Geopolymer Synthesis Using Garnet Tailings from Molybdenum Mines

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Geopolymer Synthesis

2.3. Characterization

3. Results

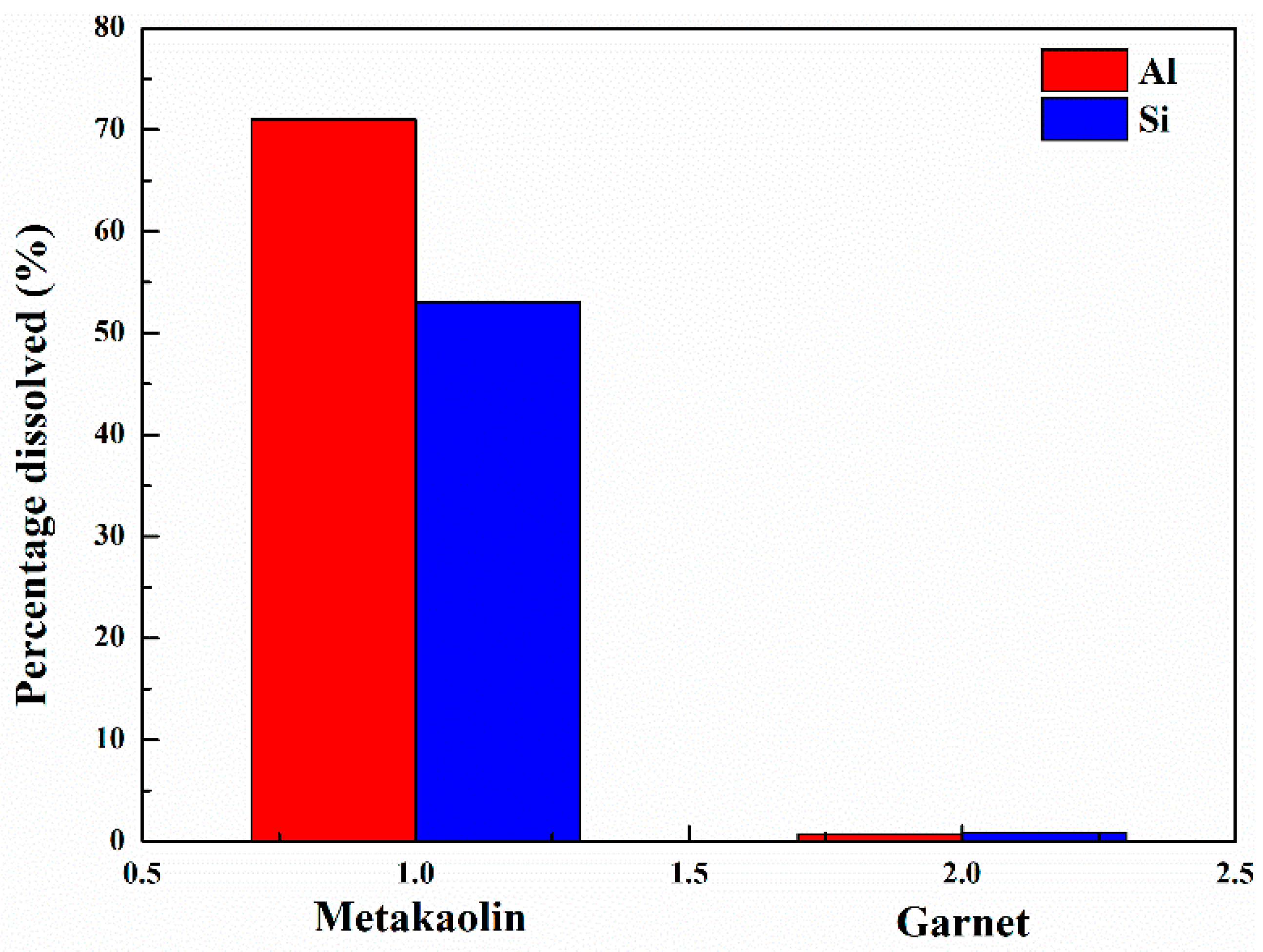

3.1. Transformations of Soluble Al and Si

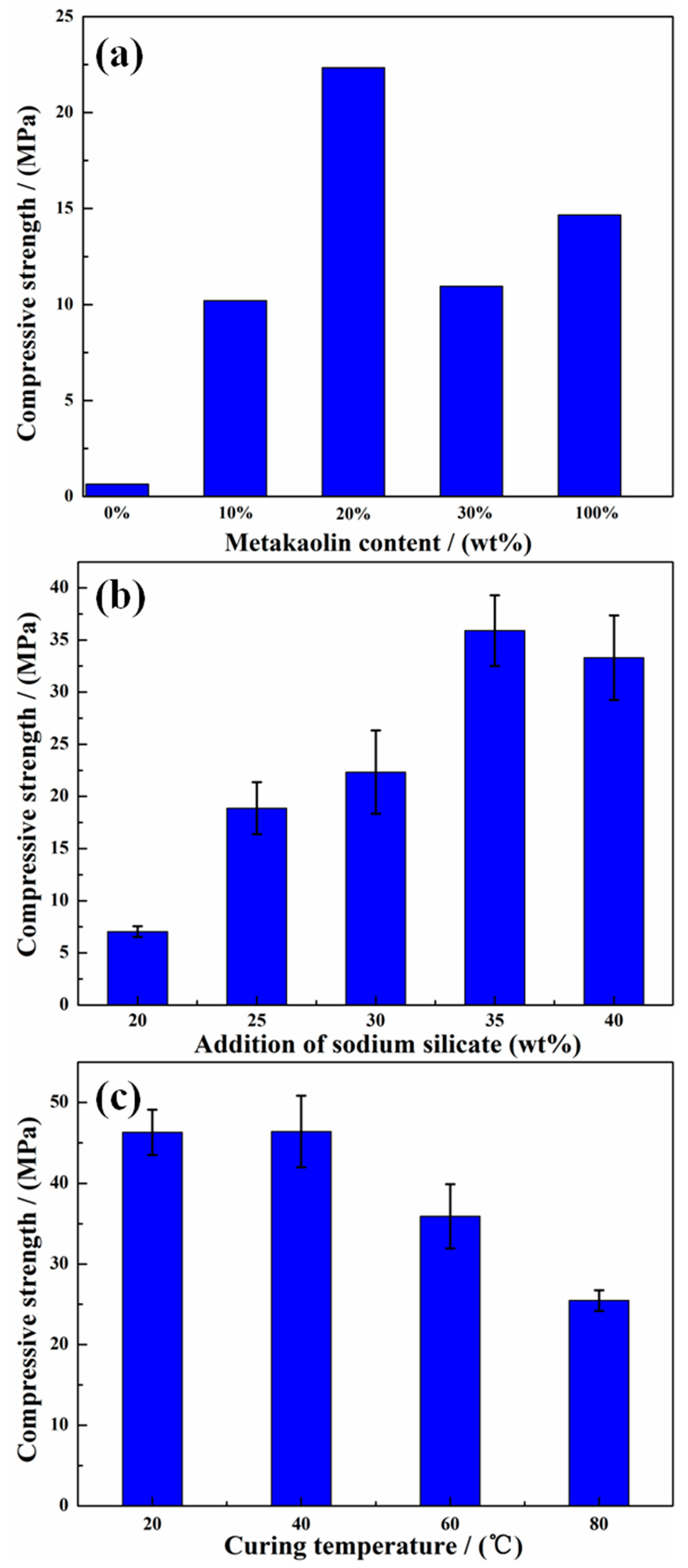

3.2. Compressive Strength Test

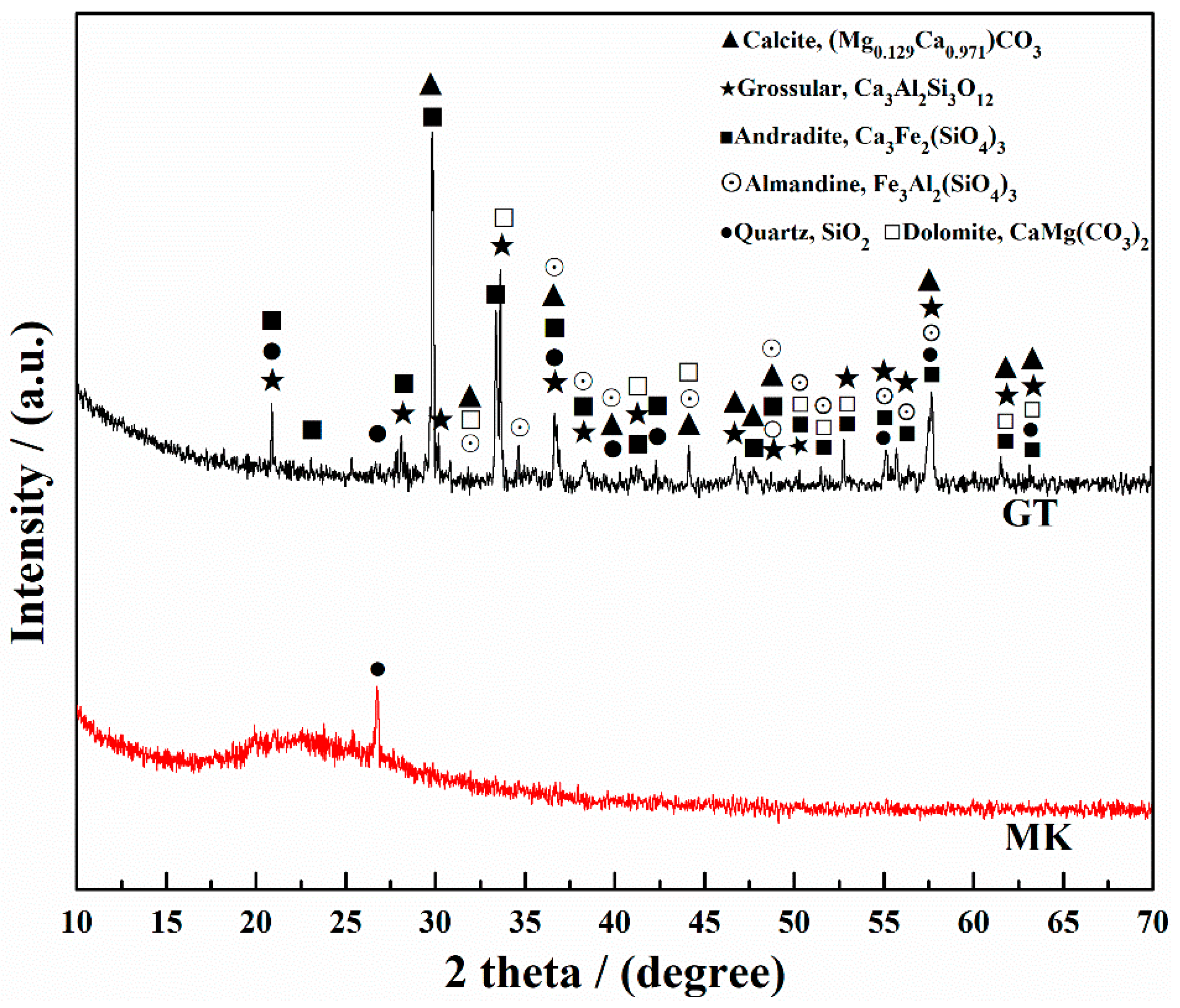

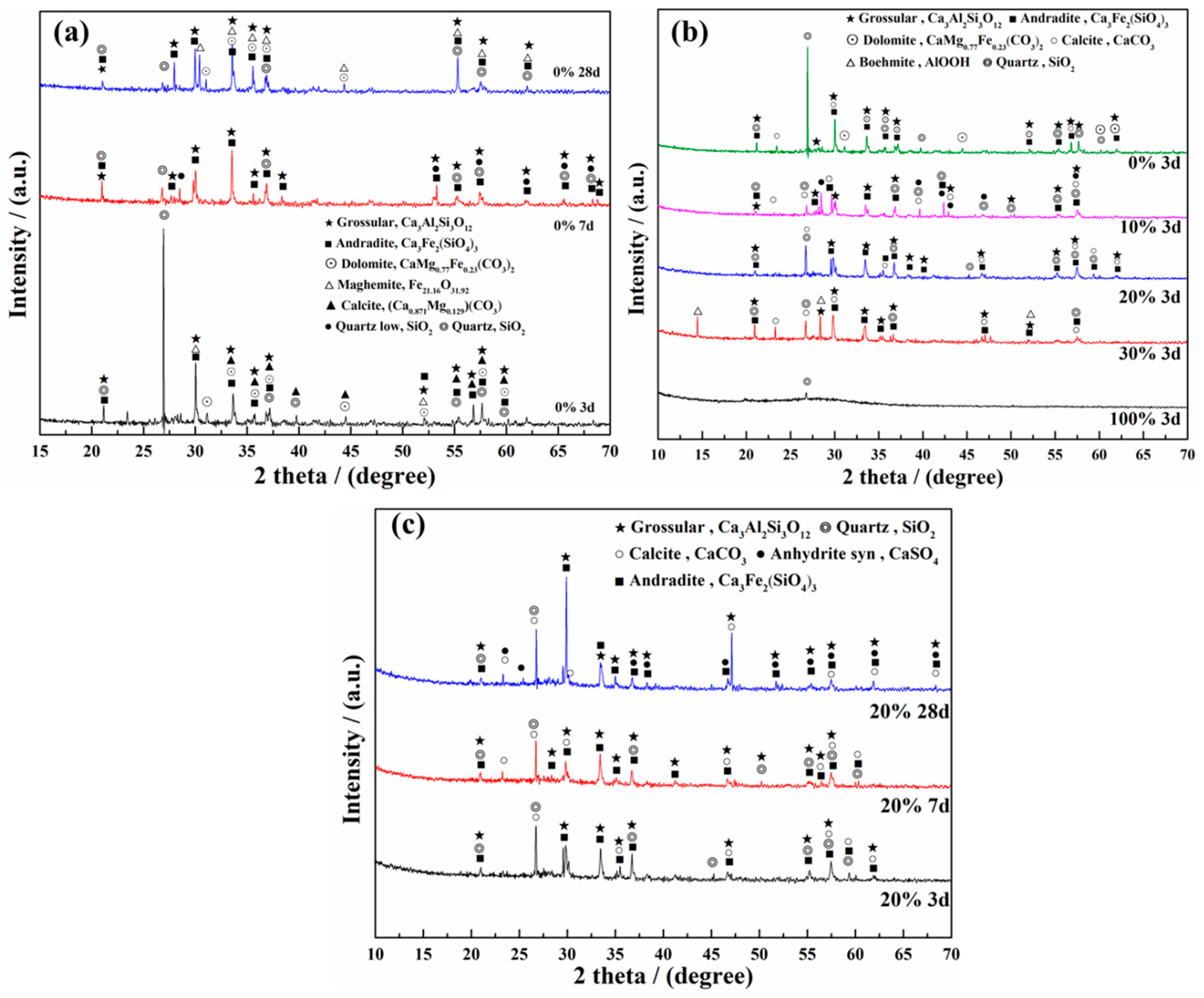

3.3. X-Ray Diffraction Results

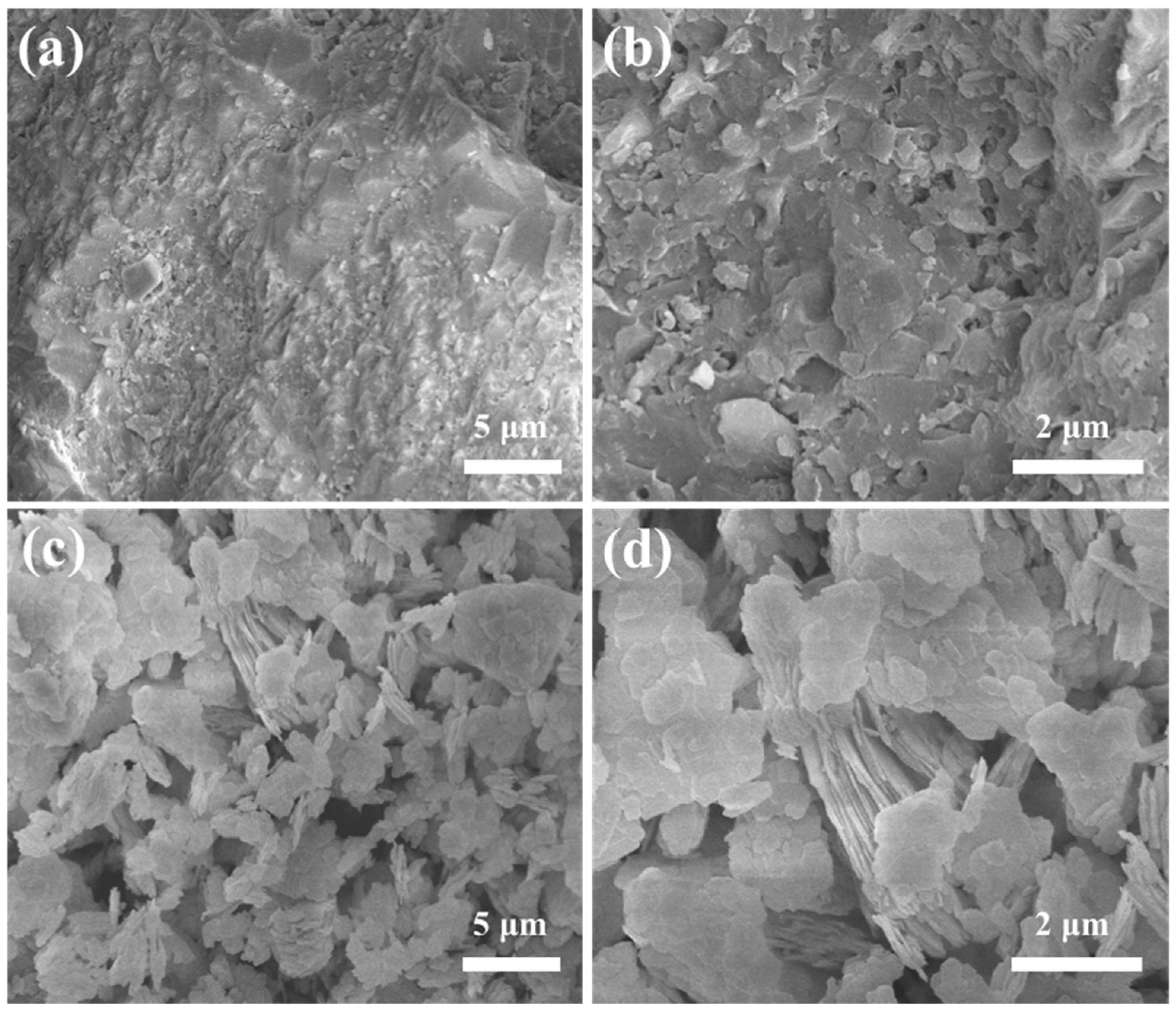

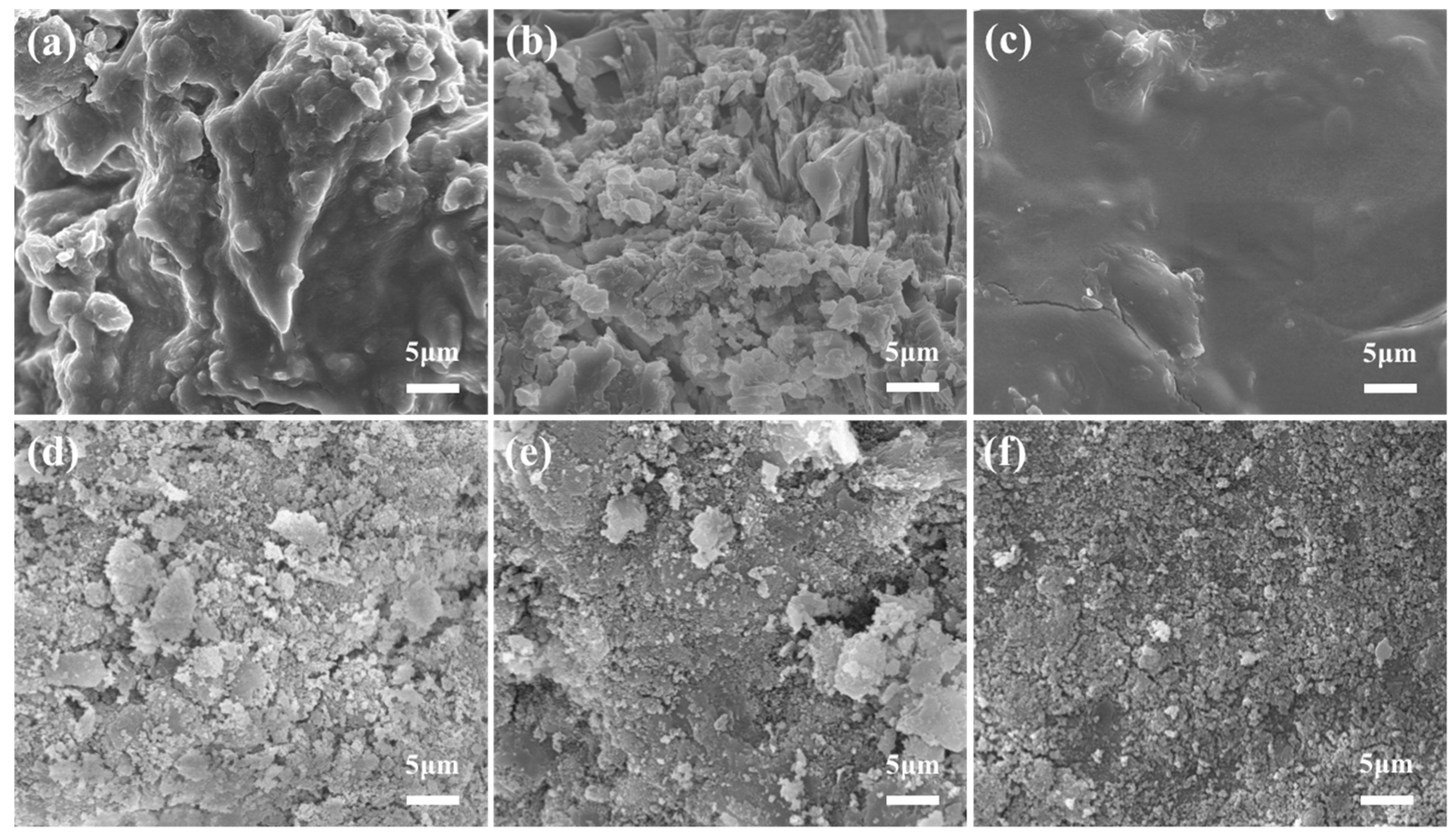

3.4. Scanning Electron Microscopy (SEM)

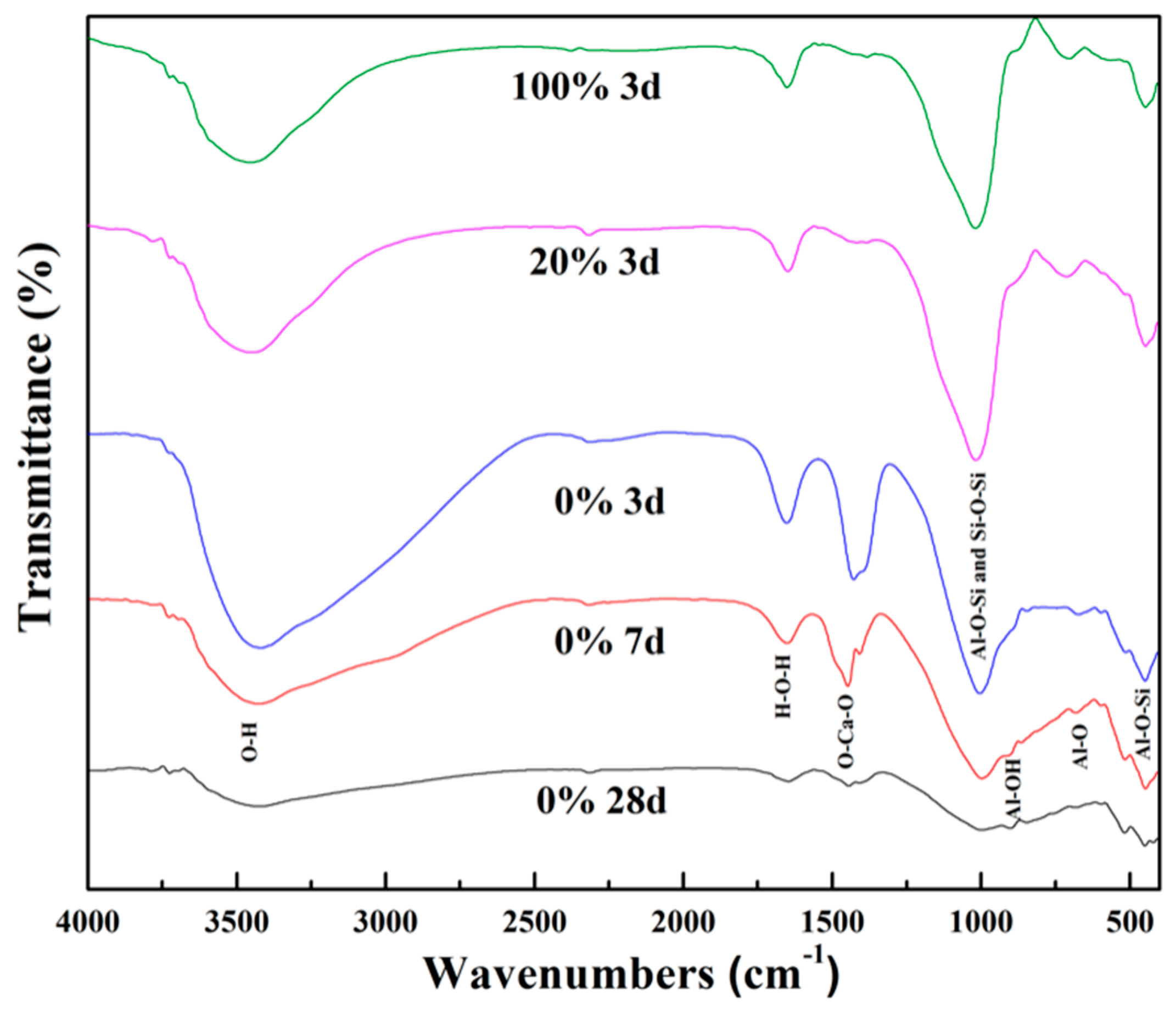

3.5. The FTIR Spectra of Sample

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gitari, W.; Thobakgale, R.; Akinyemi, S. Mobility and Attenuation Dynamics of Potentially Toxic Chemical Species at an Abandoned Copper Mine Tailings Dump. Minerals 2018, 8, 64. [Google Scholar] [CrossRef]

- Xu, D.; Yang, H.; Ouyang, J.; Zhang, Y.; Fu, L.; Chen, D. Lauric Acid Hybridizing Fly Ash Composite for Thermal Energy Storage. Minerals 2018, 8, 161. [Google Scholar] [CrossRef]

- Bian, Z.; Miao, X.; Lei, S.; Chen, S.E.; Wang, W. The challenges of reusing mining and mineral-processing wastes. Science 2012, 337, 702–703. [Google Scholar] [CrossRef] [PubMed]

- Franks, D.M.; Boger, D.V.; Côte, C.M.; Mulligan, D.R. Sustainable development principles for the disposal of mining and mineral processing wastes. Resour. Policy 2011, 36, 114–122. [Google Scholar] [CrossRef]

- Amin, S.K.; El-Sherbiny, S.A.; El-Magd, A.A.M.A.; Belal, A.; Abadir, M.F.; Amin, S.K. Fabrication of geopolymer bricks using ceramic dust waste. Constr. Build. Mater. 2017, 157, 610–620. [Google Scholar] [CrossRef]

- Komnitsas, K.; Zaharaki, D.; Bartzas, G. Effect of sulphate and nitrate anions on heavy metal immobilisation in ferronickel slag geopolymers. Appl. Clay Sci. 2013, 73, 103–109. [Google Scholar] [CrossRef]

- Monosi, S.; Tittarelli, F.; Giosuè, C.; Ruello, M.L. Effect of two different sources and washing treatment on the properties of UFS by-products for mortar and concrete production. Constr. Build. Mater. 2013, 44, 260–266. [Google Scholar] [CrossRef]

- Kinnunen, P.; Ismailov, A.; Solismaa, S.; Sreenivasan, H.; Räisänen, M.L.; Levänen, E.; Illikainen, M. Recycling mine tailings in chemically bonded ceramics—A review. J Clean. Prod. 2018, 174, 634–649. [Google Scholar] [CrossRef]

- Muttashar, H.L.; Hussin, M.W.; Ariffin, M.A.M. Realisation of enhanced self-compacting geopolymer concrete using spent garnet as sand replacement. Mag. Concr. Res. 2017, 70, 558–569. [Google Scholar] [CrossRef]

- Dimas, D.D.; Giannopoulou, I.P.; Panias, D. Utilization of Alumina Red Mud for Synthesis of Inorganic Polymeric Materials. Min. Proc. Ext. Met. Rev. 2009, 30, 211–239. [Google Scholar] [CrossRef]

- Nikolov, A.; Rostovsky, I.; Nugteren, H. Geopolymer materials based on natural zeolite. Case Stud. Constr. Mater. 2017, 6, 198–205. [Google Scholar] [CrossRef]

- Villa, C.; Pecina, E.T.; Torres, R.; Gómez, L. Geopolymer synthesis using alkaline activation of natural zeolite. Constr. Build. Mater. 2010, 24, 2084–2090. [Google Scholar] [CrossRef]

- Song, L.; Li, Z.; Duan, P.; Huang, M.; Hao, X.; Yu, Y. Novel low cost and durable rapid-repair material derived from industrial and agricultural by-products. Ceram. Int. 2017, 43, 14511–14516. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers: Inorganic polymeric new materials. J. Therm. Anal. Calorim. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Ranjbar, N.; Kuenzel, C. Influence of preheating of fly ash precursors to produce geopolymers. J. Am. Ceram. Soc. 2017, 100, 3165–3174. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Behnia, A.; Alengaram, U.J.; Jumaat, M.Z. Compressive strength and microstructural analysis of fly ash/palm oil fuel ash based geopolymer mortar. Mater. Des. 2014, 59, 532–539. [Google Scholar] [CrossRef]

- Duxson, P.; Mallicoat, S.W.; Lukey, G.C. The effect of alkali and Si/Al ratio on the development of mechanical properties of metakaolin-based geopolymers. Colloids Surf. A Physicochem. Eng. Asp. 2007, 292, 8–20. [Google Scholar] [CrossRef]

- Glid, M.; Sobrados, I.; Rhaiem, H.B.; Sanz, J.; Amara, A.B.H. Alkaline activation of metakaolinite-silica mixtures: Role of dissolved silica concentration on the formation of geopolymers. Ceram. Int. 2017, 43, 12641–12650. [Google Scholar] [CrossRef]

- Sabbatini, A.; Vidal, L.; Pettinari, C.; Sobrados, I.; Rossignol, S. Control of shaping and thermal resistance of metakaolin-based geopolymers. Mater. Des. 2017, 116, 374–385. [Google Scholar] [CrossRef]

- Duan, P.; Yan, C.J.; Zhou, W.; Ren, D. Fresh properties, compressive strength and microstructure of fly ash geopolymer paste blended with iron ore tailing under thermal cycle. Constr. Build. Mater. 2016, 118, 76–88. [Google Scholar] [CrossRef]

- Duan, P.; Yan, C.J.; Zhou, W.; Ren, D. Development of fly ash and iron ore tailing based porous geopolymer for removal of Cu(II) from wastewater. Ceram. Int. 2016, 42, 13507–13518. [Google Scholar] [CrossRef]

- Pooria, G.; Navid, R. Clayey soil stabilization using geopolymer and portland cement. Constr. Build. Mater. 2018, 188, 361–371. [Google Scholar]

- Djobo, J.N.Y.; Tchakouté; Kouamo, H.; Ranjbar, N.; Elimbi, A.; Tchadjié, L.N.; Njopwouo, D. Gel composition and strength properties of alkali-activated oyster shell-volcanic ash: Effect of synthesis conditions. J Am. Ceram. Soc. 2016, 188, 361–371. [Google Scholar] [CrossRef]

- Ranjbar, N.; Kashefi, A.; Maheri, M.R. Hot-pressed geopolymer: Dual effects of heat and curing time. Cem. Concr. Comp. 2018, 86, 1–8. [Google Scholar] [CrossRef]

- Ye, N.; Chen, Y.; Yang, J.; Liang, S.; Hu, Y.; Hu, J.; Zhu, S.; Fan, W.; Xiao, B. Transformations of Na, Al, Si and Fe species in red mud during synthesis of one-part geopolymers. Cem. Concr. Res. 2017, 101, 123–130. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Palomo, A.; Criado, M. Microstructure development of alkali-activated fly ash cement: A descriptive model. Cem. Concr. Res. 2005, 35, 1204–1209. [Google Scholar] [CrossRef]

- Rosas-Casarez, C.A.; Arredondo-Rea, S.P.; Cruz-Enríquez, A.; Corral-Higuera, R.; Gómez-Soberón, J.M.; Medina-Serna, T.D.J. Influence of Size Reduction of Fly Ash Particles by Grinding on the Chemical Properties of Geopolymers. Appl. Sci. 2018, 8, 365. [Google Scholar] [CrossRef]

- Toniolo, N.; Boccaccini, A.R.; Toniolo, N.; Boccaccini, A.R. Fly ash-based geopolymers containing added silicate waste: A review. Ceram. Int. 2017, 43, 14545–14551. [Google Scholar] [CrossRef]

- Moukannaa, S.; Loutou, M.; Benzaazoua, M. Recycling of phosphate mine tailings for the production of geopolymers. J. Clean. Prod. 2018, 185, 891–903. [Google Scholar] [CrossRef]

- Dabbebi, R.; de Aguiar, J.L.B.; Camões, A.; Samet, B.; Baklouti, S. Effect of the calcinations temperatures of phosphate washing waste on the structural and mechanical properties of geopolymeric mortar. Constr. Build. Mater. 2018, 185, 489–498. [Google Scholar] [CrossRef]

- Wei, B.; Zhang, Y.; Bao, S. Preparation of geopolymers from vanadium tailings by mechanical activation. Constr. Build. Mater. 2017, 145, 236–242. [Google Scholar] [CrossRef]

- Jiao, X.; Zhang, Y.; Chen, T. Thermal stability of a silica-rich vanadium tailing based geopolymer. Constr. Build. Mater. 2013, 38, 43–47. [Google Scholar] [CrossRef]

- Muttashar, H.L.; Ariffin, M.A.M.; Hussein, M.N.; Hussin, M.W.; Ishaq, S.B. Self-compacting geopolymer concrete with spend garnet as sand replacement. J. Build. Eng. 2018, 15, 85–94. [Google Scholar] [CrossRef]

- Muttashar, H.L.; Ali, N.B.; Ariffin, M.A.M.; Hussin, M.W. Microstructures and physical properties of waste garnets as a promising construction materials. Case Stud. Constr. Mater. 2018, 8, 87–96. [Google Scholar] [CrossRef]

- Ye, N.; Yang, J.; Ke, X.; Zhu, J.; Li, Y.; Xiang, C.; Wang, H.; Li, L.; Xiao, B. Synthesis and characterization of geopolymer from Bayer red mud with thermal pretreatment. J. Am. Ceram. Soc. 2014, 97, 1652–1660. [Google Scholar] [CrossRef]

- Fernández, R.; Ruiz, AI.; Cuevas, J. Formation of CASH phases from the interaction between concrete or cement and bentonite. Clay Miner. 2016, 51, 223–235. [Google Scholar] [CrossRef]

- Mijarsh, M.J.; Johari, M.M.; Ahmad, Z.A. Effect of delay time and Na2SiO3 concentrations on compressive strength development of geopolymer mortar synthesized from TPOFA. Constr. Build Mater. 2015, 1, 64–74. [Google Scholar] [CrossRef]

- García-Lodeiro, I.; Fernández-Jiménez, A.; Palomo, A. Variation in hybrid cements over time. Alkaline activation of fly ash–Portland cement blends. Cem. Concr. Res. 2013, 52, 112–122. [Google Scholar] [CrossRef]

- Onisei, S.; Pontikes, Y.; Van Gerven, T.; Angelopoulos, G.N.; Velea, T.; Predica, V. Synthesis of inorganic polymers using fly ash and primary lead slag. J. Hazard. Mater. 2012, 9, 101–110. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Zhang, F.; Liu, M.; Hu, X. Novel sustainable geopolymer based syntactic foams: An eco-friendly alternative to polymer based syntactic foams. Chem. Eng. J. 2017, 313, 74–82. [Google Scholar] [CrossRef]

- Provis, J.L.; Palomo, A.; Shi, C. Advances in understanding alkali-activated materials. Cem. Concr. Res. 2015, 78, 110–125. [Google Scholar] [CrossRef]

- Sun, S.; Lin, J.; Zhang, P.; Fang, L.; Ma, R.; Quan, Z. Geopolymer synthetized from sludge residue pretreated by the wet alkalinizing method: Compressive strength and immobilization efficiency of heavy metal. Constr. Build. Mater. 2018, 170, 619–626. [Google Scholar] [CrossRef]

- Fardjaoui, N.E.H.; Wicklein, B.; Aranda, P. Modulation of inorganic matrices for functional nanoarchitectures fabrication: The simultaneous effect of moisture and temperature in the preparation of metakaolin based geopolymers. Bull. Chem. Soc. Jpn. 2018, 91, 1158–1167. [Google Scholar] [CrossRef]

- Provis, J.; van Deventer, J.S.J. Alkali-Activated Materials: State-of-the-Art Report; RILEM TC. 224-AAM; Springer/RILEM: Dordrecht, The Netherlands, 2014; p. 126. [Google Scholar]

- Wan, Q.; Rao, F.; Song, S.; Cholico-González, D.F.; Ortiz, N.L. Combination formation in the reinforcement of metakaolin geopolymers with quartz sand. Cem. Concr. Comp. 2017, 80, 115–122. [Google Scholar] [CrossRef]

- Król, M.; Minkiewicz, J.; Mozgawa, W. IR spectroscopy studies of zeolites in geopolymeric materials derived from kaolinite. J. Mol. Struct. 2016, 1126, 200–206. [Google Scholar] [CrossRef]

| Components (wt %) | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | K2O |

|---|---|---|---|---|---|---|---|

| MK | 53.56 | 43.92 | 1.08 | 0.14 | 0.10 | 0 | 0.78 |

| GT | 44.28 | 5.57 | 13.82 | 30.26 | 0.81 | 0.23 | 0.13 |

| Samples | Garnet/g | Metakaolin/g | Sodium Silicate/g | Water/g |

|---|---|---|---|---|

| GTGs-0 | 600 | 0 | 180 | 30 |

| GTGs-1 | 540 | 60 | 40 | |

| GTGs-2 | 480 | 120 | 60 | |

| GTGs-3 | 420 | 180 | 80 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, A.; Liu, H.; Hao, X.; Wang, Y.; Liu, X.; Li, Z. Geopolymer Synthesis Using Garnet Tailings from Molybdenum Mines. Minerals 2019, 9, 48. https://doi.org/10.3390/min9010048

Wang A, Liu H, Hao X, Wang Y, Liu X, Li Z. Geopolymer Synthesis Using Garnet Tailings from Molybdenum Mines. Minerals. 2019; 9(1):48. https://doi.org/10.3390/min9010048

Chicago/Turabian StyleWang, An, Hongzhao Liu, Xiaofei Hao, Yang Wang, Xueqin Liu, and Zhen Li. 2019. "Geopolymer Synthesis Using Garnet Tailings from Molybdenum Mines" Minerals 9, no. 1: 48. https://doi.org/10.3390/min9010048

APA StyleWang, A., Liu, H., Hao, X., Wang, Y., Liu, X., & Li, Z. (2019). Geopolymer Synthesis Using Garnet Tailings from Molybdenum Mines. Minerals, 9(1), 48. https://doi.org/10.3390/min9010048