Exploring Pore Structure Features, Crack Propagation and Failure Behavior of Fiber Reinforced Foam Tail Fill by CT Imaging and 3D Reconstruction

Abstract

1. Introduction

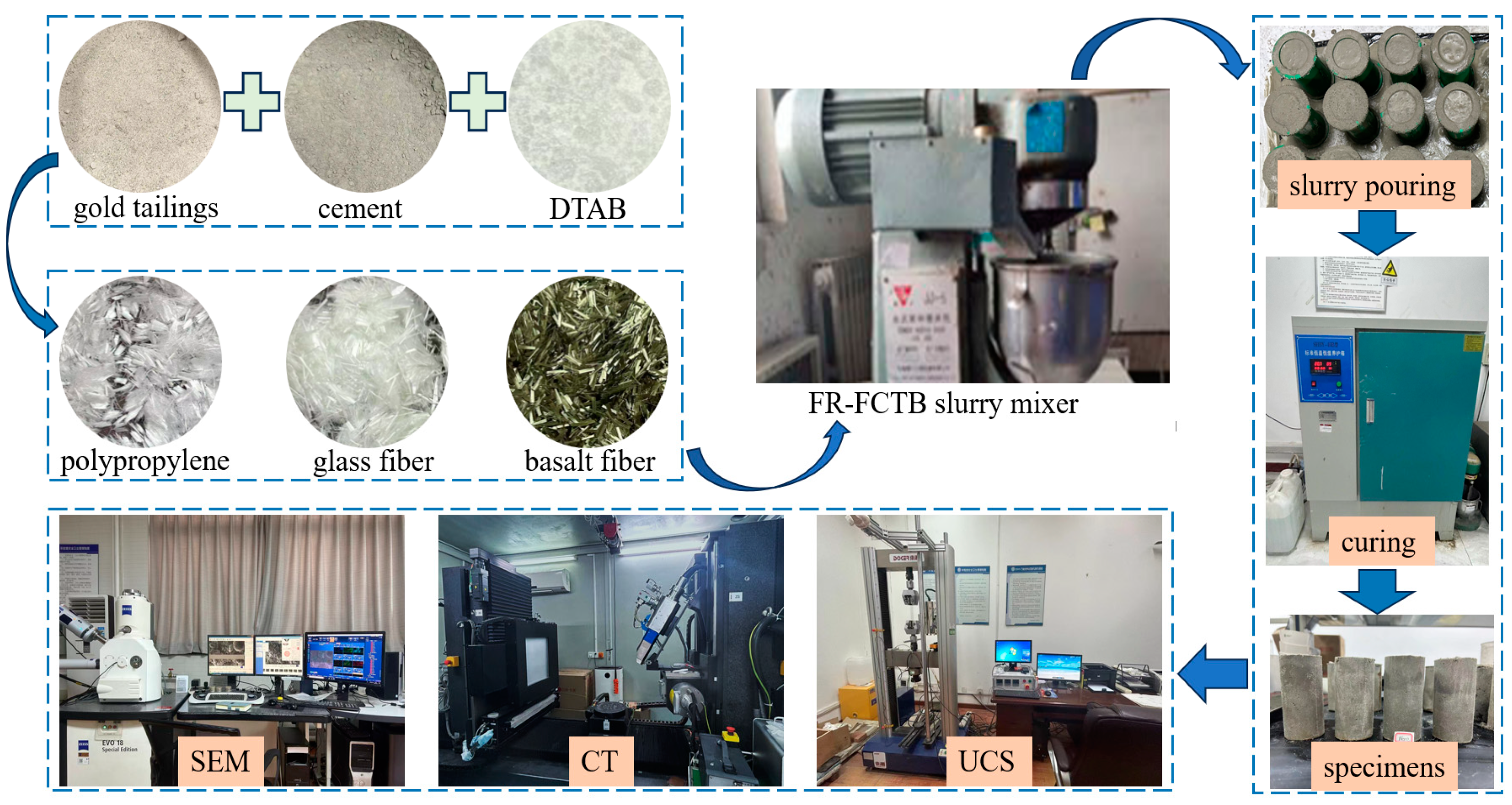

2. Materials and Methods

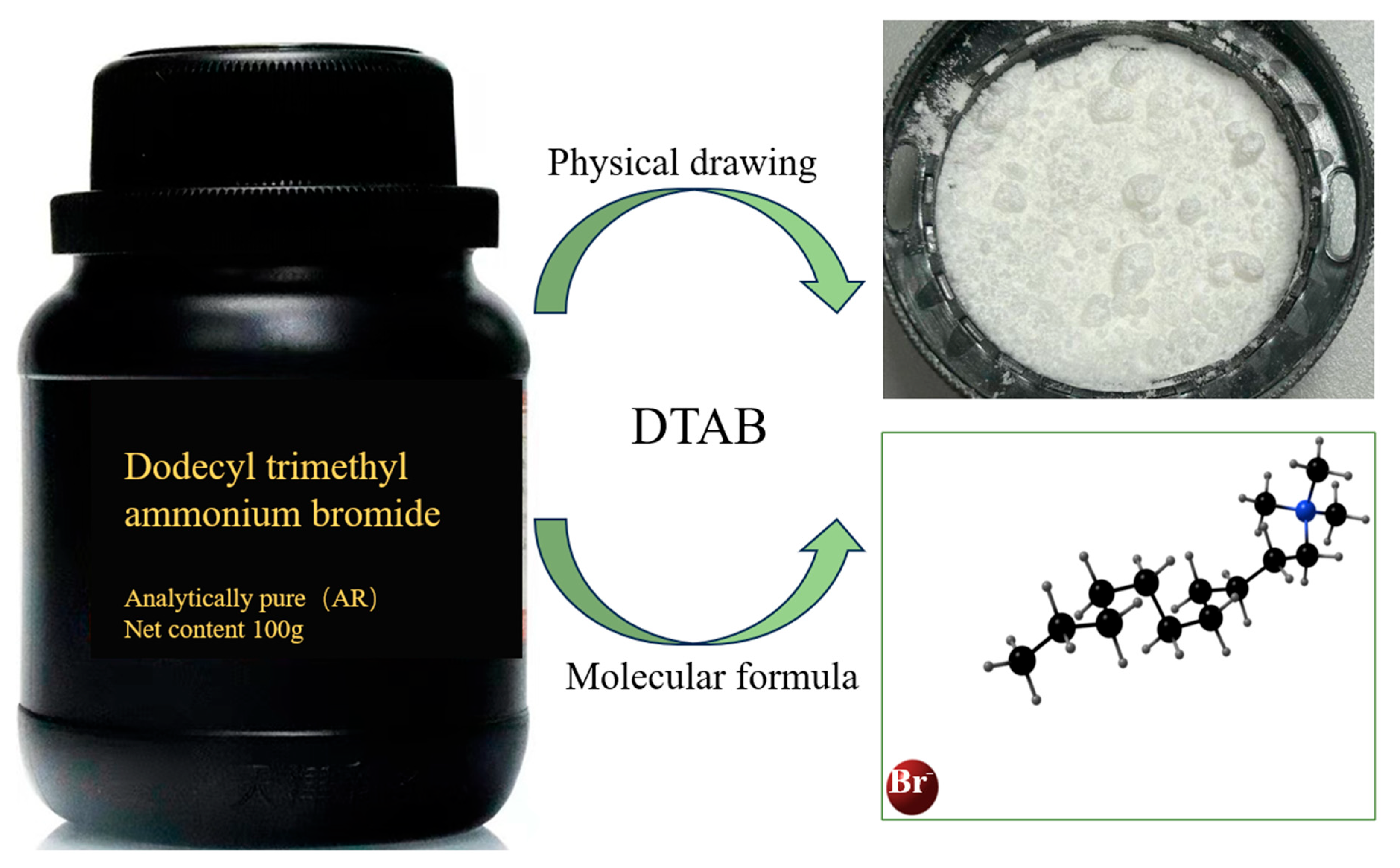

2.1. Resources

2.2. Fill Creating/Curing Environments

2.3. UCS Testing

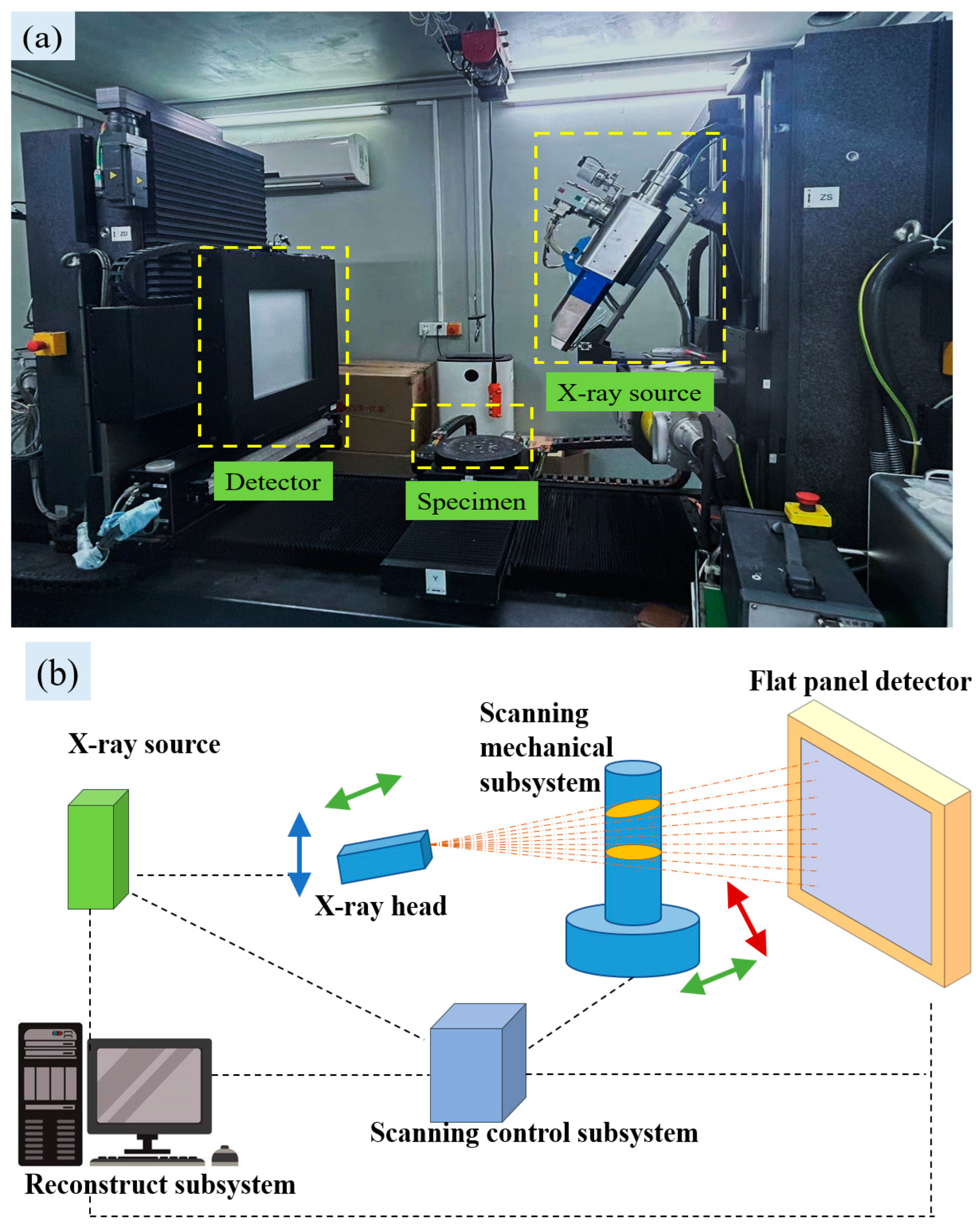

2.4. CT Scan/Image Examinations

2.5. Pore Structure Observation

3. Results and Discussion

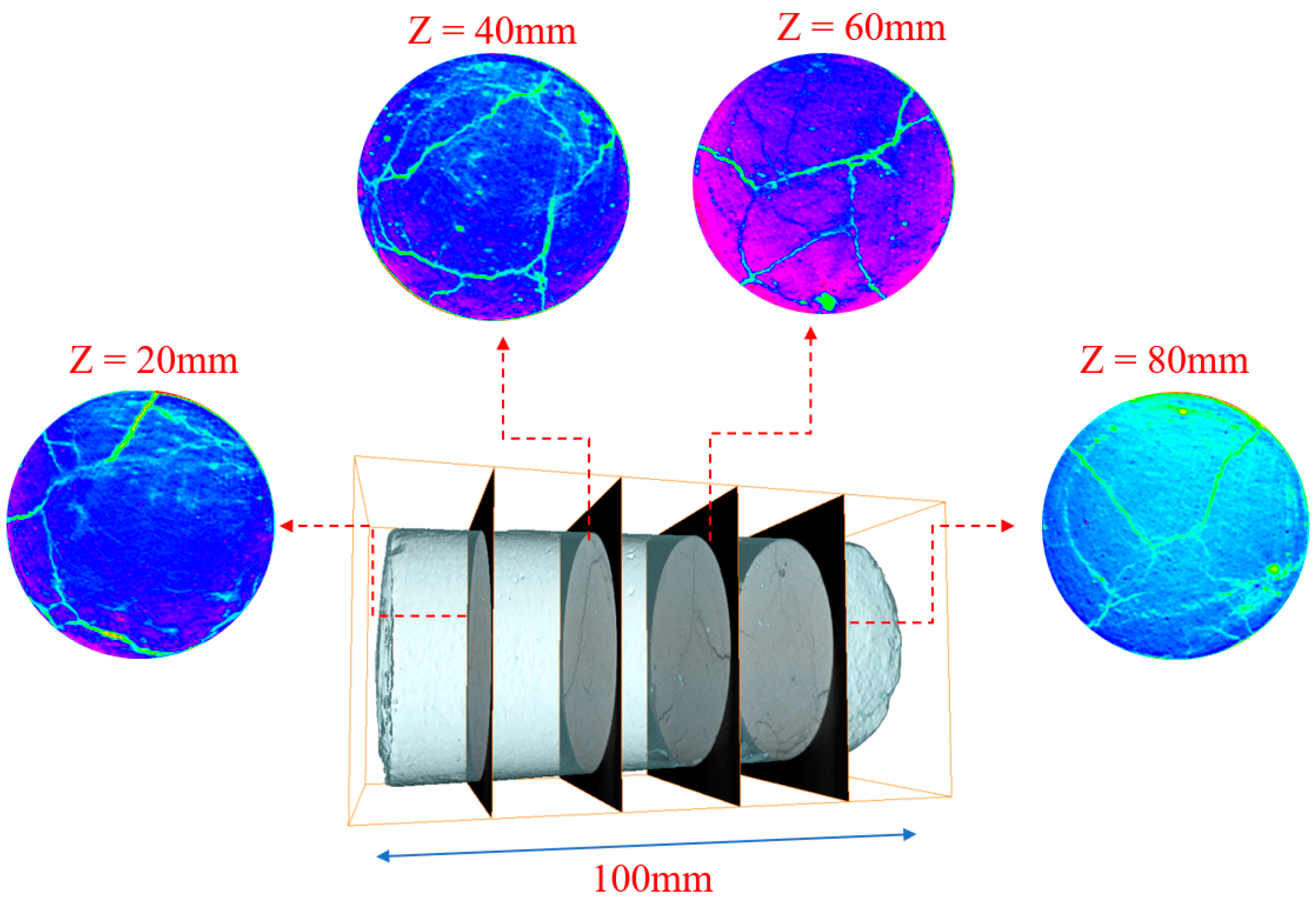

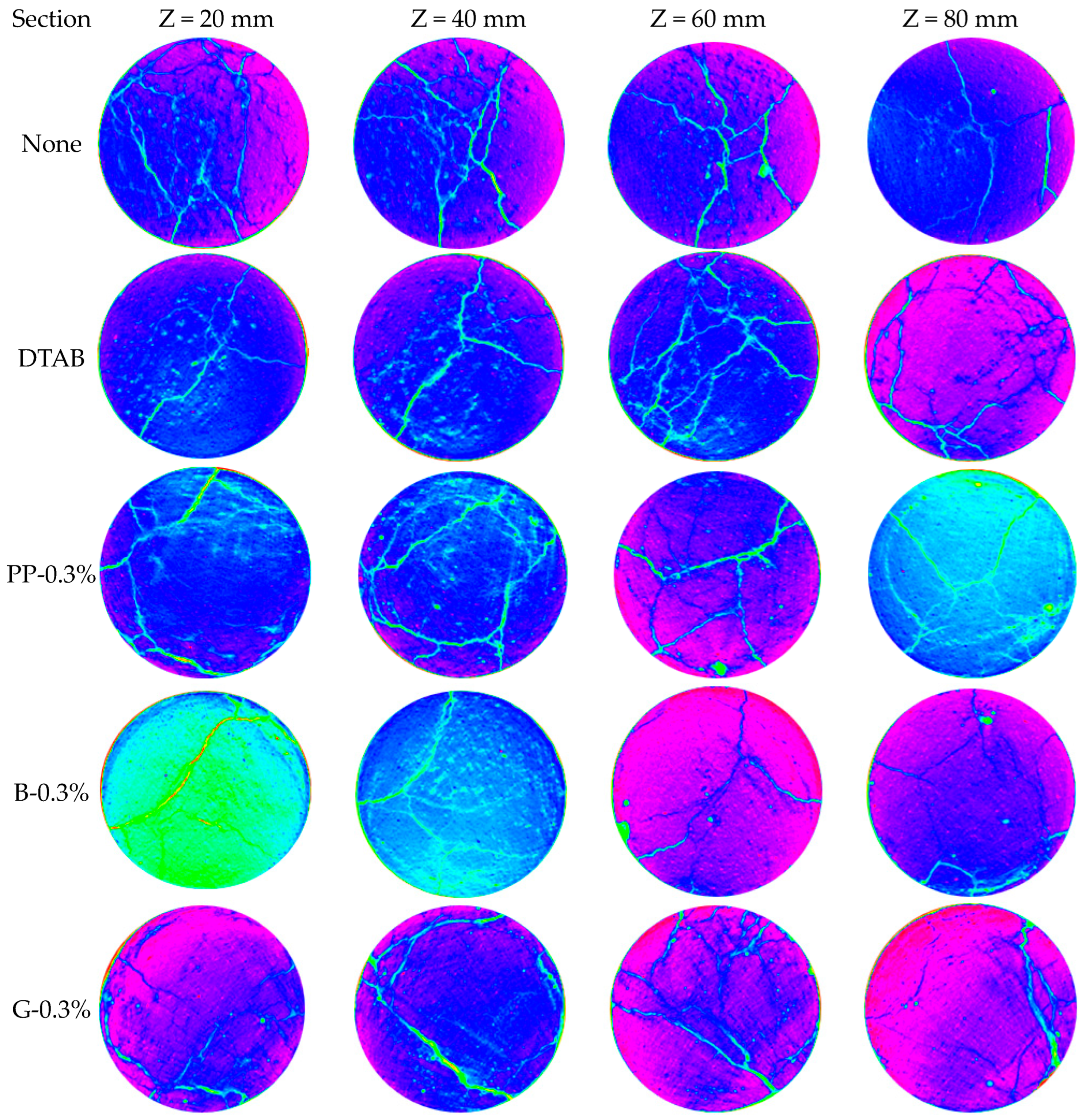

3.1. Two-Dimensional Pore Fissure Distribution

3.2. Pore Characteristics

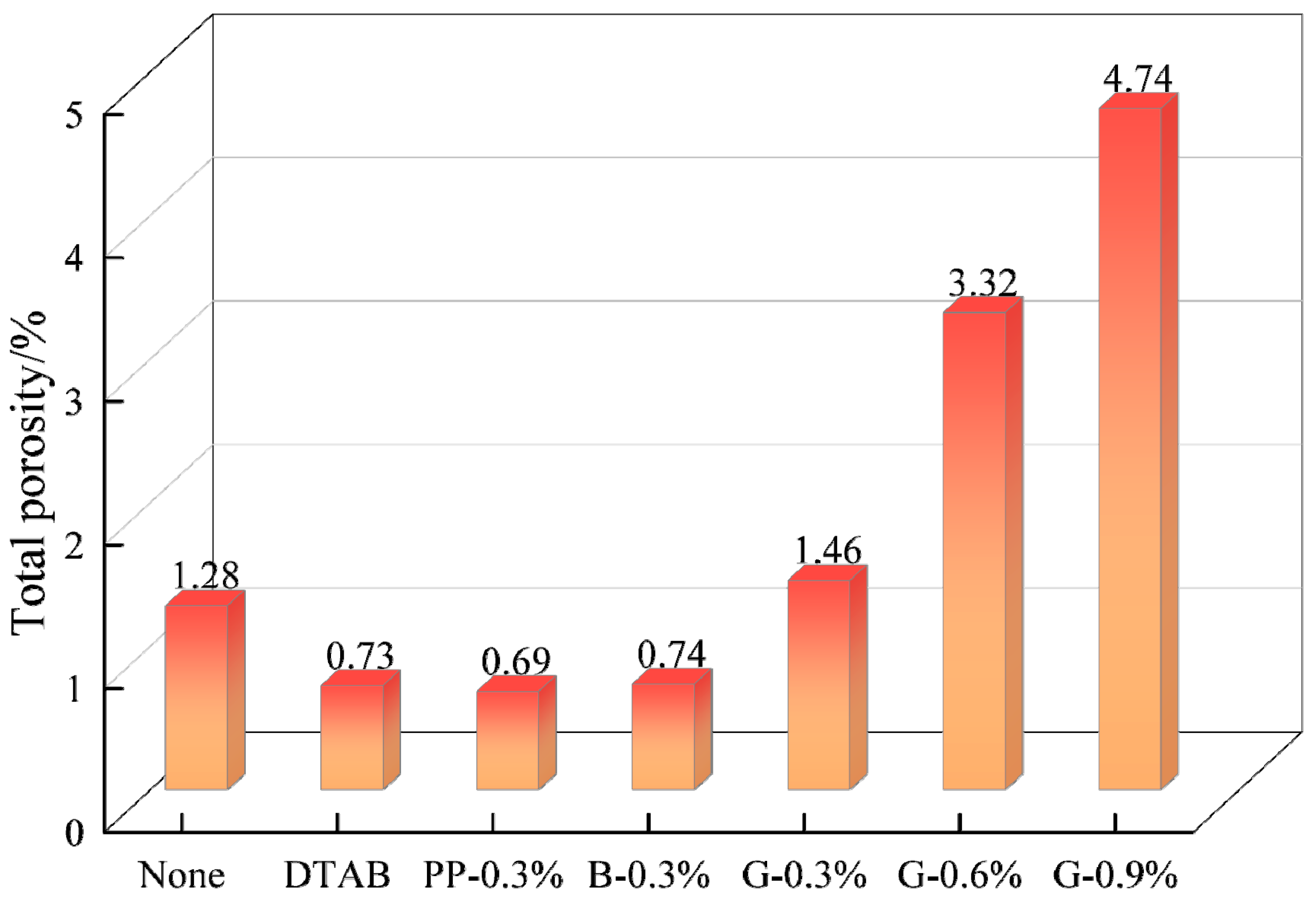

3.2.1. Porosity

3.2.2. Number of Pores

3.2.3. Sphericity

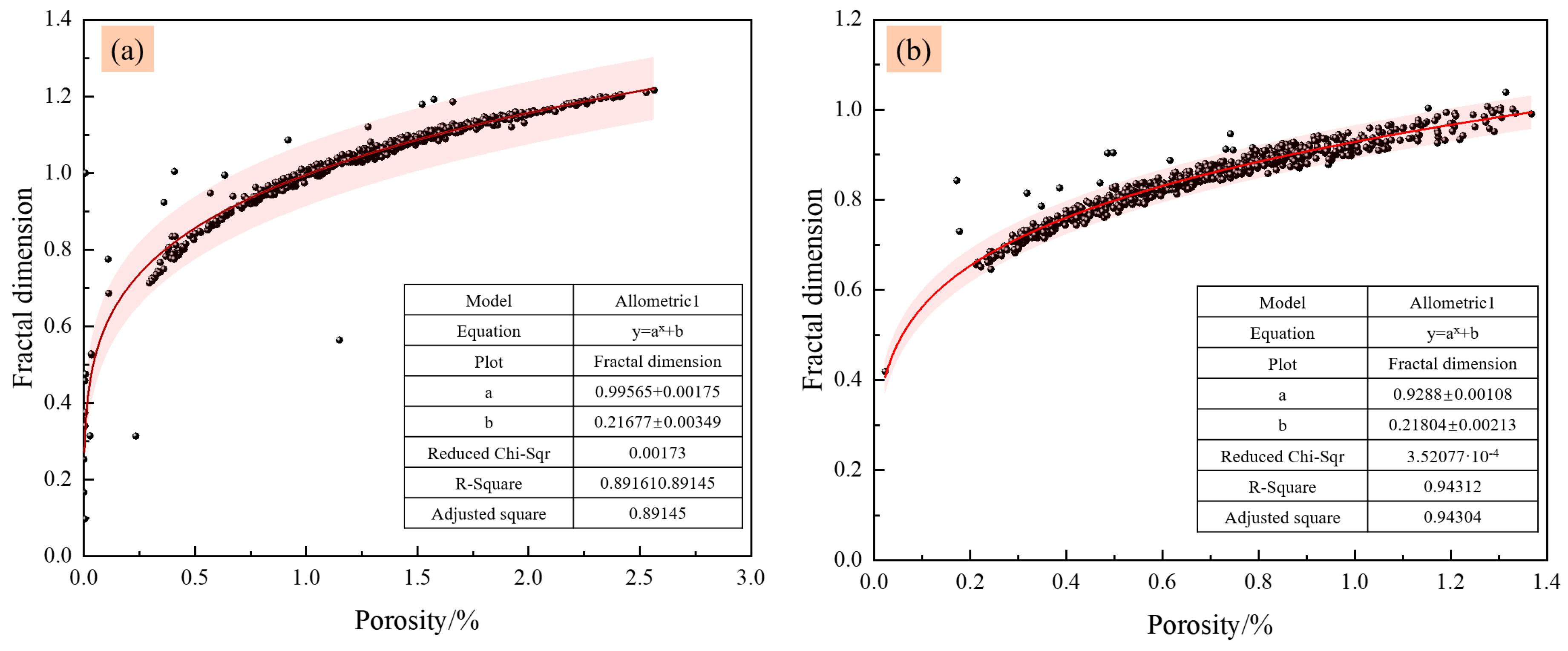

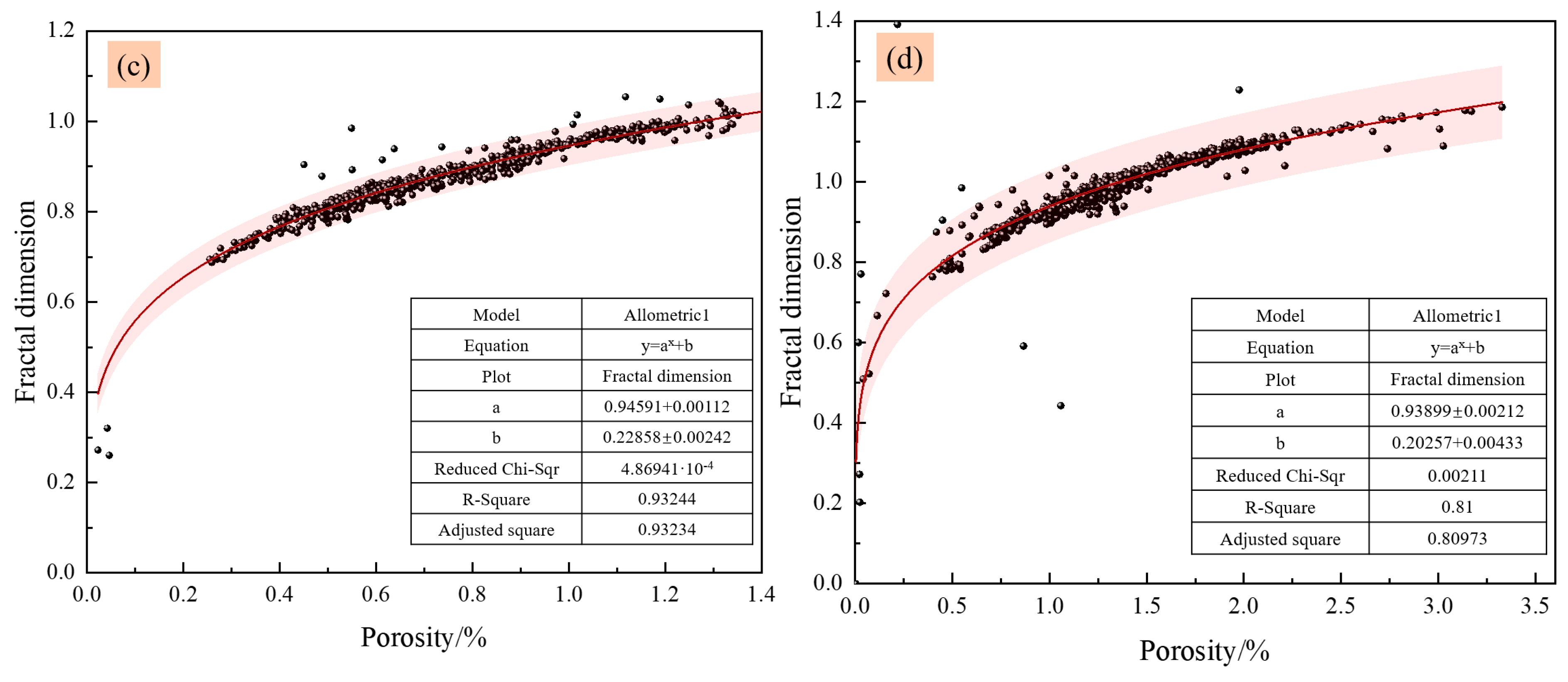

3.2.4. Fractal Dimension

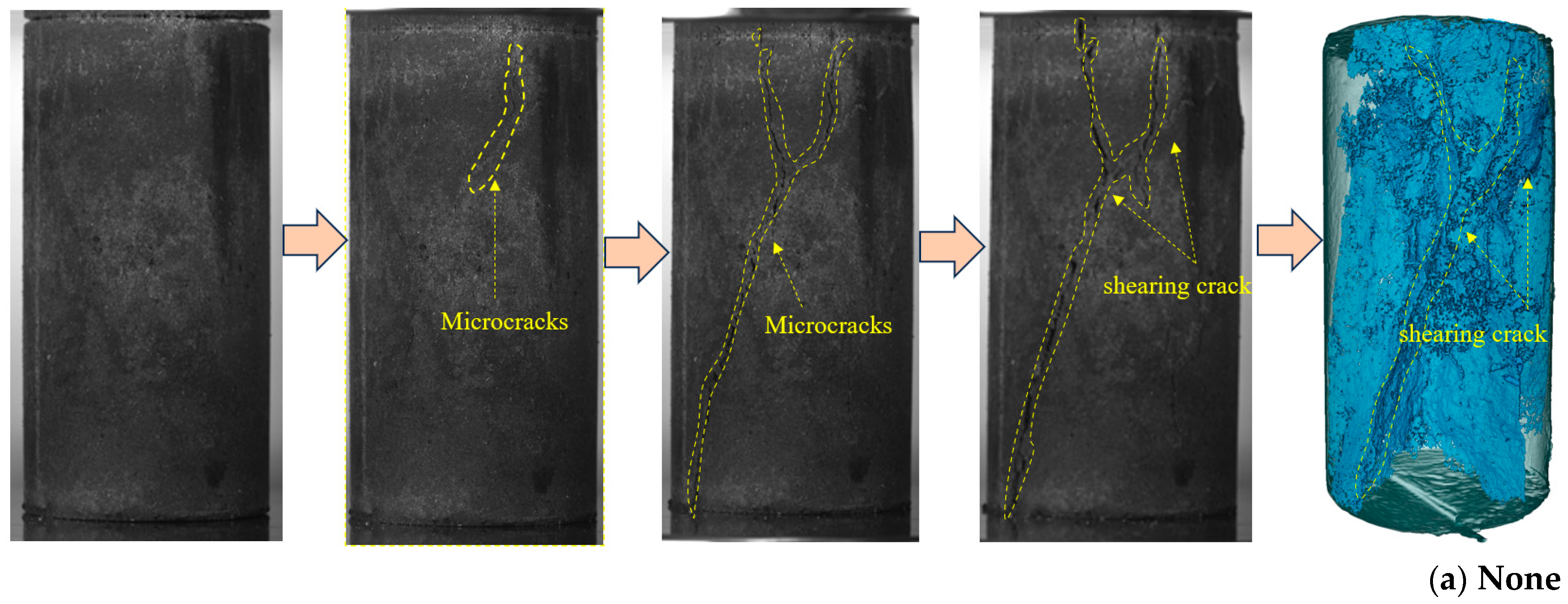

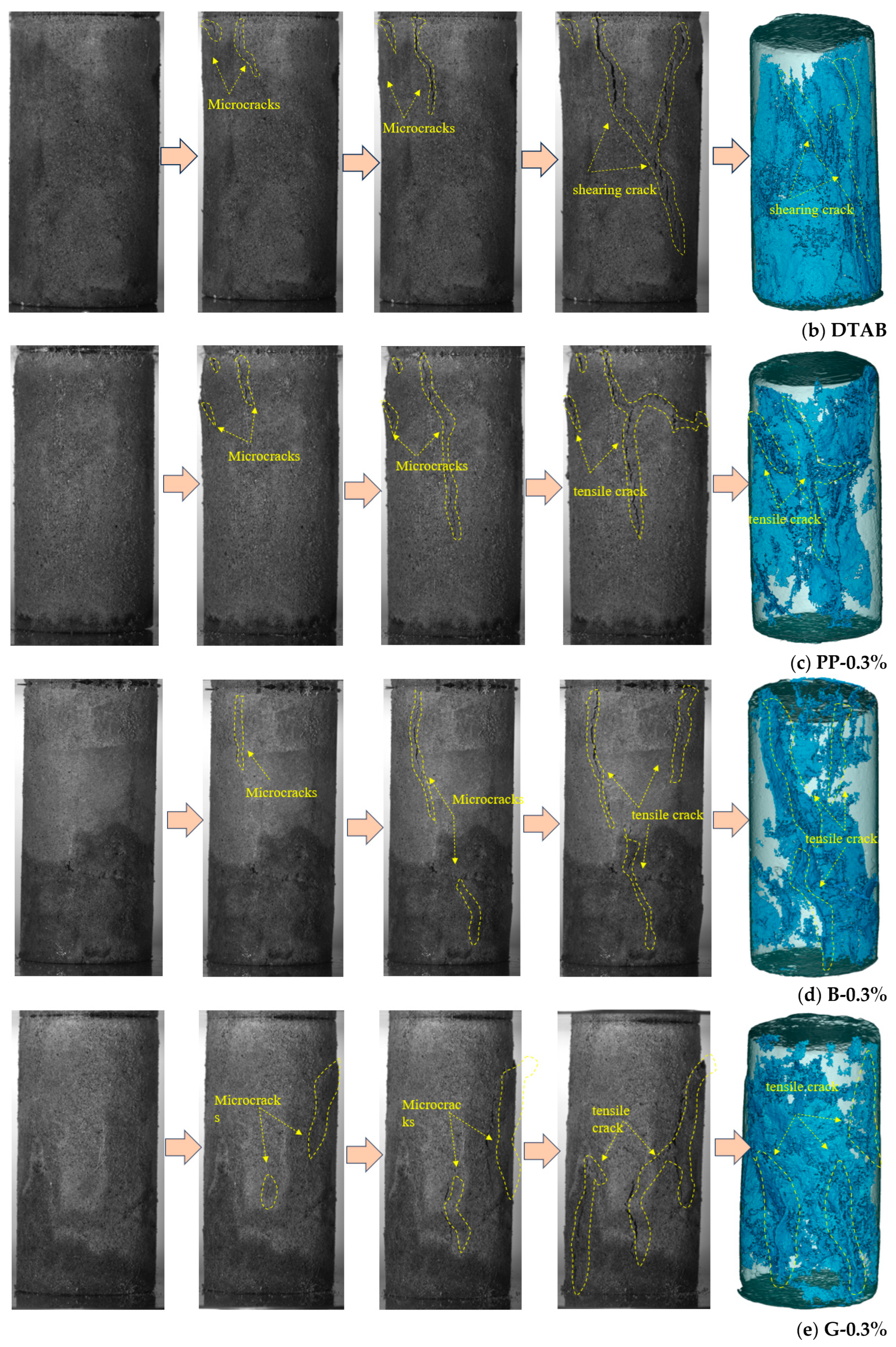

3.3. Analysis of Crack Propagation Mode and Failure Process of FRFTF Samples

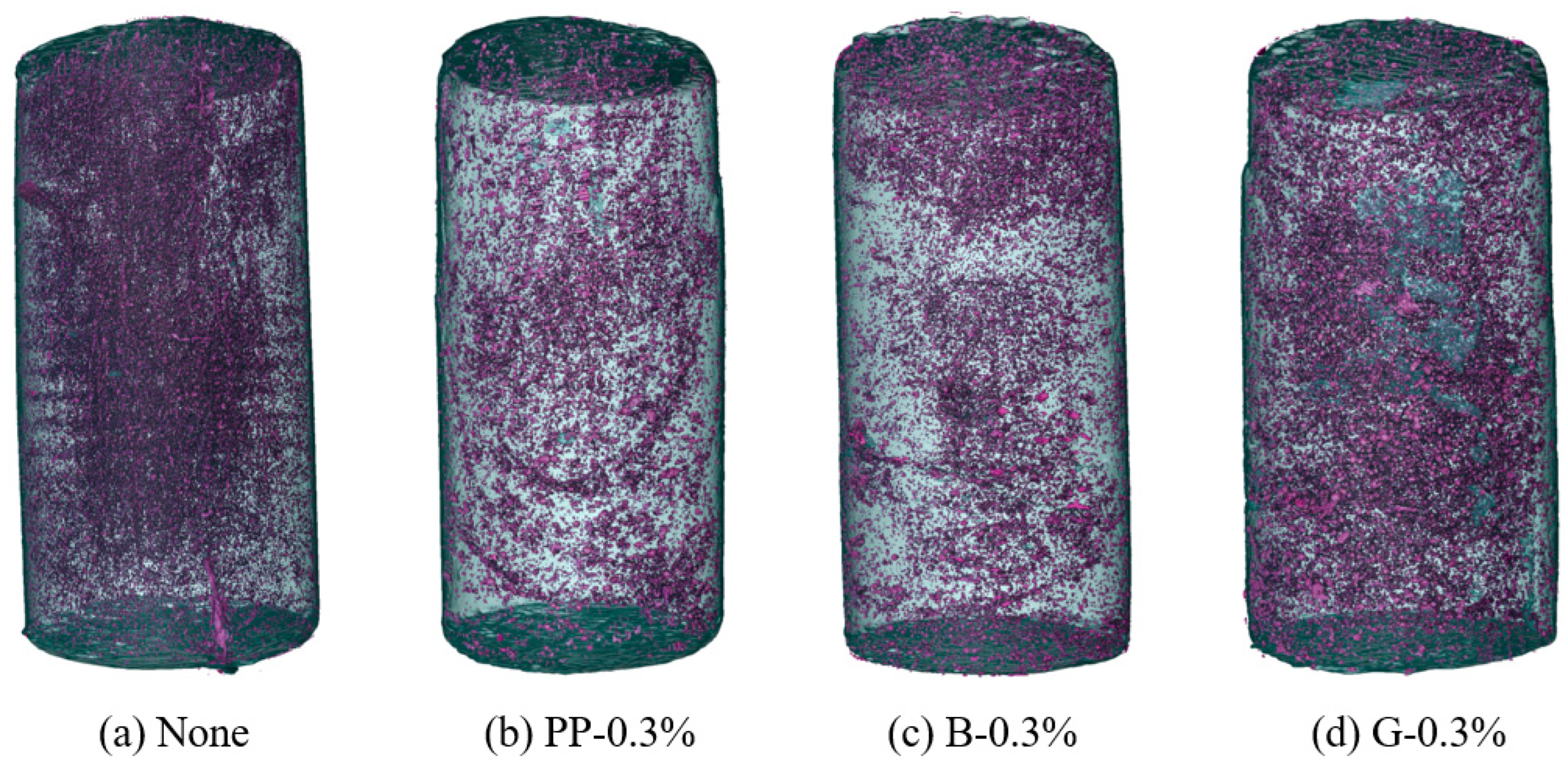

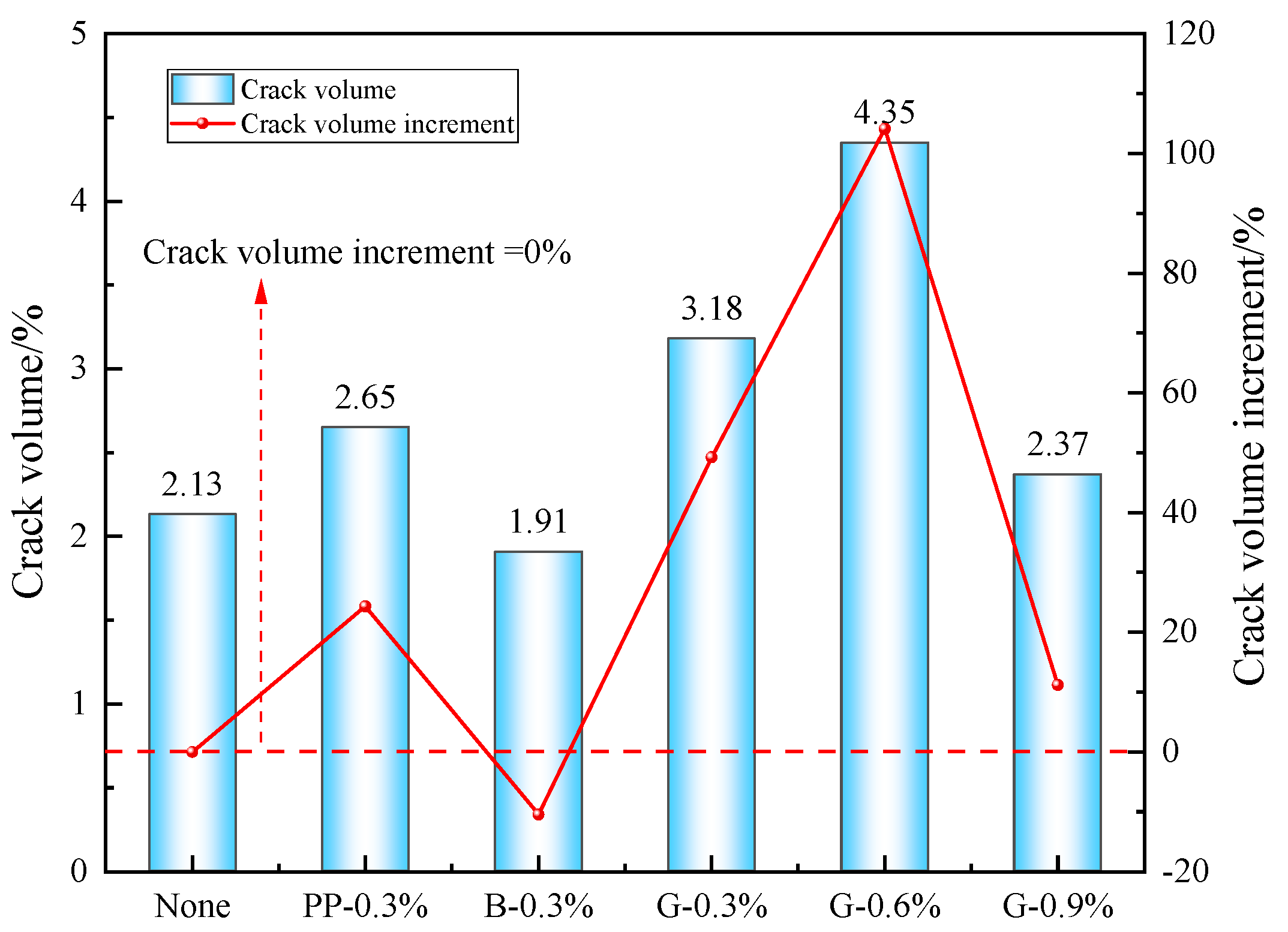

3.4. Characterization of 3D Crack Distribution of FRFTF Samples

3.5. Relationship Between Mechanical and Mesoscopic

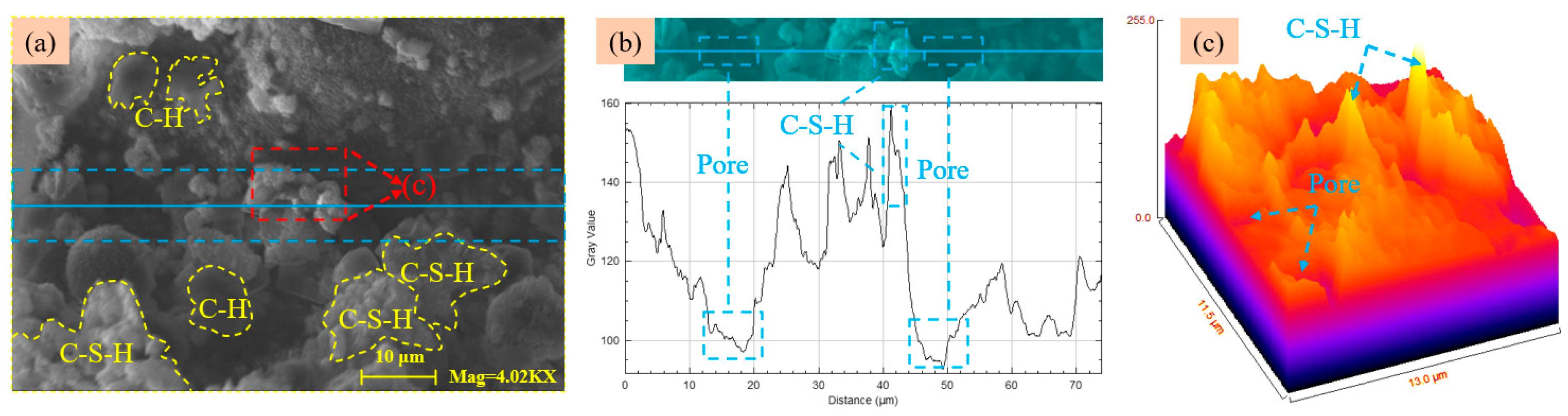

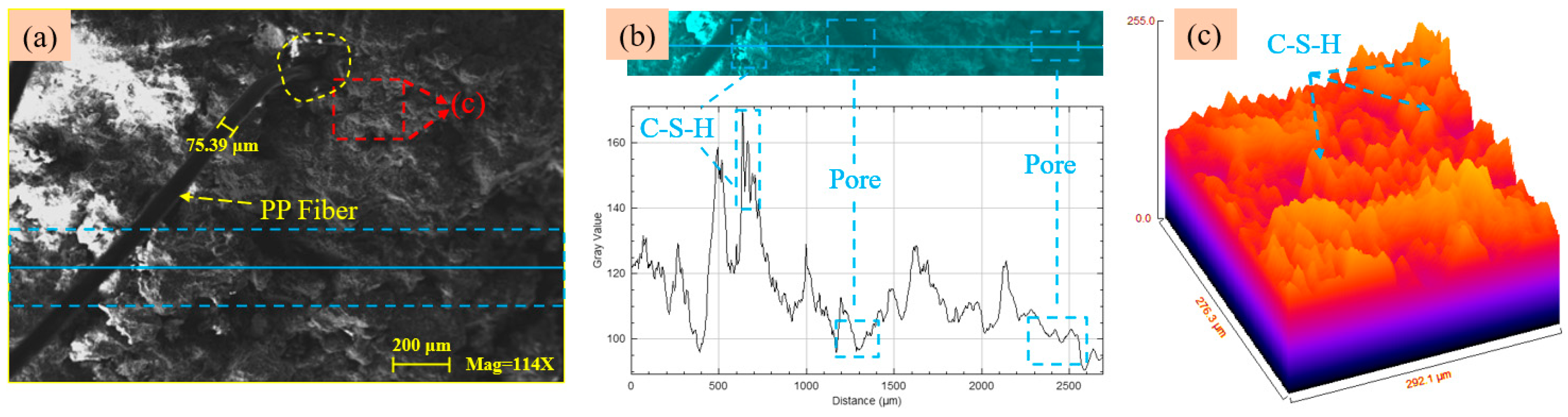

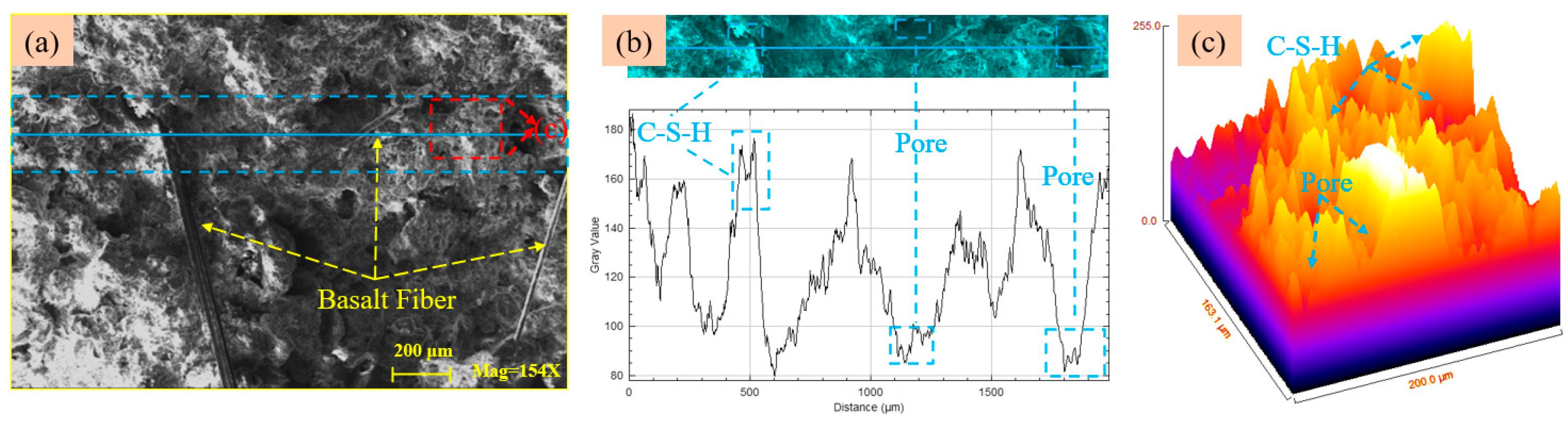

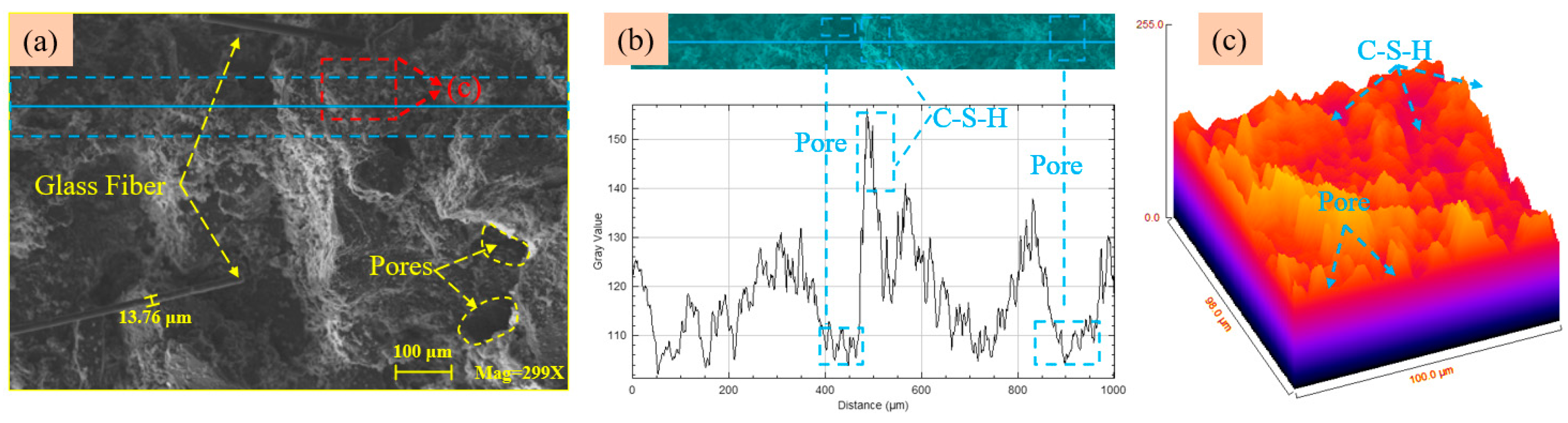

3.6. Micro Analysis of FRFTF Samples

4. Conclusions

- Implying fiber increased fill’s porosity, and the porosity of PP-0.3%, B-0.3%, and G-0.3% were 0.69%, 0.74%, and 1.46%, respectively. With the rise of glass fiber dose from 0.3% to 0.9%, the fill’s porosity improves.

- The addition of fiber and foaming agents enhanced the pore distribution and morphology of FRFTF. In None, there is a dense accumulation of connected holes in the fill’s middle, the pores in the FRFTF are evenly distributed, and the pores are mainly spherical.

- FRFTF primarily exhibits a tensile-shear mixed failure mode. The incorporation of fibers effectively reduces the number of primary cracks and enhances structural integrity. The link between fill strength and porosity/fracture rate is related to fiber type/rate.

- The fiber bridges the fill’s internal defects, with bare fiber surface gradually being encased by hydration yields. This process enhances pore structure, densifies the fill, and ultimately improves its strength.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, M.; Wang, Q. Rock dynamics in deep mining. Int. J. Min. Sci. Technol. 2023, 33, 1065–1082. [Google Scholar] [CrossRef]

- Guo, X.; Ding, C.; Wei, P.; Yang, R. Theoretical analysis of the interaction between blasting stress wave and linear interface crack under high in-situ stress in deep rock mass. Int. J. Rock Mech. Min. Sci. 2024, 176, 105723. [Google Scholar] [CrossRef]

- He, C.; Mishra, B.; Shi, Q.; Zhao, Y.; Lin, D.; Wang, X. Correlations between mineral composition and mechanical properties of granite using digital image processing and discrete element method. Int. J. Min. Sci. Technol. 2023, 33, 949–962. [Google Scholar] [CrossRef]

- Jiang, T.; Cao, S.; Yilmaz, E. Structural characteristics of cement-based tail fill with sodium dodecyl sulfate, azodicarbonamide, and dodecyl trimethyl ammonium bromide. Powder Technol. 2025, 452, 120507. [Google Scholar] [CrossRef]

- Xie, G.; Liu, L.; Suo, Y.; Zhu, M.; Yang, P.; Sun, W. Study on the green disposal of industrial high salt water and its performance as activator to prepare magnesium-coal based solid waste backfill material for mine. J. Clean. Prod. 2024, 452, 141933. [Google Scholar] [CrossRef]

- Zhao, K.; Zhou, Y.; Huang, Q.; Yin, S.; Yan, Y.; Wu, J.; Shen, L.; Zeng, X.; Liu, W. Early properties and modeling of cemented superfine tailings backfill containing sodium dodecyl sulfate: Microstructure, mechanics, and acoustics. Mech. Mater. 2023, 179, 104567. [Google Scholar] [CrossRef]

- Hou, Y.; Yin, S.; Yang, S.; Chen, X.; Du, H. Mechanical properties, damage evolution and energy dissipation of cemented tailings backfill under impact loading. J. Build. Eng. 2023, 66, 105912. [Google Scholar] [CrossRef]

- Yang, L.; Jia, H.; Jiao, H.; Dong, M.; Yang, T. The mechanism of viscosity-enhancing admixture in backfill slurry and the evolution of its rheological properties. Minerals 2023, 13, 1045. [Google Scholar] [CrossRef]

- Li, M.; Peng, Y.; Zhang, J.; Zhao, Y.; Wang, Z.; Guo, Q.; Guo, S. Properties of a backfill material prepared by cementing coal gangue and fly ash through microbial-induced calcite precipitation. Constr. Build. Mater. 2023, 384, 131329. [Google Scholar] [CrossRef]

- Zhang, T.; Yang, Y.L. Occurrence characteristics and treatment technologies of mine goaf in China: A comprehensive review. Environ. Earth Sci. 2024, 83, 441. [Google Scholar] [CrossRef]

- Guo, J.; Yang, W.; Zhao, Y.; Zhang, W. Stability analysis of a mine wall based on different roof-contact filling rates. Minerals 2024, 14, 673. [Google Scholar] [CrossRef]

- Tang, F.; Qin, Y.P.; Guo, M.Y.; Zhang, F.J.; Wang, S.B.; Yan, L.X.; Hao, J.S. Multi-angle research on the performance of self-foaming filling materials and analysis of engineering applications. Constr. Build. Mater. 2024, 449, 138447. [Google Scholar] [CrossRef]

- Zhu, T.Y.; Chen, Z.H.; Cao, J.; Nian, G.Q.; Zhang, L.F.; Hao, J.S.; Zhou, Z.H. Investigation of the fracture behavior of cemented waste rock-tailing backfill by digital image correlation technique and discrete element modeling. Constr. Build. Mater. 2024, 428, 136367. [Google Scholar] [CrossRef]

- Yin, S.; Yan, Z.; Chen, X.; Yan, R.; Chen, D.; Chen, J.; Li, G. Active roof-contact: The future development of cemented paste backfill. Constr. Build. Mater. 2023, 370, 130657. [Google Scholar] [CrossRef]

- Tu, B.; Liu, L.; Ding, X.; Ruan, S. Active roof-contacted combined backfill mining technology based on a modified magnesium slag-based cementitious material. Miner. Eng. 2024, 216, 108916. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Z.; Chen, C.; Wu, A. Insight into the active roof-contact of cemented paste backfill: A high-efficient expansion material. Case Stud. Constr. Mater. 2024, 20, e03123. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, A.; Wang, S.; Hu, X. Effect and mechanism of time-dependent and economical expansion materials in improving the active roof-contact for cemented paste backfill. Constr. Build. Mater. 2024, 439, 137339. [Google Scholar] [CrossRef]

- Yan, B.; Jia, H.; Liu, Y.; Liu, P.; Yilmaz, E. Revealing cooperative load-bearing mechanisms between mine backfill and rock pillar using a bonded-block modeling approach. Minerals 2025, 15, 210. [Google Scholar] [CrossRef]

- Gencel, O.; Nodehi, M.; Bozkurt, A.; Sarı, A.; Ozbakkaloglu, T. The use of computerized tomography (CT) and image processing for evaluation of the properties of foam concrete produced with different content of foaming agent and aggregate. Constr. Build. Mater. 2023, 399, 132433. [Google Scholar] [CrossRef]

- Liu, S.; Wang, J.; Meng, L.; Hu, C.; Meng, X. Location of the phase-change material layer on thermal performance of light-weight walls. Int. J. Low-Carbon Technol. 2024, 19, 127–134. [Google Scholar] [CrossRef]

- Abdellatief, M.; Ahmed, Y.M.; Taman, M.; Elfadaly, E.; Tang, Y.; Abadel, A.A. Physico-mechanical, thermal insulation properties, and microstructure of geopolymer foam concrete containing sawdust ash and egg shell. J. Build. Eng. 2024, 90, 109374. [Google Scholar]

- Cheng, A.; Zhou, Y.; Chen, G.; Huang, S.; Ye, Z. Acoustic emission characteristics and fracture mechanism of cemented tailings backfill under uniaxial compression: Experimental and numerical study. Environ. Sci. Pollut. Res. 2023, 30, 55143–55157. [Google Scholar]

- Guo, Y.; Chen, X.; Chen, B.; Wen, R.; Wu, P. Analysis of foamed concrete pore structure of railway roadbed based on X-ray computed tomography. Constr. Build. Mater. 2021, 273, 121773. [Google Scholar]

- Chen, L.; Chen, X.; Wang, L.; Ning, Y.; Ji, T. Compressive strength, pore structure, and hydration products of slag foam concrete under sulfate and chloride environment. Constr. Build. Mater. 2023, 394, 132141. [Google Scholar]

- Zhu, Z.; Huo, W.; Sun, H.; Ma, B.; Yang, L. Correlations between unconfined compressive strength, sorptivity and pore structures for geopolymer based on SEM and MIP measurements. J. Build. Eng. 2023, 67, 106011. [Google Scholar]

- Zhao, K.; Lai, Y.; He, Z.; Liu, W.; Zhao, R.; Wang, Y.; Tian, X.; Nie, J. Study on energy dissipation and acoustic emission characteristics of fiber tailings cemented backfill with different ash-sand ratios. Process Saf. Environ. Prot. 2023, 174, 983–996. [Google Scholar]

- Gencel, O.; Kazmi, S.M.S.; Munir, M.J.; Kaplan, G.; Bayraktar, O.Y.; Yarar, D.O.; Karimipour, A.; Ahmad, M.R. Influence of bottom ash and polypropylene fibers on the physico-mechanical, durability and thermal performance of foam concrete: An experimental investigation. Constr. Build. Mater. 2021, 306, 124887. [Google Scholar]

- Chen, L.; Li, P.; Guo, W.; Wang, R.; Zhang, D.; Gao, M.; Peng, C. Experimental investigation of the dynamic mechanical properties of polypropylene-fiber-reinforced foamed concrete at high temperatures. Polymers 2023, 15, 2544. [Google Scholar] [CrossRef]

- Cao, S.; Che, C.; Zhang, Y.; Shan, C.; Liu, Y.; Zhao, C.; Du, S. Mechanical properties and damage evolution characteristics of waste tire steel fiber-modified cemented paste backfill. Int. J. Min. Sci. Technol. 2024, 34, 909–924. [Google Scholar]

- Quan, W.; Huang, W.; An, Y.; Miao, X.; Chen, Z. The effect of natural bamboo fiber and basalt fiber on the properties of autoclaved aerated concrete. Constr. Build. Mater. 2023, 377, 131153. [Google Scholar]

- Qiu, Y.; Wang, Y.; Liu, Y.; Zhang, L.; Chen, Y.; Li, C.; Wu, T.; Wang, C. Development of fiber compound foaming agent and experimental study on application performance of foamed lightweight soil. Appl. Rheol. 2023, 33, 20230108. [Google Scholar] [CrossRef]

- Xu, Y.; Han, Y.J.; Zhao, G.Q.; Meng, S.Y. Enhancing geotechnical reinforcement: Exploring molybdenum tailings and basalt fibre-modified composites for sustainable construction. Constr. Build. Mater. 2024, 411, 134452. [Google Scholar] [CrossRef]

- Zhao, K.; Ma, C.; Yang, J.; Wu, J.; Yan, Y.; Lai, Y.; Ao, W.; Tian, Y. Pore fractal characteristics of fiber-reinforced backfill based on nuclear magnetic resonance. Powder Technol. 2023, 426, 118678. [Google Scholar] [CrossRef]

- Pi, Z.; Huang, S.; Xu, J.; Chen, Z.; Li, H.; Shen, Y.; Tian, J. The reinforcement mechanism of basalt and polypropylene fibers on the strength, toughness and crack resistance of tailing mortar. Constr. Build. Mater. 2024, 419, 135531. [Google Scholar] [CrossRef]

- Zheng, W.B.; Wang, S.L.; Quan, X.Y.; Qu, Y.; Mo, Z.K.; Lin, C.J. Carbonation Resistance and Pore Structure of Mixed-Fiber-Reinforced Concrete Containing Fine Aggregates of Iron Ore Tailings. Minerals. 2024, 15, 8992. [Google Scholar] [CrossRef]

- Liu, H.B.; Zhang, C.; Jia, C.; Tao, D.D. Freeze-thaw cycle characteristics of graphite tailing concrete and steel fiber reinforced-graphite tailing concrete. Constr. Build. Mater. 2025, 3462, 140006. [Google Scholar] [CrossRef]

- Xu, Y.; Yao, L.; Yu, X. Effect of polypropylene fibers on mechanical and wetting properties of overall superhydrophobic foamed concrete. Constr. Build. Mater. 2024, 448, 138207. [Google Scholar] [CrossRef]

- Bian, P.; Yu, Q.; Zhan, B.; Gao, P.; Guo, B.; Hong, L.; Yang, Y.; Han, A. Enhancing electromagnetic wave absorption and flexural properties in carbon fiber-reinforced foamed cement-based composites. Constr. Build. Mater. 2024, 415, 134989. [Google Scholar] [CrossRef]

- Shi, X.; Ning, B.; Wang, J.; Cui, T.; Zhong, M. Improving flexural toughness of foamed concrete by mixing polyvinyl alcohol-polypropylene fibers: An experimental study. Constr. Build. Mater. 2024, 400, 132689. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Sun, W.; Hou, Z.M.; Wu, A.X.; Li, Z.Y.; He, Y.Y.; Liu, B.; Jiang, M.G.; Wang, S.Y. Research on the strength influence and crack evolution law of layered backfill based on macro and meso mechanical response. Constr. Build. Mater. 2024, 449, 138493. [Google Scholar] [CrossRef]

- Song, Q.; Zou, Y.J.; Bao, J.W.; Zhang, P. Disposal of solid waste as building materials: A study on the mechanical and durability performance of concrete composed of gold tailings. J. Mater. Res. Technol. 2024, 30, 2111–2124. [Google Scholar]

- Wang, S.; Li, J.; Li, F.; Li, J.; Zhang, C.; Ji, M.; Man, J.; Peng, S. Study on the influential effect of different CaCO3 particle sizes on the internal pore structure of starch/fiber foaming composite materials. Mater. Today Commun. 2024, 38, 107867. [Google Scholar] [CrossRef]

- Li, Z.; Sun, W.; Gao, T.; Zhao, J.; Lu, K.; Cheng, H. Experimental study on evolution of pore structure of inclined layered cemented tailings backfill based on X-ray CT. Constr. Build. Mater. 2023, 366, 130242. [Google Scholar]

- Li, J.; Han, X.; Li, X.; Diao, H.; He, Z. Investigation of aggregate gradation on air voids distribution in porous asphalt concrete using X-ray CT scanning images. Case Stud. Constr. Mater. 2024, 21, e03710. [Google Scholar] [CrossRef]

- Meng, Y.; Pei, J.; Chen, Z.; Guo, F.; Dai, X.; Huang, G. Study on sound absorption characteristic of porous asphalt mixture based on macroscale and mesoscale analysis. Constr. Build. Mater. 2023, 408, 133776. [Google Scholar]

- Yang, J.; Chen, B.; Wu, X.; Xu, G. Quantitative analysis of steel fibers on UHPFRC uniaxial tensile behavior using X-CT and UTT. Constr. Build. Mater. 2023, 368, 130349. [Google Scholar] [CrossRef]

- Jiang, M.; Cao, S.; Yilmaz, E. Analyzing microscopic structure and macroscopic strength behavior of cement-based tail fills incorporating fiber by X-ray CT scanning technique. Constr. Build. Mater. 2024, 440, 137453. [Google Scholar] [CrossRef]

- Li, J.; Cao, S.; Yilmaz, E. Analyzing the microstructure of cemented fills adding polypropylene-glass fibers with X-ray micro-computed tomography. J. Mater. Res. Technol. 2023, 27, 2627–2640. [Google Scholar] [CrossRef]

- Hao, Z.; Lu, C.; Dong, B.; Li, V.C. 3D crack recognition in Engineered Cementitious Composites (ECC) based on super-resolution reconstruction and semantic segmentation of X-ray Computed Microtomography. Compos. B Eng. 2024, 285, 111730. [Google Scholar]

- Chen, S.; Xiang, Z.G.; Yao, N.; Liu, G.; Hou, C.; Li, Z.P. Effects of superabsorbent polymer on mechanical properties of cemented paste backfill and its mechanism evolution. Constr. Build. Mater. 2024, 445, 137911. [Google Scholar]

- Wu, A.X.; Wang, Y.; Ruan, Z.E.; Xiao, B.L.; Wang, J.D.; Wang, L.Q. Key theory and technology of cemented paste backfill for green mining of metal mines. Green Smart Min. Eng. 2024, 1, 27–39. [Google Scholar]

- Liu, P.; Yang, K.; Li, C.; Li, C.; Zhang, S. Experimental study on microstructural properties of iron tailings foam concrete and its relationship with macromechanical properties. Constr. Build. Mater. 2025, 462, 139984. [Google Scholar]

- Zhao, D.; Xu, J.; Han, Z.; Liu, Y.; Liu, Y.; Yang, X. Study on the correlation between pore structure characterization and early mechanical properties of foamed concrete based on X-CT. Constr. Build. Mater. 2024, 450, 138603. [Google Scholar]

- Yang, Z.; Dong, S.; Zhong, Y. Particle packing optimization and pore structure assessment of ternary cementitious system based on X-ray computed tomography and mercury intrusion porosimetry. Constr. Build. Mater. 2024, 413, 134913. [Google Scholar]

- Sun, J.L.; Sun, M.; Su, A.S.; Gao, X.J. Influence of graphite tailings on the mechanical performance, of ultra-high performance concrete. Case Stud. Constr. Mater. 2025, 221, e04246. [Google Scholar]

| Materials | SiO2 | Al2O3 | K2O | CaO | Fe2O3 | Na2O | MgO | TiO2 | P2O5 |

|---|---|---|---|---|---|---|---|---|---|

| Tailings | 74.43 | 11.71 | 4.79 | 2.89 | 2.79 | 1.43 | 0.97 | 0.34 | 0.23 |

| Cement | 21.64 | 6.88 | 1.29 | 60.00 | 3.80 | 0.29 | 2.57 | 0.44 | 0.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, T.; Cao, S.; Yilmaz, E. Exploring Pore Structure Features, Crack Propagation and Failure Behavior of Fiber Reinforced Foam Tail Fill by CT Imaging and 3D Reconstruction. Minerals 2025, 15, 354. https://doi.org/10.3390/min15040354

Jiang T, Cao S, Yilmaz E. Exploring Pore Structure Features, Crack Propagation and Failure Behavior of Fiber Reinforced Foam Tail Fill by CT Imaging and 3D Reconstruction. Minerals. 2025; 15(4):354. https://doi.org/10.3390/min15040354

Chicago/Turabian StyleJiang, Tingting, Shuai Cao, and Erol Yilmaz. 2025. "Exploring Pore Structure Features, Crack Propagation and Failure Behavior of Fiber Reinforced Foam Tail Fill by CT Imaging and 3D Reconstruction" Minerals 15, no. 4: 354. https://doi.org/10.3390/min15040354

APA StyleJiang, T., Cao, S., & Yilmaz, E. (2025). Exploring Pore Structure Features, Crack Propagation and Failure Behavior of Fiber Reinforced Foam Tail Fill by CT Imaging and 3D Reconstruction. Minerals, 15(4), 354. https://doi.org/10.3390/min15040354