Dewatering of Mine Tailings Slurries Using Superabsorbent Polymers (SAPs) Reclaimed from Industrial Reject of Baby Diapers: A Preliminary Study †

Abstract

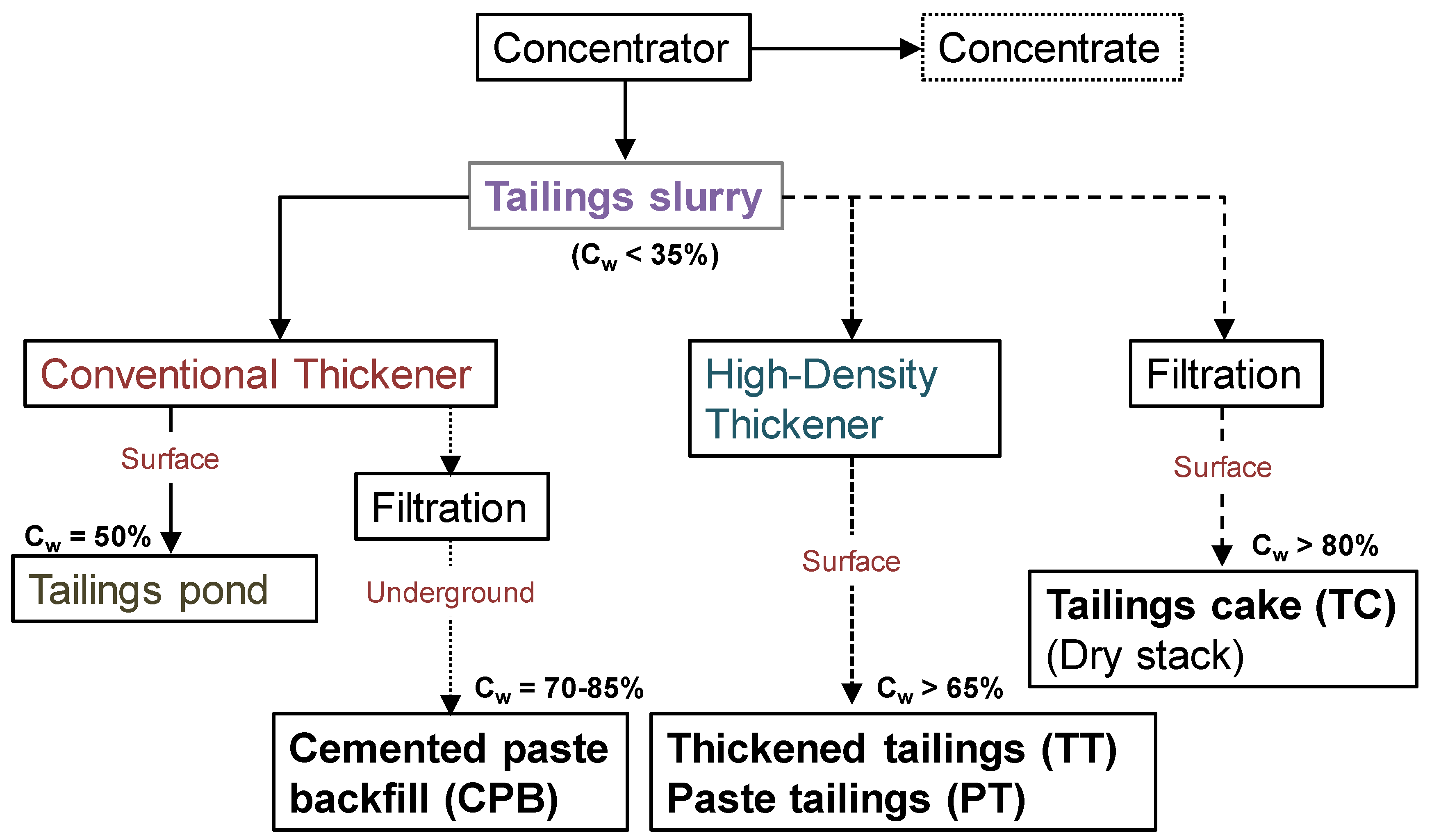

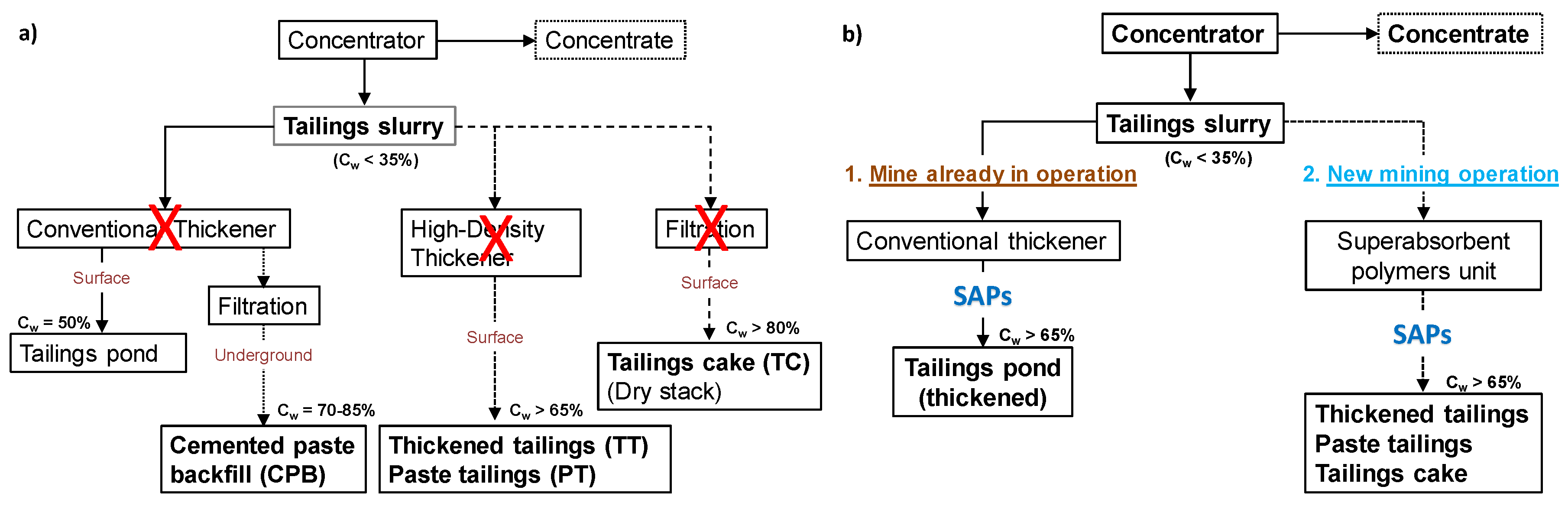

1. Introduction

2. Materials and Methods

2.1. Materials

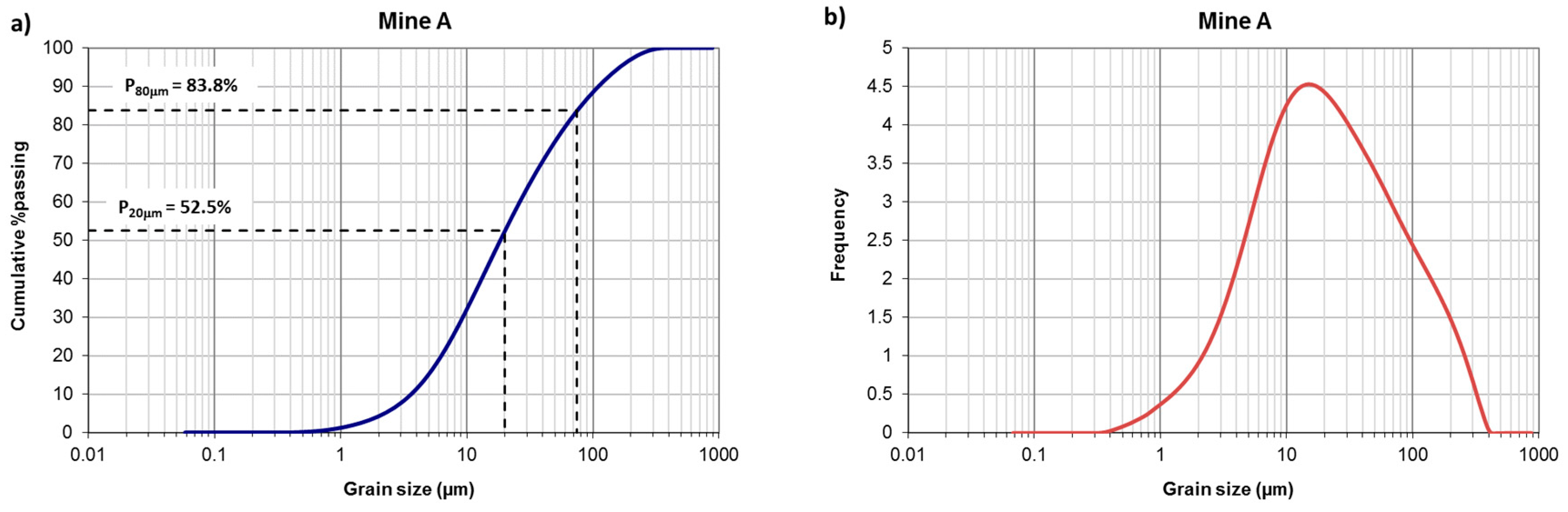

2.1.1. Tailings Sample and Slurry Supernatant Water

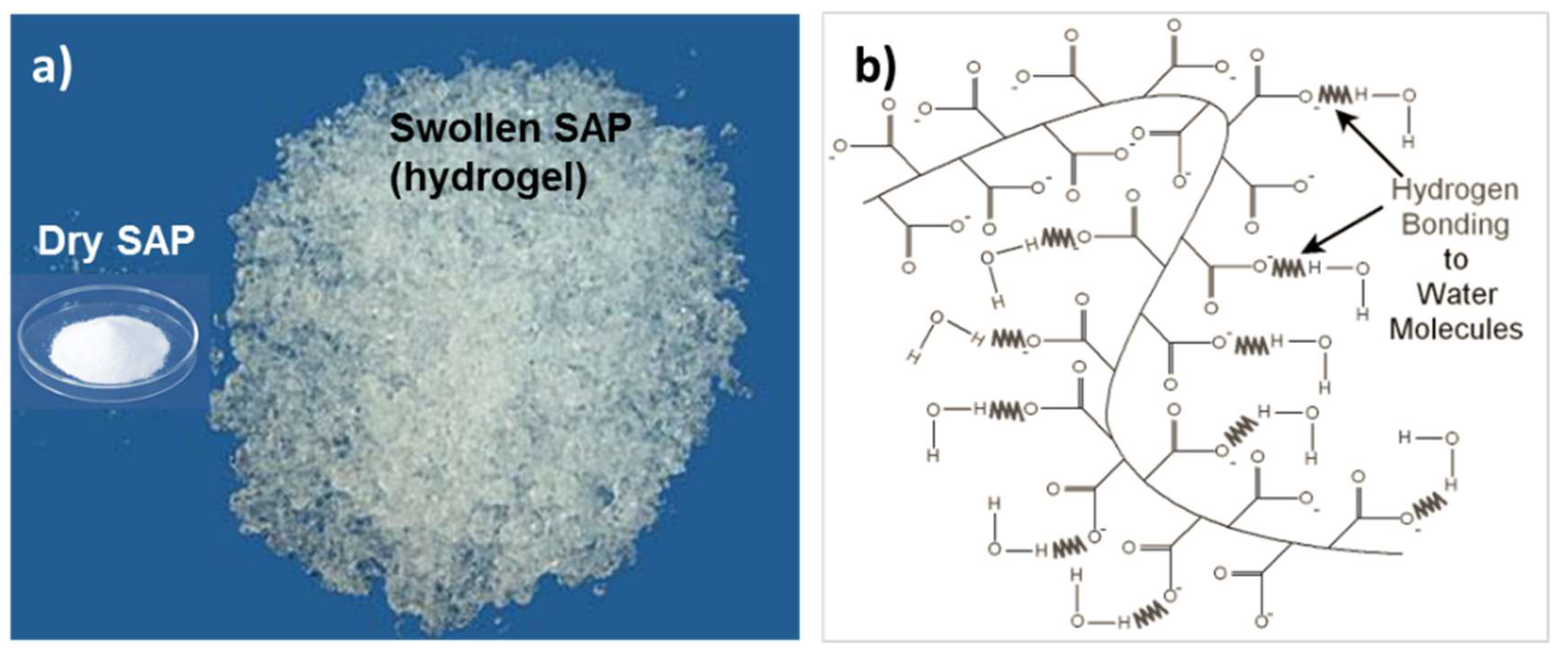

2.1.2. Superabsorbent Polymers (SAPs) Reclaimed from Industrial Reject of Baby Diapers

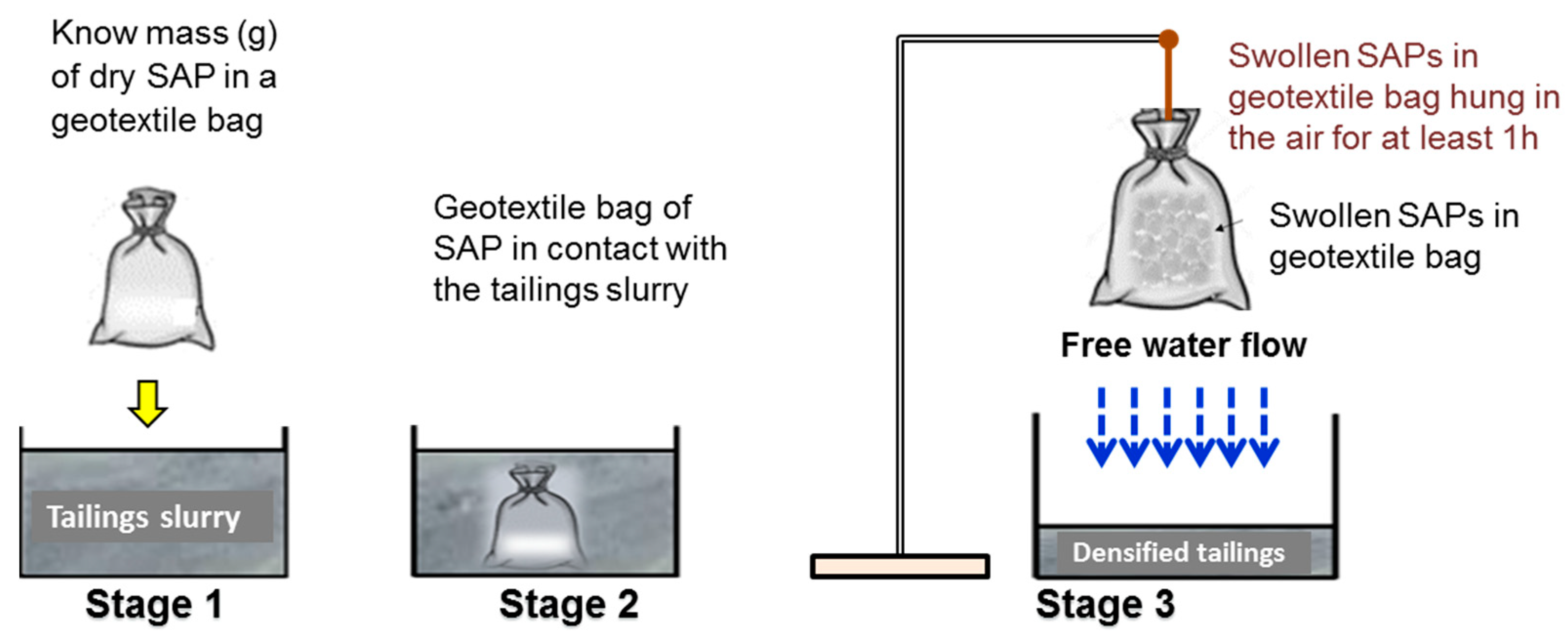

2.2. Methods

2.2.1. SAP Dosages Calculation and Expression for the Absorbency Parameters

- DmSAP: in kg of SAP/ton of slurry/water (is equivalent to g/kg), or in g of SAP/g of slurry/water (or in kg/kg, ton/ton).

- DvSAP: in kg of SAP/m3 of slurry/water (is equivalent to g/L), or in ton of SAP/m3 of slurry/water (is equivalent to g/mL). In the following, only the units in kg/m3 for DvSAP are used for the presentation of the obtained results.

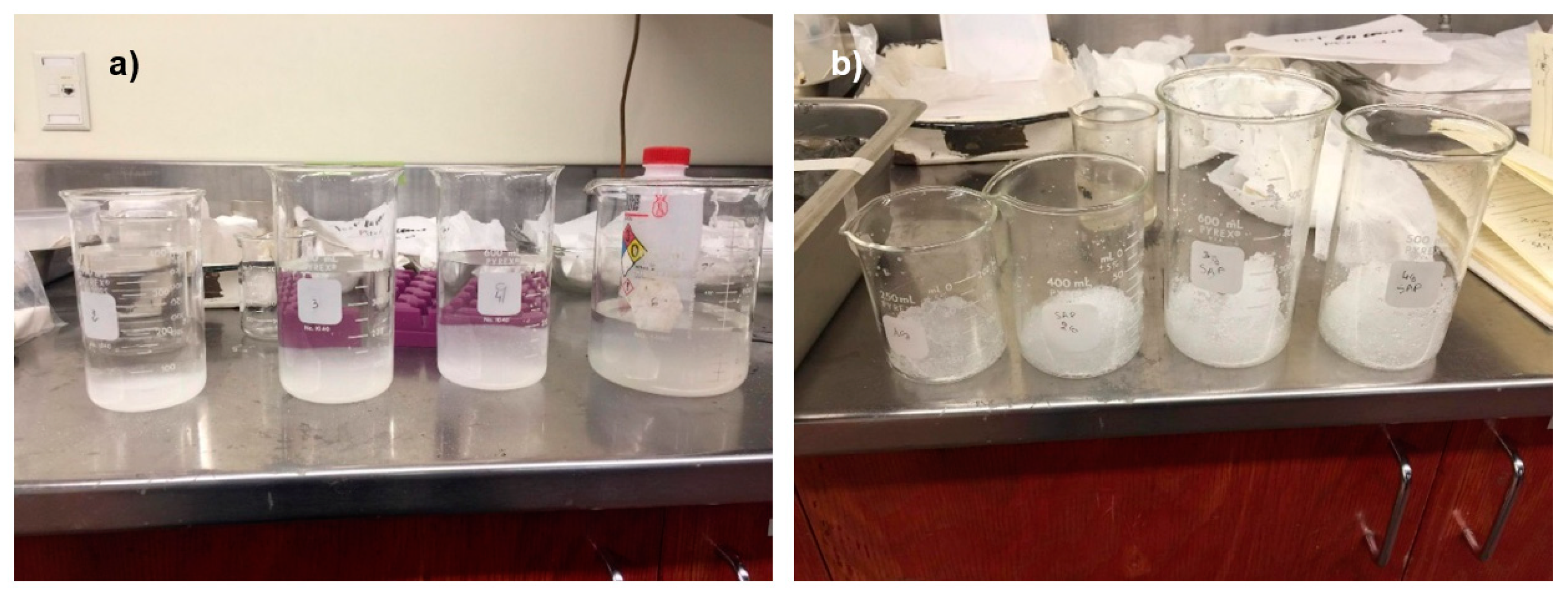

2.2.2. Series #1: Mine Water Absorbency Tests Using Beakers

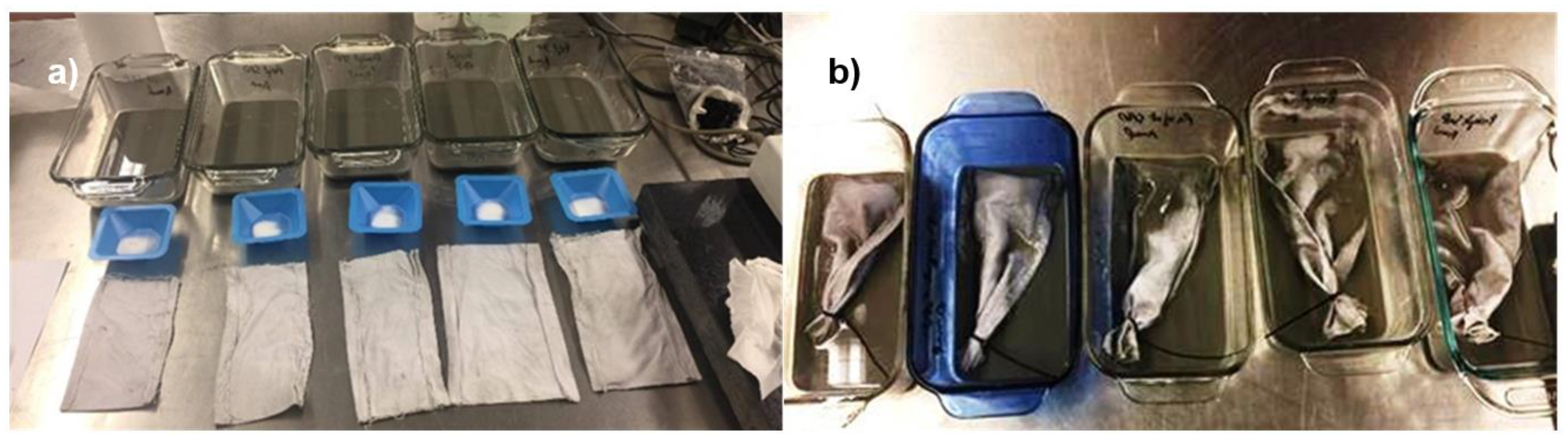

2.2.3. Series #2: Mine Tailings Slurry Dewatering Tests Using Pyrex Dishes

2.2.4. Series #3: Mine Tailings Slurry Dewatering Tests Using Plastic Bins

3. Results

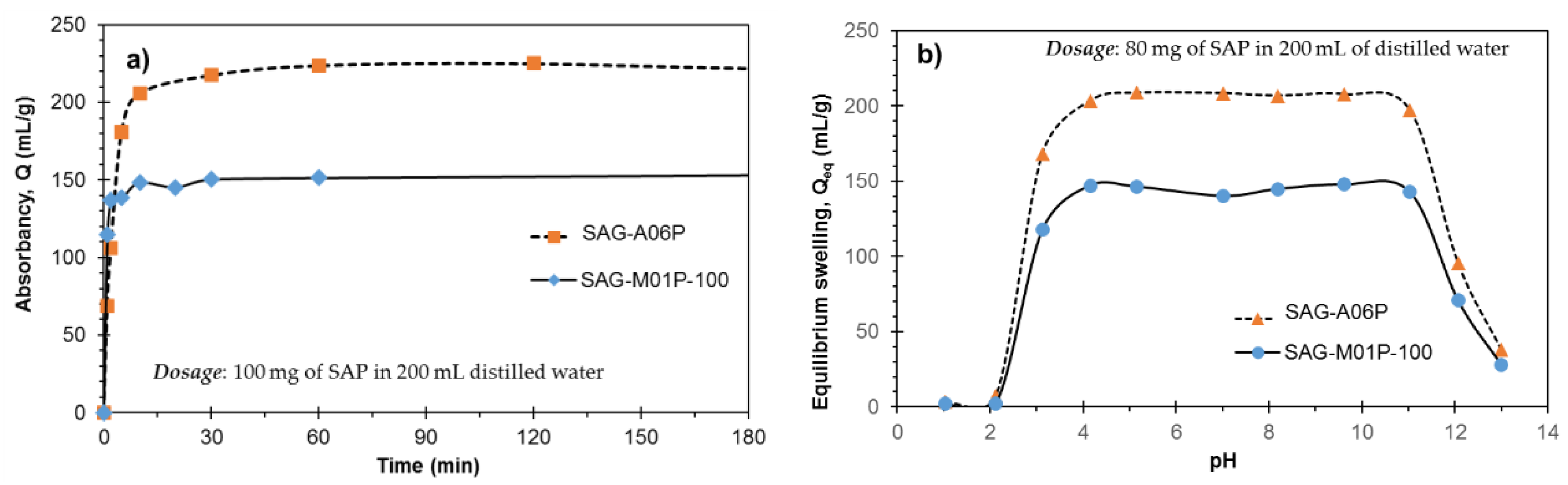

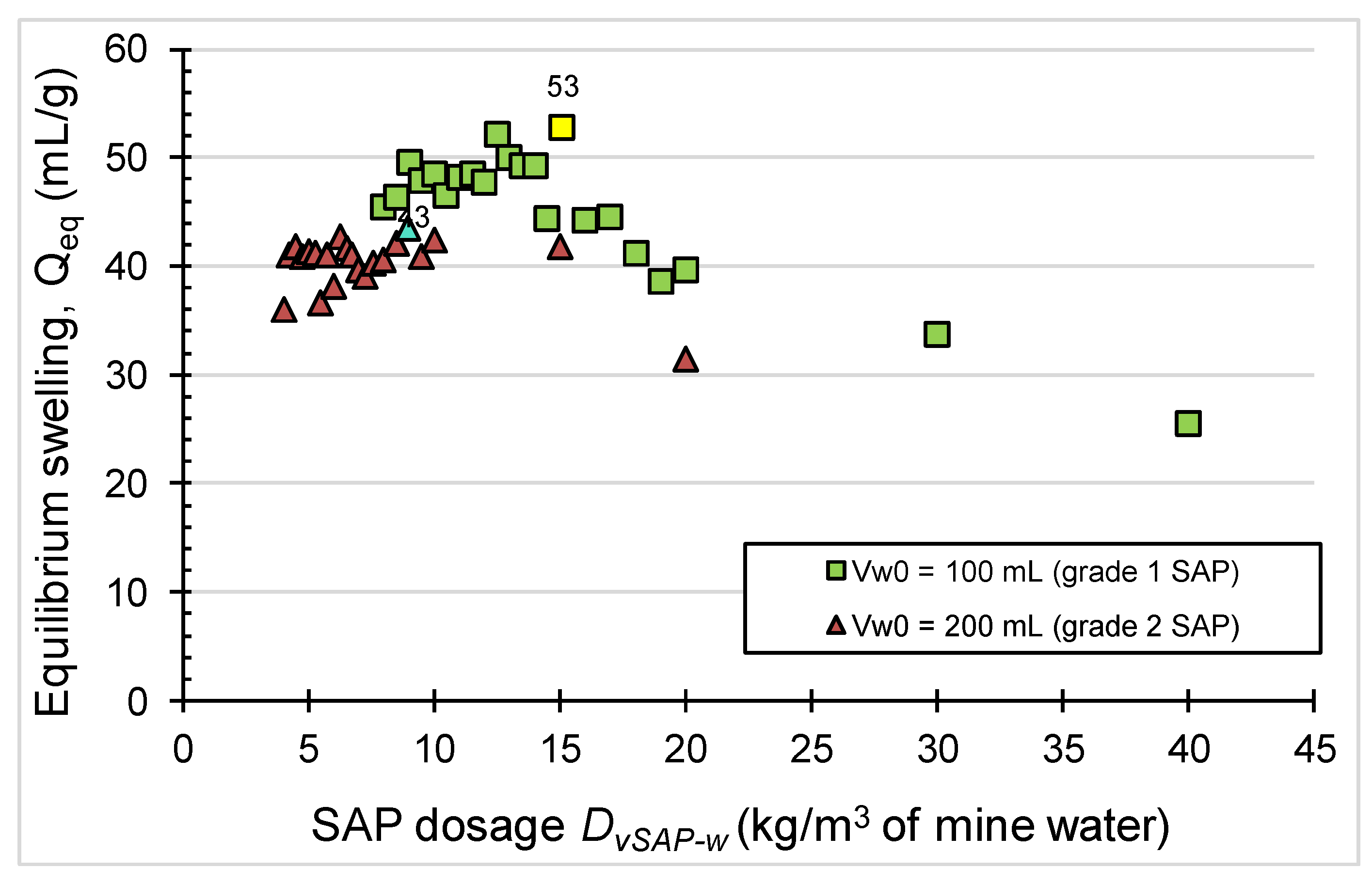

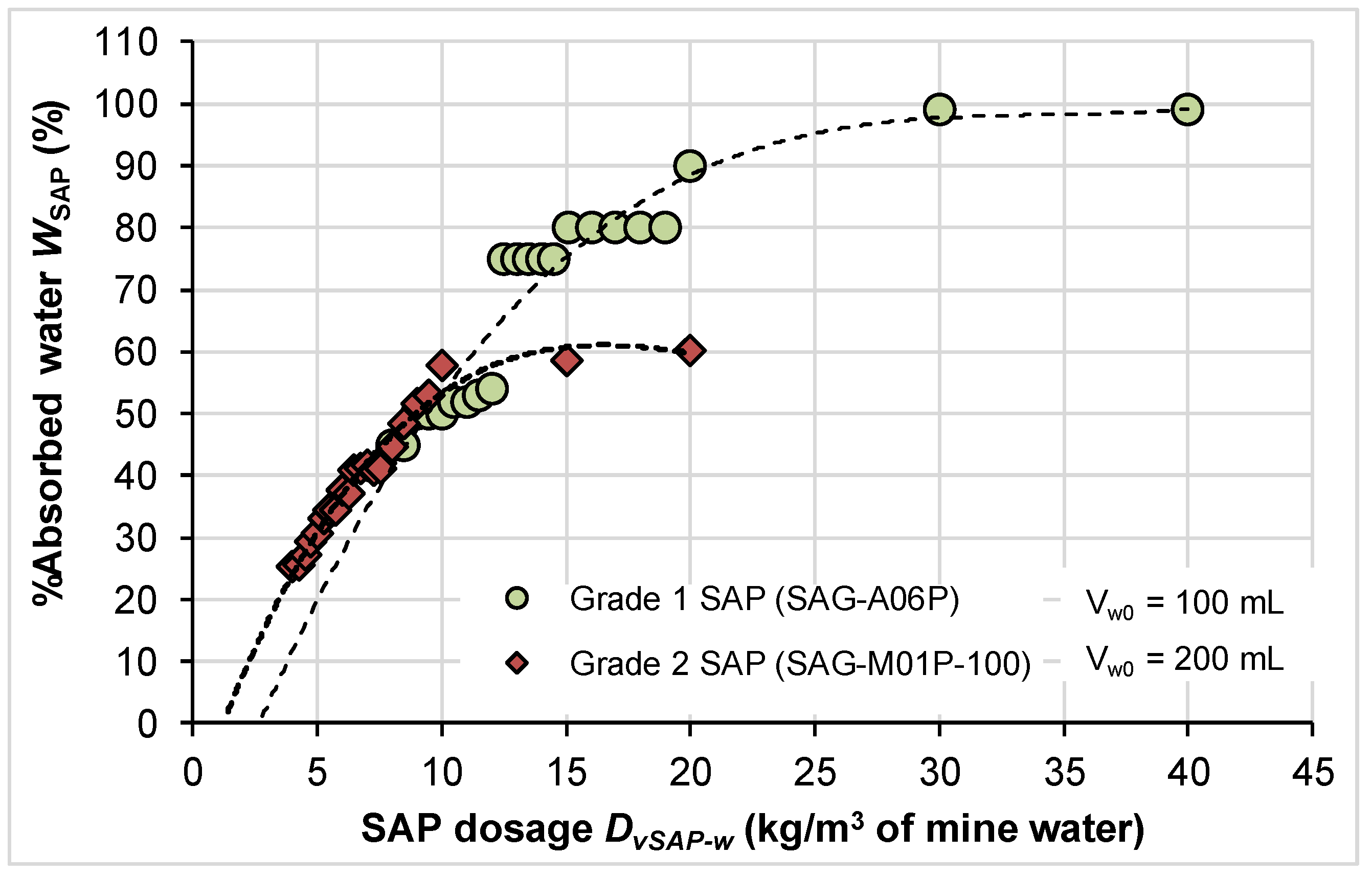

3.1. Equilibrium Degree of Swelling of SAP (Qeq) Using Mine Water (Series #1 Tests)

3.2. Dewatering of Tailings Slurry Using SAP Geotextile Bags

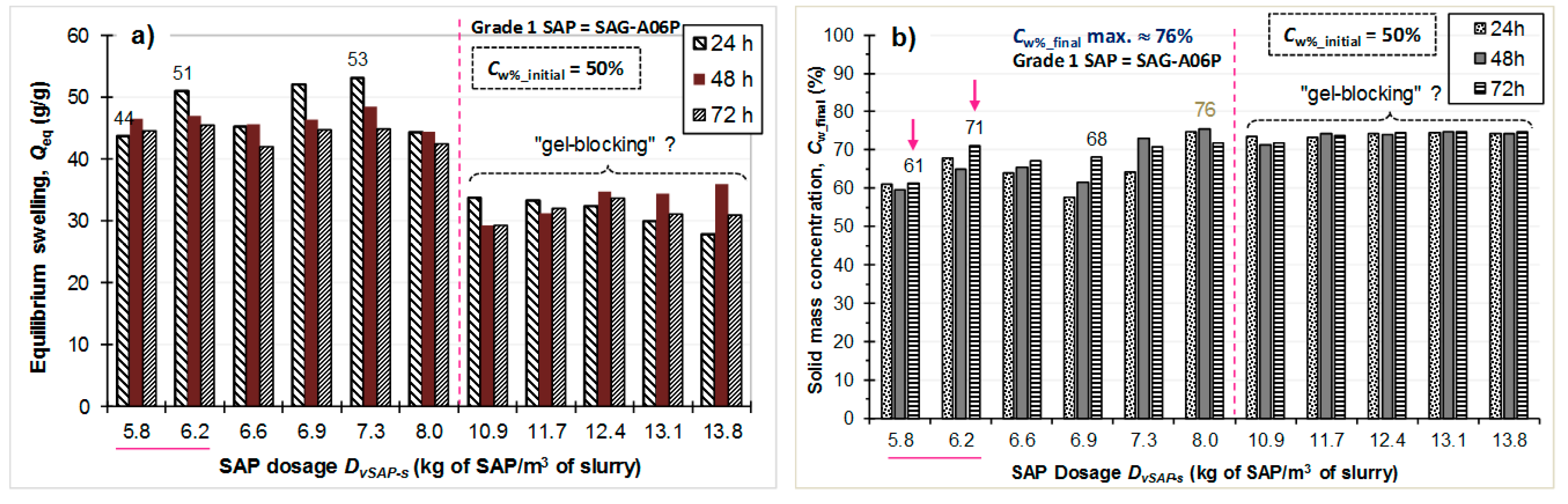

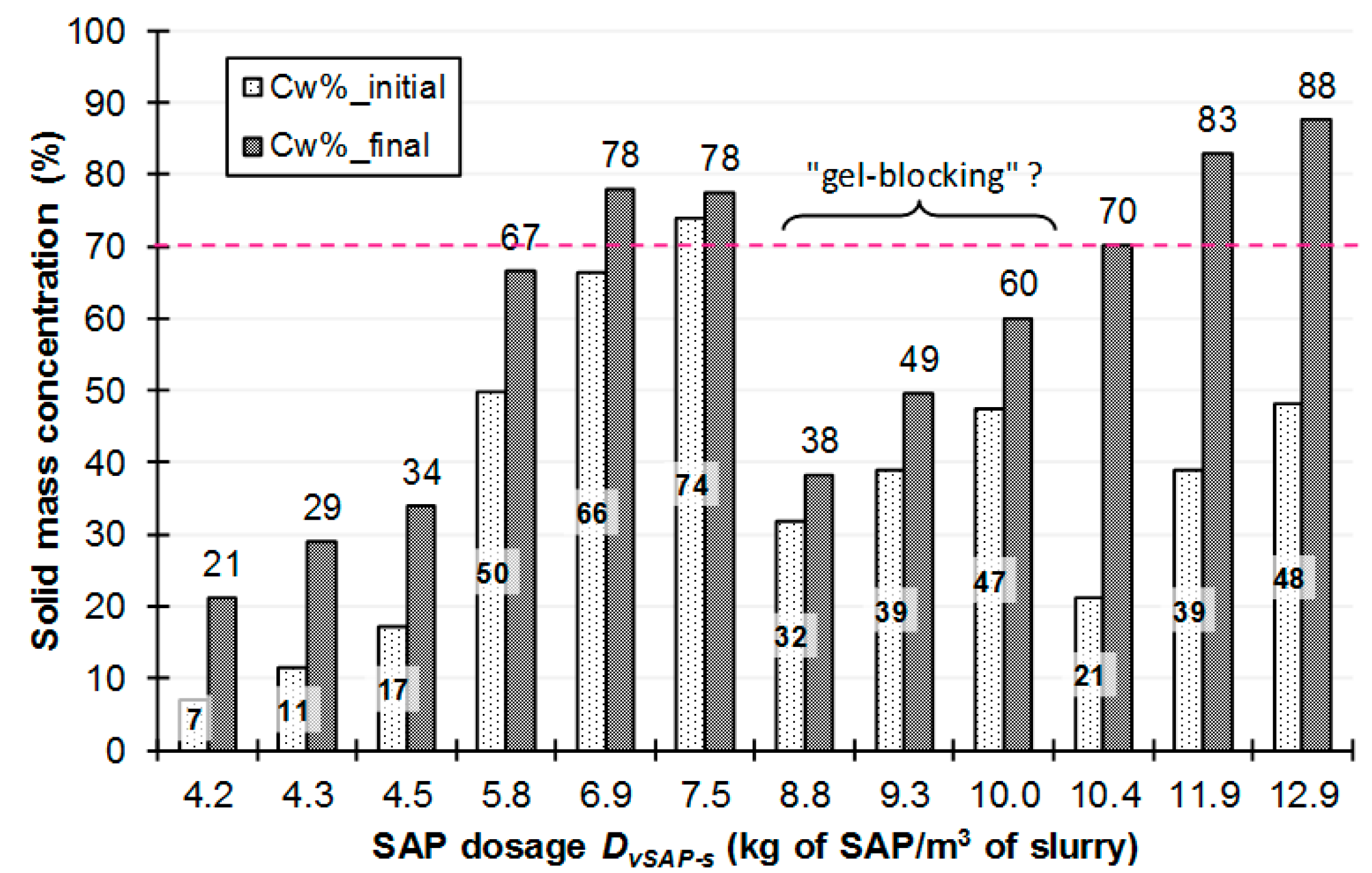

3.2.1. Pyrex Dishes Tailings Dewatering Tests (Series #2 Tests)

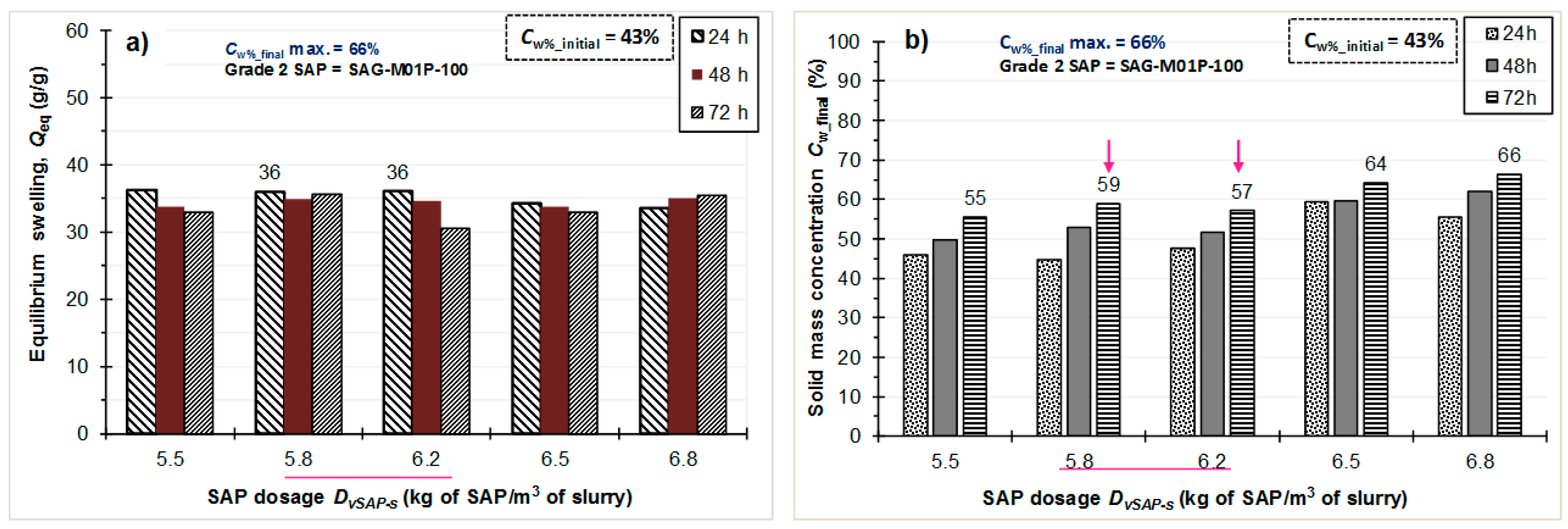

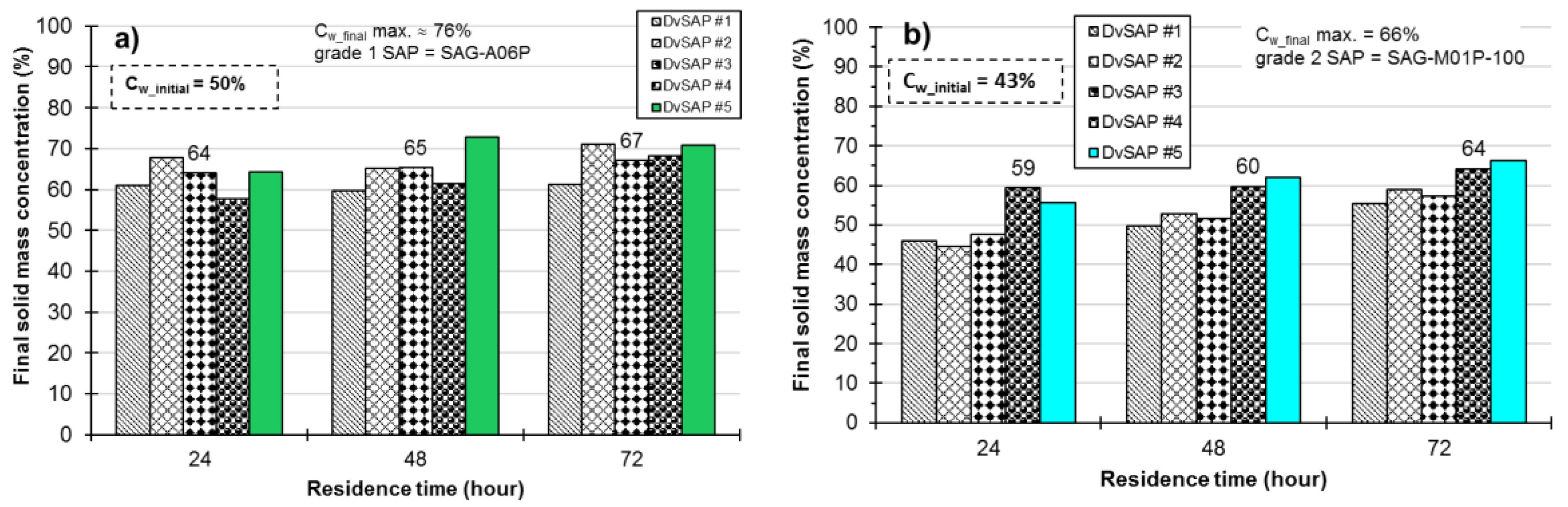

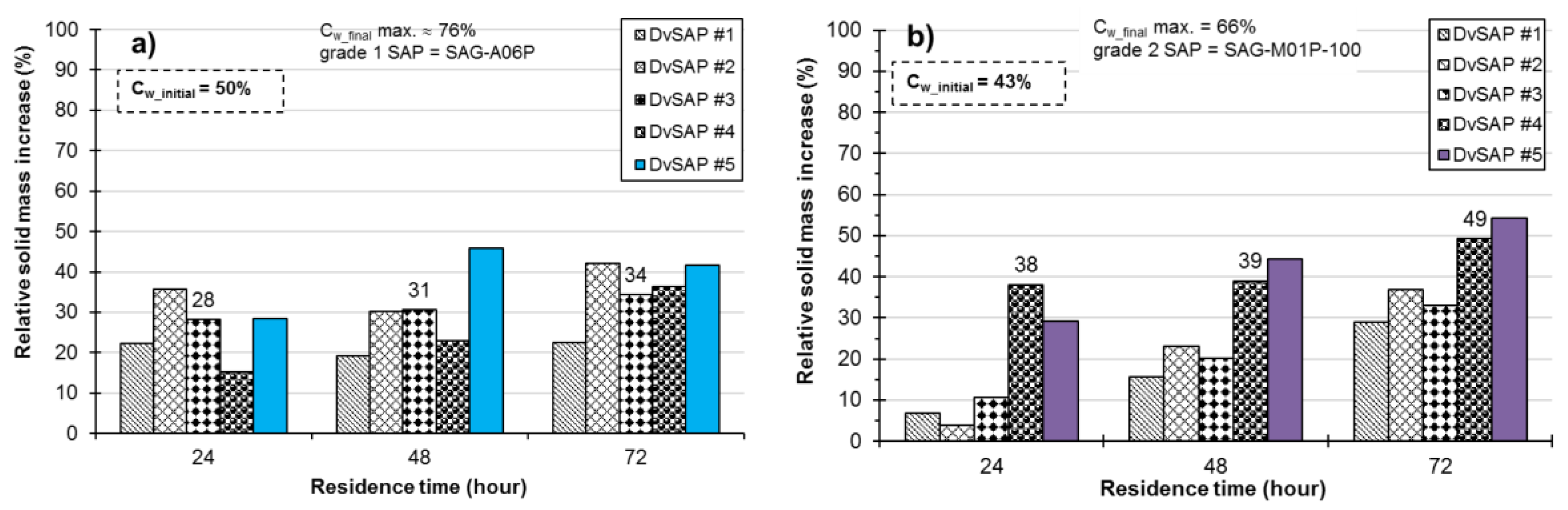

3.2.2. Plastic Bins Tailings Dewatering Tests (Series #3 Tests)

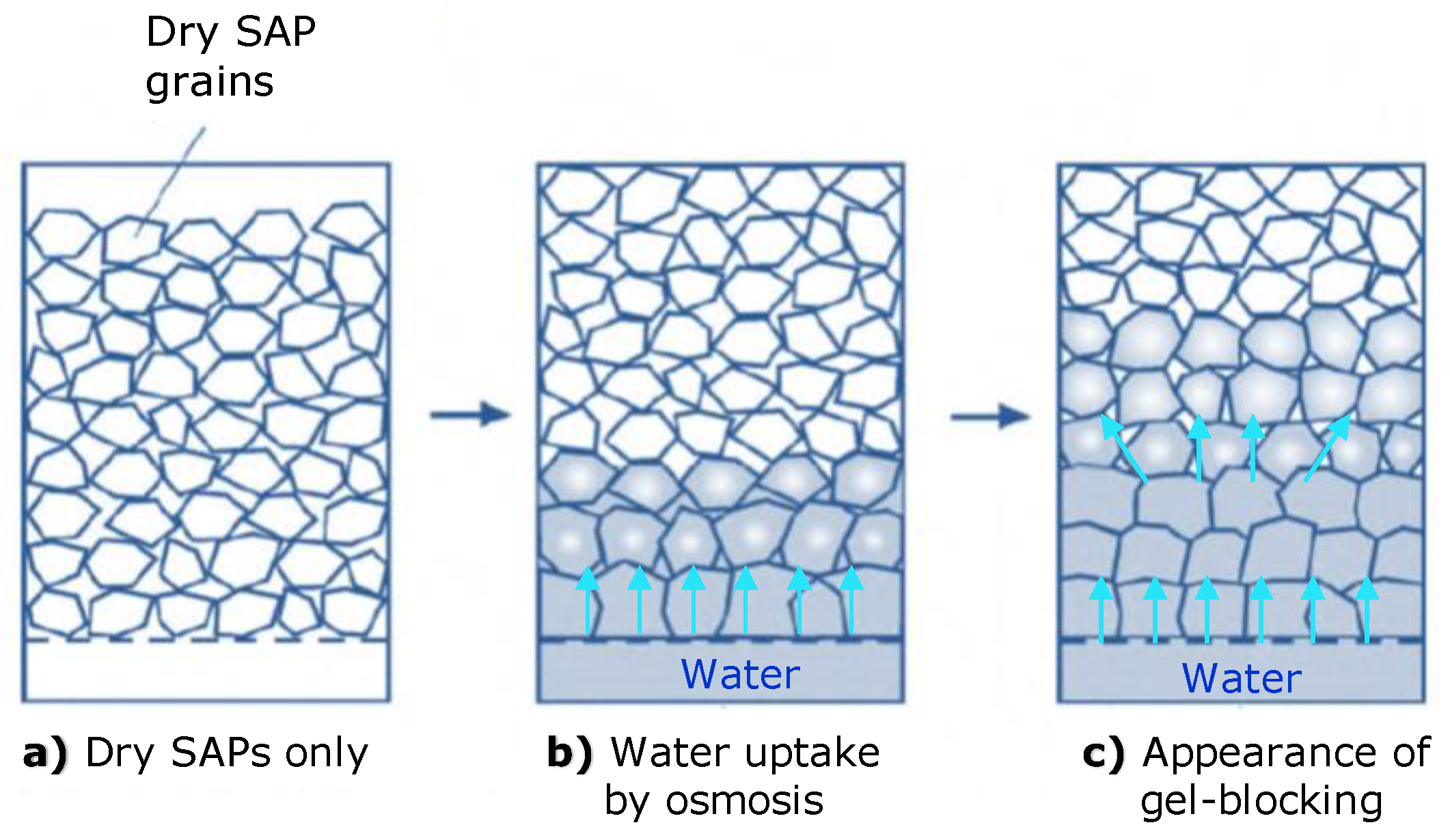

4. Discussion

4.1. Evolution of the Percentage of Absorbed Mine Water

4.2. Effect of Residence Time on Tailings Dewatering

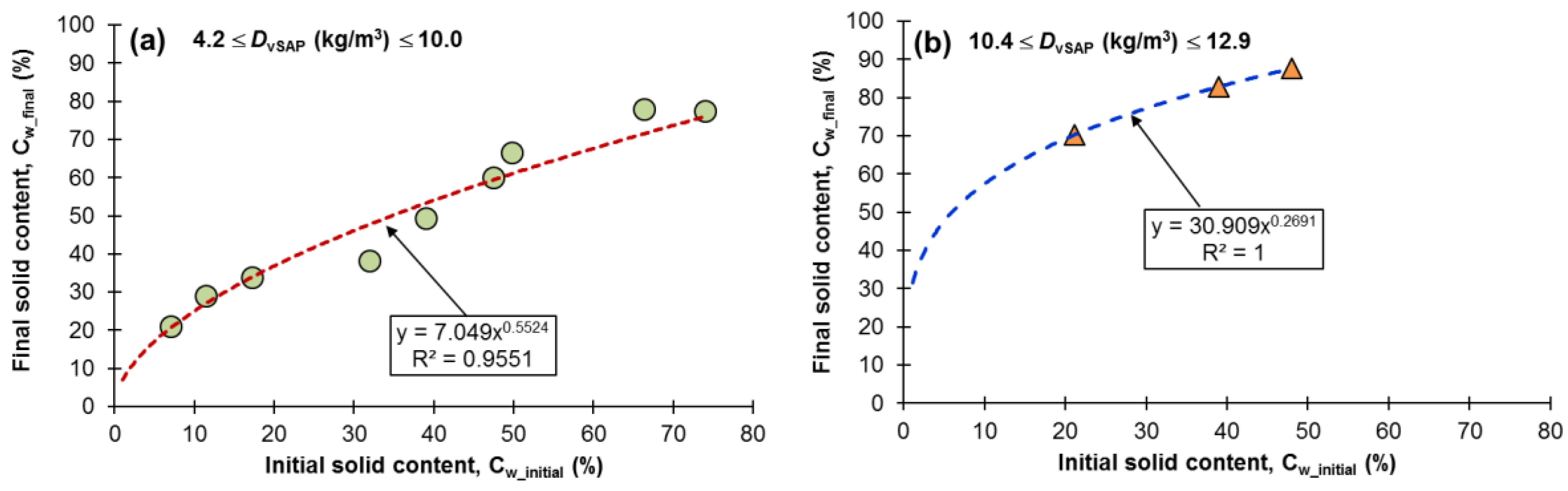

4.3. Empirical Relationship for Tailings Dewatering Using SAPs

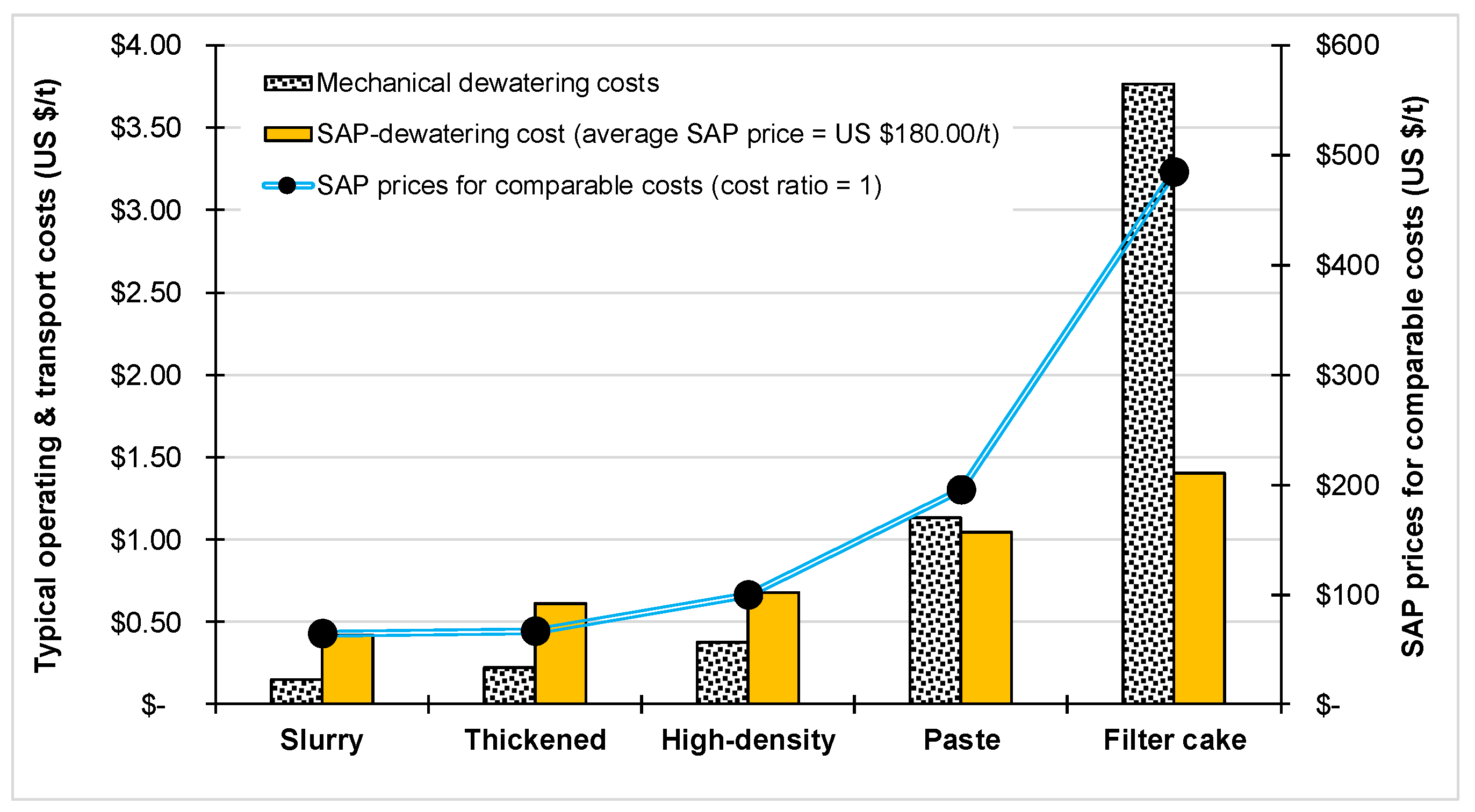

4.4. Regeneration of the SAPs for Their Multiple Reuse and Preliminary Economic Analysis

5. Conclusions

- The target final solids content Cw%_final of 68% was achieved for the Mine A tailings slurry;

- The coarser super absorbent polymers (SAPs) exhibit a higher absorbency (or equilibrium degree of swelling, Qeq) than the finer super absorbent polymers;

- The contact or residence time of the super absorbent polymers does not have a major impact on the amount of water absorbent capacity;

- Only the SAP dosages ≥ 10 kg/m3 would make it possible to achieve the consistency of thickened tailings with a final solids mass concentration greater than 70%;

- The occurrence of the gel-blocking phenomenon, which is reducing the water absorbent capacity of the super absorbent polymers in geotextile bags, has also been highlighted;

- Preliminary economic analysis has shown that, given the realities of the current SAP market, the costs of dewatering of tailings slurries would be very exorbitant for large-scale application;

- According to the results of this preliminary study, the acceptable price of SAPs would be only 18% of the current minimum market price of US $1000/t (i.e., a price reduction of almost 82%).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Aubertin, M.; Bussière, B.; Bernier, L. Environnement et Gestion des Résidus Miniers [CD-ROM]; Les Presses Internationales Polytechniques: Montreal, QC, Canada, 2002. [Google Scholar]

- Santamarina, J.C.; Torres-Cruz, L.A.; Bachus, R.C. Why coal ash and tailings dam disasters occur: Knowledge gaps and management shortcomings contribute to catastrophic dam failures. Sci. Mag. 2019, 364, 526–528. Available online: https://worldminetailingsfailures.org/ (accessed on 18 October 2019).

- Bowker, L.N.; Chambers, D.M. In the dark shadow of The supercycle: Tailings failure risk & public liability reach all time highs. Environments 2017, 4, 75. [Google Scholar] [CrossRef]

- Bowker, L.N.; Chambers, D.M. Root Causes of Tailings Management Failures: The Severity of Consequence of Failures Attributed to Overtopping; Colorado State University: Fort Collins, CO, USA, 2016; pp. 1915–2015. [Google Scholar]

- Bowker, L.N.; Chambers, D.M. The Risk, Public Liability and Economics of Tailings Storage Facility Failures; U.S. Department of Agriculture. Tonto National Forest: Payson, AZ, USA, 2015; 56p. Available online: https://www.resolutionmineeis.us/documents/bowker-chambers-2015 (accessed on 18 October 2019).

- Azam, S.; Li, Q. Tailings dam failures: A review of the last one hundred years. Geotech. News 2010, 28, 50–53. [Google Scholar]

- Davies, M.P. Tailings impoundment failures: Are geotechnical engineers listening. Geotech. News 2002, 20, 31–36. [Google Scholar]

- International Commission on Large Dams (ICOLD), United Nations Environment Programme (UNEP). Tailings dams risk of dangerous occurrences—Lessons learnt from practical experiences. Bulletin 2001, 121, 1–144. [Google Scholar]

- Robinsky, E.I. Thickened discharge—New approach to tailings disposal. CIM Bull. 1975, 68, 47–53. [Google Scholar]

- Landriault, D.A.; Verburg, R.; Cincilla, W.; Welch, D. Paste Technology for Underground Backfill and Surface Tailings Disposal Applications; Short Course Notes; Canadian Institute of Mining and Metallurgy, Technical Workshop: Vancouver, BC, Canada, 1997; 120p. [Google Scholar]

- Jewell, R.J.; Fourie, A.B.; Lord, E.R. Paste and Thickened Tailings—A Guide; The Australian Center for Geomechanics: Nedlands, Australia, 2006; 173p. [Google Scholar]

- Crowder, J.J. Deposition, Consolidation, and Strength of a Non-Plastic Tailings Paste for Surface Disposal. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2004; 162p. [Google Scholar]

- Belem, T.; Benzaazoua, M. Design and application of underground mine paste backfill technology. Geotech. Geol. Eng. 2008, 26, 147–174. [Google Scholar] [CrossRef]

- Benzaazoua, M.; Fall, M.; Belem, T. A contribution to understanding the hardening process of cemented pastefill. Miner. Eng. 2004, 17, 141–152. [Google Scholar] [CrossRef]

- Kesimal, A.; Yilmaz, E.; Ercikdi, B. Evaluation of paste backfill mixtures consisting of sulphide-rich mill tailings and varying cement contents. Cem. Concr. Res. 2004, 34, 1817–1822. [Google Scholar] [CrossRef]

- Lapierre, J. Étude Expérimentale du Comportement en Cisaillement de Résidus Miniers épaissis. Master’s Thesis, Université de Sherbrooke, Sherbrooke, QC, Canada, 2014; 29p. [Google Scholar]

- Wang, C.; Harbottle, D.; Liu, Q.; Xu, Z. Current state of fine mineral tailings treatment: A critical review on theory and practice. Miner. Eng. 2014, 58, 113–131. [Google Scholar] [CrossRef]

- Zohuriaan-Mehr, M.J.; Kabiri, K. Superabsorbent polymer materials: A review. Iran. Polym. J. 2008, 17, 451477. [Google Scholar]

- Ma, S.; Liu, M.; Chen, Z. Preparation and properties of a salt-resistant superabsorbent polymer. J. Appl. Polym. Sci. 2004, 93, 2532–2541. [Google Scholar] [CrossRef]

- Staples, T.L.; Chatterjee, P.K. Chapter VIII—Synthetic superabsorbents. Absorbent Technol. 2002, 13, 283–318. [Google Scholar] [CrossRef]

- Hassan, C.M.; Peppas, N.A. Structure and applications of Poly (Vinyl Alcohol) hydrogels produced by conventional crosslinking or by freezing/thawing methods. Adv. Polym. Sci. 2000, 153, 37–65. [Google Scholar]

- Peer, F.; Venter, T. Dewatering of coal fines using a super absorbent polymer. J. South. Afr. Inst. Min. Metall. 2003, 103, 403–409. [Google Scholar]

- Wang, X.; Feng, X.; Xu, Z.; Masliyah, J.H. Polymer aids for settling and filtration of oil sands tailings. Can. J. Chem. Eng. 2010, 88, 403–410. [Google Scholar] [CrossRef]

- Farkich, A. SAP Based Rapid Dewatering of Oil Sands Mature Fine Tailings. Ph.D. Thesis, Université d’Ottawa/University of Ottawa, Ottawa, ON, Canada, 2013. [Google Scholar]

- Farkish, A.; Fall, M. Rapid dewatering of oil sand mature fine tailings using super absorbent polymer (SAP). Miner. Eng. 2013, 50, 38–47. [Google Scholar] [CrossRef]

- Ismi, I.; Elaidi, H.; Rifi, E.H.; Lebkiri, A.; Skalli, A. Comportement de polyacrylate de sodium au contact des solutions aqueuses en absence et en présence d’ions métalliques (Ag+, Cu2+, Cr3+). J. Mater. Environ. Sci. 2015, 6, 1060–1067. [Google Scholar]

- Bahaj, H.; Benaddi, R.; Bakass, M.; Bayane, C.; Bellat, J.P. Comportement du gonflement d’un polymère superabsorbant vis-à-vis de l’eau dans un sol sableux. In JEEP–Journées d’Étude des Équilibres entre Phases (p. 00018); EDP Sciences: Annecy, France, 2009. [Google Scholar]

- El’yashevich, G.K.; Bel’nikevich, N.G.; Vesnebolotskaya, S.A. Swelling–Contraction of Sodium Polyacrylate Hydrogels in Media with Different pH Values. Polym. Sci. Ser. A 2009, 51, 550–553. [Google Scholar] [CrossRef]

- Sahi, A.; Belem, T.; Maqsoud, A.; Mbonimpa, M. Preliminary assessment of tailings pulp thickening using super absorbent polymers. In Proceedings of the 70th Canadian Geotechnical Conference GeoOttawa 2017, Ottawa, ON, Canada, 1–4 October 2017. 8p. [Google Scholar]

- Wack, H.; Ulbricht, M. Gel blocking effects during the swelling of polymeric hydrogels. Ind. Eng. Chem. Res. 2007, 46, 359. [Google Scholar] [CrossRef]

- Kuruwita-Mudiyanselage, T.D. Smart Polymer Materials. Ph.D. Thesis, Bowling Green State University, Graduate College, Bowling Green, OH, USA, 2008; 129p. [Google Scholar]

- Klohn Crippen Berger (KCB). Report 2.50.1, Study of Tailings Management Technologies; Prepared for the Mine Environment Neutral Drainage (MEND) Project; NRCan: Ottawa, ON, Canada, 2017; 164p. [Google Scholar]

| Parameter | Value | Mineral | Grade (%) |

|---|---|---|---|

| D10 | 3.2 µm | Quartz | 28.14 |

| D30 | 9.8 µm | Chlorite | 4.3 |

| D50 | 21.7 µm | Albite | 30 |

| D60 | 31.6 µm | Oligoclase | 4.8 |

| D90 | 112.1 µm | Labradorite | 6.2 |

| CU | 9.8 | Orthoclase | 14 |

| Cc | 0.9 | Biotite | 6.4 |

| P20 µm | 52.5% | Calcite | 3.2 |

| P80 µm | 83.8% | Pyrite | 1.62 |

| Particle Gradation | Grade 1 SAP = Grade SAG-A06P (Larger Size Particles) | Grade 2 SAP = Grade SAG-M01P-100 (Medium Size Particles) |

|---|---|---|

| >1200 µm | 0% | 0% |

| between 600 and 1200 µm | 4% | ≈1% |

| between 300 and 600 µm | 91% | 78% |

| between 150 and 300 µm | ≈5% | 20% |

| between 75 and 150 µm | trace | ≈1% |

| <75 µm | 0% | trace |

| Test# | Grade 1 SAP | Grade 2 SAP | ||

|---|---|---|---|---|

| Mdry-SAP (g) | * DvSAP-s (kg/m3) | Mdry-SAP (g) | * DvSAP-s (kg/m3) | |

| #1 | 0.8 | 5.8 | 0.8 | 5.5 |

| #2 | 0.85 | 6.2 | 0.85 | 5.8 |

| #3 | 0.9 | 6.6 | 0.9 | 6.2 |

| #4 | 0.95 | 6.9 | 0.95 | 6.5 |

| #5 | 1 | 7.3 | 1 | 6.8 |

| #6 | 1.1 | 8.0 | 1.05 | 7.2 |

| #7 | 1.5 | 10.9 | 1.1 | 7.5 |

| #8 | 1.6 | 11.7 | 1.15 | 7.9 |

| #9 | 1.7 | 12.4 | 1.2 | 8.2 |

| #10 | 1.8 | 13.1 | 1.25 | 8.6 |

| #11 | 1.9 | 13.8 | ||

| Test# | Mdry-SAP* (g) | ρslurry (kg/m3) | Cw%_initial (%) | DvSAP-s (kg/m3) |

|---|---|---|---|---|

| #1 | 120 | 1049 | 7 | 4.2 |

| #2 | 120 | 1078 | 11 | 4.3 |

| #3 | 120 | 1121 | 17 | 4.5 |

| #4 | 120 | 1457 | 50 | 5.8 |

| #5 | 120 | 1717 | 66 | 6.9 |

| #6 | 120 | 1873 | 74 | 7.5 |

| #7 | 210 | 1252 | 32 | 8.8 |

| #8 | 210 | 1326 | 39 | 9.3 |

| #9 | 210 | 1426 | 47 | 10.0 |

| #10 | 270 | 1153 | 21 | 10.4 |

| #11 | 270 | 1325 | 39 | 11.9 |

| #12 | 270 | 1434 | 48 | 12.9 |

| Tailings Consistency | Initial Solids Content (%) | Typical Solids Content at Deposition (%) | Thickeners & Filtration Systems Costs (US $/t Slurry) | SAP Dosage (kg/t Slurry) * |

|---|---|---|---|---|

| Slurry | 25 | 45 | 0.15 | 11.65 |

| Thickened | 25 | 65 | 0.23 | 17.01 |

| High-density | 25 | 70 | 0.38 | 18.83 |

| Paste | 25 | 78 | 1.13 | 28.97 |

| Filter cake | 25 | 85 | 3.76 | 35.15 |

| Equivalent Consistency | Mass of SAP Needed (t/Day) | Cost of SAP (US $/t Slurry) | Total Cost of SAP for 1 Use (US $/Day) | Total Cost of SAP for 5 Uses (US $/Day) |

|---|---|---|---|---|

| Slurry | 2498 | 11.65 | 29,107 | 5821 |

| Thickened | 3648 | 17.01 | 62,051 | 12,410 |

| High-density | 4038 | 18.83 | 76,039 | 15,208 |

| Paste | 6213 | 28.97 | 179,985 | 35,997 |

| Filter cake | 8347 | 38.92 | 324,851 | 64,970 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sahi, A.; El Mahboub, K.; Belem, T.; Maqsoud, A.; Mbonimpa, M. Dewatering of Mine Tailings Slurries Using Superabsorbent Polymers (SAPs) Reclaimed from Industrial Reject of Baby Diapers: A Preliminary Study. Minerals 2019, 9, 785. https://doi.org/10.3390/min9120785

Sahi A, El Mahboub K, Belem T, Maqsoud A, Mbonimpa M. Dewatering of Mine Tailings Slurries Using Superabsorbent Polymers (SAPs) Reclaimed from Industrial Reject of Baby Diapers: A Preliminary Study. Minerals. 2019; 9(12):785. https://doi.org/10.3390/min9120785

Chicago/Turabian StyleSahi, Amal, Khadija El Mahboub, Tikou Belem, Abdelkabir Maqsoud, and Mamert Mbonimpa. 2019. "Dewatering of Mine Tailings Slurries Using Superabsorbent Polymers (SAPs) Reclaimed from Industrial Reject of Baby Diapers: A Preliminary Study" Minerals 9, no. 12: 785. https://doi.org/10.3390/min9120785

APA StyleSahi, A., El Mahboub, K., Belem, T., Maqsoud, A., & Mbonimpa, M. (2019). Dewatering of Mine Tailings Slurries Using Superabsorbent Polymers (SAPs) Reclaimed from Industrial Reject of Baby Diapers: A Preliminary Study. Minerals, 9(12), 785. https://doi.org/10.3390/min9120785