Comparative Evaluation of X-Ray Transmission and X-Ray Luminescence Sorting Technologies for Fine Diamond Recovery

Abstract

1. Introduction

2. Materials and Methods

2.1. Diamond and Gangue Samples

2.2. Diamond Characterization

- Weight: Diamonds were weighed to four decimal places in grams using a Mettler Toledo XS205 Dual Range scale, professionally calibrated to ensure precise measurements.

- Size: Diamonds were measured in millimeters for their X, Y, and Z dimensions. The X dimension represents the largest dimension, the Y dimension is the largest perpendicular to the X dimension, and the Z dimension is the smallest perpendicular to the X dimension.

- Shape: Shape classification followed the Saskatchewan Research Council’s rough diamond definitions and methodology, with visual assessments conducted to ensure consistency [22].

- Clarity: Clarity was classified following the Saskatchewan Research Council’s definitions, recording the presence of inclusions [22]. Diamonds without inclusions were classified as having the highest clarity.

- Transparency: Transparency was evaluated based on the Saskatchewan Research Council’s methodology [22]. This measures the ability of light to travel through the diamond. The categories include transparent, translucent, and opaque in order of decreasing transparency.

- Fluorescence: Fluorescence was measured as the diamond’s visible blue light response to ultraviolet light (320–400 nm), using the OGI Systems Ltd. ColorGrade F300 rough grading colorimeter.

- Stress: Diamond stress was measured using the I.David Polariscope, recording birefringence as low, moderate, or high, according to the Saskatchewan Research Council’s definitions [22].

- Nitrogen Concentration, Nitrogen Aggregation State, and Diamond Typing: Fourier transform infrared spectroscopy (FTIR) was used to measure nitrogen concentration, nitrogen aggregation state (including the percentage of 1aA and 1aB centers), and diamond type. The Perkin Elmer Spotlight 400 FTIR unit was used to capture the diamond’s infrared spectra, identifying nitrogen-related internal bonds. The nitrogen content was determined by calculating the normalized area under spectral peaks corresponding to A-center (1282 cm−1), B-center (1185 cm−1), and platelet peaks (1358–1380 cm−1) based on established absorption coefficients. Nitrogen defects associated with N3, N2, and NV centers were not measured, as they do not contribute to A-band luminescence.

2.3. X-Ray Transmission Tests

- -

- The average high-intensity value (x);

- -

- Average low-intensity value (y);

- -

- Number of pixels.

2.4. X-Ray Luminescence Tests

- -

- Luminescence intensity;

- -

- Total fast center luminescence intensity;

- -

- Total slow center luminescence intensity;

- -

- Fast center decay time;

- -

- Slow center decay time.

2.5. Statistical Diamond Sample Set Analysis

- -

- Weight;

- -

- Size;

- -

- Fluorescence;

- -

- Nitrogen concentration;

- -

- The percentage of 1aA centers.

- -

- Color;

- -

- Shape;

- -

- Clarity;

- -

- Transparency;

- -

- Stress;

- -

- Diamond typing.

3. Results and Discussion

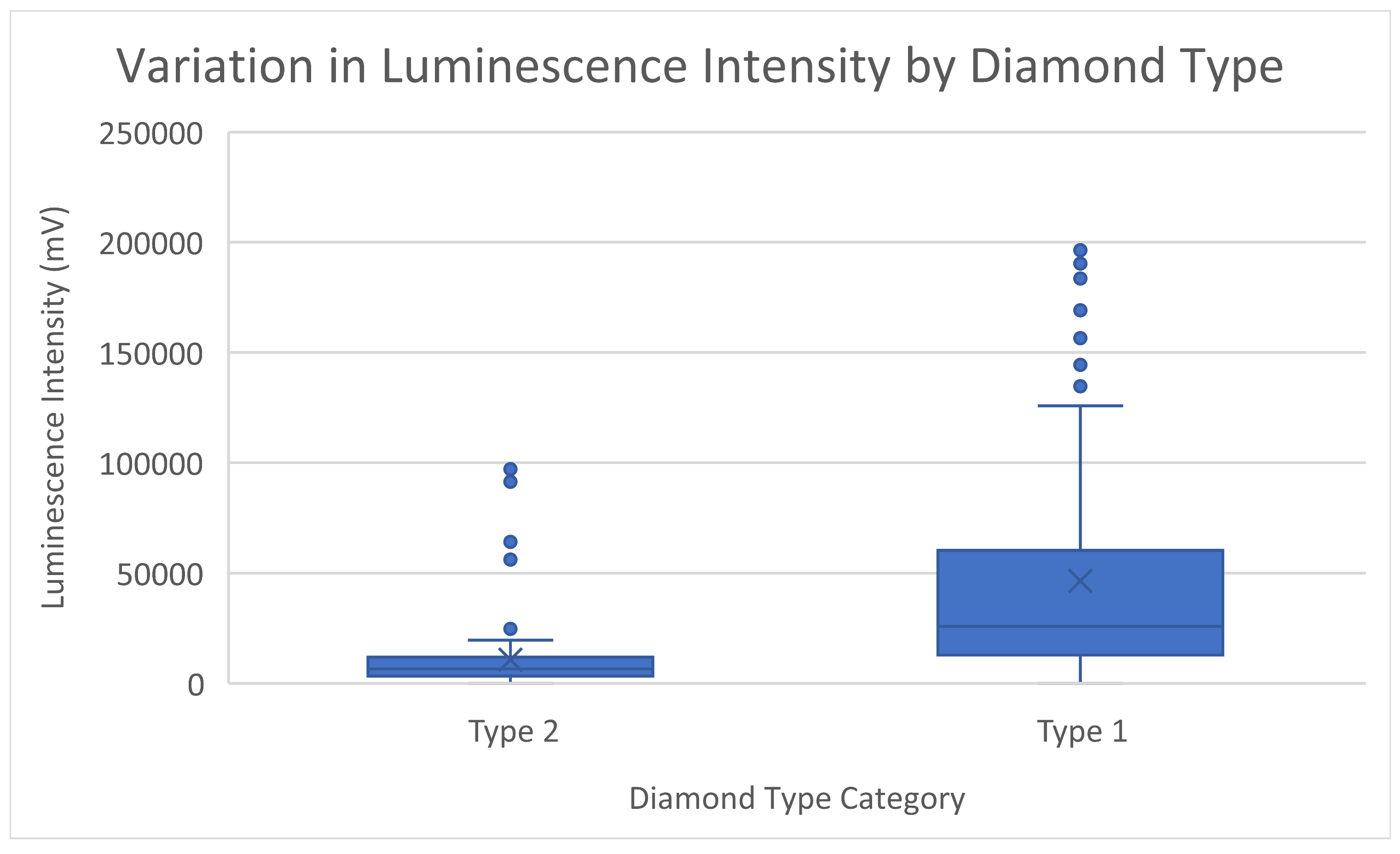

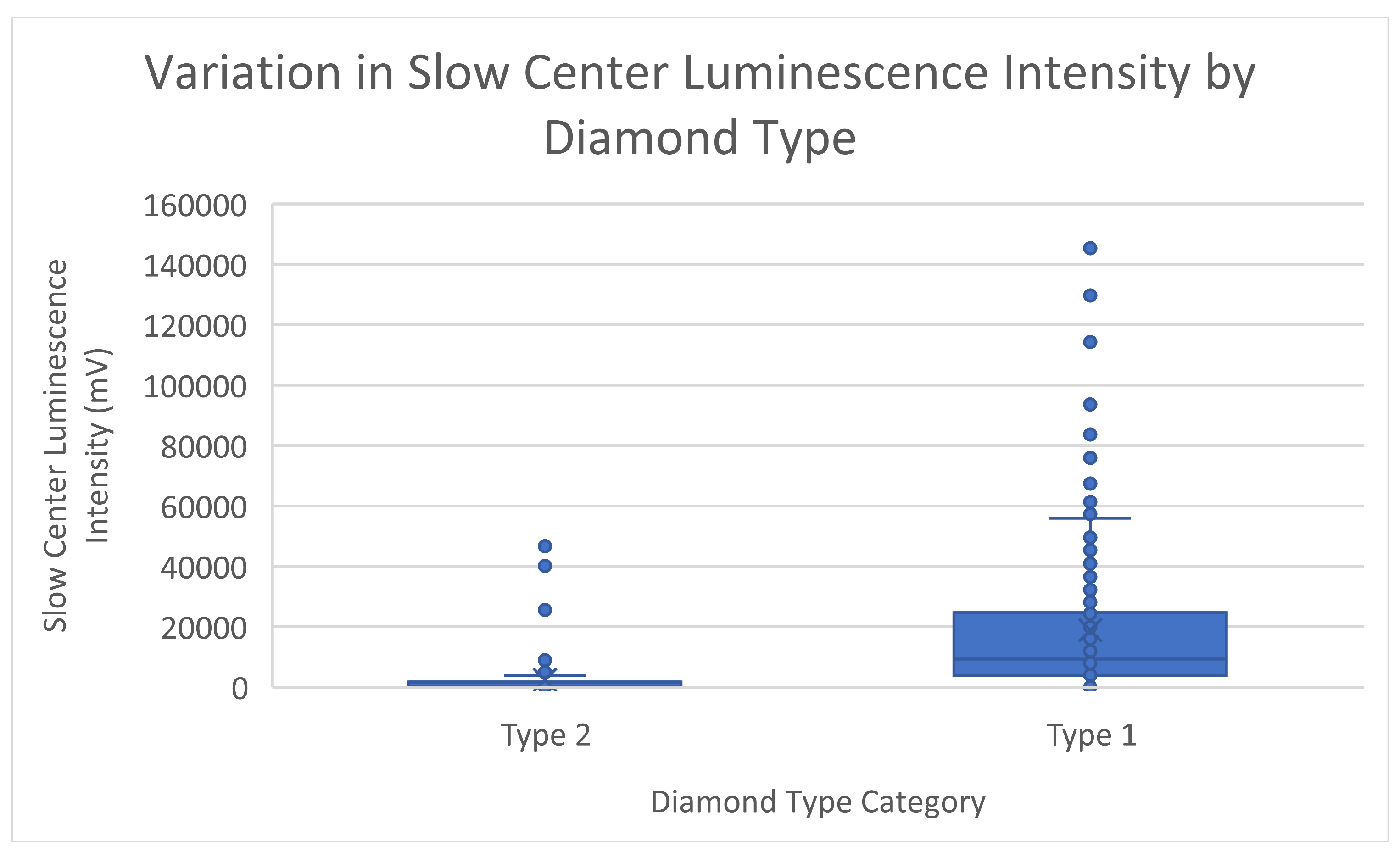

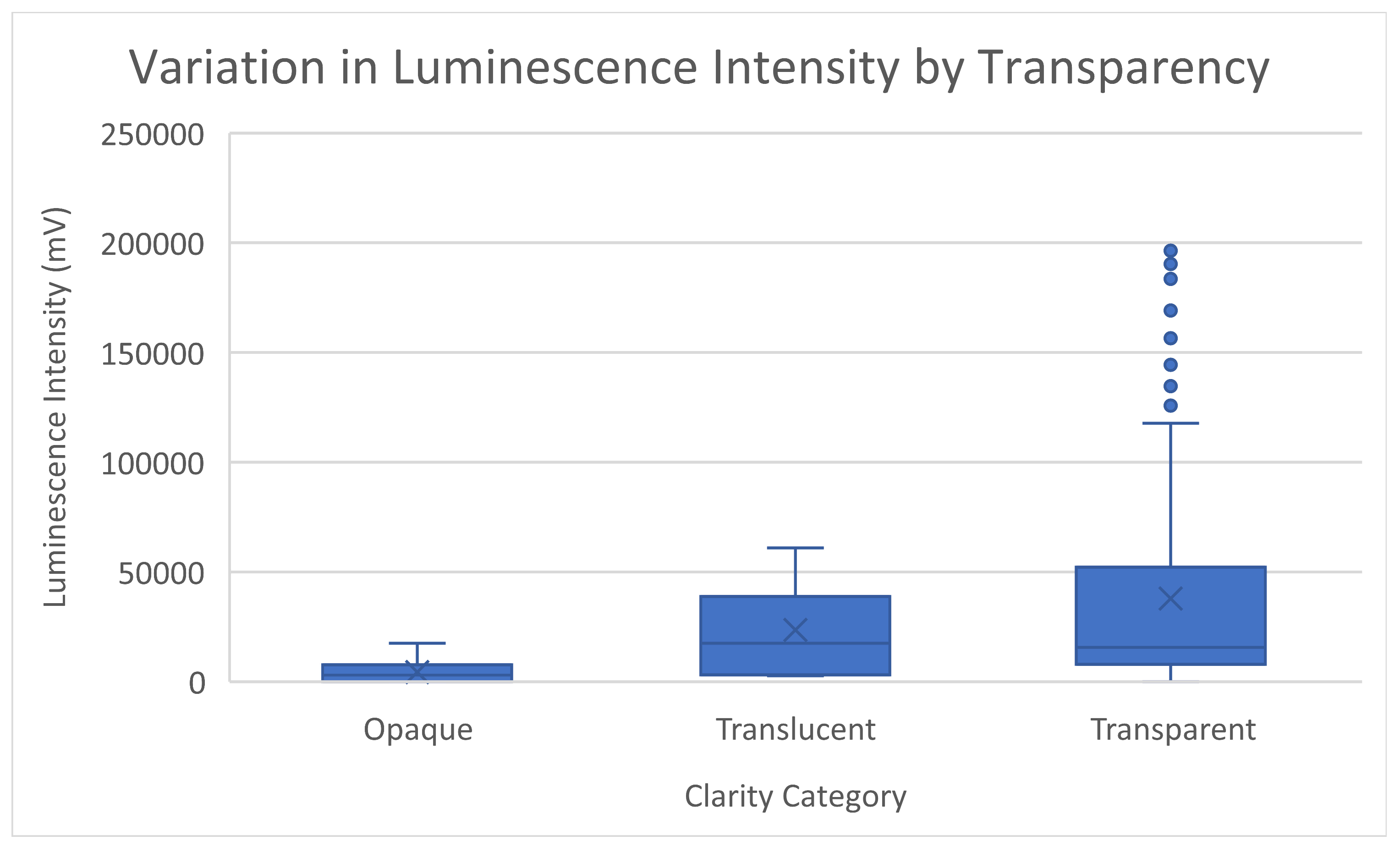

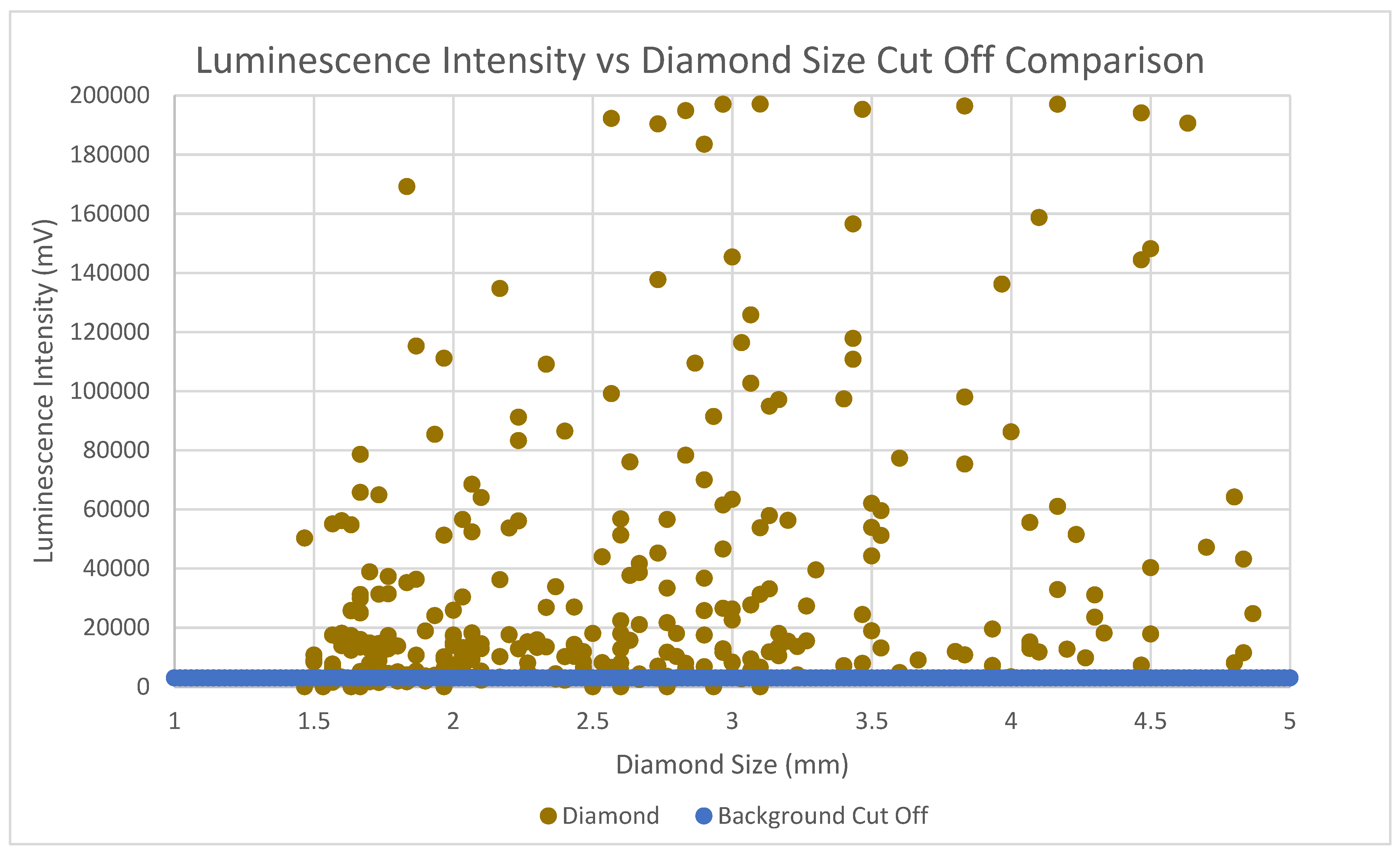

3.1. XRL Diamond Response

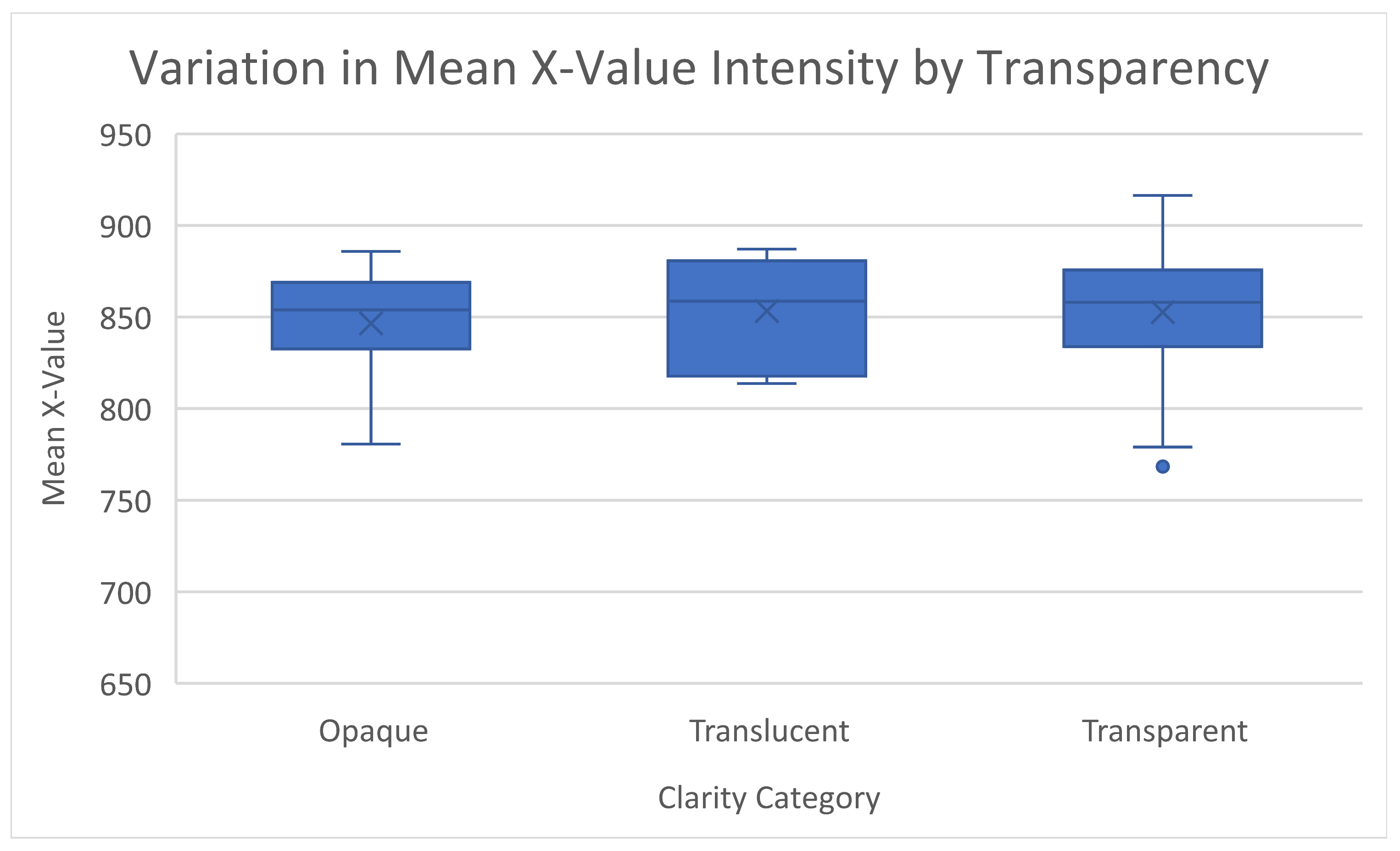

3.2. XRT Diamond Response

3.3. Diamond and Gangue XRL Response Comparison

3.4. Diamond and Gangue XRT Response Comparison

3.5. Sorter Performance Comparison

4. Conclusions

- ▪

- Sensor-based sorting technology using XRT is a feasible alternative to XRL for diamond recovery within the 2–4 mm size range. Although XRT is unsuitable for wet conditions in this size range, it demonstrates significant advantages, including high consistency, greater control, and increased flexibility in adjustments.

- ▪

- The impact of diamond characteristics on XRT and XRL responses emphasizes the importance of application-specific considerations when selecting a sorting technology. XRL sorting is vulnerable to variations in diamond clarity, transparency, and nitrogen content, potentially leading to inconsistent and unpredictable detection outcomes. In contrast, XRT technology provides more reliable and predictable detection, resulting in superior diamond recovery rates. However, XRT may be susceptible to greater gangue mineral misclassification.

- ▪

- A comparative evaluation of sorting performance within a single diamond deposit revealed that XRT technology recovered a higher proportion of diamonds compared to XRL—99% versus 91%. Additionally, the concentrate produced by XRT contained less gangue material, a result attributed to the differences in the specific ejection mechanisms employed by each unit. The XRT concentrate contained 3.45% diamonds versus 2.63% of the XRL concentrate. Consequently, the choice between XRT and XRL technologies should be guided by a thorough assessment of ore body geology, mineral constituents, and diamond characteristics, as these factors collectively determine the contrast between diamonds and the surrounding ore—a critical factor in the effectiveness of the sorting technology for any given application.

- ▪

- The authors recommend that research building upon this study should focus on assessing additional crystal lattice defects in future research. These defects should be evaluated with XRL response using the methodology established in this study. Furthermore, it is recommended to evaluate the responses of additional gangue minerals, such as zircons, to the XRL and XRT response.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wotruba, H. Sensor Sorting Technology—Is the Minerals Industry Missing a Chance? 2015. Available online: https://www.semanticscholar.org/paper/Sensor-sorting-technology-is-the-minerals-industry-Wotrnba/a5077e93683462c42c74f602fcba3d85df385d82 (accessed on 4 January 2024).

- Wotruba, H.; Robben, C. Sensor-based ore sorting in 2020. At-Automatisierungstechnik 2020, 68, 231–238. [Google Scholar] [CrossRef]

- Loftus, W.K.B.; Simpson, H.S.; King, M.J. Recovery Plant Practice at DeBeers Consolidated; The Southern African Institute of Mining and Metallurgy: Johannesburg, South Africa, 1970; Available online: https://pdf4pro.com/view/recovery-plant-practice-atdebeers-consolidated-2a191a.html (accessed on 20 December 2023).

- Robben, C.; Wotruba, H. Sensor-Based Ore Sorting Technology in Mining—Past, Present and Future. Minerals 2019, 9, 523. [Google Scholar] [CrossRef]

- Robben, C. Characteristics of Sensor-Based Sorting Technology and Implementation in Mining; Rheinisch-Westfälische Technische Hochschule: Aachen, Germany, 2013. [Google Scholar]

- Mironov, V.P.; Emelyanova, A.S.; Shabalin, S.A.; Bubyr, E.V.; Kazakov, L.V.; Martynovich, E.F. X-ray luminescence in diamonds and its application in industry. AIP Conf. Proc. 2021, 2392, 020010. [Google Scholar] [CrossRef]

- Raman, C.V.; Jayaraman, A. The luminescence of diamond and its relation to crystal structure. Proc. Indian Acad. Sci. Sect. A 1950, 32, 65. [Google Scholar] [CrossRef]

- Dean, P.J. Bound Excitons and Donor-Acceptor Pairs in Natural and Synthetic Diamond. Phys. Rev. B 1965, 139, A588–A602. [Google Scholar] [CrossRef]

- Gaft, M.; Reisfeld, R.; Panczer, G. Modern Luminescence Spectroscopy of Minerals and Materials; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar] [CrossRef]

- Lang, A.R.; Field, J.E. Internal Structure. In The Properties of Diamond; Academic Press: Cambridge, MA, USA, 1979; pp. 425–469. [Google Scholar]

- Zaitsev, A.M. Optical Properties of Diamond; Springer: Berlin/Heidelberg, Germany, 2001. [Google Scholar] [CrossRef]

- Chappell, M. Transmission—X-rays. In Principles of Medical Imaging for Engineers: From Signals to Images; Springer: Berlin/Heidelberg, Germany, 2019; pp. 9–18. [Google Scholar] [CrossRef]

- Rutherford, R.A.; Pullan, B.R.; Isherwood, I. X-ray energies for effective atomic number determination. Neuroradiology 1976, 11, 23–28. [Google Scholar] [CrossRef] [PubMed]

- Zabinsky, S.I.; Rehr, J.J.; Ankudinov, A.; Albers, R.C.; Eller, M.J. Multiple-scattering calculations of x-ray-absorption spectra. Phys. Rev. B Condens. Matter. 1995, 52, 2995–3009. [Google Scholar] [CrossRef] [PubMed]

- Veras, M.M.; Young, A.S.; Born, C.R.; Szewczuk, A.; Neto, A.C.B.; Petter, C.O.; Sampaio, C.H. Affinity of dual energy X-ray transmission sensors on minerals bearing heavy rare earth elements. Miner. Eng. 2020, 147, 106151. [Google Scholar] [CrossRef]

- Riedel, F.; Dehler, M. Recovery of unliberated diamonds by x-ray transmission sorting. In Proceedings of the Diamonds Source to Use Conference, SAIMM, Gaborone, Botswana, 1–3 March 2010. [Google Scholar]

- Neubert, K.; Wotruba, H. Investigations on the Detectability of Rare-Earth Minerals Using Dual-Energy X-ray Transmission Sorting. J. Sustain. Met. 2016, 3, 3–12. [Google Scholar] [CrossRef]

- Zhang, Y.; Yoon, N.; Holuszko, M.E. Assessment of Sortability Using a Dual-Energy X-ray Transmission System for Studied Sulphide Ore. Minerals 2021, 11, 490. [Google Scholar] [CrossRef]

- Sasman, F.; Deetlefs, B.; van der Westhuyzen, P. Application of diamond size frequency distribution and XRT technology at a large diamond producer. J. South. Afr. Inst. Min. Met. 2018, 118, 1–6. [Google Scholar] [CrossRef]

- Star–Orion South Diamond Project, Significant Proportions of Type IIa Diamonds Present at Star and Orion South. Star Diamonds. 4 March 2019. Available online: www.stardiamondcorp.com (accessed on 7 January 2024).

- GIA. GIA 4Cs Color D-to-Z. 2023. Available online: https://4cs.gia.edu/en-us/diamond-color/ (accessed on 5 January 2024).

- Saskatchewan Research Council. Rough Diamond Descriptions; An internal resource of the Saskatchewan Research Council (SRC); Saskatchewan Research Council: Saskatoon, SK, Canada, 2023. [Google Scholar]

- Dean, P.; Male, J. Some properties of the visible luminescence excited in diamond by irradiation in the fundamental absorption edge. J. Phys. Chem. Solids 1964, 25, 1369–1383. [Google Scholar] [CrossRef]

- Vladimirov, E. X-Ray Luminescence Sorters: A Series of Lectures; Bourevestnik: Saint-Petersburg, Russia, 2012. [Google Scholar]

- Breeding, C.M.; Shigley, J.E. The “Type” Classification System of Diamonds and Its Importance in Gemology. Gems Gemol. 2009, 45, 96–111. [Google Scholar] [CrossRef]

- Hastie, T.; Tibshirani, R.; Friedman, J. The Elements of Statistical Learning; Springer Science & Business Media: New York, NY, USA, 2009. [Google Scholar]

- Hosmer, D.W.; Jovanovic, B.; Lemeshow, S. Best Subsets Logistic Regression. Biometrics 1989, 45, 1265–1270. [Google Scholar] [CrossRef]

- King, J.E. Running a Best-Subsets Logistic Regression: An Alternative to Stepwise Methods. Educ. Psychol. Meas. 2003, 63, 392–403. [Google Scholar] [CrossRef]

- Pennsylvania State University. Best Subsets Regression, Adjusted R-Sq, Mallows Cp. 2018. Available online: https://online.stat.psu.edu/stat462/node/197/ (accessed on 8 October 2023).

- Vyatkin, S.V.; Kriulina, G.Y.; Garanin, V.K.; Koshchug, D.G.; Vasilyev, E.A. The Effect of Aggregation of Impurity Nitrogen on Diamond X-Ray Luminescence. Mosc. Univ. Geol. Bull. 2018, 73, 161–165. [Google Scholar] [CrossRef]

| Luminescence Intensity | Fast Center Luminescence Intensity | Fast Center Decay Time | Slow Center Luminescence Intensity | Slow Center Decay Time | |

|---|---|---|---|---|---|

| Fluorescence | X | X | X | X | X |

| Weight | — | — | X | — | — |

| X Dimension Measurement (mm) | — | — | — | — | — |

| Y Dimension Measurement (mm) | X | X | — | X | — |

| Z Dimension Measurement (mm) | — | — | — | — | — |

| Percentage of 1aA Centers | X | X | X | X | X |

| Nitrogen Content (ppm) | — | — | X | — | X |

| Adj R2% | 41.50 | 33.57 | 36.19 | 47.71 | 22.41 |

| Average Low-Intensity Value | Average High-Intensity Value | Standard Deviation of the Low-Intensity Values | Standard Deviation of the High-Intensity Values | Number of Pixels | |

|---|---|---|---|---|---|

| Fluorescence | — | — | — | — | — |

| Weight | X | X | X | X | X |

| X Dimension Measurement (mm) | — | — | — | — | — |

| Y Dimension Measurement (mm) | — | — | — | — | — |

| Z Dimension Measurement (mm) | X | X | X | X | — |

| Percentage of 1aA Centers | — | — | — | — | — |

| Nitrogen Content (ppm) | — | — | — | — | — |

| Adj R2% | 87.42 | 88.23 | 87.05 | 86.11 | 96.27 |

| Type 1 | Type 2 | |

|---|---|---|

| Diamond Count | 212 | 88 |

| % Recoverable by XRL | 95% | 77% |

| % of Particles Classified as Diamond Density at a Given Threshold | |||||

|---|---|---|---|---|---|

| Material | Total Number of Particles | 5% Low-Density Pixels | 10% Low-Density Pixels | 20% Low-Density Pixels | 30% Low-Density Pixels |

| Kimberlite | 21 | 0% | 0% | 0% | 0% |

| Mudstone | 23 | 19% | 0% | 0% | 0% |

| Serpentinised Olivine | 32 | 13% | 3% | 0% | 0% |

| Ilmenite | 29 | 90% | 66% | 3% | 0% |

| Garnets | 30 | 0% | 0% | 0% | 0% |

| Clinopyroxenes | 24 | 0% | 0% | 0% | 0% |

| Mica Schist | 18 | 0% | 0% | 0% | 0% |

| Mica Flakes | 23 * | 0% | 0% | 0% | 0% |

| kg of Concentrate Created Per g of Diamonds Separated | g of Material Separated per Fire of the Separation | % of Incidental Separations | # of Fires of the Separation Mechanism per Diamond | Diamond Recovery | |

|---|---|---|---|---|---|

| XRL | 0.37 | 0.87 | 85% | 7 | 91% |

| XRT | 0.28 | 0.52 | 92% | 13 | 99% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lang, Z.; Alam, S.; Hunt, L.; Di Feo, A.; Robben, C.; Kinakin, Y.; Tjossem, R. Comparative Evaluation of X-Ray Transmission and X-Ray Luminescence Sorting Technologies for Fine Diamond Recovery. Minerals 2025, 15, 773. https://doi.org/10.3390/min15080773

Lang Z, Alam S, Hunt L, Di Feo A, Robben C, Kinakin Y, Tjossem R. Comparative Evaluation of X-Ray Transmission and X-Ray Luminescence Sorting Technologies for Fine Diamond Recovery. Minerals. 2025; 15(8):773. https://doi.org/10.3390/min15080773

Chicago/Turabian StyleLang, Zachary, Shafiq Alam, Lucy Hunt, Antonio Di Feo, Chris Robben, Yuri Kinakin, and Russell Tjossem. 2025. "Comparative Evaluation of X-Ray Transmission and X-Ray Luminescence Sorting Technologies for Fine Diamond Recovery" Minerals 15, no. 8: 773. https://doi.org/10.3390/min15080773

APA StyleLang, Z., Alam, S., Hunt, L., Di Feo, A., Robben, C., Kinakin, Y., & Tjossem, R. (2025). Comparative Evaluation of X-Ray Transmission and X-Ray Luminescence Sorting Technologies for Fine Diamond Recovery. Minerals, 15(8), 773. https://doi.org/10.3390/min15080773