Flocs Properties and Flotation Performance of Fine Diaspore with Energy Input Pretreatment Induced Using Sodium Oleate

Abstract

:1. Introduction

2. Materials and Methods

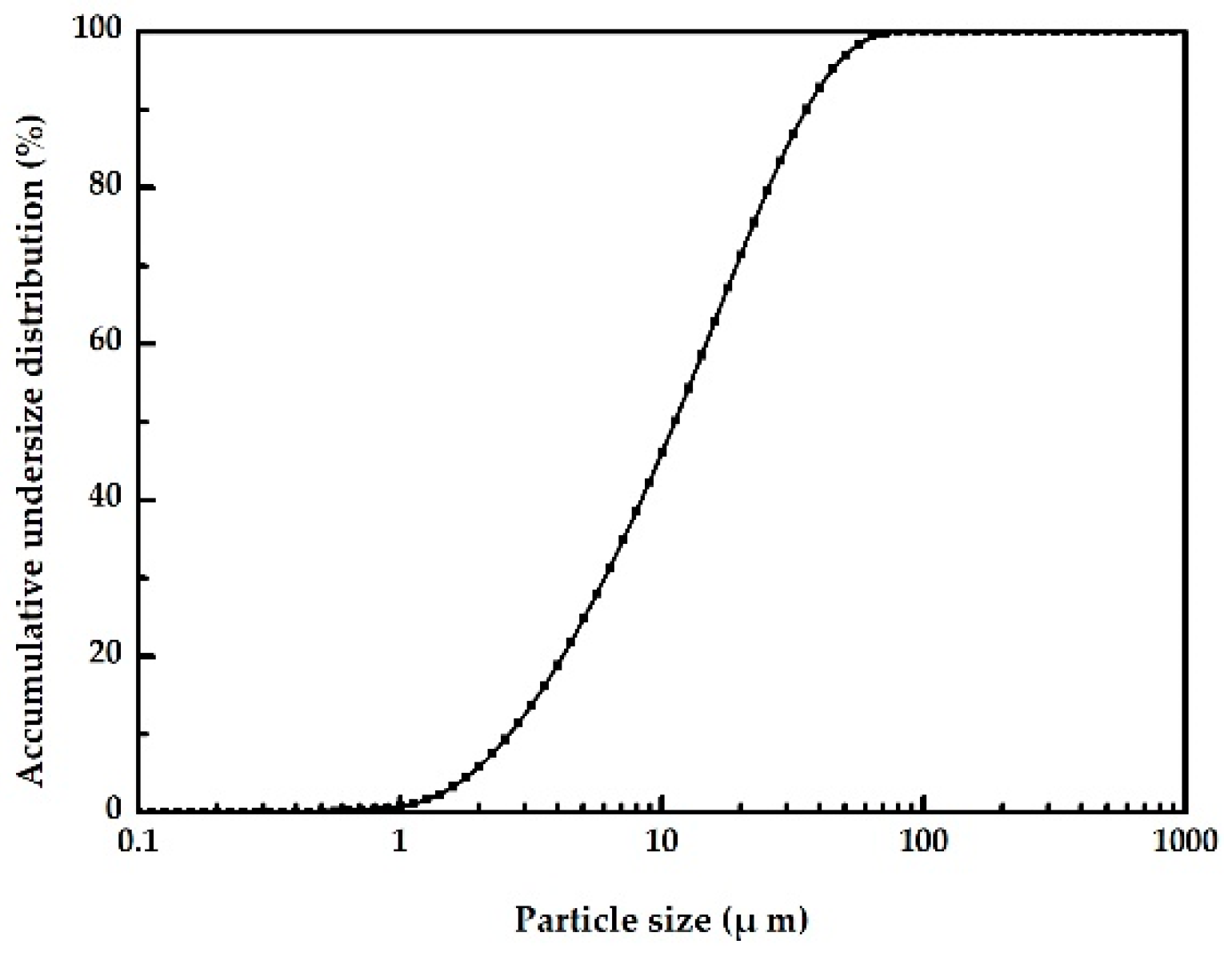

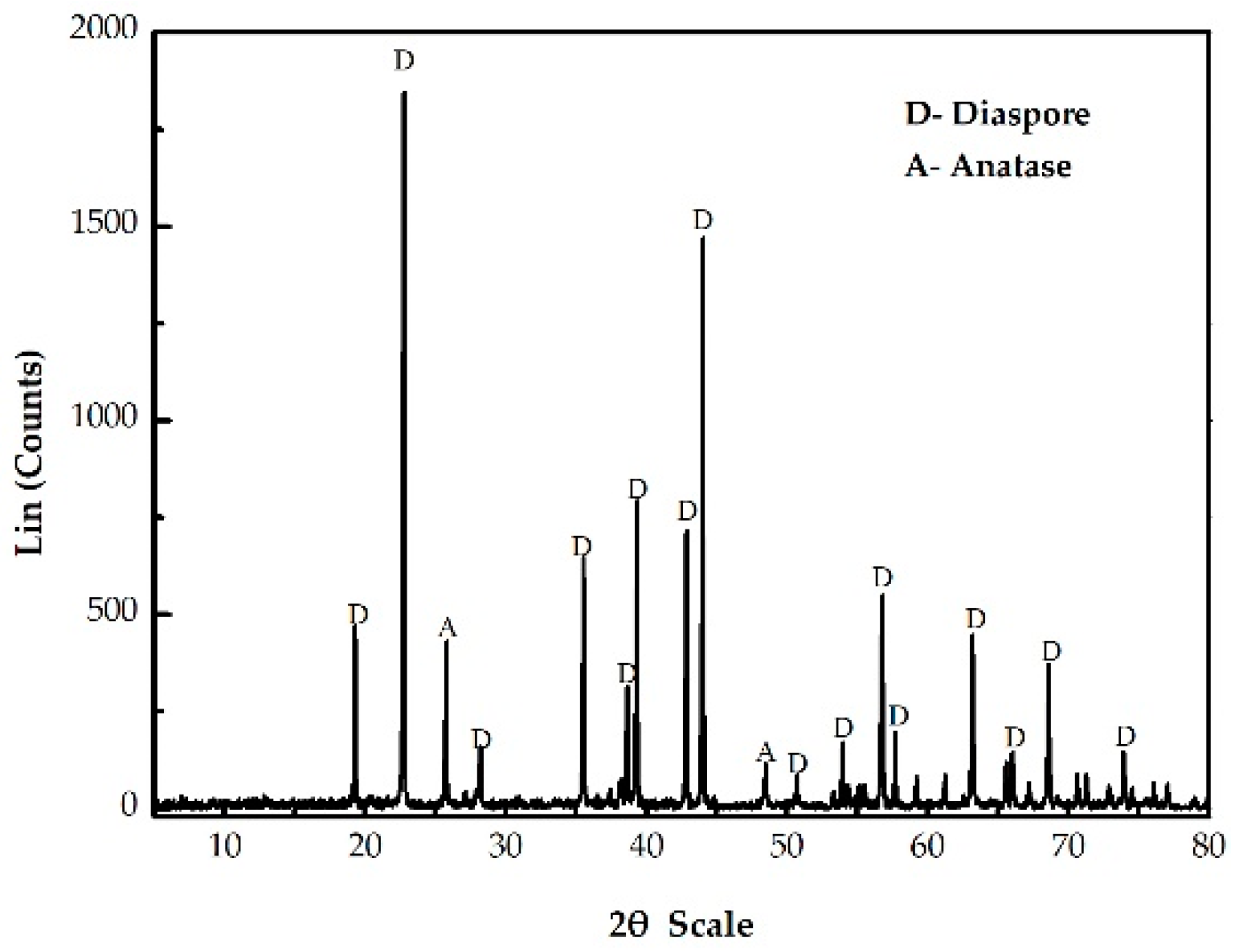

2.1. Materials and Reagents

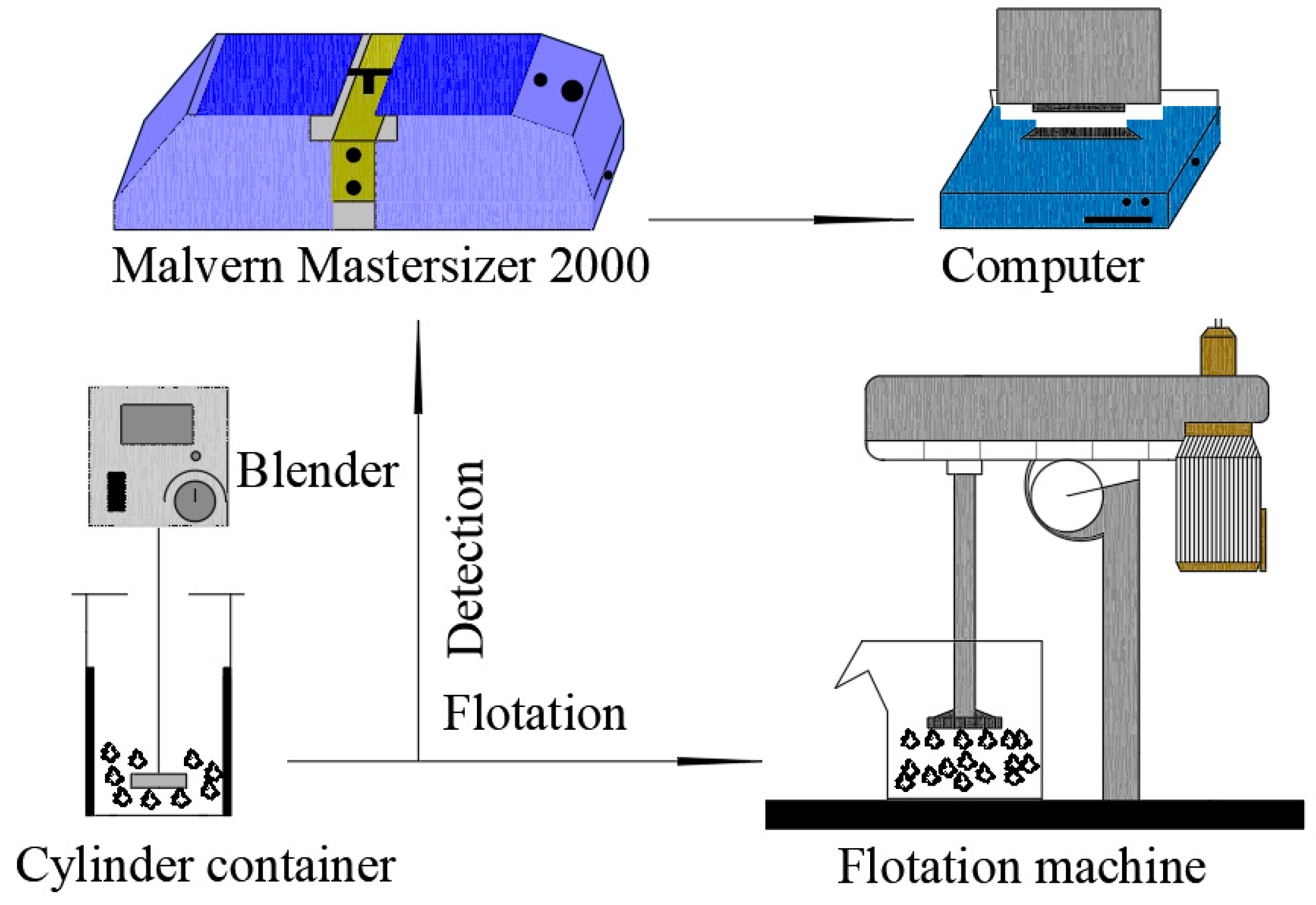

2.2. Hydrophobic Flocculation and Energy Input Measurement

2.3. Flocs Size and Fractal Dimension Measurements

2.4. Flotation Tests

3. Results

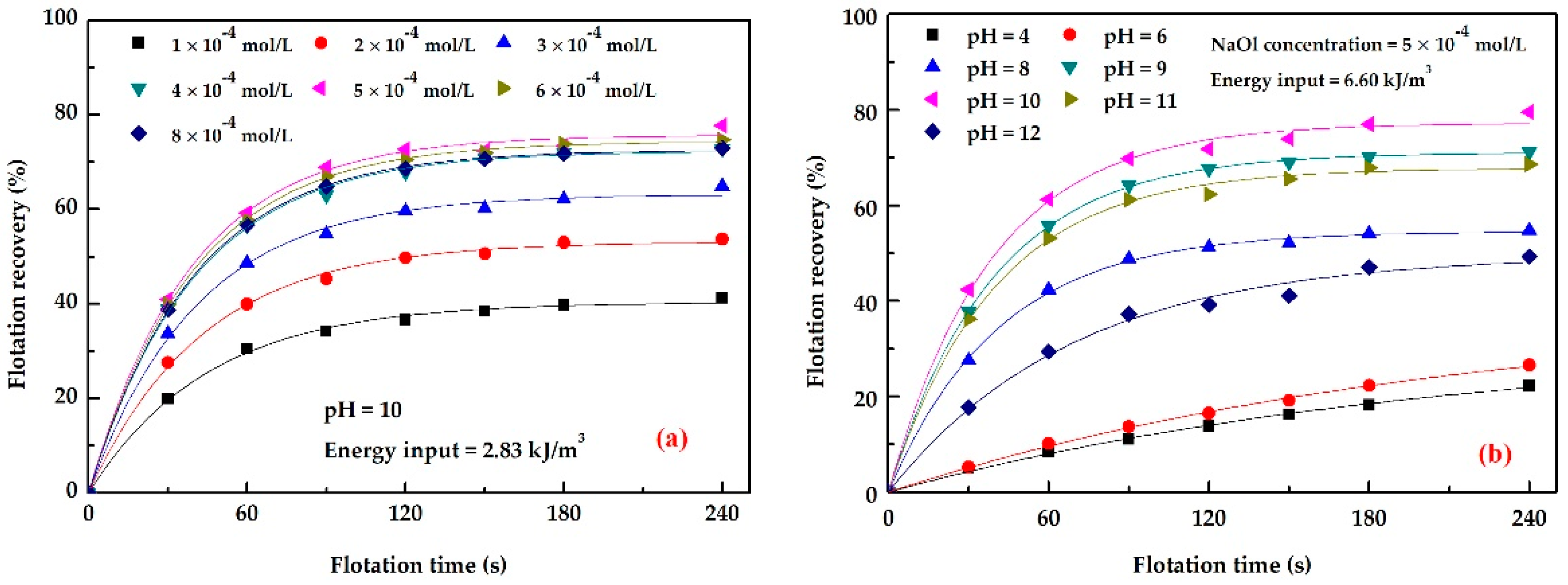

3.1. Effect of NaOl Concentration and pH on the Flotation Performance of Fine Diaspore

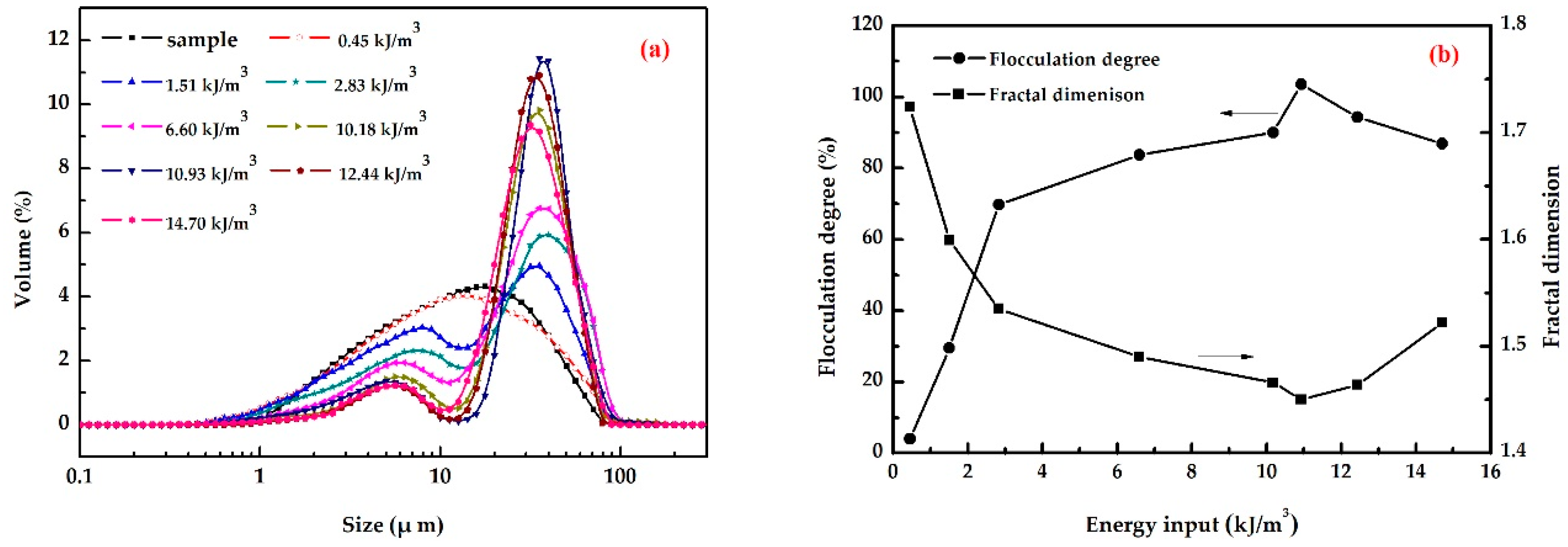

3.2. Effect of Energy Input Pretreatment on Flocs Properties of Fine Diaspore

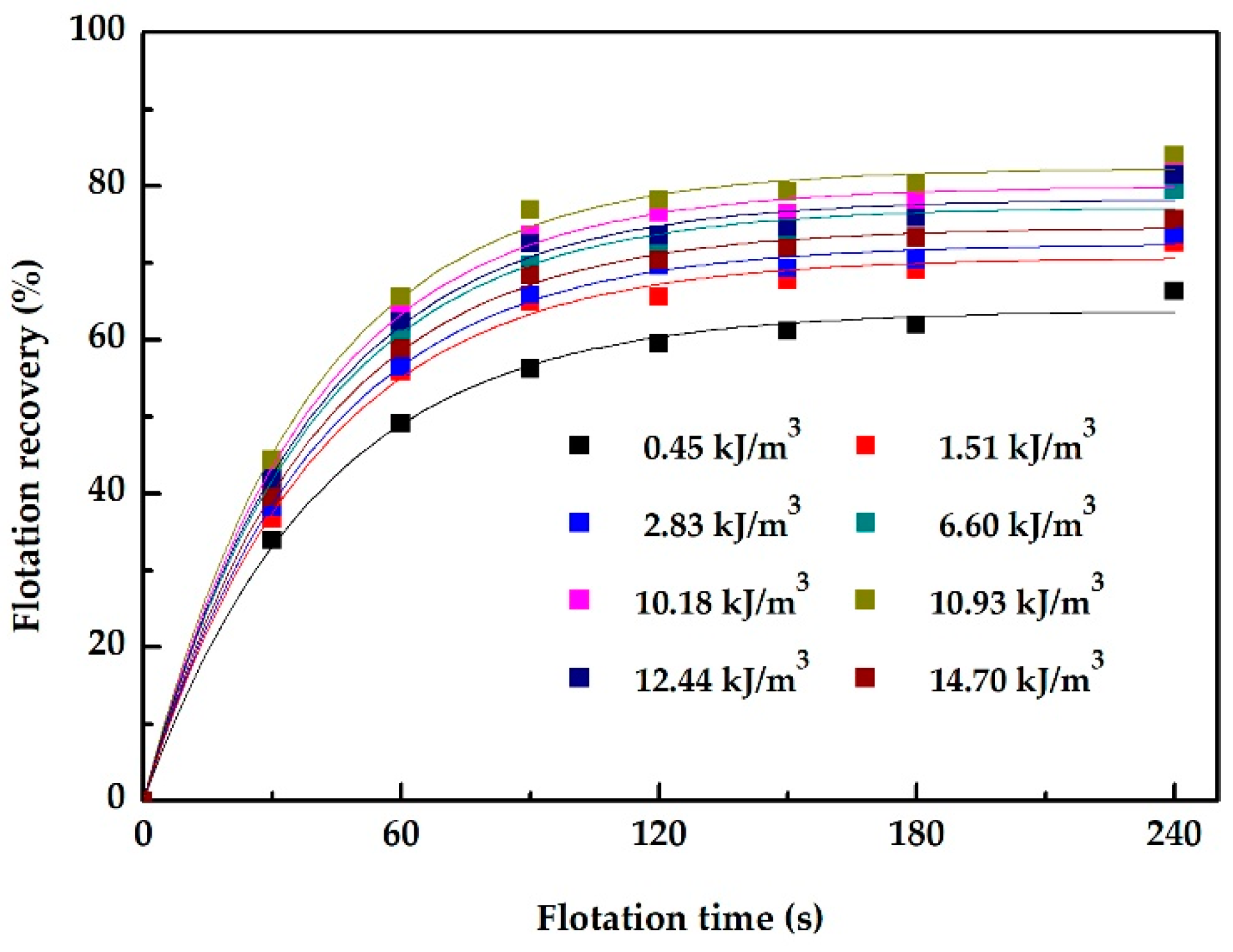

3.3. Effect of Energy Input Pretreatment on Flotation Performance of Fine Diaspore

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hu, Y.; Chen, P.; Sun, W. Study on quantitative structure–activity relationship of quaternary ammonium salt collectors for bauxite reverse flotation. Miner. Eng. 2012, 26, 24–33. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, Y.; Zhang, Q.; Lu, D.; Hu, Y. Flotation separation of diaspore from aluminosilicates using commercial oleic acids of different iodine values. Int. J. Miner. Process. 2017, 168, 95–101. [Google Scholar] [CrossRef]

- Gibson, B.; Wonyen, D.G.; Chelgani, S.C. A review of pretreatment of diasporic bauxite ores by flotation separation. Miner. Eng. 2017, 114, 64–73. [Google Scholar] [CrossRef]

- Chen, W.; Feng, Q.; Zhang, G.; Li, L.; Jin, S. Effect of energy input on flocculation process and flotation performance of fine scheelite using sodium oleate. Miner. Eng. 2017, 112, 27–35. [Google Scholar] [CrossRef]

- Coufort, C.; Dumas, C.; Bouyer, D.; Liné, A. Analysis of floc size distributions in a mixing tank. Chem. Eng. Process. Process Intensif. 2008, 47, 287–294. [Google Scholar] [CrossRef]

- Chaignon, V.; Lartiges, B.S.; El Samrani, A.; Mustin, C. Evolution of size distribution and transfer of mineral particles between flocs in activated sludges: An insight into floc exchange dynamics. Water Res. 2002, 36, 676–684. [Google Scholar] [CrossRef]

- He, W.P.; Nan, J.; Li, H.Y.; Li, S.N. Characteristic analysis on temporal evolution of floc size and structure in low-shear flow. Water Res. 2012, 46, 509–520. [Google Scholar] [CrossRef] [PubMed]

- Vassileva, N.D.; van den Ende, D.; Mugele, F.; Mellema, J. Fragmentation and erosion of two-dimensional aggregates in shear flow. Langmuir 2007, 23, 2352–2361. [Google Scholar] [CrossRef]

- Lee, C.; Kramer, T.A. Prediction of three-dimensional fractal dimensions using the two-dimensional properties of fractal aggregates. Adv. Colloid Interface Sci. 2004, 112, 49–57. [Google Scholar] [CrossRef]

- Tang, S.; Preece, J.M.; McFarlane, C.M.; Zhang, Z. Fractal Morphology and Breakage of DLCA and RLCA Aggregates. J. Colloid Interface Sci. 2000, 221, 114–123. [Google Scholar] [CrossRef]

- Guesnet, E.; Dendievel, R.; Jauffrès, D.; Martin, C.L.; Yrieix, B. A growth model for the generation of particle aggregates with tunable fractal dimension. Phys. A Stat. Mech. Its Appl. 2019, 513, 63–73. [Google Scholar] [CrossRef]

- Li, T.; Du, A.; Zhang, T.; Ding, W.; Liu, M.; Shen, J.; Zhang, Z.; Zhou, B. Continuous adjustment of fractal dimension of silica aerogels. J. Non-Cryst. Solids 2018, 499, 159–166. [Google Scholar] [CrossRef]

- Wu, H.; Lattuada, M.; Morbidelli, M. Dependence of fractal dimension of DLCA clusters on size of primary particles. Adv. Colloid Interface Sci. 2013, 195–196, 41–49. [Google Scholar] [CrossRef] [PubMed]

- Changunda, K.; Harris, M.; Deglon, D.A. Investigating the effect of energy input on flotation kinetics in an oscillating grid flotation cell. Miner. Eng. 2008, 21, 924–929. [Google Scholar] [CrossRef]

- Gui, X.; Liu, J.; Cao, Y.; Cheng, G.; Li, S.; Wu, L. Flotation process design based on energy input and distribution. Fuel Process. Technol. 2014, 120, 61–70. [Google Scholar] [CrossRef]

- Safari, M.; Deglon, D. An attachment-detachment kinetic model for the effect of energy input on flotation. Miner. Eng. 2018, 117, 8–13. [Google Scholar] [CrossRef]

- Massey, W.T.; Harris, M.C.; Deglon, D.A. The effect of energy input on the flotation of quartz in an oscillating grid flotation cell. Miner. Eng. 2012, 36–38, 145–151. [Google Scholar] [CrossRef]

- Yu, Y.; Cheng, G.; Ma, L.; Huang, G.; Wu, L.; Xu, H. Effect of agitation on the interaction of coal and kaolinite in flotation. Powder Technol. 2017, 313, 122–128. [Google Scholar] [CrossRef]

- Gui, X.; Cao, Y.; Xing, Y.; Yang, Z.; Wang, D.; Li, C. A two-stage process for fine coal flotation intensification. Powder Technol. 2017, 313, 361–368. [Google Scholar] [CrossRef]

- Yuhua, W.; Daxiang, S.; Liguang, W.; Yulin, Z. Effects of sodium tripolyphosphate and sodium carbonate on the selective flocculation of diasporic-bauxite in the presence of calcium and magnesium ions. Miner. Eng. 2011, 24, 1031–1037. [Google Scholar] [CrossRef]

- Deng, L.; Wang, S.; Zhong, H.; Liu, G. A novel surfactant 2-amino-6-decanamidohexanoic acid: Flotation performance and adsorption mechanism to diaspore. Miner. Eng. 2016, 93, 16–23. [Google Scholar] [CrossRef]

- Bushell, G.C.; Yan, Y.D.; Woodfield, D.; Raper, J.; Amal, R. On Techniques for the Measurement of the Mass Fractal Dimension of Aggregates. Adv. Colloid Interface Sci. 2002, 95, 1–50. [Google Scholar] [CrossRef]

- Li, T.; Zhu, Z.; Wang, D.; Yao, C.; Tang, H. The strength and fractal dimension characteristics of alum–kaolin flocs. Int. J. Miner. Process. 2007, 82, 23–29. [Google Scholar] [CrossRef]

- Ai, G.; Yang, X.; Li, X. Flotation characteristics and flotation kinetics of fine wolframite. Powder Technol. 2017, 305, 377–381. [Google Scholar] [CrossRef]

- Lyu, F.; Gao, J.; Sun, N.; Liu, R.; Sun, X.; Cao, X.; Wang, L.; Sun, W. Utilisation of propyl gallate as a novel selective collector for diaspore flotation. Miner. Eng. 2019, 131, 66–72. [Google Scholar] [CrossRef]

- Zhang, N.; Nguyen, A.V.; Zhou, C. A review of the surface features and properties, surfactant adsorption and floatability of four key minerals of diasporic bauxite resources. Adv. Colloid Interface Sci. 2018, 254, 56–75. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Hu, Y.; Dong, F.; Gao, Z.; Wu, H.; Wang, Z. Anisotropic adsorption of oleate on diaspore and kaolinite crystals: Implications for their flotation separation. Appl. Surf. Sci. 2014, 321, 331–338. [Google Scholar] [CrossRef]

- Warren, L.J. Shear-flocculation of ultrafine scheelite in sodium oleate solutions. J. Colloid Interface Sci. 1975, 50, 307–318. [Google Scholar] [CrossRef]

- Chakraborti, R.K.; Gardner, K.H.; Atkinson, J.F.; Van Benschoten, J.E. Changes in fractal dimension during aggregation. Water Res. 2003, 37, 873–883. [Google Scholar] [CrossRef]

- Liang, L.; Peng, Y.; Tan, J.; Xie, G. A review of the modern characterization techniques for flocs in mineral processing. Miner. Eng. 2015, 84, 130–144. [Google Scholar] [CrossRef]

- Ofori, P.; Nguyen, A.V.; Firth, B.; McNally, C.; Ozdemir, O. Shear-induced floc structure changes for enhanced dewatering of coal preparation plant tailings. Chem. Eng. J. 2011, 172, 914–923. [Google Scholar] [CrossRef]

- Neelakantan, R.; Vaezi, G.F.; Sanders, R.S. Effect of shear on the yield stress and aggregate structure of flocculant-dosed, concentrated kaolinite suspensions. Miner. Eng. 2018, 123, 95–103. [Google Scholar] [CrossRef]

- Biggs, S.; Habgood, M.; Jameson, G.J.; Yan, Y.-d. Aggregate structures formed via a bridging flocculation mechanism. Chem. Eng. J. 2000, 80, 13–22. [Google Scholar] [CrossRef]

- Meng, Z.; Hashmi, S.M.; Elimelech, M. Aggregation rate and fractal dimension of fullerene nanoparticles via simultaneous multiangle static and dynamic light scattering measurement. J. Colloid Interface Sci. 2013, 392, 27–33. [Google Scholar] [CrossRef] [PubMed]

- Franks, G.V.; Zhou, Y.; Yan, Y.D.; Jameson, G.J.; Biggs, S. Effect of aggregate size on sediment bed rheological properties. Phys. Chem. Chem. Phys. 2004, 6, 4490–4498. [Google Scholar] [CrossRef]

- Petrenko, V.I.; Artykulnyi, O.P.; Bulavin, L.A.; Almásy, L.; Garamus, V.M.; Ivankov, O.I.; Grigoryeva, N.A.; Vekas, L.; Kopcansky, P.; Avdeev, M.V. On the impact of surfactant type on the structure of aqueous ferrofluids. Colloids Surf. A Physicochem. Eng. Asp. 2018, 541, 222–226. [Google Scholar] [CrossRef]

| Components | Al2O3 | SiO2 | TiO2 | Fe2O3 | CaO | MgO | K2O | Na2O | LOI |

|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 80.77 | 0.89 | 2.76 | 0.756 | 0.01 | 0.053 | 0.008 | 0.025 | 14.728 |

| Agitation Speed(rpm) | 900 | 1200 | 1500 | 2100 | 2700 | 3000 | 3300 | 3900 |

|---|---|---|---|---|---|---|---|---|

| Torque (N∙m) | 0.004 | 0.010 | 0.015 | 0.025 | 0.030 | 0.029 | 0.030 | 0.030 |

| Energy input (kJ/m3) | 0.45 | 1.51 | 2.83 | 6.60 | 10.18 | 10.93 | 12.44 | 14.70 |

| Energy Input (kJ/m3) | Flotation Recovery ± RSD (%) | Fitting Results | ||

|---|---|---|---|---|

| Rmax (%) | k (s−1) | R2 | ||

| 0.45 | 66.32 ± 1.11 | 63.80 | 0.0244 | 0.9961 |

| 1.51 | 72.56 ± 0.57 | 70.69 | 0.0251 | 0.9963 |

| 2.83 | 73.73 ± 0.47 | 72.44 | 0.0253 | 0.9974 |

| 6.60 | 79.56 ± 0.38 | 77.24 | 0.0259 | 0.9967 |

| 10.18 | 81.95 ± 0.61 | 79.90 | 0.0262 | 0.9973 |

| 10.93 | 83.98 ± 0.28 | 82.30 | 0.0265 | 0.9972 |

| 12.44 | 81.39 ± 0.80 | 78.30 | 0.0260 | 0.9947 |

| 14.70 | 75.69 ± 0.36 | 74.61 | 0.0256 | 0.9986 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, S.; Ou, L. Flocs Properties and Flotation Performance of Fine Diaspore with Energy Input Pretreatment Induced Using Sodium Oleate. Minerals 2019, 9, 433. https://doi.org/10.3390/min9070433

Liao S, Ou L. Flocs Properties and Flotation Performance of Fine Diaspore with Energy Input Pretreatment Induced Using Sodium Oleate. Minerals. 2019; 9(7):433. https://doi.org/10.3390/min9070433

Chicago/Turabian StyleLiao, Shishuang, and Leming Ou. 2019. "Flocs Properties and Flotation Performance of Fine Diaspore with Energy Input Pretreatment Induced Using Sodium Oleate" Minerals 9, no. 7: 433. https://doi.org/10.3390/min9070433

APA StyleLiao, S., & Ou, L. (2019). Flocs Properties and Flotation Performance of Fine Diaspore with Energy Input Pretreatment Induced Using Sodium Oleate. Minerals, 9(7), 433. https://doi.org/10.3390/min9070433