Total Porosity Measured for Shale Gas Reservoir Samples: A Case from the Lower Silurian Longmaxi Formation in Southeast Chongqing, China

Abstract

:1. Introduction

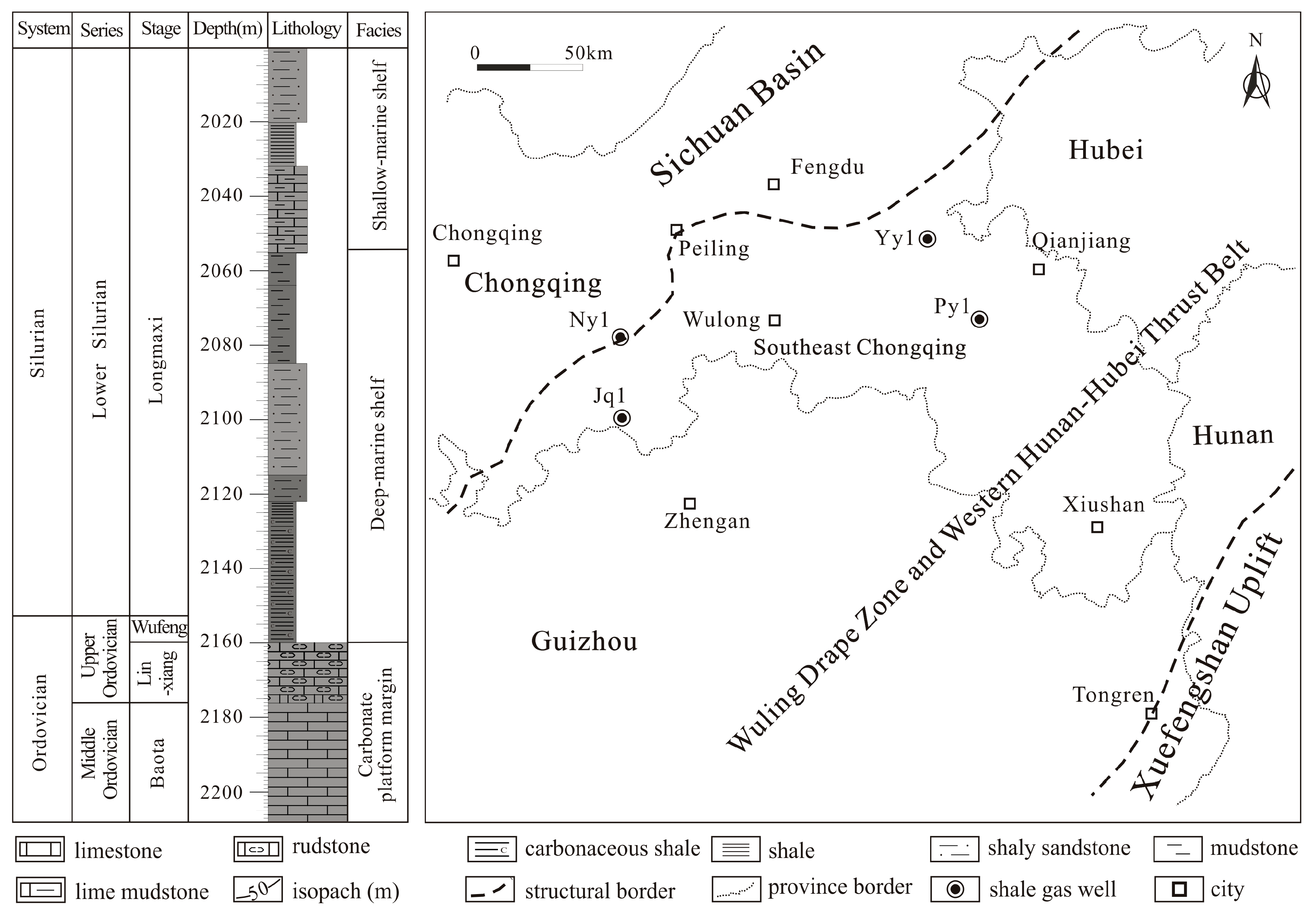

2. Materials and Methods

2.1. Samples

2.2. TOC, Maturity and XRD Analyses

2.3. CCP Method

2.4. GRI Method

3. Results

3.1. Composition of Sample

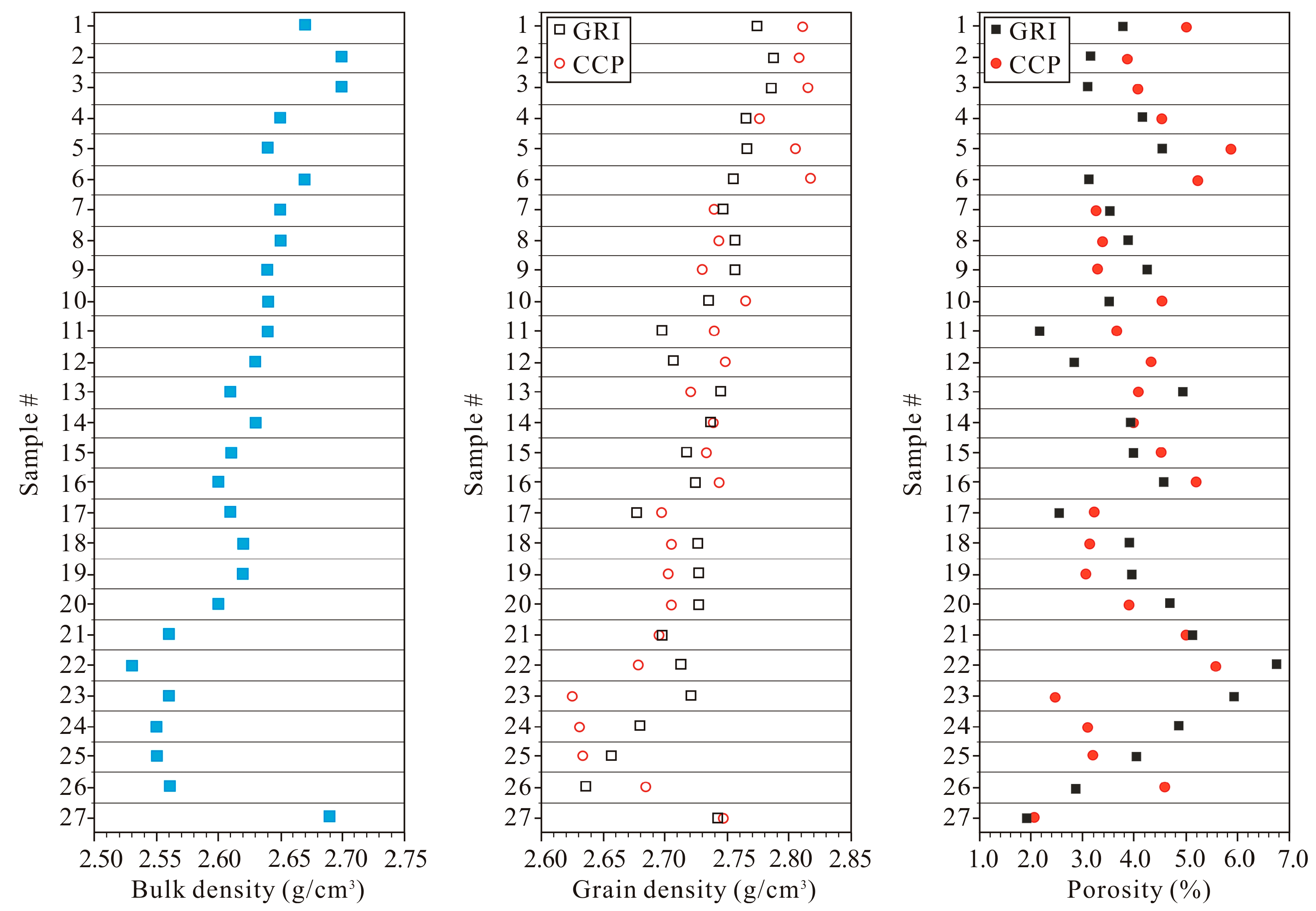

3.2. Sample Density

3.3. Porosity Values from CCP and GRI Methods

4. Discussion

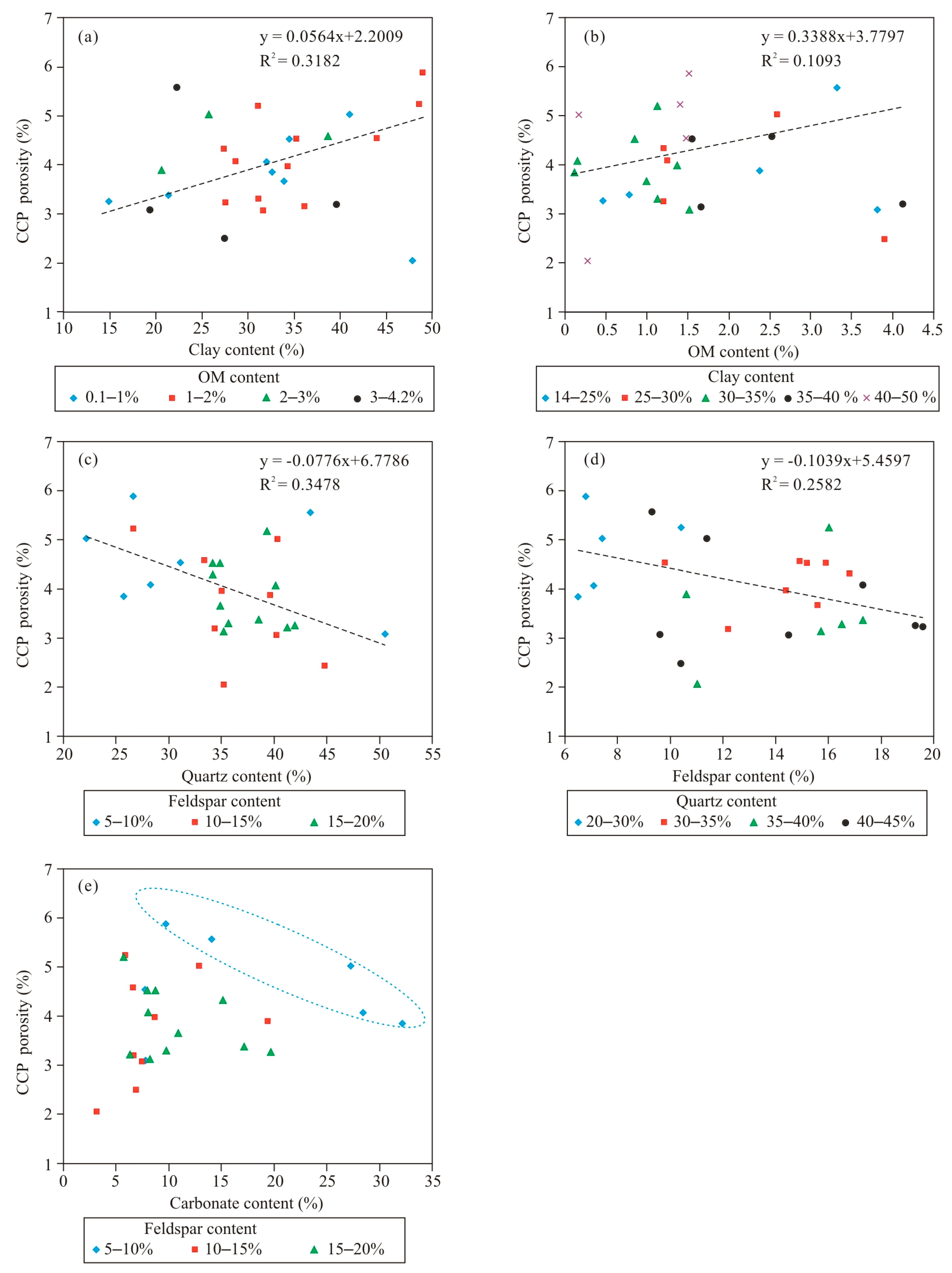

4.1. Relationship between Compositions and CCP Porosity

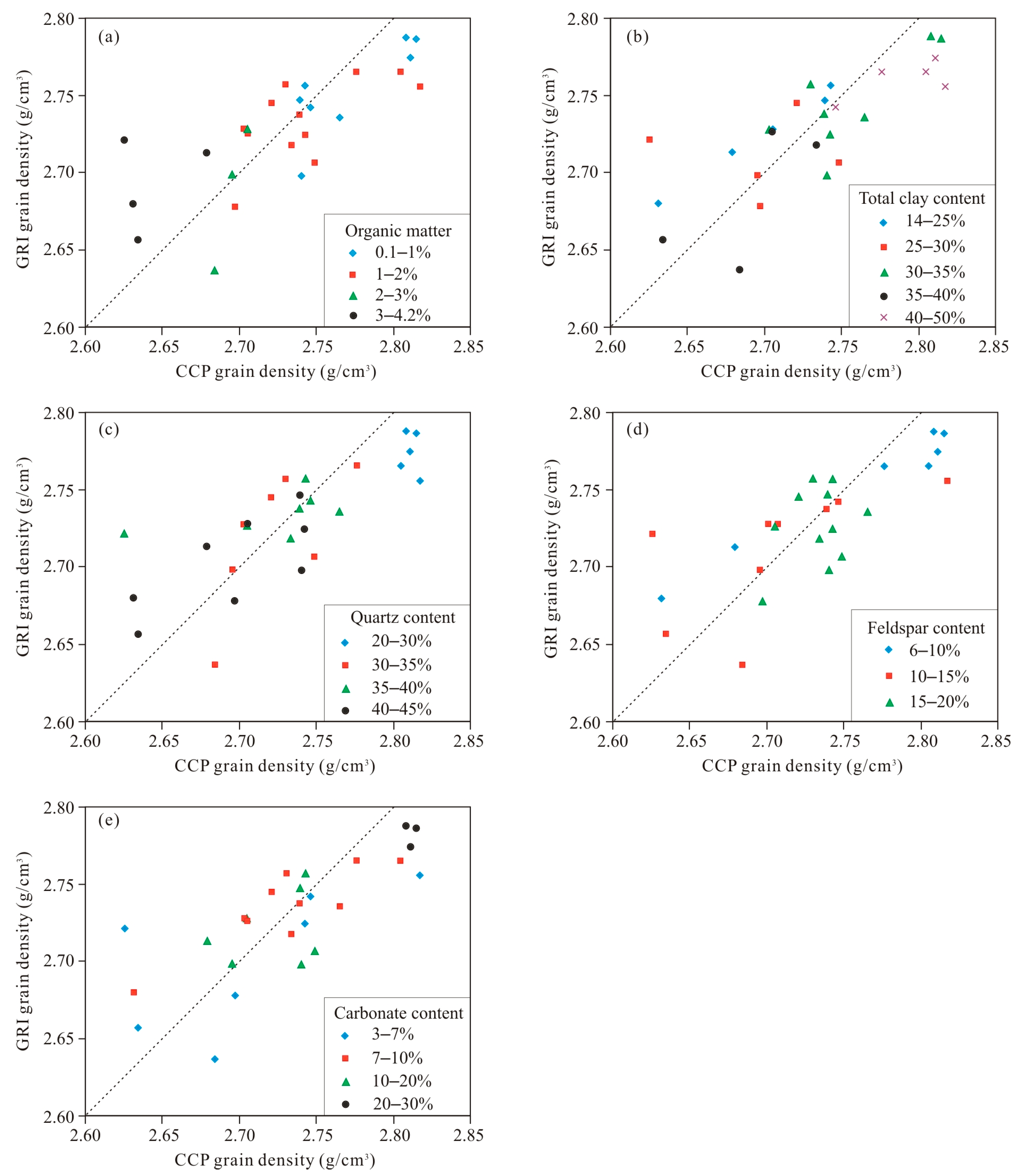

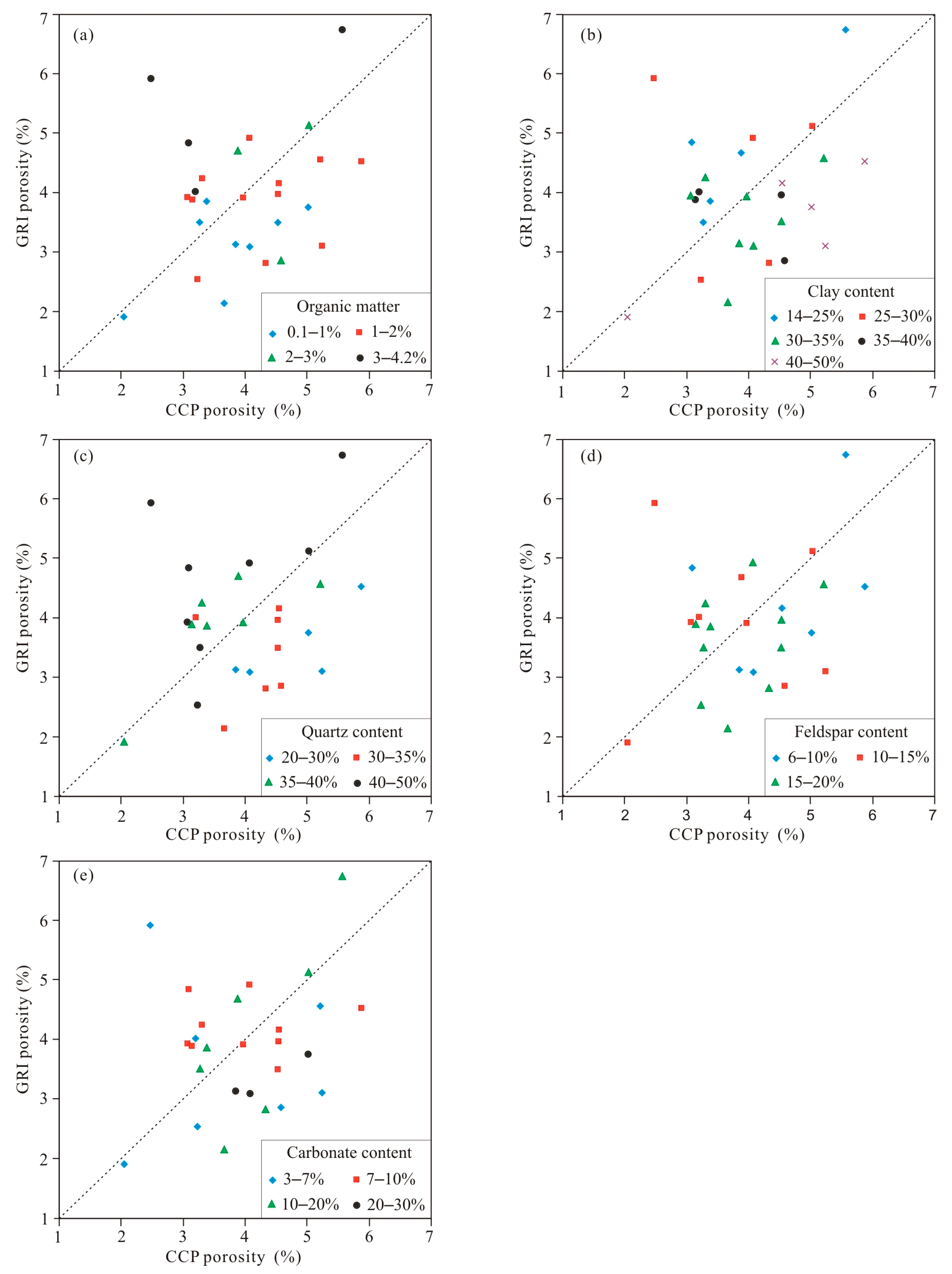

4.2. Comparison of the Results of CCP and GRI Methods

4.3. Advantages of the CCP Method

4.4. Disadvantages of the CCP Method

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kuila, U.; McCarty, D.K.; Arkadiusz, D.; Fischer, T.B.; Prasad, M. Total porosity measurement in gas shales by the water immersion porosimetry (WIP) method. Fuel 2014, 117, 1115–1129. [Google Scholar] [CrossRef]

- Pan, Z.J.; Ma, Y.; Connell, L.D.; Down, D.I.; Camilleri, M. Measuring anisotropic permeability using a cubic shale sample in a triaxial cell. J. Nat. Gas Sci. Eng. 2015, 26, 336–344. [Google Scholar] [CrossRef]

- Ma, Y.; Pan, Z.J.; Zhong, N.N.; Connell, L.D.; Down, D.I.; Lin, W.L.; Zhang, Y. Experimental study of anisotropic gas permeability and its relationship with fracture structure of Longmaxi Shales, Sichuan Basin, China. Fuel 2016, 180, 106–115. [Google Scholar] [CrossRef]

- Wang, L.; Wang, S.H.; Zhang, R.L.; Wang, C.; Xiong, Y.; Zheng, X.S.; Li, S.R.; Jin, K.; Rui, Z.H. Review of multi-scale and multi-physical simulation technologies for shale and tight gas reservoirs. J. Nat. Gas Sci. Eng. 2017, 37, 560–578. [Google Scholar] [CrossRef]

- Jiang, F.J.; Chen, D.; Wang, Z.F.; Xu, Z.Y.; Chen, J.; Liu, L.; Huyan, Y.Y.; Liu, Y. Pore characteristic analysis of a lacustrine shale: A case study in the Ordos Basin, NW China. Mar. Petrol. Geol. 2016, 73, 554–571. [Google Scholar] [CrossRef]

- Sun, J.M.; Dong, X.; Wang, J.J.; Schmitt, D.R.; Xu, C.L.; Mohammed, T.; Chen, D.W. Measurement of total porosity for gas shales by gas injection porosimetry (GIP) method. Fuel 2016, 186, 694–707. [Google Scholar] [CrossRef]

- Zolfaghari, A.; Dehghanpour, H.; Xu, M.X. Water sorption behaviour of gas shales: II Pore size distribution. Int. J. Coal Geol. 2017, 179, 187–195. [Google Scholar] [CrossRef]

- Chen, F.W.; Lu, S.F.; Ding, X. Organoporosity evaluation of shale: A case study of the Lower Silurian Longmaxi Shale in Southeast Chongqing, China. Sci. World J. 2014, 1–9. [Google Scholar] [CrossRef]

- Tuo, J.C.; Wu, C.J.; Zhang, M.F. Organic matter properties and shale gas potential of Paleozoic shales in Sichuan Basin, China. J. Nat. Gas Sci. Eng. 2016, 28, 434–446. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, Y.M.; Wang, Y.; Kang, W.; Chen, S.B. Comparison of organic matter occurrence and organic nanopore structure within marine and terrestrial shale. J. Nat. Gas Sci. Eng. 2016, 32, 356–363. [Google Scholar] [CrossRef]

- Chen, F.W.; Ding, X.; Lu, S.F. Organic porosity evaluation of lower cambrian Niutitang shale in Qiannan depression, China. Petrol. Sci. Technol. 2016, 34, 1083–1090. [Google Scholar] [CrossRef]

- Nelson, P.H. Pore-throat sizes in sandstones, tight sandstones, and shales. AAPG Bull. 2009, 93, 329–340. [Google Scholar] [CrossRef]

- Shi, M.; Yu, B.S.; Xue, Z.P.; Wu, J.S.; Yuan, Y. Pore characteristics of organic-rich shales with high thermal maturity: A case study of the Longmaxi gas shale reservoirs from well Yuye-1 in southeastern Chongqing, China. J. Nat. Gas Sci. Eng. 2015, 26, 948–959. [Google Scholar] [CrossRef]

- Chen, F.W.; Ding, X.; Lu, S.F.; Ju, Y.W. The pore characterization of the lower silurian Longmaxi shale in the southeast Chongqing, China using FE-SEM, LTNA and MIP methods. J. Nanosci. Nanotechnol. 2017, 17, 6482–6488. [Google Scholar] [CrossRef]

- Lu, S.F.; Chen, F.W.; Ju, Y.W. Type and quantitative evaluation of micropores in Longmaxi shale of southeast Chongqing, China. J. Nanosci. Nanotechnol. 2017, 17, 7035–7043. [Google Scholar] [CrossRef]

- Chen, F.W.; Lu, S.F.; Ding, X.; He, X.P.; Xing, H.L. The splicing of backscattered scanning electron microscopy method used on evaluation of microscopic pore characteristics in shale sample and compared with results from other methods. J. Petrol. Sci. Eng. 2018, 160, 207–218. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Solano, N.; Bustin, R.M.; Bustin, A.M.M.; Chalmers, G.R.L.; Hec, L.; Melnichenko, Y.B.; Radlin´ski, A.P.; Blach, T.P. Pore structure characterization of north American shale gas reservoirs using USANS/SANS, gas adsorption, and mercury intrusion. Fuel 2019, 103, 606–616. [Google Scholar] [CrossRef]

- Chen, F.W.; Lu, S.F.; Ding, X. Pore types and quantitative evaluation of pore volumes in the Longmaxi shale of southeast Chongqing, China. Acta Geol. Sin.-Engl. 2018, 92, 342–353. [Google Scholar] [CrossRef]

- Slatt, R.M.; O’Brien, N.R. Pore types in the Barnett and Woodford gas shales: Contribution to understanding gas storage and migration pathways in fine-grained rocks. AAPG Bull. 2011, 95, 2017–2030. [Google Scholar] [CrossRef]

- Curtis, M.E.; Cardott, B.J.; Sondergeld, C.H.; Rai, C.S. Development of organic porosity in the Woodford shale with increasing thermal maturity. Int. J. Coal Geol. 2012, 103, 26–31. [Google Scholar] [CrossRef]

- Curtis, M.E.; Sondergeld, C.H.; Ambrose, R.J.; Rai, C.S. Microstructural investigation of gas shales in two and three dimensions using nanometer-scale resolution imaging. AAPG Bull. 2012, 96, 665–677. [Google Scholar] [CrossRef]

- Long, H.; Swennen, R.; Foubert, A.; Dierick, M.; Jacobs, P. 3D quantification of mineral components and porosity distribution in Westphalian C sandstone by microfocus X-ray computed tomography. Sediment. Geol. 2009, 220, 116–125. [Google Scholar] [CrossRef]

- Okolo, G.N.; Everson, R.C.; Neomagus, H.W.J.P.; Roberts, M.J.; Sakurovs, R. Comparing the porosity and surface areas of coal as measured by gas adsorption, mercury intrusion and SAXS techniques. Fuel 2015, 141, 293–304. [Google Scholar] [CrossRef]

- Li, J.; Wang, W.; Cao, Q.; Shi, Y.; Yan, X.; Tian, S. Impact of hydrocarbon expulsion efficiency of continental shale upon shale oil accumulations in eastern China. Mar. Pet. Geol. 2015, 59, 467–479. [Google Scholar] [CrossRef]

- Chen, F.W.; Zhao, H.Q.; Lu, S.F.; Ding, X.; Ju, Y.W. The effects of composition, laminar structure and burial depth on connected pore characteristics in a shale oil reservoir, the Raoyang Sag of the Bohai Bay Basin, China. Mar. Pet. Geol. 2019, 101, 290–302. [Google Scholar] [CrossRef]

- Kuila, U.; Prasad, M. Specific surface area and pore-size distribution in clays and shales. Geophys. Prospect. 2013, 61, 341–362. [Google Scholar] [CrossRef]

- Lin, B.T.; Chen, M.A.; Jin, Y.; Pang, H.W. Modeling pore size distribution of southern Sichuan shale gas reservoirs. J. Nat. Gas Sci. Eng. 2015, 26, 883–894. [Google Scholar] [CrossRef]

- Luffel, D.L.; Guidry, F.K.; Curtis, J.B. Evaluation of devonian shale with new core and log analysis methods. J. Petrol. Technol. 1992, 44, 1192–1198. [Google Scholar] [CrossRef]

- Omotoso, O.; McCarty, D.K.; Hillier, S.; Kleeberg, R. Some successful approaches to quantitative mineral analysis as revealed by the 3rd Reynolds Cup contest. Clays Clay Miner. 2006, 54, 748–760. [Google Scholar] [CrossRef]

- Chalmers, G.R.L.; Bustin, R.M. Lower Cretaceous gas shales in northeastern British Columbia, Part I: Geological controls on methane sorption capacity. Bull. Can. Petrol. Geol. 2008, 56, 1–21. [Google Scholar] [CrossRef]

- Pan, Z.L. Crystallography and Mineralogy, 3rd ed.; Geological Press: Bejing, China, 2006; pp. 130–174. [Google Scholar]

- Okiongbo, K.S.; Aplin, A.C.; Larter, S.R. Changes in type II kerogen density as a function of maturity: Evidence from the Kimmeridge Clay Formation. Energy Fuels 2005, 19, 2495–2499. [Google Scholar] [CrossRef]

- Löhr, S.C.; Baruch, E.T.; Hall, P.A.; Kennedy, M.J. Is organic pore development in gas shales influenced by the primary porosity and structure of thermally immature organic matter? Org. Geochem. 2015, 87, 119–132. [Google Scholar] [CrossRef]

- Zolfaghari, A.; Dehghanpour, H.; Holyk, J. Water sorption behaviour of gas shales: I. Role of clays. Int. J. Coal Geol. 2017, 179, 130–138. [Google Scholar] [CrossRef]

- Guo, H.J.; Jia, W.L.; Peng, P.A.; Zeng, J.; He, R.L. Evolution of organic matter and nanometer-scale pores in an artificially matured shale undergoing two distinct types of pyrolysis: A study of the Yanchang Shale with Type II kerogen. Org. Geochem. 2017, 105, 56–66. [Google Scholar] [CrossRef]

- Jia, B.; Tsau, J.S.; Barati, R. A workflow to estimate shale gas permeability variations during the production process. Fuel 2018, 220, 879–889. [Google Scholar] [CrossRef]

- Cui, X.; Bustin, A.M.; Bustin, R.M. Measurements of gas permeability and diffusivity of tight reservoir rocks: Different approaches and their applications. Geofluids 2009, 9, 208–223. [Google Scholar] [CrossRef]

- Jia, B.; Tsau, J.S.; Barati, R. Different flow behaviors of low-pressure and high-pressure carbon dioxide in shales. SPE J. 2018, 23, 1452–1468. [Google Scholar] [CrossRef]

| Density (g/cm3) | Quartz | Orthoclase | Plagioclase | Calcite | Dolomite | Pyrite |

| Max true density | 2.65 | 2.57 | 2.76 | 2.80 | 3.20 | 5.20 |

| Min true density | 2.22 | 2.54 | 2.61 | 2.60 | 2.86 | 4.90 |

| Average true density | 2.44 | 2.56 | 2.69 | 2.70 | 3.03 | 5.05 |

| Density (g/cm3) | Barite | Marcasite | Smectite | Chlorite | Illite | OM |

| Max true density | 4.60 | 4.90 | 2.70 | 3.60 | 2.90 | 1.20 |

| Min true density | 4.00 | 4.80 | 2.00 | 3.60 | 2.60 | 1.20 |

| Average true density | 4.30 | 4.85 | 2.35 | 3.60 | 2.75 | 1.20 |

| Sample No. | TOC (%) | Ro (%) | Quartz | Orthoclase | Plagioclase | Calcite | Dolomite | Aragonite | Pyrite | Barite | Clay | I | C | I/S | %S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.17 | 2.54 | 22.2 | 1.2 | 6.2 | 24.2 | 3.1 | 0.5 | 1.4 | 22.2 | 41.0 | 49 | 17 | 34 | 5 |

| 2 | 0.11 | 2.47 | 25.7 | 1.1 | 5.4 | 27.3 | 4.9 | 1.0 | 1.9 | 25.7 | 32.6 | 36 | 18 | 46 | 5 |

| 3 | 0.13 | 2.73 | 28.3 | 1.5 | 5.6 | 21.7 | 6.7 | 2.1 | 1.9 | 28.3 | 32.1 | 39 | 20 | 41 | 5 |

| 4 | 1.48 | 2.70 | 31.1 | 1.6 | 8.2 | 7.8 | / | 3.0 | 2.8 | 31.1 | 44.0 | 38 | 15 | 47 | 5 |

| 5 | 1.51 | 2.83 | 26.6 | 2.1 | 4.7 | 6.1 | 3.6 | 4.1 | 2.3 | 26.6 | 49.0 | 45 | 13 | 42 | 5 |

| 6 | 1.40 | 2.78 | 26.6 | 1.8 | 8.6 | 2.6 | 3.3 | 3.7 | 3.4 | 26.6 | 48.6 | 35 | 16 | 49 | 5 |

| 7 | 0.46 | 3.09 | 42.0 | 2.1 | 17.2 | 9.0 | 10.7 | 1.4 | 2.2 | 42.0 | 14.9 | 50 | 11 | 39 | 5 |

| 8 | 0.78 | 2.75 | 38.5 | 5.0 | 12.3 | 10.4 | 6.7 | 2.9 | 2.1 | 38.5 | 21.3 | 40 | 10 | 50 | 5 |

| 9 | 1.12 | 2.48 | 35.6 | 3.7 | 12.8 | 6.5 | 3.2 | 3.5 | 2.4 | 35.6 | 31.2 | 47 | 5 | 48 | 10 |

| 10 | 0.84 | 2.55 | 34.2 | 3.7 | 12.2 | 5.1 | 3.6 | 2.2 | 3.7 | 34.2 | 34.5 | 48 | 12 | 40 | 5 |

| 11 | 0.99 | 2.31 | 34.9 | 3.6 | 12.0 | 6.4 | 4.5 | 2.3 | 1.4 | 34.9 | 33.9 | 34 | 14 | 52 | 5 |

| 12 | 1.21 | 2.81 | 34.2 | 4.1 | 12.7 | 8.9 | 6.2 | 3.2 | 2.1 | 34.2 | 27.4 | 39 | 11 | 50 | 5 |

| 13 | 1.25 | 1.91 | 40.1 | 4.7 | 12.6 | 3.8 | 4.2 | 3.2 | 1.5 | 40.1 | 28.7 | 45 | 15 | 40 | 10 |

| 14 | 1.37 | 2.90 | 35.0 | 3.4 | 11.0 | 5.9 | 2.8 | 2.7 | 3.5 | 35.0 | 34.3 | 40 | 10 | 50 | 10 |

| 15 | 1.55 | / 1 | 34.8 | 3.3 | 11.9 | 5.9 | 2.0 | 3.5 | 1.8 | 34.8 | 35.3 | 48 | 14 | 38 | 10 |

| 16 | 1.12 | 2.91 | 39.3 | 3.9 | 12.1 | 3.8 | 1.9 | 2.4 | 4.4 | 39.3 | 31.1 | 40 | 13 | 47 | 10 |

| 17 | 1.21 | / | 41.2 | 5.6 | 14.0 | 3.4 | 3.0 | 2.0 | 2.0 | 41.2 | 27.6 | 47 | 12 | 41 | 10 |

| 18 | 1.66 | 2.66 | 35.2 | 4.0 | 11.7 | 5.3 | 2.5 | 1.8 | 1.7 | 35.2 | 36.1 | 44 | 13 | 43 | 10 |

| 19 | 1.51 | 2.59 | 40.2 | 3.5 | 11.0 | 4.1 | 3.4 | 1.7 | 2.9 | 40.2 | 31.7 | 50 | 11 | 39 | 15 |

| 20 | 2.38 | 2.76 | 39.6 | 4.0 | 6.6 | 14.7 | 4.7 | 5.0 | 2.4 | 39.6 | 20.6 | 56 | 7 | 37 | 5 |

| 21 | 2.59 | 2.50 | 40.3 | 3.6 | 7.8 | 7.2 | 5.7 | 5.0 | 2.1 | 40.3 | 25.7 | 59 | 9 | 32 | 10 |

| 22 | 3.32 | 2.81 | 43.4 | 2.7 | 6.6 | 8.5 | 5.6 | 5.1 | 2.5 | 43.4 | 22.3 | 43 | 14 | 43 | 5 |

| 23 | 3.90 | 2.68 | 44.8 | 2.8 | 7.6 | 4.8 | 2.1 | 3.6 | 2.9 | 44.8 | 27.5 | 65 | 9 | 26 | 10 |

| 24 | 3.81 | 2.87 | 50.5 | 3.0 | 6.6 | 5.5 | 2.2 | 4.2 | 4.8 | 50.5 | 19.4 | 45 | 8 | 47 | 10 |

| 25 | 4.12 | 2.57 | 34.3 | 1.5 | 10.7 | 2.3 | 4.4 | / | 3.1 | 34.3 | 39.6 | 35 | 14 | 51 | 5 |

| 26 | 2.52 | 2.79 | 33.4 | 5.1 | 9.8 | 0.0 | 6.6 | 2.2 | 1.7 | 33.4 | 38.7 | 36 | 7 | 57 | 5 |

| 27 | 0.27 | 2.49 | 35.2 | 2.6 | 8.4 | 1.1 | 2.1 | 1.1 | 1.4 | 35.2 | 47.8 | 46 | 8 | 46 | 10 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, F.; Lu, S.; Ding, X.; Zhao, H.; Ju, Y. Total Porosity Measured for Shale Gas Reservoir Samples: A Case from the Lower Silurian Longmaxi Formation in Southeast Chongqing, China. Minerals 2019, 9, 5. https://doi.org/10.3390/min9010005

Chen F, Lu S, Ding X, Zhao H, Ju Y. Total Porosity Measured for Shale Gas Reservoir Samples: A Case from the Lower Silurian Longmaxi Formation in Southeast Chongqing, China. Minerals. 2019; 9(1):5. https://doi.org/10.3390/min9010005

Chicago/Turabian StyleChen, Fangwen, Shuangfang Lu, Xue Ding, Hongqin Zhao, and Yiwen Ju. 2019. "Total Porosity Measured for Shale Gas Reservoir Samples: A Case from the Lower Silurian Longmaxi Formation in Southeast Chongqing, China" Minerals 9, no. 1: 5. https://doi.org/10.3390/min9010005

APA StyleChen, F., Lu, S., Ding, X., Zhao, H., & Ju, Y. (2019). Total Porosity Measured for Shale Gas Reservoir Samples: A Case from the Lower Silurian Longmaxi Formation in Southeast Chongqing, China. Minerals, 9(1), 5. https://doi.org/10.3390/min9010005