Reliability and Performance Optimization of Multi-Subsystem Systems Using Copula-Based Repair

Abstract

1. Introduction

2. Description of the Model and Its Notation

2.1. Description of the State

2.2. Assumptions

- Initially, all the subsystems function perfectly.

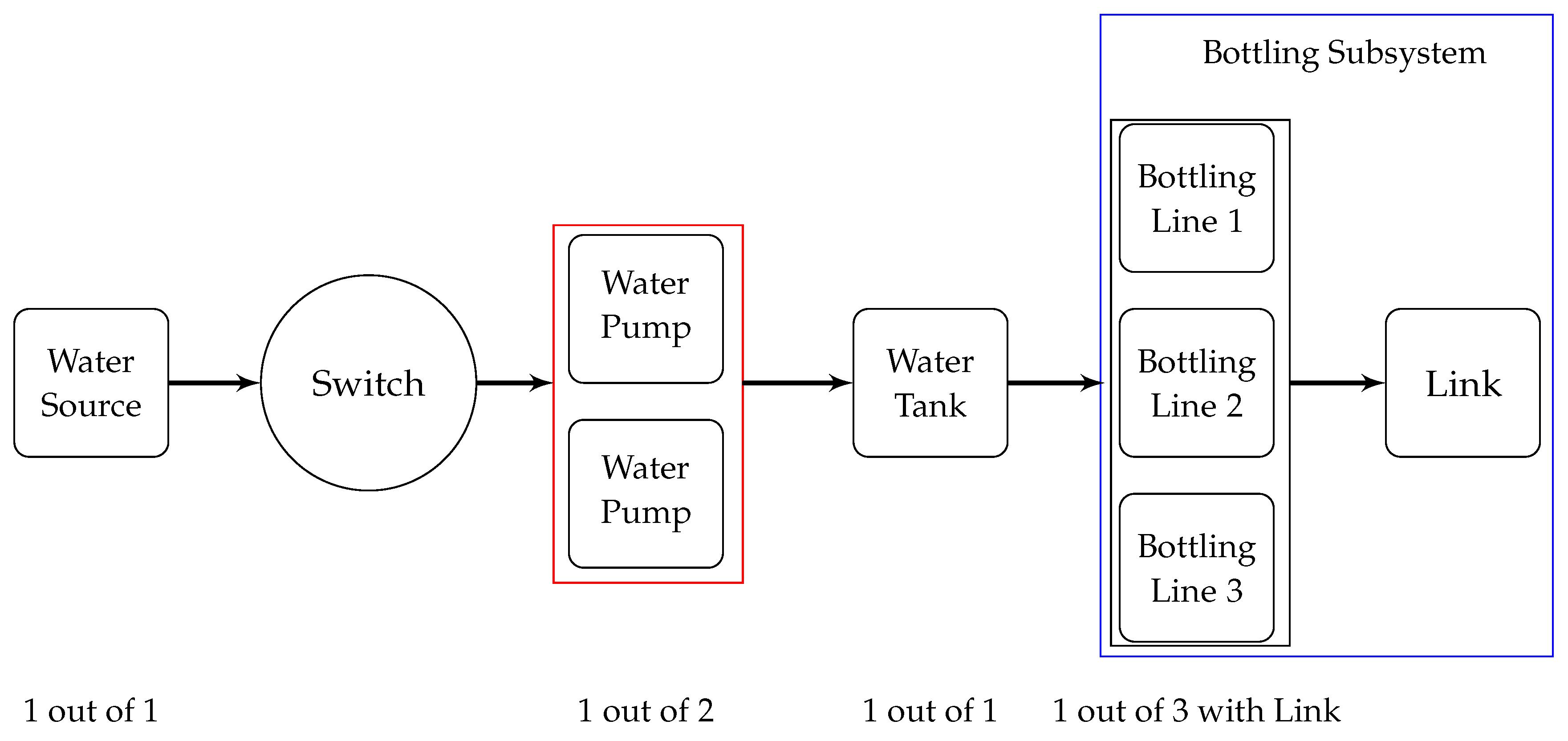

- The system consists of four series-parallel subsystems, as illustrated in Figure 1. In Subsystem 1 (water source), there is a single unit operating in a 1-out-of-1 configuration. Subsystem 2 (water pump) contains two identical units that work in a 1-out-of-2 setup. Subsystem 3 (water tank) has a single unit operating as 1-out-of-1 configuration. Three identical components are stacked in a 1-out-of-3 configuration to form Subsystem 4 (bottling line). Furthermore, failure of the link unit within Subsystem 4 will cause the entire system to become inoperative.

- The system contains a switching device that may be unreliable, and if the switch fails, the system will immediately fail.

- Failures occur at a steady rate throughout time, and this rate is governed by an exponential distribution.

- The Gumbel–Hougard family copula is used to fully restore failed states, whereas the general distribution is used to repair states that have experienced partial failure.

- There have been no reports of damage following the system repair.

- After the repair, the system performs as reliably and efficiently as a new model.

2.3. Notation

3. The Solution and Model in Mathematics

4. Analysis of the Model

4.1. Formulating and Analyzing System Availability

4.2. Formulating and Analyzing System Reliability

4.3. Assessment and Formulating Mean Time to Failure

4.4. Sensitivity Analysis of the

4.5. Cost Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Maihulla, A.S.; Yusuf, I.; Bala, S.I. Performance Evaluation of a Complex Reverse Osmosis Machine System in Water Purification using Reliability, Availability, Maintainability and Dependability Analysis. Reliab. Theory Appl. 2021, 16, 115–131. [Google Scholar]

- Sadri, S.; Khoshkhoo, R.H.; Ameri, M. Multi objective optimization of reverse osmosis desalination plant with energy approach. J. Mech. Sci. Technol. 2016, 30, 4807–4814. [Google Scholar] [CrossRef]

- Lee, Y.G.; Lee, Y.S.; Jeon, J.J.; Lee, S.; Yang, D.R. Artificial neural network model for optimizing operation of a seawater reverse osmosis desalination plant. Desalination 2009, 247, 180–189. [Google Scholar] [CrossRef]

- Ezugbe, E.O.; Rathilal, S. Membrane technologies in wastewater treatment. Membranes 2020, 5, 89. [Google Scholar] [CrossRef]

- Shalana, L.B.; Kathleen, M.L.; Sherri, L.M. Evaluation of Ozone Pretreatment on Flux Parameters of Reverse Osmosis for Surface Water Treatment. Ozone Sci. Eng. 2008, 30, 152–164. [Google Scholar] [CrossRef]

- Gulati, J.; Singh, V.V.; Rawal, D.K.; Goel, C.K. Performance analysis of complex system in series configuration under different failure and repair discipline using copula. Int. J. Reliab. Qual. Saf. Eng. 2016, 23, 812–832. [Google Scholar]

- Yusuf, I.; Hussaini, N. A comparative analysis of three redundant unit systems with three types of failures. Arab. J. Sci. Eng. 2014, 39, 3337–3349. [Google Scholar] [CrossRef]

- Yusuf, I.; Yusuf, B.; Bala, S.I. Meantime to system failure analysis of a linear consecutive 3-out-of-5 warm standby system in the presence of common cause failure. J. Math. Comput. Sci. 2014, 4, 58–66. [Google Scholar]

- Gokdere, G.; Keung, H.; Tony, N. Time-dependent reliability analysis for repairable consecutive k-out-of-n: F system. Stat. Theory Rel. Fields 2021, 6, 139–147. [Google Scholar] [CrossRef]

- Elshoubary, E.E. Effect of reduction method on the performance a software defined network system using Gumbel Hougaard family copula distribution. J. N Soc. Phys. Sci. 2023, 5, 1402. [Google Scholar] [CrossRef]

- Elshoubary, E.E.; Radwan, T. Studying the Efficiency of the Apache Kafka System Using the Reduction Method, and Its Effectiveness in Terms of Reliability Metrics Subject to a Copula Approach. Appl. Sci. 2024, 14, 6758. [Google Scholar] [CrossRef]

- Ram, M.; Kumar, A. Performability analysis of a system under 1-out-of-2: G scheme with perfect reworking. J. Braj. Soc. Mech. Sci. Eng. 2015, 37, 1029–1038. [Google Scholar] [CrossRef]

- Temraz, N. Availability and reliability of a parallel system under imperfect repair and replacement: Analysis and cost optimization. Int. J. Syst. Assur. Eng. Manag. 2019, 10, 1002–1009. [Google Scholar] [CrossRef]

- Singh, V.V.; Gahlot, M. Reliability analysis of (n) clients system under startopology and copula linguistic approach. Int. J. Comput. Syst. Eng. 2021, 6, 123–133. [Google Scholar] [CrossRef]

- Anas, S.M.; Yusuf, I. Reliability modeling and performance analysis of reverse osmosis machine in water purification using Gumbel–Hougaard family copula. Life Cycle Reliab. Saf. Eng. 2022, 12, 11–22. [Google Scholar] [CrossRef]

| State | Description |

|---|---|

| The system is in an optimal state, with every component performing perfectly and free from any malfunctions. | |

| , | The current condition has deteriorated, classifying it is considered a small system failure. Nevertheless, even with the malfunction of a single unit in Subsystems 2 and 4, the system as a whole continues to operate since the other units remain functional. Restoration efforts are in progress, focusing on thorough repairs. |

| This condition explains the deteriorated state brought on by the breakdown of two Subsystem 4 units. | |

| , | These states have faced severe disruptions caused by the complete failure of all units inside Subsystems 2 and 4. The system is being restored using the Gumbel–Hougaard copula distribution in order to address this issue. |

| , , , | The described state signifies which the system is in a completely failed condition and is currently undergoing repair, modeled utilizing the Gumbel- Hougaard family copula distribution. |

| Time | Case I | Case II | Case III |

|---|---|---|---|

| 0 | 1 | 1 | 1 |

| 1 | 0.899566 | 0.819661 | 0.961529 |

| 2 | 0.900053 | 0.782666 | 0.960475 |

| 3 | 0.90109 | 0.77405 | 0.960756 |

| 4 | 0.901353 | 0.771794 | 0.960872 |

| 5 | 0.901413 | 0.77115 | 0.960908 |

| 6 | 0.901426 | 0.770955 | 0.960918 |

| 7 | 0.901429 | 0.770895 | 0.960921 |

| 8 | 0.901429 | 0.770875 | 0.960922 |

| 9 | 0.901429 | 0.770869 | 0.960923 |

| 10 | 0.90143 | 0.770867 | 0.960923 |

| Time | Case I | Case II |

|---|---|---|

| 0 | 1 | 1 |

| 1 | 0.770609 | 0.947872 |

| 2 | 0.576193 | 0.897254 |

| 3 | 0.422199 | 0.848292 |

| 4 | 0.305042 | 0.801091 |

| 5 | 0.218207 | 0.755726 |

| 6 | 0.154981 | 0.71224 |

| 7 | 0.109517 | 0.670657 |

| 8 | 0.0771142 | 0.630978 |

| 9 | 0.0541674 | 0.59319 |

| 10 | 0.0379904 | 0.557266 |

| Failure Rates | MTTF () | MTTF () | MTTF () | MTTF () | MTTF () | MTTF () |

|---|---|---|---|---|---|---|

| 0.01 | 3.62236 | 3.34019 | 3.87752 | 4.27994 | 4.16968 | 5.93178 |

| 0.02 | 3.50655 | 3.33961 | 3.74576 | 4.23984 | 4.01849 | 5.63712 |

| 0.03 | 3.39767 | 3.33086 | 3.62236 | 4.17902 | 3.87752 | 5.36959 |

| 0.04 | 3.29511 | 3.31559 | 3.50655 | 4.10749 | 3.74576 | 5.1256 |

| 0.05 | 3.19836 | 3.29511 | 3.39767 | 4.03123 | 3.62236 | 4.90216 |

| 0.06 | 3.10693 | 3.2705 | 3.29511 | 3.95385 | 3.50655 | 4.6968 |

| 0.07 | 3.0204 | 3.24263 | 3.19836 | 3.87752 | 3.39767 | 4.50741 |

| 0.08 | 2.93841 | 3.2122 | 3.10693 | 3.80348 | 3.29511 | 4.33221 |

| 0.09 | 2.8606 | 3.1798 | 3.0204 | 3.73245 | 3.19836 | 4.16968 |

| Failure Rates | ||||||

|---|---|---|---|---|---|---|

| 0.01 | −11.9484 | 0.414756 | −13.6212 | −1.45843 | −15.6658 | −16.8632 |

| 0.02 | −11.224 | −0.496713 | −12.7443 | −3.10996 | −14.5905 | −15.6658 |

| 0.03 | −10.5627 | −1.22542 | −11.9484 | −4.0822 | −13.6212 | −14.5905 |

| 0.04 | −9.95734 | −1.8072 | −11.224 | −4.6198 | −12.7443 | −13.6212 |

| 0.05 | −9.40188 | −2.27033 | −10.5627 | −4.87727 | −11.9484 | −12.7443 |

| 0.06 | −8.89097 | −2.63722 | −9.95734 | −4.95397 | −11.224 | −11.9484 |

| 0.07 | −8.41999 | −2.92577 | −9.40188 | −4.91468 | −10.5627 | −11.224 |

| 0.08 | −7.98492 | −3.15037 | −8.89097 | −4.80215 | −9.95734 | −10.5627 |

| 0.09 | −7.58221 | −3.32262 | −8.41999 | −4.64478 | −9.40188 | −9.95734 |

| Time | |||||

|---|---|---|---|---|---|

| 0 | 0 | 0 | 0 | 0 | 0 |

| 1 | 0.424006 | 0.524006 | 0.624006 | 0.724006 | 0.824006 |

| 2 | 0.82331 | 1.02331 | 1.22331 | 1.42331 | 1.62331 |

| 3 | 1.22398 | 1.52398 | 1.82398 | 2.12398 | 2.42398 |

| 4 | 1.62524 | 2.02524 | 2.42524 | 2.82524 | 3.22524 |

| 5 | 2.02663 | 2.52663 | 3.02663 | 3.52663 | 4.02663 |

| 6 | 2.42805 | 3.02805 | 3.62805 | 4.22805 | 4.82805 |

| 7 | 2.82948 | 3.52948 | 4.22948 | 4.92948 | 5.62948 |

| 8 | 3.23091 | 4.03091 | 4.83091 | 5.63091 | 6.43091 |

| 9 | 3.63233 | 4.53233 | 5.43233 | 6.33233 | 7.23233 |

| 10 | 4.03376 | 5.03376 | 6.03376 | 7.03376 | 8.03376 |

| Time | |||||

|---|---|---|---|---|---|

| 0 | 0 | 0 | 0 | 0 | 0 |

| 1 | 0.386284 | 0.486284 | 0.586284 | 0.686284 | 0.786284 |

| 2 | 0.682954 | 0.882954 | 1.08295 | 1.28295 | 1.48295 |

| 3 | 0.960347 | 1.26035 | 1.56035 | 1.86035 | 2.16035 |

| 4 | 1.23303 | 1.63303 | 2.03303 | 2.43303 | 2.83303 |

| 5 | 1.50444 | 2.00444 | 2.50444 | 3.00444 | 3.50444 |

| 6 | 1.77548 | 2.37548 | 2.97548 | 3.57548 | 4.17548 |

| 7 | 2.04639 | 2.74639 | 3.44639 | 4.14639 | 4.84639 |

| 8 | 2.31728 | 3.11728 | 3.91728 | 4.71728 | 5.51728 |

| 9 | 2.58815 | 3.48815 | 4.38815 | 5.28815 | 6.18815 |

| 10 | 2.85902 | 3.85902 | 4.85902 | 5.85902 | 6.85902 |

| Time | Origin () | General () | () |

|---|---|---|---|

| 0 | 0 | 0 | 0 |

| 1 | 0.424006 | 0.386284 | 0.472112 |

| 2 | 0.82331 | 0.682954 | 0.932731 |

| 3 | 1.22398 | 0.960347 | 1.39336 |

| 4 | 1.62524 | 1.23303 | 1.85418 |

| 5 | 2.02663 | 1.50444 | 2.31508 |

| 6 | 2.42805 | 1.77548 | 2.77599 |

| 7 | 2.82948 | 2.04639 | 3.23691 |

| 8 | 3.23091 | 2.31728 | 3.69783 |

| 9 | 3.63233 | 2.58815 | 4.15875 |

| 10 | 4.03376 | 2.85902 | 4.61968 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elshoubary, E.E.; Radwan, T.; Attwa, R.A.E.-W. Reliability and Performance Optimization of Multi-Subsystem Systems Using Copula-Based Repair. Axioms 2025, 14, 163. https://doi.org/10.3390/axioms14030163

Elshoubary EE, Radwan T, Attwa RAE-W. Reliability and Performance Optimization of Multi-Subsystem Systems Using Copula-Based Repair. Axioms. 2025; 14(3):163. https://doi.org/10.3390/axioms14030163

Chicago/Turabian StyleElshoubary, Elsayed E., Taha Radwan, and Rasha Abd El-Wahab Attwa. 2025. "Reliability and Performance Optimization of Multi-Subsystem Systems Using Copula-Based Repair" Axioms 14, no. 3: 163. https://doi.org/10.3390/axioms14030163

APA StyleElshoubary, E. E., Radwan, T., & Attwa, R. A. E.-W. (2025). Reliability and Performance Optimization of Multi-Subsystem Systems Using Copula-Based Repair. Axioms, 14(3), 163. https://doi.org/10.3390/axioms14030163