1. Introduction

Statistical process monitoring (SPM) serves as the technical foundation for ensuring the stability of manufacturing processes and the quality of product outputs [

1]. Process monitoring schemes are the most essential tools for monitoring the parameter of the discrete distributions within production processes. Since the seminal introduction of schemes by Shewhart, these tools have become fundamental in SPM, with widespread application across various industrial sectors [

2]. These schemes are indispensable in the production line, particularly relevant to equipment maintenance, production decision-making, and pharmaceutical management [

3]. Traditional monitoring schemes, such as the Shewhart scheme, are adept at identifying large process shifts, while cumulative sum (CUSUM) and exponentially weighted moving average (EWMA) schemes are effective for detecting small-to-moderate shifts.

Despite the proven effectiveness of traditional SPM schemes in various scenarios, these schemes are based on the presumption of a normal distribution that is not universally present in real-world settings, presenting a limitation [

4]. In recent years, this acknowledgment has stimulated the advancement of non-parametric and distribution-specific SPM methodologies, designed to more closely align with the distributional attributes of actual data [

5]. The geometric distribution is a vital discrete probability distribution that has wide applications in practice [

6]. Quesenberry [

7] used Q statistics to detect shifts in the parameter of geometric distribution. Yang et al. [

8] investigated the sample size effect when the process parameter needs to be estimated for geometric distribution. Chan et al. [

9] proposed the cumulative probability scheme when processes with low defect rates can not be satisfactorily monitored using the traditional p-scheme, np-scheme, c-scheme, or u-scheme. Zhang et al. [

10] addressed several theoretic issues related to the design of geometric schemes. Based on geometric distribution, Hong and Lee [

11] investigated the performance of Bayes estimator and maximum likelihood estimation for the geometric scheme, and Kim and Lee [

12] used the Bayes estimator to design a geometric scheme with bootstrap-based control limits. Moreover, Mohammadian et al. [

13] utilized risk-adjusted schemes to monitor health-care systems. Researchers are conducting further exploration into monitoring the parameter of geometric distribution (see Quesenberry [

14], Schwertman [

15], Majeed et al. [

16], KazemiNia [

17], Shahzad et al. [

18], Park et al. [

19]).

Amid the growing complexity of production processes, the pursuit of monitoring scheme enhancements and innovations has caught the research community’s attention [

20]. Notably, Zou and Tsung [

21] proposed a distribution-agnostic EWMA scheme based on the weighted likelihood ratio, which stands out due to its exceptional ability to monitor shifts across location, scale, and shape parameters. Moreover, Aslam et al. [

22] introduced a hybrid EWMA-CUSUM scheme for Weibull distribution traits, demonstrating heightened sensitivity to small process shifts. The application scope of EWMA schemes has also been broadened in recent years to include non-parametric and multivariate process monitoring. For instance, Riaz et al. introduced a sensitive non-parametric EWMA scheme in 2015 and a non-parametric double EWMA scheme in 2016 for an improved monitoring of process location [

23,

24]. Xue et al. [

25] designed a non-parametric adaptive EWMA scheme for monitoring multivariate time-between-events-and-amplitude data.

In parallel, recent academic research has generated numerous schemes based on the weighted likelihood ratio test (WLRT), aimed at improving the detection of small-to-moderate process shifts. Zhou et al. [

26] unveiled a WLRT-based EWMA scheme for overseeing Poisson processes. Qi et al. [

27,

28] used the WLRT scheme to monitor generalized linear profiles and queuing systems. Zhang et al. [

29] proposed a WLRT scheme for monitoring censored lifetime data, and Yu et al. [

30] presented an enhanced weighted Poisson CUSUM scheme based on the WLRT to monitor an overdispersed counting process. Yao et al. [

31] used the WLRT scheme for monitoring polynomial profiles. Moreover, Song et al. [

32] further extended the WLRT framework to design a scheme for simultaneous mean and variance monitoring in normal distribution processes. This situation makes it possible to study EWMA schemes supported by WLRT for detecting changes in the geometric distribution parameter. WLRT-based schemes, distinguished by their simplicity and minimal parameter requirements beyond smoothing factors and control limits, are straightforward to design and implement. The WLRT methodology, known for its robustness in identifying a range of parameter shifts, excels in detecting upward shifts and is apt for scenarios involving single observation.

In the contemporary environment, market competition is becoming increasingly fierce, and customer demands are also rising. High-quality production is becoming more and more essential. Although companies have taken various measures to strengthen product quality management and improve production processes, which have significantly reduced the nonconforming rate of products and ensured their quality, the generation of nonconforming products is inevitable due to various reasons in actual production. Therefore, in the process of achieving a small nonconforming rate, how to apply more efficient and accurate process monitoring schemes to achieve real-time monitoring of product quality, reduce the nonconforming rate, ensure production stability, and maximize enterprise production profits has become an urgent issue for companies and researchers. Therefore, maximizing the control of the small nonconforming rate is of great significance.

However, to the best of our knowledge, there is no studies on refined EWMA schemes employing the WLRT (EWLRT) to monitor the small nonconforming rate in geometric distributions, and this paper will fill this gap. The rest of this paper is structured as follows:

Section 2 illustrates an overview of some existing schemes.

Section 3 delves into the characteristics of the EWLRT scheme, computing the corresponding values of average run length

for different parameter situations with the Monte Carlo simulation. Additionally,

Section 3 also provides the optimal statistical design of the EWLRT scheme and the control limits under different parameter settings when the size of the shift is known. The performance comparison with other competing schemes is presented in

Section 4. An example is included in

Section 5 for validating the utility of the new EWLRT scheme.

Section 6 contains conclusions for this research.

2. An Overview of Some Existing Schemes

The number of the conforming items produced preceding the first nonconforming item is modeled to follow a geometric distribution with the parameter p, so p is the rate of the nonconforming item that remains constant across the production. In the in-control (IC) state, the parameter p is set to be a value of , which is precisely estimated during Phase I. Our focus lies in Phase II, where schemes are deployed to identify any factors that may degrade process quality, consequently leading to an increase in the parameter p within the range of .

Let the random variable

represent the count of conforming items preceding the first nonconforming item being produced, where

t is the

t-th sample, and each sample involves only one observation.

are independent of each other, and when the variables are not independent, some transformation techniques can be used to transform a geometrically distributed quality characteristic to independent normal statistics [

33]. However, in this paper, we focus on the process observations being independent. Furthermore, we denote the variable

, which follows a geometric distribution with nonconforming item rate of

, as

. The probability mass function (PMF) of

is expressed as follows:

Next, we will provide a concise overview of several existing process monitoring schemes for geometric distribution, which include three competing schemes, namely the EWMA, CUSUM, and GLR (generalized likelihood ratio) schemes. These three schemes will also be included in the performance comparisons discussed in

Section 4.

2.1. The EWMA Scheme

For the random variables

, the EWMA scheme employs the statistic

defined as follows:

where

is the process mean, and

is the smoothing parameter. For the geometric distribution, the scheme’s upper control limit (UCL), central line (CL), and lower control limit (LCL) are given as follows:

where

L is a constant determined by the pre-specified value of IC

(

). A deviation of

beyond the specified limits indicates a potential process shift, necessitating further examination.

2.2. The CUSUM Scheme

For swifter detecting of small-to-moderate shifts in p, the CUSUM scheme represents a preferable alternative. By adjusting the preset out-of-control (OOC) nonconforming item rate , where , the scheme can enhance its sensitivity to variations close to , and the efficiency of CUSUM in monitoring the parameter of geometric distribution highly depends on the parameter of . Suboptimal choices may result in inadequate detection capabilities for certain shifts. Thus, providing a rigorous framework for monitoring and acting upon incremental changes in process probabilities is necessary.

Under the assumption that when the process is IC up to the

-th sample, then a change in

p has occurred between samples

and

, shifting to some OOC value. We are left with

,

, …,

after the

t-th sample. Following the observation of

t samples, we aim to assess if

p has escalated from

within the interval between

and

samples. The increment accumulated in the CUSUM statistic at sample

i is given as follows:

Then, the statistic of the CUSUM scheme is as follows:

The CUSUM scheme signals when , where is a predetermined control limit chosen to achieve the desired IC performance.

2.3. The GLR Scheme

GLR schemes break away from the fixed-parameter characteristic of CUSUM or EWMA schemes. GLR schemes excel in pinpointing process shifts, and this ability to monitor adaptive fluctuations emphasizes the exceptional versatility and adaptability of these schemes, making them well-suited for the dynamic and unpredictable characteristics of production environments.

The formula for the one-sided geometric distribution GLR statistic, aimed at detecting an increase in

, is shown as follows:

The maximum likelihood estimation of

is given by the following:

Therefore, the statistic of the GLR scheme is reduced to the following:

Maximizing over

at each sampling point may be computationally complex when

t is very large, so an alternative is to maximize only for a window of the past

m samples [

34]. Let

be the GLR scheme statistic when maximization is taken over

if

and over

if

. The window size

m will be chosen to be large enough such that the performance of the GLR scheme with the window is essentially the same as that using no window. The GLR scheme for geometric distribution signals when

, where

is the predetermined control limit.

3. The EWLRT Scheme for Geometric Distribution

For the monitoring of the parameter for geometric distribution, schemes that utilize the likelihood ratio test have emerged as essential tools for monitoring the nonconforming item rate p. These schemes go beyond conventional likelihood ratio analysis, which traditionally depends on the current sample alone, by employing a weighted likelihood ratio method. This novel method enhances the monitoring effectiveness by assigning dynamic weights to the likelihood ratios of evolving samples, thereby leveraging the entirety of the sample data. The cumulative integration of historical data markedly bolsters the detection of shifts in the process parameter.

This paper unveils an extended EWMA scheme based on WLRT for detecting shifts in the geometric distribution parameter p. Through various performance evaluation metrics, this study appraised the effectiveness of this scheme in monitoring the parameter of geometric distribution. For simplicity, this new scheme is henceforth designated as the EWLRT scheme for geometric distribution.

3.1. Design of the EWLRT Scheme for Geometric Distribution

In order to maintain consistency with the notation previously defined, we still assume that each IC data

follows a geometric distribution with parameter

, where

is known a priori, and this model transitions to

when the process is OOC. The hypothesis test is formulated as follows:

The log-likelihood function for a singular observation

is given by the following:

Assigning varying weights to samples as time progresses, we assume the following:

with

, the smoothing parameter, lying within (0, 1]. Let

be the weights of EWMA, expressed as follows:

where

serves as an initial value. Given

, the weighted maximum likelihood estimation for

p is given by the following:

The computation of Equation (

13) unfolds as follows:

where

. From the derivative

and under the restriction

, it follows that

Therefore, the EWLRT scheme’s statistic is as follows:

with the recursion applied to

as follows:

initiating with

. The monitoring of the parameter

p utilizes the statistic

within the EWLRT scheme, integrating WLRT with EWMA for an optimized monitoring strategy.

Interestingly, with samples from a geometric distribution and as

,

, the following can be derived:

The proof of the asymptotic distribution (22) is given in the

Appendix A, and this result indicates that, for substantial

t, the asymptotic distribution’s quantiles can serve as control limits. Moreover, we assume that the control limit for the EWLRT scheme is

h, and an alarm signal will be generated when

.

3.2. Performance Metric

In this study, Monte Carlo simulation techniques were leveraged to perform an extensive series of simulations aimed at determining control limits and values. The methodology involved setting the number of experimental iterations to 10,000. The investigation primarily utilized the zero-state (ZS-ARL) as a crucial metric for assessing the performance of schemes.

The calculation of the ZS-ARL involves assuming that a persistent shift in the parameter occurs at the start of Phase-II monitoring. Moreover, in this paper, ZS-ARL in its IC and OOC states is represented as and , respectively. The metric is instrumental in evaluating the sensitivity of schemes to Type I error—instances where the scheme indicates an alarm despite the process operating in control. An elevated value is preferable, as it reduces the likelihood of false alarms attributed to IC process variation.

3.3. Control Limits

Table 1 presents the control limits of the EWLRT scheme for different combinations of

,

, and

. When considering fixed combinations of

values, the control limit

h demonstrates an approximate linear relationship with the logarithm of the

. Therefore, linear interpolation can be employed to determine the corresponding

h values for

values that are not listed in

Table 1. We illustrate the utilization of

Table 1 to determine

h for the EWLRT scheme through an example.

Suppose samples are taken every 8 h from a product manufacturing process (i.e., observing the number of conforming items before the first non-conforming item is produced), with the aim of having false alarms occur no more than once every 5 months on average. Assuming a month consists of 30 days, then 5 months correspond to

samples (i.e.,

). In this example,

and

are considered. Therefore, according to

Table 1, we observe that the corresponding values of

h are 0.1229 and 0.1347 for

= 400 and 500, respectively. The linear interpolation used to determine

h for achieving the desired

= 450 is as follows:

With h = 0.1291, the simulated actual is 451.95, which is a practical and accurate approximation.

3.4. The Implementation of the EWLRT Scheme

In

Table 2, it is apparent that EWLRT schemes with smaller

values are optimally suited for detecting smaller shifts in the process. Moreover, schemes with larger

values present enhanced sensitivity to larger shifts. The standard deviation of run length (SDRL) values associated with the schemes are considerably high, particularly for small shifts, sometimes nearing the schemes’

values. Moreover, in this paper,

in its IC and OOC states is denoted as

and

, respectively. For example, when

,

and

, the corresponding values of

and

for the EWLRT scheme, are 147.29 and 144.10, respectively. Nonetheless, with the increase in shift magnitude, the decrease in SDRL values occurs at a rate significantly more pronounced than that of

values.

3.5. ARL Optimization for the EWLRT Scheme

In scenarios involving process parameter shift, the impact of varying smoothing parameters on the performance of the EWLRT scheme is significant. Generally, a smaller indicates improved detection capability. It is possible to determine the optimal smoothing parameter that minimizes the in a specific parameter shift scenario. This process involves matching appropriate control limits h for each , forming parameter pairs, with a desired while the process is being monitored in IC state . In situations where the shift size of the parameter p is known, a pair of and h can be found such that is minimized, which constitutes the optimal selection. The EWLRT scheme we adopt is based on this logic to determine the best combination of and h for any given parameter shifts.

For a predetermined

value, a range of the variable

from 0.01 to 1, increasing by 0.01 each time, we search for the

that significantly reduces

under a given shift

. Once these parameters and shift magnitude are fixed,

values can be derived through simulation calculations. Therefore, the ideal pairing of

i.e.,

, can be found through the following expression:

subject to the condition

Table 3 shows the optimal selection results. When the process is IC, with

, and the

, we select

. When the shift

is determined, the optimal combinations of

are identified where

is minimized. For example, when

and

, the optimal combinations of

, i.e.,

, and the value of

are 68.99.

4. Performance Comparisons with Competing Schemes

Exploring scenarios with nonconforming item rate and , we aim for approximately equal to 350. Shifted nonconforming item rates are selected across a broad range——for the smaller and extending up to for the larger . This Section evaluates the performance of various schemes by analyzing their values.

4.1. The Comparison of the EWLRT and EWMA Schemes

According to

Table 4, the EWLRT and EWMA schemes show comparable performance across most evaluated scenarios. Notably, the EWLRT schemes demonstrate a marginal advantage under certain conditions, particularly when dealing with larger

values and smaller shifts in the parameter. For example, when

,

, and

, the values of

corresponding to the EWLRT scheme and the EWMA scheme are 154.13 and 161.29, respectively.

Furthermore, the methodology for setting control limits distinguishes the two scheme types. EWLRT schemes utilize weighted likelihood ratio statistics to determine control limits, typically yielding smaller limit values. This characteristic of EWLRT schemes contributes to their stable performance amid small changes in . Conversely, EWMA schemes base control limits on expected values, which can result in larger limit values and more pronounced performance fluctuations due to small changes in , a trait less suited for practical manufacturing processes.

In practical production environments, the exact value of

is often unknown ahead of time; instead, we depend on an estimation of

. Consequently, the effectiveness of the schemes should not be significantly affected by small adjustments in

. This subsection is dedicated to assessing the robustness of schemes by implementing a small shift to

and then comparing the performance (measured in

) with the original

. In this paper, the original

is the estimation of IC

p from Phase I. A scheme is deemed robust if such alterations do not significantly impact its performance. Given the already-investigated

, with similar performance of the EWLRT and EWMA schemes in many cases, this analysis will focus on comparing the robustness between the EWLRT and EWMA schemes. The superior robustness of EWLRT schemes in comparison to EWMA schemes is shown in

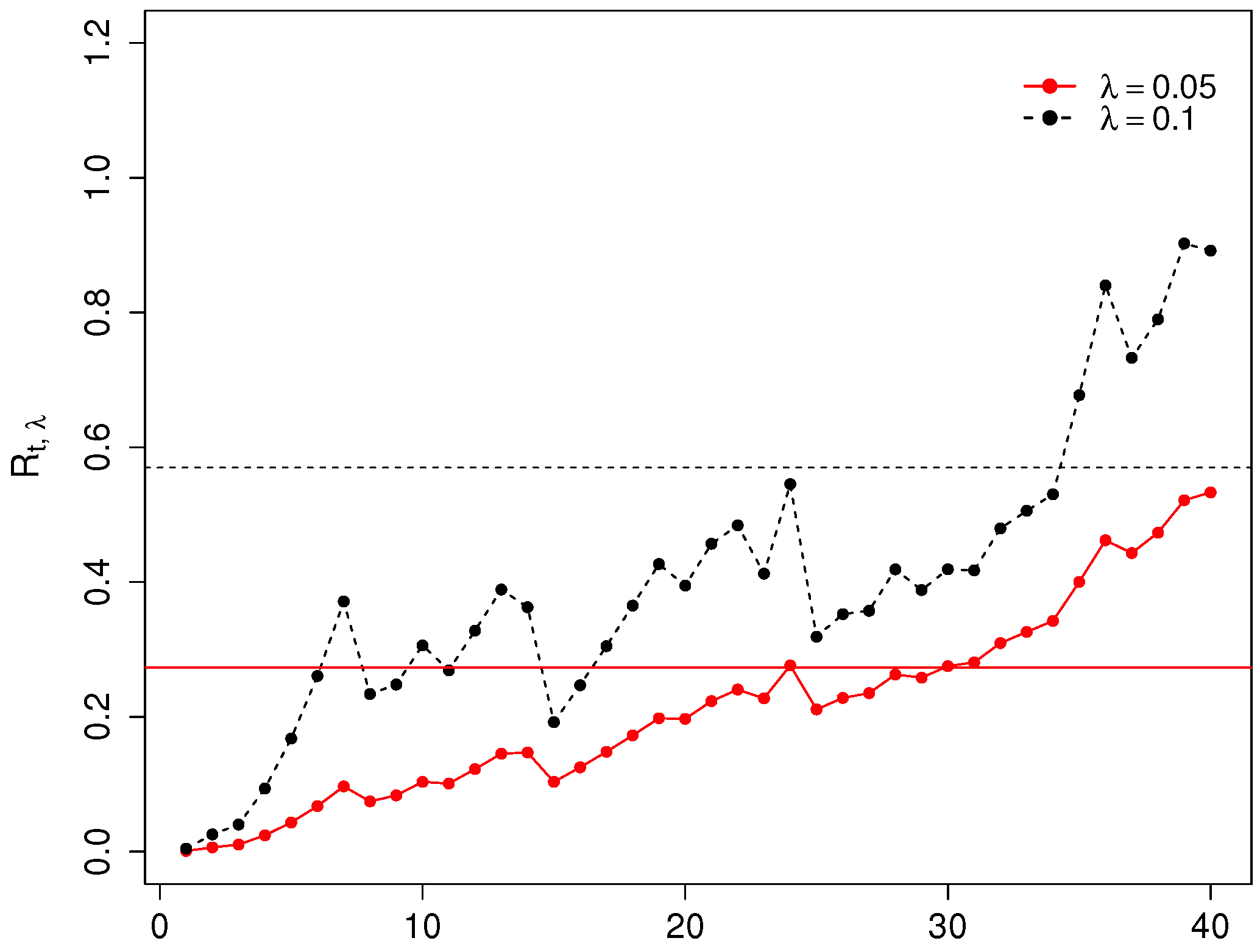

Table 5.

Table 5 illustrates that for the original nonconforming item rate of

, slight variations with the actual

barely affect the

values of the EWLRT scheme, distinguishing it significantly from the EWMA scheme where

values are markedly influenced. For example, when the original

is 0.01, the

values for the EWLRT and EWMA schemes are both approximately 350, but when the actual

is 0.008, the corresponding

values for the EWLRT and EWMA schemes are 361.35 and 6531.7. For a larger original

, although small variations with the actual

also impact the

values of the EWLRT scheme, the degree of this impact is significantly less than that observed in the EWMA scheme.

These findings highlight the robustness of the EWLRT scheme, confirming its superiority over the EWMA scheme, particularly for geometric distributions characterized by smaller values. This analysis points out the EWLRT scheme as a more robust option and better suited for scenarios where is estimated rather than precisely known.

4.2. The Comparison of the EWLRT and CUSUM Schemes

Considering the different parameters of the EWLRT and CUSUM schemes, this subsection outlines the comparison of the optimal detection performance of the two schemes for specific shifts. The comparative result presented in

Table 6 highlights the distinct advantages of EWLRT schemes over CUSUM schemes when monitoring small shifts, but for large shifts, both schemes have a similar monitoring performance. For example, when

, the optimal parameters for the EWLRT scheme and the CUSUM scheme are 0.01 and 0.012, respectively, with corresponding

values of 68.99 and 83.97. When

, the optimal parameters for the EWLRT scheme and the CUSUM scheme are 0.34 and 0.04, respectively, with corresponding

values of 7.24 and 7.33.

4.3. The Comparison of the EWLRT and GLR Schemes

In this subsection, we outline the comparison of the performance of the EWLRT and GLR schemes for monitoring the geometric distribution parameter. When , through simulation studies, it was found that the monitoring performance of the GLR scheme is similar when the window sizes and are chosen. Therefore, it is reasonable to select a window size of when exploring the monitoring capability of the GLR scheme.

The comparison result, as detailed in

Table 7, suggests that both the EWLRT and GLR schemes possess specific benefits. EWLRT schemes are particularly sensitive to small process shifts, whereas GLR schemes excel in detecting large shifts. For example, when

,

, and

, the values of

corresponding to the EWLRT scheme and the GLR scheme are 78.83 and 131.74, respectively; meanwhile, when

, the values of

corresponding to the EWLRT scheme and the GLR scheme are 10.41 and 7.31, respectively.

The selection between EWLRT and GLR schemes should be customized based on the specific monitoring needs and process characteristics in the industry. A notable advantage of GLR schemes is their convenience in not necessitating a predefined parameter value, but they require a large amount of computation.