1. Introduction

For natural reasons, the Russian Federation controls mineral resources, unique in terms of both the reserves and diversity, and a major share of its territory is occupied by natural ecosystems. The available reserves entirely cover the domestic demand for minerals. However, the Russian mining and minerals industry is mainly composed of long-term projects. The current high consumption level of resources and energy by the mining industry is a major obstacle to upgrades and retrofits at the existing projects.

The adverse impacts of the industry on the environment have acquired a long-term character in the mining regions. Prevention and mitigation of the environmental damage is often impracticable given the engineering and economic resources available to the industry and the existing environmental safety regulations.

Mining waste is composed of overburden and host rock piles, low-grade ore, processing tailings, waste generated by the coal industry, ferrous and non-ferrous metals, and building materials industries. In Russia, mining waste dumps occupy a combined area of more than 300,000 ha [

1,

2]. According to the Ministry of Natural Resources and Environment, the Russian mining and minerals industry has over at least the past 100 years accumulated 100 billion tons of waste in tailings and mining waste dumps. Therefore, developing and commercializing efficient processing methods for the MMPW to mitigate the adverse environmental impact and potentially recover the minerals held therein is highly relevant.

Regardless of the fact that MMPW, given its mineral composition, allows further processing, the economic feasibility of its further processing and disposal of the resulting waste needs to be examined. The findings of such feasibility studies should serve as a starting point for decision–making on waste processing.

The problem is aggravated by the fact that the existing mineral reserve calculation methodology is not fully meant to take into consideration parameters such as the prospective use of anthropogenic resources, MMPW life cycle, changes in the valuable component grade, business environment, motivation behind waste processing, potential environmental and economic risks, in addition to those involved in the reserve calculation, etc. [

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14].

Furthermore, calculating reserves, including those in anthropogenic deposits, is known to be a costly procedure, involving geological, economic, and specialized engineering and environmental assessments. Consequently, the outcome, to a large extent, is determined not only by the value of the resources held in the waste, but also by the costs involved in the preparation, approval, and implementation of an MMPW processing project that a potential investor can afford.

30 years ago, a classification of anthropogenic mineral resources was proposed in the USSR (Union of Soviet Socialist Republics) [

15].

The classification included the following main categories:

- -

anthropogenic mineral resources encompass all anthropogenic mineral raw materials in MMPW within a region or a country;

- -

anthropogenic mineral resources (AMR) are minerals on the surface or underground formed as a result of separation from the mineral mass and storage as MMPW;

- -

anthropogenic deposits are AMR holding mineral resources capable of being efficiently recovered in the existing or future industrial processes;

- -

anthropogenic mineral body is a conventional spatial accumulation of anthropogenic minerals satisfying the industry standards and having constant properties.

In this paper, we examine some environmental and business challenges of MMPW processing, both in Russia and other economies.

2. Supergene Processes under MMPW Storage. Environmental Footprint and Processing Challenges

The problem of environmental safety of MMPW storage is a challenging issue globally [

16]. In the Russian Federation, this problem is further complicated by the fact that the relatively low-grade mineral resources being extracted are often unconventional and contain more than one valuable component. This leads to unavoidable losses of the valuable components in ore concentration processes and conversion into MMPW. Another distinctive feature is the geographical location of the Russian mineral resources. A major share of the commercial deposits is situated in the Far North and Siberia.

It is worth noting that the composition and properties changes in the minerals under MMPW storage occur considerably faster than in a natural geological setting. One of the factors intensifying supergene processes is activation of the mineral surfaces, which takes place when they are crushed and ground. The degree of this alteration depends on the particle size of the MMPW, porosity and chemical composition of the wastes, and potential for acid mine drainage (AMD). Depending on the above properties, this process may occur mainly in the top surface layers of the tailings and in the areas acting as selective water channels in the waste dump.

The findings presented below, using Murmansk Region, a major Russian mining region, as a case study, confirm that MMPW cause environmental damage even after the exhaustion of the deposit. In the storage process, MMPW composition undergoes significant changes of the process properties of the recoverable minerals. Consequently, the potential value of the AMR as a mineral resource decreases.

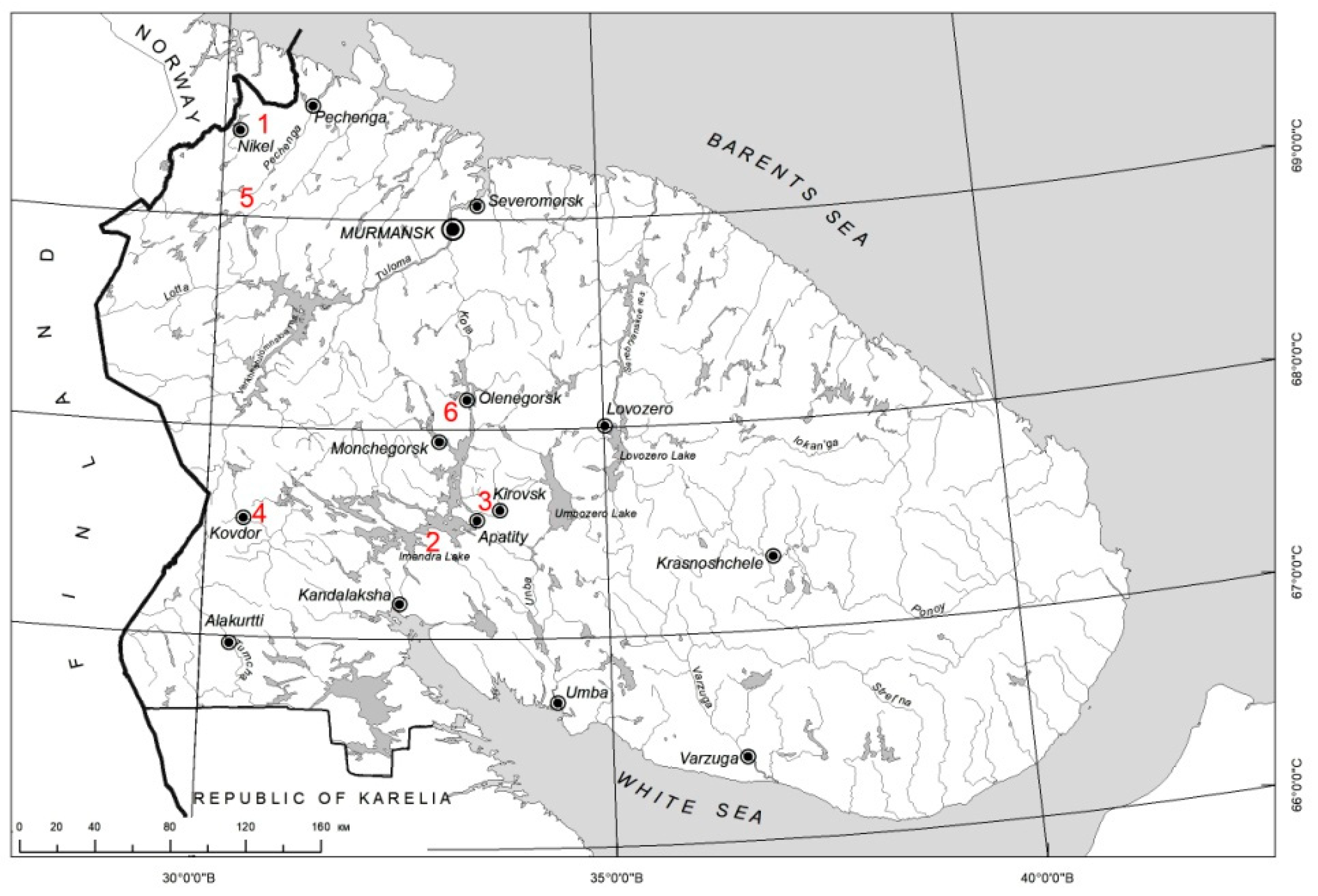

Table 1 presents some of the tailings ponds of the mineral processing industry in Murmansk Region examined in this paper. A location map of the MMPW sites discussed in

Section 2 is shown in

Figure 1.

2.1. Allarechensk Copper-Nickel Mining Waste Dump

Allarechensk Copper-Nickel Mining Waste Dump is located in Pechenga District, Murmansk Region. It holds the mining wastes of the Allarechensk sulfide copper-nickel ore deposit. The deposit was developed as an open pit mine until exhaustion in 1971. The main valuable metals in the deposit were nickel, copper, cobalt [

17]. The dump’s rocks are mineralized peridotites, olivinites, contact amphibolites, etc. Total surface area of the waste dump is 33 ha, and the rock volume amounts to 6.7 million m

3. The dump is an uneven-grained mix of loose quaternary and hard rock discarded as mining waste, including several types of sulfide copper-nickel ores and a wide range of mineral grades. Dumping was carried out by bulldozers by leveling the delivered and unloaded rock on the dump site and by pushing the material down the slope along the edges. The dump was deposited in layers up to 2.0 m thick with benches ranging between 4.5 m and 17.5–20 m. In some areas, the benches merged into a continuous slope at least 40 m high. The particle size distribution of the waste rock is heterogeneous and has the following average values: (500–2000 mm)—5–15%; (300–500 mm)—15–25%; (150–300 mm)—25–35%; (5–150 mm)—25–30%; (minus 5 mm)—10–15%. The ores are of two morphological types—bulk and disseminated. The main ore minerals of both ore types are pyrrhotite, pentlandite, and to a lesser extent chalcopyrite intergrown with magnetite. The bulk of the ore mass is composed of the fractions 40–150 mm. However, disseminated ore fragments can be one meter and larger in size.

Weathering effects on the primary ores during the long-term storage in the dump and the related supergene processes have resulted in the development of oxidized ores. As a result of oxidation and dissolution, a considerable share of the ore has lost its original grade. High-grade primary ores have developed the following mineral composition: Ni 18%, Cu 8%, Co 0.3% [

17]. Their oxidized counterparts have grades not higher than: Ni 3.3%, Cu 2.0%, Co 0.05%. Considering the high permeability of the ore material in the waste dump, these processes are also recorded at a depth of several meters under the surface.

Massive pyrrhotite-pentlandite ores are mostly exposed to supergene processes due to the chemical and physical instability of their main constituent minerals and their increased oxidation potential. This can be observed visually: ore fragments are covered by a crust of iron hydroxides and these start to peel off. Apart from physical breakage, the ore undergoes continuous chemical reactions. As a result of the chemical changes, characteristic supergene minerals form. This is an extensive phenomenon. The continuous presence of violarite in the ores draws attention, as well as the ubiquitous retgersite, forming easy-to-see blue-green leakages in the host rocks. The mineral is partially accumulated as the fine grain fraction, and due to its high dissolution ability, is leached away with atmospheric precipitates and flood waters deeper into the dump and into the surrounding environment.

Regardless of the fact that the site is geographically located in the subarctic zone, thionic acidophilic ferrous and sulfur-oxidizing bacteria, accelerating sulfide leaching, were found in the water and ore samples.

Experimental modeling of the supergene processes demonstrated a high rate of non-ferrous metals transition into soluble forms during the interaction of the AMR with diluted sulfuric acid [

17]. The lack of chemically-active rock-forming alkaline minerals in the ore, capable of neutralizing AMD, and the occasional acidic rain in the region significantly accelerate the supergene alteration rate of the sulfide minerals, as well as the transition of environmentally hazardous elements into active forms.

Surface water examination as part of the environmental monitoring revealed nickel pollution in all of the water bodies located close to and downstream of the AMR. Concentration of Ni was 3–79 times the maximum permissible concentration (MPC), the highest observed values were 4736 times the MPC (0.01 mg/L). The normal ion distribution, characteristic of freshwater lakes, was upset in all the water bodies. The soils were no less contaminated than the lakes. For instance, in the top organic soil horizon of the marsh 300 m to the south of the AMR, the heavy metal concentrations exceeded the normal background values for nickel by a factor of 877, for copper by a factor of 227, for cobalt by a factor of 61 [

17].

Due to the anthropogenic stress, progressive ecosystem degradation is observed in the areas adjacent to the AMR sites. Some sites have developed into anthropogenic badlands. In addition, the disturbed area exceeds the dump waste footprint.

Consequently, even in the early stages of the AMR storage, disintegration of ore materials is observed. As a result, its process properties deteriorate, valuable components are diluted and migrate to the lower levels due to supergene processes. The long-term storage phase is characterized by a major contamination of the environment [

17].

2.2. Copper-Nickel Ore Flotation Tailings

A comparison of two AMR—the tailings storage facility at Pechenganickel Plant 1, JSC Kola MMC, in Zapolyarny, Murmansk Region, which is in operation at present, and the processing tailings of copper-nickel ores from the Afrikanda pilot plant, Murmansk Region, decommissioned 40 years ago, demonstrated the effects of the supergene processes.

First and foremost, significant oxidation of the sulfide minerals and replacement by ferrous hydroxides was observed. Comparing the primary mineral’s chemical composition with the newly formed minerals suggests the following sequence of supergene processes: similar to the Allarechensk Copper-Nickel Mining Waste Dump, pyrrhotite oxidation with formation of sulfuric acid takes place in the tailings, which affects both the pyrrhotite and the accompanying pentlandite. As a result of this effect, violarite forms on the pentlandite surface, which results in an increased porosity and accelerated mineral weathering. Higher content of chlorites and hydro-chlorites in the tailings, as well as the nearly complete disappearance of calcite CaCO

3 and development of gypsum CaSO

4·2H

2O can be explained by the supergene processes [

17,

18].

The content of metals in the pore solutions of recently produced tailings is 5–30 times lower than in aged tailings. Regardless of the fact that the pH of the solutions is higher than 7.8 in all samples, heavy metals concentrations significantly exceed the fisheries MPC: nickel on the average by a factor of 486, copper by a factor of 394, and cobalt by a factor of 102. This situation has existed (and even worsened) for a long period of time after the decommissioning of the facility [

17,

18].

In tailings storage, not only metal contents, but also their form, specifically the ratio of the sulfide and oxygen-containing phases, change. Due to supergene processes, ratio redistribution of silicate and sulfide forms of nickel to the benefit of the former takes place [

18]. Silicate nickel content in the current tailings amounts to 10% on the average, while in the storage tailings it reaches 40%. Nickel migration in the form of sulfates and its precipitation by chemically-active silicates distort the distribution of nickel across the fine and coarse size classes, characteristic of the current copper-nickel ore tailings.

Monitoring at the AMR and pilot experiments showed that the supergene effects have resulted in a substantial change in the process properties of both the ores and rock-forming minerals [

19]. Alterations in the process properties of the minerals were studied in both concentration tailings of different ages and copper and nickel ore samples oxidized in a laboratory setting. The tailings were sampled down to a depth of 2 m. It was established that the use of the traditional AMR processing methods is ineffective: a reduction of sulfides floatability and an increased loss of valuable components with the water-soluble form and in the flotation tailings were observed. The flow rate of the flotation reagents increased. The research allows one to conclude that the supergene processes reduce the value of the AMR.

2.3. Apatite Flotation Tailings of JSC Apatit Concentrators

Apatite flotation tailings of JSC Apatit concentrators are known to be the largest multiple-aged AMR in Murmansk Region. The tailings storage facility at the apatite-nepheline plant 1 (ANOF 1) is situated on the Belaya River, 3 km from the town of Kirovsk. In 1957–1962, it was filled with concentration wastes of the Kukisvumchorr and Jukspor deposits. The tailings storage facility of the apatite-nepheline plant 2 (ANOF 2) is situated in the Belaya Bay of Lake Imandra, 1.5 km to the north-west of the industrial site. The plant has been in operation since 1968. The tailings storage facility, which is located 3 km from the community of Titan, has been operated since 1963. Between 1963 and 1992, it was receiving mineral processing waste from ANOF 1. After 1989, it was supplied with the waste from apatite-nepheline plant 3 (ANOF 3) processing the Koashva and Nyorkpakhk ores. Characteristics of these tailings ponds are given in

Table 1.

The main minerals in the tailings are nepheline, feldspars, aegirine. The mineral composition includes also apatite, titanite, magnetite, titanomagnetite, ilmenite, and nepheline secondary minerals, such as natrolite, annite, lepidomelane and liebnerite. Due to high nepheline content (from 52% to 60%) the tailings should be viewed as a feed for the production of alumina, potash, soda and portland cement, using the sintering process.

The geology of the multiple-aged concentration tailings of apatite-nepheline ores has been studied before [

20,

21]. It was found that, alongside some consolidation of the mineral matrix of the engineered soil, its particle size distribution was altered. Comparing the share of fine-dispersed particles in the tailings upper layers revealed that their content markedly decreased during the storage process. These layers are 1.5–2 m thick. However, one can notice a change in the true density of differently sized particles. Particle density of the currently produced tailings is nearly the same. The longer the period of storage, the greater is the difference in the true density of coarse and fine particles. The true density of the coarse particles decreases, while that of the fine ones increases. This fact can be explained by suffusion. The finest and the lightest material is carried away with the hydrolytic decomposition of silicates. Due to this, materials most resistant to supergene alteration are accumulated in the fine particle sizes: titanomagnetite, ilmenite, and aegirine. In the coarse particle sizes, partial substitution of nepheline by its supergene transformation products leads to a true density decrease. Eolian factor plays a substantial role in the upper horizons.

Pore solution analysis of the tailings demonstrated concentrations of aluminum (8–12.5× MPC (MPC 0.04 mg/L)), strontium (1–1.2× MPC (MPC 0.4 mg/L)), fluorine (5–8× MPC (MPC 0.75 mg/L)) dangerous for the ecosystems of fishery water bodies [

20].

In the early 2000s, JSC Apatit and JSC Murmansk Geological Survey undertook geological exploration for apatite-nepheline ores at ANOF 1 tailings storage facility [

22]. It was shown that the AMR could be conventionally divided into four horizons (levels) 4 to 6 m thick. Particle size composition analysis of the tailings and apatite content revealed that all the horizons, with the exception of the upper layer, are characterized by slime-sized apatite. Apatite yields in the size class minus 40 µm are 20 to 90% and increase from the first to the fourth horizon. Apatite fine particles size can be explained by the fact that the tailings mostly contain the mineral lost from the slimes during the dehydration of the apatite concentrate. Apatite distribution by particle size in the tailings horizons is related both to the pulp washing direction and suffusion phenomena during the storage, when fine fractions with a high apatite content were carried to the lower horizons.

It was found that a special technology, mostly for the dewatering and drying processes, had to be developed for the processing of the ANOF 1 tailings. In this case, the resulting apatite concentrate will be by more than 70% composed of the size class minus 40 µm. The poor pilot flotation performance at JSC Apatit resulted in the economic infeasibility of the AMR development [

22].

2.4. Wet Magnetic Separation Tailings at JSC Kovdorsky GOK

Flotation tailings reprocessing by wet magnetic separation to recover apatite and baddeleyite concentrate was implemented at JSC Kovdorsky GOK in 1995, which is considered to be a major achievement in the AMR processing in Russia [

23]. The AMR formed during the operating period of JSC Kovdorsky GOK, when only magnetite was recovered from the ore, while apatite and baddeleyite were dumped in the tailings. The AMR is composed of two sites: the south-eastern (150.4 ha, with a depth of up to 30 m) and the north-western (34.2 ha, with a depth of about 15 m). The two sites are divided by the former circulating water pond. The maximum width of the mineral body reaches 1000 m, the minimum is 150 m. The length of the tailings storage facility is about 4 km.

The tailings dump was initially mined by removing horizons 3 to 8 m thick. To extract the reserves below the groundwater horizon, surface water discharge and tailings dewatering were implemented. To monitor the dehydration process, 24 boreholes were drilled.

Process parameters of the storage tailings concentration during the initial period (from 1995 to 2001) were comparable to those of the primary ore. P

2O

5 recovery into the apatite concentrate was 60–62%, ZrO

2 recovery into the baddeleyite concentrate was 23–25% [

23]. However, due to increasing involvement of the lower horizons into processing, the recovery of P

2O

5 into apatite concentrate decreased by 3–5%. It was estimated that the elevated concentration of fine particles, the presence of products due to disintegration of flotation reagents, the increased content of iron oxides and hydroxides, as well as the presence of secondary alterations on the mineral surface explained the low recovery of P

2O

5 from the tailings [

23].

To produce saleable apatite concentrate, reagent regimes and process schemes of flotation were modified to a significant degree. To activate the fine-grained apatite, attrition combined with washing in the diluted and thick pulps, selective flocculation, heat processing, advanced reagent floatation regimes, and other processes were tested [

23]. Three samples were examined with −0.071 mm size yields between 57% and 75.5%. Sample flotation without preliminary grinding and after attrition, as well as grinding for 1–3 min, do not allow to achieve the required process parameters. Favorable results are observed under integrated treatment of the fine-grained products, which includes deep grinding, raising of pulp temperature up to 25–28 °C, and adding sulfite waste liquor as the depressant instead of liquid glass or a mixture thereof. One of the main factors to be taken into consideration, while preparing the given raw materials for flotation, is the desliming level of the newly ground product. It was estimated that the optimal slime minus 20 µm yield was 12–19%. The highest quality of the apatite concentrate (P

2O

5 grade up to 39.7% at a recovery of more than 64%) is achieved by feeding liquid glass to the rougher flotation, and sulfite waste liquor to the I cleaner flotation [

23].

An advanced method was developed for the processing of fine-grained sands containing 55–65% of the size class minus 0.071 mm [

24]. The concentration process of the aged tailings included the following stages: unloading of the feed into a feeder hopper through a static screen; removing the metallic (ferrous) waste in a magnetic separator; crushing the frozen clumps (in the winter period) down to 100–150 mm in a rotor-screw crusher; transporting with belt conveyor into an intermediate ore hopper; feed comminution down to 6–10 mm in a scrubber-washing trommel to eliminate the impurities; transferring of the re-pulped material into the comminution section; removal of the primary slimes up to 5%; grinding of the feed material to rejuvenate and activate the mineral surfaces; classification; secondary desliming; pulp conditioning with flotation reagents; flotation (rougher flotation, scavenger and three cleaner operations); thickening, filtration, and drying of the apatite concentrate; production of rougher baddeleyite concentrate from the flotation tailings using gravitation and flotation processes. Following flotation reagents were fed: tall oil fatty acid fraction, foaming regulator M-246, soda ash as a pH regulator, spent sulfite liquor as a rock mineral depressant.

2.5. Overburden Rock of the Olenegorsky Iron Ore Deposits

Several major iron ore deposits are located in the Olenegorsky mining region (in Murmansk Region): the Olenegorsky deposit, the Kirovogorsky deposit, the Komsomolsky deposit, the Bauman deposit, the 25th Anniversary deposit, all operated by JSC Olkon (Olenegorsky GOK). The maximum annual ore production in the 1980s was up to 20 Mt. 8.5 Mt of magnetite concentrate was shipped [

25].

The rock mass, containing ferruginous quartzites, is represented mostly by formations (sheet deposits) of amphibolic, biotite-amphibolic, and biotite gneisses, garnet-biotite calciphyres, garnet-biotite gneisses with single beds of feldspars, corniferrous, tremolitic, gedrite, and garnetiferrous amphibolites. Amphibolic and biotite-amphibolic gneisses predominate.

The host rocks of the Olenegorsky deposit of ferruginous quartzites were mined for construction-grade crushed stone. Analysis findings, both of the rock and crushed stone properties, are presented in [

25].

Studies were undertaken to assess the viability of processing the overburden rock stored in the dumps into crushed stone. It was found that the physico-mechanical properties of the crushed stone considerably deteriorated in the rocks stored in the dumps longer than 15–20 years.

Table 2 presents the crushing performance of the overburden rock from the dumps of the Olenegorsky iron ore deposit depending on the storage time [

25]. As can be seen from the table, the crushing performance deteriorates.

3. Losses and Lost Profit Caused by the Long-Term Storage of the AMR

The existing legal framework of MMPW processing in Russia does not take into consideration the main economic factors: depletion of the reserves and the infrastructural factor. Using the Allarechensk Copper-Nickel Mining Waste Dump as a case study, we will examine the losses and lost profit caused by the long-term storage of the AMR.

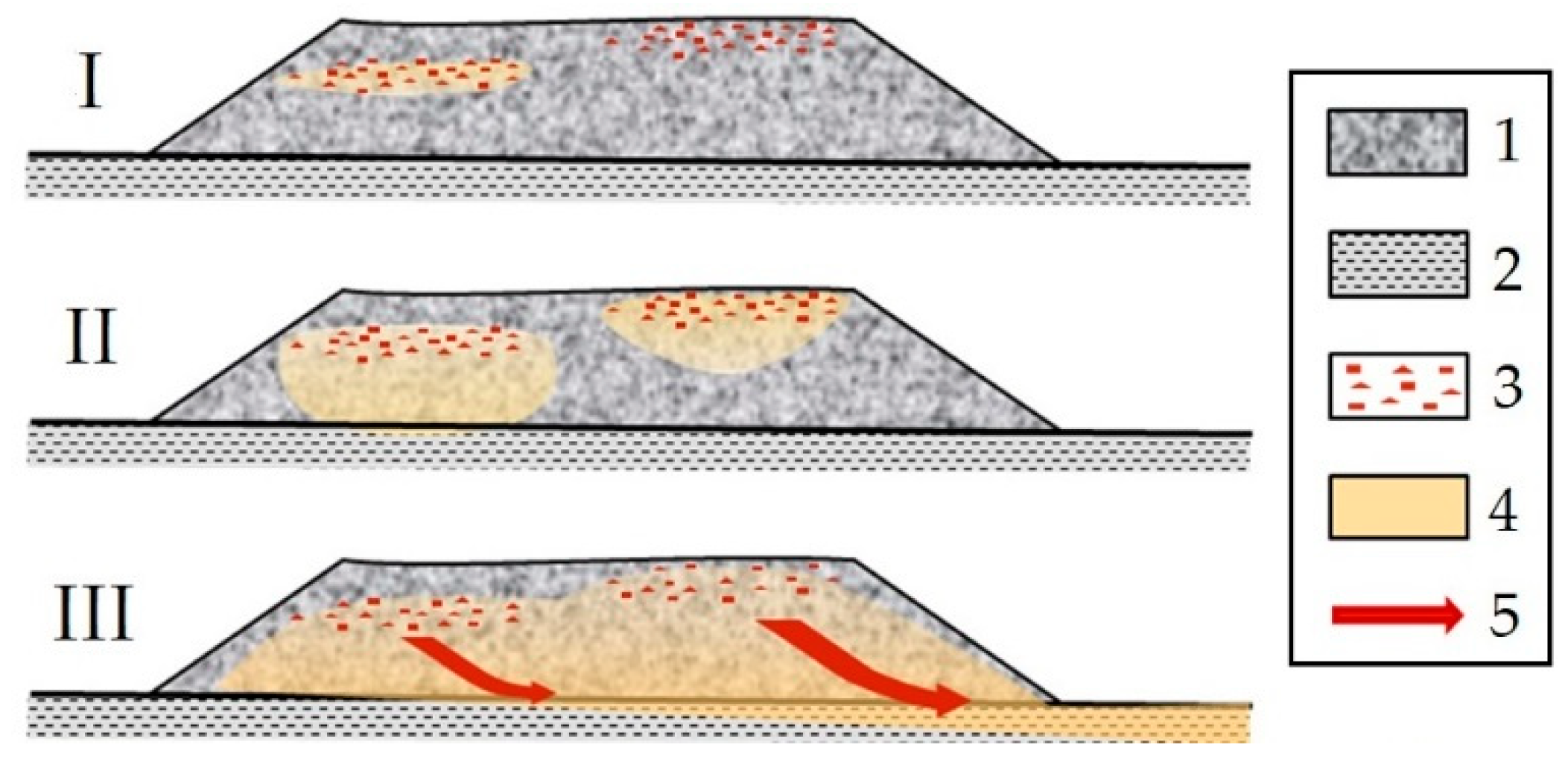

The entire storage period at any MMPW disposal site can be conventionally divided into stages (phases), each of which describes the condition of the site and the extent of the changes in it (

Figure 2). The initial stage of the site development is characterized by the accumulation of mineral resources. Ore components preserve their initial properties in this stage.

Later on, in the early stage of storage, ore disintegration starts, and as a consequence, deterioration of its process properties and dilution of the valuable components, as these start to migrate to the lower horizons due to the supergene processes. The long-term storage stage is characterized by a considerable decline in the reserves over time and a large-scale contamination of the environment in some situation, for example, if MMPW contain sulfides. In a later stage, the site loses its industrial value, and the territory is considered contaminated.

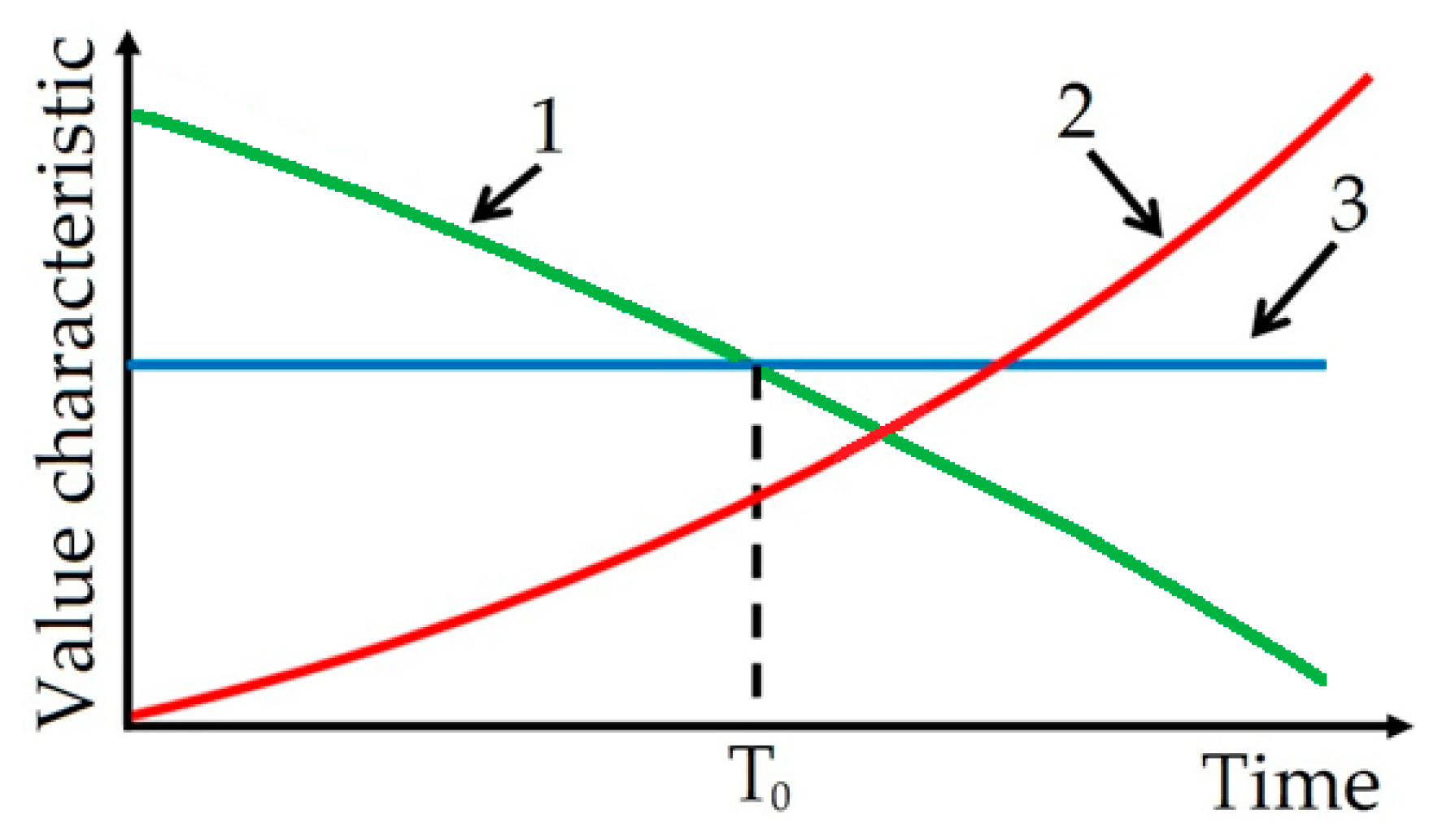

The described stages can be illustrated by a diagram of loss accumulation as a function of the storage time on the site (

Figure 3). In the initial storage stage, MMPW disposal can be economically viable. As time goes on (point T

0 in the diagram), the utility of the mineral resources becomes lower compared to the recovery costs. Consequently, the mining waste dump loses its value and becomes a source of negative environmental impacts. Mitigation and mining waste disposal will require considerable maintenance [

26]. In the case of the Allarechensk Mining Waste Dump, the total environmental costs can be estimated.

Here, one should also take into account the avoided MMPW reclamation costs if the sites are processed and valuable minerals are recovered, for example, non-ferrous metal sulfides. Such processing is expected to reduce the environmental burden.

3.1. Calculation of Losses and Lost Profit Caused by the Long-Term Storage of the AMR

3.1.1. Losses due to the Decline in the Reserves

Currently, approximately 4%, or 250 tons, of the total nickel in the AMR of the Allarechensk Mining Waste Dump (including resources and reserves) is sulfates, which can be classified as a process loss. The overall loss of metallic nickel due to migration to the lower horizons and outside the dump site during the storage period can be easily estimated. As shown in [

17,

26], all sulfide ore types in the original Allarechensk Mining Waste Dump had same ore mineralogy and differed only in quantitative ratios. However, nickel and copper ratios varied, though nickel dominated. Nickel and copper ratio in the massive ores was 3.3:1, in the high-grade disseminated ore 2.7:1, in the low-grade disseminated ore 2.3:1, in the mineralized host rocks 0.9:1. The share of massive ores in the total reserves of the deposit was 20%, of high-grade disseminated ores—47%, of low-grade disseminated ores—33%. Consequently, the average weighted Ni/Cu ratio in the deposit was within 2.6–2.7:1.

However, the Ni/Cu ratio in the Allarechensk Mining Waste Dump was altered. For example, the Ni/Cu ratio in the size class plus 40 mm coincided with the primary deposit and varied depending on the dominant ore type. However, starting at the size class with minus 40 mm, the Ni/Cu ratio consistently decreased and reached the minimum value of 0.3. On average, it was 0.6 in the size class minus 10 mm. However, the copper content remained stable in all examined size classes, slightly varying from 0.4% to 0.6%.

The size class minus 10 mm composed 20–30% of the total volume of the dump and contained about 30–35% of all copper [

26]. Consequently, if we assume the minimum estimated total copper reserves in the dump to be 2500 tons, we can estimate that these size classes contain no less than 800 tons of copper. Taking into account the natural Ni/Cu ratio, it should contain no less than 1700 tons of nickel. Nevertheless, the true nickel content is 800 × 0.6 = 480 tons. Consequently, during the 45 years of storage, more than 1200 tons of nickel, namely 20% of the reserves originally accumulated in the dump, migrated outside the dump site and to the lower horizons.

If we assume the average nickel price to be US$ 12,000 per ton, the estimated loss caused by the decline in the AMR reserves of the Allarechensk Mining Waste Dump exceeds US$ 14,000,000 over the 40 years of storage.

3.1.2. Environmental Damage

Environmental damage

D can be estimated according to the method described in [

27] as follows:

where

is the damage caused by the disposal of 1 ton of mining waste, calculated as follows:

where

is standard land reclamation costs, ₽/ha;

S is the area of the waste dump, ha;

is the environmental value index of the soils and land resources in the given economic region of the Russian Federation;

is the atmospheric pollution index;

is the effective pollution load, conventional tons;

is the environmental value index of the atmospheric airin the given economic region of the Russian Federation;

is the amount of waste on the dump site, tons;

is the waste hazard index.

The indices calculated according to the described method for the AMR of the Allarechensk Mining Waste Dump are:

= 115.6 ₽ in 1999 prices [

27]. It should be noted that the method assumes annual indexing of price parameters, but no indexing was done;

= 2.5 assuming sulfide waste of hazard class II–III [

27].

We assume a RUB to USD exchange rate of 60:1, thus 115.6 ₽ = US$ 1.93.

Thus, according to the formula (1), the following environmental damage was caused to the soils and land resources at Allarechensk:

D = 1.93 × 2.5 × 12 million tons = US$ 57.9 million.

Apart from the direct damage, the indirect one should also be mentioned, such as the socioeconomic losses due to the reduction in the AMR, reduction of budgetary allocations and taxes, loss of jobs, health effects on the local residents as a result of the MMPW, loss of biological resources, and other damage.

4. Marginal Cost of the Minerals Recovered from the AMR

4.1. The Existing Regulatory Framework of AMR Processing

The AMR are characterized by low profitability of processing. The marginal cost of the extracted minerals is determined by the existing regulatory framework of the Russian Federation, namely the provisions of the Federal Law (FL) 2395-1 On the Mineral Resources [

28].

Pre-commissioning and operation of an AMR processing project is complicated and prolonged as similarly to conventional deposits, it must include the following stages: obtaining a prospecting and mining license; phased geological survey; planning an AMR extraction project; obtaining a license to process the AMR; support of minerals recovery from the AMR.

The procedure of launching AMR processing gives rise to criticism, as in compliance with the requirements of the FL 2395-1, it should be conducted on a competitive basis (by tender). However, holding a tender is problematic in the context of weak demand and AMR of national significance risk never being extracted.

Given the weak interest of the investors, licenses to extract mineral resources from AMR should be issued free of charge based on a processing project employing an advanced technology or based on a project competition if the project is of interest for several businesses.

In general, the AMR reserves are minor compared to Russia’s primary mineral resources. Given the cross-border nature of the majority of mining and metals companies and the use of tolling schemes, the AMR have no effect on the national strategic potential. However, mining businesses are required to maintain a geologic survey function over the period of AMR commissioning and extraction, which affects the economic viability of the project.

Low volume of the reserves and poor exploration quality, especially for coarse waste, predetermine errors in reserve estimates. This predetermines problems at the deregistration of the reserves in future. In case the reserves deviate by more than 20% (and this is very likely, considering the minor AMR reserves), geological and economic re-evaluation and recalculation of the reserves and re-approval by the regional reserves commission of the Federal Agency for Mineral Reserves is required.

Considerable investment into the frozen exploration projects of AMR could significantly influence business profitability.

Nevertheless, after the AMR reserves have been registered, the site is assigned the AMR status. As the result, the enterprise processing the AMR is considered a full-fledged mining and processing project, for which development of the design documentation can be carried out only by an organization holding a self-regulating organization certificate (SROC). Design scope and necessary approvals and expert reviews of the project documentation include: geological surveys; reasoning of the feasibility study; development of an MMPW mining project; state expert review of the project documentation as part of an expert review of the design solutions, expert review of industrial safety and environmental safety review; design approval in the Central Committee for the development of solid mineral resources at the Federal Agency for Mineral Resources.

Approval of the mining site’s boundaries by the Federal Service for Environmental, Technology and Nuclear Power Supervision (Rostekhnadzor) is a necessary condition of the mining license, to which a mining lease certificate is attached. This document is issued only on the basis of all the necessary approvals and expert reviews of the project. However, if the project is not considered as a mining one, only environmental safety review is required. Any organization could implement the project without holding a SROC certificate.

The amendments in 2012–2013 aimed at simplifying the mineral resources management procedures, specifically by declassifying projects aimed at “extracting common mineral resources and developing placer deposits of mineral resources by open-cut mining without the use of rock blasting” as hazardous industrial sites (HIS), did not cover AMR. In accordance with the existing FL 116-FZ On the Industrial Safety of Hazardous Industrial Sites [

29], the HIS are classified not by the actual evidence of existing hazard, but by the category of the extracted or produced minerals. Consequently, even if the ore is mined manually, it would be classified by the Rostekhnadzor as a hazardous industrial site in Class III (of the four classes regulated by the federal law), and all the consequences of this classification would apply. For example, in case of entering an agreement with a licensed surveyor, it will take additional expenses.

Thus, the existing statutory and regulatory rules for AMR mining cause major economic loss. This approach may be justified in individual projects. For example, it is justified for the unique pyrrhotite and magnetite sands and slag dumps at the Zapolyarny branch, PJSC MMC Norilsk Nickel, Norilsk, Russia [

30]. For instance, pyrrhotite sands contain up to 10 g/t and more of PGM, 0.3 g/t of Au, over 10 g/t of Ag, 1–3% of Ni and Cu, 0.1% of Co. The nickel mill’s slag dumps contain, in addition to nickel (0.04–0.12%), copper (0.2–0.37%), and cobalt (0.05–0.07%), 1 to 2.2 g/t of PGM and Au combined. This does not apply to smaller projects.

For instance, it took six years to plan and design the development of the Allarechensk Mining Waste Dump. During this time, the site suffered a decline in the reserves, caused by the fracture dynamics of the ores during the 40 years, amounting to not less than 180 tons of nickel [

26].

Lake Baryernoye in Norilsk can serve as an example. Until mid-2016, anthropogenic material accumulated in the lake due to the loss of the primary (Ni, Cu, Co) and secondary minerals (Pt, Pd, Ir, Ru, Au, Ag, Se, Te) from the Nickel metals operation (Zapolyarny branch, PJSC MMC Norilsk Nickel, Norilsk, Russia). The material accumulated as sand on the bottom of the lake, which was used as a cooling pond for the circulating water. Several tons of nickel were deposited annually. But to extract it (can be easily done with a dredger), the regulations mandated geological prospecting and exploration and to registering the reserves with the State Reserves Committee (SRC), as soon as the explored reserves have been processed and included in the balance sheet. As a consequence, any processing small business had either to maintain a geological survey function or outsource these services.

It is remarkable that if the operator licensed to process the AMR missed the deadlines for completing the scheduled stages as stipulated in the license, it could be fined by Rosprirodnadzor. Classification of the operator as a mining business, deprives the AMR project of the state support for research and commercialization of innovative technology pursuant to FL 209-FZOn the Development ofSmall and Medium Businesses in the Russian Federation [

31], and of the tax benefits available to waste processors in conformity with FL 7-FZ On Environmental Protection [

32].

4.2. Examples of the Simplified Approval Procedure for AMR Projects in the Russian Federation

Simplifying the procedures of AMR mining and processing was proposed previously. In this connection, in May 2010, the Magadan Regional Duma submitted to the State Duma of the Russian Federation a proposal to streamline the access procedure to anthropogenic placer deposits by amending FL 2395–1. The region has a number of such placer deposits, most of them holding from 1 to 10 kg of gold. However, according to industry experts, the combined potential reserves in the anthropogenic placer deposits may range from 250 to 1000 tons [

33].

However, placer deposits, similarly to gold-bearing concentration tailings, pose environmental hazards, as they contain mercury and other contaminants used in gold amalgamation.

Placer mining is not a highly profitable process, it is rather a social and economic element required to maintain the mining industry in Magadan Region, suffering from skilled labor outflow due to job cuts. Both the regulatory framework and taxation rules should make a provision for these aspects, particularly in the context of placer mining.

A long-term study of gold mining tailings revealed that the free gold content in the tailings is 0.26–0.68 g/m

3, which is higher than the average grade of the operated placers, 0.17–0.25 g/m

3. Large-scale processing of gold mining tailings using high performance modular plants will be instrumental in recovering free gold and concentrate with a gold grade of up to 500 g/t, followed by further processing [

33].

The transition to a new method of mineral recovery from placers will provide (in Magadan Region) the following benefits: stabilize gold production at 15–20 tons of gold per year; create new jobs for a long period of time; completely reclaim the sites contaminated by gold mining.

The following conditions should be met to switch to the new placer mining technology [

33]:

- -

massive processing of the dump using advanced flushing equipment;

- -

implementing a simplified mineral resource management procedure for placer deposits and reducing the amount of paperwork.

Draft Federal Law on Amendments to the Federal Law on the Mineral Resources proposed the following measures in Magadan Region:

- (1)

licensing AMR mining without holding a tender, based on an opinion issued by a commission established by the federal agency for mineral resources management;

- (2)

authorizing mineral resource operators to extract minerals from the waste dumps within the boundaries of the mining lease without geological prospecting; waiving the requirement of expert review of mineral reserves in respect of waste dumps considered secondary mineral resources. Reserves should be updated based on the actual output in the end of the mining season.

Besides, AMR licensing was suggested to be transferred to the regional level. PJSC ALROSA Diamond Company can be used as an example of the fast-track mechanism in the operation of AMR. In 2013, the Company successfully disputed the claims by Rosprirodnadzor concerning unauthorized extraction of mineral resources and diamond mining from concentration tailings without a license. When processed at JSC Mirninsky GOK, the diamond-containing sands of the placer deposit Vodorazdelnyegalechniki were concentrated at the Processing Plant 5 and then deposited at the tailings storage facility. The sands were concentrated without using chemical reagents by mechanical washing. Processing Plant 5 at the primary placer deposit Vodorazdelnyegalechniki demonstrated a diamond recovery of 88%. The plant and its tailings storage facility had been out of service since October 2004. In 2005 the plant was shut down, and the tailings storage facility was reclaimed in 2010 as part of a dedicated project. Later, further diamond recovery became possible at the existing Processing Plant 3, JSC Mirninsky GOK. As a result, geological exploration was completed on the disposal site of the washed sands, technical documentation was prepared, and the accumulated sands were reclassified as the tailings storage facility of Plant 5 for further processing.

5. Prospects of Amendments to the Russian Regulatory Framework to Promote Investment in MMPW Processing

One of the potential resources to promote the investors’ interest In MMPW processing is the abandonment of the provisions of FL 2395-1, and further development of the tools made available by FL 89-FZ On the Production and Consumption Waste. This can be demonstrated by comparing the business efficiency of the MMPW projects operating under the requirements of the two laws [

27,

34].

For example, if a project meets all the requirements of FL 2395-1, its net profit

P in nominal terms during the entire project life will be:

where

R is the sales revenuesover the entire project life;

L is the mining license cost;

Eg is the geological prospecting costs;

Epr is the project development and approval costs;

EHIF is the costs of the mandatory third-party liability insurance required from operators of hazardous industrial sites;

Egs is the geological and mine survey monitoring costs;

Tmet is the mineral resource extraction tax;

Tp is the corporate tax;

Tot is other taxes and fees;

t is the project life;

Ekex is the capital and operating expenses over the entire project life;

Eab is reclamation costs.

Net profit of a project operating in accordance with FL 89-FZ is given by the following formula:

where

EMMPW is the MMPW acquisition costs.

The second option is obviously commercially more viable. Besides, no capital is frozen for an indefinite time, and the payback period is reduced.

Consequently, to make mining waste processing more attractive to potential investors, the requirements of the Federal Law 2395-1 should be waived.

Due to high economic significance of MMPW processing, mining licenses should be offered free of charge. As soon as this is implemented in FL 89-FZ, the formula (4) will take the form:

Tax preferences can become another motivating factor of supporting investors’ interest in MMPW processing. Taking into consideration the environmental impact of MMPW disposal on the soils, water, and human health, this meets the public interest.

It is quite evident that an MMPW processor should be exempted from mining taxes. In this regard, amendments in the Tax Code of the Russian Federation are essential. According to many economists, corporate tax on revenues from MMPW processing should be waived [

35]. All taxes on MMPW processing should be waived. This can be explained by the fact that the business performance of an MMPW processor is inevitably connected with the prevention of environmental damage caused by the wastes. Damage prevention should prevail over the cost aspects.

Consequently, the net profit formula of an MMPW processor should theoretically take the form:

Considering the significance of the MMPW processing, state support to technology research and development could be of substantial importance to prospective investors and should be legislated as amendments to FL 209-FZ Onthe Development of Small and Medium Businesses in the Russian Federation.

Amendments to FL 224-6-FZ On the Public-Private Partnership and Municipal-Private Partnership in the Russian Federation [

36], namely Article 7.1, classifying MMPW disposal sites as eligible projects would contribute to MMPW management and mining.

In these circumstances, state supervision over MMPW management is advisable to be kept. In this regard, amendments to FL 89-FZ are warranted. Currently, in accordance with this Law, MMPW are classified in hazard classes I–IV. But because of their distinctive properties, they should be classified separately, and a system of licensing by the Federal Service for Supervision of Natural Resource Management should be reinstated.

Therefore, the licensing procedure should be modified. The only requirement for issuing the license should be an MMPW processing project based on an efficient concentration technology and endorsed, for example, by the Federal State Budgetary Institution Fedorovsky Federal Research Institute of Mineral Resources. Before an MMPW processing project can start, an environmental impact assessment has to be conducted and approved.

The Russian Federation can use the positive experience of European Union, where activities related to MMPW are an independent subject of legislative regulation aimed—encouraging waste recovery [

37]. Facilitation of waste recovery provides also Best Available Techniques (BAT) Reference Document for the Management of Waste from Extractive Industries in accordance with Directive 2006/21/EC, 2018 [

38].

6. Conclusions

(1) The extremely significantMMPW reserves give rise to major economic and environmental challenges in the mining regions. Maintenance of overburden rocks dumps, tailings and sludge dumps requires considerable investments. Major areas are rendered unusable for extended periods of time. Large amounts of rock mass distort the existing geological balance. Dust from mining waste dumps, acid mine drainage (AMD), reagents, and heavy metals leaching into the soils and subsurface waters have an adverse impact on the environment and human health.

(2) Considering the extent of loss of the valuable components in the process of extraction and concentration of mineral resources, exhaustion of the reserves and ore grade deterioration, the wastes are regarded as a potential source of valuable minerals, regardless of a lower grade compared to primary raw materials. Wastes require less investment in extraction and processing. During storage, high concentration zones may develop due to the differentiation of the material in terms of particle size and density. Currently, anthropogenic mineral reserves are comparable to primary mineral reserves.

(3) Implementation of the 3R pyramid (“reduce, reuse, recycle”) in waste management requires extensive mining and reprocessing of the stored and currently generated MMPW.

(4) By the example of the MMPW facilities in one of the major mining regions of the Russian Federation, Murmansk Region, we have established the following. During the MMPW storage, its mineral composition and properties change due to supergene processes and its volume is reduced as the result of surface removal, chemical weathering, and suffusion processes. In this case, the physical and chemical properties of the mineral surfaces change.

(5) Supergene processes are reflected in the geological body condition, lead to a considerable alteration of the process properties both of ore minerals and non-metallic minerals, and require the adoption of a new waste reprocessing technology. The prolonged storage stage of the MMPW is characterized by declining reserves and large-scale pollution in the surrounding areas.

(6) A number of business issues involved in MMPW processing in Russiaand disposal of the resulting waste are connected with imperfections of the regulatory framework. An analysis of the existing regulations showed that in the initial stage, investing into MMPW processing is completely unprofitable because of the low-cost effectiveness, substantial investment in the initial phase, where the capital remains frozen for a long period of time. As a consequence of this, high business risks are combined with a long payback period.

(7) Equal treatment of MMPW and primary mineral resources significantly complicates the design and planning of waste processing projects and necessitates significant investment in the initial phase. Exempting MMPW processing projects from the statutory requirements of FL 2395–1 On the Mineral Resources will significantly simplify and streamline the design phase of MMPW processing projects.