Study on Flocculant Selection for Fine Iron Tailing Slurry Based on Multi-Process Data Monitoring

Abstract

1. Introduction

2. Materials and Methods

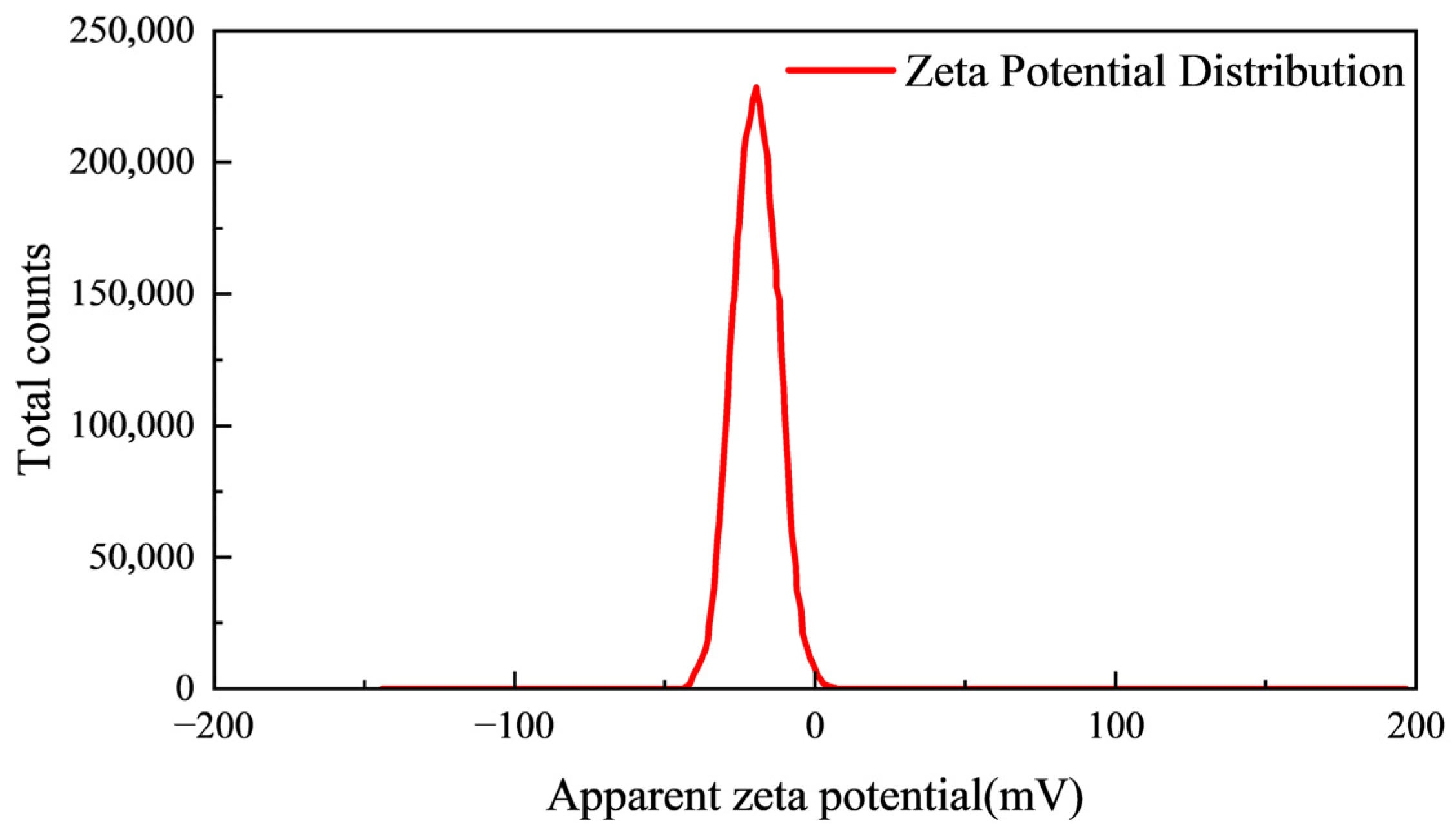

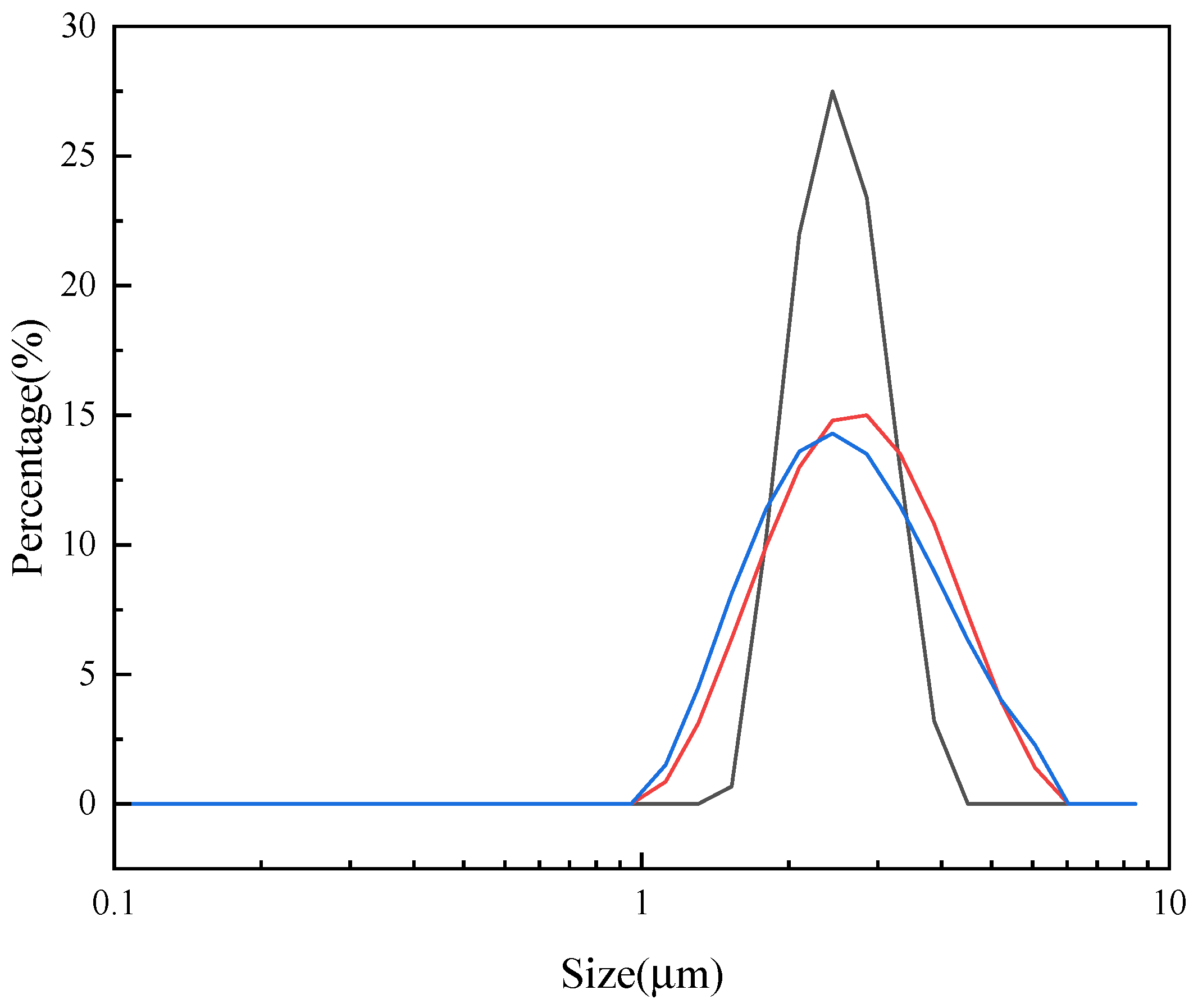

2.1. Materials

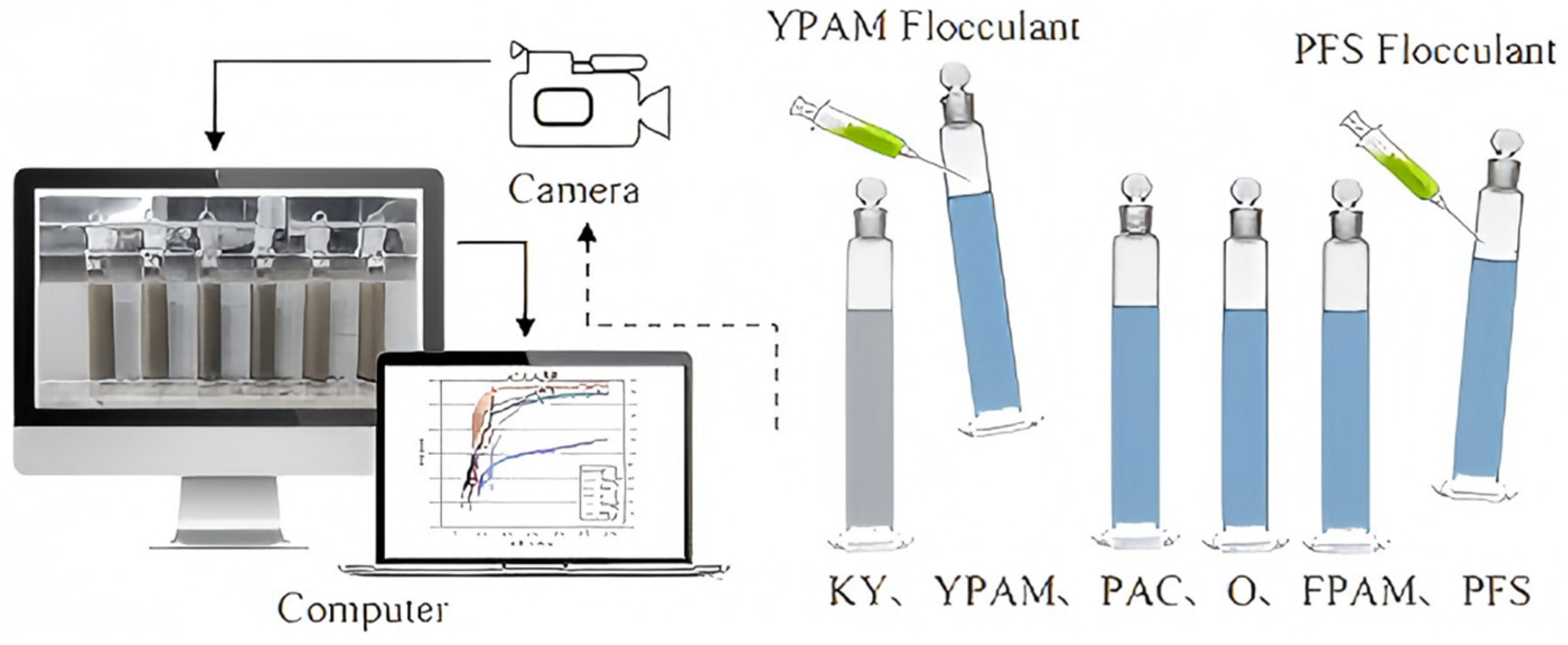

2.2. Experimental Methods

2.2.1. Tailing Flocculation and Settling Test

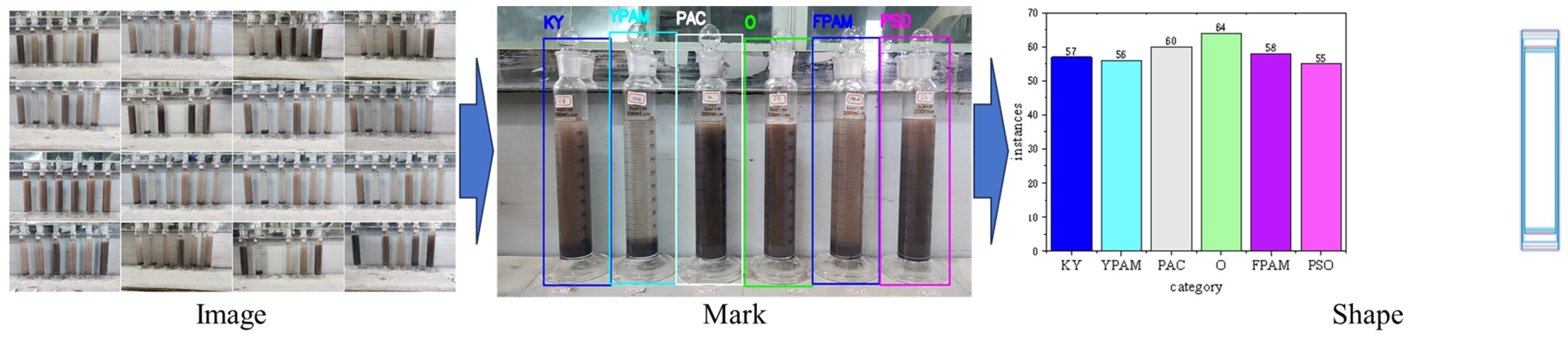

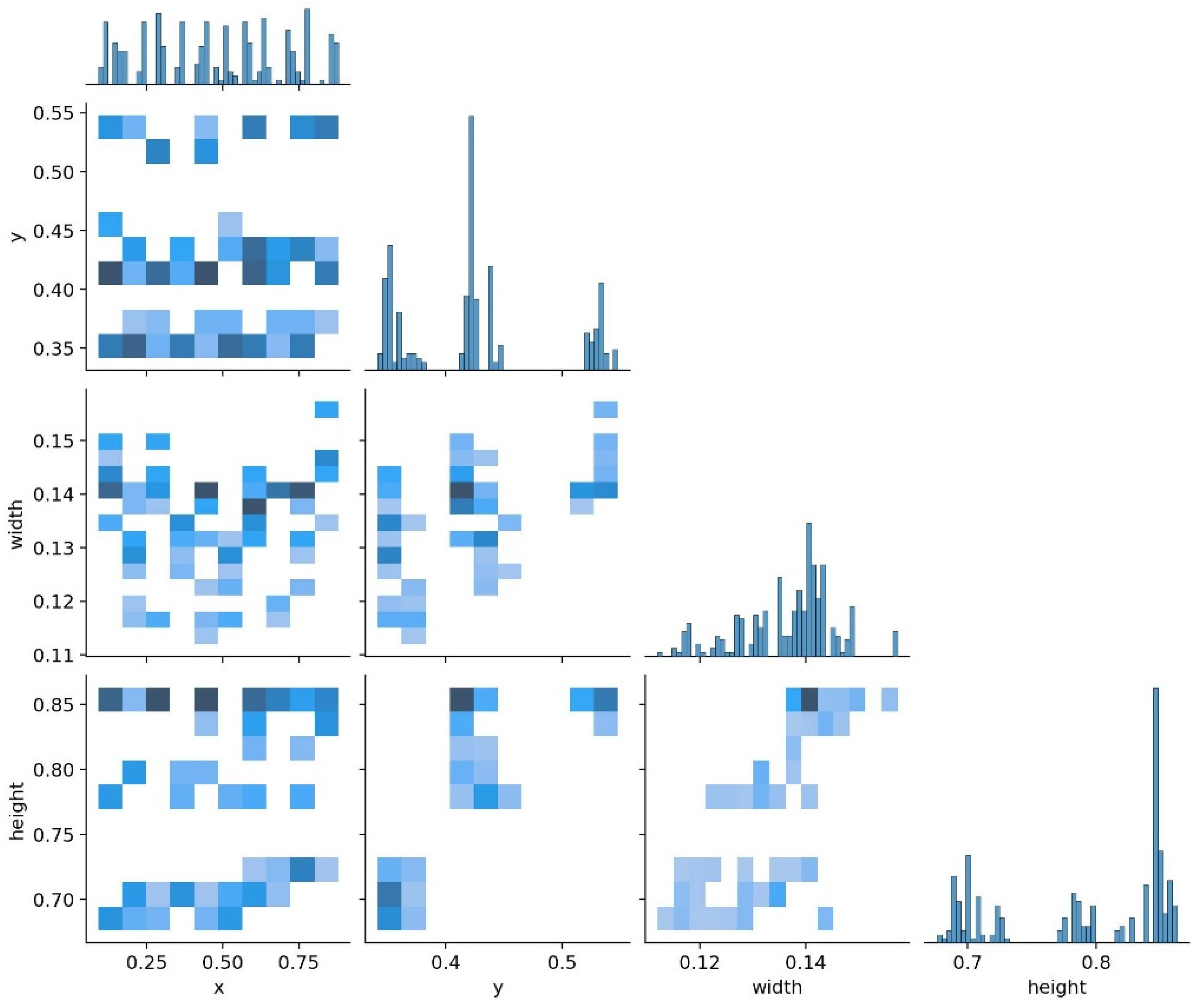

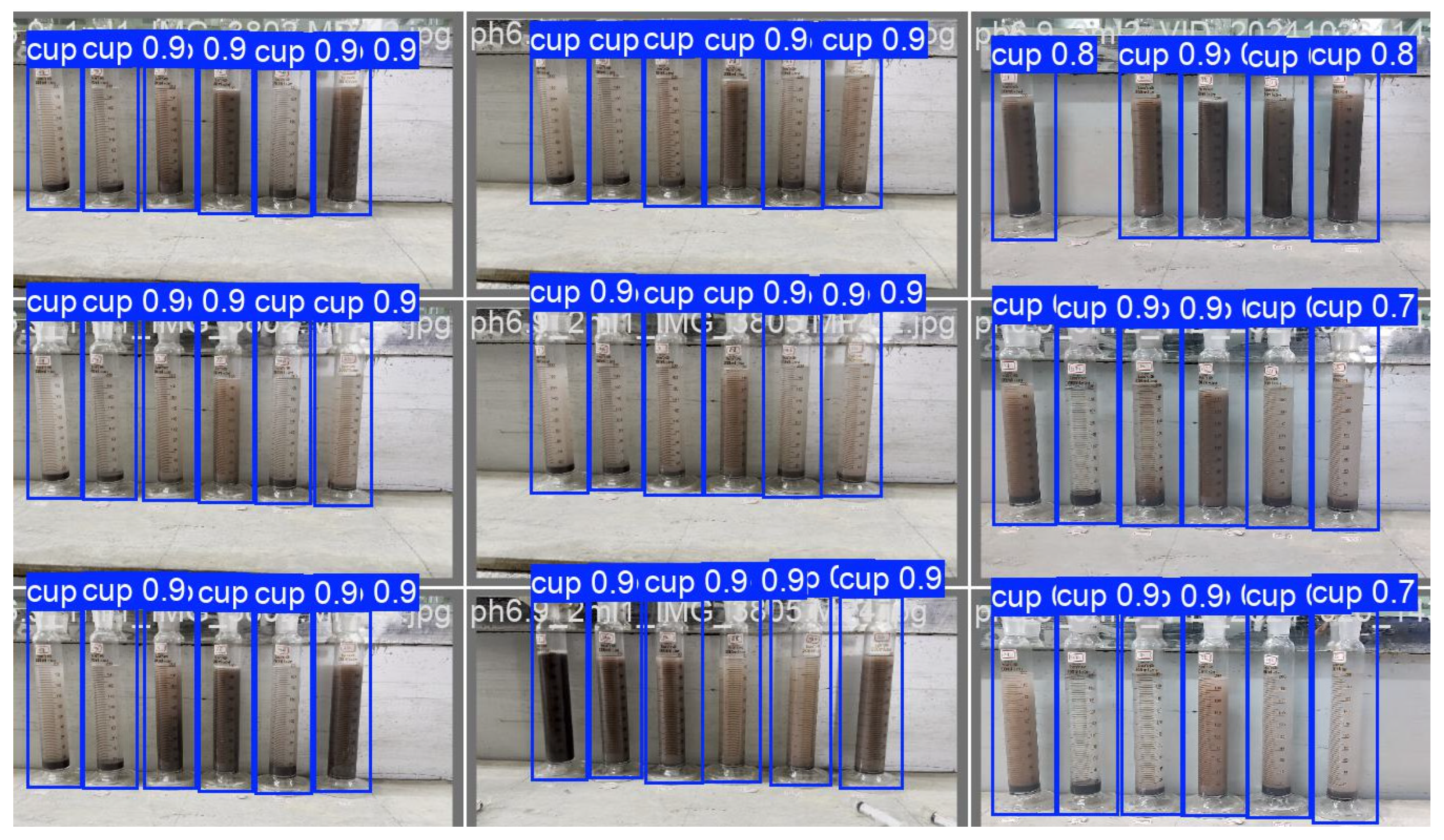

2.2.2. Data Fusion Extraction Model Based on Yolov8n

3. Results

3.1. Multi-Process Data Detection Construction

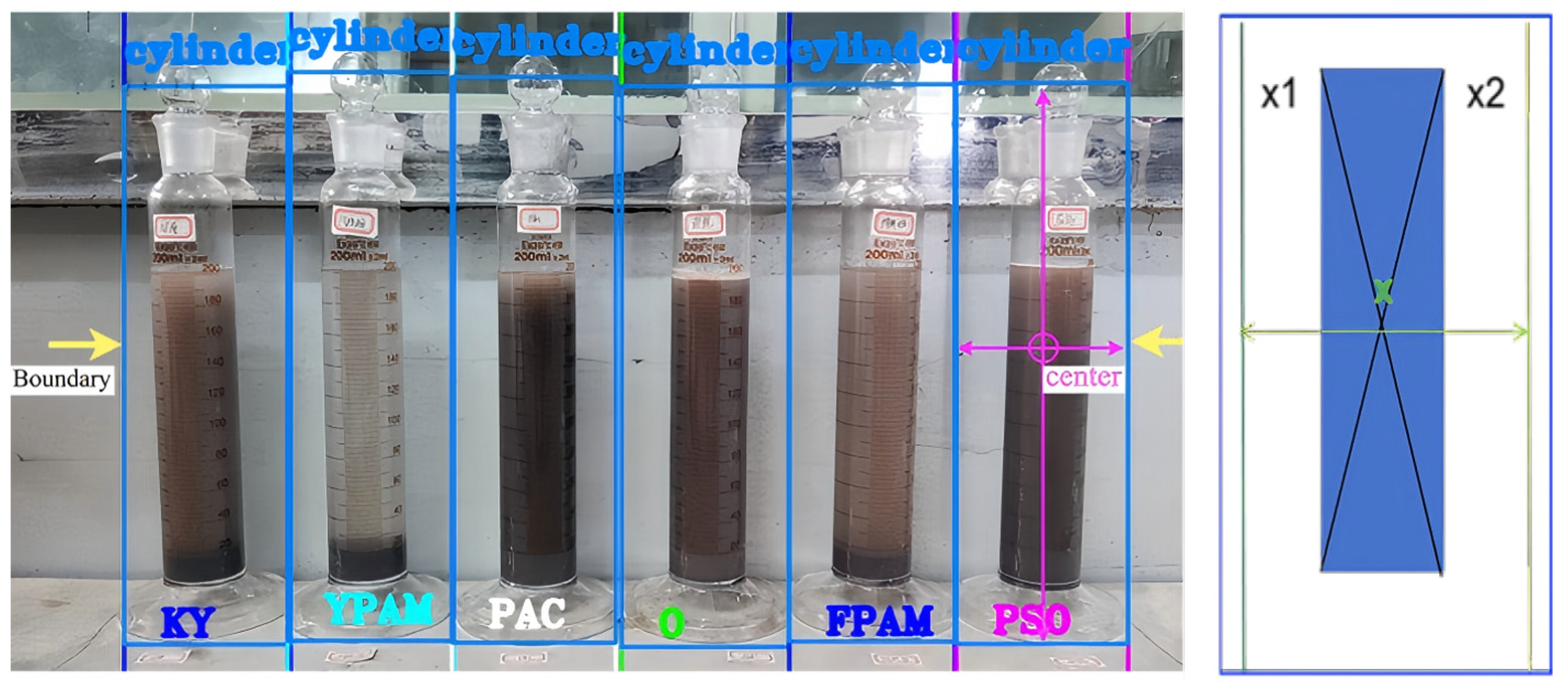

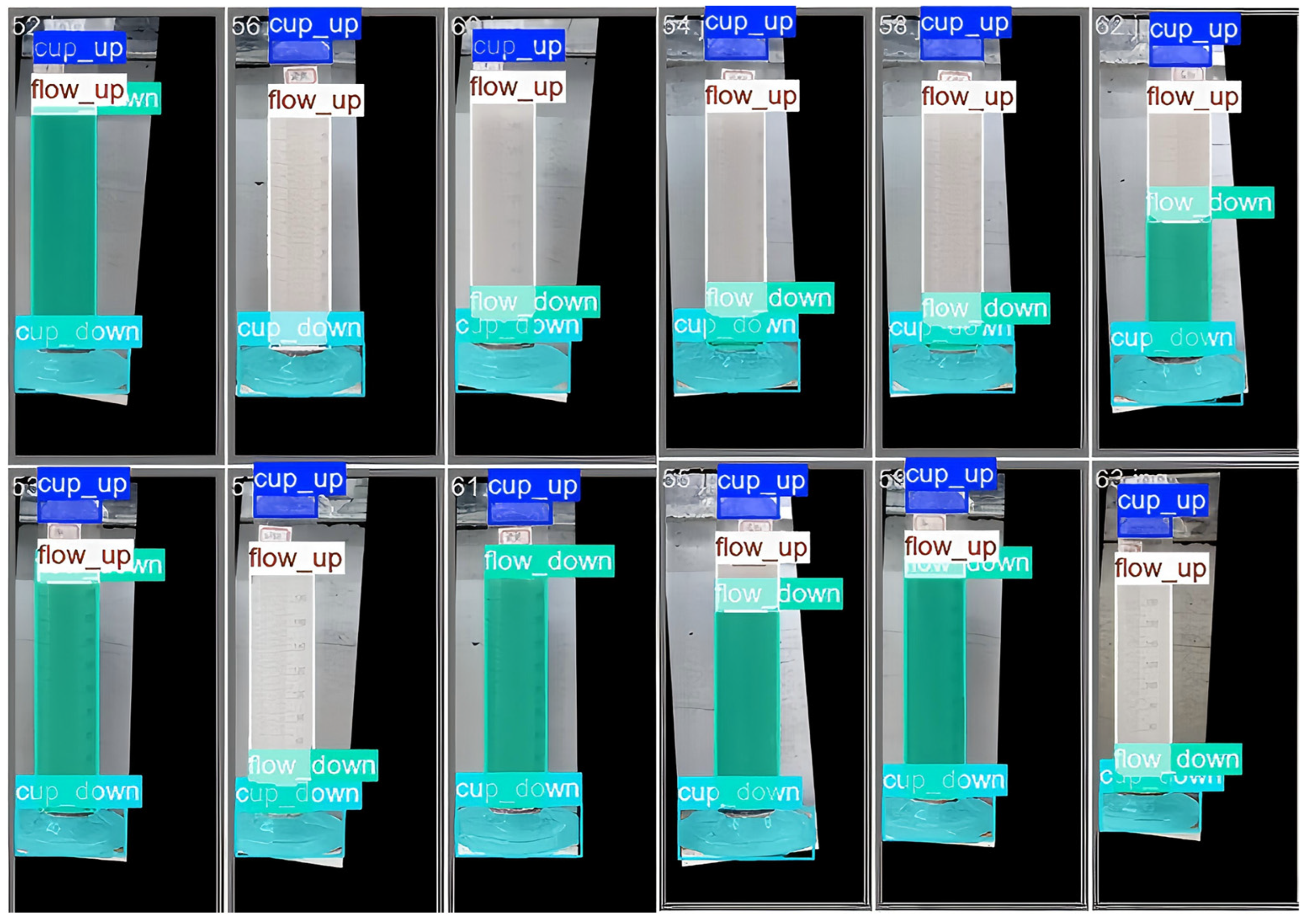

3.1.1. Graduated Cylinder Identification and Position Detection

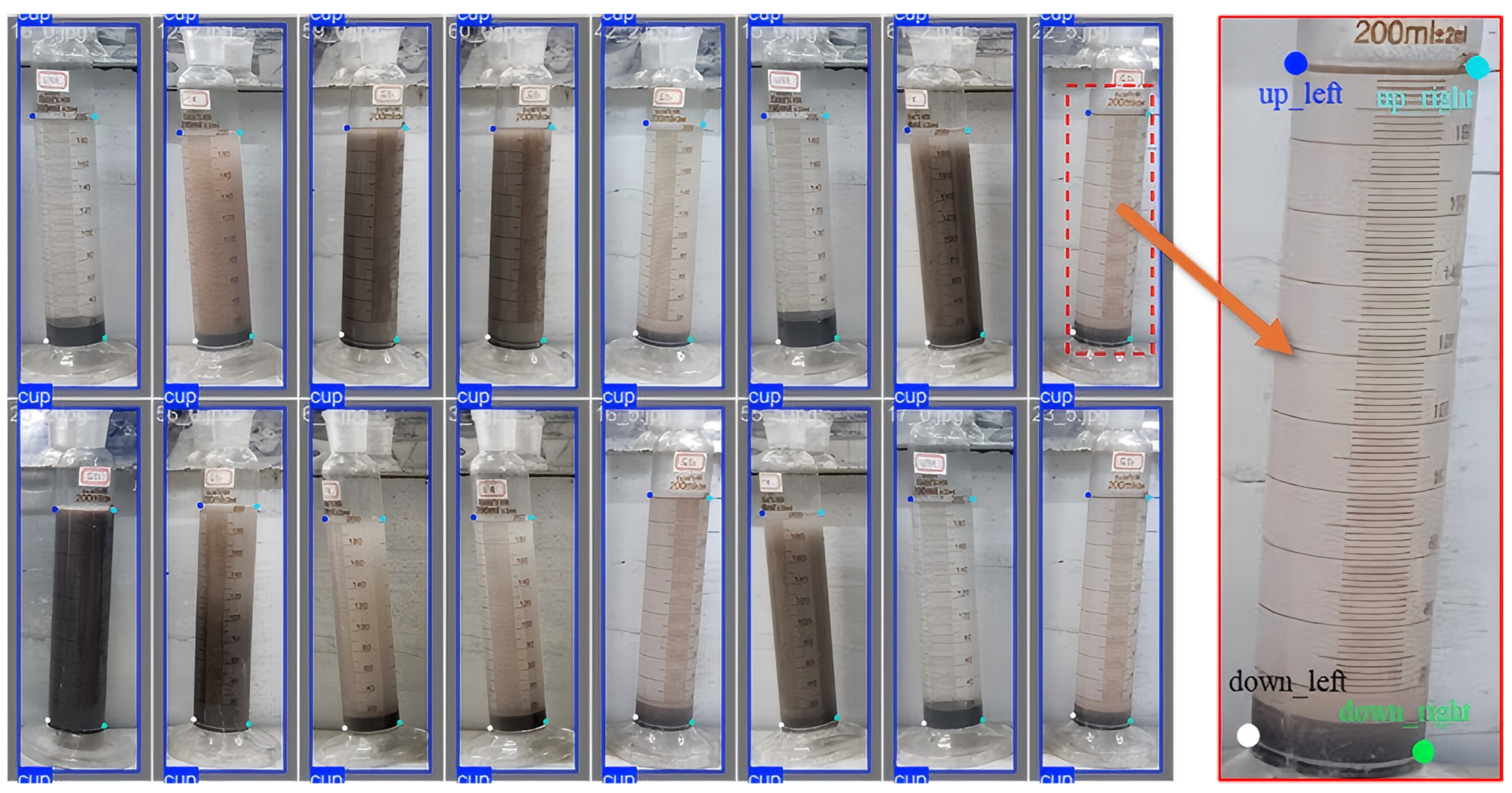

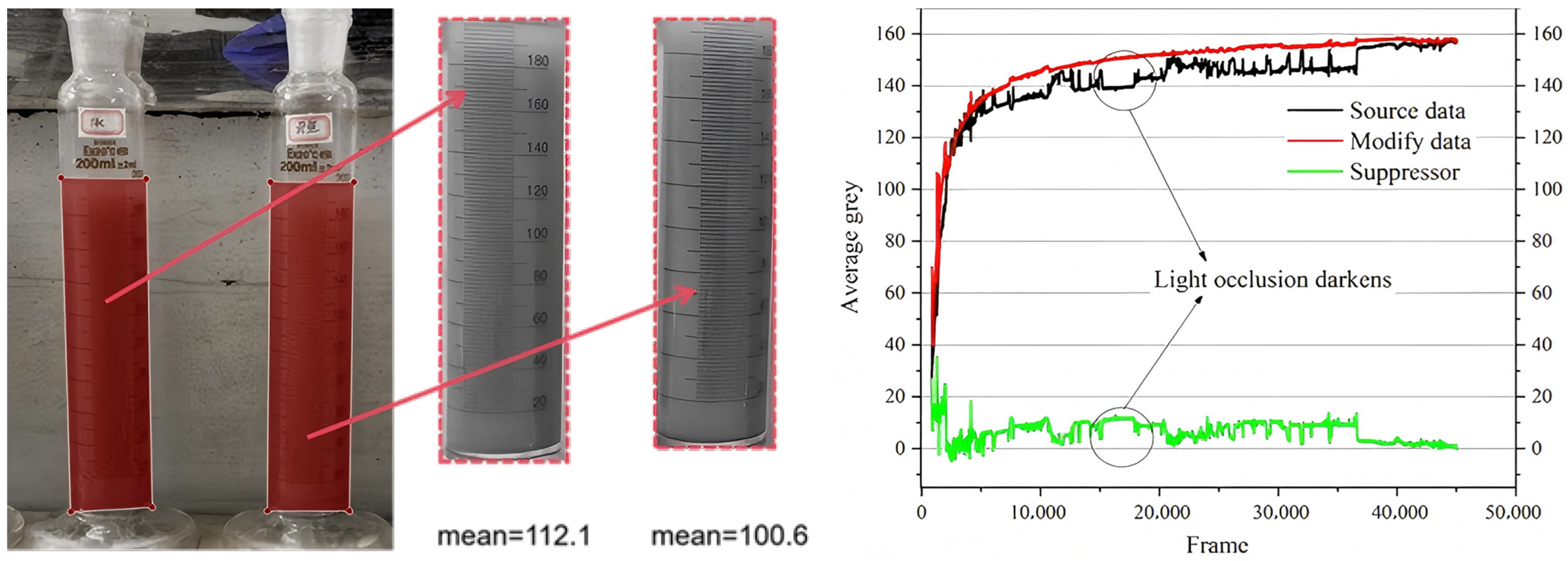

3.1.2. Liquid Level Key Point Detection and Graduated Cylinder Perspective Orthodontic Model

3.2. Analysis of Flocculation and Sedimentation

3.2.1. Experimental Phenomena

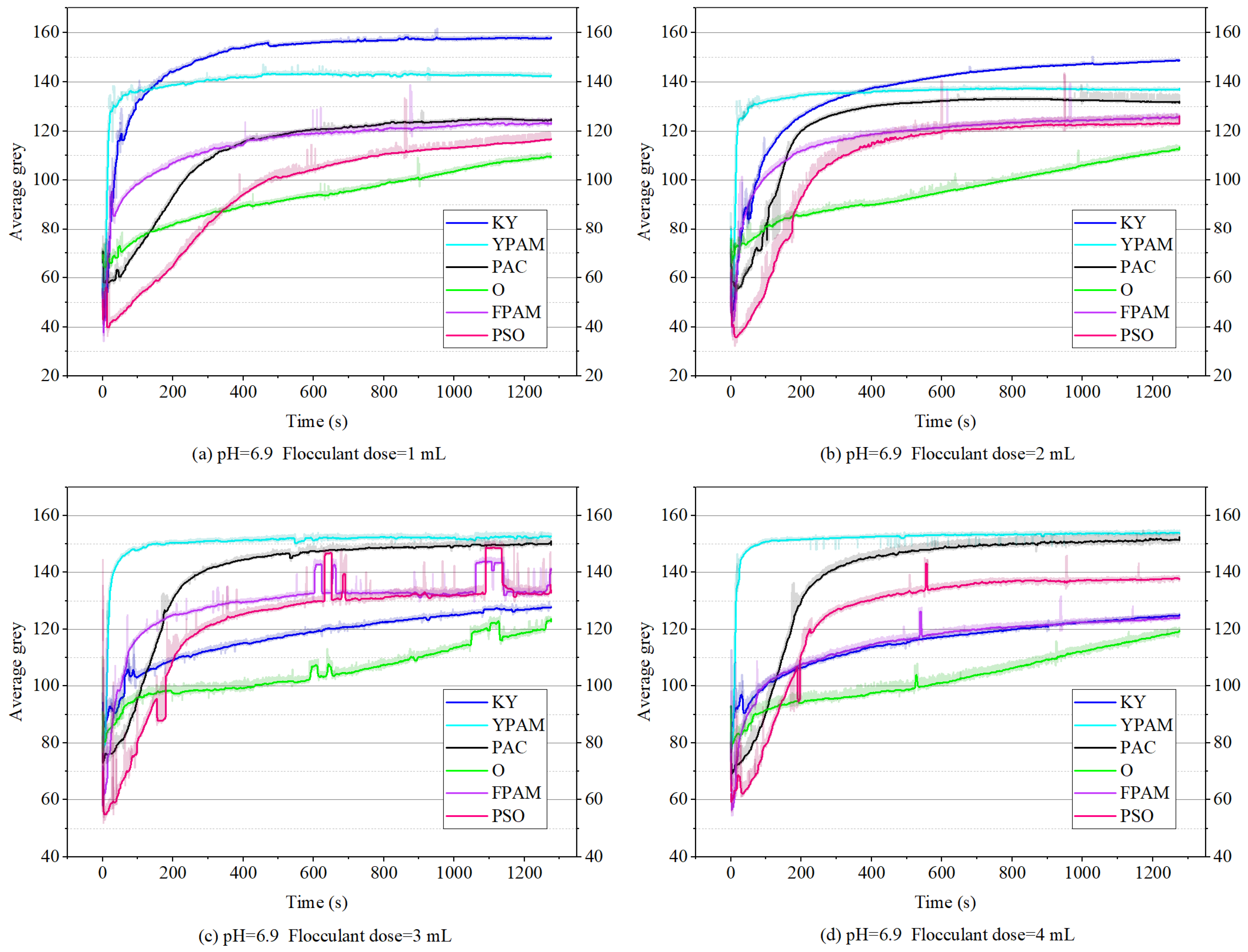

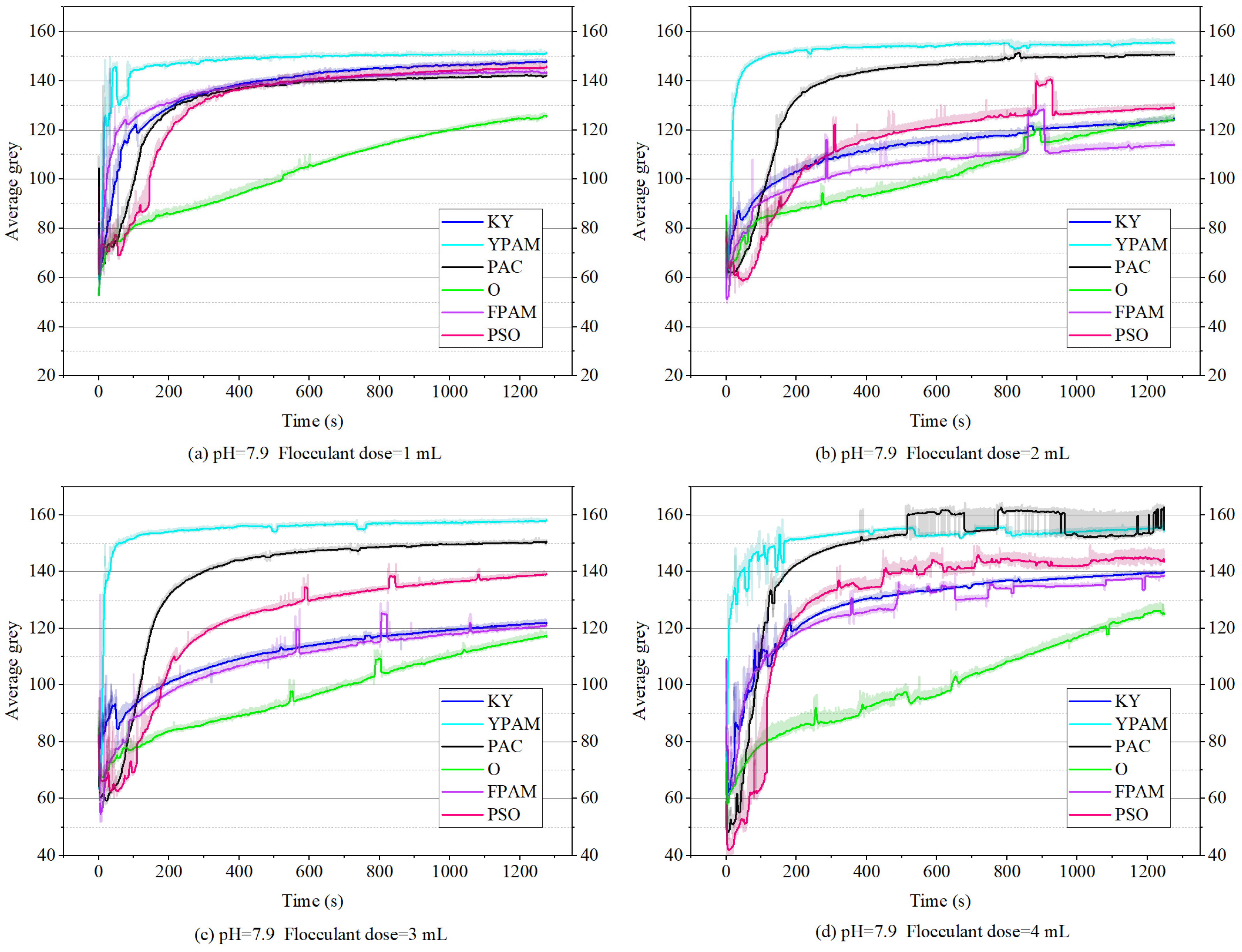

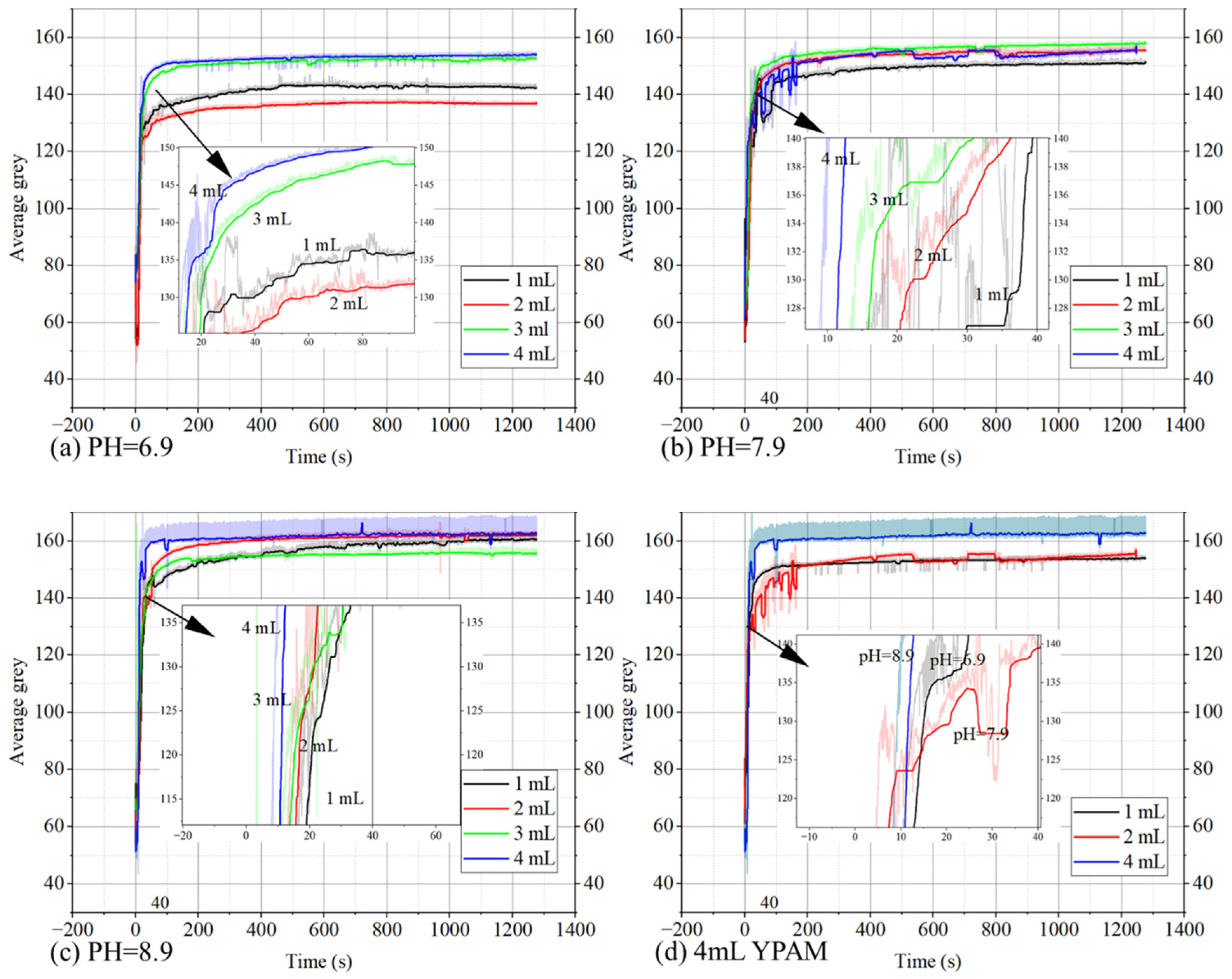

3.2.2. The Effect of Flocculants Under Different Dosages

3.2.3. The Effects of the Best Flocculant YPAM at Different pHs

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| FPAM | 90% nonionic polyacrylamide |

| YPAM | 90% cationic acrylamide |

| PAC | 26% polyaluminum chloride |

| KY | Mining flocculant |

References

- Wang, K.; Fu, J.; Wang, J.; Li, Y. Assessing the Hydration Behavior of Rice Husk and Shell Ashes as Supplementary Cementitious Materials during Initial Curing Stages. Constr. Build. Mater. 2025, 491, 142773. [Google Scholar] [CrossRef]

- He, Q.; Cao, S.; Yilmaz, E. Sustainable Stabilization of Sulfidic Mine Tailings Using Fly Ash and Sodium Bicarbonate: A Multiscale Analysis. Powder Technol. 2026, 467, 121573. [Google Scholar] [CrossRef]

- Adiguzel, D.; Tuylu, S.; Eker, H. Utilization of Tailings in Concrete Products: A Review. Constr. Build. Mater. 2022, 360, 129574. [Google Scholar] [CrossRef]

- Luo, T.; Yi, Y.; Liu, F.; Sun, Q.; Pan, X.; Hua, C. Early-Age Hydration and Strength Formation Mechanism of Composite Concrete Using Molybdenum Tailings. Case Stud. Constr. Mater. 2022, 16, e01101. [Google Scholar] [CrossRef]

- Fu, J.-X.; Wang, K.; Wang, J. Internal Pore Evolution and Early Hydration Characterization of Fly Ash Cement Backfill. J. Build. Eng. 2023, 72, 106716. [Google Scholar] [CrossRef]

- Jiao, H.; Chen, W.; Wu, A.; Yu, Y.; Ruan, Z.; Honaker, R.; Chen, X.; Yu, J. Flocculated Unclassified Tailings Settling Efficiency Improvement by Particle Collision Optimization in the Feedwell. Int. J. Miner. Metall. Mater. 2022, 29, 2126–2135. [Google Scholar] [CrossRef]

- Ishigami, T.; Karasudani, T.; Onitake, S.; Shirzadi, M.; Fukasawa, T.; Fukui, K.; Mino, Y. Effect of Liquid Volume Fraction and Shear Rate on Rheological Properties and Microstructure Formation in Ternary Particle/Oil/Water Dispersion Systems under Shear Flow: Two-Dimensional Direct Numerical Simulation. Soft Matter 2022, 18, 4338–4350. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, R.; Chen, M.; Li, J.; Wang, X.; Liu, Y.; Zhu, Z.; Wang, M.; Fan, F. Influence of the Flocculation Effect on the Rheological Properties of Cement Slurry. Powder Technol. 2022, 398, 117118. [Google Scholar] [CrossRef]

- Chen, Q.; Tao, Y.; Zhang, Q.; Qi, C. The Rheological, Mechanical and Heavy Metal Leaching Properties of Cemented Paste Backfill under the Influence of Anionic Polyacrylamide. Chemosphere 2022, 286, 131630. [Google Scholar] [CrossRef]

- Aldajani, M.; Alipoormazandarani, N.; Fatehi, P. Two-Step Modification Pathway for Inducing Lignin-Derived Dispersants and Flocculants. Waste Biomass Valoriz. 2022, 13, 1077–1088. [Google Scholar] [CrossRef]

- Lu, C.; Xu, Z.; Zhang, Y.; Dong, B. Rapid and Clean Dewatering of Dredged Sediment via Coupling of a Two-Step Flocculation and Geotextile Filtration. Chem. Eng. J. 2024, 480, 147604. [Google Scholar] [CrossRef]

- Dixon, D.V.; Soares, J.B.P. Flocculating Oil Sands Tailings with Dual Anionic/Cationic Polymers: Dose and Charge Density Effects. Can. J. Chem. Eng. 2024, 102, 88–101. [Google Scholar] [CrossRef]

- Xu, R.; Zou, W.; Wang, T.; Huang, J.; Zhang, Z.; Xu, C. Adsorption and Interaction Mechanisms of Chi-g-P(AM-DMDAAC) Assisted Settling of Kaolinite in a Two-Step Flocculation Process. Sci. Total Environ. 2022, 816, 151576. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Liu, X.; Zhang, L.; Guo, M. Two-Step Shear Flocculation for High-Efficiency Dewatering of Ultra-Fine Tailings. Minerals 2025, 15, 176. [Google Scholar] [CrossRef]

- Zeng, H.; Shi, C.; Huang, J.; Li, L.; Liu, G.; Zhong, H. Recent Experimental Advances on Hydrophobic Interactions at Solid/Water and Fluid/Water Interfaces. Biointerphases 2015, 11, 018903. [Google Scholar] [CrossRef]

- Ali, A.; Meena, B.V.; Shah, N.A.; Kaushik, T.; Dolkar, T.; Ghoroi, C.; Dutta, A. Deploying a Molecular Copper Catalyst for Efficient Degradation of Commercial and Industrial Dyes under Practical Conditions. Environ. Sci. Water Res. Technol. 2023, 9, 2219–2225. [Google Scholar] [CrossRef]

- Dixon, D.V.; Soares, J.B.P. Using Polymer Adsorption Data and a Population Balance Model to Estimate How Polymer Dosage Affects the Flocculation of Oil Sands Tailings. Can. J. Chem. Eng. 2023, 101, 6126–6134. [Google Scholar] [CrossRef]

- Gao, R.; Zhou, K.; Zhang, J.; Guo, H.; Ren, Q. Research on the Dynamic Characteristics in the Flocculation Process of Mineral Processing Tailings. IEEE Access 2019, 7, 129244–129259. [Google Scholar] [CrossRef]

- Nieto, S.; Piceros, E.; Reyes, E.; Ramos, J.; Robles, P.; Jeldres, R. Structural Analysis of Aggregates in Clayey Tail ings Treated with Coagulant and Flocculant. Minerals 2025, 15, 627. [Google Scholar] [CrossRef]

- Bergani, A.; Ait-Khouia, Y.; El-Bahi, A.; Hakkou, R.; Benzaazoua, M.; Taha, Y. Advancing Sustainable Dewatering of Fine Phosphate Tailings: Evaluating Xanthan Gum, Sodium Alginate, and Carboxymethyl Cellulose as Flocculating Agents. Water Res. 2025, 280, 123526. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, W.; Wang, R.; Li, G.; Wang, X.; Zhong, J. Cyanobacterial Bloom Removal by Rapid Flocculation and Settling Using Modified Iron Tailings Sand Materials. J. Ocean. Limnol. 2025, 43, 1501–1514. [Google Scholar] [CrossRef]

- Boshrouyeh, B.; Edraki, M.; Baumgartl, T.; Costine, A.; Quintero Olaya, S.; Lepková, K.; Dwivedi, D. Impact of Inline Polyacrylamide Polymer Flocculation on the Mechanical and Hydrological Properties of Saline Tailings. Minerals 2024, 14, 1180. [Google Scholar] [CrossRef]

- Luo, Y.; Ekanayake, N.I.K.; Amini, N.; Moon, E.M.; Scales, P.J.; Stickland, A.D. Improved Suspension Dewaterability Using a Novel Pelleting Flocculation Device. Miner. Eng. 2026, 235, 109762. [Google Scholar] [CrossRef]

- Huang, Y.; Chen, J.; Wang, C. Optimization of Flocculation Settling Parameters of Whole Tailings Based on Spatial Difference Algorithm. Symmetry 2019, 11, 1371. [Google Scholar] [CrossRef]

- Liu, D.; Edraki, M.; Fawell, P.; Berry, L. Improved Water Recovery: A Review of Clay-Rich Tailings and Saline Water Interactions. Powder Technol. 2020, 364, 604–621. [Google Scholar] [CrossRef]

- Gungoren, C.; Unver, I.K.; Ozdemir, O. Investigation of Flocculation Properties and Floc Structure of Coal Processing Plant Tailings in the Presence of Monovalent and Divalent Ions. Physicochem. Probl. Miner. Process. 2020, 56, 747–758. [Google Scholar] [CrossRef]

- Entezari, I.; Rivard, B.; Vajihinejad, V.; Wilson, W.G.; Soares, J.B.P.; Fisseha, B.; Beier, N. Monitoring Tailings Floc culation Performance Using Hyperspectral Imagery. Can. J. Chem. Eng. 2019, 97, 2465–2471. [Google Scholar] [CrossRef]

- Ruan, Z.; Wu, A.; Buerger, R.; Betancourt, F.; Ordonez, R.; Wang, J.; Wang, S.; Wang, Y. A Population Balance Model for Shear-Induced Polymer-Bridging Flocculation of Total Tailings. Minerals 2022, 12, 40. [Google Scholar] [CrossRef]

- Sasar, M.; Johnston, C.T.; Kaminsky, H.; Santagata, M. Oscillatory Rheometry to Characterize Polymer Flocculation of Fluid Fine Tailings. Rheol. Acta 2021, 60, 457–479. [Google Scholar] [CrossRef]

- Yin, S.; Hou, Y.; Yang, S.; Chen, X. Study on Static and Dynamic Flocculation Settlement Characteristics of Fine Tailings Slurry and Influence of Flocculant on Strength of Fine Tailings Backfill. Case Stud. Constr. Mater. 2022, 17, e01525. [Google Scholar] [CrossRef]

- Quezada, G.R.; Ayala, L.; Leiva, W.H.; Toro, N.; Toledo, P.G.; Robles, P.; Jeldres, R.I. Describing Mining Tailing Flocculation in Seawater by Population Balance Models: Effect of Mixing Intensity. Metals 2020, 10, 240. [Google Scholar] [CrossRef]

- Shi, Y.; Zheng, B.; Lai, W.; Sheng, J.; Peng, L.; Qi, H.; Zhou, J. Ultrasonic-Enhanced Flocculation and Sedimentation of Lead-Zinc Tailings: Mechanisms and Efficiency Improvements. Ultrasonics 2025, 156, 107751. [Google Scholar] [CrossRef] [PubMed]

- Panda, L.; Biswal, S.K.; Venugopal, R.; Mandre, N.R. Investigation of the Mechanism for Selective Flocculation Process Using Natural Iron Ore Tailings. Metall. Res. Technol. 2020, 117, 102. [Google Scholar] [CrossRef]

- Costine, A.D.; Vajihinejad, V.; Botha, L.; Fawell, P.D.; Soares, J.B.P. Aggregate Structures Formed by Hyper branched Functionalized Polyethylene (HB f PE) Treatment of Oil Sands Tailings. Can. J. Chem. Eng. 2019, 97, 99–102. [Google Scholar] [CrossRef]

- Xie, Z.; Liu, W.; Li, Y.; Du, J.; Long, T.; Xu, H.; Long, Y.; Zhao, J. Enhanced Litchi Fruit Detection and Segmentation Method Integrating Hyperspectral Reconstruction and YOLOv8. Comput. Electron. Agric. 2025, 237, 110659. [Google Scholar] [CrossRef]

- Li, H.; Yuan, W.; Xia, Y.; Wang, Z.; He, J.; Wang, Q.; Zhang, S.; Li, L.; Yang, F.; Wang, B. YOLOv8n-WSE-Pest: A Lightweight Deep Learning Model Based on YOLOv8n for Pest Identification in Tea Gardens. Appl. Sci. 2024, 14, 8748. [Google Scholar] [CrossRef]

- Ma, S.; Liu, Y.; Zhang, Y. Fabric Defect Detection Based on Improved Lightweight YOLOv8n. Appl. Sci. 2024, 14, 8000. [Google Scholar] [CrossRef]

- Yi, W.; Yang, J.; Yan, L. Research on Underwater Small Target Detection Technology Based on Single-Stage USSTD-YOLOv8n. IEEE Access 2024, 12, 69633–69641. [Google Scholar] [CrossRef]

- Wan, J.; Xue, F.; Shen, Y.; Song, H.; Shi, P.; Qin, Y.; Yang, T.; Wang, Q.J. Automatic Segmentation of Urban Flood Extent in Video Image with DSS-YOLOv8n. J. Hydrol. 2025, 655, 132974. [Google Scholar] [CrossRef]

- Liu, Q.; Jiang, R.; Xu, Q.; Wang, D.; Sang, Z.; Jiang, X.; Wu, L. YOLOv8n_BT: Research on Classroom Learning Behavior Recognition Algorithm Based on Improved YOLOv8n. IEEE Access 2024, 12, 36391–36403. [Google Scholar] [CrossRef]

| Sample | Flocculant | Source | Solution (mg/L) | Flocculant Dosage (mL) | pH |

|---|---|---|---|---|---|

| 1 | FPAM YPAM PAC PFS KY | Market | 10 | 1 | 6.9 |

| 2 | 10 | 1 | 7.9 | ||

| 3 | 10 | 1 | 8.9 | ||

| 4 | 20 | 2 | 6.9 | ||

| 5 | 20 | 2 | 7.9 | ||

| 6 | 20 | 2 | 8.9 | ||

| 7 | 30 | 3 | 6.9 | ||

| 8 | 30 | 3 | 7.9 | ||

| 9 | 30 | 3 | 8.9 | ||

| 10 | 40 | 4 | 6.9 | ||

| 11 | 40 | 4 | 7.9 | ||

| 12 | 40 | 4 | 8.9 | ||

| 13 | Control | Mine | 6.9 | ||

| 14 | 7.9 | ||||

| 15 | 8.9 |

| Data Augmentation Parameters | Value | Data Augmentation Parameters | Value |

|---|---|---|---|

| hsv_h | 0.015 | hsv_s | 0.7 |

| hsv_v | 0.4 | degrees | 0 |

| translate | 0.1 | scale | 0.5 |

| fliplr | 0 | mosaic | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Qiao, X.; Wang, K.; Wang, J.; He, J.; Bai, R. Study on Flocculant Selection for Fine Iron Tailing Slurry Based on Multi-Process Data Monitoring. Minerals 2026, 16, 37. https://doi.org/10.3390/min16010037

Qiao X, Wang K, Wang J, He J, Bai R. Study on Flocculant Selection for Fine Iron Tailing Slurry Based on Multi-Process Data Monitoring. Minerals. 2026; 16(1):37. https://doi.org/10.3390/min16010037

Chicago/Turabian StyleQiao, Xiaofei, Kun Wang, Jie Wang, Juntao He, and Ruisi Bai. 2026. "Study on Flocculant Selection for Fine Iron Tailing Slurry Based on Multi-Process Data Monitoring" Minerals 16, no. 1: 37. https://doi.org/10.3390/min16010037

APA StyleQiao, X., Wang, K., Wang, J., He, J., & Bai, R. (2026). Study on Flocculant Selection for Fine Iron Tailing Slurry Based on Multi-Process Data Monitoring. Minerals, 16(1), 37. https://doi.org/10.3390/min16010037