Modeling and Analyzing Air Supply Control to Optimize Thermal Pattern in Iron-Ore-Sintering Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Description of Sintering Process

2.2. Numerical Simulation Model of Sintering

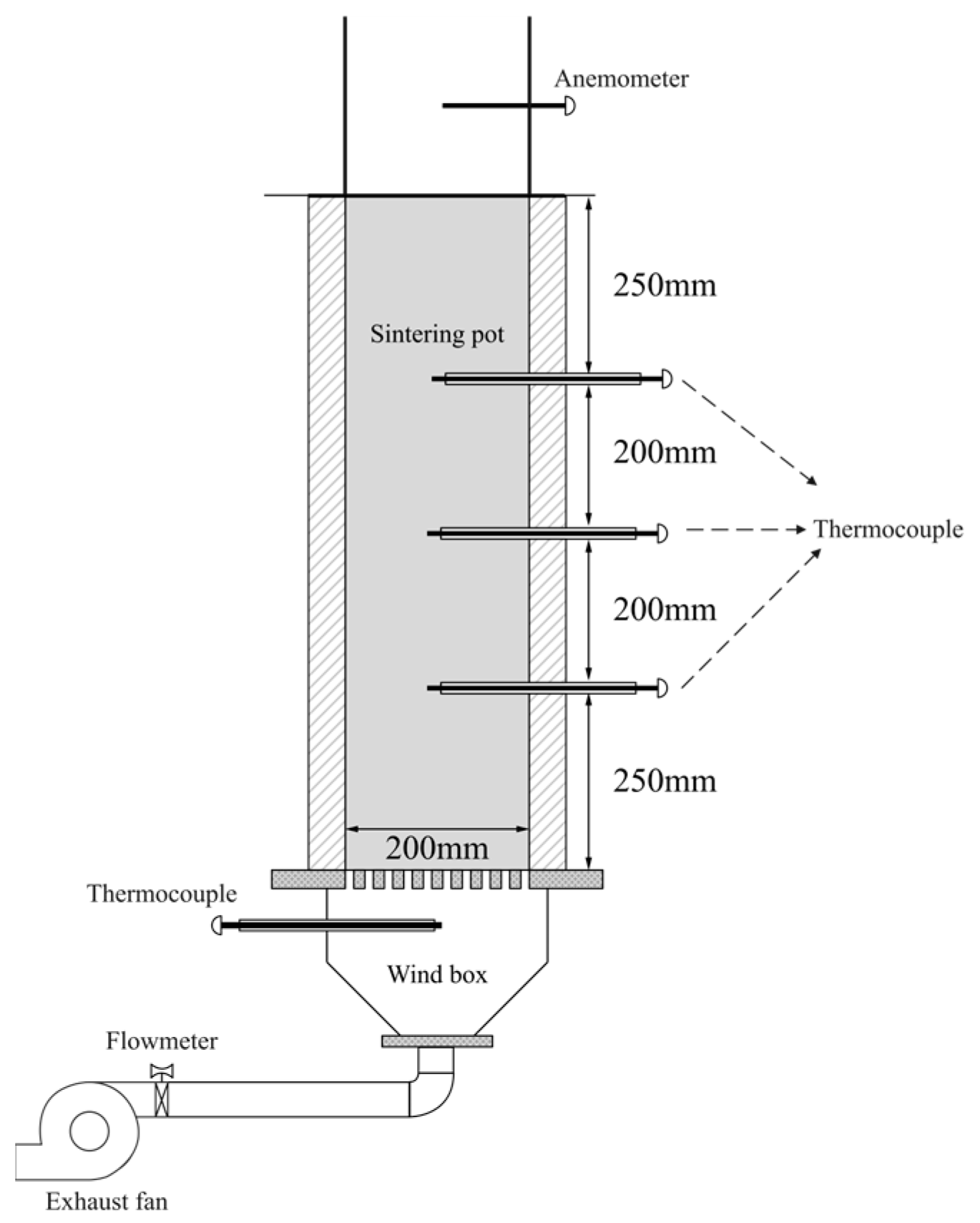

2.3. Experimental Setup

3. Results

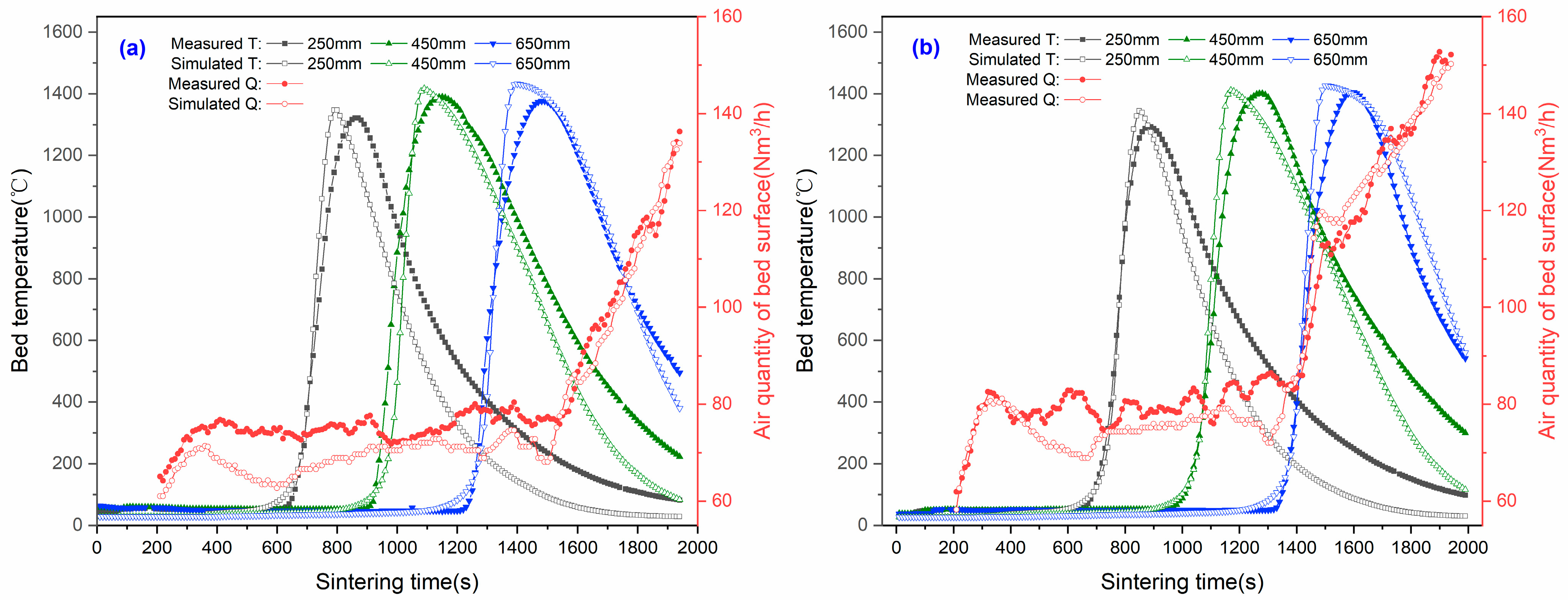

3.1. Model Validation

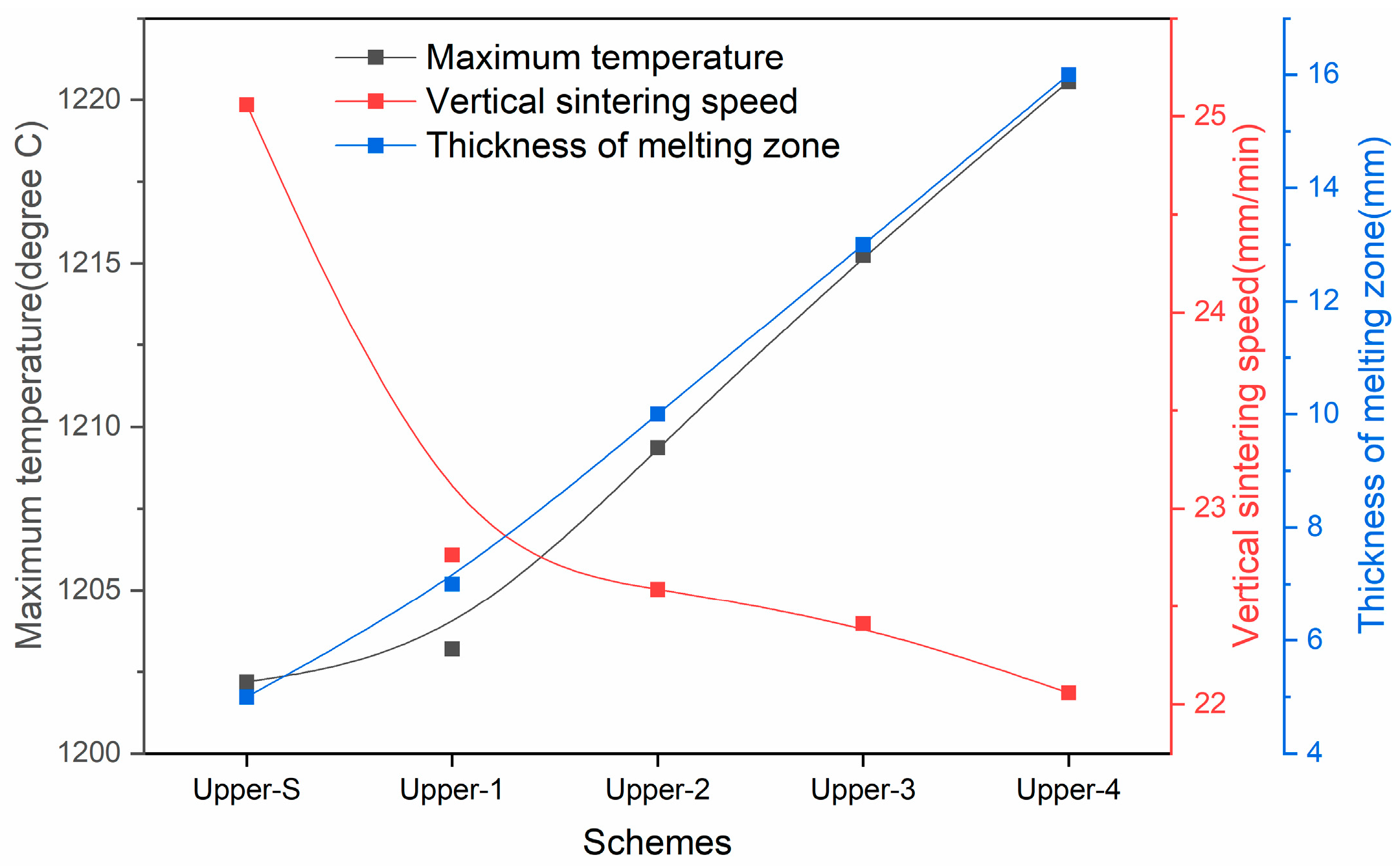

3.2. Effect of Air Supply on the Thermal State of Upper Layer

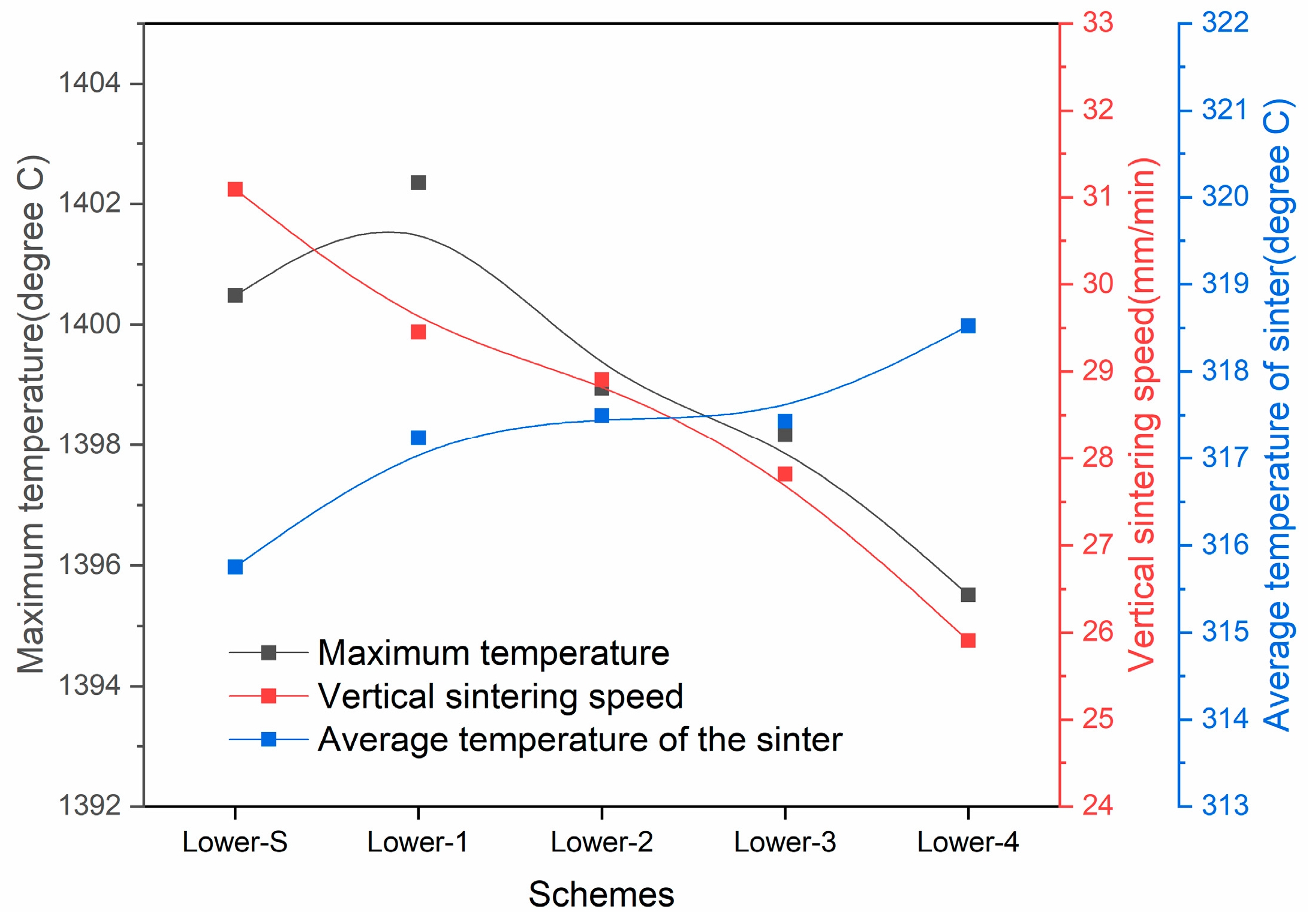

3.3. Effect of Air Supply on the Thermal State of the Lower Layer

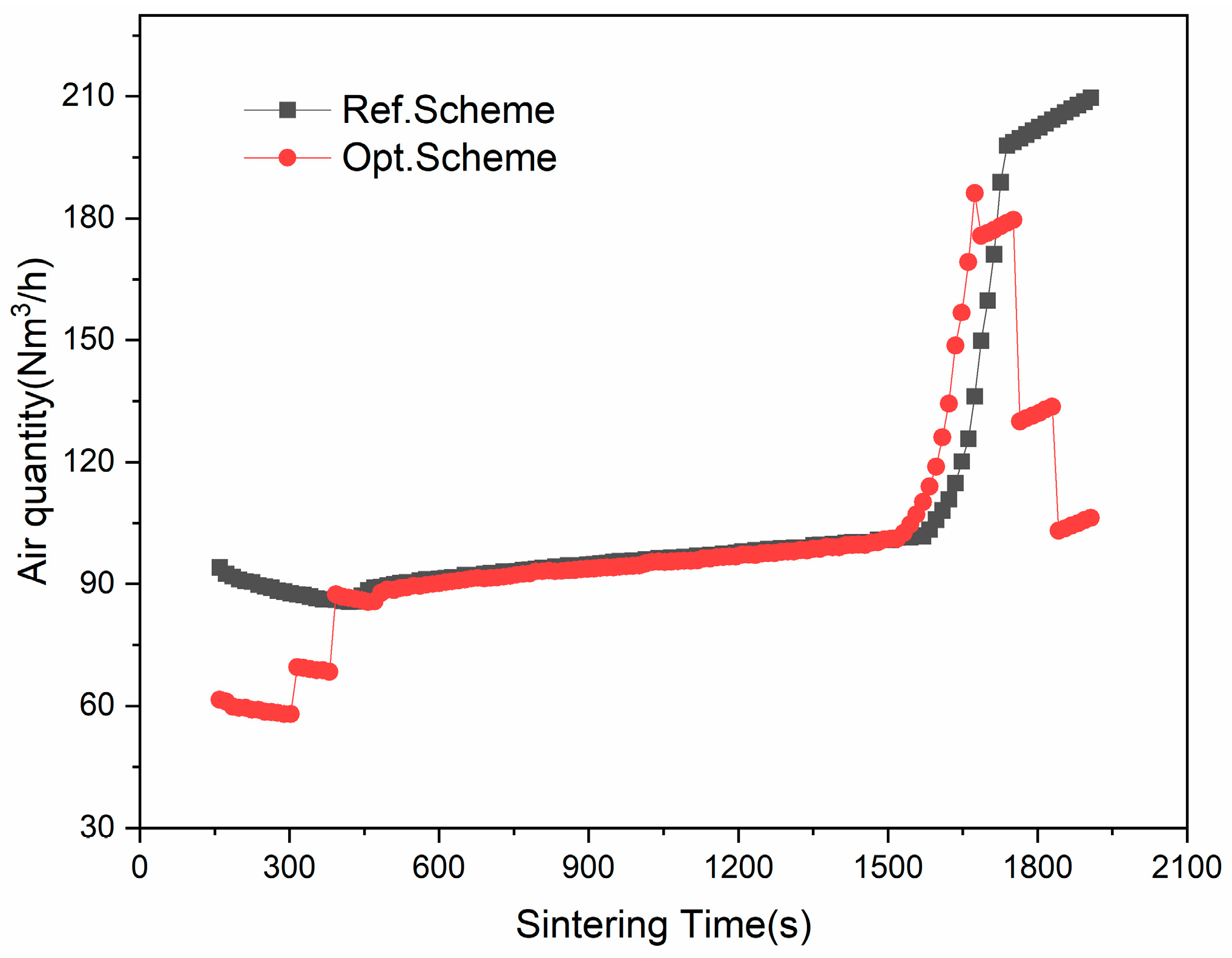

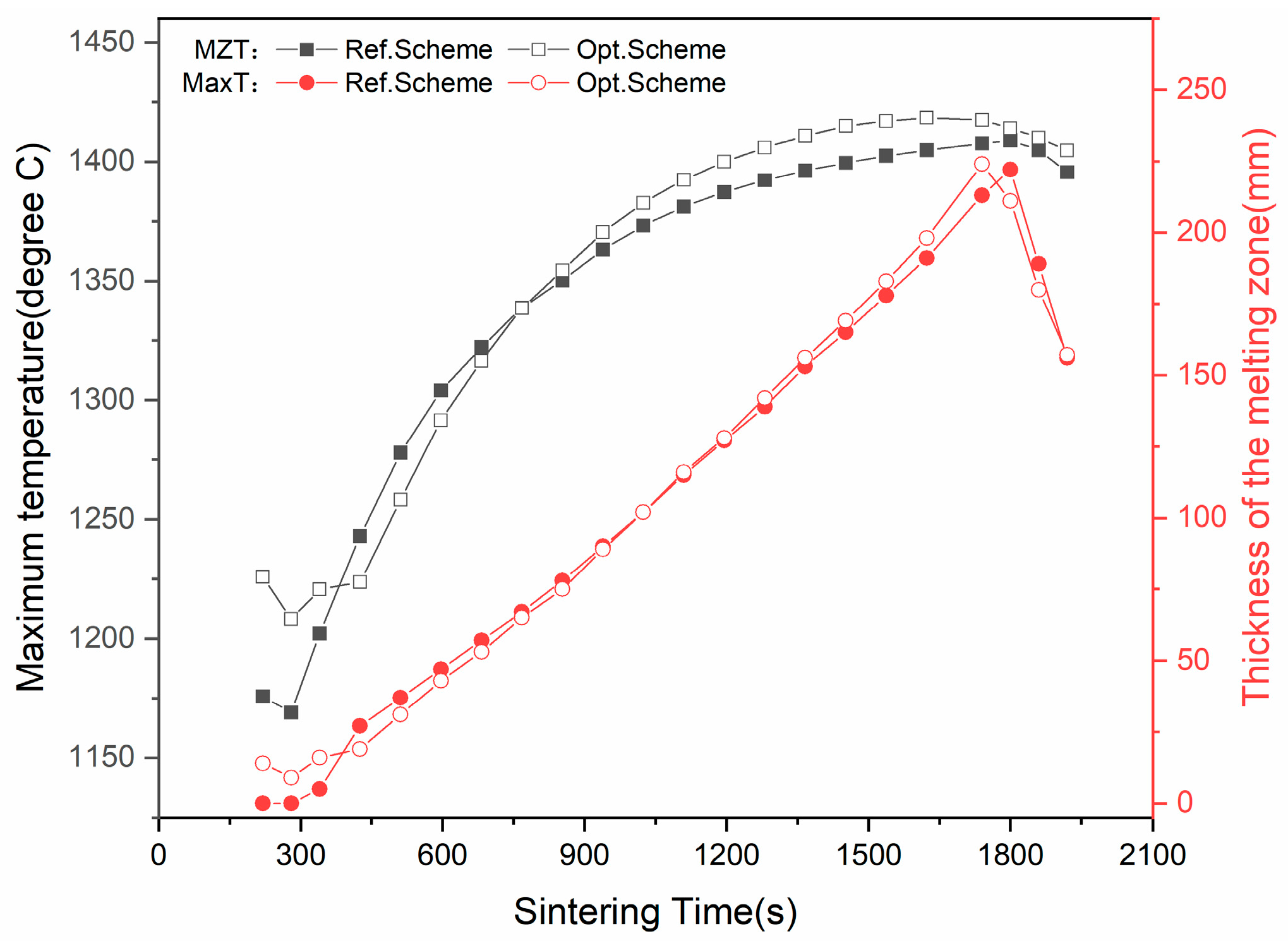

3.4. Optimization of Air Supply Distribution

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fan, X.; Zhao, Y.; Ji, Z.; Li, H.; Gan, M.; Zhou, H.; Chen, X.; Huang, X. New understanding about the relationship between surface ignition and low-carbon iron ore sintering performance. Process Saf. Environ. 2021, 146, 267–275. [Google Scholar] [CrossRef]

- Qie, J.; Zhang, C.; Guo, Y.; Wang, H.; Wu, S. Reducing the sintering flue gas pollutants emissions based on the accumulation heat effect in iron ore sintering process. Trans. Indian Inst. Met. 2019, 72, 581–589. [Google Scholar] [CrossRef]

- Huang, Z.; Jiang, Y.; Mao, X.; Xu, B.; Guo, Y.; Jiang, T. Fuel appropriate distribution in iron ore sintering. J. Cent. South Univ. 2006, 37, 884–890. [Google Scholar]

- Dai, F.; Fan, X.; Huang, X.; Chen, X.; Gan, M.; Ji, Z.; Sun, Z. Fuel-Appropriate Distribution of the Material Layer Based on Numerical Model of Sintering with Particle Swarm Optimization Algorithm. Minerals 2023, 13, 511. [Google Scholar] [CrossRef]

- Li, F.; Zhang, X.; Zhang, J.; Tian, W. Fuel appropriate distribution based on the highest temperature control in iron ore sintering. J. Cent. South Univ. 2015, 46, 386–393. [Google Scholar] [CrossRef]

- Zhang, X.; Feng, P.; Xu, J.; Feng, L.; Qing, S. Numerical research on combining flue gas recirculation sintering and fuel layered distribution sintering in the iron ore sintering process. Energy 2020, 192, 116660. [Google Scholar] [CrossRef]

- Shrestha, S.; Xu, J.; Yu, A.; Zhou, Z. Numerical simulation of fuel layered distribution iron ore sintering technology. Ironmak. Steelmak. 2022, 49, 83–100. [Google Scholar] [CrossRef]

- Huang, X.; Fan, X.; Ji, Z.; Gan, M.; Chen, X.; Zhao, Y.; Jiang, T. Investigation into the characteristics of H2-rich gas injection over iron ore sintering process: Experiment and modelling. Appl. Therm. Eng. 2019, 157, 113709. [Google Scholar] [CrossRef]

- Ni, W.; Li, H.; Shao, L.; Zou, Z. Numerical Simulation on Influence of Coke Oven Gas Injection on Iron Ore Sintering. ISIJ Int. 2020, 60, 662–673. [Google Scholar] [CrossRef]

- Oyama, N.; Iwami, Y.; Yamamoto, T.; Machida, S.; Higuchi, T.; Sato, H.; Sato, M.; Takeda, K.; Watanabe, Y.; Shimizu, M.; et al. Development of secondary-fuel injection technology for energy reduction in the iron ore sintering process. ISIJ Int. 2011, 51, 913. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, J.; Wei, S.; Guo, Z.; Yang, J.; Wang, Q. Optimization of gaseous fuel injection for saving energy consumption and improving imbalance of heat distribution in iron ore sintering. Appl. Energy 2017, 207, 230–242. [Google Scholar] [CrossRef]

- Cheng, Z.; Fu, P.; Guo, Z.; Yang, J.; Wang, Q. CFD prediction of heat/mass transfer in multi-layer sintering process assisted with gaseous fuel injection. Int. Commun. Heat Mass Transf. 2021, 128, 105654. [Google Scholar] [CrossRef]

- Reidetschlger, J.; Stiasny, H.; Htzinger, S.; Aichinger, C.; Fulgencio, A. Siemens VAI sintering selective waste gas recirculation system: Meet the future’s environmental requirements today. Iron Steel Technol. 2010, 7, 54–59. [Google Scholar]

- Fan, X.; Yu, Z.; Gan, M.; Chen, X.; Huang, Y. Flue gas recirculation in iron ore sintering process. Ironmak. Steelmak. 2016, 43, 403–410. [Google Scholar] [CrossRef]

- Wang, G.; Wen, Z.; Lou, G.; Dou, R.; Li, X.; Liu, X.; Su, F. Mathematical modeling and combustion characteristic evaluation of a flue gas recirculation iron ore sintering process. Int. J. Heat Mass Transf. 2016, 97, 964–974. [Google Scholar] [CrossRef]

- Wang, G.; Wen, Z.; Lou, G.; Dou, R.; Li, X.; Liu, X.; Su, F. Mathematical modeling of and parametric studies on flue gas recirculation iron ore sintering. Appl. Therm. Eng. 2016, 102, 648–660. [Google Scholar] [CrossRef]

- Zhao, G.; Wu, D.; Yang, S.; Liu, L.; Yu, W.; Tang, L.; Wu, D. Effect of three-layer carbon distribution on heat and mass transfer processes in iron ore sintering. Iron Steel 2024, 59, 28–38. [Google Scholar] [CrossRef]

- Zhang, X.; Li, X.; Liu, Y. Testing analysis and evaluation about airflow distribution on bed surface of Masteel’s 300m2 sintering. Sinter. Pellet. 2017, 42, 7–11. [Google Scholar]

- Zhou, J.; Zhang, Y.; Huang, S.; Long, H.; Zhang, X.; Yu, Z.; Wang, J.; Qian, L. Experimental study on equitable distribution of air quantity in sintering process. Sinter. Pellet. 2021, 46, 37–42. [Google Scholar]

- Pahlevaninezhad, M.; Emami, M.; Panjepour, M. Identifying major zones of an iron ore sintering bed. Appl. Math. Model. 2016, 40, 8475–8492. [Google Scholar] [CrossRef]

- Feng, J.; Dong, H.; Dong, H. Modification of Ergun’s correlation in vertical tank for sinter waste heat recovery. Powder Technol. 2015, 280, 89–93. [Google Scholar] [CrossRef]

- Hinkley, J.; Waters, A.; Litster, J. An investigation of pre-ignition air flow in ferrous sintering. Int. J. Miner. Process. 1994, 42, 37–52. [Google Scholar] [CrossRef]

- Chen, X.; Wang, X.; Huang, X.; Fan, X.; Gan, M.; Ji, Z.; Luo, W.; Zhao, G.; Tang, L.; Fang, T. Numerical simulation of gas flow field and optimization of air volume distribution for sintering process in iron and steel production. J. Cent. South Univ. 2022, 53, 4217–4225. [Google Scholar] [CrossRef]

- Zheng, F.; Guo, Y.; Xiang, J.; Wang, S.; Yang, L.; Chen, F. Improvement of Iron Ore Sintering Productivity by Redistributing Air Volume during Sintering Process. ISIJ Int. 2022, 62, 74–82. [Google Scholar] [CrossRef]

- Zhang, B.; Zhou, J.; Li, M. Prediction of sinter yield and strength in iron ore sintering process by numerical simulation. Appl. Therm. Eng. 2018, 131, 70–79. [Google Scholar] [CrossRef]

| Reaction Zones | (×108 m−2) | (×103 m−1) |

|---|---|---|

| Condensing zone | 1.61 | 3.39 |

| Drying and preheating zone | 2.71 | 21.54 |

| Reaction zone | 2.02 | 8.63 |

| Melting zone | 1.18 | 0.10 |

| Sinter zone | 0.67 | 1.21 |

| Initial Parameters | Values |

|---|---|

| Bed height/mm | 900 |

| Bed porosity | 0.53 |

| Average particle size/mm | 3.05 |

| Bulk density/kg·m−3 | 1680 |

| Particle shape factor | 0.85 |

| Specific surface area/m2·m−3 | 303 |

| Phase | Pressure /kPa | Temperature /°C | Gas Compositions/% | |||

|---|---|---|---|---|---|---|

| O2 | CO2 | CO | Other | |||

| Ignition | −5/−6 | 1050 | 8.5 | 13.0 | 1.0 | 77.5 |

| Heat preservation | −10/−12 | 500 | 15.0 | 7.5 | 0.8 | 76.7 |

| Sintering | −10/−12 | 27 | 20.9 | 0 | 0 | 79.1 |

| Schemes | Negative Pressure/kPa | Air Supply /Nm3·h−1 | ||

|---|---|---|---|---|

| 1 min | 2 min | 3 min | ||

| Upper-S | −12 | −12 | −12 | 88.79 |

| Upper-1 | −6 | −8 | −10 | 69.65 |

| Upper-2 | −6 | −8 | −8 | 66.20 |

| Upper-3 | −6 | −6 | −8 | 62.61 |

| Upper-4 | −6 | −6 | −6 | 58.92 |

| Schemes | Negative Pressure/kPa | Air Supply /Nm3·h−1 | |||

|---|---|---|---|---|---|

| Stage-1 | Stage-2 | Stage-3 | Stage-4 | ||

| Lower-S | −12 | −12 | −12 | −12 | 168.49 |

| Lower-1 | −12 | −10 | −6 | −4 | 127.81 |

| Lower-2 | −10 | −10 | −8 | −4 | 128.89 |

| Lower-3 | −10 | −8 | −8 | −6 | 129.91 |

| Lower-4 | −8 | −8 | −8 | −8 | 130.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, X.; Li, Z.; Zou, P.; Yuan, J.; Chen, X.; Feng, Z.; Fan, X. Modeling and Analyzing Air Supply Control to Optimize Thermal Pattern in Iron-Ore-Sintering Process. Minerals 2025, 15, 770. https://doi.org/10.3390/min15080770

Huang X, Li Z, Zou P, Yuan J, Chen X, Feng Z, Fan X. Modeling and Analyzing Air Supply Control to Optimize Thermal Pattern in Iron-Ore-Sintering Process. Minerals. 2025; 15(8):770. https://doi.org/10.3390/min15080770

Chicago/Turabian StyleHuang, Xiaoxian, Zongping Li, Pengfei Zou, Jun Yuan, Xuling Chen, Zhenxiang Feng, and Xiaohui Fan. 2025. "Modeling and Analyzing Air Supply Control to Optimize Thermal Pattern in Iron-Ore-Sintering Process" Minerals 15, no. 8: 770. https://doi.org/10.3390/min15080770

APA StyleHuang, X., Li, Z., Zou, P., Yuan, J., Chen, X., Feng, Z., & Fan, X. (2025). Modeling and Analyzing Air Supply Control to Optimize Thermal Pattern in Iron-Ore-Sintering Process. Minerals, 15(8), 770. https://doi.org/10.3390/min15080770