1. Introduction

In situ blasting leaching within stopes represents an innovative and environmentally sustainable mining approach that integrates the processes of ore extraction, beneficiation, and metallurgy. This method involves directly fragmenting the ore body underground into smaller rock fragments, with approximately 70%–80% of the ore remaining in situ. Subsequently, leaching solutions are applied via spraying systems to the retained ore mass, and the resulting liquid containing dissolved valuable metals is collected and processed for metal recovery [

1,

2,

3]. This technique effectively addresses the ground-pressure control challenges associated with conventional mining methods while significantly reducing the transportation costs related to surface processing. It is particularly applicable to the development of low-grade ore deposits. In countries such as the United States and Canada, heap leaching and in situ blasting leaching are predominantly employed for the recovery of metals from copper ores with grades ranging from 0.15% to 0.45%, oxidized copper ores exceeding a 2% grade, and uranium ores with concentrations between 0.02% and 0.1% [

4,

5,

6]. The efficiency and effectiveness of the stope leaching technology primarily depend on the leaching rate and overall leaching performance. Key factors influencing the leaching rate include ore characteristics, the selection of leaching reagents, fluid dynamics, and environmental conditions [

7,

8,

9,

10]. Among these, solution flow behavior plays a critical role, as it governs both the chemical reaction kinetics within the ore and the transport of fine particles—both of which are fundamental to the leaching process. The leaching solution is typically introduced at the upper portion of the ore deposit through a network of spray pipes and percolates downward under gravitational forces. The pore structure within the ore body serves as the primary conduit for this fluid movement [

11,

12]. Consequently, the characteristics of the pore structure exert a significant influence on both fluid flow and leaching efficiency.

Pores within the ore body originate from the accumulation of fragmented ore particles generated by blasting operations. Ore constitutes the foundational element of the leaching system. Blasting produces particles of varying shapes and size distributions, which collectively form a granular skeleton. The interstitial voids between these particles provide the necessary space for fluid migration and chemical interactions between the solution and the ore matrix [

13,

14,

15]. However, due to their irregular sizes and geometries, these pores exhibit heterogeneous structural features. Pore structure parameters such as porosity, pore-size distribution, and connectivity directly affect seepage velocity and efficiency, thereby playing a decisive role in determining leaching outcomes [

16,

17,

18]. Therefore, variations in pore structure characteristics represent the underlying mechanism governing leaching performance.

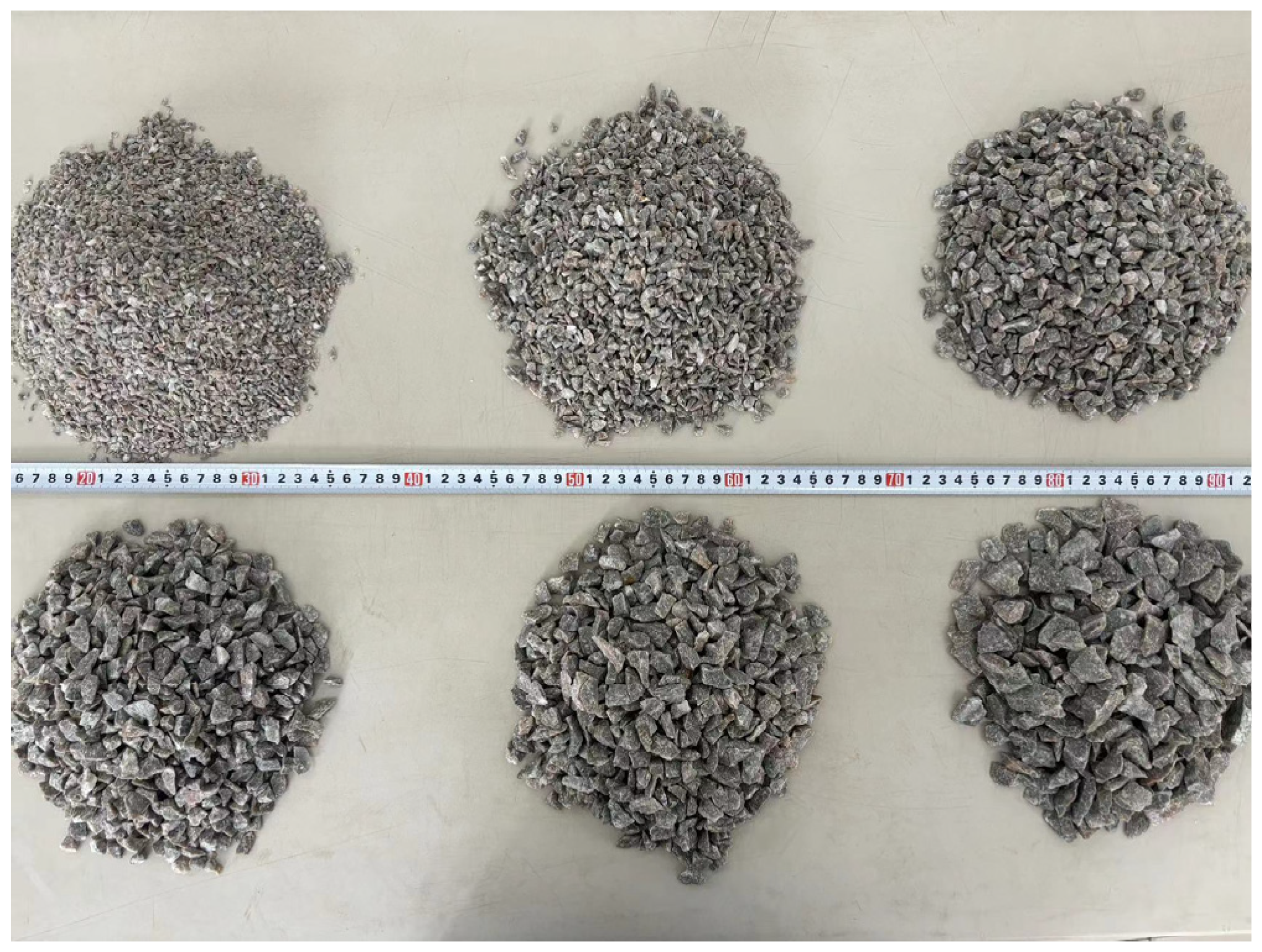

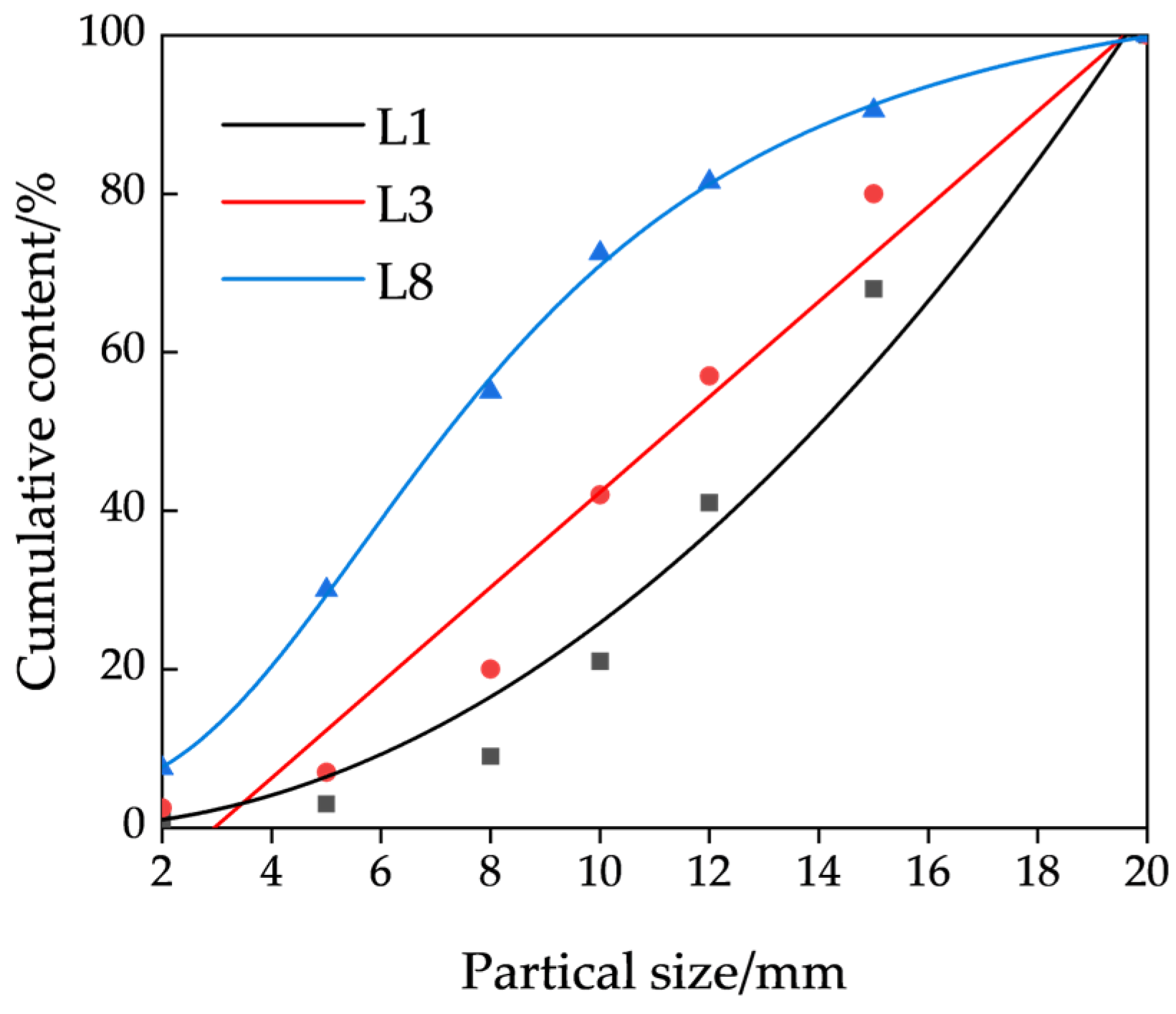

Several factors contribute to the formation and evolution of pore structures, including particle size, shape, gradation, and contact configurations, all of which collectively define the spatial distribution of pores [

19,

20,

21]. Of particular significance are the particle size and gradation of the blasted ore. The ore to be leached typically consists of a mixture of coarse, medium, and fine particles. The gradation of these particles primarily determines the compaction degree of the ore pile and the spatial arrangement of primary pores, which, in turn, influences the seepage behavior of the leaching solution. When the proportion of fine particles is minimal, the ore pile exhibits high permeability; however, the pore distribution may become highly uneven, potentially leading to preferential flow paths. Conversely, when coarse particles dominate, although chemical reactions between the ore and the solution may proceed more efficiently, the resulting pore structure tends to be finer and less porous, thereby restricting fluid flow rates [

22,

23,

24,

25]. Numerous studies have focused on experimental and numerical investigations of the effects of particle size and gradation on leaching performance. Researchers such as Ilankoon [

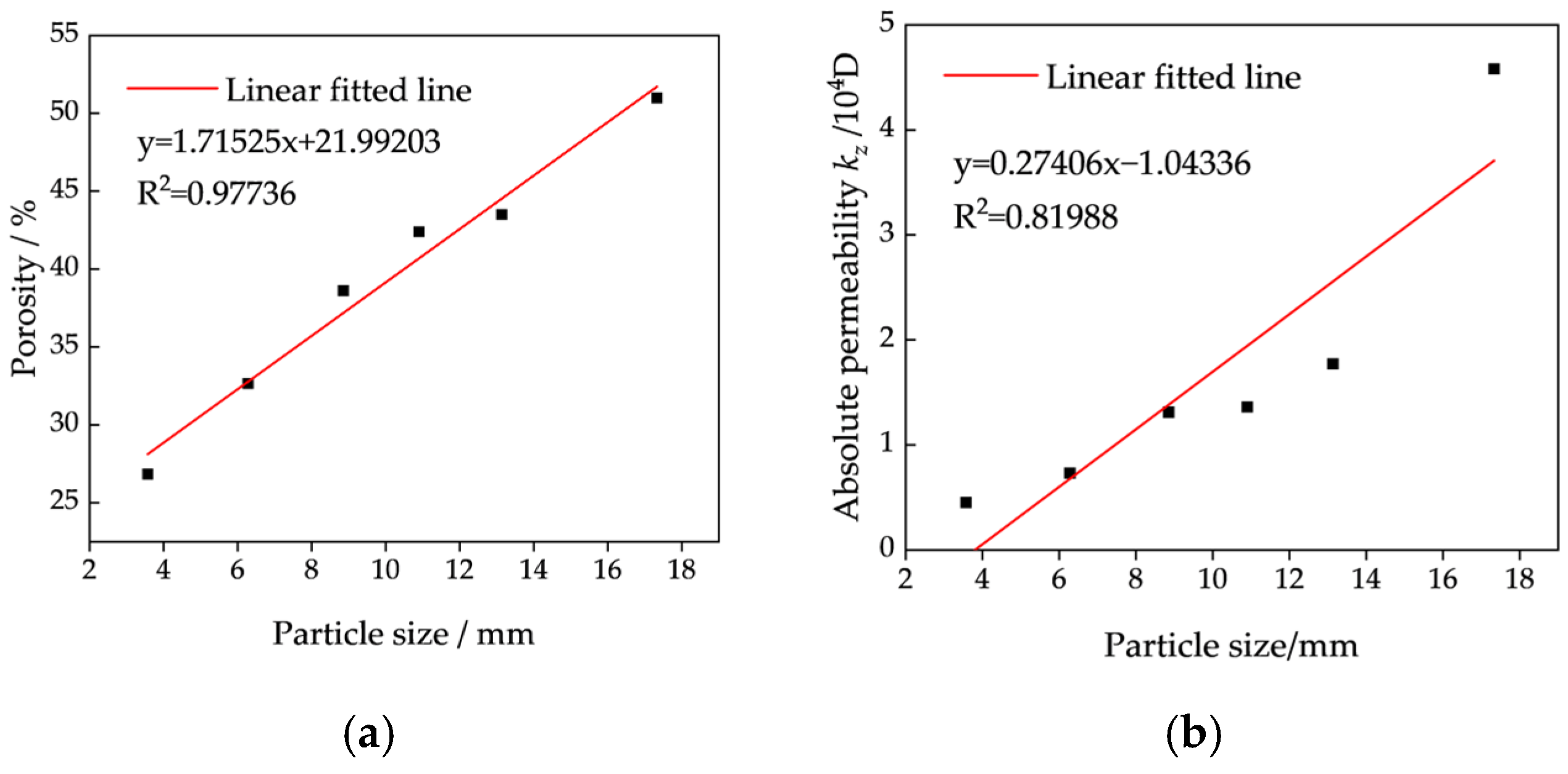

26], Liu [

27], Hao [

28], and Prasomsri [

29] have conducted seepage experiments using particle models with different size distributions, analyzing how gradation affects porosity and seepage characteristics. Additionally, Karlsons [

30], Stewart [

31], and Su [

32] have performed numerical simulations to model single-phase fluid flow in various ore types, predict permeability tensors under saturated conditions, and assess seepage behavior and its controlling mechanisms in earth structures. Currently, most studies adopt a macroscopic perspective in analyzing seepage phenomena, which are essentially manifestations of micro-scale changes in pore structure. As a result, the intrinsic influence of pore structure characteristics formed under different particle sizes and gradations on seepage and leaching remains largely overlooked.

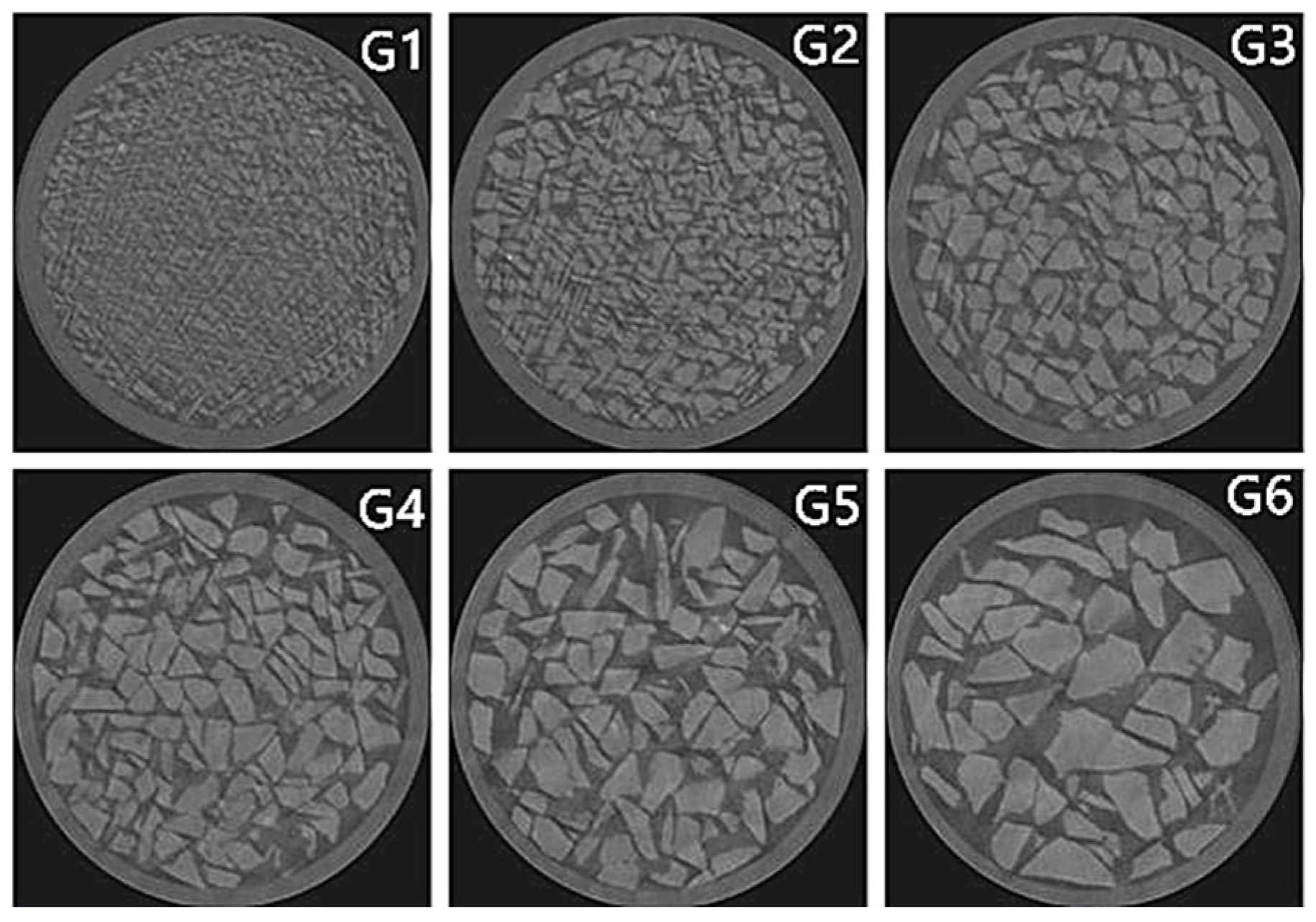

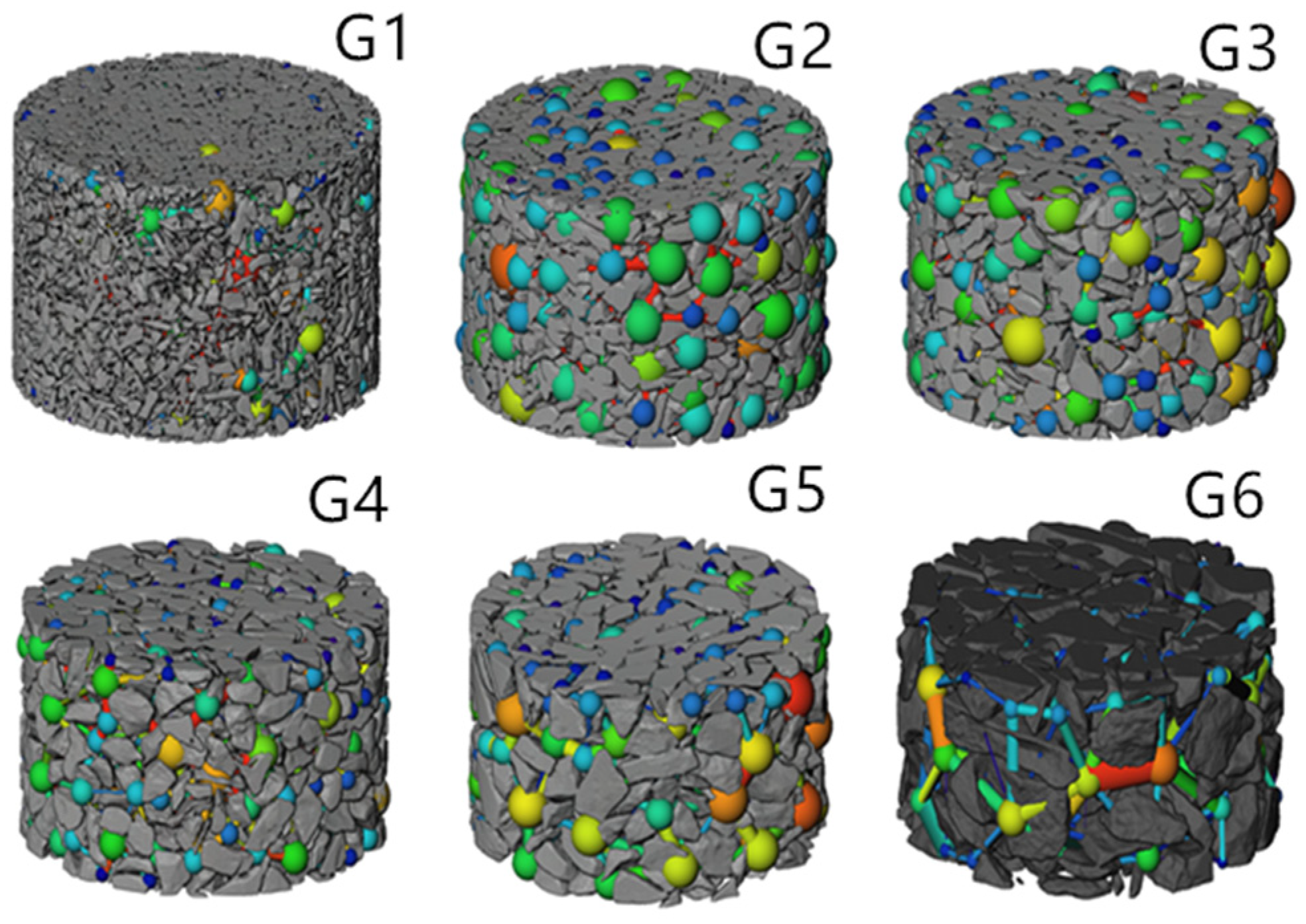

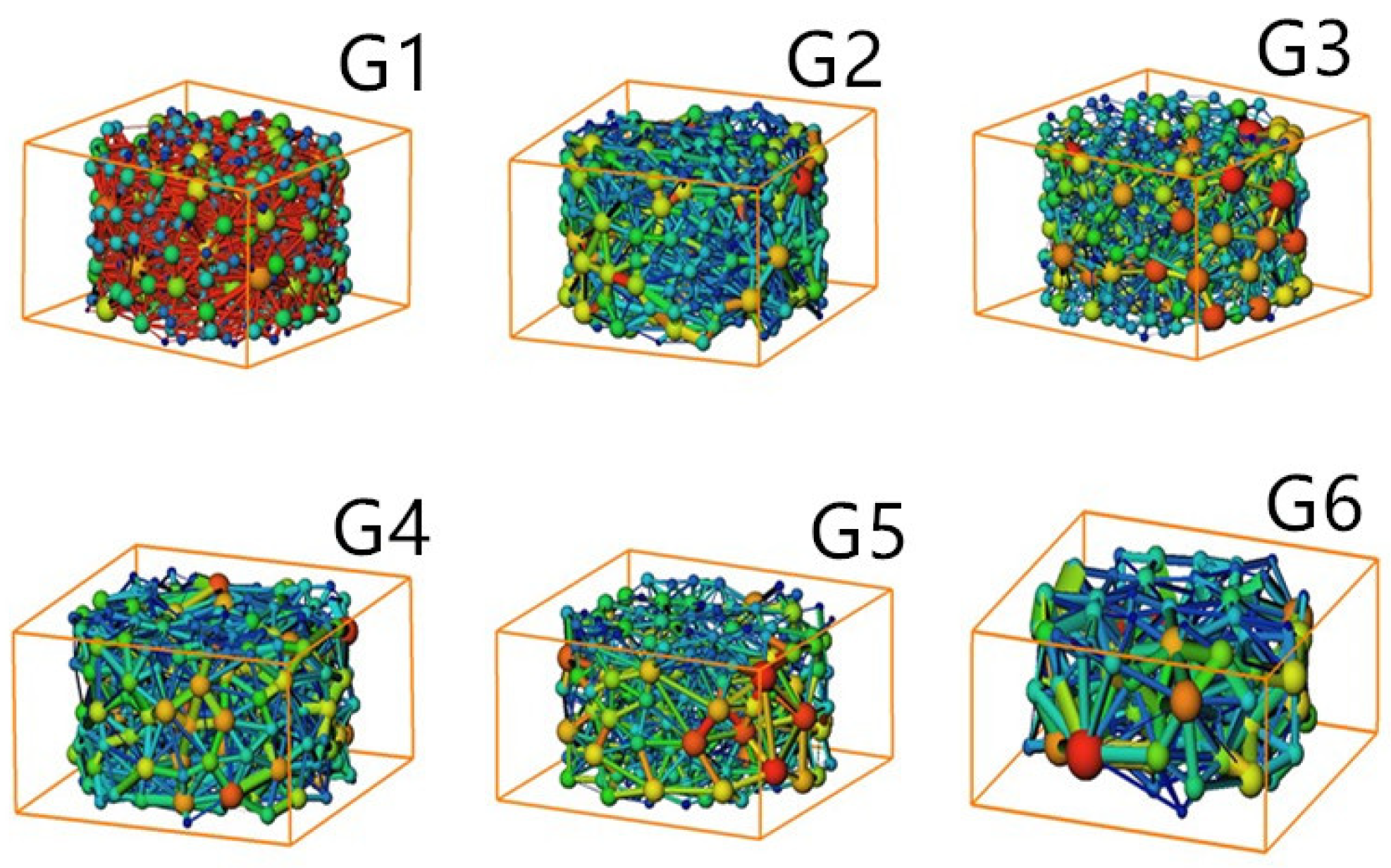

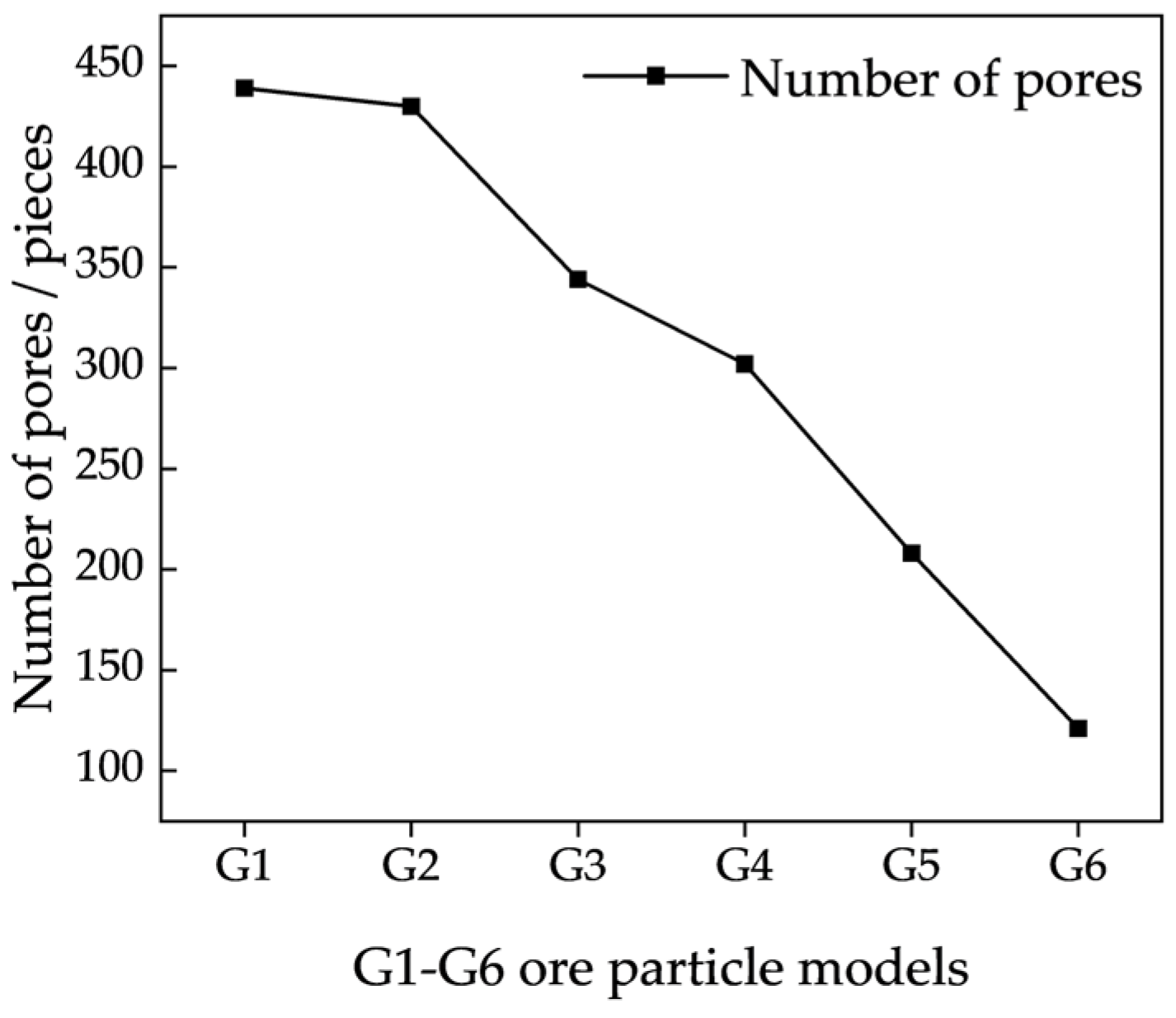

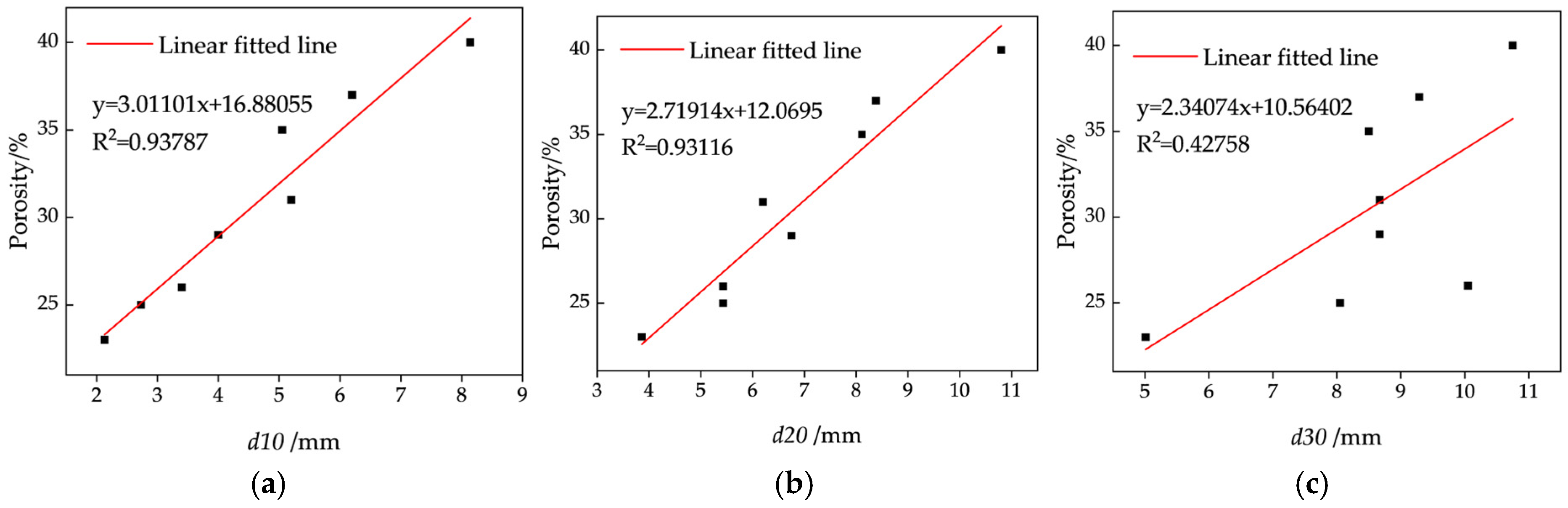

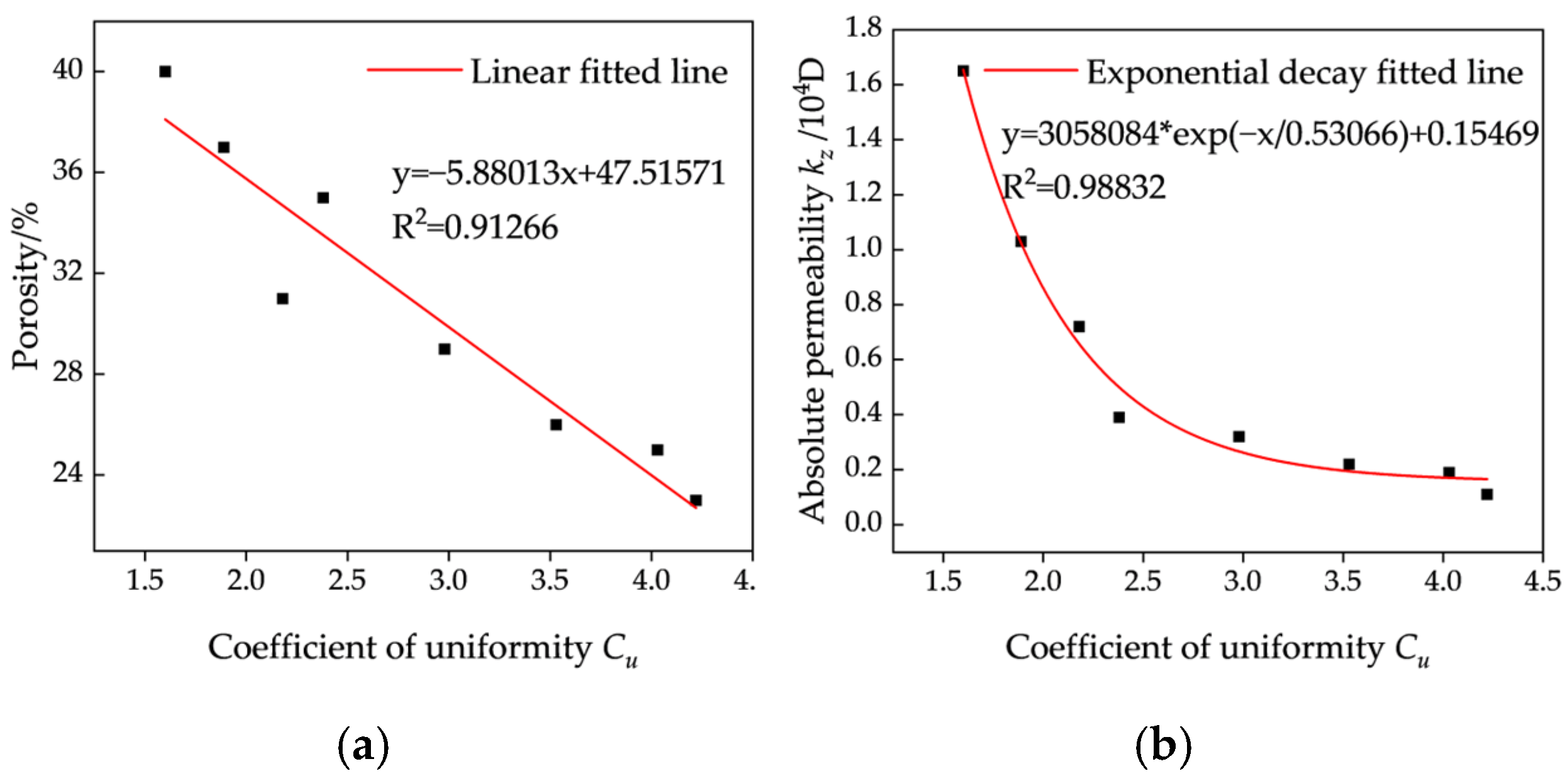

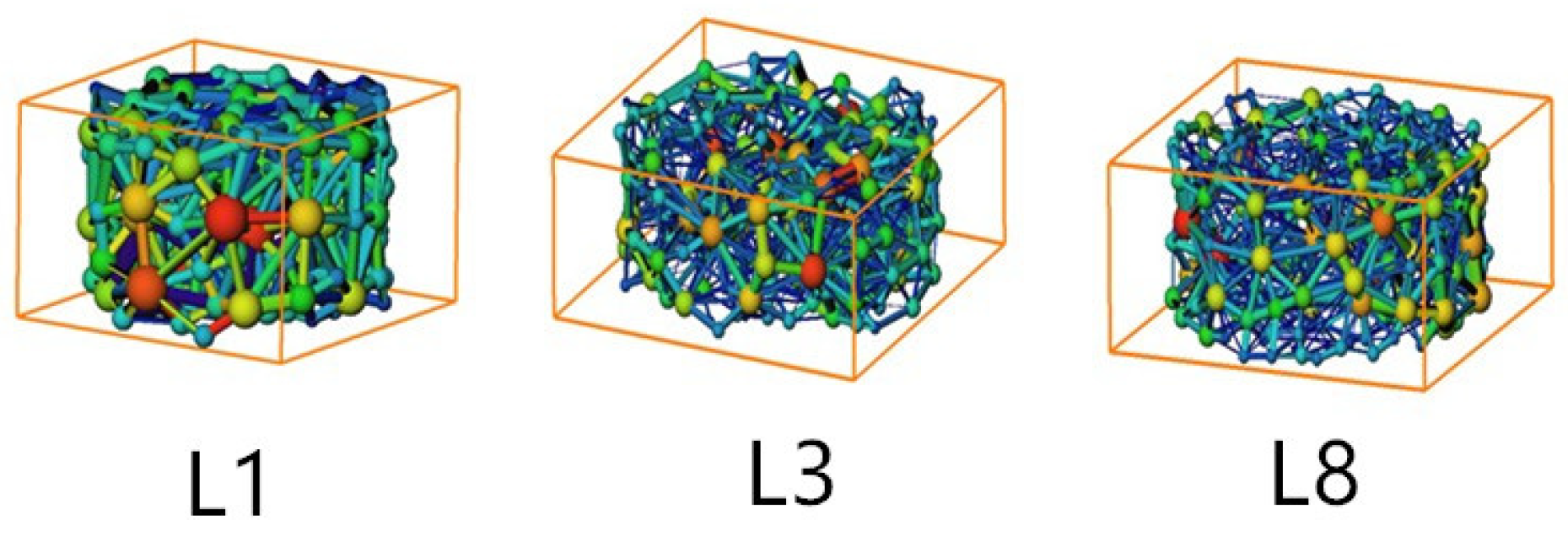

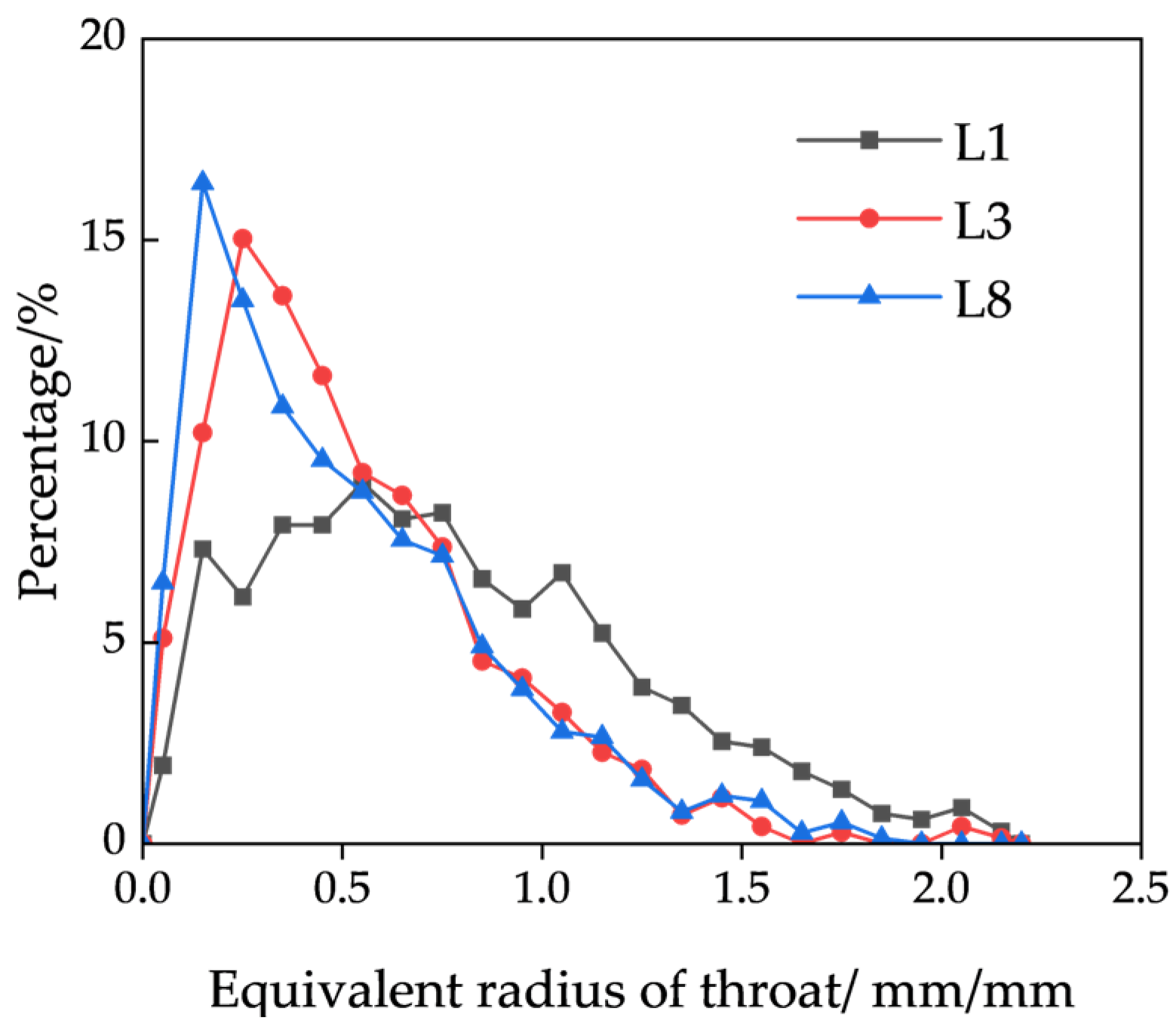

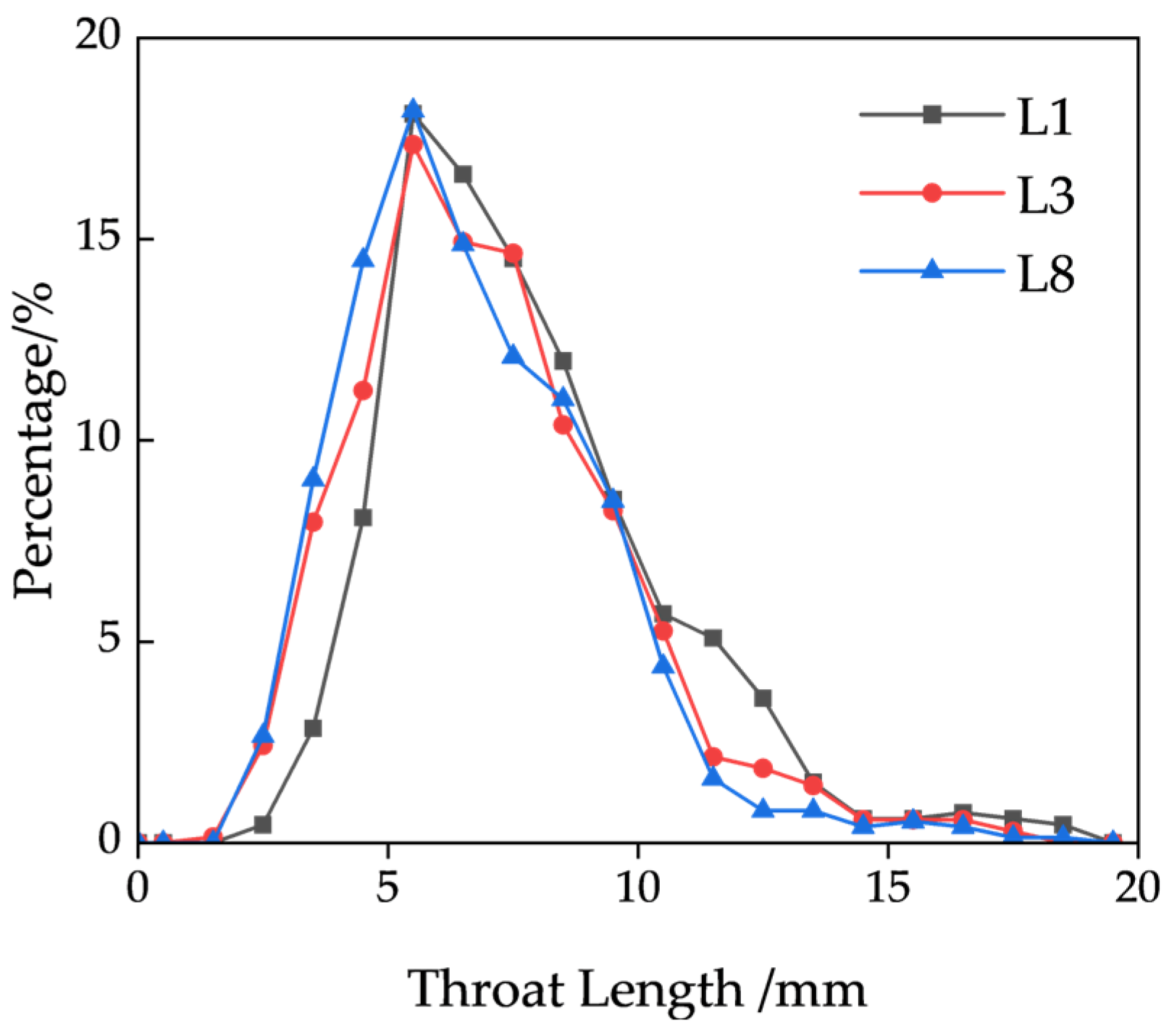

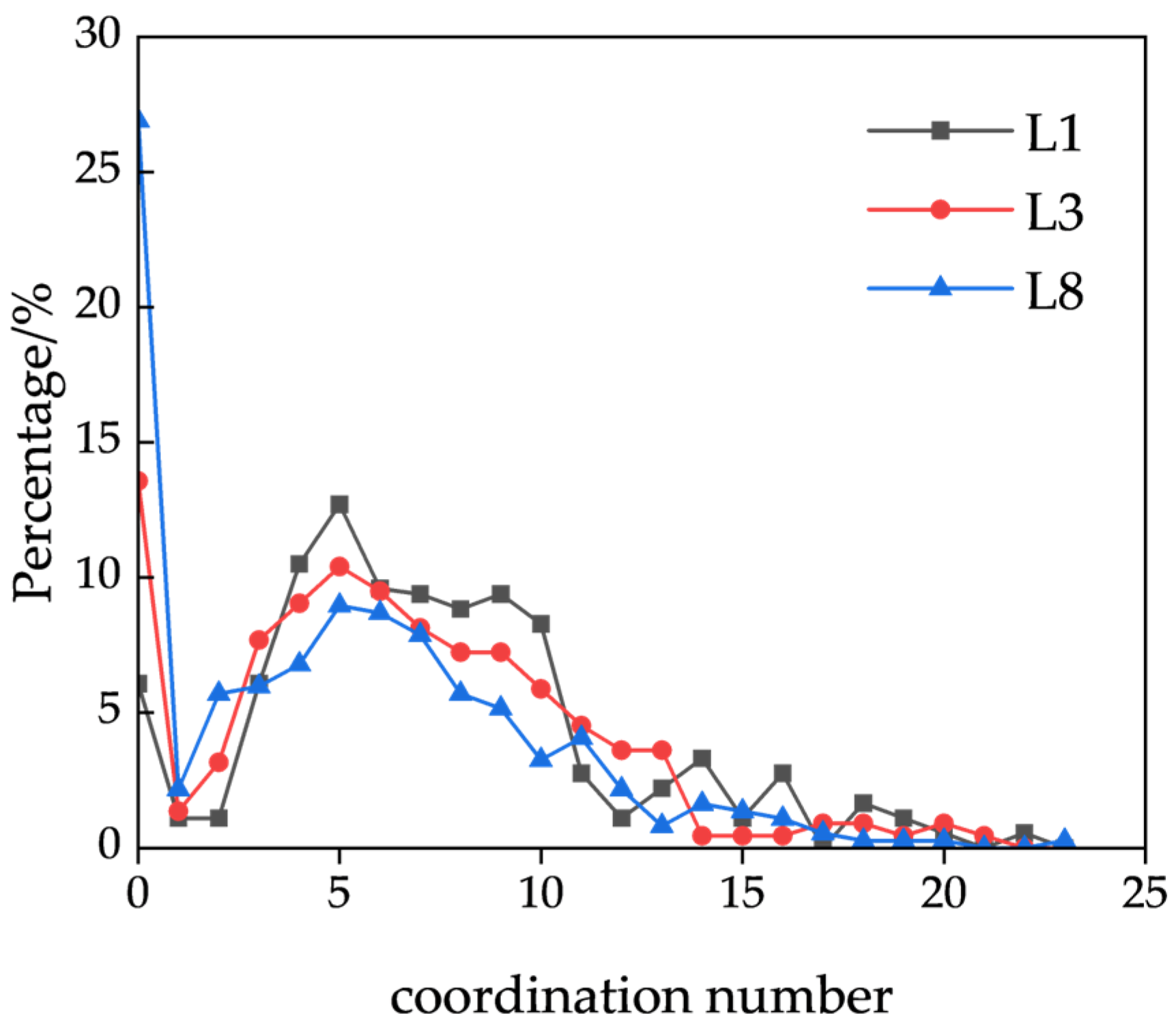

Therefore, this study focuses on investigating the impact of particle size and gradation on pore structure parameters from a microscopic viewpoint. CT scanning is employed to acquire two-dimensional images of physical models with varying particle sizes and gradations. These images are then reconstructed into three-dimensional representations using Avizo software, enabling the quantitative extraction of pore structural parameters. The influence of particle size and gradation on meso-scale pore characteristics is analyzed in detail. Furthermore, permeability is evaluated based on the pore structure, and the relative influence of individual pore parameters on permeability is assessed to provide a theoretical foundation for understanding the fluid flow behavior and optimizing the metal leaching efficiency. Multiple regression analysis reveals that porosity and throat size are dominant factors affecting permeability. Based on these findings, an improved Purcell model is developed for permeability prediction.

4. Assessment of Permeability in Relation to Pore Structure Characteristics

Permeability represents the capacity of leachable ore to allow fluid passage and serves as a critical parameter influencing leaching efficiency. The cumulative effect of microscopic pore structure characteristics ultimately manifests macroscopically as permeability. For example, when pores are large and exhibit strong interconnectivity, fluid-flow resistance is relatively low, resulting in higher permeability at the macroscopic level. Conversely, if pores are small and poorly connected, fluid movement becomes restricted, leading to reduced permeability. Establishing an accurate evaluation model for the influence of pore structure parameters on permeability facilitates a deeper understanding of fluid seepage mechanisms within porous media and provides theoretical support and decision-making foundations for relevant engineering applications.

In this study, pore structure parameters include porosity, equivalent pore diameter, equivalent throat diameter, throat length, pore coordination number, and pore connectivity. Following three-dimensional modeling and reconstruction analysis, it was determined that the connectivity of all the models exceeds 97%. Consequently, pore connectivity was excluded from the analysis of permeability-influencing factors. Using the aforementioned five pore structure parameters as independent variables and permeability as the dependent variable, a multiple linear regression fitting was conducted. The resulting model equation is as follows:

where

k denotes the permeability (m

2),

c is the connectivity,

ϕ is the porosity,

pr is the equivalent pore diameter (m),

tr is the equivalent throat diameter (m),

tl is the throat length (m), and

cn is the pore coordination number.

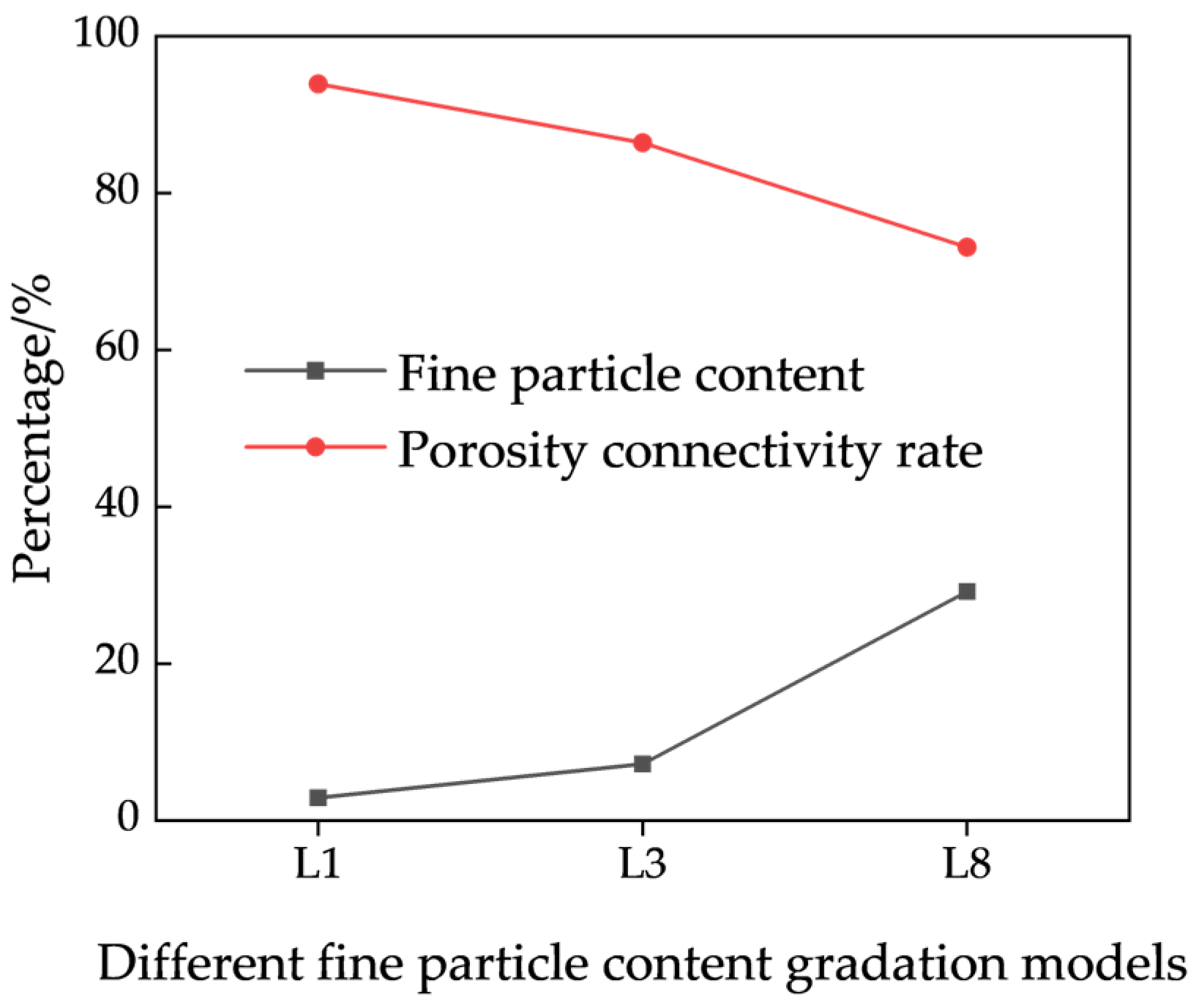

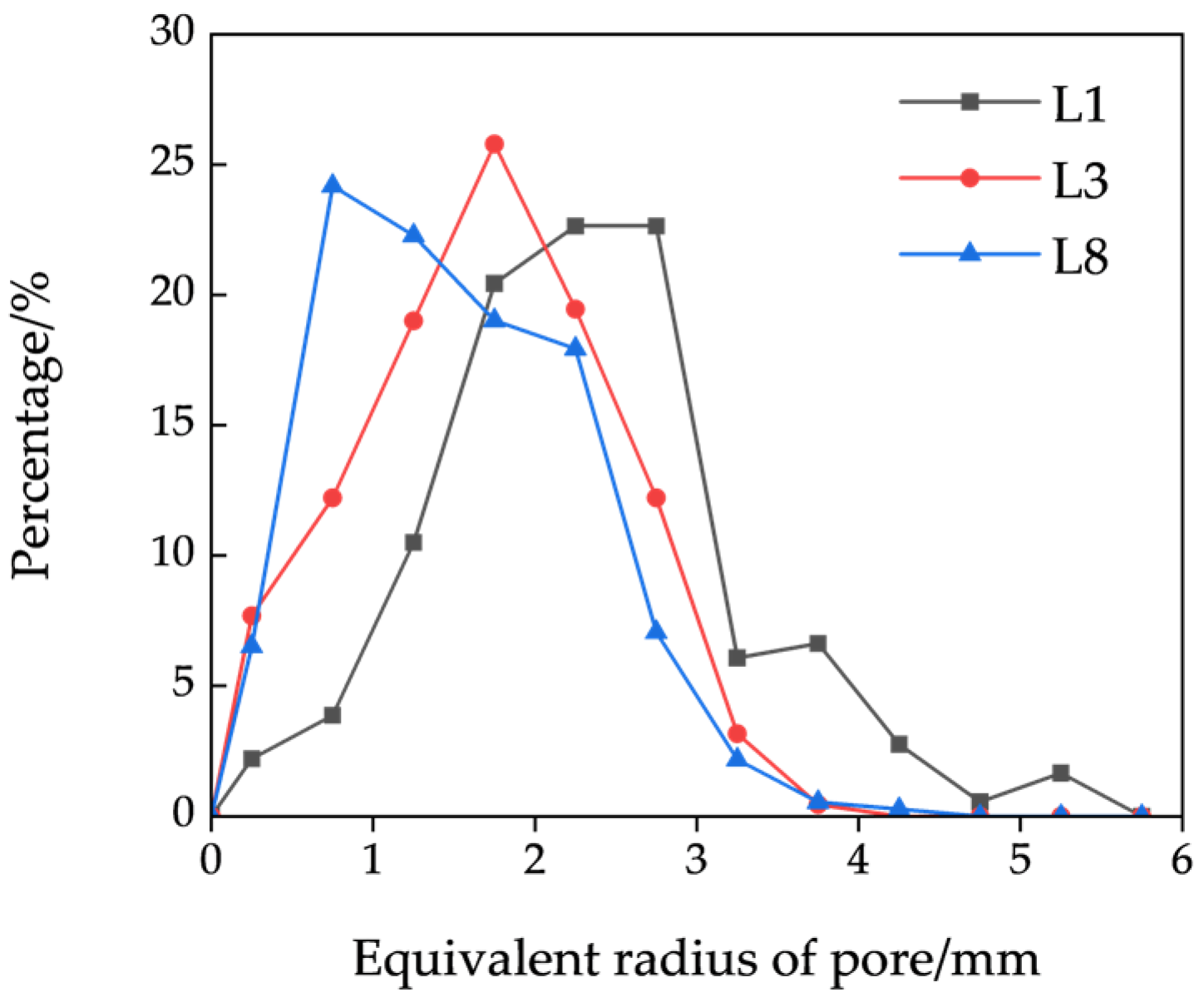

In the multiple linear regression equation, the correlation coefficient R2 is 0.98922, indicating a strong ability to accurately reflect the influence of various factors on permeability. Analysis of the constructed regression model reveals that pore connectivity rate is the most influential factor affecting permeability, followed by throat equivalent diameter, and then porosity and pore equivalent diameter. In contrast, throat length and coordination number have a relatively minor influence on permeability. These findings suggest that for ore scheduled for leaching after blasting in the stope, pore connectivity rate should be the primary focus. A higher connectivity rate generally corresponds to increased porosity and, consequently, higher permeability. The key to enhancing both connectivity rate and porosity lies in optimizing the particle-size distribution resulting from blasting. Second, the equivalent throat diameter—i.e., throat size—also significantly influences permeability. As the narrowest connection between pores, the throat acts as a key constraint on solution flow. Five primary types of throats were identified: pore-reduced type, necked type, sheet type, tubular type, and bundle type. Among these, the pore-reduced type features large pores and wide throats, with a pore-to-throat diameter ratio close to unity, which are commonly formed between floating particles and conducive to fluid flow. The necked type exhibits large pores but narrow throats, resulting in a high pore-to-throat diameter ratio, typically caused by linear or point contacts between ore particles, potentially rendering certain pores ineffective. Other throat types generally feature smaller pores and extremely narrow throats, primarily formed through concave–convex or suture-type particle contacts. Therefore, even with large pore sizes, narrow throats may still impede fluid flow, significantly reducing permeability and consequently impairing leaching performance.

In previous studies on permeability prediction, most scholars have focused on the relationship between permeability and particle size, such as the semi-theoretical and semi-empirical Hagen and Kozeny–Carman equations [

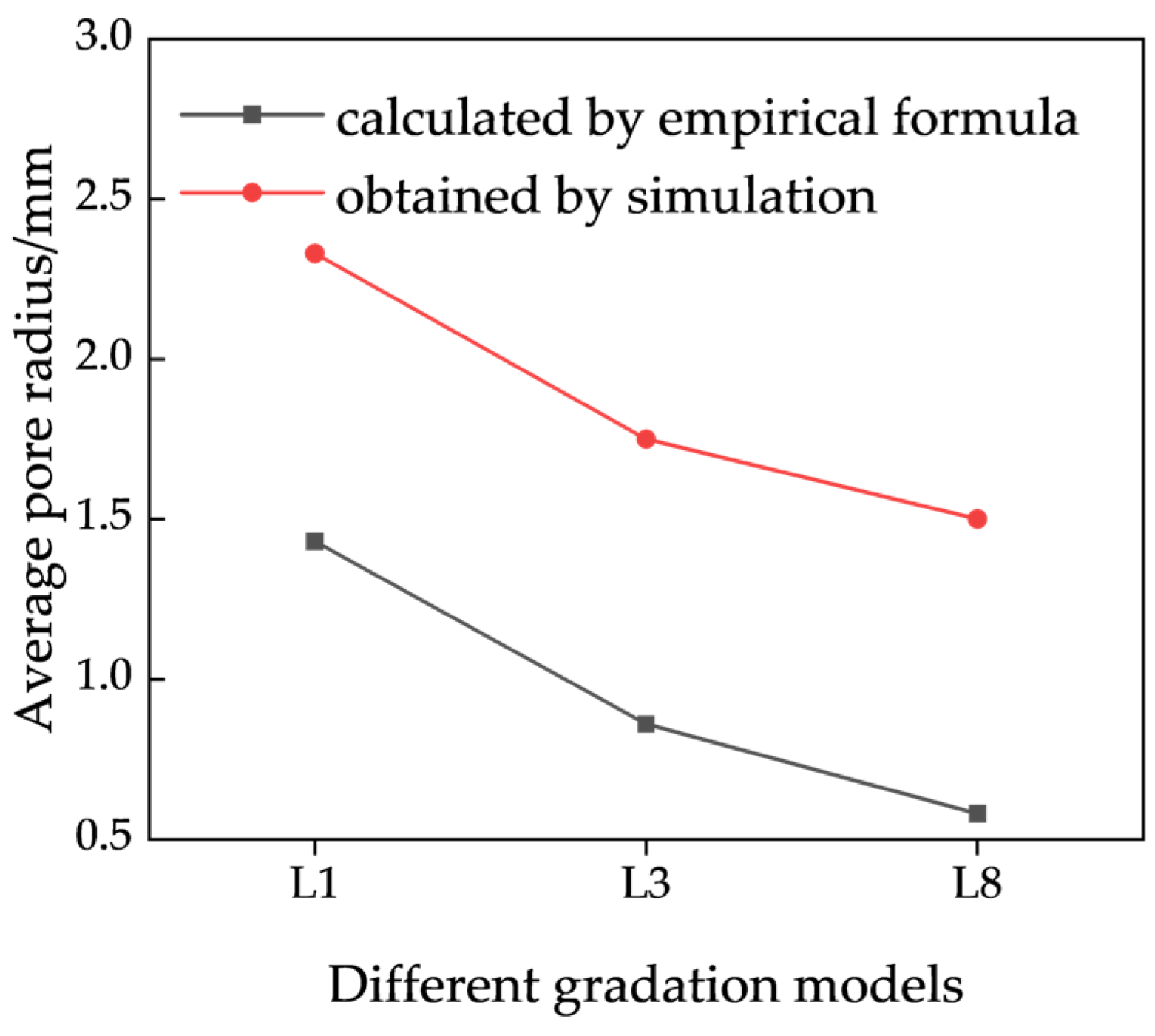

33]. In these formulations, permeability is proportional to the square of the particle size corresponding to a cumulative content of 10%–20%. A prerequisite for applying these equations is prior knowledge of the particle-size distribution, which is conventionally obtained via sieve analysis. However, for blasted ores, sieve-based determination of particle-size distribution is impractical. Thus, analyzing permeability based on pore structure parameters has become increasingly important. Porosity is primarily influenced by particle size and gradation; maintaining a consistent particle-size range and gradation ensures stable porosity in post-blast ore piles, assuming negligible segregation effects. Based on regression analysis, throat size emerges as the dominant factor influencing permeability in blasted ores intended for leaching.

This study conducts permeability analysis and prediction using an improved Purcell formula. Originally proposed by W. R. Purcell in 1949 [

34], the Purcell formula is a classical rock physics model used to describe the relationship between permeability (

k) and average throat radius (

r). The original formulation is expressed as

where

k is the permeability (m

2),

ϕ is the porosity, r is the average throat radius (m), and

τ is the tortuosity.

Considering the throat-radius distribution derived from three-dimensional pore network reconstruction, the single throat radius

r in the original formula is replaced with a weighted average of

r2:

where

f(

r) denotes the probability density function of throat radius

r, reflecting the relative proportion of different-sized throats.

Fitting analysis of the throat data extracted from the three-dimensional pore structure models indicates that the throat radius follows a log-normal distribution:

where

σ is the standard deviation and

μ is the mean of ln(

r). Substituting Equation (8) into Equation (7) yields

Permeability

k is calculated based on the permeability coefficient

K obtained from constant-head permeability tests, using the following relation:

where

k is the permeability (m

2),

K is the permeability coefficient (m/s),

μ is the dynamic viscosity (Pa·s),

ρ is the fluid density (kg/m

3), and

g is the gravitational acceleration (9.81 m/s

2).

Constant-head permeability tests were performed on models with varying throat sizes. The tests were conducted using pure water at a room temperature of 20 °C, with a fluid density of 1000 kg/m

3 and a dynamic viscosity of 0.001 Pa·s. A constant water head of 20 cm was applied during the experiments. Constant-head permeability tests were performed on models with varying throat sizes, as illustrated in

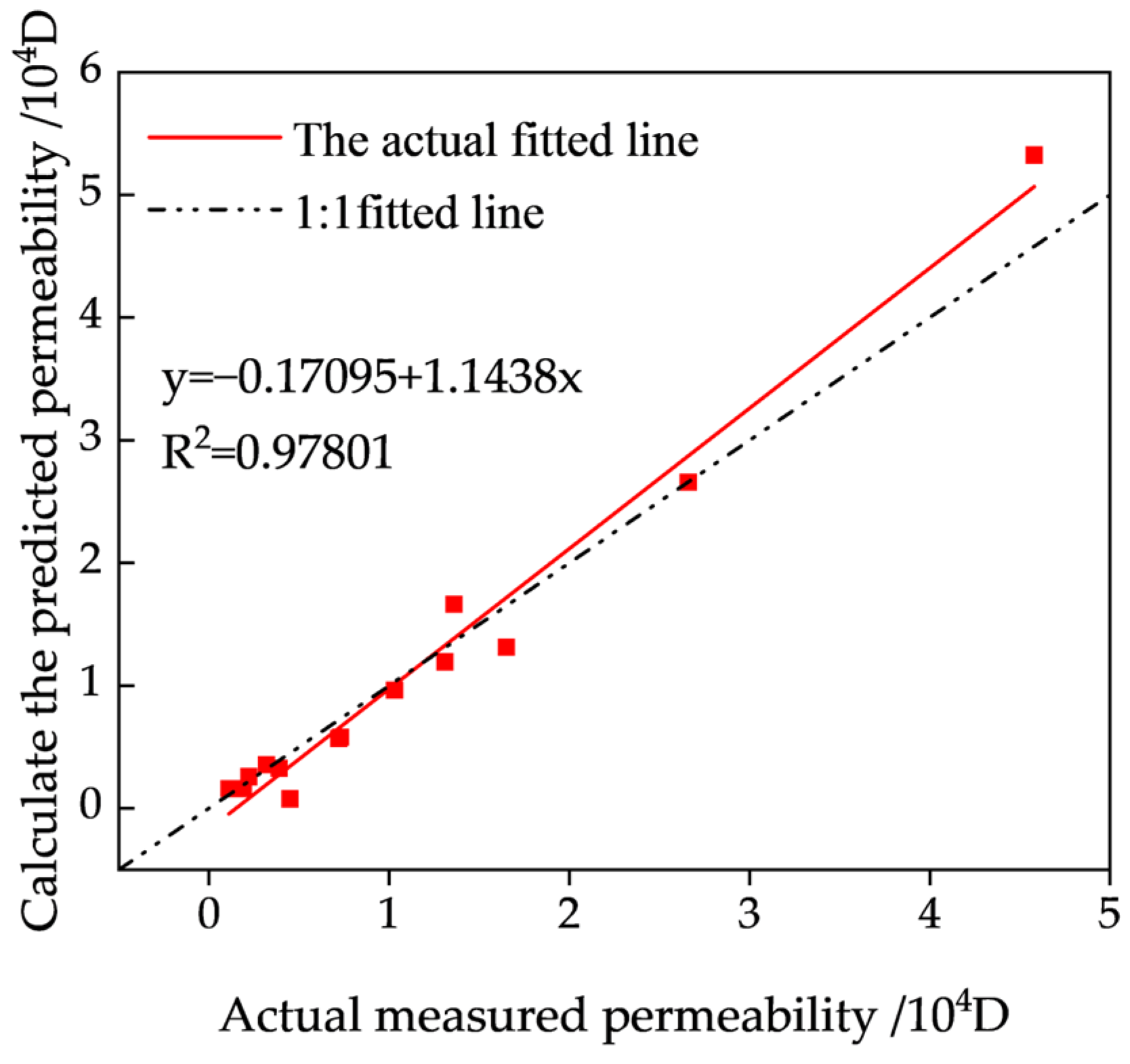

Figure 18. The predicted permeability values using the improved Purcell formula align closely with the experimentally measured results, validating the effectiveness of the proposed permeability prediction model. Furthermore, based on the established empirical relationship, the corresponding throat radius can be inversely estimated using known values of permeability and porosity.

6. Discussion and Future Prospects

CT scanning combined with 3D reconstruction using Avizo software enables effective analysis of key pore structural parameters, including porosity, pore-throat-size distribution, throat length, and pore coordination number. This approach provides robust data support for understanding how ore particle gradation influences pore structure distribution characteristics and permeability evolution. However, several limitations remain. First, partial volume effects may occur during CT scanning, whereby small pores can be misclassified as solid phases due to gray-value averaging within voxels containing mixed materials. Second, edge effects can distort the statistical analysis of pore parameters, as larger pore structures may form at the interface between the sample and the acrylic model, introducing measurement bias. Additionally, the topological parameters extracted by Avizo, such as throat radius and tortuosity, are based on an idealized spherical-tube model, which may not accurately represent real pore structures with complex geometries, such as plate-like pores or fractal surfaces. Future studies should account for these factors and aim to design more refined experimental methodologies.

Although there has been some quantitative analysis of the influence of particle gradation on pore structure parameters, the interaction mechanism between particles at the microscopic level requires further in-depth research to achieve optimal particle gradation after blasting. Future studies could leverage advanced microscopic testing techniques to reveal the impact of inter-particle forces on the formation and evolution of pore structures at the atomic and molecular scales, thereby laying the foundation for establishing more accurate theoretical models. This will optimize the pore structure of ores, enhance their permeability and solubility, and, ultimately, increase the mining value of ores. Future research should focus on further elucidating the impact of solution leaching behavior on pore structure evolution. Particular attention should be given to the mechanisms underlying pore structural changes and permeability variations resulting from chemical reactions between the solution and the ore, as well as fine-particle migration induced by solution scouring. Numerical simulations and predictive modeling should be conducted using the extensive datasets collected to enhance understanding and to support the development of more accurate theoretical frameworks.