Pre-Concentration of Iron-Rich Sphalerite by Magnetic Separation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Methods

3. Results and Discussion

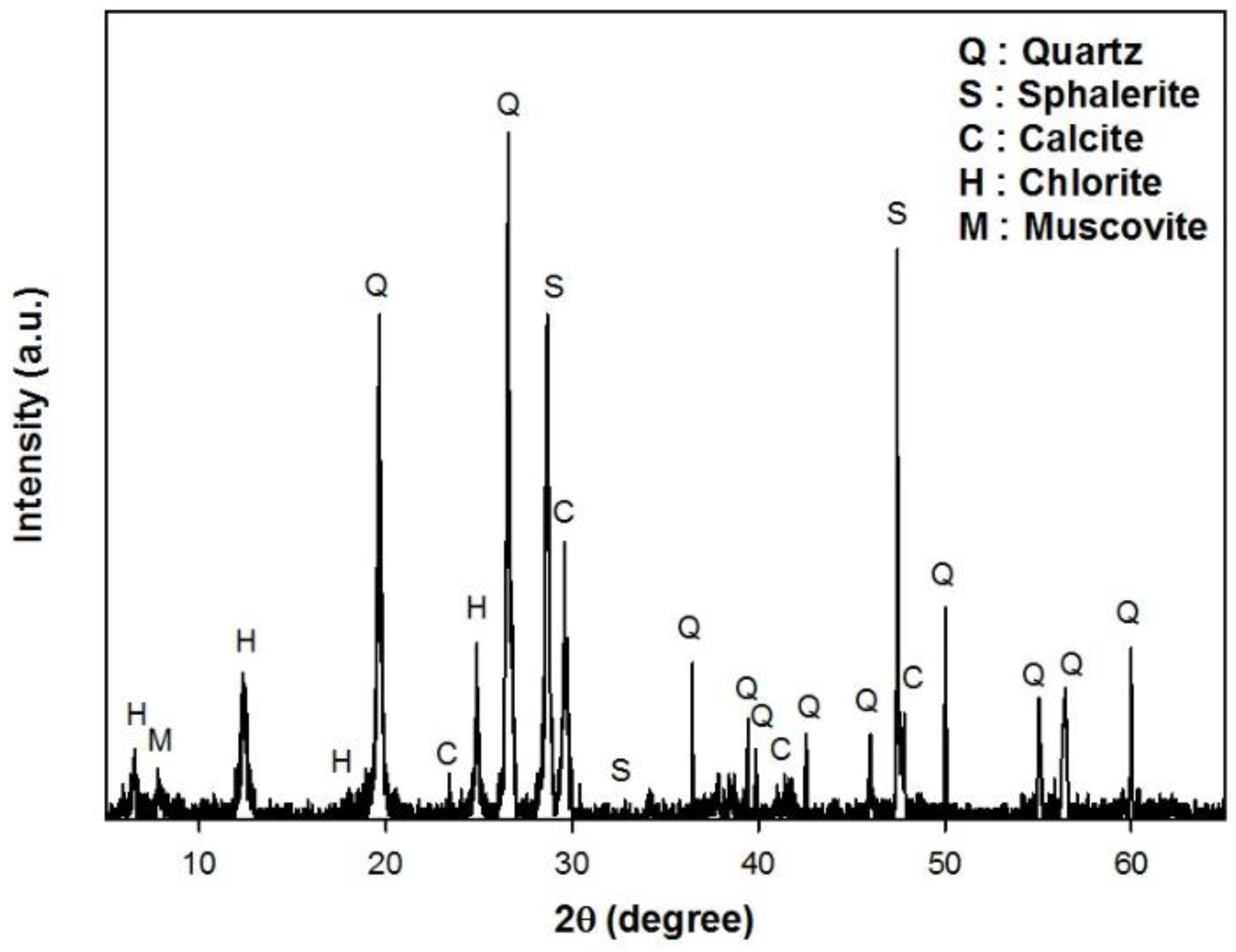

3.1. Chemical Composition of Feed Sample

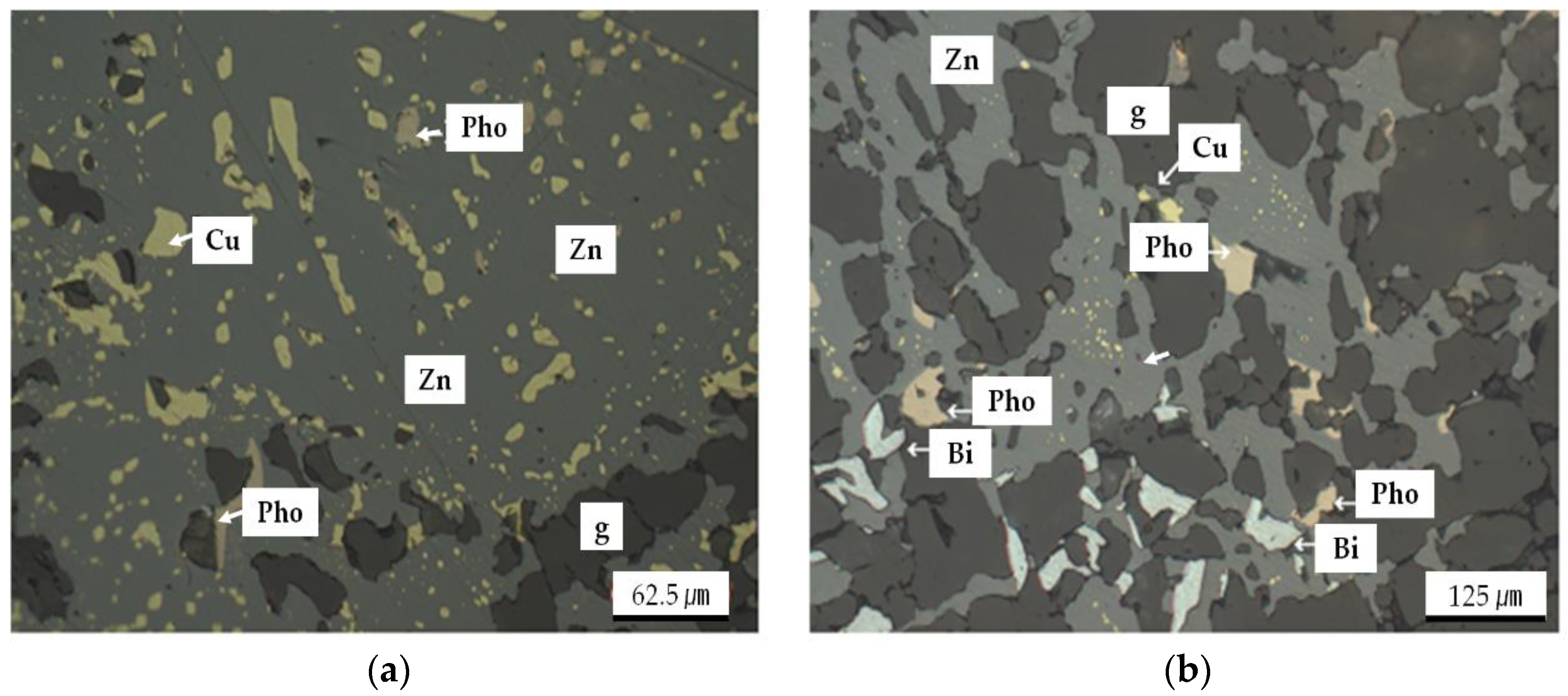

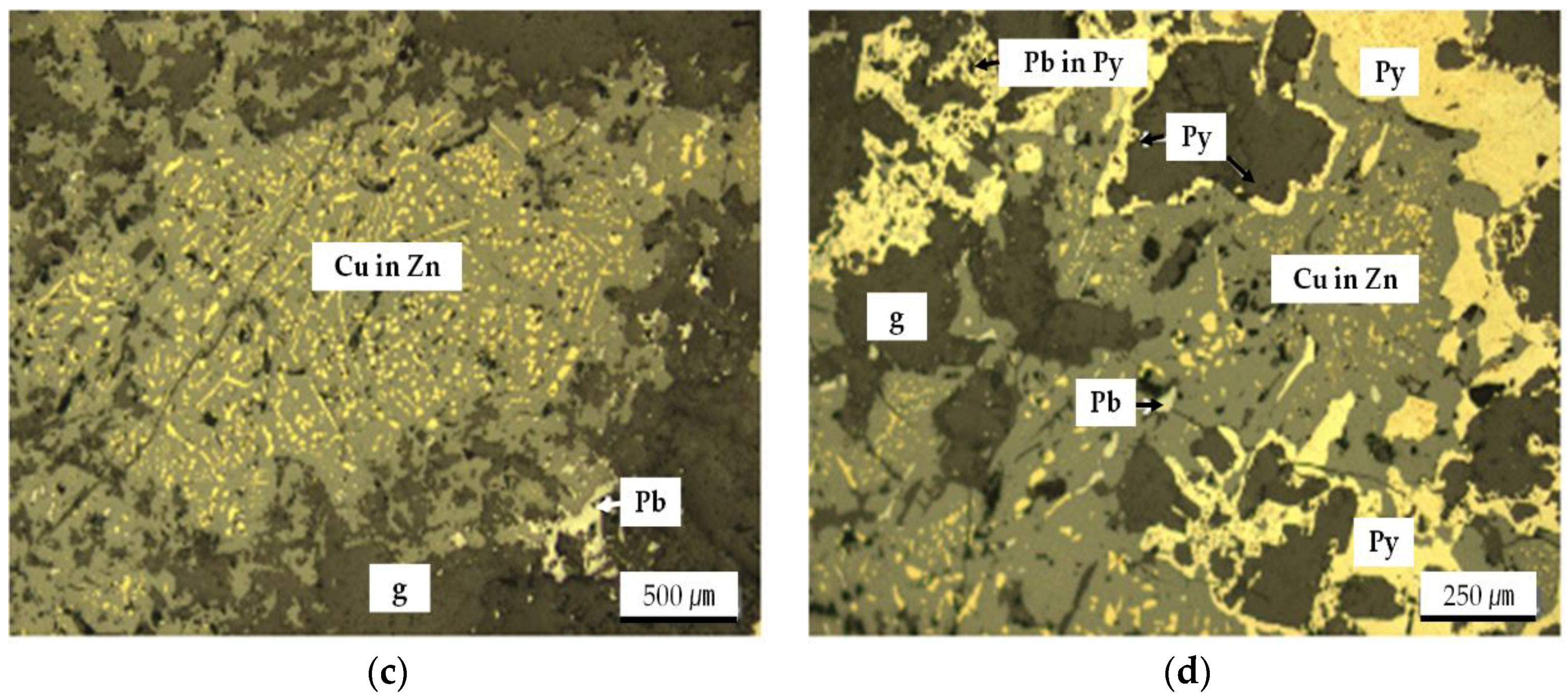

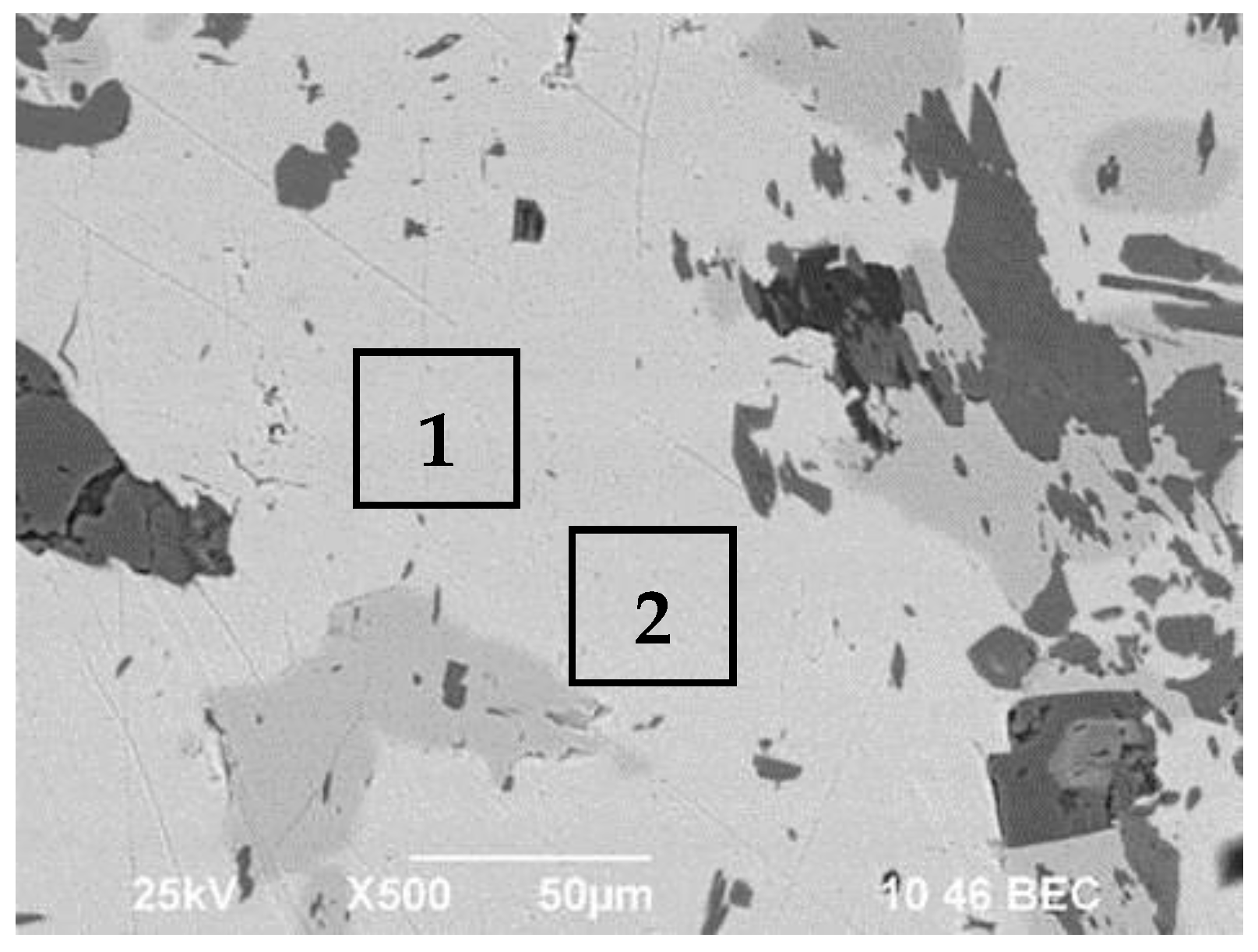

3.2. Microscope Analysis of Feed Sample

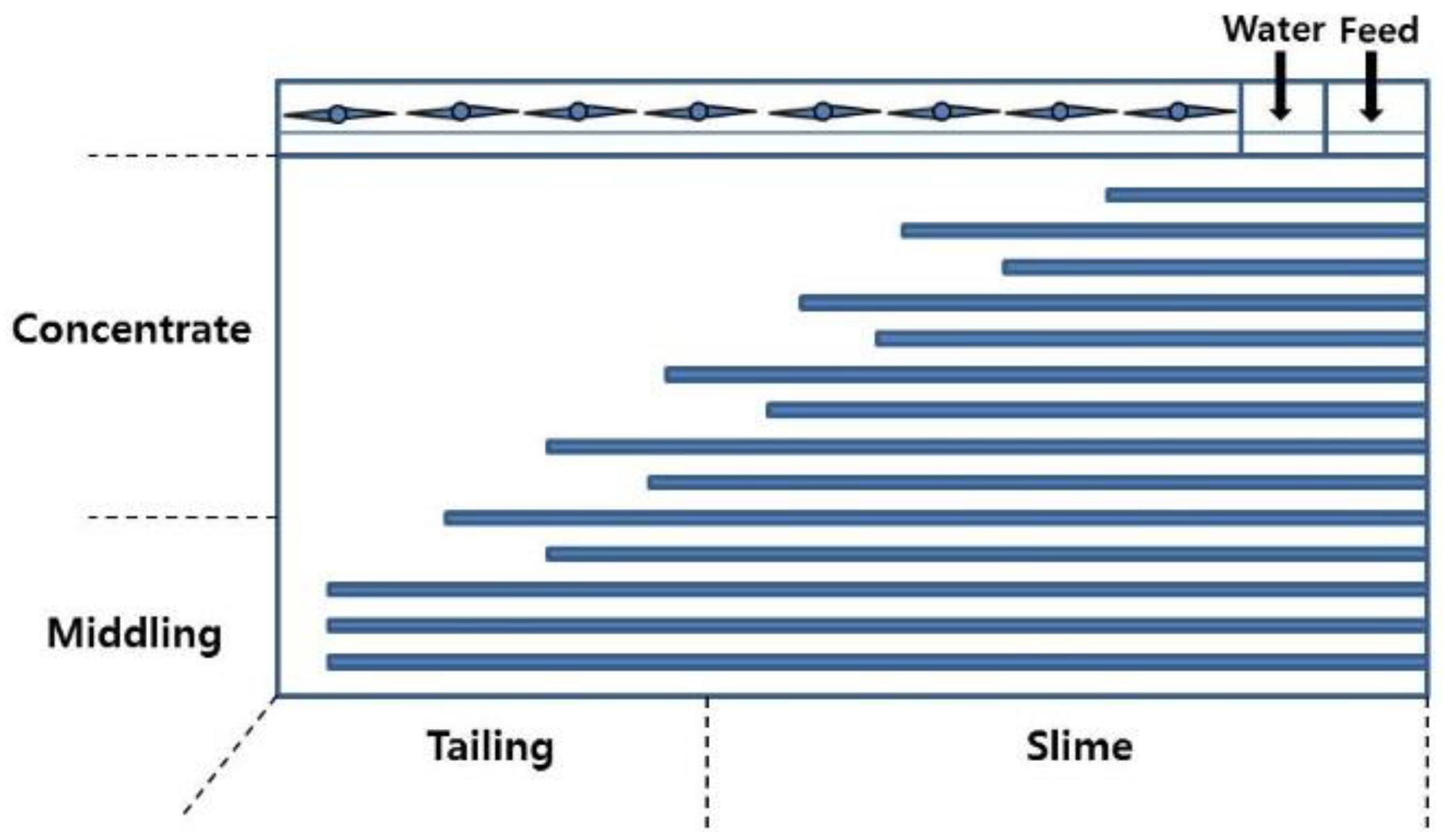

3.3. Using Gravity Separation for Pre-Concentration

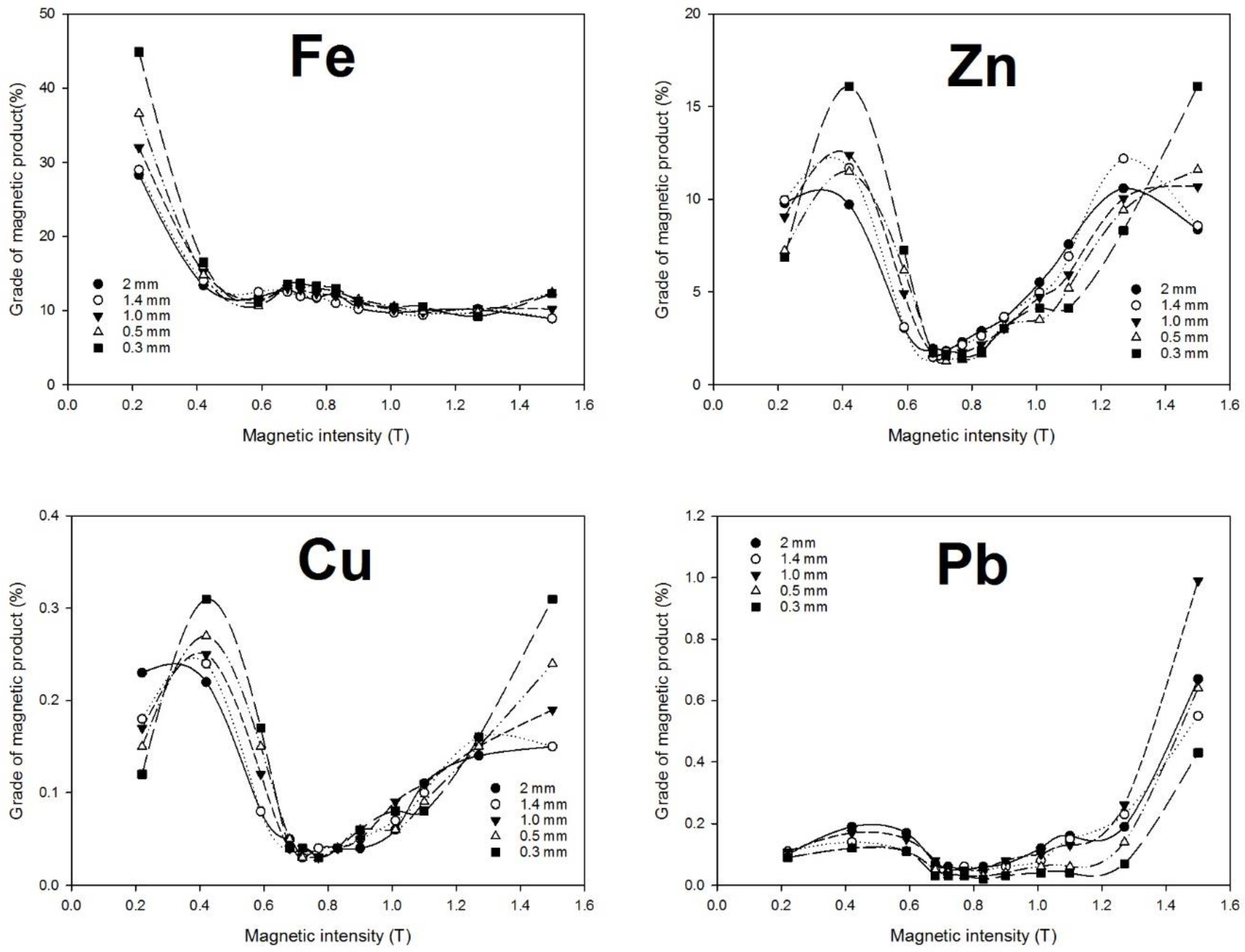

3.4. Using Magnetic Separation for Pre-Concentration

3.5. Pre-Concentration Process of Sphalerite

4. Conclusions

- Sphalerite was the major sulfide mineral in the Pb–Zn deposits obtained from the Gagok mine, and galena and chalcopyrite were not detected by XRD analysis owing to their low content. The grades of zinc, lead, copper, and iron were 4.88%, 0.09%, 0.09%, and 15.3%, respectively. The high content of iron in the feed sample can be attributed to the iron-rich sphalerite and iron- bearing minerals, such as pyrrhotite.

- Because target minerals (sphalerite, chalcopyrite, and galena) were concentrated by crushing in the portion of fine particles with sizes below 74 μm, the gravity separation method using a shaking table was not effective for this sample.

- The dry magnetic separation experiment confirmed that concentrations of target elements were low in the products separated at intermediate magnetic intensity (0.6–0.85 T magnetic products), and the maximum particle size of 1 mm was appropriate from the viewpoint of mass reduction and loss ratio of target elements.

- The pre-concentration process was developed using the results of magnetic separation. After the crushing stage, to limit the maximum particle size to 1 mm, the portion of coarse particles with sizes above 74 μm was fed to the magnetic separation process to remove low-grade target elements from the products extracted at intermediate magnetic intensity. About 48.5% of the feed sample was removed in the pre-concentration stage, and the grades of the target elements were enhanced: 65% for zinc, 55% for lead, and 33% for copper. Consequently, it is expected that the economic efficiency of the entire process will be significantly improved because the cost of grinding and flotation can be greatly reduced by removing the low-grade fraction of separated products in the pre-concentration stage. However, it is difficult to estimate the process costs from a simple flowchart. Generally speaking, the grinding and flotation process account for more than 50% of the total process cost. Therefore, cost saving of 20% or higher can be expected for the entire process by adopting the pre-concentration process.

Author Contributions

Funding

Conflicts of Interest

References

- Fuerstenau, M.C.; Flotation, A.M. Gaudin Memorial Volume 2; American Institute of Mining, Metallurgical and Petroleum Engineers: New York, NY, USA, 1976; pp. 1029–1231. [Google Scholar]

- Gómez, F.L.; Sierra, J.R.; Carcedo, F.G.; Garcia, F.M.; Garcia, J.M. Influence of ultrafine grain size in differential flotation of galena and sphalerite. Int. J. Miner. Process. 1986, 17, 303–316. [Google Scholar] [CrossRef]

- Sehlotho, N.; Sindane, Z.; Bryson, M.; Lindvelt, L. Flowsheet development for selective Cu-Pb-Zn recovery at Rosh Pinah concentrator. Miner. Eng. 2018, 122, 10–16. [Google Scholar] [CrossRef]

- Forssberg, K.E.; Subrahmanyam, T.; Nilsson, L.K. Influence of grinding method on complex sulphide ore flotation: A pilot plant study. Int. J. Miner. Process. 1993, 38, 157–175. [Google Scholar] [CrossRef]

- Mehrabani, J.; Noaparast, M.; Mousavi, S.; Dehghan, R.; Ghorbani, A. Process optimization and modelling of sphalerite flotation from a low-grade Zn–Pb ore using response surface methodology. Sep. Purif. Technol. 2010, 72, 242–249. [Google Scholar] [CrossRef]

- Pérez-Garibay, R.; Ramírez-Aguilera, N.; Bouchard, J.; Rubio, J. Froth flotation of sphalerite: Collector concentration, gas dispersion and particle size effects. Miner. Eng. 2014, 57, 72–78. [Google Scholar] [CrossRef]

- Fosu, S.; Skinner, W.; Zanin, M. Detachment of coarse composite sphalerite particles from bubbles in flotation: Influence of xanthate collector type and concentration. Miner. Eng. 2015, 71, 73–84. [Google Scholar] [CrossRef]

- Wang, J.; Xie, L.; Liu, Q.; Zeng, H. Effects of salinity on xanthate adsorption on sphalerite and bubble–sphalerite interactions. Miner. Eng. 2015, 77, 34–41. [Google Scholar] [CrossRef]

- Ejtemaei, M.; Nguyen, A.V. A comparative study of the attachment of air bubbles onto sphalerite and pyrite surfaces activated by copper sulphate. Miner. Eng. 2017, 109, 14–20. [Google Scholar] [CrossRef]

- Finkelstein, N. The activation of sulphide minerals for flotation: A review. Int. J. Miner. Process. 1997, 52, 81–120. [Google Scholar] [CrossRef]

- Laskowski, J.; Liu, Q.; Zhan, Y. Sphalerite activation: Flotation and electrokinetic studies. Miner. Eng. 1997, 10, 787–802. [Google Scholar] [CrossRef]

- Rao, S.; Nesset, J.; Finch, J. Activation of sphalerite by Cu ions produced by cyanide action on chalcopyrite. Miner. Eng. 2011, 24, 1025–1027. [Google Scholar] [CrossRef]

- Albrecht, T.; Addai-Mensah, J.; Fornasiero, D. Critical copper concentration in sphalerite flotation: Effect of temperature and collector. Int. J. Miner. Process. 2016, 146, 15–22. [Google Scholar] [CrossRef]

- Yang, B.; Tong, X.; Lan, Z.; Cui, Y.; Xie, X. Influence of the interaction between sphalerite and pyrite on the copper activation of sphalerite. Minerals 2018, 8, 16. [Google Scholar] [CrossRef]

- Dávila-Pulido, G.; Uribe-Salas, A.; Espinosa-Gómez, R. Comparison of the depressant action of sulfite and metabisulfite for Cu-activated sphalerite. Int. J. Miner. Process. 2011, 101, 71–74. [Google Scholar] [CrossRef]

- Huang, P.; Cao, M.; Liu, Q. Selective depression of sphalerite by chitosan in differential Pb–Zn flotation. Int. J. Miner. Process. 2013, 122, 29–35. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Y.; Luo, D.; Zeng, Y. Use of ZnSO4 and SDD mixture as sphalerite depressant in copper flotation. Miner. Eng. 2018, 121, 31–38. [Google Scholar] [CrossRef]

- Solecki, J.; Komosa, A.; Szczypa, J. Copper ion activation of synthetic sphalerites with various iron contents. Int. J. Miner. Process. 1979, 6, 221–228. [Google Scholar] [CrossRef]

- Buckley, A.; Woods, R.; Wouterlood, H. An XPS investigation of the surface of natural sphalerites under flotation-related conditions. Int. J. Miner. Process. 1989, 26, 29–49. [Google Scholar] [CrossRef]

- Boulton, A.; Fornasiero, D.; Ralston, J. Effect of iron content in sphalerite on flotation. Miner. Eng. 2005, 18, 1120–1122. [Google Scholar] [CrossRef]

- Tong, X.; Song, S.; He, J.; Rao, F.; Lopez-Valdivieso, A. Activation of high-iron marmatite in froth flotation by ammoniacal copper (ii) solution. Miner. Eng. 2007, 20, 259–263. [Google Scholar] [CrossRef]

- Gaudin, A.; Spedden, H. Magnetic separation of sulphide minerals. Trans. Am. Inst. Min. Metall. Eng. 1943, 153, 563–575. [Google Scholar]

- Keys, J.; Horwood, J.; Baleshta, T.; Cabri, L.; Harris, D. Iron-iron interaction in iron-containing zinc sulphide. Can. Miner. 1968, 9, 453–467. [Google Scholar]

- Jirestig, J.; Forssberg, E. Magnetic characterization of sulphide ores: Examples from Sweden. Phys. Sep. Sci. Eng. 1992, 4, 31–45. [Google Scholar] [CrossRef]

- Pearce, C.I.; Pattrick, R.A.; Vaughan, D.J. Electrical and magnetic properties of sulfides. Rev. Miner. Geochem. 2006, 61, 127–180. [Google Scholar] [CrossRef]

- Yun, S.; Einaudi, M.T. Zinc-lead skarns of the Yeonhwa-Ulchin district, South Korea. Econ. Geol. 1982, 77, 1013–1032. [Google Scholar] [CrossRef]

| Size Fraction | Yield (wt %) | Concentration (wt %) | |||

|---|---|---|---|---|---|

| Fe | Zn | Pb | Cu | ||

| >212 μm | 12.5 | 14.6 | 2.90 | 0.05 | 0.06 |

| 106–212 μm | 16.0 | 15.0 | 3.62 | 0.06 | 0.07 |

| 74–106 μm | 21.6 | 15.6 | 4.92 | 0.06 | 0.08 |

| 37–74 μm | 13.1 | 16.1 | 5.69 | 0.10 | 0.10 |

| <37 μm | 36.8 | 15.3 | 5.79 | 0.13 | 0.11 |

| Total | 100.0 | 15.3 | 4.88 | 0.09 | 0.09 |

| Mineral | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Sphalerite | 14 | 15 | 17 | 7 | 20 | - | 18 | 20 | 5 | 8 |

| Chalcopyrite | <0.5 | 1 | 1 | 1 | 1 | 1 | 1 | <0.5 | <0.5 | <0.5 |

| Galena | <0.5 | - | - | - | <0.5 | - | - | - | - | 1 |

| Pyrrhotite | <0.5 | 16 | 18 | 8 | 3 | 9 | 16 | <0.5 | 3 | <0.5 |

| Pyrite | <0.5 | 1 | 3 | 2 | <0.5 | <0.5 | 2 | 2 | <0.5 | 30 |

| Marcasite | - | 1 | 1 | 1 | - | 2 | - | - | - | |

| Magnetite | - | - | - | 1 | - | - | - | - | - | - |

| Pb-Bi-S | - | <0.5 | <0.5 | - | - | - | <0.5 | - | - | - |

| Ilmenite | <0.5 | - | - | - | - | - | - | - | - | - |

| Pyroxenes | 1 | 56 | 46 | 58 | 37 | 61 | 22 | 62 | 88 | 34 |

| Garnet | - | - | - | - | 22 | - | 13 | - | - | 2 |

| Amphiboles | 7 | - | 2 | 3 | <0.5 | 12 | 1 | - | <0.5 | 2 |

| Calcite | 32 | <0.5 | 5 | 11 | 8 | 6 | 9 | <0.5 | - | 10 |

| Epidote | - | - | - | - | - | - | 3 | 12 | 1 | - |

| Quartz | 36 | - | - | 2 | 1 | <0.5 | <0.5 | - | - | 2 |

| Biotite | 7 | 5 | 4 | 4 | 4 | 4 | 4 | <0.5 | - | 3 |

| Fluorite | - | - | - | - | - | - | 5 | - | - | - |

| Location | 1 | 2 | |

|---|---|---|---|

| Elemental composition (wt %) | S | 46.15 | 45.37 |

| Fe | 10.97 | 10.99 | |

| Zn | 42.88 | 43.64 | |

| Yield (wt %) | Fe | Zn | Pb | Cu | |||||

|---|---|---|---|---|---|---|---|---|---|

| 1 G (%) | 2 Re (%) | G (%) | Re (%) | G (%) | Re (%) | G (%) | Re (%) | ||

| Concentrate | 4.31 | 29.3 | 5.8 | 17.8 | 10.2 | 0.82 | 18.1 | 0.39 | 10.5 |

| Middling | 10.74 | 21.9 | 10.8 | 10.2 | 14.6 | 0.11 | 5.9 | 0.20 | 13.4 |

| Tailing | 65.61 | 14.3 | 42.9 | 3.2 | 28.0 | 0.06 | 20.1 | 0.07 | 27.0 |

| Slime | 19.35 | 13.5 | 40.5 | 5.4 | 47.2 | 0.17 | 55.9 | 0.12 | 49.1 |

| Yield (wt %) | Fe | Zn | Pb | Cu | |||||

|---|---|---|---|---|---|---|---|---|---|

| 1 G (%) | 2 Re (%) | G (%) | Re (%) | G (%) | Re (%) | G (%) | Re (%) | ||

| Ferromagnetic product | 23.1 | 27.5 | 36.3 | 8.93 | 42.0 | 0.12 | 31.0 | 0.15 | 42.3 |

| Paramagnetic product | 48.5 | 14.3 | 39.6 | 1.55 | 15.3 | 0.04 | 21.1 | 0.04 | 22.5 |

| Diamagnetic product | 15.2 | 12.7 | 11.1 | 7.3 | 22.7 | 0.16 | 27.3 | 0.10 | 17.5 |

| Fine particle (<74 μm) | 13.2 | 17.2 | 13.0 | 7.45 | 20.0 | 0.14 | 20.6 | 0.11 | 17.7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, S.; Kim, K. Pre-Concentration of Iron-Rich Sphalerite by Magnetic Separation. Minerals 2018, 8, 272. https://doi.org/10.3390/min8070272

Jeong S, Kim K. Pre-Concentration of Iron-Rich Sphalerite by Magnetic Separation. Minerals. 2018; 8(7):272. https://doi.org/10.3390/min8070272

Chicago/Turabian StyleJeong, Soobok, and Kwanho Kim. 2018. "Pre-Concentration of Iron-Rich Sphalerite by Magnetic Separation" Minerals 8, no. 7: 272. https://doi.org/10.3390/min8070272

APA StyleJeong, S., & Kim, K. (2018). Pre-Concentration of Iron-Rich Sphalerite by Magnetic Separation. Minerals, 8(7), 272. https://doi.org/10.3390/min8070272