In Situ X-Ray CT Investigations of Meso-Damage Evolution of Cemented Waste Rock-Tailings Backfill (CWRTB) during Triaxial Deformation

Abstract

1. Introduction

2. Material and Methods

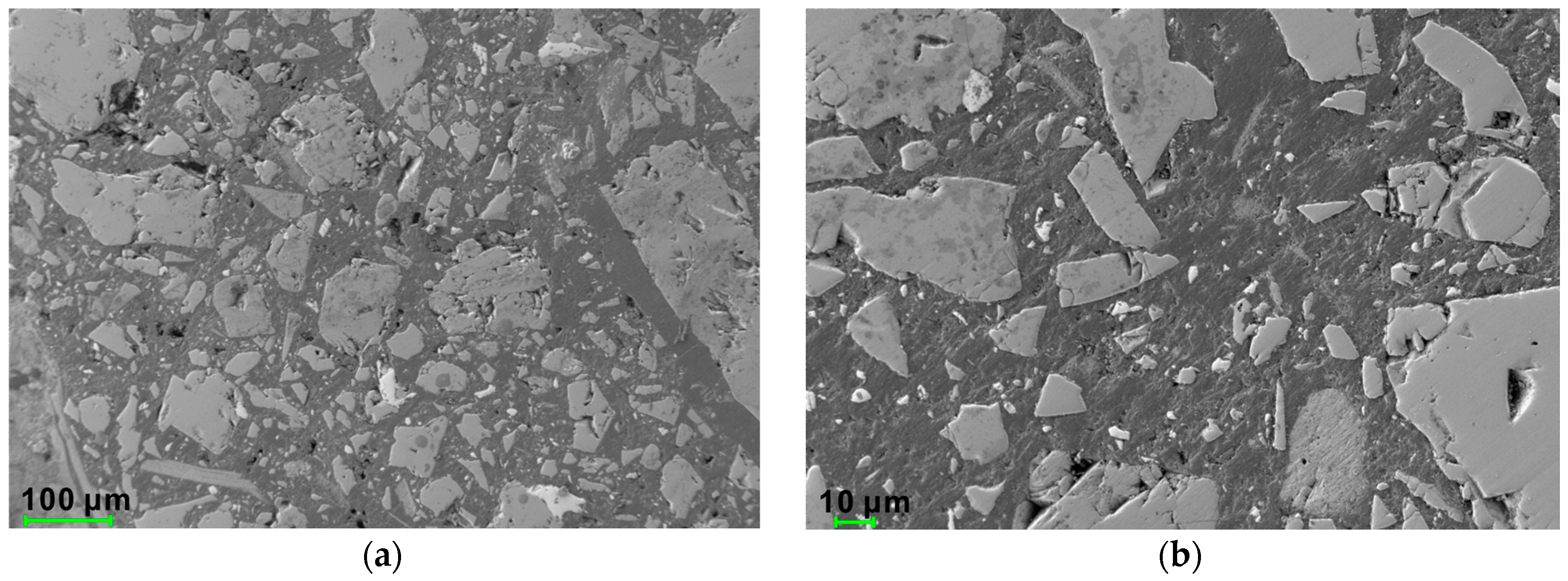

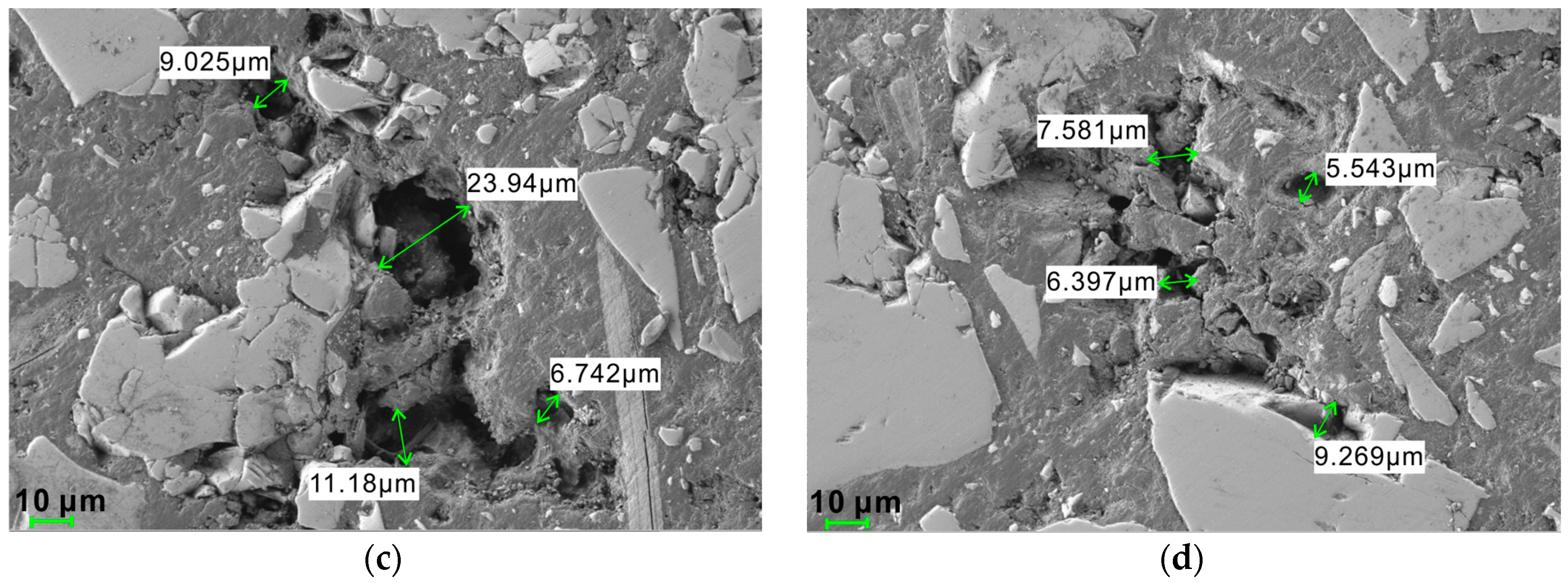

2.1. Tailings and Binders

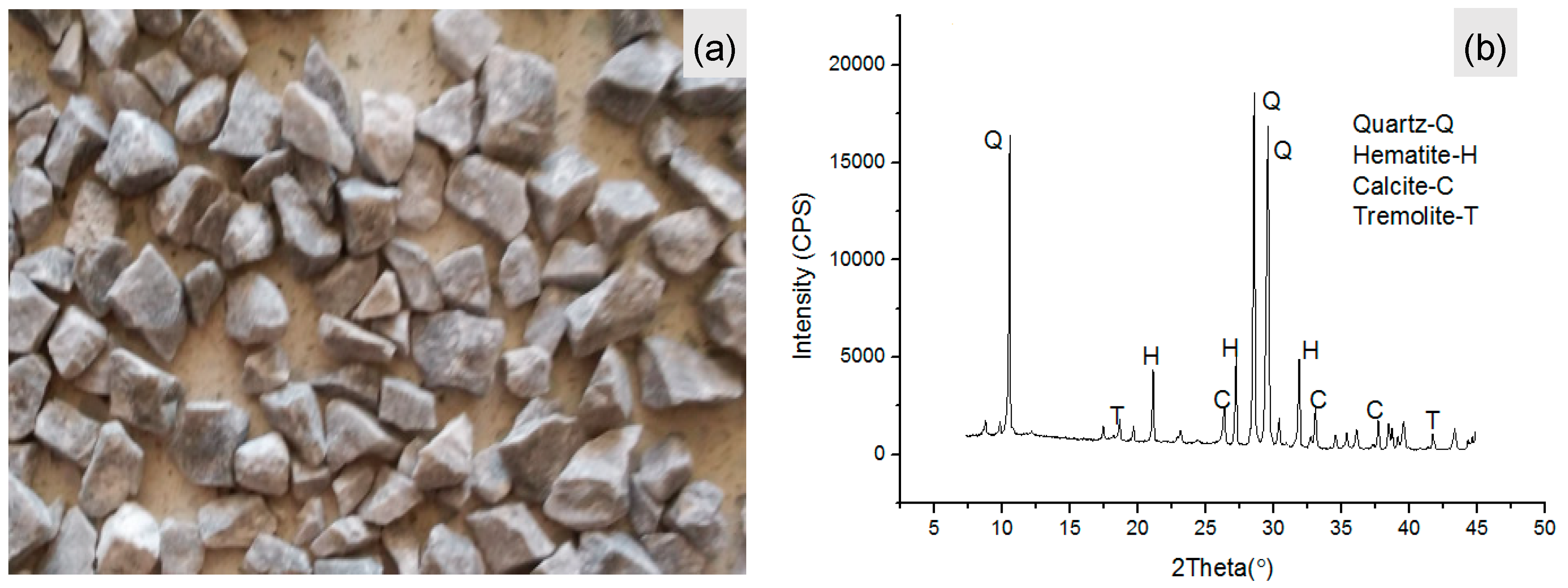

2.2. Waste Rock

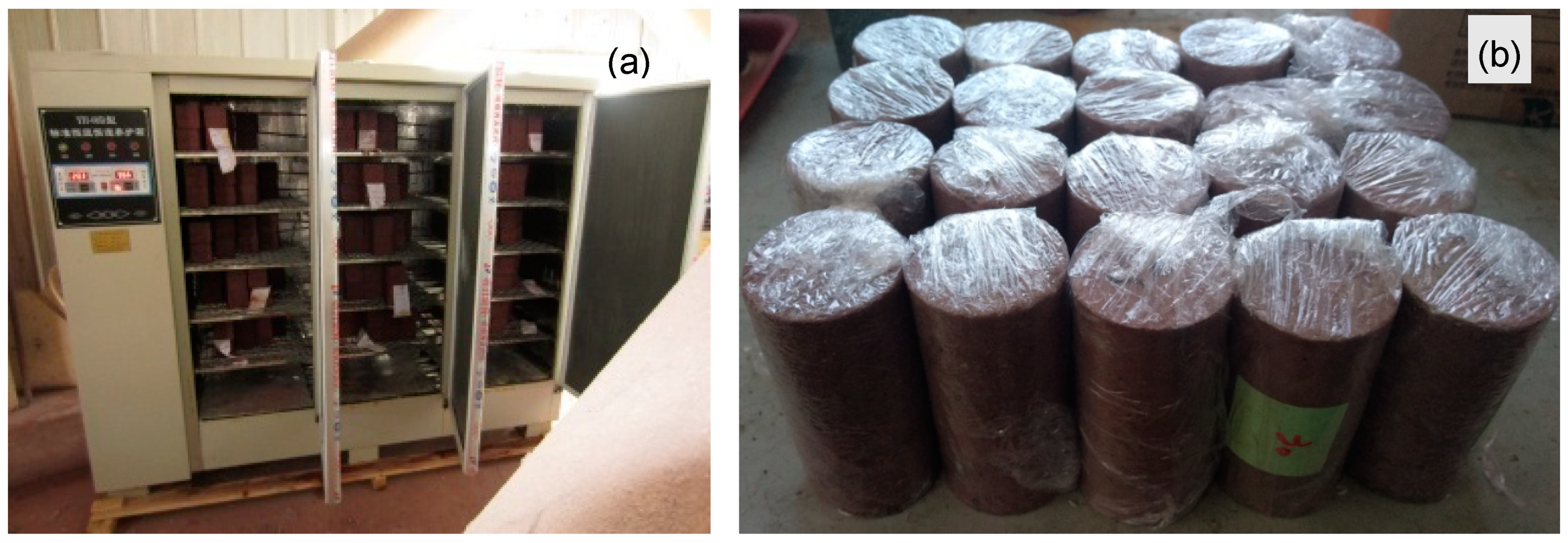

2.3. CWRTB Sample Preparation

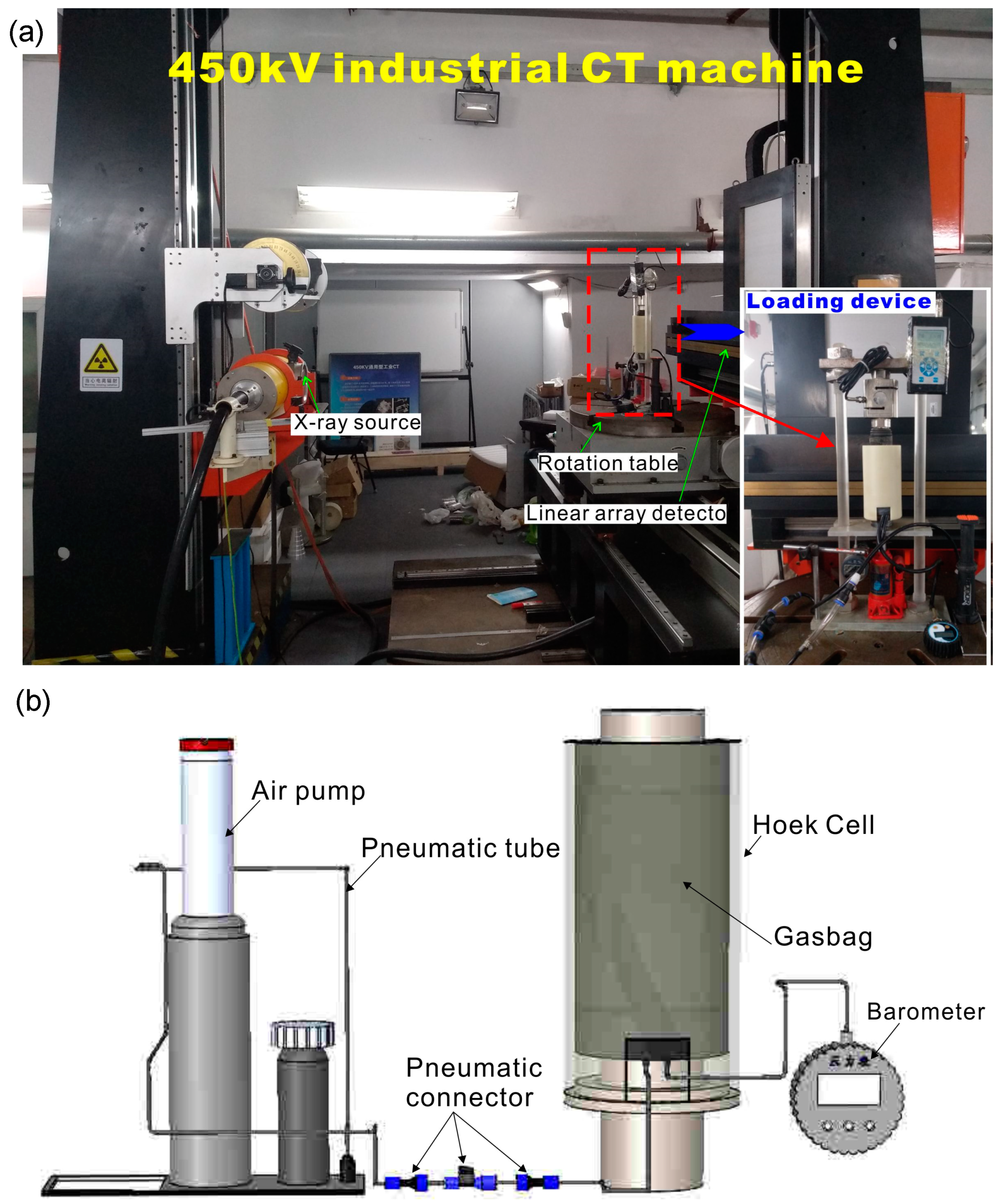

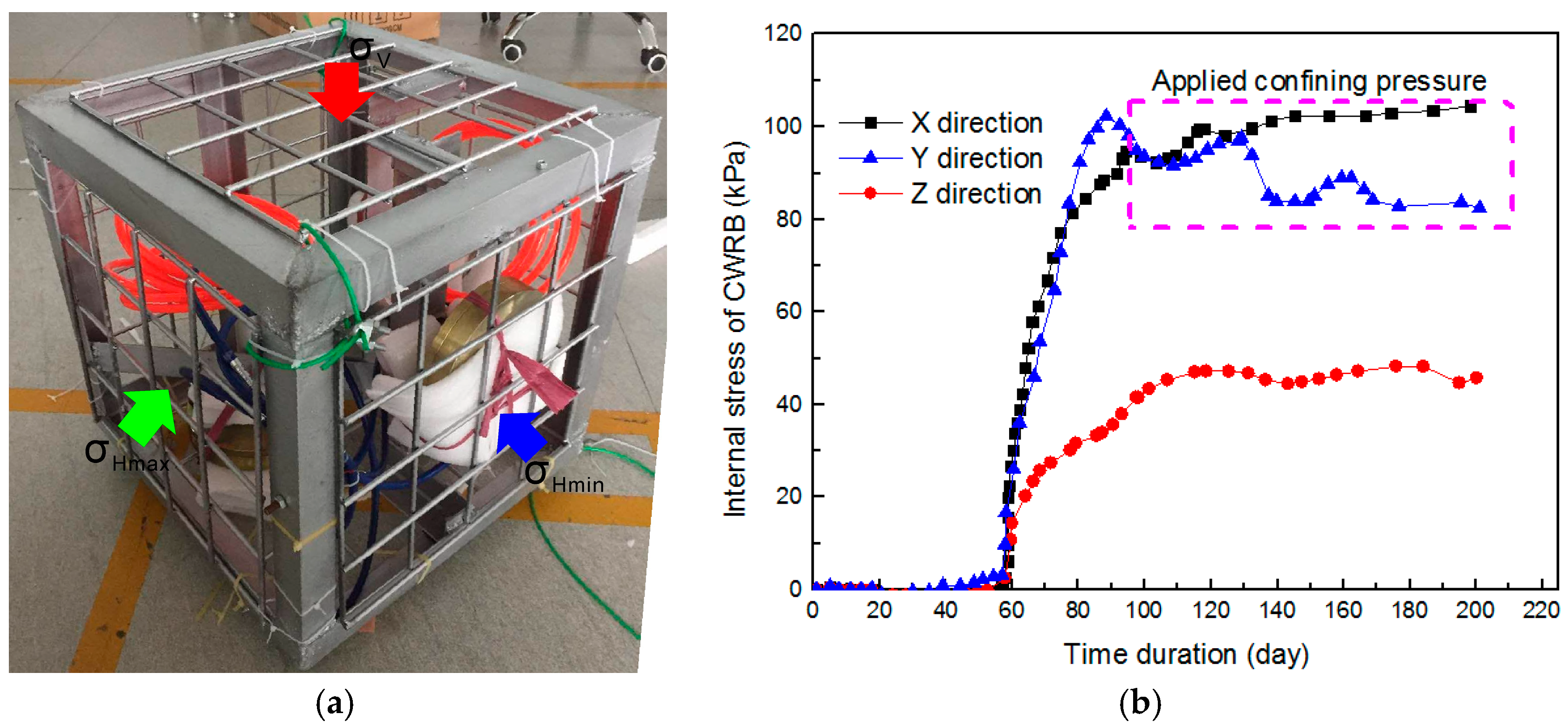

2.4. Lab Test Set-up

2.5. Testing Scheme

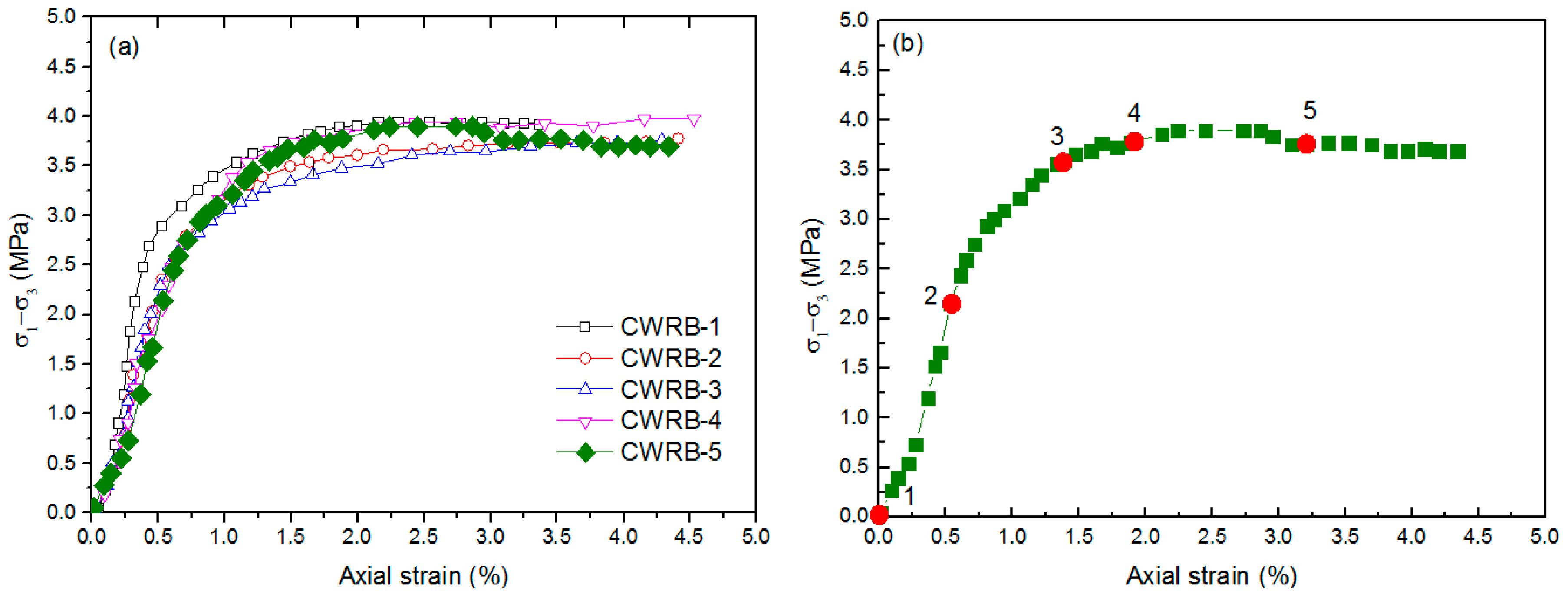

3. Results and Discussions

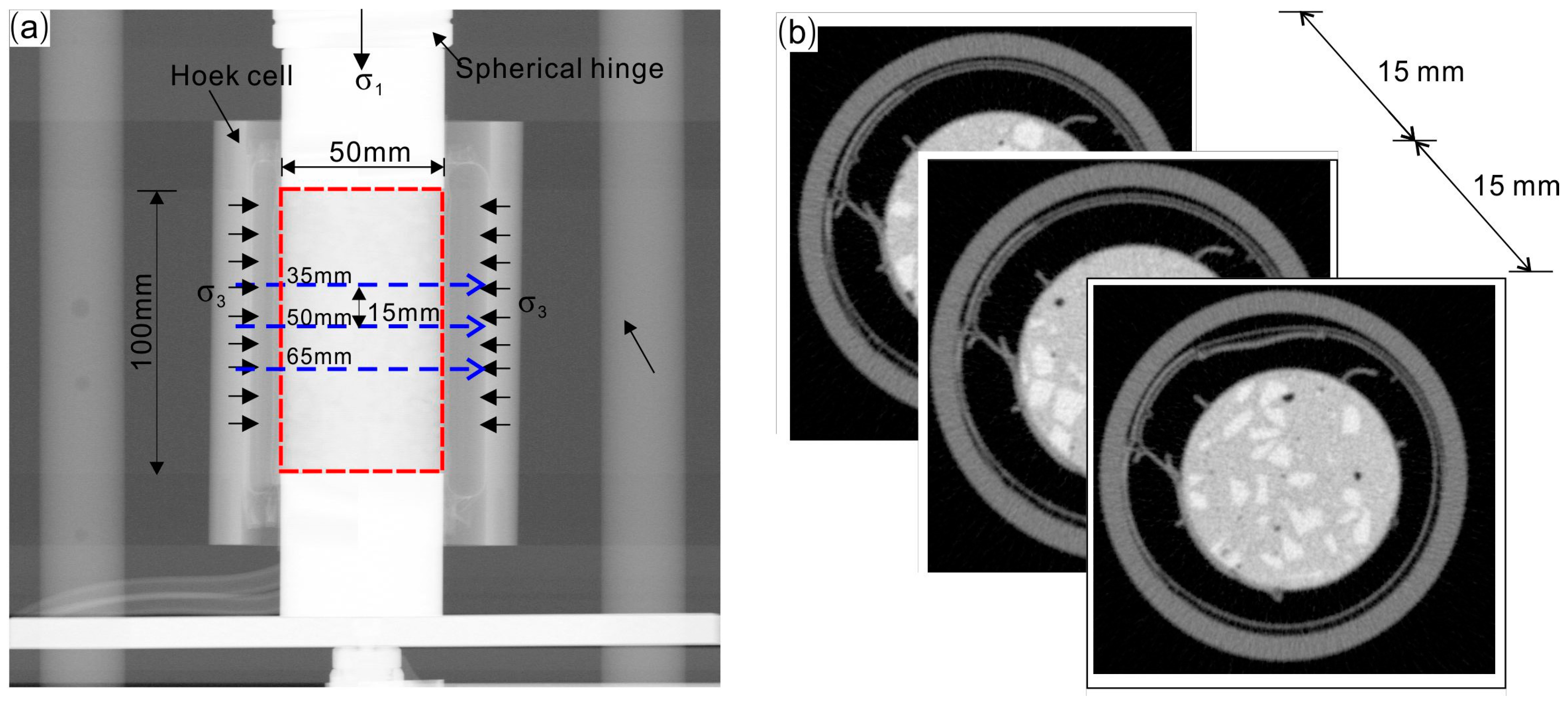

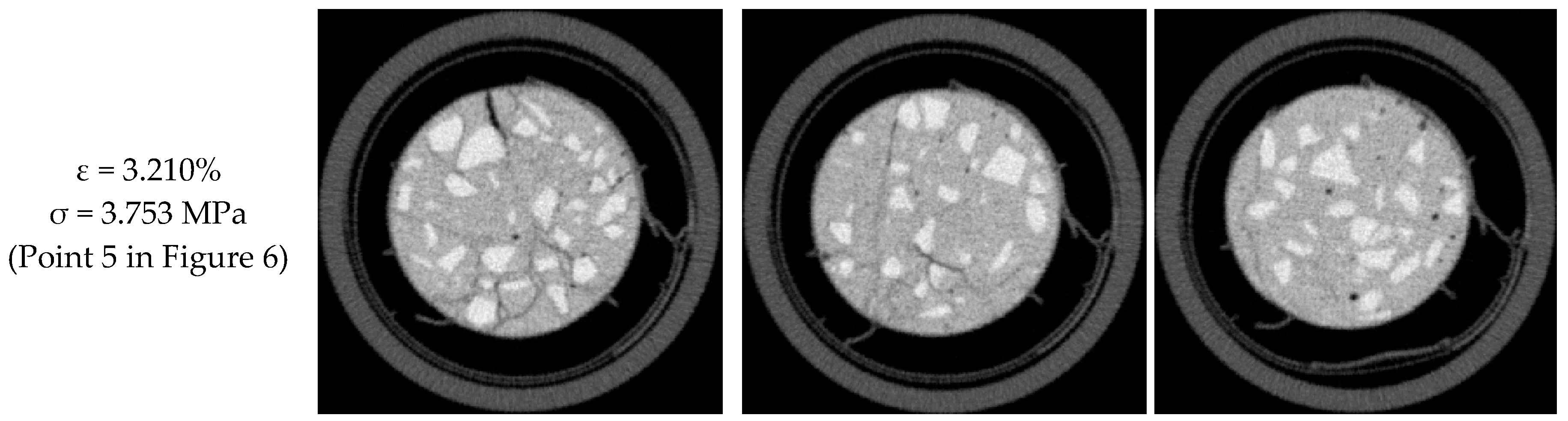

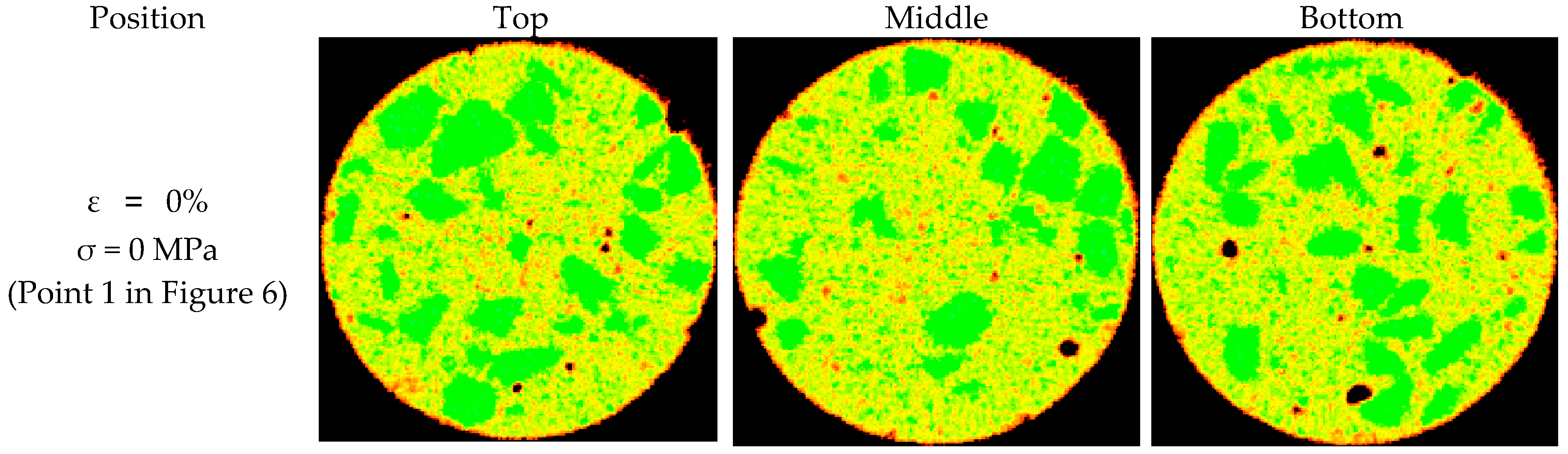

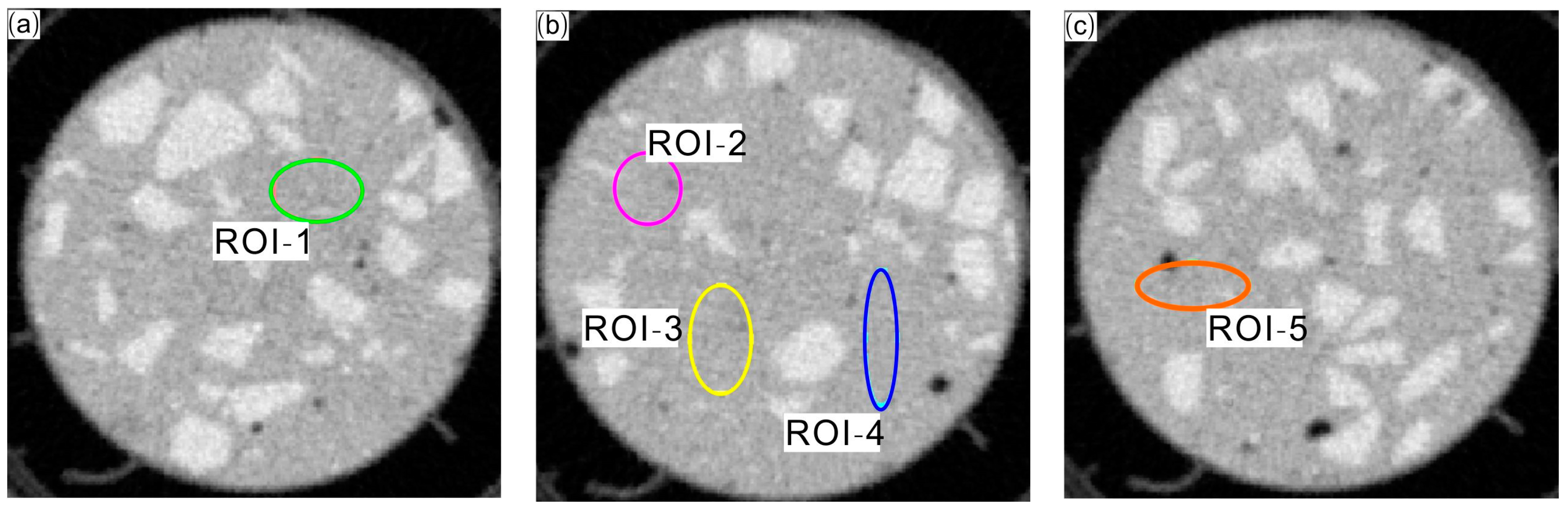

3.1. Observation of Structural Changes

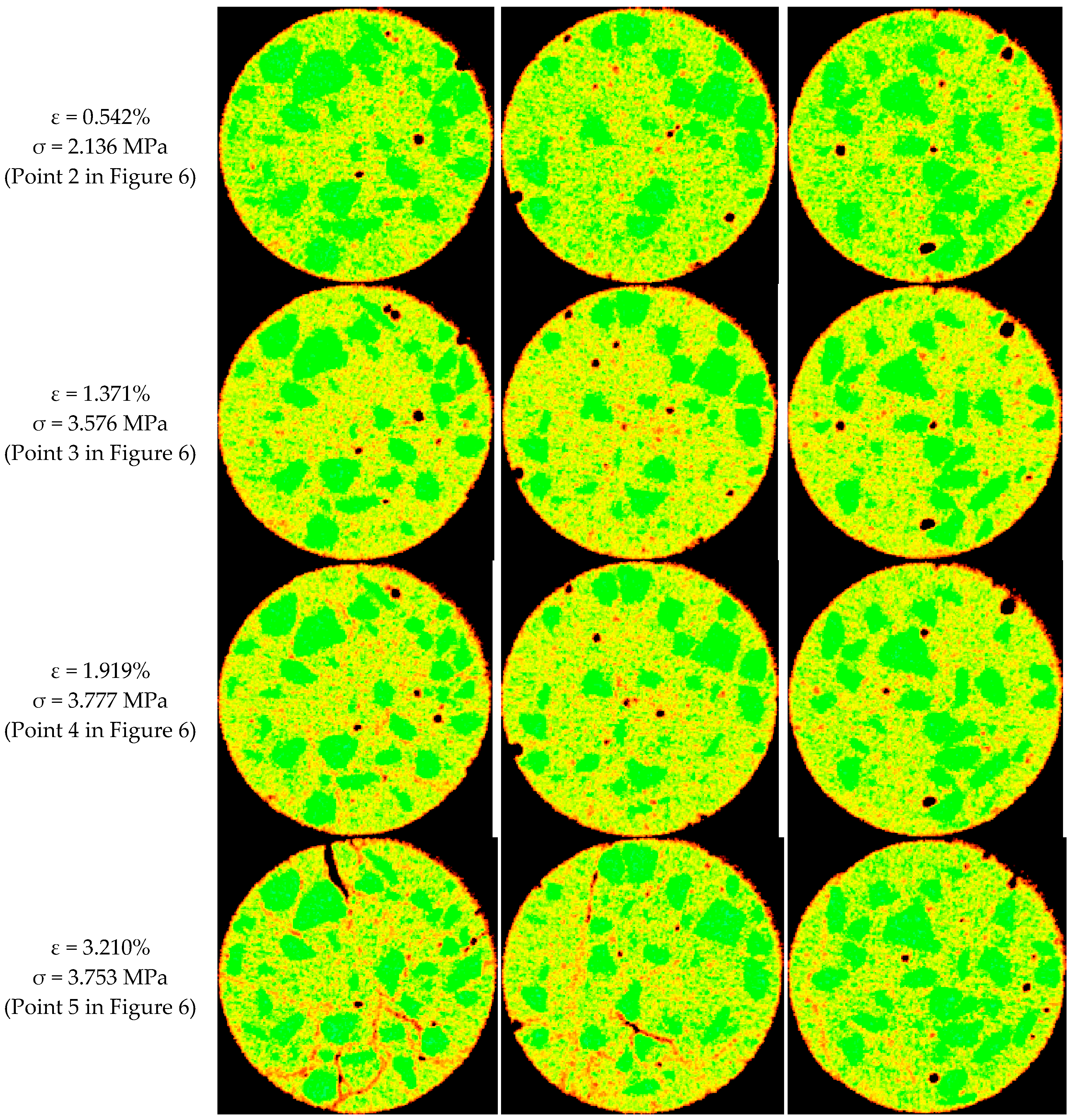

3.2. CT Value Characteristics of ROI Regions

3.3. Meso-damage Evolution Analysis

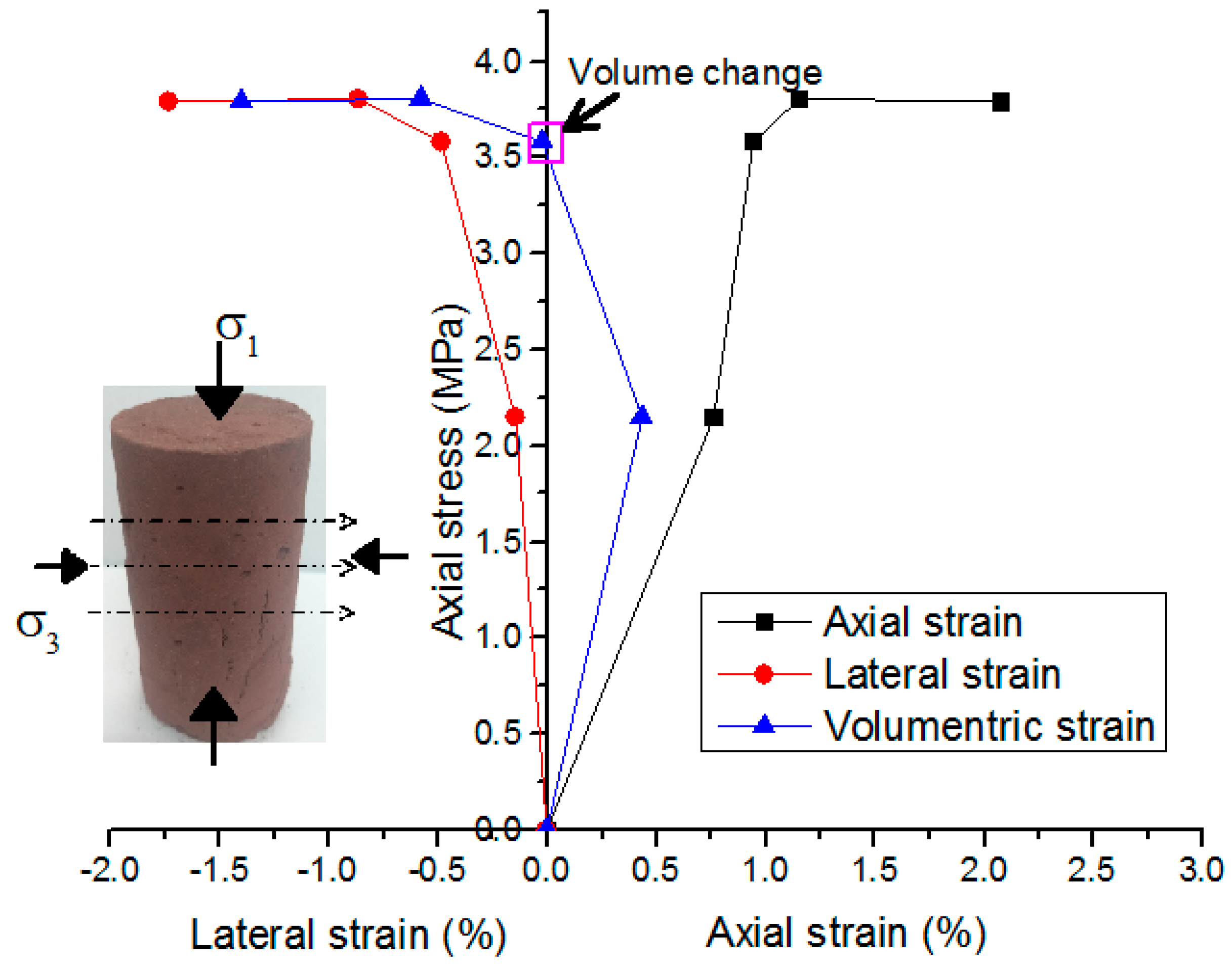

3.4. Dilatancy Behavior Analysis

4. Discussions

5. Conclusion Remarks

Author Contributions

Funding

Acknowledgements

Conflicts of Interest

References

- Roux, K.L.; Bawden, W.F.; Grabinsky, M.F. Field properties of cemented paste backfill at the golden giant mine. Mining Technol. 2013, 114, 65–80. [Google Scholar] [CrossRef]

- Yilmaz, E. Advances in reducing large volumes of environmentally harmful mine waste rocks and tailings. Miner. Resour. Manag. 2011, 27, 89–112. [Google Scholar]

- Koohestani, B.; Bussière, B.; Belem, T.; Koubaa, A. Influence of polymer powder on properties of cemented paste backfill. Int. J. Miner. Process. 2017, 167, 1–8. [Google Scholar] [CrossRef]

- Yilmaz, E. One-dimensional consolidation parameters of cemented paste backfills/parametry Jednowymiarowej Konsolidacji Podsadzki W Postaci Cementowej Pasty. Gospod. Surow. Miner.-Miner. Resour. Manag. 2012, 28, 29–45. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, H.; Taheri, A.; Deng, J.; Ke, B. Effects of superplasticizer on the hydration, consistency, and strength development of cemented paste backfill. Minerals 2018, 8, 381. [Google Scholar] [CrossRef]

- Sivakugan, N.; Rankine, R.M.; Rankine, K.J.; Rankin, K.S. Geotechnical considerations in mine backfilling in Australia. J. Clean. Prod. 2006, 14, 1168–1175. [Google Scholar] [CrossRef]

- Licskó, I.; Lois, L.; Szebényi, G. Tailings as a source of environmental pollution. Water Sci. Technol. 1999, 39, 333–336. [Google Scholar] [CrossRef]

- Passariello, B.; Giuliano, V.; Quaresima, S.; Barbaro, M.; Caroli, S.; Forte, G.; Carelli, G.; Iavicoli, I. Evaluation of the environmental contamination at an abandoned mining site. Microchem. J. 2002, 73, 245–250. [Google Scholar] [CrossRef]

- Yin, S.H.; Wu, A.X.; Hu, K.J.; Wang, Y.; Zhang, Y.K. The effect of solid components on the rheological and mechanical properties of cemented paste backfill. Miner. Eng. 2012, 35, 61–66. [Google Scholar] [CrossRef]

- Fall, M.; Benzaazoua, M. Modeling the effect of sulphate on strength development of paste backfill and binder mixture optimization. Cem. Concr. Res. 2005, 35, 301–314. [Google Scholar] [CrossRef]

- Fall, M.; Pokharel, M. Coupled effects of sulphate and temperature on the strength development of cemented tailings backfills: Portland cement-paste backfill. Cem. Concr. Compos. 2013, 32, 819–828. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, J.; Zhang, Q.; Nie, S. Backfilling technology of substituting waste and fly ash for coal underground in China coal mining area. Environ. Eng. Manag. J. 2011, 10, 112–121. [Google Scholar] [CrossRef]

- Liu, L.; Fang, Z.F.; Wu, Y.P.; Lai, X.P.; Wang, P.; Song, K.I. Experimental investigation of solid-liquid two-phase flow in cemented rock-tailings backfill using Electrical Resistance Tomography. Construct. Build. Mater. 2018, 175, 267–276. [Google Scholar] [CrossRef]

- Hane, I.; Belem, T.; Benzaazoua, M.; Maqsoud, A. Laboratory Characterization of Cemented Tailings Paste Containing Crushed Waste Rocks for Improved Compressive Strength Development. Geotech. Geol. Eng. 2017, 35, 645–662. [Google Scholar] [CrossRef]

- Wu, J.Y.; Feng, M.M.; Yu, B.Y.; Chen, Z.Q.; Mao, X.B.; Han, G.S. Experimental study of strength and deformation characteristics of cemented waste rock backfills with continuous gradation. Rock Soil Mech. 2017, 38, 101–107. [Google Scholar]

- He, G.C.; Liu, Y.; Ding, D.X.; Zhang, Z.J. Strength characteristic of cemented waste rock backfills and its application. J. Min. Saf. Eng. 2013, 30, 75–79. [Google Scholar]

- He, G.C.; Liu, S.L.; Huang, B.X.; Zhang, Z.J.; Ding, D.X. Reasonable matching for cemented waste rock backfill and sand shale. J. Min. Saf. Eng. 2017, 34, 371–377. [Google Scholar]

- Liu, C.; Han, B.; Sun, W.; Wu, J.X.; Yao, S.; Hu, H.Y. Experimental study of strength of backfillings of cemented rock debris and its application under low temperature condition. Chin. J. Rock Mech. Eng. 2015, 34, 139–147. [Google Scholar]

- Du, X.J.; Feng, G.R.; Guo, Y.X.; Qi, T.Y.; Zhang, Y.J.; Guo, J. Failure analyses of unconfined CCWBM body in uniaxial compression based on central pressure variation. Waste Manag. Res. 2018, 36, 159–168. [Google Scholar] [CrossRef] [PubMed]

- Anay, R.; Soltangharaei, V.; Assi, L.; DeVol, T.; Ziehl, P. Identification of damage mechanisms in cement paste based on acoustic emission. Construct. Build. Mater. 2018, 164, 286–296. [Google Scholar] [CrossRef]

- Assi, L.; Anay, R.; Leaphart, D.; Soltangharaei, V.; Ziehl, P. Understanding Early Geopolymerization Process of Fly Ash-Based Geopolymer Paste Using Pattern Recognition. ConsJ. Mater. Civ. Eng. 2018, 30, 04018092. [Google Scholar] [CrossRef]

- Pierce, M.E. Laboratory and Numerical Analysis of the Strength and Deformation. Behaviour of Paste Backfill; Queen’s University: Kingston, ON, Canada, 1997. [Google Scholar]

- Liu, Q.; Liu, D.; Tian, Y.; Liu, X. Numerical simulation of stress–strain behaviour of cemented paste backfill in triaxial compression. Eng. Geol. 2017, 231, 165–175. [Google Scholar] [CrossRef]

- Fall, M.; Belem, T.; Samb, S.; Benzaazoua, M. Experimental characterization of the stress–strain behaviour of cemented paste backfill in compression. J. Mater. Sci. 2007, 42, 3914–3922. [Google Scholar] [CrossRef]

- Wu, J.; Feng, M.; Xu, J.; Qiu, P.; Wang, Y.; Han, G. Particle size distribution of cemented rockfill effects on strata stability in filling mining. Minerals 2018, 8, 407. [Google Scholar] [CrossRef]

- Xu, W.B.; Song, W.D.; Wang, D.X.; Ma, Y. Characteristic analysis of deformation failure and energy dissipation of cemented backfill body under triaxial compression. Rock Soil Mech. 2014, 35, 3421–3429. [Google Scholar]

- De ARAÚJO, E.E.B.; Simon, D.; de FRANÇA, F.A.N.; de Freitas Neto, O. Shear Strength of a Cemented Paste Backfill Submitted to High Confining Pressure. In Applied Mechanics and Materials; Trans Tech Publications: Zurich, Switzerland, 2017; Volume 858, pp. 219–224. [Google Scholar]

- Deng, D.Q.; Gao, Y.T.; Wu, S.C.; Yu, W.J. Experimental study of destructive energy dissipation properties of backfill under complicated stress condition. Rock Soil Mech. 2010, 31, 737–742. [Google Scholar]

- Wang, Y.; Li, C.; Hou, Z.; Yi, X.; Wei, X. In Vivo X-ray Computed Tomography Investigations of Crack Damage Evolution of Cemented Waste Rock Backfills (CWRB) under Uniaxial Deformation. Minerals 2018, 8, 539. [Google Scholar] [CrossRef]

- Sun, W.; Hou, K.; Yang, Z.; Wen, Y. X-ray CT three-dimensional reconstruction and discrete element analysis of the cement paste backfill pore structure under uniaxial compression. Construct. Build. Mater. 2017, 138, 69–78. [Google Scholar] [CrossRef]

- GB/T 175-2007, Common Portland Cement; Standards Press of China: Beijing, China, 2007.

- MWRPRC (Ministry of Water Resources of the People’s Republic of China). GB/T 50123-1999: Standard for Soil Test Method; MWRPRC: Beijing, China, 1999.

- Hirono, T.; Takahashi, M.; Nakashima, S. In situ visualization of fluid flow image within deformed rock by X-ray CT. Eng. Geol. 2003, 70, 37–46. [Google Scholar] [CrossRef]

- Cnudde, V.; Boone, M.N. High-resolution X-ray computed tomography in geosciences: A review of the current technology and applications. Earth-Sci. Rev. 2013, 123, 1–17. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.H.; Hao, J.; Zhou, R.Q. X-ray micro-tomography for investigation of meso-structural changes and crack evolution in Longmaxi formation shale during compressive deformation. J. Pet. Sci. Eng. 2018, 164, 278–288. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Wu, Y.F.; Lin, C.; Zhang, B. Experimental study on meso-damage cracking characteristics of RSA by CT test. Environ. Earth Sci. 2015, 73, 5545–5558. [Google Scholar] [CrossRef]

- Zhou, X.P.; Zhang, Y.X.; Ha, Q.L. Real-time computerized tomography (CT) experiments on limestone damage evolution during unloading. Theor. Appl. Fract. Mech. 2008, 50, 49–56. [Google Scholar] [CrossRef]

- Karpyn, Z.T.; Alajmi, A.; Radaelli, F.; Halleck, P.M.; Grader, A.S. X-ray CT and hydraulic evidence for a relationship between fracture conductivity and adjacent matrix porosity. Eng. Geol. 2009, 103, 139–145. [Google Scholar] [CrossRef]

- Watanabe, Y.; Lenoir, N.; Otani, J.; Nakai, T. Displacement in sand under triaxial compression by tracking soil particles on X-ray CT data. Soils Found. 2012, 52, 312–320. [Google Scholar] [CrossRef]

- Wang, Y.; Hou, Z.Q.; Hu, Y.Z. In situ X-ray micro-CT for investigation of damage evolution in black shale under uniaxial compression. Environ. Earth Sci. 2018, 77, 717. [Google Scholar] [CrossRef]

- Singh, U.K.; Digby, P.J. A continuum damage model for simulation of the progressive failure of brittle rocks. Int. J. Solids Struct. 1989, 25, 647–663. [Google Scholar] [CrossRef]

- Lemaitre, J.; Chaboche, J.L. Mechanics of Solid Materials; Cambridge University Press: Cambridge, UK, 1990. [Google Scholar]

| Grain Size (μm) | 5 | 10 | 20 | 50 | 75 | 100 | 150 | 180 | 360 |

| Cumulative Proportion/% | 9.25 | 13.56 | 19.83 | 38.01 | 51.50 | 62.71 | 76.39 | 81.65 | 100 |

| Loading Stage | ε1 (%) | σ1 − σ3 (MPa) | εV (%) | ROI-1 | ROI-2 | ROI-3 | ROI-4 | ROI-5 | Sample | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mean | SD | mean | SD | mean | SD | mean | SD | mean | SD | mean | SD | ||||

| 1 | 0 | 0 | 0 | 944.69 | 9.85 | 945.53 | 8.19 | 944.6 | 10.35 | 946.82 | 10.75 | 943.09 | 21.79 | 953.4 | 17.13 |

| 2 | 0.542 | 2.136 | 0.15 | 947.7 | 10.6 | 949.2 | 8.3 | 951.36 | 9.44 | 951.03 | 8.48 | 950.11 | 19.35 | 958.08 | 18.23 |

| 3 | 1.371 | 3.576 | −0.285 | 943.67 | 8.39 | 946.22 | 9.86 | 947.49 | 14.09 | 945.33 | 8.59 | 946.36 | 15.84 | 951.09 | 19.53 |

| 4 | 1.919 | 3.777 | −3.317 | 945.07 | 10.18 | 947.28 | 9.96 | 950.54 | 17.62 | 944.57 | 9.42 | 949.677 | 12.65 | 945.04 | 21.87 |

| 5 | 3.21 | 3.753 | −7.306 | 949.89 | 16.06 | 951.89 | 11.17 | 952.77 | 21.44 | 944.61 | 10.58 | 953.73 | 14.37 | 933.83 | 23.22 |

| Scan Stage | σ1 (MPa) | ε1 (%) | Mean CT Value | Damage Factor | Cracking Behavior |

|---|---|---|---|---|---|

| 1 | 0 | 0 | 953.4 | 0 | No |

| 2 | 2.136 | 0.542 | 958.08 | 0.089 | Compression |

| 3 | 3.576 | 1.371 | 951.09 | 0.267 | damage |

| 4 | 3.777 | 1.919 | 945.04 | 0.534 | Cracking |

| 5 | 3.753 | 3.21 | 933.83 | 0.802 | Propagation |

| Loading Stage | Axial Stress (%) | Axial Strain (%) | Volumetric Strain (%) | Top Slice Δs (mm2) | Middle Slice Δs (mm2) | Bottom Slice Δs (mm2) |

|---|---|---|---|---|---|---|

| 1 | 0 | 0 | 0 | / | / | / |

| 2 | 2.136 | 0.542 | 0.15 | 8.143 | 6.725 | 7.6 |

| 3 | 3.576 | 1.371 | −0.285 | 27.586 | 16.354 | 15.86 |

| 4 | 3.777 | 1.919 | −3.317 | 94.588 | 72.682 | 19.937 |

| 5 | 3.753 | 3.21 | −7.306 | 223.461 | 179.577 | 89.725 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Wang, H.; Zhou, X.; Yi, X.; Xiao, Y.; Wei, X. In Situ X-Ray CT Investigations of Meso-Damage Evolution of Cemented Waste Rock-Tailings Backfill (CWRTB) during Triaxial Deformation. Minerals 2019, 9, 52. https://doi.org/10.3390/min9010052

Wang Y, Wang H, Zhou X, Yi X, Xiao Y, Wei X. In Situ X-Ray CT Investigations of Meso-Damage Evolution of Cemented Waste Rock-Tailings Backfill (CWRTB) during Triaxial Deformation. Minerals. 2019; 9(1):52. https://doi.org/10.3390/min9010052

Chicago/Turabian StyleWang, Yu, Huajian Wang, Xiaolong Zhou, Xuefeng Yi, Yonggang Xiao, and Xiaoming Wei. 2019. "In Situ X-Ray CT Investigations of Meso-Damage Evolution of Cemented Waste Rock-Tailings Backfill (CWRTB) during Triaxial Deformation" Minerals 9, no. 1: 52. https://doi.org/10.3390/min9010052

APA StyleWang, Y., Wang, H., Zhou, X., Yi, X., Xiao, Y., & Wei, X. (2019). In Situ X-Ray CT Investigations of Meso-Damage Evolution of Cemented Waste Rock-Tailings Backfill (CWRTB) during Triaxial Deformation. Minerals, 9(1), 52. https://doi.org/10.3390/min9010052