Enrichment Mechanism and Development Technology of Deep Marine Shale Gas near Denudation Area, SW CHINA: Insights from Petrology, Mineralogy and Seismic Interpretation

Abstract

1. Introduction

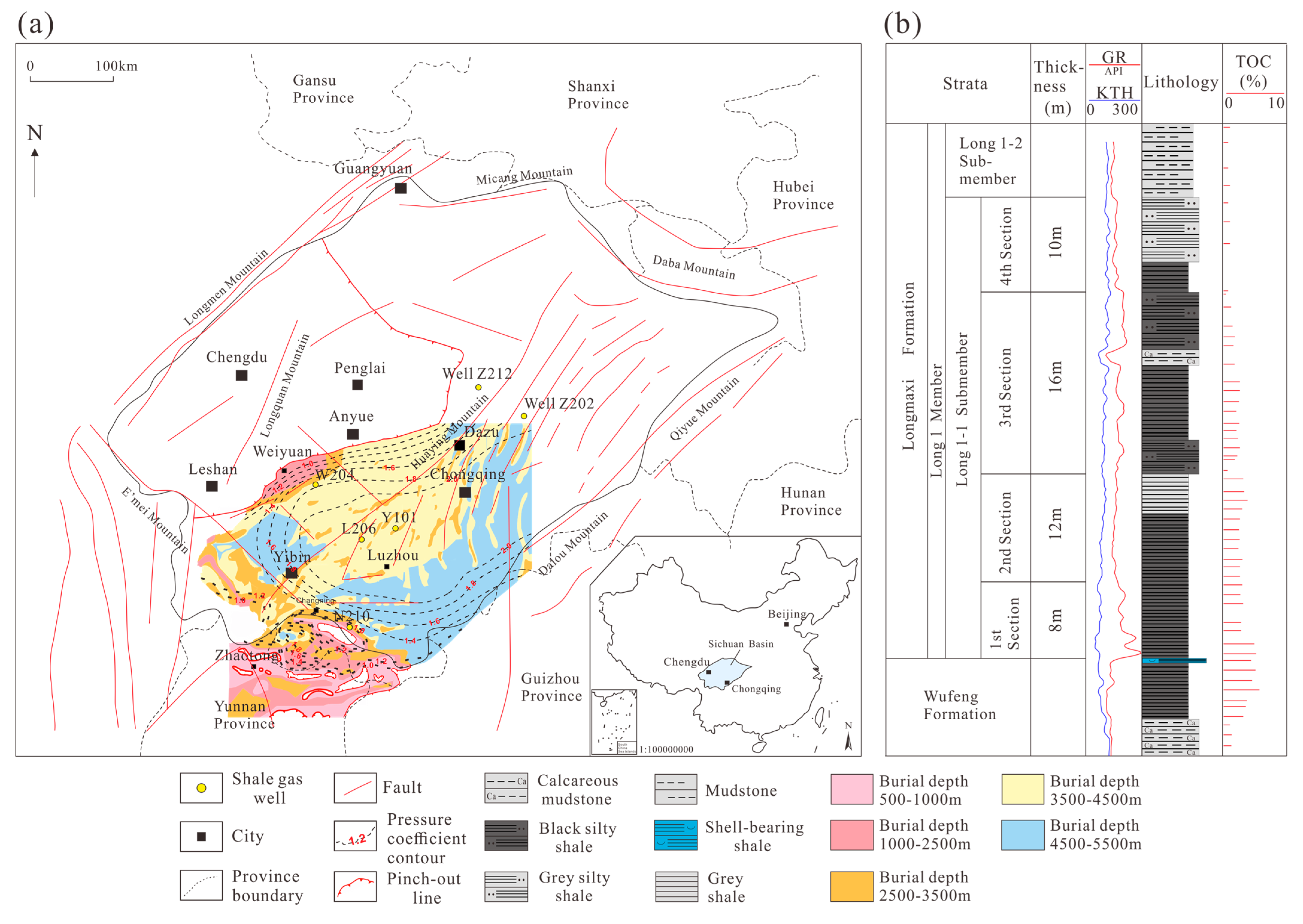

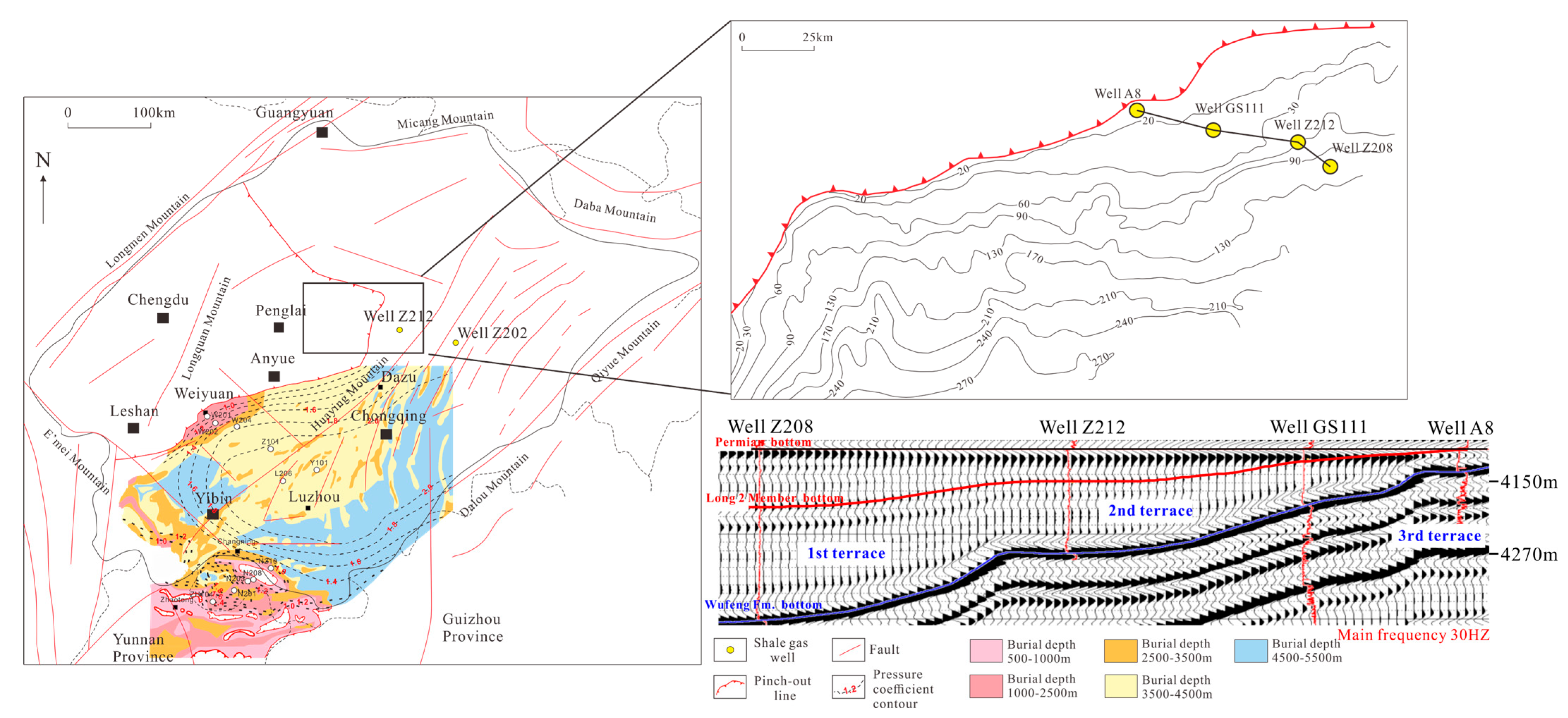

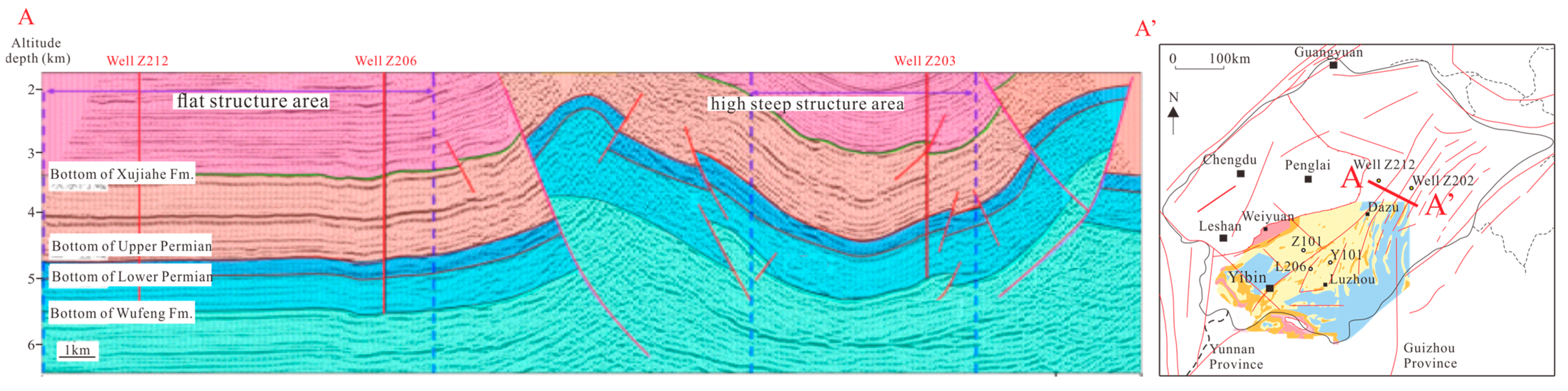

2. Geological Setting

3. Materials and Methods

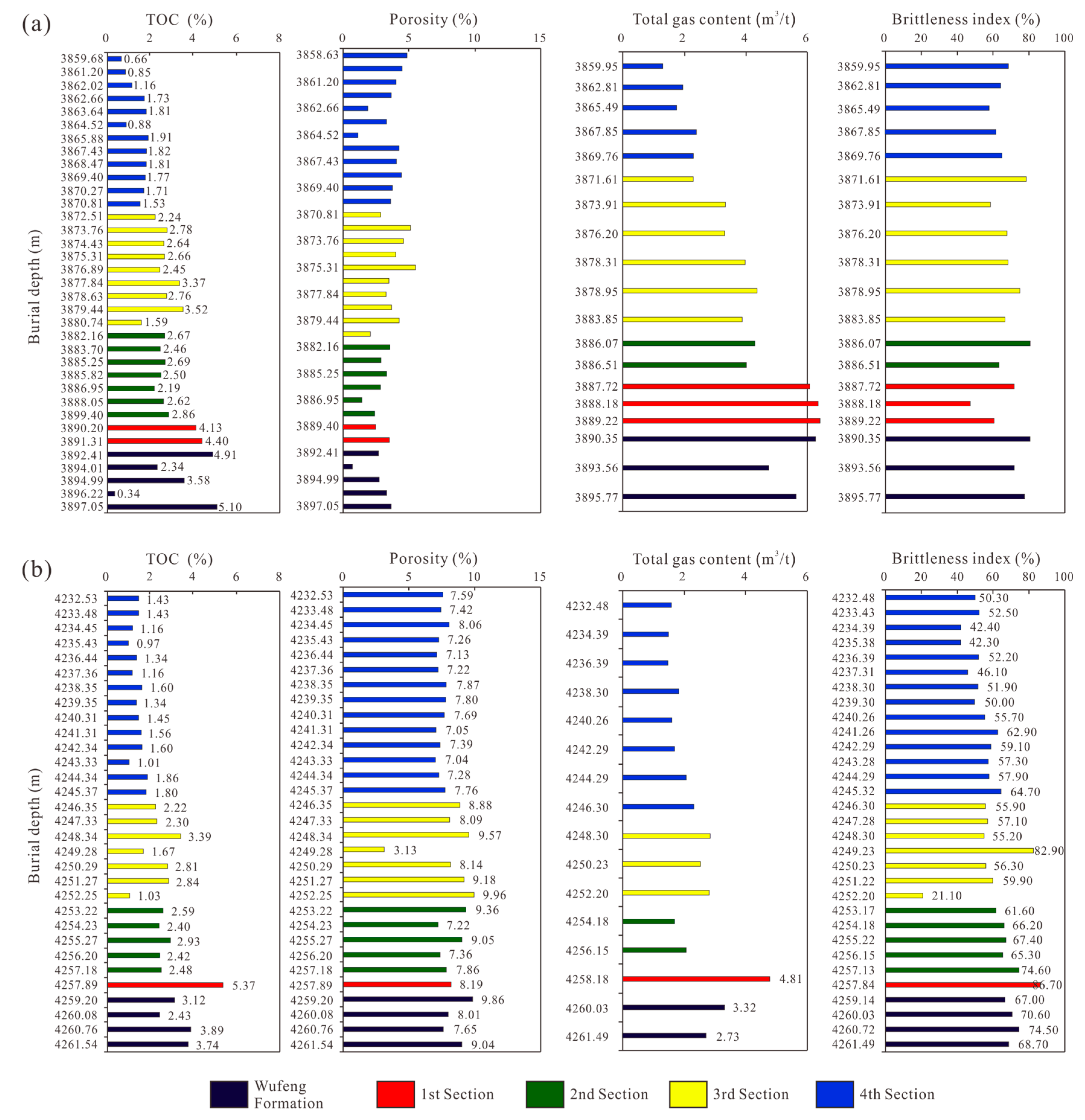

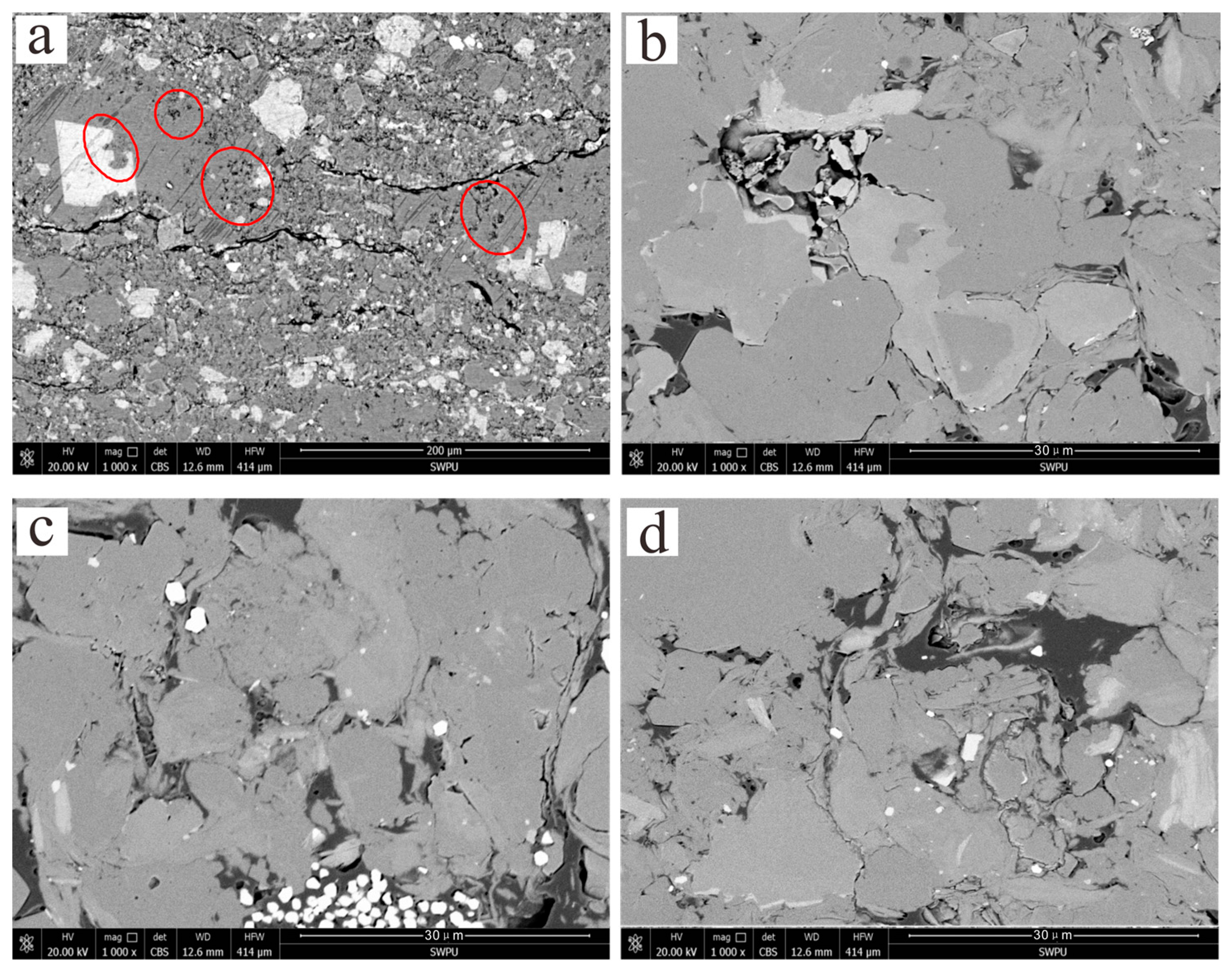

4. Shale Gas Reservoir Characteristics

5. Enrichment Mechanism of Shale Gas

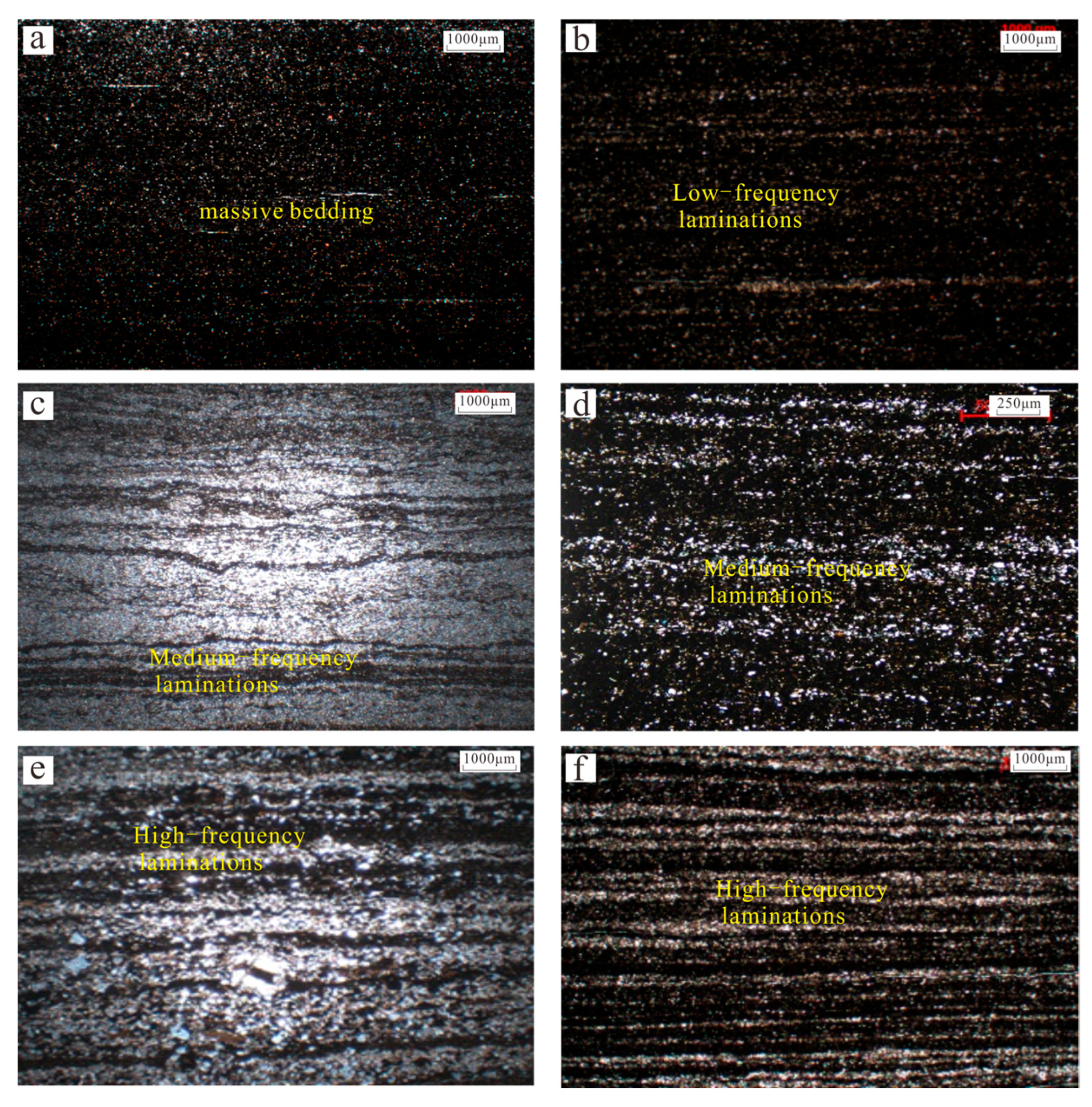

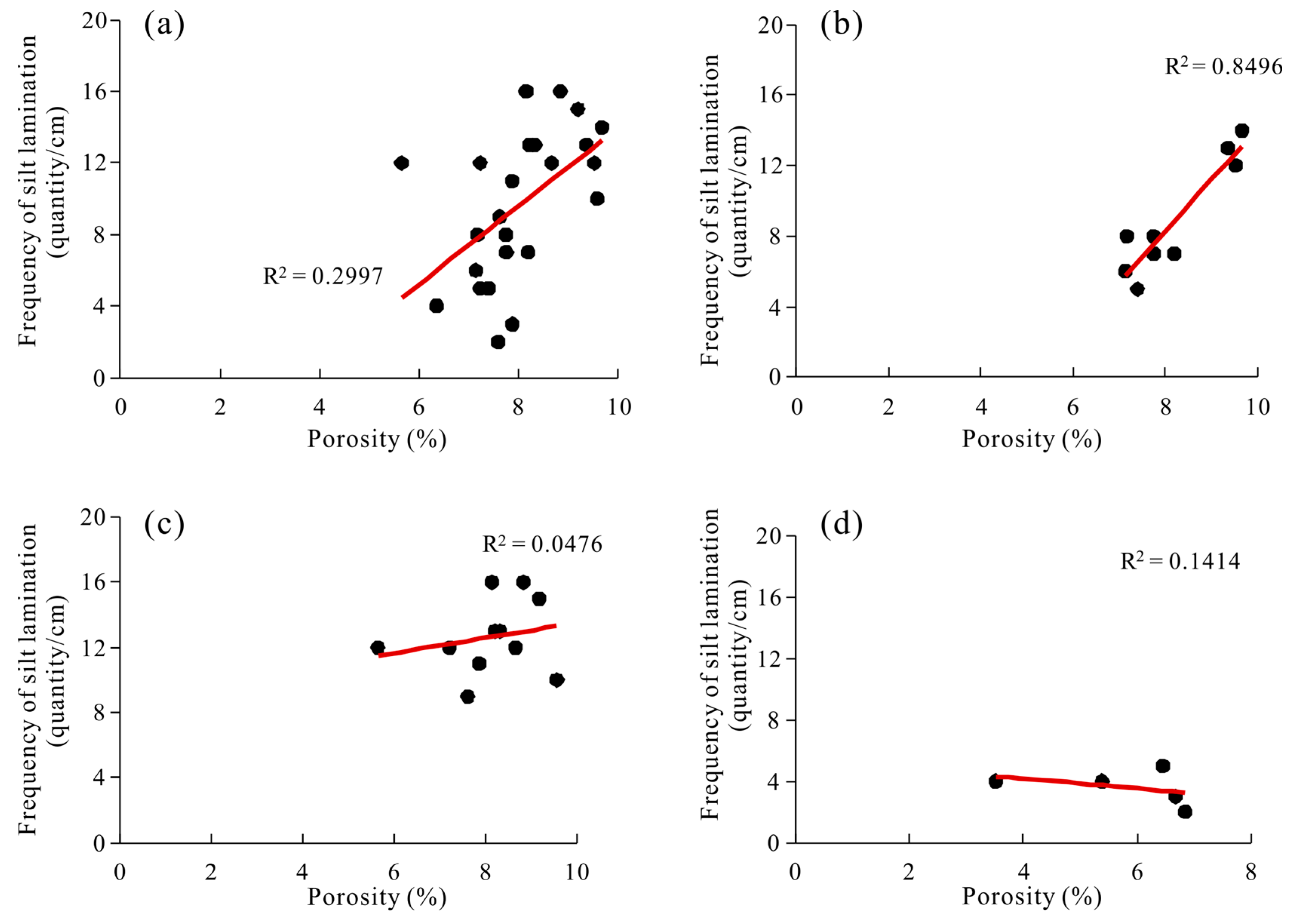

5.1. Controlling Effect of Shale Lamination on Porosity

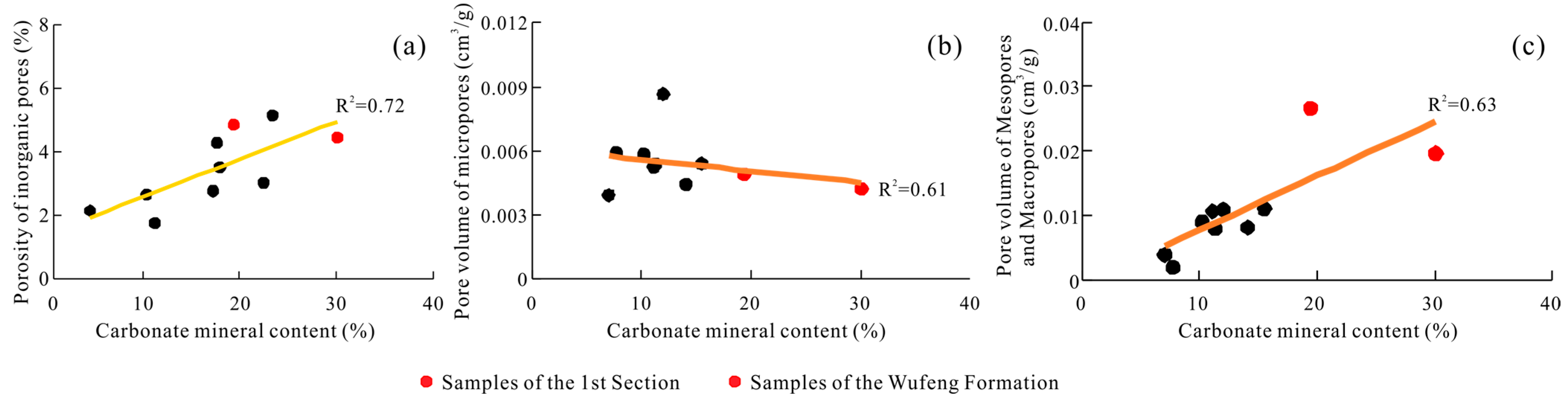

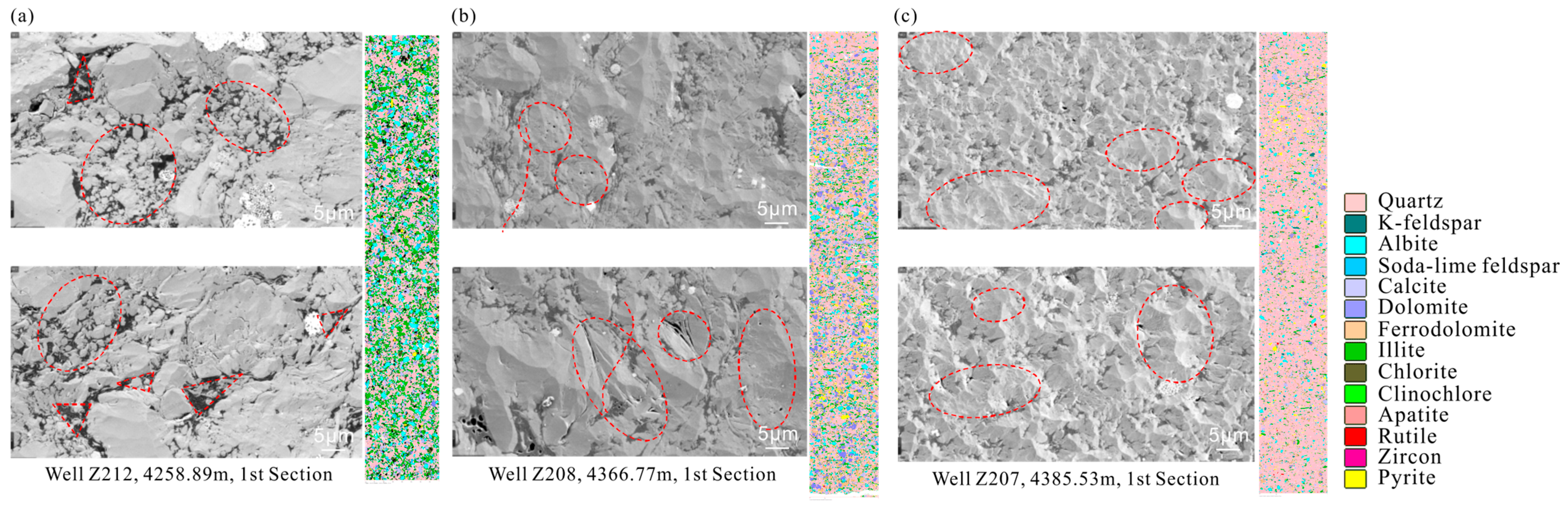

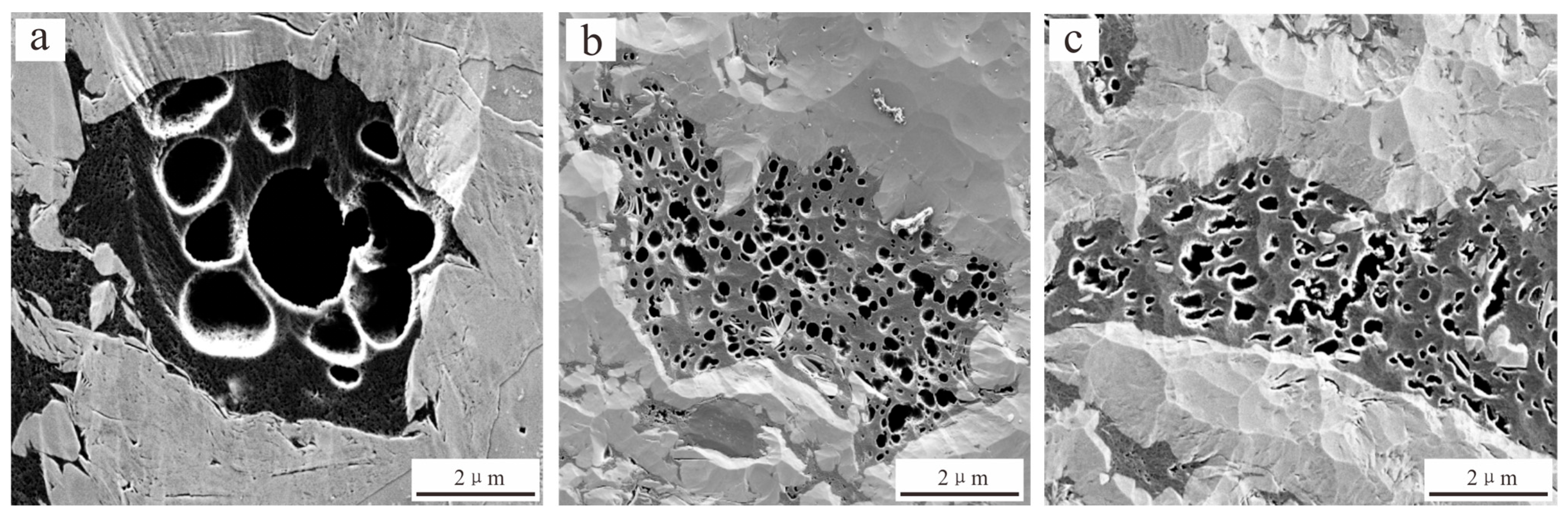

5.2. Controlling Effect of Inorganic Minerals on Porosity

5.3. Controlling Effect of Structural Preservation

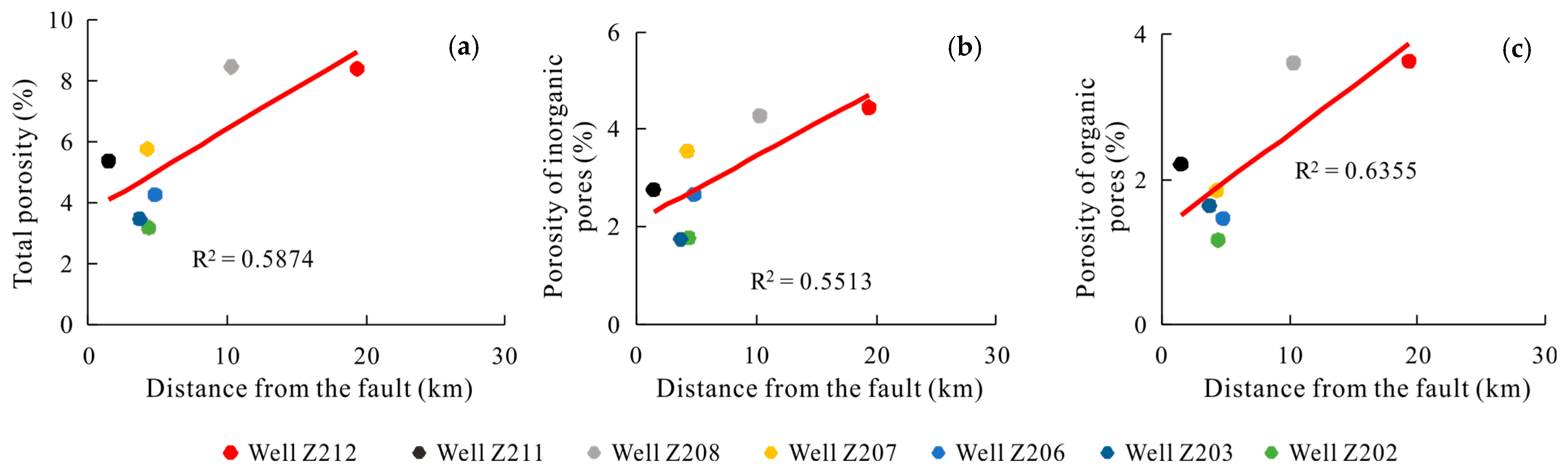

6. Development Technology of Shale Gas

6.1. Integrated Geo-Steering Technology

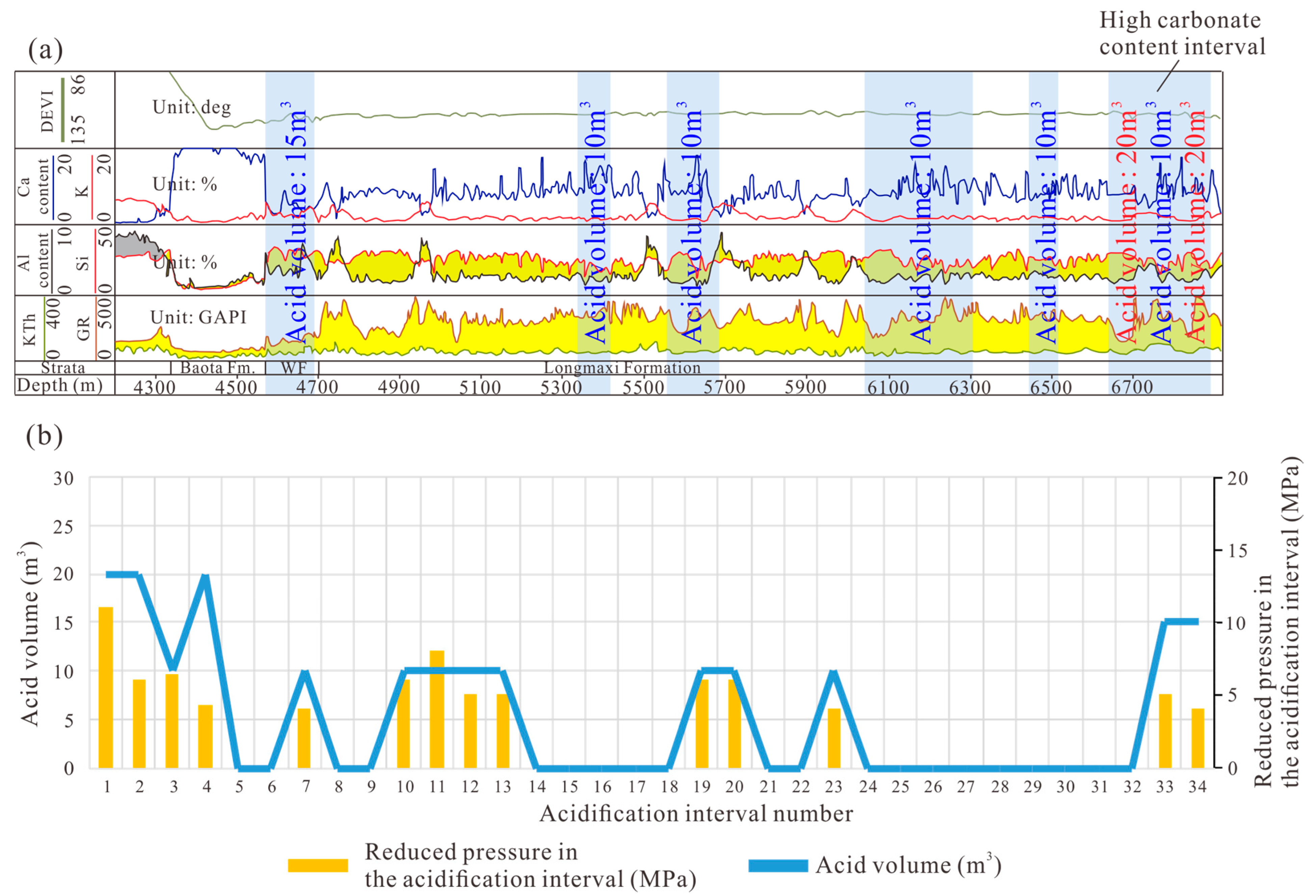

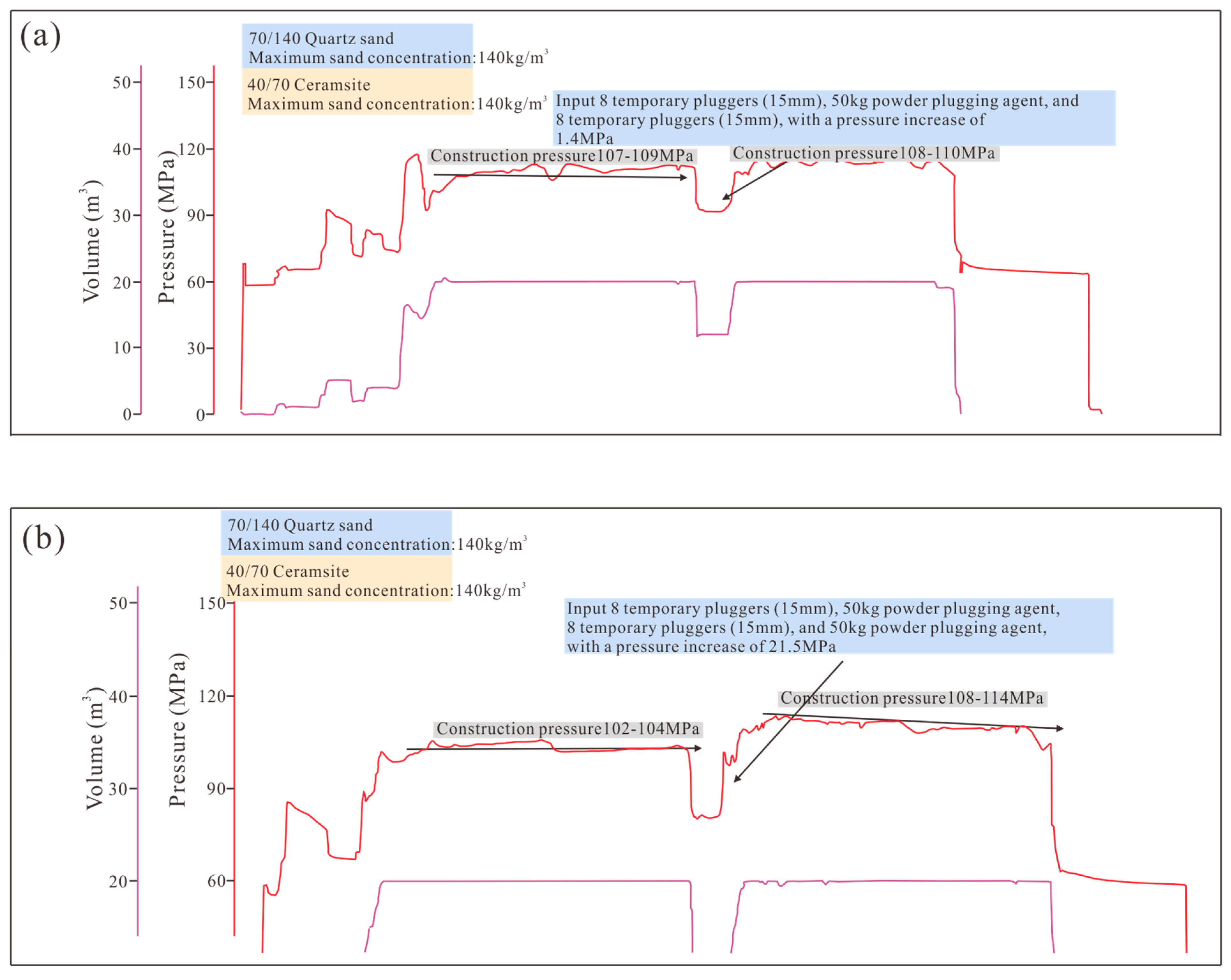

6.2. Acidification and Volume Fracturing Technology

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, X.; Zhang, T.; Zhao, X.; Zhu, H.; Mihai, E.P.; Chen, L.; Yong, J.; Xiao, Q.; Li, H. Effects of astronomical orbital cycle and volcanic activity on organic carbon accumulation during Late Ordovician–Early Silurian in the Upper Yangtze area, South China. Pet. Explor. Dev. 2021, 48, 850–863. [Google Scholar] [CrossRef]

- Zou, C.; Dong, D.; Wang, Y.; Li, X.; Huang, J.; Wang, S.; Guan, Q.; Zhang, C.; Wang, H.; Liu, H.; et al. Shale gas in China: Characteristics, challenges and prospects (II). Pet. Explor. Dev. 2016, 43, 166–178. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, L.; Qi, L.; Luo, M.; Chen, X.; Tao, Y.; Wang, Z. Characterization of the Lower Silurian Longmaxi marine shale in Changning area in the south Sichuan Basin, China. Geol. J. 2018, 53, 1656–1664. [Google Scholar] [CrossRef]

- Li, H.; Zhou, J.; Mou, X.; Guo, H.; Wang, X.; An, H.; Mo, Q.; Long, H.; Dang, C.; Wu, J.; et al. Pore structure and fractal characteristics of the marine shale of the Longmaxi Formation in the Changning Area, Southern Sichuan Basin, China. Front. Earth Sci. 2022, 10, 1018274. [Google Scholar] [CrossRef]

- Li, J.; Li, H.; Yang, C.; Wu, Y.; Gao, Z.; Jiang, S. Geological characteristics and controlling factors of deep shale gas enrichment of the Wufeng-Longmaxi Formation in the southern Sichuan Basin, China. Lithosphere 2022, 12, 4737801. [Google Scholar] [CrossRef]

- Li, H. Research progress on evaluation methods and factors influencing shale brittleness: A review. Energy Rep. 2022, 8, 4344–4358. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, X.; Fu, Y.; Chen, H.; Zhang, H.; Yan, J.; Chen, C.; Gu, Y. Evaluation of effective porosity in marine shale reservoir, western Chongqing. Acta Pet. Sin. 2019, 40, 1233–1243. [Google Scholar]

- Liu, S.; Jiao, K.; Zhang, J.; Ye, Y.; Xie, G.; Deng, B.; Ran, B.; Li, Z.; Wu, J.; Li, J.; et al. Research progress on the pore characteristics of deep shale gas reservoirs: An example from the Lower Paleozoic marine shale in the Sichuan Basin. Nat. Gas Ind. 2021, 41, 29–41. [Google Scholar]

- Jiang, C.; Zhang, H.; Zhou, Y.; Gan, H.; Pu, J.; Jiang, Y.; Fu, Y.; Gu, Y.; Li, M.; Wang, Z.; et al. Paleogeomorphic characteristics of Wufeng-Longmaxi formation and its influence on development of high-quality shale in Dazu area, Western Chongqing. J. Cent. South Univ. (Sci. Technol.) 2022, 53, 3628–3640. [Google Scholar]

- Ma, X.; Xie, J. The progress and prospects of shale gas exploration and exploitation in southern Sichuan Basin, NW China. Pet. Explor. Dev. 2018, 45, 161–169. [Google Scholar] [CrossRef]

- Long, S.; Lu, T.; Li, Q.; Yang, G.; Li, D. Discussion on China’s shale gas development ideas and goals during the 14th Five-Year Plan. Nat. Gas Ind. 2021, 41, 1–10. [Google Scholar]

- Nie, H.; Li, P.; Dang, W.; Ding, J.; Sun, C.; Liu, M.; Wang, J.; Du, W.; Zhang, P.; Li, D. Enrichment characteristics and exploration directions of deep shale gas of Ordovician-Silurian in the Sichuan Basin and its surrounding areas, China. Pet. Explor. Dev. 2022, 49, 648–659. [Google Scholar] [CrossRef]

- Chen, Z.; Liang, X.; Zhang, J.; Wang, G.; Liu, C.; Li, Z.; Zou, C. Genesis analysis of shale reservoir over-pressure of Longmaxi Formation in Zhaotong Demonstration Area, Dianqianbei Depression. Nat. Gas Geosci. 2016, 27, 442–448. [Google Scholar]

- Dong, D.; Liang, F.; Guan, Q.; Jiang, Y.; Zhou, S.; Yu, R.; Gu, Y.; Zhang, S.; Qi, L.; Liu, Y. Development model and identification evaluation technology of Wufeng-Longmaxi Formation quality shale gas reservoirs in the Sichuan Basin. Nat. Gas Ind. 2022, 42, 96–111. [Google Scholar] [CrossRef]

- Yu, T.; Liu, H.; Liu, B.W.; Tang, S.; Tang, Y.Z.; Yin, C. Restoration of karst paleogeomorphology and its significance in petroleum geology—Using the top of the Middle Triassic Leikoupo Formation in the northwestern Sichuan Basin as an example. J. Petrol. Sci. Eng. 2022, 208, 109638. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Hammes, U. Spectrum of pore types and networks in mudrocks and a descriptive classification for matrix related pores. AAPG Bull. 2012, 96, 1071–1098. [Google Scholar] [CrossRef]

- Shi, Z.; Dong, D.; Wang, H.; Sun, S.; Wu, J. Reservoir characteristics and genetic mechanisms of gas-bearing shales with different laminae and laminae combinations: A case study of Member 1 of the Lower Silurian Longmaxi shale in Sichuan Basin, SW China. Pet. Explor. Dev. 2020, 47, 829–840. [Google Scholar] [CrossRef]

- Shi, Z.; Zhao, S.; Zhou, T.; Sun, S.; Yuan, Y.; Zhang, C.; Li, B.; Qi, L. Types and genesis of horizontal bedding of marine gas-bearing shale and its significance for shale gas: A case study of the Wufeng-Longmaxi shale in southern Sichuan Basin, China. Oil Gas Geol. 2023, 44, 1499–1514. [Google Scholar]

- Hou, H.; Yang, W.; Du, W.; Feng, X.; Jiang, Z.; Shi, F.; Lin, R.; Wang, Y.; Zhang, D.; Chen, Y.; et al. Implications of multi-stage deformation on the differential preservation of Lower Paleozoic shale gas in tectonically complex regions: New structural and kinematic constraints from the Upper Yangtze Platform, South China. Mar. Pet. Geol. 2024, 160, 106629. [Google Scholar] [CrossRef]

- Tan, R.; Wang, R.; Huang, Y.; Yang, R.; Li, H.; Lu, K. Mechanism of the enrichment and loss progress of deep shale gas: Evidence from fracture veins of the Wufeng-Longmaxi formations in the southern Sichuan Basin. Minerals 2022, 12, 897. [Google Scholar] [CrossRef]

- Xiang, J.; Zhu, Y.; Wang, Y.; Chen, S.; Jiang, Z. Effect of faults on shale pore fracture and shale gas preservation: A case study of the Wufeng-Longmaxi Formation in the Northeast Yunnan area. Energy Fuels 2022, 36, 8238–8255. [Google Scholar] [CrossRef]

- Yang, W.; Wang, Y.; Du, W.; Song, Y.; Jiang, Z.; Wang, Q.; Xu, L.; Zhao, F.; Chen, Y.; Shi, F. Behavior of organic matter-hosted pores within shale gas reservoirs in response to differential tectonic deformation: Potential mechanisms and innovative conceptual models. J. Nat. Gas Sci. Eng. 2022, 102, 104571. [Google Scholar] [CrossRef]

- Tang, H.; Liu, X.; Chen, Y.; Yu, W.; Zhao, N.; Shi, X.; Wang, M.; Liao, J. Pore structure difference of shale in different structural units and its petroleum geological implications: A case study on deep shale in the Luzhou area, southern Sichuan Basin. Nat. Gas Ind. 2024, 44, 16–28. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Shi, Z.; Jiang, L.; Chen, W.; Luo, T.; Qi, L. Enrichment Mechanism and Development Technology of Deep Marine Shale Gas near Denudation Area, SW CHINA: Insights from Petrology, Mineralogy and Seismic Interpretation. Minerals 2025, 15, 619. https://doi.org/10.3390/min15060619

Zhang H, Shi Z, Jiang L, Chen W, Luo T, Qi L. Enrichment Mechanism and Development Technology of Deep Marine Shale Gas near Denudation Area, SW CHINA: Insights from Petrology, Mineralogy and Seismic Interpretation. Minerals. 2025; 15(6):619. https://doi.org/10.3390/min15060619

Chicago/Turabian StyleZhang, Haijie, Ziyi Shi, Lin Jiang, Weiming Chen, Tongtong Luo, and Lin Qi. 2025. "Enrichment Mechanism and Development Technology of Deep Marine Shale Gas near Denudation Area, SW CHINA: Insights from Petrology, Mineralogy and Seismic Interpretation" Minerals 15, no. 6: 619. https://doi.org/10.3390/min15060619

APA StyleZhang, H., Shi, Z., Jiang, L., Chen, W., Luo, T., & Qi, L. (2025). Enrichment Mechanism and Development Technology of Deep Marine Shale Gas near Denudation Area, SW CHINA: Insights from Petrology, Mineralogy and Seismic Interpretation. Minerals, 15(6), 619. https://doi.org/10.3390/min15060619