Dry Iron Ore Fluidization, Flowability, and Handling: Supporting Dry Processing of Iron Ores and Guiding Industrial Designing

Abstract

1. Introduction

Bulk Materials Handling and Iron Ore Processing

2. Materials and Methods

2.1. Jenike’s Flowability Determination

2.2. Geldart’s Fluidization Properties

3. Results

3.1. Chemical Composition

3.2. Particle Size Distributions

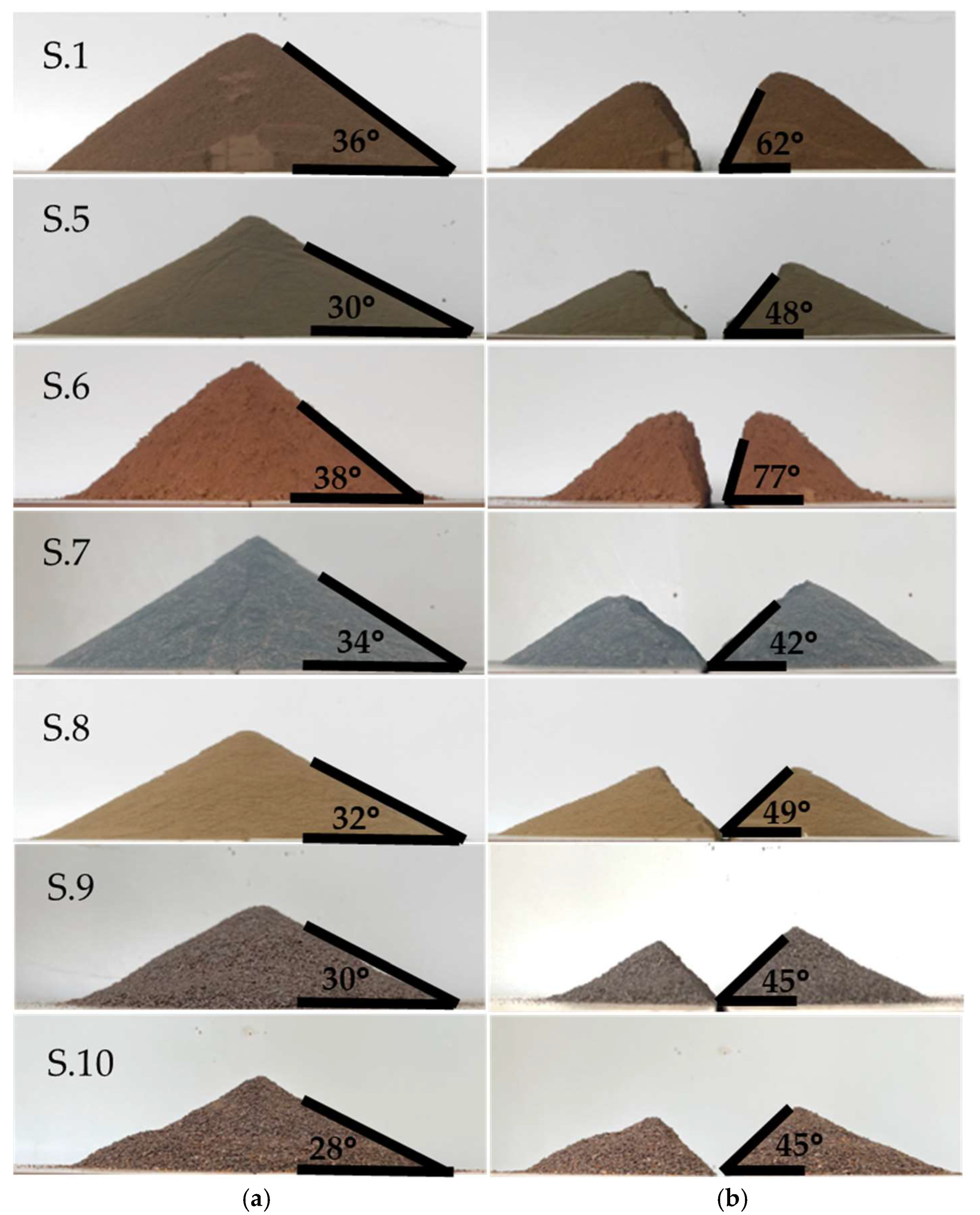

3.3. Flow Function and Material Flowability According to Jenike’s Method

4. Discussion

5. Conclusions

- Bulk materials with pellet feed fraction (S.4, S.5, S.7, and S.8) are free-flowing, exhibiting a steady-state fluidization condition and good air retention to air-assisted conveying.

- Coarse iron ore fractions (S.1, S.2, S.3, S.9, and S.10) are easy-flowing bulk material. However, most of them are not likely to be handled through air slides due to low air retention.

- Ultrafines, even though dried, are cohesive and may require air-assisting to aid the discharge from a bin. They are frictional and require steep walls on hopper and chute structures and may be conveyed on air slides.

- Air-assisted conveyors are highly recommended to handle fine liberated iron ore, a latent reality for low-grade deposits. However, some margin to the group D boundary must be considered to avoid designing at the edge of the technology, which may cause operational issues.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pinto:, P.F.; Junior, H.D. Comminution circuits for compact itabirites. Int. Eng. J. 2016, 69, 355–359. [Google Scholar] [CrossRef]

- Metso: Outotec. Basics in Minerals Processing. Available online: https://www.metso.com/insights/e-books/basics-in-minerals-processing-handbook/ (accessed on 27 August 2025).

- Segura-Salazar, J.; Santos, N.d.S.L.; Tavares, L.M. Holistic Pre-Feasibility Study of Comminution Routes for a Brazilian Itabirite Ore. Minerals 2021, 11, 894. [Google Scholar] [CrossRef]

- Bajda, M.; Hardygóra, M.; Marasová, D. Energy Efficiency of Conveyor Belts in Raw Materials Industry. Energies 2022, 15, 3080. [Google Scholar] [CrossRef]

- Hakamia, F.; Pramanik, A.; Ridgway, N.; Basak, A.K. Development of rubber material wear in conveyor belt system. Trybology Int. 2017, 111, 148–158. [Google Scholar] [CrossRef]

- Silva, B.B.; Bergerman, M.G.; Chave, A.P. Management of Iron Ore Ultrafine Tailings: State-of-Art, Challenges, and Perspectives. Miner. Process. Extr. Metall. Rev. 2025, 1–20. [Google Scholar] [CrossRef]

- Prokesch, M.E. Selection and Sizing of Concentrate Drying, Handling and Storage Equipment. In Mineral Processing Plant Design, Practice, and Control; Mular, A.L., Halbe, D.N., Barratt, D.J., Eds.; Society for Mining, Metallurgy, and Exploration Inc.: Littleton, CO, USA, 2002; Volume 2, pp. 1463–1477. [Google Scholar]

- França, J.R.O.; Barrios, G.K.P.; Turrer, H.D.G.; Tavares, L.M. Comminution and liberation response of iron ore types in a low-grade deposit. Miner. Eng. 2020, 158, 106590. [Google Scholar] [CrossRef]

- Rodrigues, A.F.d.V.; Junior, H.D.; Silva, K.; Zhou, J.; Galvin, K.P.; Filippov, L.O. Transforming iron ore processing—Simplifying the comminution and replacing reverse flotation with magnetic and gravity separation. Miner. Eng. 2023, 199, 108112. [Google Scholar] [CrossRef]

- Safari, M.; Hoseinian, F.S.; Deglon, D.; Filho, L.L.; Pinto, T.C.S. Impact of flotation operational parameters on the optimization of fine and coarse Itabirite iron ore beneficiation. Powder Technol. 2022, 408, 117772. [Google Scholar] [CrossRef]

- Runge, K.; Forbes, L.; Brito e Abreu, S.; Yahyaei, M. Advances in flotation which have the potential to address the challenges associated with energy transition. In Proceedings of the XXXI International Mineral Processing Congress Proceedings, Washington, DC, USA, 29 September–3 October 2024. [Google Scholar]

- Mattioli, G.G.; Martins, A.H.; Lins, V.d.F.C.; Brandão, P.R.G.; Torres, A.S.G. Evaluation of internal corrosion in a Brazilian iron ore slurry pipeline based on the characterization of scales and tubercles. REM Int. Eng. J. 2018, 71, 203–208. [Google Scholar] [CrossRef]

- Metso: Outotec. Guidlelines in Slurry Pumpring. Slurry Pump Handobook. Available online: https://www.metso.com/insights/e-books/slurry-pump-basic-handbook/ (accessed on 27 August 2025).

- Macía, Y.M.; Pedrera, J.; Castro, M.T.; Vilalta, G. Analysis of Energy Sustainability in Ore Slurry Pumping Transport System. Sustainability 2019, 11, 3191. [Google Scholar] [CrossRef]

- Oliazadeh, M. Chapter 13: Dewatering and Water Management. In Proceedings of the XXVII International Mineral Processing Congress (IMPC), Santiago, Chile, 20–23 October 2014. [Google Scholar]

- Reemeyer, H.C.L.; Kinal, J. The World of Water in Mining. In Proceedings of the XXXI International Mineral Processing Congress (IMPC), Washington, DC, USA, 29 September–3 October 2024. [Google Scholar]

- Gunson, A.J.; Klein, B.; Veiga, M.; Dunbar, S. Reducing mine water requirements. J. Clean. Prod. 2012, 21, 71–82. [Google Scholar] [CrossRef]

- Otieno, F.; Shukla, S.K. An insight into failure of iron ore mine tailings dams. Int. J. Min. Reclam. Environ. 2023, 37, 127–147. [Google Scholar] [CrossRef]

- Garcia, F.F.; Cotrim, C.F.C.; Caramori, S.S.; Bailao, E.F.L.C.; Nabout, J.C.; Junior, G.d.F.N.G.; Almeida, L.M. Mine tailings dams’ failures: Serious impacts, remote solutions. Environ. Dev. Sustain. 2025, 27, 18179–18201. [Google Scholar] [CrossRef]

- Tripathy, S.K.; Banarjee, P.K.; Suresh, N.; Murthy, Y.R.; Singh, V. Dry High-Intensity Magnetic Separation In Mineral Industry—A Review Of Present Status And Future Prospects. Miner. Process. Extr. Metall. Rev. 2017, 38, 339–365. [Google Scholar] [CrossRef]

- Nanda, N.K.; Sreedhar, G.E.; Kumar, R. Dry beneficiation of high silica blue dust—Turning waste to wealth. In Proceedings of the SME Annual Meeting, Denver, CO, USA, 24–27 February 2019. [Google Scholar]

- Ku, J.; Lei, Z.; Xia, J.; Guo, B.; Chen, H.; Peng, X.; Ran, H.; Deng, R. Dynamic behavior and separation prediction of magnetic ore bulks in dry medium-intensity magnetic separator. Miner. Eng. 2021, 171, 107113. [Google Scholar] [CrossRef]

- Yi, F.; Chen, L.; Zeng, J.; Jiang, Y.; Ren, X. Separation characteristics of dry-high drum magnetic separator. Miner. Eng. 2022, 189, 107861. [Google Scholar] [CrossRef]

- Ripke, S.J. Dry beneficiation. In Proceedings of the International Mineral Processing Congress (IMPC), Washington, DC, USA, 29 September–3 October 2024. [Google Scholar]

- Vale to Invest 11 Billion Reais in Dry Iron Ore Processing over the Next Five Years. Press Release. Media Relations Office. Available online: https://vale.com/w/vale-to-invest-11-billion-reais-in-dry-iron-ore-processing-over-the-next-five-years (accessed on 27 August 2025).

- Neves, G.R. Vale’s cold iron ore briquettes, an innovative solution. In Proceedings of the 17th Arab Steel Sumit & International Iron and Steel Exhibition, Doha, Qatar, 14–15 October 2024. Available online: https://2024.aisusteel.org/en/presentations-download/ (accessed on 27 August 2025).

- Napier-Munn, T.J.; Morrison, R.D. The Potential for the Dry Processing of Ores. In Proceedings of the Water in Mining Conference, Brisbane, Australia, 13–14 October 2003. [Google Scholar]

- Halt, J.A.; Nitz, M.C.; Kawatra, S.K.; Dubé, M. Iron Ore Pellet Dustiness Part I: Factors Affecting Dust Generation. Miner. Process. Extr. Metall. Rev. 2015, 36, 258–266. [Google Scholar] [CrossRef]

- Halt, J.A.; Kawatra, S.K. Iron Ore Pellet Dustiness Part II: Effects of Firing Route and Abrasion Resistance on Fines and Dust Generation. Miner. Process. Extr. Metall. Rev. 2015, 36, 340–347. [Google Scholar] [CrossRef]

- Petit, H.A.; Cavalcanti, P.P.; Tavares, L.M. Modeling the emission of dust due to abrasion during stockpiling of iron ore pellets. In Proceedings of the XXX International Mineral Processing Congress (IMPC), Cape Town, South Africa, 18–22 October 2020. [Google Scholar]

- Torabi, A.; Moosavirad, S.H.; Ariafar, S.; Eftekhari, A. Dust emission reduction in iron ore concentrate production plant using value engineering method. Environ. Sci. Pollut. Res. 2021, 28, 37647–37660. [Google Scholar] [CrossRef]

- Petit, H.A.; Thomazini, A.; França, F.F.; Tavares, L.M.M. Estimation of Dust Emission During Handling of Iron Ore Pellets Using Mechanistic Modelling and DEM-CFD-DPM Simulations. In Proceedings of the 9th Brazilian Symposium on Agglomeration of Ores—ABM 7th Week, São Paulo, Brazil, 1–3 August 2023. [Google Scholar]

- Katariya, N.K.; Choudhary, B.S.; Pandey, P. Air Quality Predictions through Mathematical Modeling for Iron Ore MineProject. Appl. Sci. 2024, 14, 5992. [Google Scholar] [CrossRef]

- Nie, M.; Li, S.; Li, X.; Bao, S.; Chen, P.; Zhang, Y.; Ding, S.; Li, J. The Preparation and Dust Suppression Performance Evaluation of Iron Ore Tailing-Based Cementitious Composites. Molecules 2024, 29, 2056. [Google Scholar] [CrossRef] [PubMed]

- Song, C.; Wang, C.; Cong, W. Characterization of dust emission during ore unloading and analysis of its influencing factors. Powder Technol. 2024, 438, 119688. [Google Scholar] [CrossRef]

- Chaves, A.P. Teoria e Prática do Tratamento de Minérios, Vol. 5—Manuseio de Sólidos Granulados, 2nd ed.; Oficina de Textos: São Paulo, Brazil, 2012; pp. 1–384. [Google Scholar]

- Marin, F.C.; Arias, A.d.C.; Silva, R.V.G.; Mendes, P.J.S.; Ribeiro, R.V.; Guimarães, M.A. Fundamentals of Iron Ore, Sinter Feed and Pellet Feed Storage and Handling: What You Need to Know. In Proceedings of the 41st International Meeting on Iron Making and 12th International Symposium on Iron Ore, Vila Velha, Brazil, 29 July–4 August 2011; pp. 914–927. [Google Scholar] [CrossRef]

- Fekete, R.; Peciar, M.; Hanzel, M. Influence of Powder Material Moisture on the Angle of Wall Friction. Part. Part. Syst. Charact. 2007, 24, 276–283. [Google Scholar] [CrossRef]

- Sun, C.C. Quantifying effects of moisture content on flow properties of microcrystalline cellulose using a ring shear test. Powder Technol. 2016, 289, 104–108. [Google Scholar] [CrossRef]

- Jin, Y.; Lu, H.; Guo, X.; Gong, X. Effect of water addition on flow properties of lignite particles. Chem. Eng. Res. Des. 2018, 132, 1020–1029. [Google Scholar] [CrossRef]

- Chen, W.; Roberts, A.; Williams, K.; Miller, J.; Plinke, J. On uniaxial compression and Jenike direct shear testings of cohesive iron ore materials. Powder Technol. 2017, 312, 184–193. [Google Scholar] [CrossRef]

- Kulwiec, R.A. Materials Handling Handbook, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 1985. [Google Scholar]

- Klinzing, G.E.; Marcus, R.D.; Rizk, F.; Leung, L.S. Pneumatic Conveying of Solids; Springer: Dordrecht, The Netherlands, 1997. [Google Scholar] [CrossRef]

- Perry, R.H.; Green, D.W. Perry’s Chemical Engineers’ Handbook, 7th ed.; MacGraw-Hill: Columbus, OH, USA, 1997. [Google Scholar]

- Mills, D. Pneumatic Conveying Design Guide, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2004. [Google Scholar]

- Engblom, N.; Saxén, H.; Zevenhoven, R.; Nylander, H.; Enstad, G.G. Analysis of Segregation Data for a Dry Mineral-Based Construction Materials Plant. Ind. Eng. Chem. Res. 2012, 51, 9427–9440. [Google Scholar] [CrossRef]

- Yamamoto, M. Method and System of Total Dry Refining of Iron Oxide Ore Through a Magnetic Separation Unit. Patent WO 2016/054707 AI, 14 April 2016. [Google Scholar]

- Jenike, A.W. Storage and Flow of Solids. In Bulletin 123; University of Utah: Salt Lake City, UT, USA, 1964; Volume 53. [Google Scholar]

- Carson, J.W.; Pittenger, B.H. Bulk Properties of Powders. In ASM Handbook, Volume 7: Powder Technologies and Applications; ASM International: Arizona, NY, USA, 1998; pp. 287–301. [Google Scholar]

- ASTM D6128-22; Standard Test Method for Shear Testing of Bulk Solids Using the Jenike Shear Tester. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D7743-12; Standard Test Method for Measuring the Minimum Fluidization Velocities of Free Flowing Powders. ASTM International: West Conshohocken, PA, USA, 2012.

- Geldart, D. Types of Gas Fluidization. Powder Technol. 1973, 7, 285–292. [Google Scholar] [CrossRef]

- Geldart, D.; Wong, A.C.Y. Fluidization of powders showing degrees of cohesiveness—I. Bed Expansion. Chem. Eng. Sci. 1984, 39, 1481–1488. [Google Scholar] [CrossRef]

- Cocco, R.; Chew, J.W. 50 years of Geldart classification. Powder Technol. 2023, 428, 118861. [Google Scholar] [CrossRef]

- Geldart, D.; Wong, A.C.Y. Fluidization of powders showing degrees of cohesiveness—II. Experiments on rates of de-aeration. Chem. Eng. Sci. 1985, 40, 653–661. [Google Scholar] [CrossRef]

- Abrahamsen, A.R.; Geldart, D. Behaviour of Gas-Fluidized Beds of Fine Powders Part I. Homogeneous Expansion. Powder Technol. 1980, 26, 35–46. [Google Scholar] [CrossRef]

- Geldart, D.; Harnby, N.; Wong, A.C. Fluidization of Cohesive Powders. Powder Technol. 1984, 37, 25–37. [Google Scholar] [CrossRef]

- Abrahamsen, A.R.; Geldart, D. Behaviour of Gas-Fluidized Beds of Fine Powders Part II. Voidage of the Dense Phase in Bubbling Beds. Powder Technol. 1980, 26, 47–55. [Google Scholar] [CrossRef]

- Kong, W.; Tan, T.; Bayens, J.; Flamant, G.; Zhang, H. Bubbling and Slugging of Geldart Group A Powders in Small Diameter Columns. Ind. Eng. Chem. Res. 2017, 56, 4136–4144. [Google Scholar] [CrossRef]

- Guo, Q.; Meng, S.; Zhao, Y.; Ma, L.; Wang, D.; Ye, M.; Yang, W.; Liu, Z. Experimental Verification of Solid-like and Fluid-like States in the Homogeneous Fluidization Regime of Geldart A Particles. Ind. Eng. Chem. Res. 2018, 57, 2670–2686. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhu, J. On the Two-Phase Theory of Group C+ and Geldart Group A Particles. Ind. Eng. Chem. Res. 2020, 59, 12600–12609. [Google Scholar] [CrossRef]

| Features | PC | DCC | SC | AS |

|---|---|---|---|---|

| Distance covered 1 | Max 200 m | Max 40 m–50 m | Max 12 m | Unlimited but requires verticalization |

| Tonnage 1 | Low <50 t/h | Fair Max 650 t/h | Fairly low Max 250 t/h | Very high Max 4000 t/h |

| Power consumption 2 | Very high 2 to 5 kWh/t | High 0.1 to 0.4 kWh/t | High 0.1 to 0.2 kWh/t | Very low 0.01 to 0.05 kWh/t |

| Investment expenditures 2 | Very high | Very high | Very high | Low |

| Equipment weight 2 | 15 to 80 kg/m | 800 to 2000 kg/m | 40 to 200 kg/m | 10 to 120 kg/m |

| Availability 1 | Fairy high | Fairy high | Consistent high | Very high |

| Material temperature 1 | Max 700 °C | Max 700 °C | Max 700 °C | Max 450 °C |

| Bulk material top size limit 1 | 500 mm | 150 mm | 400 mm | 0.040 to 0.5 mm |

| ID | Description | Fe | SiO2 | P | Al2O3 | Mn | TiO2 | CaO | MgO | LOI |

|---|---|---|---|---|---|---|---|---|---|---|

| S.1 | Ground ROM −2.000 mm | 49.38 | 27.28 | 0.057 | 0.69 | 0.014 | 0.066 | 0.020 | 0.048 | 1.08 |

| S.2 | Ground ROM −1.000 mm | 47.50 | 31.06 | 0.051 | 0.65 | 0.013 | 0.068 | 0.010 | 0.051 | 0.95 |

| S.3 | Ground ROM −0.500 mm | 42.49 | 38.70 | 0.037 | 0.58 | 0.010 | 0.061 | 0.010 | 0.024 | 0.72 |

| S.4 | Ground ROM −0.150 mm | 40.13 | 41.79 | 0.032 | 0.57 | 0.010 | 0.054 | 0.010 | 0.014 | 0.67 |

| S.5 | Ground ROM deslimed −0.150 + 0.010 mm | 45.79 | 33.05 | 0.049 | 0.59 | 0.013 | 0.062 | 0.015 | 0.035 | 0.94 |

| S.6 | Ultrafines −0.025 mm | 51.07 | 17.17 | 0.085 | 5.99 | 0.125 | 0.260 | 0.021 | 0.149 | 3.10 |

| S.7 | Pellet feed concentrate −0.150 + 0.015 mm | 67.73 | 1.82 | 0.010 | 0.18 | 0.080 | 0.038 | 0.095 | 0.167 | 0.36 |

| S.8 | Pellet tailings −0.150 + 0.010 mm | 36.51 | 46.99 | 0.016 | 0.74 | 0.016 | 0.120 | 0.011 | 0.052 | 0.56 |

| S.9 | Coarse concentrate −0.500 + 0.150 mm | 65.60 | 5.64 | 0.022 | 0.46 | 0.013 | 0.041 | 0.010 | 0.085 | 0.43 |

| S.10 | Coarse tailings −0.500 + 0.150 mm | 39.12 | 38.11 | 0.043 | 1.02 | 0.029 | 0.091 | 0.010 | 0.041 | 4.38 |

| Sample | W (kN) | σ1 (kPa) | FC (kPa) | FF | Yield Locus (°) | Eff. Angle (°) |

|---|---|---|---|---|---|---|

| S.1 | 0.015 | 5.44 | 1.10 | 4.95 | 39 | 44 |

| 0.103 | 31.90 | 6.10 | 5.23 | 35 | 40 | |

| 0.221 | 62.86 | 10.80 | 5.82 | 35 | 40 | |

| S.5 | 0.015 | 5.30 | 0.30 | 17.67 | 40 | 41 |

| 0.074 | 23.30 | 1.40 | 16.64 | 37 | 39 | |

| 0.152 | 46.10 | 2.50 | 18.44 | 37 | 39 | |

| S.6 | 0.015 | 6.04 | 3.60 | 1.68 | 32 | 51 |

| 0.064 | 17.00 | 8.16 | 2.08 | 27 | 42 | |

| 0.132 | 36.60 | 15.40 | 2.38 | 31 | 44 | |

| S.7 | 0.015 | 5.78 | 0.40 | 14.45 | 38 | 39 |

| 0.113 | 37.60 | 3.20 | 11.75 | 36 | 38 | |

| 0.221 | 62.43 | 4.85 | 12.87 | 35 | 37 | |

| S.8 | 0.005 | 2.50 | 0.20 | 12.50 | 34 | 36 |

| 0.074 | 24.40 | 1.60 | 15.25 | 37 | 38 | |

| 0.142 | 47.40 | 3.20 | 14.81 | 35 | 36 | |

| S.9 | 0.010 | 4.20 | 0.64 | 6.56 | 34 | 36 |

| 0.054 | 17.50 | 1.30 | 13.46 | 37 | 38 | |

| 0.103 | 38.10 | 2.70 | 14.11 | 35 | 36 | |

| S.10 | 0.005 | 2.60 | 0.66 | 3.94 | 37 | 43 |

| 0.103 | 37.70 | 3.80 | 9.92 | 39 | 41 | |

| 0.201 | 65.91 | 5.58 | 11.81 | 37 | 39 |

| Sample ID | Loose Density (kg/m3) | Tapped Density (kg/m3) | HR |

|---|---|---|---|

| S.1 | 2189 | 2703 | 1.23 |

| S.5 | 1632 | 1963 | 1.20 |

| S.6 | 920 | 1524 | 1.66 |

| S.7 | 2514 | 2883 | 1.15 |

| S.8 | 1521 | 1902 | 1.25 |

| S.9 | 2408 | 2654 | 1.10 |

| S.10 | 2254 | 2536 | 1.13 |

| Sample ID | Conical Hopper—Exit 0.5 m (°) | Pyramidal Hopper—Exit 0.5 m (°) | Chutes (°) |

|---|---|---|---|

| S.1 | 73 | 61 | 29 |

| S.5 | 75 | 65 | 34 |

| S.6 | 80 | 69 | 44 * (86) |

| S.7 | 73 | 61 | 30 |

| S.8 | 73 | 62 | 25 |

| S.9 | 78 | 66 | 32 |

| S.10 | 72 | 61 | 26 |

| Sample ID | Absolute Density (kg/m3) | Min. Fluid. Velocity (mm/s) | De-Aeration Rate (s/m) | Fluidized Bulk Density (kg/m3) | Initial/Fluidized/Final Bed Height (mm) |

|---|---|---|---|---|---|

| S.1 | 4151 | - | - | - | - |

| S.2 | 4055 | - | - | - | - |

| S.3 | 3821 | 75 | 111 | 1145 | 204/370/228 |

| S.4 | 3755 | 45 | 142 | 1179 | 221/350/230 |

| S.5 | 3984 | 145 | 113 | 1099 | 212/390/218 |

| S.6 | 4326 | 120 | 203 | 631 | 206/295/208 |

| S.7 | 5205 | 20 | 174 | 1219 | 206/308/197 |

| S.8 | 3633 | 55 | 146 | 1115 | 209/360/217 |

| S.9 | 5006 | - | - | - | - |

| S.10 | 3725 | 100 | 151 | 1318 | 214/340/221 |

| Sample ID | Flow Function (Jenike’s Method) | Mills Classification |

|---|---|---|

| S.1 | Easy-flowing | Easy-flowing |

| S.5 | Free-flowing | Free-/Easy-flowing |

| S.6 | Cohesive | Easy-flowing |

| S.7 | Free-flowing | Easy-flowing |

| S.8 | Free-flowing | Easy-flowing |

| S.9 | Free-flowing | Free-/Easy-flowing |

| S.10 | Easy-flowing | Free-flowing |

| Sample ID | Optimal Fluidization Velocity Range (mm/s) |

|---|---|

| S.3 | 113 to 150 |

| S.4 | 68 to 90 |

| S.5 | 218 to 280 |

| S.6 | 180 to 240 |

| S.7 | 225 to 300 |

| S.8 | 83 to 110 |

| S.9 | * not reached steady-state fluidization (group D) |

| S.10 | 150 to 200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, B.B.e.; Soares, A.d.A.; Vieira, M.G.; Ruiz, R.; Chaves, A.P.; Bergerman, M.G. Dry Iron Ore Fluidization, Flowability, and Handling: Supporting Dry Processing of Iron Ores and Guiding Industrial Designing. Minerals 2025, 15, 998. https://doi.org/10.3390/min15090998

Silva BBe, Soares AdA, Vieira MG, Ruiz R, Chaves AP, Bergerman MG. Dry Iron Ore Fluidization, Flowability, and Handling: Supporting Dry Processing of Iron Ores and Guiding Industrial Designing. Minerals. 2025; 15(9):998. https://doi.org/10.3390/min15090998

Chicago/Turabian StyleSilva, Benito Barbabela e, Anderson de Araújo Soares, Monica Guimarães Vieira, Rogério Ruiz, Arthur Pinto Chaves, and Maurício Guimarães Bergerman. 2025. "Dry Iron Ore Fluidization, Flowability, and Handling: Supporting Dry Processing of Iron Ores and Guiding Industrial Designing" Minerals 15, no. 9: 998. https://doi.org/10.3390/min15090998

APA StyleSilva, B. B. e., Soares, A. d. A., Vieira, M. G., Ruiz, R., Chaves, A. P., & Bergerman, M. G. (2025). Dry Iron Ore Fluidization, Flowability, and Handling: Supporting Dry Processing of Iron Ores and Guiding Industrial Designing. Minerals, 15(9), 998. https://doi.org/10.3390/min15090998