 |

| 0.70 | 18.39 | 19.23 | 10.66 | 11.17 | 12.43 | 9.92 | 18.65 | 19.56 | 10.96 | 11.48 | 12.84 | 10.20 |

| 0.65 | 11.88 | 12.38 | 7.39 | 7.51 | 9.81 | 7.64 | 11.93 | 12.57 | 7.56 | 7.75 | 10.15 | 7.80 |

| 0.60 | 7.84 | 8.13 | 5.39 | 5.37 | 7.96 | 6.01 | 7.87 | 8.26 | 5.52 | 5.53 | 8.18 | 6.13 |

| 0.55 | 5.24 | 5.50 | 4.11 | 4.01 | 6.53 | 4.82 | 5.39 | 5.57 | 4.21 | 4.09 | 6.71 | 4.92 |

| 0.50 | 3.69 | 3.79 | 3.22 | 3.08 | 5.40 | 3.94 | 3.77 | 3.91 | 3.27 | 3.17 | 5.52 | 3.99 |

| SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | |

| h = 12.21 | h = 2.44 | h = 116.43 | h = 4.08 | h = 357.48 | h = 3.66 | h = 12.78 | h = 2.47 | h = 117.69 | h = 4.06 | h = 363.62 | h = 3.61 | |

| 370.58 | 369.38 | 370.74 | 370.35 | 370.81 | 369.84 | 370.15 | 370.59 | 370.37 | 370.11 | 370.05 | 369.12 | |

| 0.90 | 136.49 | 139.05 | 86.15 | 94.15 | 33.20 | 33.04 | 137.22 | 139.63 | 88.66 | 95.89 | 33.92 | 32.90 |

| 0.85 | 83.21 | 85.55 | 44.44 | 48.97 | 15.78 | 14.07 | 85.20 | 87.10 | 45.31 | 50.19 | 16.47 | 14.96 |

| 0.80 | 51.75 | 53.41 | 23.90 | 26.63 | 9.82 | 8.33 | 52.29 | 54.00 | 24.48 | 27.48 | 10.27 | 8.33 |

| 0.75 | 32.13 | 33.49 | 13.97 | 15.03 | 7.01 | 5.43 | 33.05 | 34.17 | 14.30 | 15.68 | 7.31 | 5.48 |

| 0.70 | 20.46 | 21.24 | 8.67 | 9.31 | 5.51 | 3.95 | 20.84 | 21.94 | 9.01 | 9.49 | 5.76 | 3.99 |

| 0.65 | 13.14 | 13.84 | 5.91 | 6.13 | 4.59 | 3.09 | 13.45 | 14.11 | 6.14 | 6.37 | 4.71 | 3.12 |

| 0.60 | 8.68 | 9.11 | 4.33 | 4.36 | 3.89 | 2.56 | 8.86 | 9.39 | 4.48 | 4.51 | 4.00 | 2.55 |

| 0.55 | 5.87 | 6.13 | 3.37 | 3.30 | 3.38 | 2.19 | 5.99 | 6.30 | 3.47 | 3.40 | 3.48 | 2.14 |

| 0.50 | 4.09 | 4.30 | 2.74 | 2.64 | 2.98 | 1.86 | 4.22 | 4.42 | 2.81 | 2.71 | 3.05 | 1.89 |

| SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | |

| h = 5.24 | h = 1.63 | h = 97.04 | h = 4.07 | h = 318.98 | h = 3.77 | h = 5.42 | h = 1.66 | h = 97.78 | h = 4.07 | h = 321.51 | h = 3.75 | |

| 370.23 | 369.45 | 370.84 | 370.35 | 370.60 | 370.21 | 370.60 | 369.92 | 370.83 | 370.98 | 370.48 | 370.00 | |

| 0.90 | 123.45 | 123.91 | 80.82 | 87.72 | 28.52 | 29.52 | 124.48 | 125.32 | 81.61 | 89.24 | 29.17 | 29.09 |

| 0.85 | 72.02 | 73.77 | 39.93 | 44.33 | 13.50 | 12.59 | 73.14 | 74.07 | 40.09 | 45.01 | 13.80 | 12.85 |

| 0.80 | 43.17 | 44.09 | 20.86 | 23.30 | 8.26 | 6.94 | 43.42 | 44.63 | 21.27 | 23.61 | 8.41 | 7.15 |

| 0.75 | 26.17 | 27.00 | 11.83 | 12.97 | 5.95 | 4.72 | 26.49 | 27.11 | 12.14 | 13.21 | 6.11 | 4.79 |

| 0.70 | 16.15 | 16.73 | 7.34 | 7.79 | 4.71 | 3.49 | 16.33 | 17.02 | 7.45 | 7.99 | 4.79 | 3.55 |

| 0.65 | 10.24 | 10.73 | 4.93 | 5.10 | 3.89 | 2.79 | 10.40 | 10.77 | 5.01 | 5.22 | 3.97 | 2.83 |

| 0.60 | 6.66 | 6.96 | 3.62 | 3.66 | 3.33 | 2.31 | 6.82 | 7.06 | 3.67 | 3.71 | 3.38 | 2.32 |

| 0.55 | 4.54 | 4.69 | 2.82 | 2.80 | 2.91 | 1.99 | 4.56 | 4.74 | 2.85 | 2.84 | 2.93 | 1.99 |

| 0.50 | 3.20 | 3.29 | 2.29 | 2.25 | 2.56 | 1.73 | 3.22 | 3.31 | 2.33 | 2.27 | 2.58 | 1.71 |

| SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | |

| h = 7.97 | h = 2.04 | h = 105.47 | h = 4.07 | h = 337.52 | h = 3.70 | h = 8.24 | h = 2.07 | h = 106.67 | h = 4.06 | h = 342.67 | h = 3.68 | |

| 370.27 | 370.83 | 370.01 | 370.07 | 370.15 | 370.39 | 370.15 | 369.91 | 370.77 | 370.11 | 370.64 | 369.91 | |

| 0.90 | 130.29 | 132.33 | 83.55 | 91.23 | 30.90 | 30.83 | 130.79 | 132.70 | 84.67 | 92.52 | 32.15 | 31.55 |

| 0.85 | 77.84 | 80.29 | 42.36 | 46.95 | 14.60 | 13.46 | 78.24 | 80.82 | 42.88 | 47.98 | 15.07 | 13.77 |

| 0.80 | 47.49 | 49.30 | 22.53 | 24.96 | 9.09 | 7.53 | 47.89 | 49.52 | 23.02 | 25.29 | 9.30 | 7.83 |

| 0.75 | 29.10 | 30.25 | 12.86 | 14.17 | 6.49 | 5.13 | 29.68 | 30.78 | 13.20 | 14.37 | 6.67 | 5.32 |

| 0.70 | 18.33 | 18.98 | 8.03 | 8.59 | 5.10 | 3.69 | 18.40 | 19.37 | 8.17 | 8.69 | 5.25 | 3.77 |

| 0.65 | 11.66 | 12.27 | 5.39 | 5.64 | 4.22 | 2.92 | 11.83 | 12.38 | 5.52 | 5.78 | 4.33 | 2.96 |

| 0.60 | 7.57 | 8.05 | 3.96 | 3.96 | 3.61 | 2.41 | 7.74 | 8.16 | 4.04 | 4.07 | 3.68 | 2.45 |

| 0.55 | 5.17 | 5.42 | 3.06 | 3.05 | 3.13 | 2.06 | 5.28 | 5.49 | 3.13 | 3.10 | 3.18 | 2.06 |

| 0.50 | 3.61 | 3.75 | 2.51 | 2.43 | 2.75 | 1.78 | 3.68 | 3.82 | 2.55 | 2.47 | 2.80 | 1.78 |

| SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | SR | CUSUM | |

| h = 7.96 | h = 2.04 | h = 106.11 | h = 4.07 | h = 338.31 | h = 3.71 | h = 8.24 | h = 2.07 | h = 107.23 | h = 4.06 | h = 341.46 | h = 3.68 | |

| 370.47 | 370.25 | 370.19 | 369.87 | 370.49 | 369.96 | 370.37 | 370.67 | 370.44 | 370.36 | 370.59 | 369.62 | |

| 0.90 | 129.45 | 133.10 | 83.61 | 90.66 | 30.52 | 30.04 | 130.72 | 131.52 | 84.66 | 92.12 | 31.45 | 31.38 |

| 0.85 | 78.04 | 80.04 | 41.92 | 47.13 | 14.62 | 13.32 | 78.42 | 80.97 | 43.18 | 48.38 | 15.14 | 14.07 |

| 0.80 | 47.71 | 48.99 | 22.54 | 25.01 | 9.04 | 7.64 | 48.24 | 49.27 | 23.09 | 25.48 | 9.30 | 7.65 |

| 0.75 | 29.21 | 30.51 | 12.87 | 14.15 | 6.52 | 5.12 | 29.46 | 30.73 | 13.18 | 14.32 | 6.65 | 5.26 |

| 0.70 | 18.04 | 18.97 | 8.05 | 8.55 | 5.11 | 3.72 | 18.50 | 19.45 | 8.22 | 8.76 | 5.24 | 3.75 |

| 0.65 | 11.79 | 12.20 | 5.42 | 5.59 | 4.22 | 2.90 | 11.88 | 12.38 | 5.60 | 5.71 | 4.33 | 2.97 |

| 0.60 | 7.61 | 7.98 | 3.95 | 3.99 | 3.60 | 2.43 | 7.78 | 8.17 | 4.05 | 4.07 | 3.67 | 2.42 |

| 0.55 | 5.13 | 5.40 | 3.08 | 3.04 | 3.14 | 2.05 | 5.23 | 5.50 | 3.14 | 3.09 | 3.18 | 2.03 |

| 0.50 | 3.62 | 3.77 | 2.51 | 2.45 | 2.75 | 1.77 | 3.67 | 3.80 | 2.55 | 2.48 | 2.79 | 1.80 |

| SR | CUSUM | SR | CUSUM | SR | CUSUM | EWMA | CNN | LSTM | EWMA | CNN | LSTM | |||||||

| CEV | CM | CEV | CM | CEV | CM | CEV | CM | CEV | CM | CEV | CM | |||||||

| h = 6.08 | h = 1.76 | h = 57.02 | h = 3.54 | h = 177.91 | h = 3.29 | h = 0.78 | h = 0.41 | h = −0.11 | h = −0.03 | h = −0.81 | h = −0.40 | h = 0.69 | h = 0.36 | h = −0.06 | h = −0.05 | h = −0.79 | h = −0.40 | |

| 0.80 | 27.36 | 28.75 | 14.87 | 16.29 | 7.08 | 6.29 | 15.52 | 17.85 | 21.59 | 21.86 | 32.63 | 95.62 | 15.50 | 17.21 | 18.01 | 23.91 | 26.72 | 130.62 |

| 0.70 | 11.52 | 12.10 | 5.97 | 6.47 | 4.21 | 3.20 | 8.78 | 9.73 | 7.38 | 8.80 | 12.53 | 41.08 | 8.08 | 8.57 | 7.30 | 8.87 | 11.48 | 45.06 |

| 0.60 | 5.42 | 5.67 | 3.29 | 3.34 | 3.10 | 2.22 | 4.99 | 6.78 | 3.71 | 4.88 | 6.51 | 16.26 | 5.27 | 5.50 | 3.01 | 4.39 | 6.30 | 16.46 |

| 0.50 | 2.87 | 2.99 | 2.21 | 2.17 | 2.44 | 1.70 | 3.64 | 4.16 | 2.36 | 2.75 | 3.72 | 7.92 | 3.90 | 3.92 | 2.25 | 2.06 | 3.88 | 9.34 |

| 0.20 | 1.07 | 1.07 | 1.09 | 1.07 | 1.28 | 1.05 | 2.38 | 2.55 | 1.19 | 1.17 | 1.29 | 2.44 | 2.07 | 2.26 | 1.13 | 1.00 | 1.23 | 2.52 |

| SR | CUSUM | SR | CUSUM | SR | CUSUM | EWMA | CNN | LSTM | EWMA | CNN | LSTM | |||||||

| CEV | CM | CEV | CM | CEV | CM | CEV | CM | CEV | CM | CEV | CM | |||||||

| h = 6.23 | h = 1.77 | h = 58.43 | h = 3.56 | h = 179.86 | h = 3.27 | h = 0.83 | h = 0.27 | h = −0.06 | h = −0.02 | h = −0.80 | h = −0.15 | h = 0.73 | h = 0.25 | h = −0.06 | h = −0.02 | h = −0.79 | h = −0.15 | |

| 0.80 | 28.22 | 28.86 | 15.21 | 17.45 | 7.30 | 6.19 | 10.96 | 12.37 | 15.82 | 13.60 | 29.42 | 20.26 | 12.28 | 10.34 | 14.71 | 13.20 | 23.71 | 19.39 |

| 0.70 | 11.81 | 12.24 | 6.15 | 6.61 | 4.26 | 3.24 | 5.48 | 5.19 | 5.32 | 4.31 | 13.53 | 6.95 | 6.54 | 5.26 | 4.75 | 4.03 | 12.07 | 7.68 |

| 0.60 | 5.44 | 5.74 | 3.36 | 3.41 | 3.14 | 2.20 | 3.49 | 3.55 | 3.04 | 1.86 | 7.03 | 3.60 | 4.09 | 3.36 | 2.58 | 2.01 | 5.87 | 3.58 |

| 0.50 | 2.96 | 3.09 | 2.24 | 2.18 | 2.46 | 1.68 | 3.73 | 3.61 | 2.05 | 1.26 | 3.70 | 2.08 | 3.14 | 2.48 | 1.42 | 1.27 | 3.78 | 1.97 |

| 0.20 | 1.07 | 1.08 | 1.10 | 1.08 | 1.28 | 1.05 | 1.68 | 2.21 | 1.26 | 1.00 | 1.27 | 1.04 | 1.84 | 1.39 | 1.00 | 1.00 | 1.30 | 1.02 |

| SR | CUSUM | SR | CUSUM | SR | CUSUM | EWMA | CNN | LSTM | EWMA | CNN | LSTM | |||||||

| CEV | CM | CEV | CM | CEV | CM | CEV | CM | CEV | CM | CEV | CM | |||||||

| h = 6.38 | h = 1.80 | h = 58.95 | h = 3.49 | h = 184.91 | h = 3.17 | h = 0.88 | h = 0.39 | h = −0.06 | h = −0.03 | h = −0.65 | h = −0.21 | h = 0.82 | h = 0.37 | h = −0.05 | h = −0.01 | h = −0.66 | h = −0.22 | |

| 0.80 | 29.32 | 30.49 | 16.17 | 17.34 | 7.95 | 6.73 | 9.78 | 9.23 | 10.03 | 8.88 | 20.20 | 18.41 | 9.49 | 8.21 | 8.83 | 7.80 | 22.51 | 21.44 |

| 0.70 | 12.12 | 12.90 | 6.62 | 6.96 | 4.55 | 3.55 | 4.78 | 5.99 | 4.46 | 3.61 | 9.51 | 8.11 | 4.85 | 4.49 | 3.69 | 3.15 | 9.23 | 9.22 |

| 0.60 | 5.81 | 5.95 | 3.56 | 3.59 | 3.31 | 2.17 | 4.48 | 3.96 | 1.98 | 1.51 | 4.39 | 3.39 | 3.09 | 2.92 | 2.43 | 1.68 | 4.71 | 4.10 |

| 0.50 | 3.06 | 3.19 | 2.34 | 2.26 | 2.54 | 1.60 | 2.11 | 2.70 | 1.38 | 1.14 | 2.45 | 1.90 | 2.27 | 2.23 | 1.58 | 1.31 | 2.71 | 2.35 |

| 0.20 | 1.08 | 1.08 | 1.10 | 1.07 | 1.28 | 1.02 | 2.58 | 1.28 | 1.00 | 1.00 | 1.06 | 1.01 | 1.25 | 1.31 | 1.00 | 1.01 | 1.05 | 1.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Chen, P.; Ma, R.; Zhang, J. Performance Evaluation of Shiryaev–Roberts and Cumulative Sum Schemes for Monitoring Shape and Scale Parameters in Gamma-Distributed Data Under Type I Censoring. Axioms 2025, 14, 713. https://doi.org/10.3390/axioms14090713

Li H, Chen P, Ma R, Zhang J. Performance Evaluation of Shiryaev–Roberts and Cumulative Sum Schemes for Monitoring Shape and Scale Parameters in Gamma-Distributed Data Under Type I Censoring. Axioms. 2025; 14(9):713. https://doi.org/10.3390/axioms14090713

Chicago/Turabian StyleLi, He, Peile Chen, Ruicheng Ma, and Jiujun Zhang. 2025. "Performance Evaluation of Shiryaev–Roberts and Cumulative Sum Schemes for Monitoring Shape and Scale Parameters in Gamma-Distributed Data Under Type I Censoring" Axioms 14, no. 9: 713. https://doi.org/10.3390/axioms14090713

APA StyleLi, H., Chen, P., Ma, R., & Zhang, J. (2025). Performance Evaluation of Shiryaev–Roberts and Cumulative Sum Schemes for Monitoring Shape and Scale Parameters in Gamma-Distributed Data Under Type I Censoring. Axioms, 14(9), 713. https://doi.org/10.3390/axioms14090713