Micropore Structural Heterogeneity of Siliceous Shale Reservoir of the Longmaxi Formation in the Southern Sichuan Basin, China

Abstract

:1. Introduction

2. Geological Setting

3. Materials and Methods

3.1. Sample Collection

3.2. Low Pressure N2 Adsorption Analysis

3.3. MIP Analysis

3.4. Fractal Dimension Analysis

4. Results

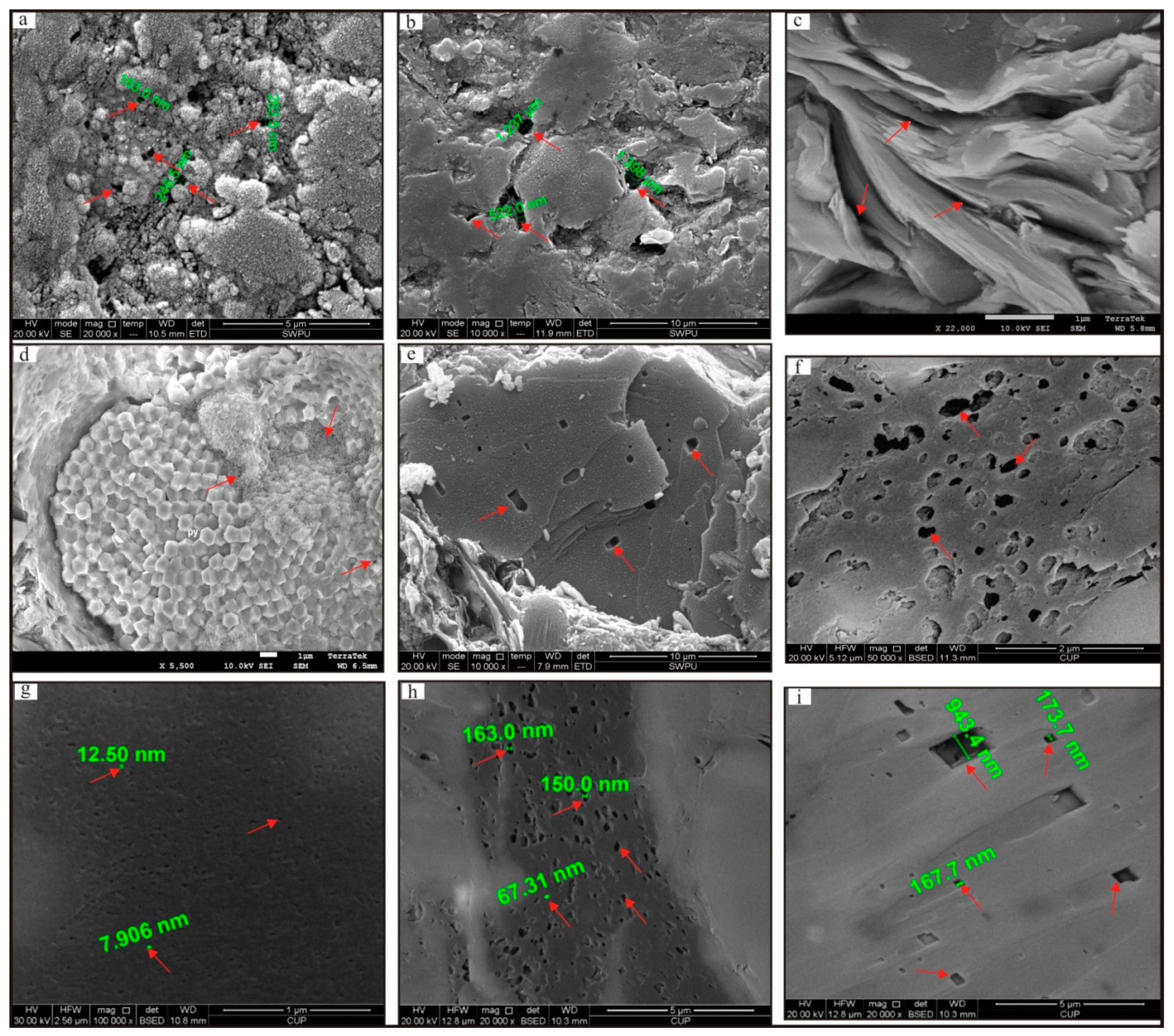

4.1. Micropore Types and Characteristics

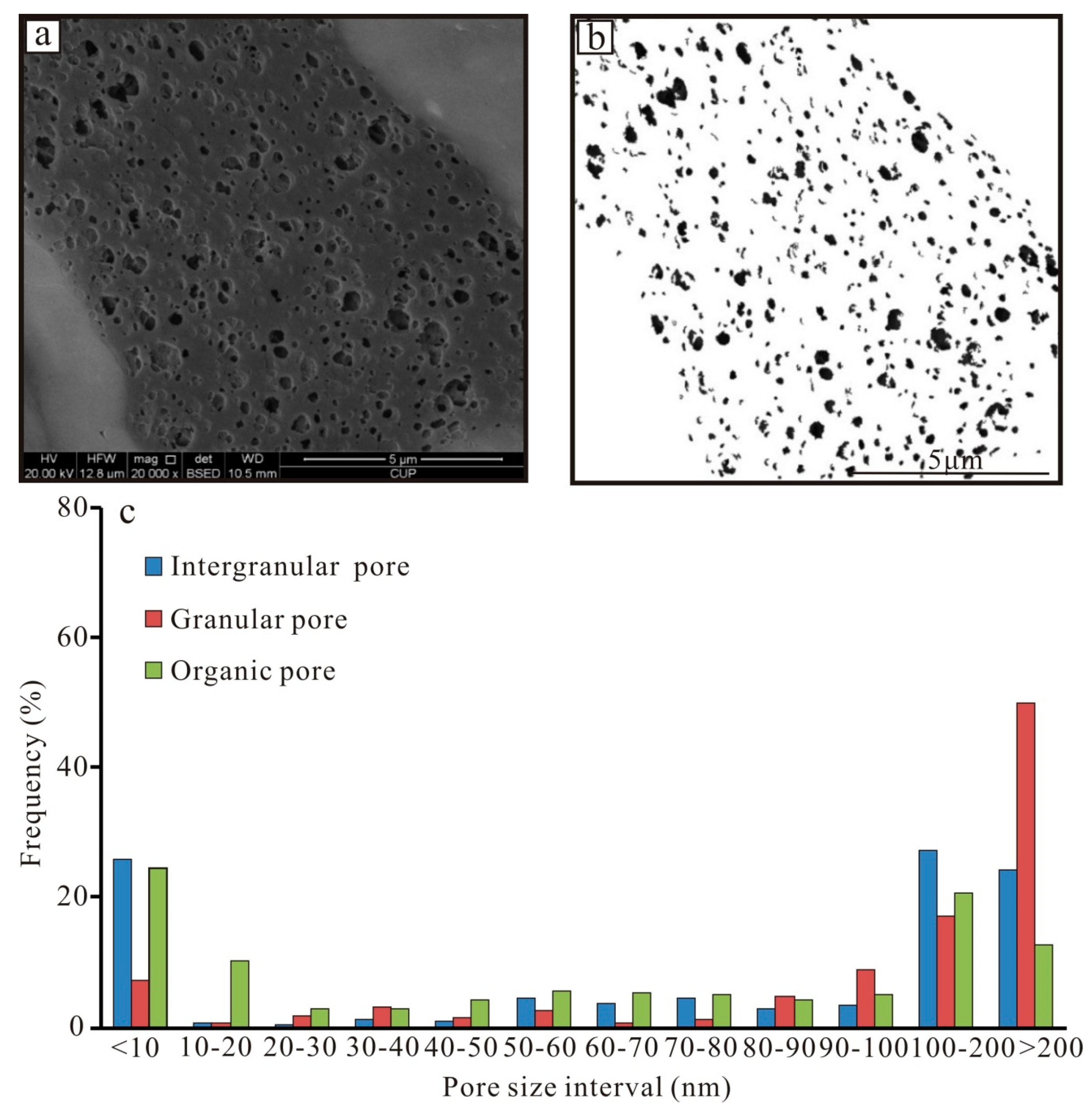

4.2. Pore Size Distribution Characteristics

4.2.1. Pore Size Characterization through Image Analysis

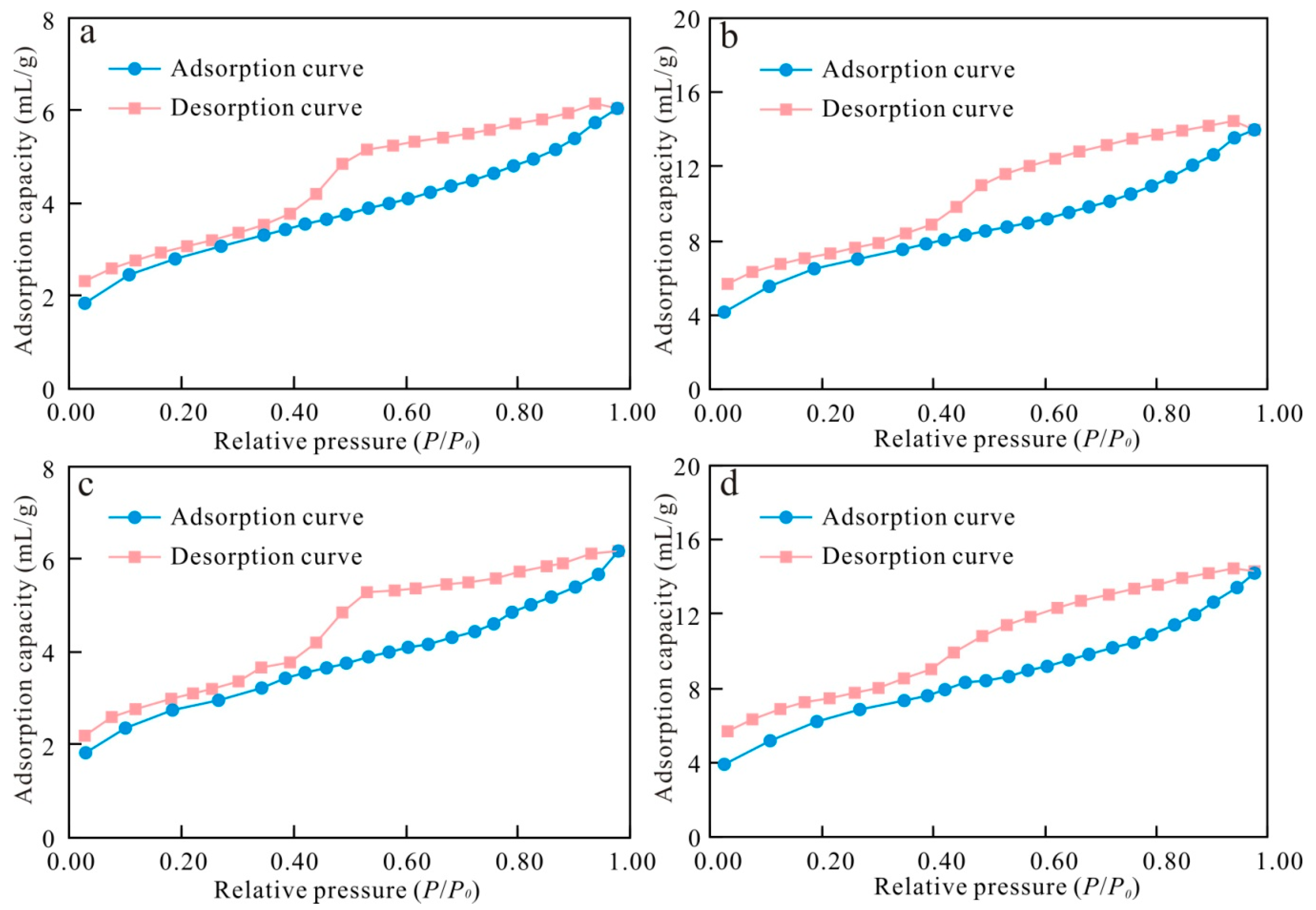

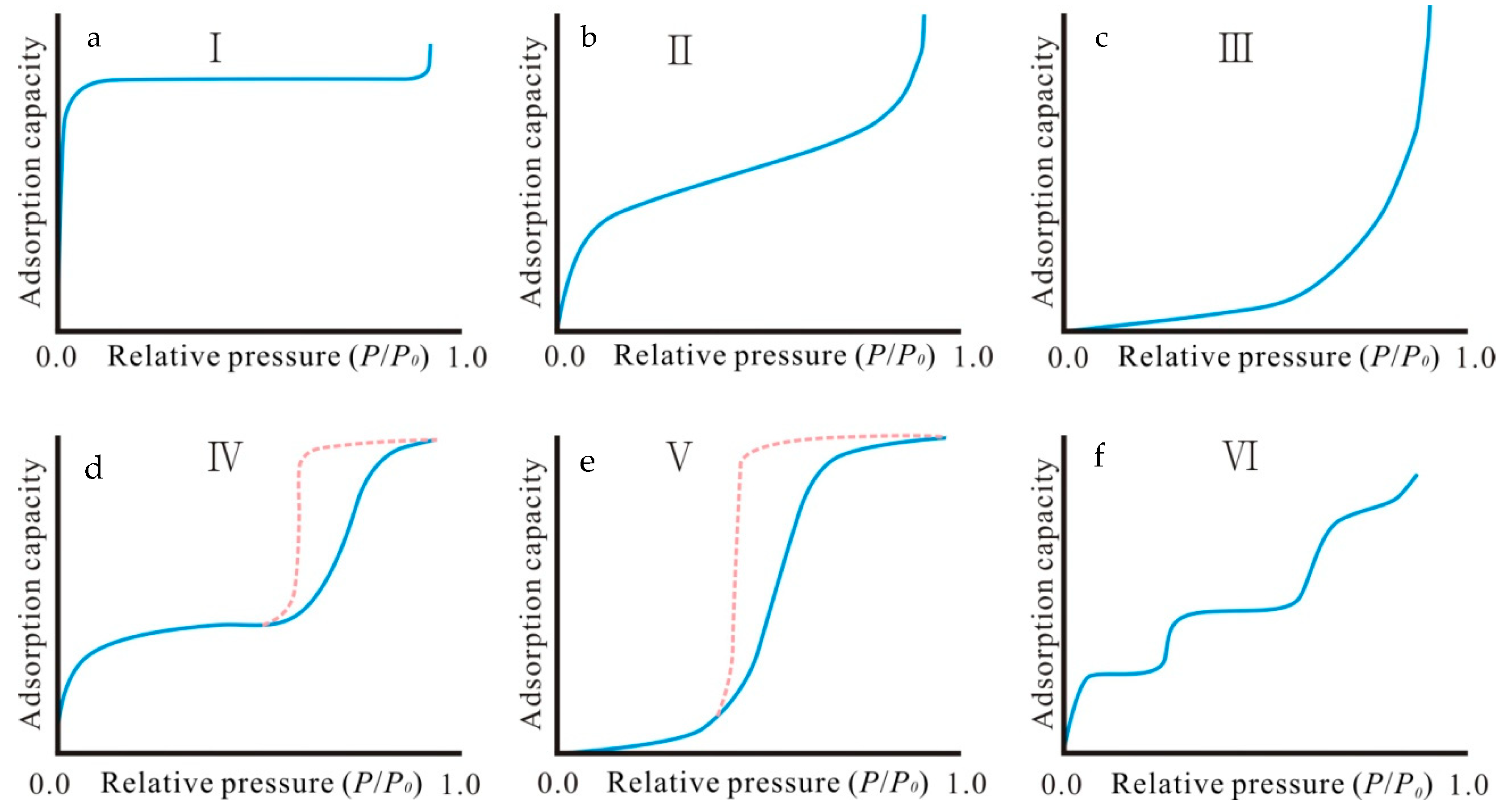

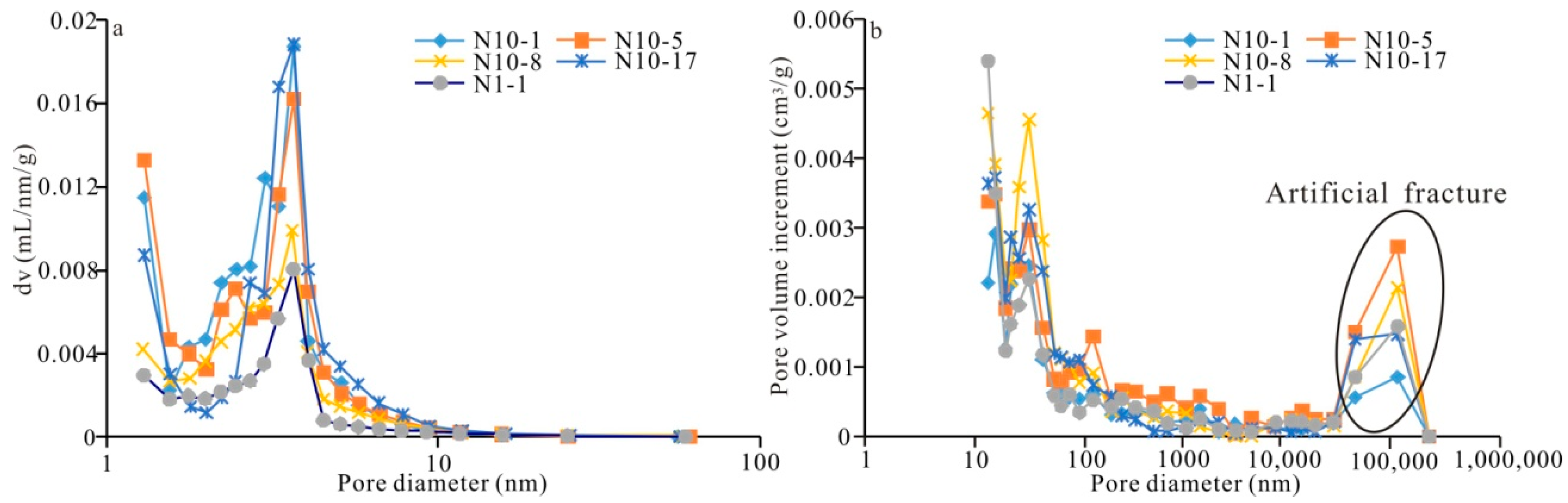

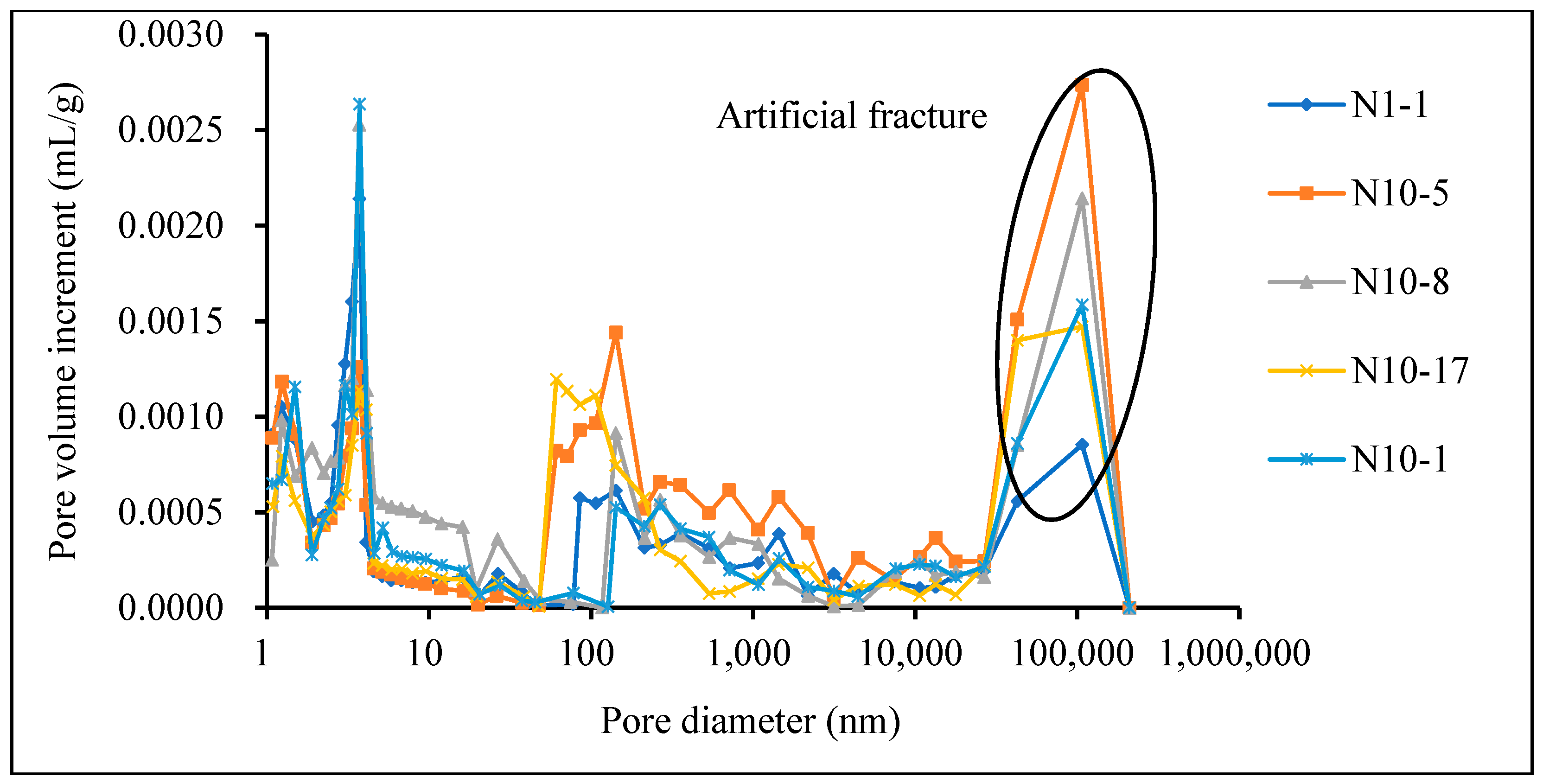

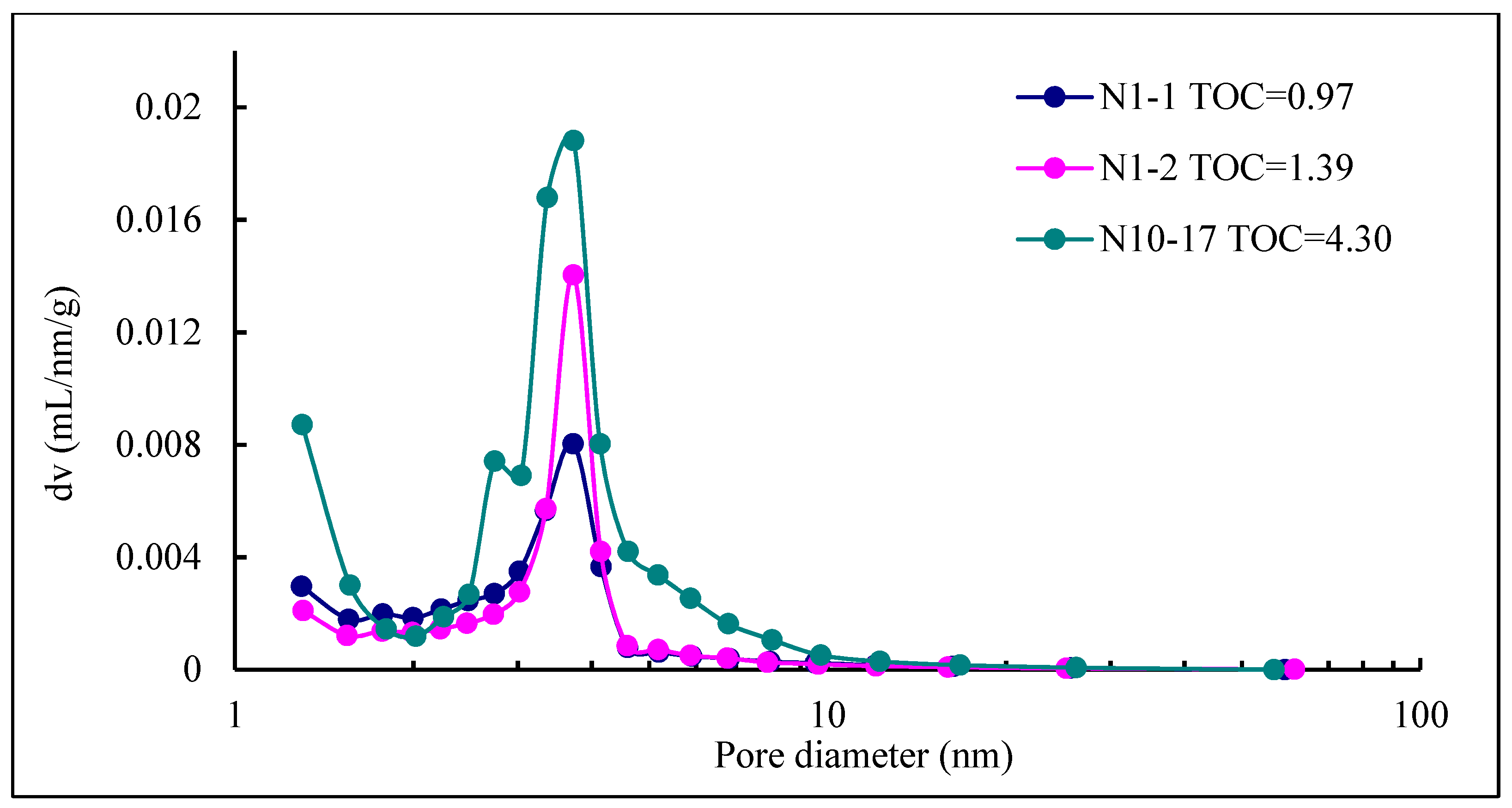

4.2.2. Pore Size Characterization through Nitrogen Adsorption and Mercury Pressure Method

4.3. Fractal Characteristics of Pore Structure

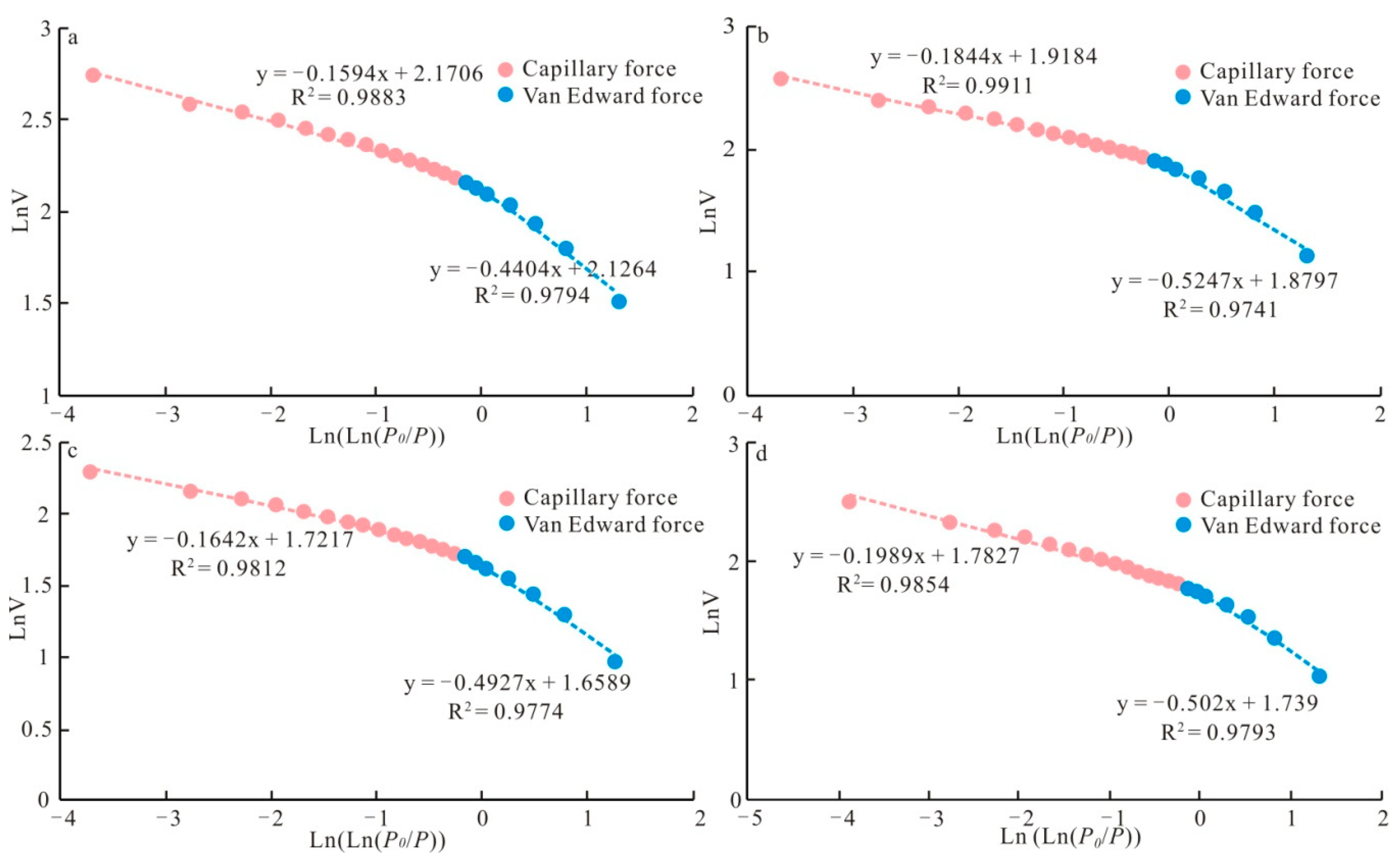

4.3.1. Fractal Dimension of Micropores and Mesopores

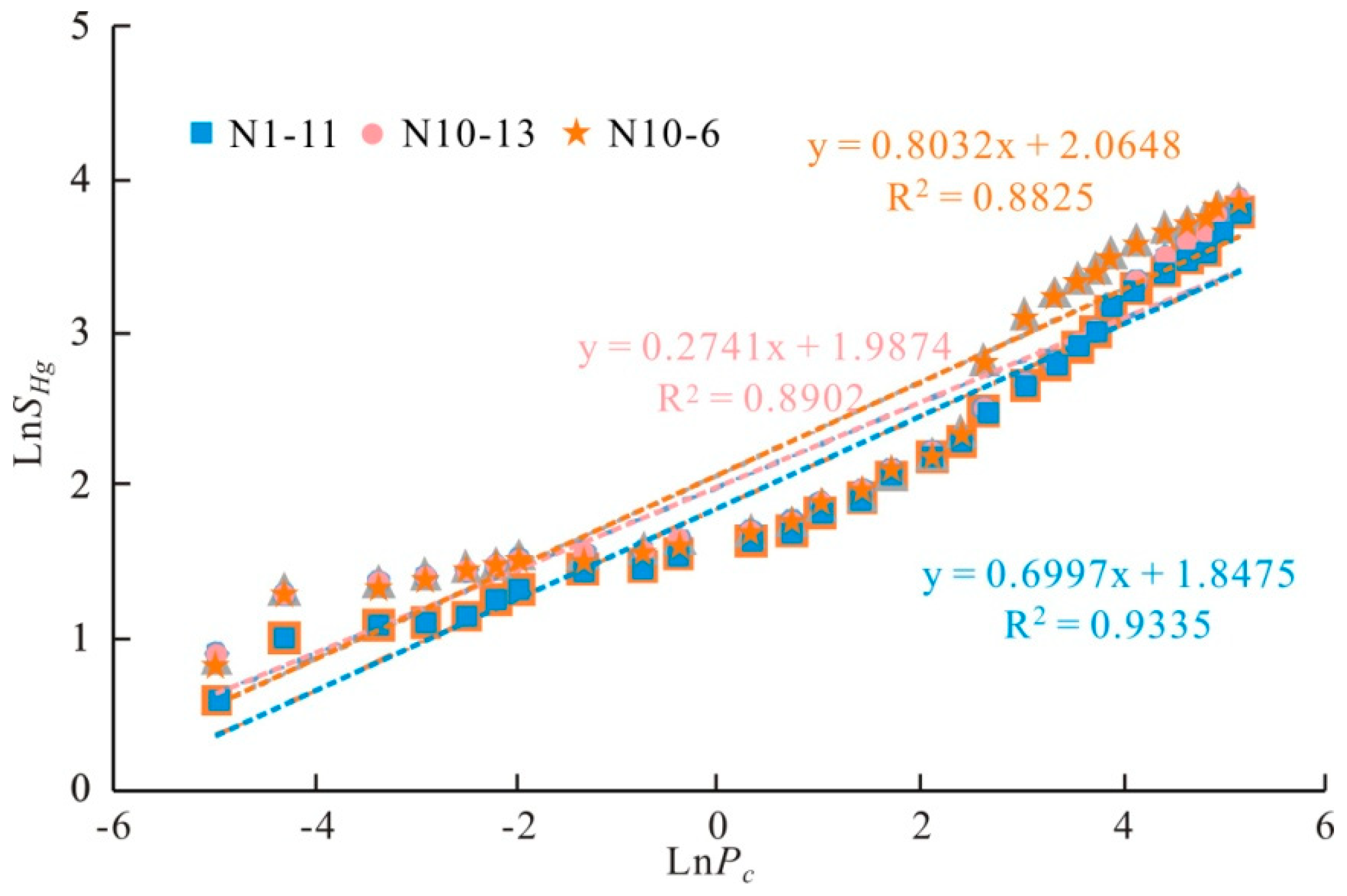

4.3.2. Fractal Dimension of Macropores

5. Discussion

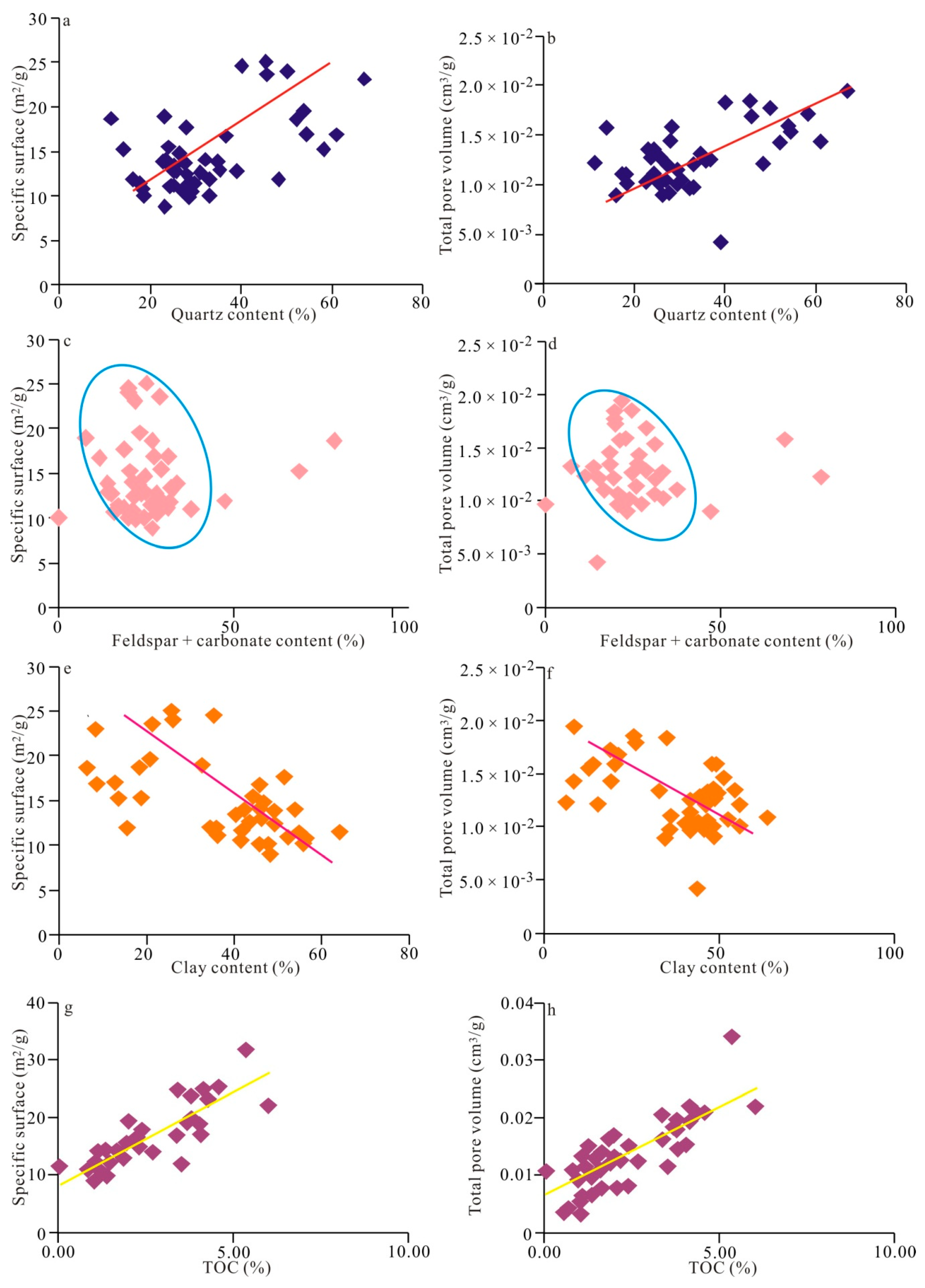

5.1. Correlation of Pore Structure with Material Composition and TOC

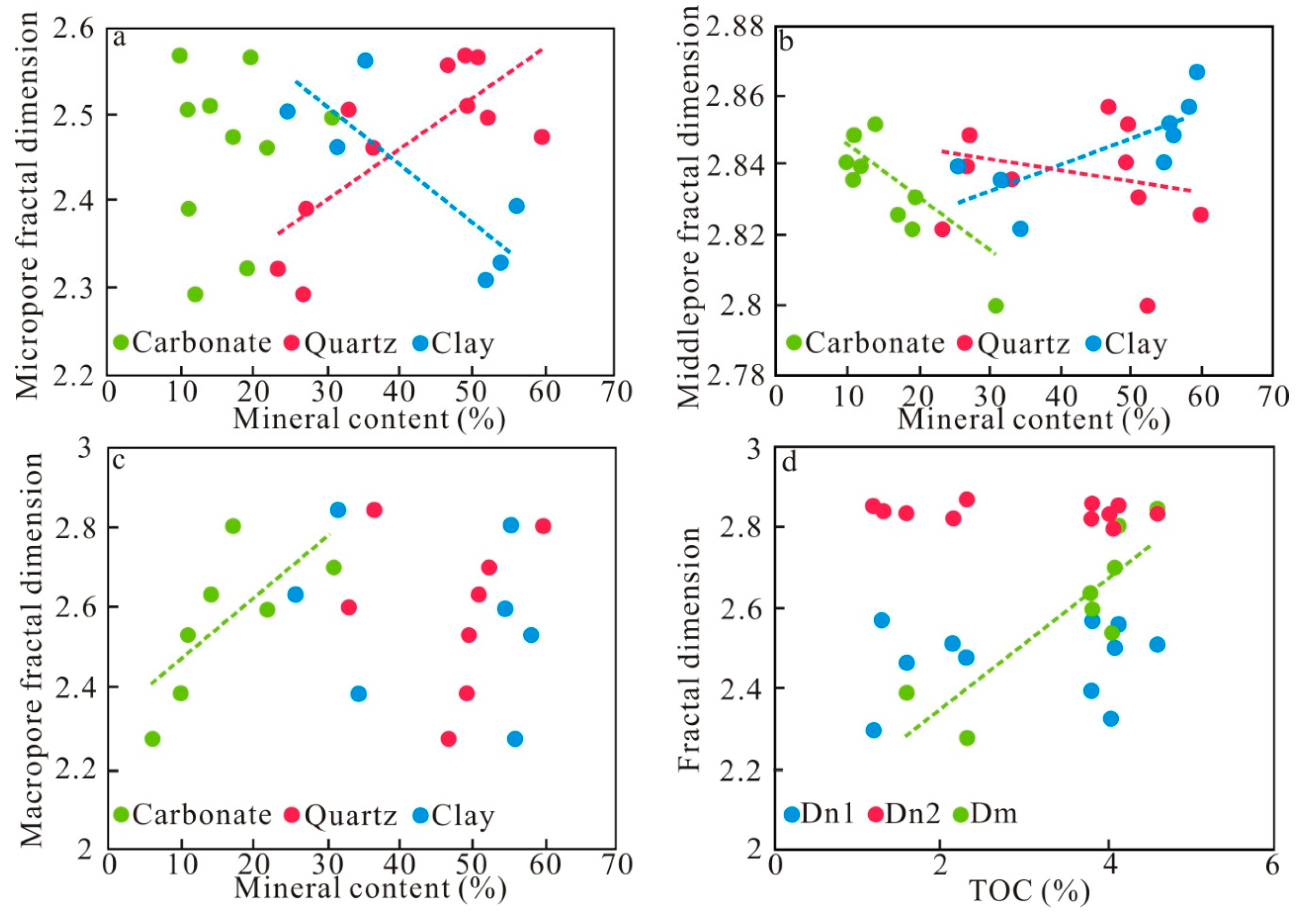

5.2. The Correlation between Fractal Dimension with Mineral Composition and TOC

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Borkloe, J.K.; Pan, R.F.; Jin, J.N.; Nyantakyi, E.K.; Meng, J.H. Evaluation of shale gas potential of Cambrian Jiulaodong Formation in Wei-201 well block in Sichuan Basin, China. Interpretation 2016, 4, 123–140. [Google Scholar] [CrossRef]

- Wang, D.; Shao, L.; Li, Z.; Li, M.; Lv, D.; Liu, H. Hydrocarbon generation characteristics, reserving performance and preservation conditions of continental coal measure shale gas: A case study of mid-jurassic shale gas in the Yan’an formation, Ordos Basin. J. Petrol. Sci. Eng. 2016, 145, 609–628. [Google Scholar] [CrossRef]

- Lv, D.W.; Wang, D.D.; Li, Z.X.; Liu, H.Y.; Li, Y. Depositional environment, sequence stratigraphy and sedimentary mineralization mechanism in the coal bed- and oil shale-bearing succession: A case from the Paleogene Huangxian Basin of China. J. Petrol. Sci. Eng. 2018, 148, 32–51. [Google Scholar] [CrossRef]

- Liu, J.; Yao, Y.B.; Elsworth, D.; Liu, D.M.; Cai, Y.D. Vertical heterogeneity of the shale reservoir in the Lower Silurian Longmaxi Formation: Analogy between the southeastern and northeastern Sichuan Basin, SW China. Minerals 2017, 7, 151. [Google Scholar] [CrossRef]

- Fan, C.H.; Zhong, C.; Zhang, Y.; Qin, Q.R.; He, S. Geological factors controlling the accumulation and high yield of marine-facies shale gas: Case study of the Wufeng-Longmaxi Formation in the Dingshan area of southeast Sichuan, China. Acta Geol. Sin. (Eng. Edi.) 2019, 93, 536–560. [Google Scholar] [CrossRef]

- Ma, X.H. Natural gas and energy revolution: A case study of Sichuan-Chongqing gas province. Nat. Gas Ind. 2017, 37, 1–8, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Liang, C.; Jiang, Z.X.; Cao, Y.C.; Zhang, J.C.; Guo, L. Sedimentary characteristics and paleoenvironment of shale in the Wufeng-Longmaxi Formation, North Guizhou Province, and its shale gas potential. J. Ear. Sci. 2017, 28, 1020–1031. [Google Scholar] [CrossRef]

- Han, C.; Jiang, Z.X.; Han, M.; Wu, M.H.; Lin, W. The lithofacies and reservoir characteristics of the Upper Ordovician and Lower Silurian black shale in the Southern Sichuan Basin and its periphery, China. Mar. Petrol. Geol. 2016, 75, 181–191. [Google Scholar] [CrossRef]

- Hill, R.J.; Zhang, E.; Kate, B.J. Modeling of gas generation from the Barnett shale, Fort worth Basin, Texas. Int. J. Coal Geol. 2014, 126, 64–76. [Google Scholar]

- Tang, X.L.; Jiang, Z.X.; Li, Z.; Gao, Z.Y.; Bai, Y.Q.; Zhao, S.; Feng, J. The effect of the variation in material composition on the heterogeneous pore structure of high-maturity shale of the Silurian Longmaxi formation in the southeastern Sichuan Basin, China. J. Nat. Gas Sci. Eng. 2015, 23, 464–473. [Google Scholar] [CrossRef]

- Su, S.Y.; Jiang, Z.X.; Shan, X.L.; Zhang, C.W.; Zou, Q.T.; Li, Z.; Zhu, R.F. The effects of shale pore structure and mineral components on shale oil accumulation in the Zhanhua Sag, Jiyang Depression, Bohai Bay Basin, China. J. Petrol. Sci. Eng. 2018, 165, 365–374. [Google Scholar] [CrossRef]

- Pang, H.; Pang, X.Q.; Dong, L.; Zhao, X. Factors impacting on oil retention in lacustrine shale: Permian Lucaogou Formation in Jimusaer Depression, Junggar Basin. J. Petrol. Sci. Eng. 2018, 163, 79–90. [Google Scholar] [CrossRef]

- Shi, B.B.; Chang, X.C.; Yin, W.; Li, Y.; Mao, L.X. Quantitative evaluation model of tight sandstone reservoirs based on statistical methods—A case study of the Triassic Chang 8 tight sandstones, Zhenjing area, Ordos Basin, China. J. Petrol. Sci. Eng. 2019, 173, 601–616. [Google Scholar] [CrossRef]

- Wang, G.; Chang, X.; Yin, W.; Li, Y.; Song, T. Impact of diagenesis on reservoir quality and heterogeneity of the upper triassic chang 8 tight oil sandstones in the Zhenjing area, Ordos Basin, China. Mar. Petrol. Geol. 2017, 83, 84–96. [Google Scholar] [CrossRef]

- Yang, R.C.; Fan, A.P.; van Loon, A.J.; Han, Z.Z.; Wang, X.P. Depositional and diagenetic controls on sandstone reservoirs with low porosity and low permeability in the eastern sulige gas field, China. Acta Geol. Sin. (Eng. Edi.) 2014, 88, 183–204. [Google Scholar] [CrossRef]

- Wang, C.G.; Liu, J.S.; Feng, J.L.; Wei, M.Y.; Wang, C.S. Effects of gas diffusion from fractures to coal matrix on the evolution of coal strains: Experimental observations. Int. J. Coal Geol. 2016, 162, 74–84. [Google Scholar] [CrossRef]

- Lv, D.W.; Li, Z.X.; Chen, J.T.; Liu, H.Y.; Guo, J.B. Characteristics of the Permian coal-formed gas sandstone reservoirs in Bohai Bay Basin and the adjacent areas, North China. J. Petrol. Sci. Eng. 2011, 78, 516–528. [Google Scholar] [CrossRef]

- Wang, G.W.; Hao, F.; Chang, X.C.; Lan, C.J.; Li, P.P. Quantitative analyses of porosity evolution in tight grainstones: A case study of the Triassic Feixianguan formation in the Jiannan gas field, Sichuan Basin, China. Mar. Petrol. Geol. 2017, 86, 259–267. [Google Scholar] [CrossRef]

- Li, Y.; Chang, X.C.; Yin, W.; Sun, T.T.; Song, T.T. Quantitative impact of diagenesis on reservoir quality of the Triassic Chang 6 tight oil sandstones, Zhenjing area, Ordos Basin, China. Mar. Petrol. Geol. 2017, 86, 1014–1028. [Google Scholar] [CrossRef]

- Yang, Y.Q.; Qiu, L.W.; Cao, Y.C.; Chen, C.; Lei, D.W. Reservoir quality and diagenesis of the Permian Lucaogou Formation tight carbonates in Jimsar Sag, Junggar Basin, West China. J. Ear. Sci. 2017, 28, 1032–1046. [Google Scholar] [CrossRef]

- Houben, M.E.; Desbois, G.; Urai, J.L. A comparative study of representative 2D microstructures in Shaly and sandy facies of opalinus clay (Mont Terri, Switzerland) inferred form BIB-SEM and MIP methods. Mar. Petrol. Geol. 2014, 49, 143–161. [Google Scholar] [CrossRef]

- Wang, X.M.; Jiang, Z.X.; Jiang, S.; Chang, J.Q.; Zhu, L.; Li, X.H.; Li, J.T. Full-scale pore structure and fractal dimension of the Longmaxi shale from the Southern Sichuan Basin: Investigations using FE-SEM, gas adsorption and mercury intrusion porosimetry. Minerals 2019, 9, 543. [Google Scholar] [CrossRef]

- Li, J.; Zhou, S.X.; Gaus, G.; Li, Y.J.; Ma, Y. Characterization of methane adsorption on shale and isolated kerogen from the Sichuan Basin under pressure up to 60 MPa: Experimental results and geological implications. Inter. J. Coal Geol. 2018, 189, 83–93. [Google Scholar] [CrossRef]

- Tang, X.L.; Jiang, Z.X.; Jiang, S.; Wang, P.; Xiang, C. Effect of organic matter and maturity on pore size distribution and gas storage capacity in high-mature to post-mature shales. Energ. Fuel 2016, 30, 8985–8996. [Google Scholar] [CrossRef]

- Tang, X.L.; Jiang, Z.X.; Jiang, S.; Li, Z. Heterogeneous nanoporosity of the Silurian Longmaxi Formation shale gas reservoir in the Sichuan Basin using the QEMSCAN, FIB-SEM, and nano-CT methods. Mar. Petrol. Geol. 2016, 78, 99–109. [Google Scholar] [CrossRef]

- Tian, H.; Zhang, S.C.; Liu, S.B.; Zhang, H. Determination of organic-rich shale pore features by mercury injection and gas adsorption methods. Acta Pet. Sin. 2012, 33, 419–427. [Google Scholar]

- Lv, D.W.; Li, Z.X.; Liu, H.Y.; Li, Y.; Feng, T.T. The characteristics of coal and oil shale in the coastal sea areas of Huangxian coalfield, Eastern China. Oil Shale 2015, 32, 204–217. [Google Scholar] [CrossRef]

- Qiu, X.W.; Liu, C.Y.; Mao, G.Z.; Deng, Y.; Wang, F.F. Major, trace and platinum-group element geochemistry of the Upper Triassic nonmarine hot shales in the Ordos basin, Central China. Appl. Geochem. 2015, 53, 42–52. [Google Scholar] [CrossRef]

- Pfeifer, P.; Avnir, D. Chemistry in non-integer dimensions between 2 and 3, I: Fractal theory of heterogenous surface. J. Chem. Phys. 1983, 79, 3558–3565. [Google Scholar] [CrossRef]

- Wang, C.; Hao, S.; Sun, W.; Chu, W. Fractal dimension of coal particles and their CH4 adsorption. Int. J. Rock Mech. Min. 2012, 22, 855–858. [Google Scholar]

- Yang, F.; Ning, Z.; Liu, H. Fractal characteristics of shales from a shale gas reservoir in the Sichuan Basin, China. Fuel 2014, 115, 378–384. [Google Scholar] [CrossRef]

- Fan, C.H.; He, S.; Zhang, Y.; Qin, Q.R.; Zhong, C. Development phases and mechanisms of tectonic fractures in the Longmaxi Formation Shale of the Dingshan Area in southeast Sichuan Basin, China. Acta Geol. Sin. (Eng. Edi.) 2018, 92, 2351–2366. [Google Scholar]

- Li, H.; Tang, H.M.; Qin, Q.R.; Zhou, J.L.; Qin, Z.J.; Fan, C.H.; Su, P.D.; Wang, Q.; Zhong, C. Characteristics, formation periods and genetic mechanisms of tectonic fractures in the tight gas sandstones reservoir: A case study of Xujiahe Formation in YB area, Sichuan Basin, China. J. Petrol. Sci. Eng. 2019, 178, 723–735. [Google Scholar] [CrossRef]

- Li, H.; Tang, H.M.; Qin, Q.R.; Wang, Q.; Zhong, C. Effectiveness evaluation of natural fractures in Xujiahe Formation of Yuanba area, Sichuan basin, China. Arab. J. Geosci. 2019, 12, 194. [Google Scholar] [CrossRef]

- Han, C.; Han, M.; Jiang, Z.X.; Han, Z.Z.; Li, H.; Song, Z.G.; Zhong, W.J.; Liu, K.X.; Wang, C.H. Source analysis of quartz from the Upper Ordovician and Lower Silurian black shale and its effects on shale gas reservoir in the Southern Sichuan Basin and its periphery, China. Geol. J. 2019, 54, 439–449. [Google Scholar] [CrossRef]

- Yin, S.; Gao, Z. Numerical study on the prediction of “sweet spots” in a low efficiency-tight gas sandstone reservoir based on a 3D strain energy model. IEEE Access. 2019, 7, 1–12. [Google Scholar] [CrossRef]

- Zeng, P.; Guo, T. Enrichment of shale gas in different strata in Sichuan Basin and its periphery-the examples of the Cambrian Qiongzhusi Formation and the Silurian Longmaxi Formation. Energy Explor Exploit 2015, 33, 277–298. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Tang, D.; Tang, S.; Huang, W. Fractal characterization of adsorption-pores of coals from North China: An investigation on CH4 adsorption capacity of coals. Int. J. Coal Geol. 2008, 73, 27–42. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Tang, D.; Tang, S.; Huang, W.; Liu, Z.; Che, Y. Fractal characterization of seepage-pores of coals from China: An investigation on permeability of coals. Comput. Geosci. 2009, 35, 1159–1166. [Google Scholar] [CrossRef]

- Yin, S.; Lv, D.W.; Jin, L.; Ding, W.L. Experimental analysis and application of the effect of stress on continental shale reservoir brittleness. J. Geophy. Eng. 2018, 15, 478–494. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Yao, Y.B.; Liu, D.M.; Elsworth, D. Experimental evaluation of CO2 enhanced recovery of adsorbed-gas from shale. Inter. J. Coal Geol. 2017, 179, 211–218. [Google Scholar] [CrossRef]

- Zhang, M.M.; Li, Z.; Yin, J. Sedimentary and geochemical characteristics of oil shale in the Permian Lucaogou Formation in the Southeastern Junggar Basin, Northwest China: Implications for sedimentary environments. Oil Shale 2018, 35, 97–112. [Google Scholar] [CrossRef]

- Li, K. Analytical derivation of Brooks-Corey type capillary pressure models using fractal geometry and evaluation of rock heterogeneity. J. Petrol. Sci. Eng. 2010, 73, 20–26. [Google Scholar] [CrossRef]

- Li, Y.Y.; Zhang, S.C.; Zhang, X. Classification and fractal characteristics of coal rock fragments under uniaxial cyclic loading conditions. Arab. J. Geosci. 2018, 11, 201. [Google Scholar] [CrossRef]

- Yin, S.; Tian, T.; Wu, Z. Developmental characteristics and distribution law of fractures in a tight sandstone reservoir in a low-amplitude tectonic zone, eastern Ordos Basin, China. Geol. J. 2019, 54, 1–16. [Google Scholar] [CrossRef]

- Wang, P.F.; Jiang, Z.X.; Yin, L.S.; Chen, L.; Li, Z.; Zhang, C.; Li, T.W.; Huang, P. Lithofacies classifification and its effect on pore structure of the Cambrian marine shale in the Upper Yangtze Platform, South China: Evidence from FE-SEM and gas adsorption analysis. J. Petrol. Sci. Eng. 2017, 156, 307–321. [Google Scholar] [CrossRef]

- Gregg, S.J.; Sing, K.S.W. Adsorption, Surface Area and Porosity, 2nd ed.; Academic Press: London, UK, 1982. [Google Scholar]

- Tian, H.; Pan, L.; Xiao, X.; Wilkins, R.W.T.; Meng, Z.; Huang, B. A preliminary study on the pore characterization of Lower Silurian black shales in the Chuandong Thrust Fold Belt, southwestern China using low pressure N2, adsorption and FE-SEM methods. Mar. Petrol. Geol. 2013, 48, 8–19. [Google Scholar] [CrossRef]

- Zhang, X.; Feng, Q.; Sun, P.; Li, W. Characteristics of high gamma ray reservoir of Yanchang formation in Ordos Basin. Chin. J. Geophy. 2010, 53, 205–213. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, W.; Cao, J.; Wang, X.; Tang, Q.; Wu, H. Diagenetic constraints on the heterogeneity of tight sandstone reservoirs: A case study on the upper triassic Xujiahe formation in the Sichuan Basin, Southwest China. Mar. Petrol. Geol. 2017, 92, 650–669. [Google Scholar] [CrossRef]

- Li, X.; Zhang, J.L.; Liu, L.L.; Fan, Z.L.; Zhang, G.X. Reservoir architecture and fracture characterization of low-permeability sandstone reservoir: A case study of Biandong oilfield, Jinhu depression, northern Jiangsu Basin, China. Arab. J. Geosci. 2018, 11, 380. [Google Scholar] [CrossRef]

- Barett, E.P.; Joyner, L.G.; Halenda, P.P. The determination of pore volume and area distributions in porous substances. I. Computations from nitrogen isotherms. J. Am. Chem. Soc. 1951, 73, 373–380. [Google Scholar] [CrossRef]

- Wang, G.C.; Timothy, R.C. Organi-rich marcellus shale lithofacies modeling and distribution pattern anal ysis in the Appalachian Basin. AAPG Bull. 2013, 97, 2173–2205. [Google Scholar] [CrossRef]

- Chen, Z.X.; Zeng, Z.G.; Wang, X.Y.; Yin, X.B.; Chen, S. U-Th/He dating and chemical compositions of apatite in the dacite from the southwestern Okinawa Trough: Implications for petrogenesis. J. Asian Earth Sci. 2018, 161, 1–13. [Google Scholar] [CrossRef]

- Guo, H.J.; He, R.L.; Jia, W.L.; Peng, P.A.; Lei, Y.H.; Luo, X.R.; Wang, X.Z.; Zhang, L.X.; Jiang, C.F. Pore characteristics of lacustrine shale within the oil window in the Upper Triassic Yanchang Formation, southeastern Ordos Basin, China. Mar. Petrol. Geol. 2018, 91, 279–296. [Google Scholar] [CrossRef]

- Ke, C.W.; Xu, Y.H.; Chang, X.C.; Liu, W.B. Composition and distribution of NSO compounds in two different shales at the early maturity stage characterized by negative ion electrospray ionization coupled with Fourier transform ion cyclotron resonance mass spectrometry. Petrol. Sci. 2018, 15, 289–296. [Google Scholar] [CrossRef]

- Wu, K.L.; Chen, Z.X.; Li, X.F.; Guo, C.H.; Wei, M.Z. A model for multiple transport mechanisms through nanopores of shale gas reservoirs with real gas effect-adsorption-mechanic coupling. Inter. J. Heat Mass Transfer. 2016, 93, 406–426. [Google Scholar] [CrossRef]

- Wu, K.L.; Chen, Z.X.; Li, X.F.; Xu, J.Z.; Li, J.; Wang, K.; Wang, H.; Wang, S.H.; Dong, X.H. Flow behavior of gas confined in nanoporous shale at high pressure: Real gas effect. Fuel 2017, 205, 173–183. [Google Scholar] [CrossRef]

- Sing, K.S.; Everett, D.H.; Haul, R.A.W.; Moscou, L.; Pierotti, R.A.; Rouquerol, J.; Siemieniewsha, T. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Curtis, M.E.; Cardott, B.J.; Sondergeld, C.H.; Rai, C.H. Development of organic porosity in the Woodford shale with increasing thermal maturity. Int. J. Coal Geol. 2012, 26, 26–30. [Google Scholar] [CrossRef]

- Yin, S.; Lv, D.W.; Ding, W.L. New method for assessing microfracture stress sensitivity in tight sandstone reservoirs based on acoustic experiments. Inter. J. Geome. 2018, 18, 1–16. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Zhang, J.C. Lithology-dependent minimum horizontal stress and in-situ stress estimate. Tectonophysics 2017, 703, 1–8. [Google Scholar] [CrossRef]

- Shen, B.T.; Siren, T.; Rinne, M. Modelling fracture propagation in anisotropic rock mass. Rock Mech. Rock Eng. 2015, 48, 1067–1081. [Google Scholar] [CrossRef]

- Yin, S.; Jia, Q.; Ding, W.L. 3D paleotectonic stress field simulations and fracture prediction for marine-continental transitional facies forming a tight-sandstone reservoir in a highly deformed area. J. Geophy. Eng. 2018, 15, 1214–1230. [Google Scholar] [CrossRef] [Green Version]

- Xie, D.L.; Guo, Y.H.; Zhao, D.F. Fractal characteristics of adsorption pore of shale based on low temperature nitrogen experiment. J. China Coal Soc. 2014, 39, 2466–2472. [Google Scholar]

- Han, T.C.; Beloborodov, R.; Pervukhina, M.; Josh, M.; Cui, Y.L. Theoretical modeling of dielectric properties of Artificial Shales. Geofluids 2018. [Google Scholar] [CrossRef]

- Wu, K.L.; Chen, Z.X.; Li, J.; Li, X.F.; Xu, J.Z.; Dong, X.H. Wettability effect on nanoconfined water flow. Proc. Nat. Acad. Sci. Unit. Sta. Am. 2017, 114, 3358–3363. [Google Scholar] [CrossRef] [Green Version]

- Qi, H.; Ma, J.; Wong, P.Z. Adsorption isotherms of fractal surfaces. Colloid Surf. 2002, 206, 401–407. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Hammes, U. Spectrum of pore types and networks in mudrocks and a descriptive classification for matrix-related mudrock pores. AAPG Bull. 2012, 96, 1071–1098. [Google Scholar] [CrossRef] [Green Version]

- Lv, D.W.; Zong, R.F.; Li, Z.X.; Wang, D.D.; Liu, H.Y. Oil shale paleo-productivity disturbed by sea water in a coal and oil shale bearing succession: A case study from the Paleogene Huangxian basin of Eastern China. J. Petrol. Sci. Eng. 2016, 139, 62–70. [Google Scholar] [CrossRef]

- Yin, S.; Zhao, J.; Wu, Z.; Ding, W. Strain energy density distribution of a tight gas sandstone reservoir in a low-amplitude tectonic zone and its effect on gas well productivity: A 3D FEM study. J. Petrol. Sci. Eng. 2018, 170, 1–16. [Google Scholar] [CrossRef]

- Yin, S.; Xie, R.; Wu, Z.; Liu, J.; Ding, W.L. In situ stress heterogeneity in a highly developed strike-slip fault zone and its effect on the distribution of tight gases: A 3D finite element simulation study. Mar. Petrol. Geol. 2019, 81, 1–17. [Google Scholar] [CrossRef]

- Pang, Y.M.; Guo, X.W.; Han, Z.Z.; Zhang, X.H.; Zhu, X.Q.; Hou, F.H.; Han, C.; Song, Z.G.; Xiao, G.L. Mesozoic–Cenozoic denudation and thermal history in the Central Uplift of the South Yellow Sea basin and the implications for hydrocarbon systems: Constraints from the CSDP-2 borehole. Mar. Petrol. Geol. 2019, 99, 355–369. [Google Scholar] [CrossRef]

- Kong, F.M.; Li, X.P.; Wu, S.; Li, S.J.; Xu, Y.M. Petrography, mineralogy and the evolution of peridotites from the Dongdegou, southwestern Tianshan and its geological significance. Acta Petrol. Sin. 2013, 29, 723–738. [Google Scholar]

- Han, Z.Z.; Liu, H.; Song, Z.G.; Zhong, W.J.; Han, C. Geochronology, geochemistry, and tectonic implications of upper Silurian—Lower Devonian meta-sedimentary rocks from the Jiangyu Group in eastern Jilin Province, Northeast China. Can. J. Earth Sci. 2018, 55, 490–504. [Google Scholar] [CrossRef]

| No. | Specific Surface (m2/g) | Specific Pore Volume (mL/g) | Average Aperture (nm) | Pore Volume (mL/g) | Micropore Proportion (%) | Mesopore Proportion (%) | Macropore Proportion (%) |

| N10-1 | 25.08 | 0.029 | 3.79 | 0.1048 | 12.47 | 87.53 | 0 |

| N10-5 | 24.01 | 0.019 | 3.50 | 0.1007 | 9.84 | 90.16 | 0 |

| N10-8 | 12.75 | 0.012 | 3.53 | 0.0641 | 16.09 | 83.91 | 0 |

| N10-17 | 23.13 | 0.020 | 3.60 | 0.0977 | 8.90 | 91.10 | 0 |

| N1-1 | 9.61 | 0.001 | 3.85 | 0.0455 | 14.25 | 85.75 | 0 |

| No. | Micropore Proportion (%) | Mesopore Proportion (%) | Macropore Proportion (%) | Pore Volume (mL/g) | ||

|---|---|---|---|---|---|---|

| 50–100 nm | 100–1000 nm | >1000 nm | ||||

| N10-1 | 0 | 65.71 | 8.24 | 12.21 | 13.83 | 0.022 |

| N10-5 | 0 | 54.44 | 7.68 | 16.11 | 21.76 | 0.033 |

| N10-8 | 0 | 67.68 | 9.46 | 10.20 | 12.66 | 0.036 |

| N10-17 | 0 | 65.53 | 10.88 | 10.06 | 13.53 | 0.031 |

| N1-1 | 0 | 66.57 | 6.40 | 11.00 | 16.03 | 0.025 |

| No. | Micropore Proportion (%) | Mesopore Proportion (%) | Macropore Proportion (%) | ||

|---|---|---|---|---|---|

| 50–100 nm | 100–1000 nm | >1000 nm | |||

| N10-1 | 17.73 | 47.78 | 3.20 | 14.63 | 16.56 |

| N10-5 | 13.46 | 25.43 | 10.30 | 21.62 | 29.19 |

| N10-8 | 11.93 | 56.01 | 0.14 | 12.31 | 19.56 |

| N10-17 | 11.33 | 34.69 | 17.04 | 15.76 | 21.19 |

| N1-1 | 14.32 | 42.13 | 5.93 | 16.13 | 23.67 |

| Average | 13.75 | 41.21 | 7.32 | 16.09 | 22.03 |

| No. | P/P0 < 0.45 | P/P0 > 0.45 | ||||

|---|---|---|---|---|---|---|

| Fitting Equation | Fractal Dimension | Adj. R-Squared (R2) | Fitting Equation | Fractal Dimension | Adj. R-Squared (R2) | |

| N10-1 | y = −0.440x + 2.126 | 2.569 | 0.979 | y = −0.159x + 2.171 | 2.841 | 0.988 |

| N10-2 | y = −0.433x + 1.838 | 2.567 | 0.987 | y = −0.169x + 1.887 | 2.831 | 0.983 |

| N10-4 | y = −0.538x + 1.712 | 2.463 | 0.958 | y = −0.133x + 1.792 | 2.867 | 0.963 |

| N10-5 | y = −0.489x + 2.079 | 2.511 | 0.973 | y = −1483x + 2.316 | 2.852 | 0.976 |

| N10-6 | y = −0.525x + 1.880 | 2.475 | 0.974 | y = −0.184x + 1.918 | 2.826 | 0.991 |

| N10-7 | y = −0.706x + 1.550 | 2.294 | 0.971 | y = −0.160x + 1.665 | 2.840 | 0.950 |

| N10-10 | y = −0.607x + 1.456 | 2.393 | 0.955 | y = −0.151x + 1.534 | 2.849 | 0.969 |

| N1-8 | y = −0.677x + 1.500 | 2.323 | 0.962 | y = −0.178x + 1.625 | 2.822 | 0.972 |

| N1-9 | y = −0.493x + 1.660 | 2.507 | 0.977 | y = −0.164x + 1.722 | 2.836 | 0.981 |

| N1-11 | y = −0.502x + 1.939 | 2.498 | 0.979 | y = −0.200x + 1.783 | 2.800 | 0.985 |

| N10-13 | y = −0.442x + 2.067 | 2.558 | 0.980 | y = −0.153x + 2.115 | 2.857 | 0.985 |

| No. | Fitting Equation | Fractal Dimension | Adj. R-Squared (R2) |

|---|---|---|---|

| N10-2 | y = 0.633x + 2.356 | 2.633 | 0.931 |

| N10-4 | y = 0.844x + 1.986 | 2.844 | 0.902 |

| N10-5 | y = 0.534x + 1.889 | 2.534 | 0.833 |

| N10-6 | y = 0.803x + 2.065 | 2.803 | 0.882 |

| N10-8 | y = 0.648x + 2.763 | 2.854 | 0.925 |

| N10-10 | y = 0.689x + 1.879 | 2.912 | 0.933 |

| N10-12 | y = 0.769x + 2.451 | 2.924 | 0.912 |

| N10-13 | y = 0.274x + 1.987 | 2.274 | 0.890 |

| N10-15 | y = 0.489x + 2.721 | 2.778 | 0.895 |

| N1-2 | y = 0.571x + 2.146 | 2.758 | 0.886 |

| N1-5 | y = 0.787x + 1.848 | 2.864 | 0.942 |

| N1-9 | y = 0.596x + 2.236 | 2.596 | 0.923 |

| N1-11 | y = 0.700x + 1.848 | 2.700 | 0.934 |

| N1-13 | y = 0.844x + 2.007 | 2.699 | 0.936 |

| N1-20 | y = 0.498x + 1.791 | 2.905 | 0.899 |

| Calculation Method | Nitrogen Adsorption Method (Dn) | Mercury Intrusion Method (Dm) | |

|---|---|---|---|

| In the van Edward Force Stage (Dn1) | In the Capillary Force Stage (Dn2) | ||

| Diameter interval | 1–4.5 nm | 4.5–50 nm | >50 nm |

| Maximum value | 2.569 | 2.857 | 2.924 |

| Minimum value | 2.323 | 2.800 | 2.534 (removed N10-13) |

| Average value | 2.469 | 2.839 | 2.772 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Tang, H.; Zheng, M. Micropore Structural Heterogeneity of Siliceous Shale Reservoir of the Longmaxi Formation in the Southern Sichuan Basin, China. Minerals 2019, 9, 548. https://doi.org/10.3390/min9090548

Li H, Tang H, Zheng M. Micropore Structural Heterogeneity of Siliceous Shale Reservoir of the Longmaxi Formation in the Southern Sichuan Basin, China. Minerals. 2019; 9(9):548. https://doi.org/10.3390/min9090548

Chicago/Turabian StyleLi, Hu, Hongming Tang, and Majia Zheng. 2019. "Micropore Structural Heterogeneity of Siliceous Shale Reservoir of the Longmaxi Formation in the Southern Sichuan Basin, China" Minerals 9, no. 9: 548. https://doi.org/10.3390/min9090548

APA StyleLi, H., Tang, H., & Zheng, M. (2019). Micropore Structural Heterogeneity of Siliceous Shale Reservoir of the Longmaxi Formation in the Southern Sichuan Basin, China. Minerals, 9(9), 548. https://doi.org/10.3390/min9090548