Towards Representative Metallurgical Sampling and Gold Recovery Testwork Programmes

Abstract

1. Introduction

1.1. Sampling along the Mine Value Chain

1.2. Metallurgical Sampling and Testwork

1.3. Current Practice and Focus of This Contribution

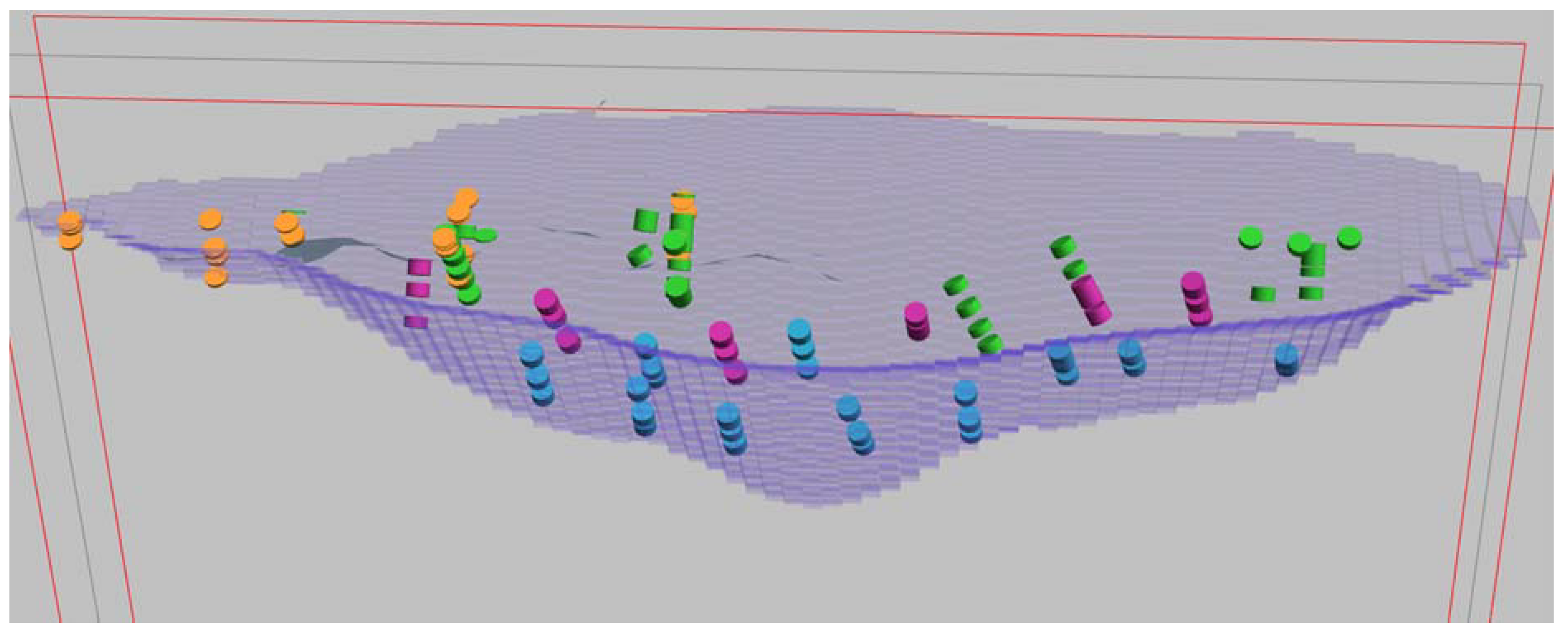

2. Mineralisation Characteristics

2.1. Geological Characteristics

2.2. Metallurgical Characteristics

3. Theory of Sampling

3.1. Overview

3.2. Nugget Effect

- Geological (geological or in-situ nugget effect: GNE) heterogeneity of the mineralisation.

- ○

- Distribution of single grains or clusters of gold or sulphide-hosting gold particles distributed through the ore to larger continuous zones.

- ○

- Continuity of structures such as high-grade gold carriers within the main structure or vein-lets within wall rocks.

- Sampling induced error variability (sampling nugget effect: SNE).

- ○

- Sample support (sample size—volume-variance).

- ○

- Sample density (number of samples at a given spacing—information effect).

- ○

- Sample collection, preparation, testwork and assay procedures.

3.3. Sampling Errors

3.4. Fundamental Sampling Error (FSE)

3.4.1. Background

3.4.2. Calibration of FSE Equation Inputs

- Realisation of gold deportment, in particular the partitioning of gold as free gold, gold in sulphides and refractory gold.

- Gold particle size curve(s), including effects of clustering and relationship between gold particle size and grade (e.g., high grade versus background grade).

- Definition of key FSE equation inputs (e.g., d95Au versus dAuClus) and the sampling constant K.

- Recommendations as to optimum in-situ sample mass requirements.

3.4.3. Applicability to Gold Ores

3.5. Sample Representativity

3.5.1. Representative Sampling

3.5.2. Fit for Purpose Samples

3.5.3. Data Quality Objectives

3.5.4. Approaches to Sampling Optimisation

4. Geometallurgy

5. Project Studies

6. Sampling for Metallurgical Testwork

6.1. Introduction

6.2. “Sampling for Sampling”—Characterisation for Sampling Programme Scoping and Development

6.3. Metallurgical Sample Mass Requirements

6.3.1. Testwork Mass Requirements

6.3.2. Theoretical In-Situ Sample Mass Evaluation

6.3.3. Sampling Domains

6.4. Number of Samples

6.5. Sample Type and Collection

6.5.1. Composites versus Variability Samples

- Composite samples should represent a given domain and comprise samples from different intersections (e.g., drill holes) or locations (e.g., other sample types) in that domain.

- Variability samples will be individual samples taken across a zone and submitted separately to investigate variability within the domain. Where possible, variability samples are preferable as they provide a measure of likely variability.

- Variability composite samples represent composites that are combined from samples with minimal spatial separation. As such they are composites, but reflect variability between localised areas.

6.5.2. Sample Type

6.5.3. Core Sample Collection

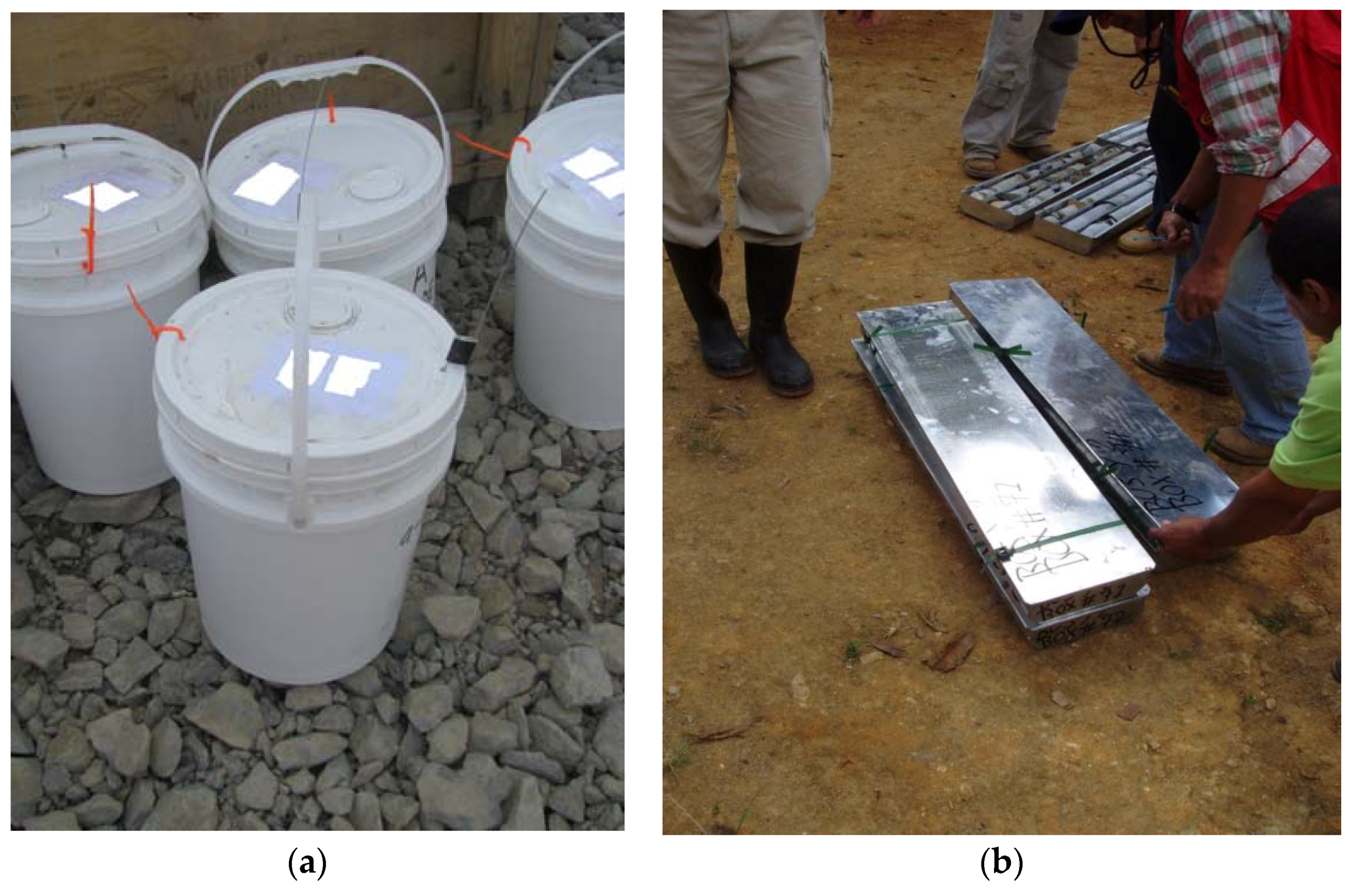

6.5.4. Sample Integrity and Chain of Custody

7. Sample Preparation, Testwork and Assaying

7.1. Overview

7.2. Drying and Weighing

7.3. Sample Mass and Size Reduction

7.4. Sample Blending

7.5. Testwork

7.6. Tailings Sampling

7.7. Assay Sub-Sample Preparation and Assaying

7.8. Reject and Residue Materials

8. Mineralogical Sampling and Analyses

8.1. Mineralogical Analysis

8.2. Sampling and Preparation

8.3. Optimal Sampling Plan

9. Quality Assurance/Control and Validation

9.1. Quality Assurance and Quality Control

- Duplicate field samples that are spatially distributed within a given domain to honour the gold grade frequency distribution. Field duplicates are rarely collected during metallurgical programmes due to the relative lack of material available, quantity of material required and high cost of testwork.

- Sub-sampling must be controlled by the FSE equation to ensure that they are representative.

- Assays to be supported by certified reference materials (CRM) and blanks to quantify analytical bias and contamination.

- Blanks should be inserted after known high-grade samples.

- Duplicate tests (e.g., two separate tests from same primary sample) should be undertaken on a regular basis (target 5% of the time) to monitor precision.

- Second test in alternate (umpire) laboratory.

- Introduction of reference material for leach and/or flotation testwork.

- Written and audited laboratory procedures with appropriate staff supervision to ensure compliance.

- Quantitative assessment of laboratory performance, enabling review and investigation of any issues.

- Experimental error for key parameters.

- Data to support design of testwork programmes.

- Compliance for public reporting and use in resource/reserve estimates.

9.2. Validation of Metallurgical Sampling and Testwork Programmes

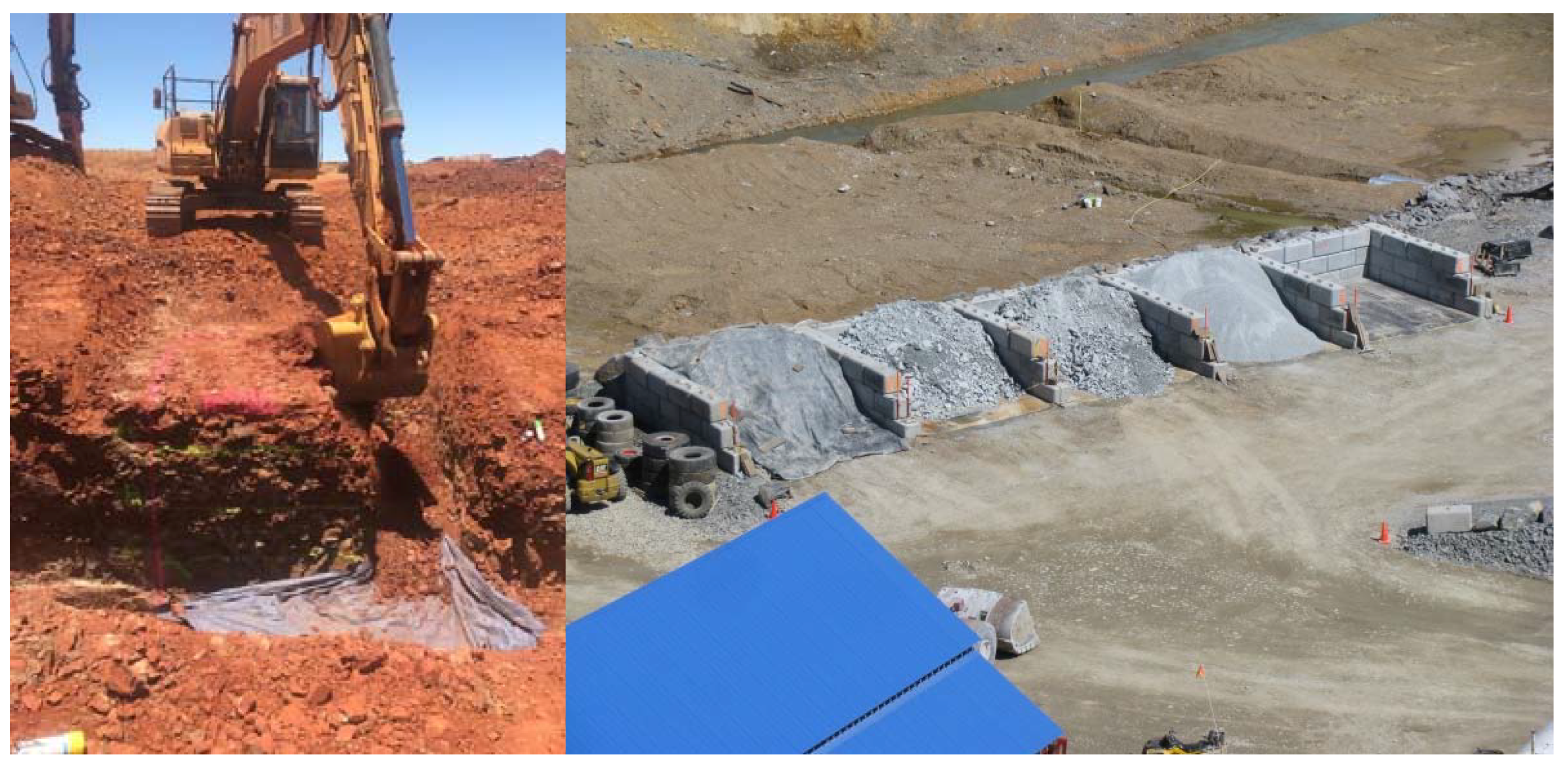

10. Large Sample Pilot and Demo Plant Testing

10.1. Introduction

10.2. Sample Collection

- Planning of blasting in relation to stope width (underground) or bench height (surface pits) and minimising of dilution to match that which is likely during mining (e.g., DE reduction).

- Avoidance of over-blasting that results in the excessive liberation and loss of gold and/or gold-bearing sulphides (e.g., EE).

- Mucking of blasted material, in particular fines, with the potential use of vacuum devices to ensure maximum recovery (e.g., EE reduction).

- Management system, involving tagging and chain of custody actions, to ensure that bulk sample mucked material is kept separate from other broken rock and trucked to the required stockpile or bulk transport bag.

10.3. Sample Processing

10.4. Limitations

11. Case Study

11.1. Project Background

11.2. Metallurgical Sampling and Testwork

11.3. Plant Design and Performance

11.4. What Went Wrong?

- HZ samples and sub-samples were unrepresentative, as they were biased to very high grade mineralisation which gave high GRG values.

- PZ samples and sub-samples were unrepresentative, as they were biased to relatively high-grade material that was occasionally present in the PZ, and thus gave high GRG values.

- Primary PZ samples and sub-samples did not represent the sulphide mineralisation, thus the flotation response was low.

- Too few samples were collected.

- Testwork laboratory used was not certificated and had a poor reputation.

- No QAQC was undertaken anywhere in the sampling chain, including during assaying.

- Geological interpretation of the HZ focused on a continuous zone down the centre of the shoot (considered to be 50% of the shoot). This was not the case, in reality there is a series of high-grade sub-shoots, forming a discontinuous zones within the main-shoot forming 25% of the shoot zone. The mine plan did not honour the geology or grade distribution.

- No mineralogical studies were undertaken.

11.5. Corrective Metallurgical Sampling and Testwork Campaign

11.5.1. Historical Data Review

11.5.2. Sampling Strategy

11.5.3. Underground Metallurgical Samples

11.5.4. Core Composite Metallurgical Samples

11.5.5. Testwork Programme

11.5.6. Pilot Programme

11.5.7. Quality Assurance/Quality Control

11.5.8. Duplicate Sample Analysis of Underground Panel Programme

11.5.9. Sampling Validation and Ore Characteristics

11.6. Communicating Sample Representativity, Testwork Quality and Fit-for-Purpose Results

11.7. Conclusions

- Poor liaison between geologists and metallurgists for sampling programme design.

- Poor geological interpretation and over-reliance on an old model.

- Too few samples collected.

- Unrepresentative (too small) sample composites and sub-samples.

- Poor laboratory practice during preparation and testwork.

- Lack of documentation and QAQC

12. Public Reporting of Metallurgical Sampling and Testwork Programmes

13. Driving Representativity: Design of a Sampling and Testwork Programme

14. Conclusions

- (1)

- Correctly collected and prepared metallurgical samples to support testwork are critical to effective gold processing plant design. There is often a paucity of material for sampling and often only half-core from resource drilling. Not only is sample material required for recovery testwork, but also for comminution and geoenvironmental testwork. Metallurgical sampling programmes should be integrated into strategic geometallurgical studies to ensure maximisation of data usage and better decision making. Early stage consideration of metallurgical sampling and testwork will lead to better decision-making with respect of resource delineation and development, more focused metallurgical studies as a project develops and ultimately optimised shareholder value.

- (2)

- During programme scoping, a sampling for sampling step should be undertaken to permit preliminary characterisation. Any in-situ coarse to very-coarse fraction (or similarly gold-bearing sulphides) will be the most material to testwork result quality. Reviewing geological and grade information as early as possible helps determine the likely heterogeneity (e.g., degree of nugget effect) and potential domains. Multi-disciplinary core logging will go a long way to resolve domains and their variability in consideration of (2) above.

- (3)

- Representativity is based on appropriate sample mass to improve precision and sampling protocols to reduce bias. An estimate of theoretical sample mass can be defined by the application of Poisson statistics, with a target precision of ±20% at 90% reliability. Subsequent sub-sampling for testwork can be controlled via the FSE equation with a target precision of ±15% at 90% reliability. The selection of precision and reliability levels depend on mineralogical assessment and practitioner judgement.

- (4)

- All samples must be collected within the framework of TOS. Where broken rock samples (e.g., crushed material) are used, the FSE equation can be applied. Large diameter diamond drill core provides the best quality samples on which to undertake testwork. The traditional paradigm is to form metallurgical composites from quarter resource evaluation core. Improved core logging, digital photography and data collection methods now provide an opportunity to use half or whole core samples for metallurgical testwork. For high-GNE mineralisation, multiple large diamond drill core and/or bulk samples may be the most appropriate.

- (5)

- During testwork, laboratory crushing, grinding, splitting and blending should be optimised in the light of TOS. Reduction of sample loss and contamination is paramount, and should be controlled via appropriate hygiene procedures. Testwork errors must be minimised. Ensure that testwork sub-samples are representative of the original sample. Particular attention is required across: equipment maintenance and operating parameters, cleaning of equipment and associated pipework, and reducing careless work practices.

- (6)

- Testwork must be accompanied by mineralogical studies which play a critical role in optimising gold recovery processes. Mineralogy is widely applied in the characterisation of gold ores and mill products, and to determine potential issue(s) that may cause gold losses. The information acquired can be used as a basis for metallurgical testwork programme design or optimisation. Ideally, a mineralogical study should be conducted prior to the start of, or at the early stage of a testwork programme.

- (7)

- A QAQC programme must be introduced to ensure on-going quality control of sampling and testwork. The association of QAQC with TOS is unequivocal. A key part of QAQC is documentation and training. Written protocols and procedures, staff training, periodic auditing of protocols and people, and re-training are required. The new DS3077 provides a framework on which to produce transparent protocols [53]. Control is through the examination of laboratory and audit procedures results, and adherence to standard or industry-accepted operating procedures. Samples must be handled to ensure their integrity and security. A chain-of-custody must be enacted.

- (8)

- Measures are recommended to reduce risk of the tampering of samples. These include: maintaining increased security between the sample site (e.g., exposure and/or drill rig) and sample shipment; recording who has access to samples between collection and shipping, and maintaining a secure copy of that record through the project life; and employing an outside agency with no vested interest in the project, to maintain custody and security over samples.

- (9)

- Technical teams should consider bulk sampling to support pilot or trial testing programmes to evaluate grade and metallurgy as part of pre-feasibility or feasibility studies. This may be particularly important in high GNE mineralisation or where high variability relates to mineralogical and/or textural complexities that impact on recovery.

- (10)

- Early collaboration across technical disciplines is required to design and implement metallurgical sampling and testwork programmes. As a multi-disciplinary approach, geometallurgy emphasises technical collaboration and is gradually producing more dual discipline professionals. Discipline sharing should be considered a key development for the future of the mining industry.

- (11)

- There is now a need to move towards proper quantification of sampling and analytical errors. A first step is the application of the RSV defined in DS3077 [53]. Beyond this, resolution of component relative errors across sampling, preparation and analysis can be gained from duplicate sample pairs [21,47,48]. Measurement uncertainty analysis also provides value in this quest [21,50,55,103].

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Dominy, S.C. Importance of good sampling practice throughout the gold mine value chain. Min. Technol. 2016, 125, 129–141. [Google Scholar] [CrossRef]

- Giblett, A.; Dunne, R.; McCaffery, K. Defining practical metallurgical accounting discrepancy limits for gold operations. In Landmark Papers by Practicing Metallurgists; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2017; pp. 365–372. [Google Scholar]

- Minnitt, R.C.A. Sampling: The impact on costs and decision making. J. S. Afr. Inst. Min. Metall. 2007, 107, 451–462. [Google Scholar]

- Parbhakar-Fox, A.; Dominy, S.C. Sampling and blending in geoenvironmental campaigns–current practice and future opportunities. In Proceedings of the World Conference on Sampling and Blending, Perth, Australia, 9–11 May 2017; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2017; pp. 45–53. [Google Scholar]

- Pitard, F.F. Sampling correctness: A comprehensive guide. In Proceedings of the World Conference on Sampling and Blending, Sunshine Coast, Australia, 10–12 May 2005; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2005; pp. 55–66. [Google Scholar]

- Gy, P.M. Sampling of Particulate Materials: Theory and Practice; Elsevier: Amsterdam, The Netherlands, 1982; p. 431. [Google Scholar]

- Pitard, F.F. From errors to uncertainty—A clarification for proper use by the Theory of Sampling. In Proceedings of the World Conference on Sampling and Blending, Perth, Australia, 9–11 May 2017; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2017; pp. 355–358. [Google Scholar]

- Bazin, C.; Hodouin, D.; Mermillod-Blondin, R. Reproducibility of low grade ore batches prepared for metallurgical testing. In Proceedings of the World Conference on Sampling and Blending, Lima, Peru, 19–22 November 2013; Gecamin: Santiago, Chile, 2013; pp. 419–433. [Google Scholar]

- McCarthy, P.L. Managing technical risk for mine feasibility studies. In Proceedings of the Mining Risk Management Conference, Sydney, Australia, 9–12 August 2003; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2003; pp. 21–27. [Google Scholar]

- Pitard, F.F. Pierre Gy’s Sampling Theory and Sampling Practice; CRC Press: Boca Raton, FL, USA, 1993; p. 488. [Google Scholar]

- Dominy, S.C.; O’Connor, L. Geometallurgy–beyond conception. In Proceedings of the International Geometallurgy Conference, Perth, Australia, 15–16 June 2016; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2016; pp. 3–10. [Google Scholar]

- Dominy, S.C.; Xie, Y. Optimising sampling protocols via the heterogeneity test: Challenges in coarse gold mineralisation. Min. Technol. 2016, 125, 103–113. [Google Scholar] [CrossRef]

- Petersen, L.; Dahl, C.K.; Esbensen, K.H. Representative mass reduction in sampling—A critical survey of techniques and hardware. Chemom. Intell. Lab. Syst. 2004, 74, 95–114. [Google Scholar] [CrossRef]

- Thompson, M.; Howarth, R.J. A new approach to the estimation of analytical precision. J. Geochem. Exp. 1978, 9, 23–30. [Google Scholar]

- Angove, J.; Acar, S. Metallurgical testwork: Gold processing options, physical ore properties and cyanide management. In Advances in Gold Ore Processing; Elsevier: Amsterdam, The Netherlands, 2016; pp. 131–140. [Google Scholar]

- Goodall, W.R.; Leatham, J.D.; Scales, P.J. A new method for the determination of preg-robbing in gold ores. Miner. Eng. 2005, 18, 1135–1141. [Google Scholar] [CrossRef]

- Hanks, J.; Barratt, D. Sampling a mineral deposit for metallurgical testing and the design of comminution and mineral separation processes. In Proceedings of the Mineral Processing Plant Design, Practice and Control, Vancouver, BC, Canada, 20–24 October 2002; Society for Mining, Metallurgy and Exploration: Littleton, CO, USA, 2002; pp. 99–116. [Google Scholar]

- Laplante, A.R.; Spiller, D.E. Bench-scale and pilot plant test work for gravity concentration circuit design. In Proceedings of the Mineral Processing Plant Design, Practice and Control, Vancouver, BC, Canada, 20–24 October 2002; Society for Mining, Metallurgy and Exploration: Littleton, CO, USA, 2002; pp. 160–175. [Google Scholar]

- Lorenzen, L.; Tumilty, J.A. Diagnostic leaching as an analytical tool for evaluating the effect of reagents on the performance of a gold plant. Miner. Eng. 1992, 5, 503–512. [Google Scholar] [CrossRef]

- Anderson, M.A. Planning the mineral processing plant. In Mineral Property Evaluation: Handbook for Feasibility Studies and Due Diligence; Society for Mining, Metallurgy and Exploration: Englewood, CO, USA, 2018; pp. 175–208. [Google Scholar]

- Ramsey, M.H.; Ellison, S.L.R. Measurement Uncertainty Arising from Sampling: A Guide to Methods and Approaches (EURACHEM/CITAC Guide); Eurachem: Olomouc, Czech Republic, 2007; p. 102. [Google Scholar]

- Rendu, J.-M. Risk Management in Evaluating Mineral Deposits; Society for Mining, Metallurgy and Exploration: Littleton, CO, USA, 2017; p. 310. [Google Scholar]

- Anderson, W. The scheduling, costing and importance of metallurgical testwork programmes in process plant feasibility studies. In Proceedings of the International Congress on Mineral Processing and Extractive Metallurgy, Melbourne, Australia, 11–13 September 2000; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2000; pp. 79–89. [Google Scholar]

- Dunham, S.; Vann, J.; Coward, S. Beyond geometallurgy–gaining competitive advantage by exploiting the broad view of geometallurgy. In Proceedings of the International Geometallurgy Conference, Brisbane, Australia, 5–7 September 2011; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2011; pp. 115–123. [Google Scholar]

- McKay, N.; Vann, J.; Ware, W.; Morley, C.S.; Hodkiewicz, P. Strategic versus tactical geometallurgy—A systematic process to add and sustain resource value. In Proceedings of the International Geometallurgy Conference, Perth, Australia, 15–16 June 2016; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2016; pp. 29–36. [Google Scholar]

- JORC. Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves—The JORC Code; Joint Ore Reserves Committee of the Australasian Institute of Mining and Metallurgy, Australian Institute of Geoscientists and Minerals Council of Australia: Melbourne, Australia, 2012; p. 44. [Google Scholar]

- NI43-101. National Instrument 43-101, Standards of Disclosure for Mineral Projects; Canadian Securities Administrators: Montreal, QC, Canada, 2011; p. 44. [Google Scholar]

- Dominy, S.C.; Platten, I.M. Clustering of gold particles and implications for sampling. Appl. Earth Sci. 2007, 116, 130–142. [Google Scholar] [CrossRef]

- Dominy, S.C.; Xie, Y.; Platten, I.M. Gold particle characteristics in narrow vein deposits: Implications for evaluation and metallurgy. In Proceedings of the Narrow Vein Mining Conference, Ballarat, Australia, 14–15 October 2008; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2008; pp. 91–104. [Google Scholar]

- Lewis, P.J. Metallurgical input to the determination of Ore Reserves. In Mineral Resource and Ore Reserve Estimation; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2014; pp. 433–441. [Google Scholar]

- Guresin, N.; Lorenzen, L.; Dominy, S.C.; Muller, H.; Cooper, A. Sampling and testwork protocols for process plant design. In Proceedings of the Sampling Conference, Perth, Australia, 21–22 August 2012; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2012; pp. 95–107. [Google Scholar]

- Dominy, S.C. Predicting the unpredictable–evaluating high-nugget effect gold deposits. In Mineral Resource and Ore Reserve Estimation; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2014; pp. 659–678. [Google Scholar]

- François-Bongarçon, D.M. Fishy samples: How big a sample to avoid the infamous Poisson effect. In Proceedings of the World Conference on Sampling and Blending, Cape Town, South Africa, 21–23 October 2009; Southern African Institute of Mining and Metallurgy: Johannesburg, South Africa, 2009; pp. 43–46. [Google Scholar]

- Pitard, F.F. Pierre Gy’s Theory of Sampling and Ingamells Poisson Process Approach: Pathways to Representative Sampling and Appropriate Industry Standards; Aalborg University: Esbjerg, Denmark, 2009; p. 309. [Google Scholar]

- Clark, I. Statistics or geostatistics-sampling error or the nugget effect? In Proceedings of the World Conference on Sampling and Blending, Cape Town, South Africa, 21–23 October 2009; Southern African Institute of Mining and Metallurgy: Johannesburg, South Africa, 2009; pp. 13–18. [Google Scholar]

- Carrasco, P.C.; Carrasco, P.; Jara, E. The economic impact of incorrect sampling and analysis practices in the copper mining industry. Chemom. Intell. Lab. Syst. 2004, 74, 209–214. [Google Scholar]

- Dominy, S.C.; Glass, H.J.; O’Connor, L.; Lam, C.K.; Purevgerel, S.; Minnitt, R.C.A. Integrating the Theory of Sampling into underground grade control strategies. Minerals 2018. under review. [Google Scholar]

- Fourie, D.; Minnitt, R.C.A. Review of gold reef sampling and its impact on the mine call factor. J. S. Afr. Inst. Min. Metall. 2013, 116, 1001–1019. [Google Scholar] [CrossRef][Green Version]

- Minnitt, R.C.A. Sampling in the South African mining industry. In Proceedings of the Sampling and Analysis Conference, Muldersdrift, South Africa, 4–6 June 2013; Southern African Institute of Mining and Metallurgy: Johannesburg, South Africa, 2013; pp. 1–28. [Google Scholar]

- François-Bongarçon, D.M.; Gy, P.M. The most common error in applying Gy’s formula in the theory of mineral sampling and the history of the Liberation factor. J. S. Afr. Inst. Min. Metall. 2002, 102, 475–479. [Google Scholar]

- Minnitt, R.C.A.; Assibey-Bonsu, W. A comparison between the duplicate series method and the heterogeneity test as methods for calculating the sampling constants. J. S. Afr. Inst. Min. Metall. 2010, 110, 251–268. [Google Scholar]

- Dominy, S.C.; Platten, I.M.; Xie, Y. Determining gold particle size in gravity ores for sampling and metallurgical characterisation: Discussion and test protocol. In Proceedings of the Gravity Gold Conference, Ballarat, Australia, 21–22 September 2010; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2010; pp. 83–95. [Google Scholar]

- Dominy, S.C.; O’Connor, L.; Xie, Y. Sampling and testwork protocol development for geometallurgical characterisation of a sheeted vein gold deposit. In Proceedings of the International Geometallurgy Conference, Perth, Australia, 15–16 June 2016; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2016; pp. 97–112. [Google Scholar]

- Pitard, F.F. The advantages and pitfalls of conventional heterogeneity tests and a suggest alternative. TOS Forum 2015, 5, 13–18. [Google Scholar]

- Gonzalez, P.; Cossio, S. A review of sampling protocol for a gold ore based on liberation study. In Proceedings of the World Conference on Sampling and Blending, Porto Alegre, Brazil, 23–25 October 2007; Fundacao Luiz Englert: Porto Alegre, Brazil, 2007; pp. 163–174. [Google Scholar]

- Villanova, F.L.S.P.; Heberle, A.; Chieregati, A.C. Heterogeneity tests and core logging: A final reconciliation. In Proceedings of the Eighth World Conference on Sampling and Blending, Perth, Australia, 9–11 May 2017; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2017; pp. 107–113. [Google Scholar]

- Carswell, J.T.; Yulia, K.; Lesmana, D.; Steamy, K. Grade control sampling quality assurance/quality control in a high-grade gold mine—Gosowong, Indonesia. In Proceedings of the International Mining Geology Conference, Perth, Australia, 17–19 August 2009; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2009; pp. 283–290. [Google Scholar]

- Stanley, C.R.; Smee, B.W. Strategies for reducing sampling errors in exploration and resource definition drilling programmes for gold deposits. Geochem. Explor. Environ. Anal. 2007, 7, 329–340. [Google Scholar] [CrossRef]

- Ramsey, M.H.; Geelhoed, B.; Wood, R.; Damant, P. Improved evaluation of measurement uncertainty from sampling by inclusion of between-sampler bias using sampling proficiency testing. Analyst 2011, 136, 1313–1321. [Google Scholar] [CrossRef] [PubMed]

- Magnusson, B.; Ornemark, U. The Fitness for Purpose of Analytical Methods: A Laboratory Guide to Method Validation and Related Topics; Eurachem: Olomouc, Czech Republic, 2014; p. 62. [Google Scholar]

- Roden, S.; Smith, T. Sampling and analysis protocols and their role in mineral exploration and new resource development, In Mineral Resource and Ore Reserve Estimation; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2014; pp. 53–60. [Google Scholar]

- Pitard, F.F. Practical and theoretical difficulties when sampling for gold. In Proceedings of the Mineral Processing Plant Design, Practice and Control, Vancouver, Canada, 20–24 October 2002; Society for Mining, Metallurgy and Exploration: Littleton, CO, USA, 2002; pp. 77–98. [Google Scholar]

- DS3077. Representative Sampling–Horizontal Standard; Danish Standards Foundation: Copenhagen, Denmark, 2013; p. 41. [Google Scholar]

- Dominy, S.C.; O’Connor, L.; Xie, Y.; Glass, H.J. Geometallurgical sampling protocol validation by bulk sampling in a sheeted vein gold deposit. In Proceedings of the World Conference on Sampling and Blending, Perth, Australia, 9–11 May 2017; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2017; pp. 185–196. [Google Scholar]

- Ellison, S.L.R.; King, B.; Rosslein, M.; Salit, M.; Williams, A. Traceability in Chemical Measurement: A Guide to Achieving Comparable Results in Chemical Measurement; Eurachem: Olomouc, Czech Republic, 2003; p. 37. [Google Scholar]

- Lyman, G.J.; Bourgeois, F.S. Sampling, corporate governance and risk analysis. In Landmark Papers by Practicing Metallurgists; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2017; pp. 349–354. [Google Scholar]

- Glass, H.J.; Zegers, T.W. Statistical aspects of sampling particulate matter. In Proceedings of the Surface Mining Conference, Johannesburg, South Africa, 30 September–4 October 1996; Southern African Institute of Mining and Metallurgy: Johannesburg, South Africa, 1996; pp. 157–164. [Google Scholar]

- Pitard, F.F. Guidelines for acceptable allotted sampling uncertainty. In Proceedings of the World Conference on Sampling and Blending, Lima, Peru, 19–22 November 2013; Gecamin: Santiago, Chile, 2013; pp. 89–98. [Google Scholar]

- Lyn, J.A.; Ramsey, M.H.; Damant, A.P.; Wood, R. Empirical versus modelling approaches to the estimation of measurement uncertainty caused by primary sampling. Analyst 2007, 132, 1231–1237. [Google Scholar] [CrossRef] [PubMed]

- Vallée, M.A. Sampling optimisation. In Guide to the Evaluation of Gold Deposits; CIM: Montreal, QC, Canada, 1992; pp. 45–62. [Google Scholar]

- Williams, S. Metallurgy and geometallurgy—Whats the difference. SEG Newslett. 2012, 88, 30–31. [Google Scholar]

- David, D. Geometallurgical guidelines for miners, geologists and process engineers—Discovery to design. In Mineral Resource and Ore Reserve Estimation; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2014; pp. 443–450. [Google Scholar]

- Kojovic, T.; Michaux, S.; Walters, S. Developments of new comminution testing methodologies for geometallurgical mapping of ore hardness and throughput. In Proceedings of the International Mineral Processing Congress, Brisbane, Australia, 6–10 September 2010; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2010; pp. 891–899. [Google Scholar]

- Ehrig, K.; Liebezeit, V.; Smith, M.; Macmillan, E.; Lower, C. Geologists and the value chain–how material characterisation by modern mineralogy can optimise design and operation of processing facilities. In Proceedings of the International Mining Geology Conference, Adelaide, Australia, 18–20 August 2014; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2014; pp. 5–13. [Google Scholar]

- Ehrig, K.; Pitard, F.F. Sampling the supergiant Olympic Dam iron-oxide Cu-U-Au-Ag deposit, South Australia. In Proceedings of the World Conference on Sampling and Blending, Perth, Australia, 9–11 May 2017; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2017; pp. 21–27. [Google Scholar]

- Ehrig, K.; Liebezeit, V.; Macmillan, E. Metallurgical QAQC–who needs it? The Olympic Dam experience. In Proceedings of the Metallurgical Plant Design and Operating Strategies, Perth, Australia, 11–12 September 2017; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2017; pp. 31–44. [Google Scholar]

- Lorenzen, L.; Barnard, M.J. Why is mineralogical data essential for designing a metallurgical testwork programme for process selection and design? In Proceedings of the International Geometallurgy Conference, Brisbane, Australia, 5–7 September 2011; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2011; pp. 163–172. [Google Scholar]

- Zhou, J.; Gu, Y. Geometallurgical characterisation and automated mineralogy of gold ores. In Advances in Gold Ore Processing; Elsevier: Amsterdam, The Netherlands, 2016; pp. 95–111. [Google Scholar]

- Leichliter, S. From the core logger to the metallurgist—A geometallurgists views on ore geology. SEG Newslett. 2013, 95, 15. [Google Scholar]

- Dominy, S.C.; Platten, I.M.; Xie, Y.; Cuffley, B.W.; O’Connor, L. Characterisation of gold ore from the Nick O’Time shoot (Tarnagulla, Australia) using high resolution X-ray computed tomography. In Proceedings of the International Geometallurgy Conference, Perth, Australia, 15–16 June 2016; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2016; pp. 241–254. [Google Scholar]

- Dominy, S.C. Effects of sample mass on gravity recoverable gold test results in low grade ores. Appl. Earth Sci. 2014, 123, 234–242. [Google Scholar] [CrossRef]

- Lorenzen, L. Some guidelines to the design of a diagnostic leaching experiment. Miner. Eng. 1995, 8, 247–256. [Google Scholar] [CrossRef]

- Goodall, W.R.; Scales, P.J.; Butcher, A.R. The use of QEMSCAN and diagnostic leaching in the characterisation of visible gold in complex ores. Miner. Eng. 2005, 18, 877–886. [Google Scholar] [CrossRef]

- Kormos, L.; Sliwinski, J.; Oliveira, J.; Hill, G. Geometallurgical characterisation and representative metallurgical sampling at Xstrata process support. In Proceedings of Annual Canadian Mineral Processors Operators Conference; CIM: Montreal, QC, Canada, 2013; pp. 3–14. [Google Scholar]

- Lotter, N.O. Stratified sampling of drill core. In Proceedings of the Annual Canadian Mineral Processors Conference, Ottawa, ON, Canada, 19–21 January 2010; CIM: Montreal, QC, Canada, 2010; pp. 163–179. [Google Scholar]

- Giblett, A.; Napier-Munn, T.J. Measuring the influence of sample size on the precision and accuracy of gravity gold estimation. In Landmark Papers by Practicing Metallurgists; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2017; pp. 361–364. [Google Scholar]

- Dominy, S.C.; Platten, I.M.; Xie, Y. Bulk sampling of complex gold deposits: Material characterisation, programme design and management. In Proceedings of the Sampling Conference, Perth, Australia, 27–29 May 2008; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2008; pp. 41–57. [Google Scholar]

- Rem, P.C.; Glass, H.J. Automated sampling of recycled glass. Glass 1996, 12, 524–527. [Google Scholar]

- Clifton, H.E.; Hunter, R.E.; Swanson, F.J.; Phillips, R.L. Sample Size and Meaningful Gold Analysis; Professional Paper 625-C; United States Geological Survey: Washington, DC, USA, 1969; p. 19.

- Dominy, S.C.; O’Connor, L.; Glass, H.J.; Xie, Y. Geometallurgical study of a gravity recoverable gold orebody. Minerals 2018, 8, 186. [Google Scholar] [CrossRef]

- Clark, I.; Dominy, S.C. Underground bulk sampling, uniform conditioning and conditional simulation-unrealistic expectations? In Proceedings of the World Conference on Sampling and Blending, Perth, Australia, 9–11 May 2017; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2017; pp. 3–19. [Google Scholar]

- Gonzalez, P. Sampling gold ores for metallurgical process design by cyanidation. In Proceedings of the World Conference on Sampling and Blending, Lima, Peru, 19–22 November 2013; Gecamin: Santiago, Chile, 2013; pp. 353–361. [Google Scholar]

- Jacobs, P.J. Large diameter core sampling. In Proceedings of the Sampling Conference, Perth, Australia, 29–30 July 2014; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2014; pp. 71–76. [Google Scholar]

- Dominy, S.C. Sampling coarse gold-bearing mineralisation-developing effective protocols and a case study from the Ballarat mine, Australia. In Proceedings of the World Conference on Sampling and Blending, Perth, Australia, 9–11 May 2017; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2017; pp. 3–19. [Google Scholar]

- Annels, A.E.; Dominy, S.C. Core recovery and quality: Important factors in mineral resource evaluation. Appl. Earth Sci. 2003, 112, 305–312. [Google Scholar] [CrossRef]

- Simon, A.; Gosson, G. Considerations on quality assurance/quality control and sample security. In Proceedings of the Sampling Conference, Perth, Australia, 27–29 May 2008; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2008; pp. 135–140. [Google Scholar]

- Whittaker, P.J. Process mineralogy at Xstrata Process Support. In Geometallurgy and Applied Mineralogy Short Course; Conference of Metallurgists; CIM: Montreal, QC, Canada, 2009; p. 34. [Google Scholar]

- Royle, A.G. The Design of Sampling Programmes; University of Leeds: Leeds, UK, 1983; p. 70. [Google Scholar]

- Royle, A.G. Splitting gold assay pulps containing coarse gold. J. Leeds Univ. Min. Assoc. 1989, 89, 63–68. [Google Scholar]

- Tickner, J.; Ganly, B.; Lovric, B.; O’Dwyer, J. Improving the sensitivity and accuracy of gamma activation analysis for the rapid determination of gold in mineral ore. Appl. Radiat. Isot. 2017, 122, 28–36. [Google Scholar] [CrossRef] [PubMed]

- Coetzee, L.L.; Theron, S.J.; Martin, G.J.; van der Merwe, J.-D.; Stanek, T.A. Modern gold deportments and its application to industry. Miner. Eng. 2011, 24, 565–575. [Google Scholar] [CrossRef]

- Henley, K.J. A combined mineralogical/metallurgical approach to determine the nature and location of gold in ores and mill products. Miner. Eng. 1989, 2, 459–470. [Google Scholar] [CrossRef]

- Lane, G.; McComb, M. The Effects of Nuggety Gold on Gold Deportment—Lessons from Beaton Creek Paleo-Placer Gold Project, Australia. In Proceedings of the 47th Annual Canadian Mineral Processors Conference, Ottawa, ON, Canada, 20–24 January 2015. [Google Scholar]

- Lastra, R.; Price, J.; Cabri, L.J.; Rudashevsky, N.S.; Rudashevsky, V.N.; McMahon, G. Gold characterisation of a sample from Malartic East (Quebec) using concentration by hydroseparator. In The International Treatment of Gold Ores Symposium; CIM: Montreal, QC, Canada, 2005; pp. 17–29. [Google Scholar]

- Zhou, J.; Jago, B.; Martin, C. Establishing the Process Mineralogy of Gold Ores; Technical Bulletin 2004-03; SGS Minerals Ltd.: Lakefield, ON, Canada, 2004; p. 16. [Google Scholar]

- Jones, M.P.; Cheung, T.S. Automatic method for finding gold grains in ores and mill products. In Proceedings of the Asian Mining Conference; Institution of Mining and Metallurgy: London, UK, 1988; pp. 73–81. [Google Scholar]

- Sketchley, D.A. Gold deposits: Establishing sampling protocols and monitoring quality control. Explor. Min. Geol. 1998, 7, 129–138. [Google Scholar]

- Andrade, V.L.L.; Santos, N.A.; Goncalves, K.L.C.; Wyslouzu, H.; Davila, G. Obtaining metallurgical data from drill core samples using a mini pilot plant. In Proceedings of the International Mining Congress of Turkey, Izmir, Turkey, 9–12 June 2005; Chamber of Mining Engineers: Ankara, Turkey, 2005; pp. 195–206. [Google Scholar]

- Dominy, S.C.; Petersen, J.S. Sampling coarse gold-bearing mineralisation-developing effective protocols and a case study from the Nalunaq mine, Southern Greenland. In Proceedings of the World Conference on Sampling and Blending, Sunshine Coast, Australia, 10–12 May 2005; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2005; pp. 151–165. [Google Scholar]

- Johansen, G.F.; Dominy, S.C. Development of sampling and assaying protocols at the new Bendigo gold project, Victoria, Australia. In Proceedings of the World Conference on Sampling and Blending, Sunshine Coast, Australia, 10–12 May 2005; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2005; pp. 175–183. [Google Scholar]

- CIM. Definition Standards for Mineral Resources and Mineral Reserves; CIM: Montreal, QC, Canada, 2014; p. 9. [Google Scholar]

- CIM. Best Practice Guidelines for Mineral Processing; CIM: Montreal, QC, Canada, 2011; p. 26. [Google Scholar]

- Esbensen, K.H.; Wagner, C. Theory of Sampling (TOS) versus measurement uncertainty (MU)—A call for integration. Trends Anal. Chem. 2014, 57, 93–106. [Google Scholar] [CrossRef]

| Location | Site/Field | Laboratory | ||||

|---|---|---|---|---|---|---|

| Stage | Planning | Collection | Transport | Preparation | Testwork | Assaying |

| 1 | 2 | 3 | 4 | 5 | 6 | |

| Activity | Scope Develop Execute | Observe Collect Bag and tag QAQC Integrity/security Chain of custody | Integrity/security Chain of custody | Equipment operation Equipment clean QAQC Integrity/security | Equipment operation Equipment clean QAQC Integrity/security | Equipment operation Equipment clean QAQC Integrity/security |

| Sampling errors | In-situ nugget effect FSE, GSE DE, EE, WE | PE | FSE, GSE DE, EE, WE, PE | FSE, GSE DE, EE, WE, PE | PE AE | |

| Dominant effect on results | Precision Bias | Bias | Precision (if splitting) Bias | Precision (if splitting) Bias | Bias | |

| Material risk assuming average practice | High | Low | Moderate | Moderate | Low | |

| Material risk assuming optimised practice | Moderate | Low | Low | Low | Low | |

| Liberation Size | Quartz | Pyrite | Arsenopyrite | High Silver |

|---|---|---|---|---|

| Very coarse: >1000 µm | Jigs, tables | Jigs, tables | Jigs, tables | Jigs, tables |

| Coarse: 100–1000 µm | Gravity, CIL/CIP | Gravity, CIL/CIP | Gravity, CIL/CIP | Gravity, CIL Merrill Crowe Flotation |

| Fine: 50–100 µm | CIL/CIP | CIL/CIP, Flotation | CIL/CIP, Flotation | |

| Very fine: 10–50 µm | CIL/CIP | Flotation | Flotation | - |

| Sub-microscopic: <10 µm | - | POX, BIOX | POX, BIOX | - |

| Sampling Error | Acronym | Error Type | Effect on Sampling | Source of Error | Error Definition |

|---|---|---|---|---|---|

| Fundamental | FSE | Correct Sampling Error (CSE) | Random Errors-Precision Generator | Characteristics of the ore type. Relates to Constitution and Distribution Heterogeneity | Results from grade heterogeneity of the broken lot. Of all sampling errors, the FSE does not cancel out and remains even after a sampling operation is perfect. Experience shows that the total nugget effect can be artificially high because sample masses are not optimal |

| Grouping and Segregation | GSE | Relates to the error due to the combination of grouping and segregation of rock fragments in the lot. Once rock is broken, there will be segregation of particles at any scale | |||

| Delimitation | DE | Incorrect Sampling Error (ISE) | Systematic Errors-Bias Generator | Sampling equipment and materials handling | Results from an incorrect shape of the volume delimiting a sample |

| Extraction | EE | Results from the incorrect extraction of a sample. Extraction is only correct when all fragments within the delimited volume are taken into the sample | |||

| Weighting | WE | Relates to collecting samples that are not of a comparable support. Samples should represent a consistent mass per unit | |||

| Preparation | PE | Refers to issues during sample transport and storage (e.g., mix-up, damage, etc.), preparation (e.g., contamination and/or losses), and intentional (e.g., sabotage and salting) and unintentional (e.g., careless work practices) actions | |||

| Analytical | AE | - | Analytical process | Relates to errors during the assay and analytical process, including issues related to rock matrix effects, careless work practices, and analytical machine maintenance and calibration. In the testwork context also refers to test machine operation parameters and maintenance |

| Sample Type | Error Type | Cause | Error | Effect | Nugget Effect Component | Solution |

|---|---|---|---|---|---|---|

| In-situ (e.g., linear samples and core) | Random (CSE) | In-situ heterogeneity (nugget effect) | Local representativity | Poor precision | Geological | Larger samples More samples |

| Broken rock (from rock chips to blasted material and laboratory pulps) | Constitution Heterogeneity | FSE | Poor precision | Sampling | Optimised protocols Larger samples More samples | |

| Constitution and Distribution Heterogeneity | GSE | Poor precision | Sampling | Optimised protocols More sample increments | ||

| Systematic (ISE) | Poor quality sampling protocols—sampling errors | DE, EE, WE, PE and AE | High bias | Sampling | Optimised protocols Efficient training Strict QAQC |

| Stage | Strategic Geometallurgy | Tactical Geometallurgy | |||

|---|---|---|---|---|---|

| Exploration-Early Evaluation | Resource Definition Drilling | Reserve Definition Drilling | Feasibility | Mining | |

| Study | Scoping (SS) | Pre-feasibility (PFS) | - | Feasibility (FS) | (Grade/ore control) (Expansion studies) |

| Resources/Reserves | Inferred Mineral Resources | Inferred and Indicated Mineral Resources | Mineral Resources and Ore Reserves | Mineral Resources and Ore Reserves | Mineral Resources and Ore Reserves |

| Key activity | Develop orebody knowledge; Drilling and sampling | Develop orebody knowledge; Drilling and sampling; Data analysis and modelling | Develop orebody knowledge; Drilling and sampling; Data analysis and modelling | Develop orebody knowledge; Drilling and sampling; Data analysis and modelling | Develop orebody knowledge; Drilling and sampling; Data analysis and modelling |

| Inputs | Core logging; Develop proxy tests; Mineralogy; Geochemistry; Met. testwork; Physical testing | Core logging; Proxy tests; Mineralogy; Geochemistry; Met. testwork; Physical testing | Core logging; Proxy tests; Mineralogy; Geochemistry; Met. testwork; Physical testing | Core logging; Proxy tests; Mineralogy; Geochemistry; Met. testwork, incl. pilot or trial plant testing; Physical testing | Core logging; Proxy tests; Mineralogy; Geochemistry; Met. testwork; Physical testing |

| Outputs | Establish database Prelim.; characteristics of mineralisation; Geological model; Geoenvironmental | Expanded database; Geomet. domains; Block model; Prelim. mine plan; Geomet. models; Prelim. process design; Geoenvironmental | Expanded database | Expanded database; Geomet. domains; Block model; Mine plan; Geomet. models; Flow sheet; Scenario analysis; Economic analysis | Expanded database; Geomet. domains; Block model; Mine plan; Geomet. models; Forecasts; Reconciliation |

| Type of Testwork | Scoping | Pre-Feasibility | Feasibility |

|---|---|---|---|

| Laboratory/bench scale | Yes | Yes | Maybe |

| Small/mini-pilot scale | Maybe | Yes | Yes |

| Pilot scale | No | Maybe | Yes |

| Demo/trial or full plant | No | Maybe | Maybe |

| Type of Test | Indicative Mass | Type of Study | ||

|---|---|---|---|---|

| Scoping | Pre-Feasibility | Feasibility | ||

| Flotation | ||||

| Rougher | 1–2 kg | X | X | X |

| Cleaner test (grind-grade recovery) | 15 kg | X | X | X |

| Locked-cycle | 15–25 kg | - | X | X |

| Circuit design (optimisation/variability) | 100–500 kg | - | X | X |

| Mini-pilot plant (Andrade et al., 2005) | 200 kg | (X) | (X) | (X) |

| Pilot plant | >10 t | - | (X) | X |

| Physical Separation | ||||

| Gravity (gravity recoverable gold: GRG) | 25–150 kg | X | X | X |

| Gravity (continuous gravity recovery: CGR) | 25–100 kg | X | X | X |

| Heavy liquid | 0.5 kg | X | X | X |

| Magnetic or electrostatic | 50–100 kg | X | X | X |

| Pilot plant | 1–20 t | - | (X) | X |

| Leaching | ||||

| Bottle roll | Up to 5 kg | X | X | X |

| Diagnostic leaching | 1–2 kg | X | (X) | (X) |

| Batch agitation (CIL/CIP) | 2–5 kg | - | (X) | X |

| Semi-continuous (CIL/CIP) | 30–50 kg | - | - | X |

| Small diameter columns | 9 kg | X | X | X |

| Intermediate diameter columns | 80 kg | - | X | X |

| Large diameter columns | 60 t | - | - | X |

| Local Domain | Type | Characteristic | Average Domain Width (m) | Grade (g/t Au) | d95Au (µm) | Sampling Constant (K) (g/cm1.5) | Theoretical Mass (90 ± 20%) (kg) | Theoretical Mass per unit Length (kg/m) |

|---|---|---|---|---|---|---|---|---|

| HW | Hangingwall | Wallrock alteration with veinlets with visible gold | 5 | 5.5 | 1100 | 12,800 | 340 | 68 |

| CZ | Core (lode) zone | Composite laminated vein with visible gold | 2 | 19 | 1600 | 6500 | 300 | 150 |

| FW | Footwall | Wallrock alteration with veinlets with visible gold | 5 | 4 | 900 | 13,000 | 260 | 52 |

| All | - | - | 11.5 | 9.5 | 1400 | 10,600 | 400 | 35 |

| DSW | Diluted mine stope width | 2.3 | 17.2 | 1500 | 6500 | 280 | 122 | |

| Local Domain | Type | Characteristic | Average Domain Width (m) | Grade (g/t Au) | d95Au (µm) | Sampling Constant (K) (g/cm1.5) | Theoretical Mass (90 ± 20%) | Theoretical Mass per unit Length (kg/m) |

|---|---|---|---|---|---|---|---|---|

| HW | Hangingwall | Wallrock alteration with minor veining | 1.5 | 4 | 50 | 170 | 10 kg | 7 |

| LV | Laminated vein | Composite laminated vein with abundant visible gold | 0.5 | 30 | 2500 | 8000 | 620 kg | 1200 |

| BV | Brecciated vein | Matrix-supported breccia vein with sulphides | 1.5 | 10 | 250 | 760 | 10 kg | 7 |

| FW | Footwall | Wallrock alteration with minor veining | 1.5 | 4 | 50 | 170 | 5 kg | 3 |

| All | - | - | 5 | 8.5 | 2000 | 20,300 | 1.1 t | 220 |

| DSW | Diluted mine stope width | 2.3 | 13.6 | 2200 | 14,600 | 930 kg | 404 | |

| Local Domain | Type | Characteristic | Average Domain Width (m) | Grade (g/t Au) | d95Au (µm) | Sampling Constant (K) (g/cm1.5) | Theoretical Mass (90 ± 20%) (kg) | Theoretical Mass per unit Length (kg/m) |

|---|---|---|---|---|---|---|---|---|

| VSK | Vein skarn | MSK with multiple veins of quartz, calcite, epidote and chlorite ±sulphides | 15 | 5 | 1000 | 12,200 | 300 | 20 |

| MSK | Massive skarn | Garnet, pyroxenite and wollastonite skarn | 20 | 6.5 | 250 | 1200 | 10 | 0.5 |

| Project Stage | Low Heterogeneity | High Heterogeneity | ||||

|---|---|---|---|---|---|---|

| Composite | Variability | Pilot | Composite | Variability | Pilot | |

| Scoping | 2–5 | 2–5 | No | 5–15 | 5–10 | No |

| Pre-feasibility | 10 | 10 | No | 20 | 20 | Maybe |

| Feasibility | 10 | 10 | Maybe | 20 | 20 | Yes |

| Total at FS | >25 | >25 | Maybe | >50 | >50 | Yes |

| Sample Characteristics | Type of Sample | |||||

|---|---|---|---|---|---|---|

| Grab | Linear | Reverse Circulation (RC) Cuttings | Small Core | Large Core | Bulk | |

| Spatial coverage | Poor | Good | Good | Good | Varies | Poor |

| Mass of sample | Low-good | Low-good | Low | Moderate-high | Good | Best |

| Particle size distribution | Poor | Fair-good | Poor | Fair-good | Good | Good |

| Cost | Low | Low | Moderate | Moderately high | High | High-very high |

| Mass | Up to 10 kg | Up to 10 kg 100 s kg for panel samples | Up to 60 kg/m | 1.5–16 kg/m | 49–90 kg/m | >1 t |

| Sample Type | Summary | Incorrect Sampling Errors | Risk Rating for Metallurgical Use | ||

|---|---|---|---|---|---|

| DE | EE | WE | |||

| Linear (underground workings or surface pits and trenches) | |||||

| Chip/chip-channel (hand cut) | Relatively easy to collect and fast Moderately high number can be collected | High | |||

| Channel (hand cut) | Less easy to collect, requires effort Moderately high number can be collected | Moderate | |||

| Channel (saw cut) | Requires effort and specialist equipment Moderate number can be collected | Low | |||

| Panel | Medium-large sample size Less easy to collect Moderate number can be collected | Low | |||

| Broken rock (underground and surface rock piles) | |||||

| Grab | Relatively easy to collect Moderate number can be collected Prone to very high FSE and GSE | High | |||

| Drilling | |||||

| Diamond core | Well established method Good geological information | Low | |||

| Large diamond drill core | Well established method Good geological information Provides much larger sample mass per m drilled | Low | |||

| RC | FSE potentially moderate-high when sub-sample split from original Potential loss of fines Fines generation during drilling problematic for metallurgical purposes | Moderate | |||

| Sludge | FSE and GSE potentially very high when collecting and/or splitting at the rig Loss of fines and fines generation problematic for metallurgical purposes | High | |||

| Bulk (underground or surface) | |||||

| Bulk | Well established approach to gain large sample mass from 1 t to 1000 s t FSE and GSE potentially high if sub-sampling Careful planning required Excellent geological and geotechnical information | Low | |||

| Validation Type | Project Stage | Activity | Comment | Validation Target |

|---|---|---|---|---|

| Duplicate samples | Advanced exploration to Feasibility | Field duplicates | Based on field duplicates (variability samples) taken proximal to each other, or duplicate composites taken from the same drill holes and intersections via half or quarter-core. In reality, rarely taken during metallurgical sampling | Total relative error: ±50% Sampling error: ±40% |

| Coarse duplicates | Splits of laboratory crushed material | Total relative error: ±25% Preparation error: ±20% | ||

| Laboratory (pulp) duplicates | Splits taken from final testwork sub-samples after grinding | Total relative error: ±15% Analytical error: ±15% | ||

| Pilot testing | Pre-feasibility and/or Feasibility | Processing of composite or variability samples through pilot plant | Tonnes-scale of material taken from core or bulk samples. Compares testwork prediction (model) with small process tonnage | Within ±20% of prediction for a given tonnage |

| Demo/full plant testing | Feasibility | Processing of composite or variability lots through process plant | Material taken from bulk sample or trial mining programmes. Compares testwork prediction (model) with large process tonnage | |

| Production plant | Production | Processing of ore through plant | Production mining. Compares testwork prediction (model) with actual mining | Within ±20% of prediction over a given time period (e.g., month) |

| Lot/Process Option | Laboratory Bench | Pilot Plant | Demo/Full Plant |

|---|---|---|---|

| Whole lot | - | (1) | (1) |

| Lot batch | - | (2) | (2) |

| Lot sub-sample | (3) | (3) | - |

| Sample Nos. | Number of Samples | Domain | Head Grade Range (g/t Au) | GRG Range (%) | Flotation Range (%) |

|---|---|---|---|---|---|

| C.01–04 | 4 | HZ | 43–95 | 91–98 | Trace |

| C.05B and 06 | 2 | PZ | 15–26 | 40–79 | 3–11 |

| Domain/FSE Value | Grade Range (g/t Au) | d95Au Range (mm) | GRG Sub-Sampling FSE (%) | Flotation Sub-Sampling FSE (%) |

|---|---|---|---|---|

| HZ | 43–95 | 1–2.5 | ±25–35 | ±40–55 |

| PZ | 15–26 | 0.2–0.5 | ±25–45 | ±40–70 |

| Domain | Number of Samples | Ave. Primary Sample Mass (kg) | RSV Head Grade (%) | RSV GRG (%) | RSV Flotation (%) |

|---|---|---|---|---|---|

| HZ | 30 | 156 | 46 | 35 | 15 |

| PZ | 28 | 154 | 32 | 17 | 27 |

| Sample | Domain | Domain Fraction | Grade Type | Composite Mass (kg) | Est. Head Grade (g/t Au) | Head Grade (g/t Au) | GRG (Au %) | Flotation Recovery (Au %) | Total Recovery (Au %) |

|---|---|---|---|---|---|---|---|---|---|

| DCM.1 | PZ | 1.0 | Low/COG | 71 | 3.9 | 4.2 | 15 | 66 | 81 |

| DCM.2 | HZ/PZ | 0.2/0.8 | ROM | 71 | 10.5 | 11.5 | 61 | 26 | 87 |

| DCM.3 | HZ/PZ | 0.3/0.7 | ROM | 75 | 13.3 | 13.6 | 60 | 24 | 84 |

| DCM.4 | HZ/PZ | 0.4/0.6 | ROM high | 69 | 17.4 | 18.1 | 65 | 20 | 85 |

| DCM.5 | HZ/PZ | 0.5/0.5 | ROM high | 73 | 19.9 | 17.7 | 71 | 15 | 86 |

| DCM.6 | HZ/PZ | 0.6/0.4 | ROM high | 71 | 23.7 | 21.0 | 76 | 13 | 89 |

| Sample | Domain | Domain Fraction | Grade Type | Head Grade (g/t Au) | GRG (Au %) | Flotation Recovery (Au %) | Total Recovery (Au %) |

|---|---|---|---|---|---|---|---|

| PVC.1 | PZ | 1.0 | Very low | 1.9 | 5 | 49 | 53 |

| PVC.2 | PZ | 1.0 | Low/COG | 5.3 | 18 | 70 | 88 |

| PVC.3A | HZ/PZ | 0.3/0.7 | ROM | 11.0 | 64 | 29 | 93 |

| PVC.3B | HZ/PZ | 0.4/0.6 | ROM | 13.2 | 66 | 24 | 90 |

| PVC.5 | HZ/PZ | 0.5/0.5 | ROM high | 23.4 | 73 | 21 | 94 |

| PVC.5 | HZ/PZ | 0.8/0.2 | ROM high | 21.6 | 77 | 18 | 95 |

| PVC.6B | HZ | 1.0 | Very high | 32.9 | 82 | 14 | 96 |

| Action/Activity | Rate/Responsibility | Performance Expectation | Actual Performance |

|---|---|---|---|

| Sample security: chain of custody | Project and laboratory | Full compliance | No security breaches No seals broken or samples lost |

| Duplicates | See next Section 11.5.8 | ||

| Certified reference material (CRM): Tails and concentrate assays from GRG and flotation testwork | 1 in 5 Project and laboratory | Limits: ±2δ–3δ (“warning”) >±3δ (“action”) Relative bias: within ± 10% | Within limits: 95% of CRM results < ± 2δ 5% of CRM results ± 2δ–3δ 0% of CRM results > ± 3δ Relative bias: Low CRM (2.9 g/t Au) + 5.5% Moderate CRM (8.7 g/t Au) + 3.1% High CRM (24.4g/t Au) + 7.9% |

| Blanks | 1 in 5 Project and laboratory | Blank assay <0.1 g/t Au | 98% <0.1 g/t Au |

| Barren “sand” flush of GRG circuit for all samples | 1 in 10 Laboratory | <1% gold loss in blank material compared to sample head grade | 100% <1% gold loss |

| Laboratory audit | Project | Full compliance across all procedures | A number of minor non-material issues were noted. All matters resolved |

| Duplicate Type | Explanation | Mass | Number (Frequency) | Estimated Stage FSE | Component Error | Component Relative Error | Proportion of Total |

|---|---|---|---|---|---|---|---|

| Field | Panel samples collected at the same location | 150 kg | 15 (1 in 4) | - | Sampling | 38% | 78% |

| Coarse | Panel samples crushed to P90 −1.5 mm and rotary sample divider split | 75 kg | 15 (1 in 4) | <±15% | Preparation | 18% | 18% |

| Laboratory pulp 1: concentrate | GRG concentrate split prior to intensive leach | 30 g | 58 (1 in 1) | <±5% | Analytical | 4% | 1% |

| Laboratory pulp 2: tailings | Core and panel sample tails after GRG stage-3 at P90 −100 µm rotary sample divider split | 10 kg | 58 (1 in 1) | <±5% | Analytical | 8% | 3% |

| - | - | - | - | <±15% | Total | 43% | 100% |

| Sample | Head Grade (g/t Au) | Est. d95Au (µm) | Theoretical Mass (kg) | Theoretical Precision Based on 150 kg Sample |

|---|---|---|---|---|

| PVC.1 | 1.9 | 120 | 15 | ±1% |

| PVC.2 | 5.3 | 250 | 25 | ±3% |

| PVC.3A | 11.0 | 1000 | 140 | ±14% |

| PVC.3B | 13.2 | 1100 | 155 | ±16% |

| PVC.4 | 23.4 | 2000 | 530 | ±28% |

| PVC.5 | 21.6 | 2100 | 660 | ±31% |

| PVC.6B | 32.9 | 2300 | 570 | ±29% |

| Key Parameter | Comment | Material Errors | Risk Rating | |

|---|---|---|---|---|

| 1 | Spatial distribution and number of samples | Samples biased to spatially restricted (clustered) areas and high grades Too few samples. Only 6 in total | GNE | High |

| 2 | Sample mass | Samples too small compared to theoretical mass | GNE | High |

| 3 | Degree of domaining | HZ and PZ defined, but unrepresentative HZ domain interpretation incorrect | GNE | Moderate |

| 4 | Collection and handling | Original core samples moderate-poor quality based on core recoveries in the 60–80% range No details on how underground samples were collected No written protocols to comply with TOS All samples placed in plastic sample bags with wire ties | DE, EE, PE | Moderate |

| 5 | Transport and security | Bags placed in unsecured wooden boxes on the back of an open truck and transported to the laboratory No chain of custody recorded | PE | Moderate |

| 6 | Preparation | Composite blending via shovelling Sub-sample splitting sub-optimal | FSE, GSE, DE, EE, PE | High |

| 7 | Testwork (incl. QAQC) | Potential for some contamination between samples due to poor laboratory practice No QAQC Non accredited laboratory | PE | Moderate |

| 8 | Assay (incl. QAQC) | No issues with assay procedure used No QAQC Non accredited laboratory | AE | Moderate |

| 9 | Validation | Via plant, poor reconciliation Grade reconciliation in the −60% to −75% range on a monthly basis Recovery 50% of that predicted on a monthly basis | - | High |

| Sample representativity (1)–(5) | Low/poor | |||

| Testwork-measurement quality (6)–(8) | Moderate | |||

| Fit-for-purpose rating (1)–(9) | Low/poor | |||

| Key Parameter | Comment | Material Error | Risk Rating | |

|---|---|---|---|---|

| 1 | Spatial distribution and number of samples | Even spatial resolution along development drives More samples across domains. 58 panel variability samples, six core composite and seven pilot variability composites | - | Low |

| 2 | Sample mass | Optimised to theoretical mass. Dominance of 150 kg samples, supported by 1 t pilot samples | - | Low |

| 3 | Degree of domaining | Refined HZ and PZ domains | - | Low |

| 4 | Collection and handling | All samples collected according to protocols written to comply with TOS All samples placed in steel drums and sealed prior to transportation | - | Low |

| 5 | Transport and security | Chain of custody procedures in place All sample drums secured into locked container for transportation | - | Low |

| 6 | Preparation | Composites blended via rotary sample splitter All splitting optimised to FSE All equipment cleaned between samples | - | Low |

| 7 | Testwork (incl. QAQC) | Good QAQC, with documentation across sample collection, preparation and testwork Rigorous cleaning of laboratory equipment No contamination Accredited laboratory | - | Low |

| 8 | Assay (incl. QAQC) | Good QAQC, with full documentation across sample collection, preparation and assaying Rigorous cleaning of laboratory equipment Accredited laboratory No contamination Acceptable analytical error and CRM relative bias | - | Low |

| 9 | Validation | Pilot programme verified testwork Ultimately optimised plant acceptable reconciliation, where grade reconciliation in the ±15% range and recovery as predicted on a monthly basis | - | Low |

| Sample representativity (1)–(5) | High/good | |||

| Testwork-measurement quality (6)–(8) | High/good | |||

| Fit-for-purpose rating (1)–(9) | High/good | |||

| Metallurgical factors or assumptions | 1 | The metallurgical process proposed and the appropriateness of that process to the style of mineralisation |

| 2 | Whether the metallurgical process is well-tested technology or novel in nature | |

| 3 | The nature, amount and representativeness of metallurgical test work undertaken, the nature of the metallurgical domaining applied and the corresponding metallurgical recovery factors applied | |

| 4 | Any assumptions or allowances made for deleterious elements | |

| 5 | The existence of any bulk sample or pilot scale test work and the degree to which such samples are considered representative of the orebody as a whole | |

| 6 | For minerals that are defined by a specification, has the ore reserve estimation been based on the appropriate mineralogy to meet the specifications? |

| Mineral processing and metallurgical testing | (a) | the nature and extent of the testing and analytical procedures, and provide a summary of the relevant results |

| (b) | the basis for any assumptions or predictions regarding recovery estimates | |

| (c) | to the extent known, the degree to which the test samples are representative of the various types and styles of mineralisation and the mineral deposit as a whole | |

| (d) | to the extent known, any processing factors or deleterious elements that could have a significant effect on potential economic extraction |

| Steps/Key Activity | |

|---|---|

| 1: Scope |

|

| 2: Develop |

|

| 3: Execute |

|

| 4: Validate |

|

| 5: Refine |

|

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dominy, S.C.; O’Connor, L.; Glass, H.J.; Purevgerel, S.; Xie, Y. Towards Representative Metallurgical Sampling and Gold Recovery Testwork Programmes. Minerals 2018, 8, 193. https://doi.org/10.3390/min8050193

Dominy SC, O’Connor L, Glass HJ, Purevgerel S, Xie Y. Towards Representative Metallurgical Sampling and Gold Recovery Testwork Programmes. Minerals. 2018; 8(5):193. https://doi.org/10.3390/min8050193

Chicago/Turabian StyleDominy, Simon C., Louisa O’Connor, Hylke J. Glass, Saranchimeg Purevgerel, and Yuling Xie. 2018. "Towards Representative Metallurgical Sampling and Gold Recovery Testwork Programmes" Minerals 8, no. 5: 193. https://doi.org/10.3390/min8050193

APA StyleDominy, S. C., O’Connor, L., Glass, H. J., Purevgerel, S., & Xie, Y. (2018). Towards Representative Metallurgical Sampling and Gold Recovery Testwork Programmes. Minerals, 8(5), 193. https://doi.org/10.3390/min8050193