One-Part Alkali-Activated Wood Biomass Binders for Cemented Paste Backfill

Abstract

1. Introduction

2. Materials and Experiments

2.1. Raw Materials

2.2. Sample Preparation

2.3. Experimental Methods

2.3.1. XRD, TGA, and FTIR Tests

2.3.2. Flow Spread and Rheology Tests

2.3.3. Zeta Potential Test

2.3.4. UCS Test

2.3.5. MIP Test

3. Results and Discussion

3.1. Characterizations of Pastes

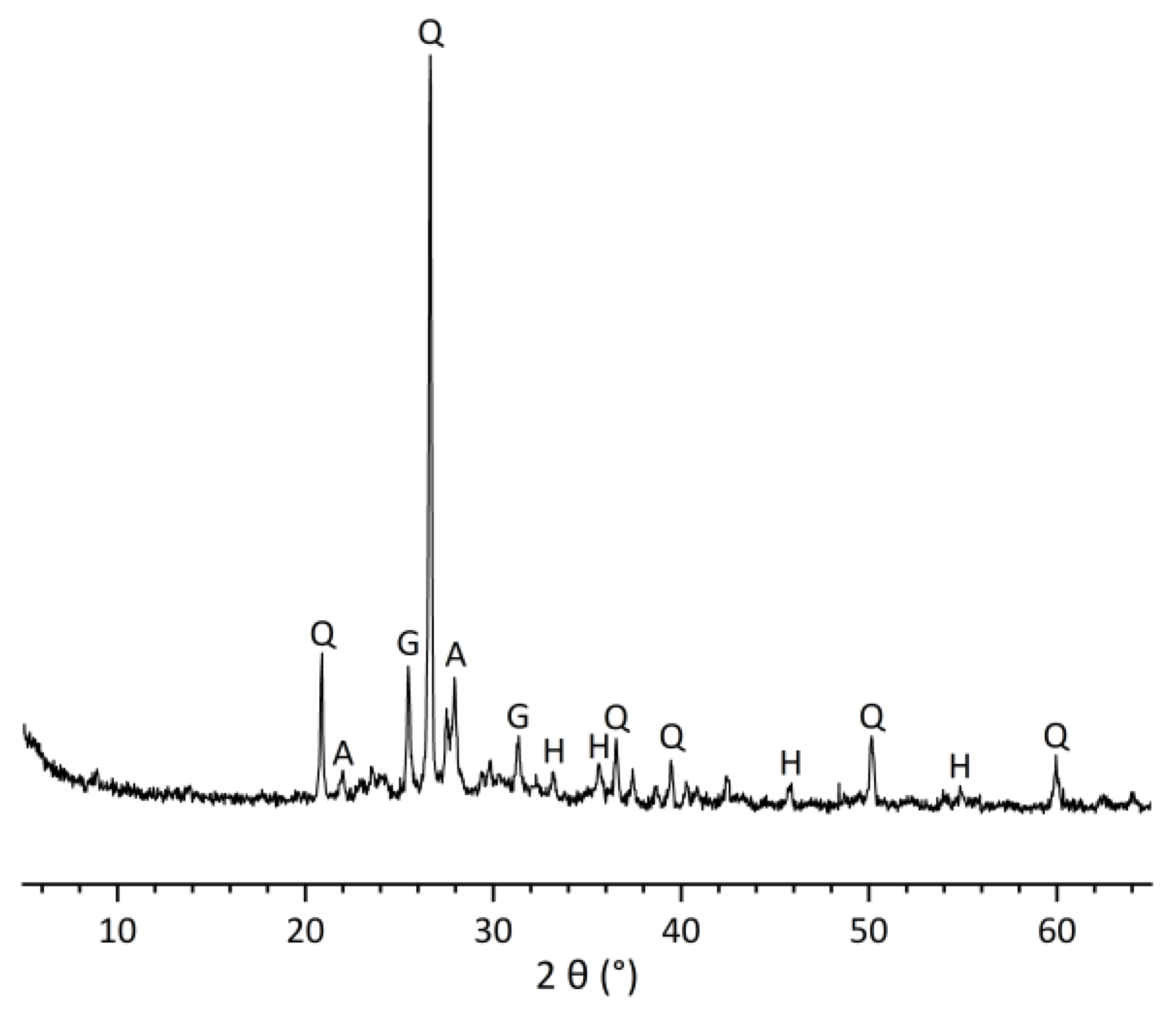

3.1.1. XRD

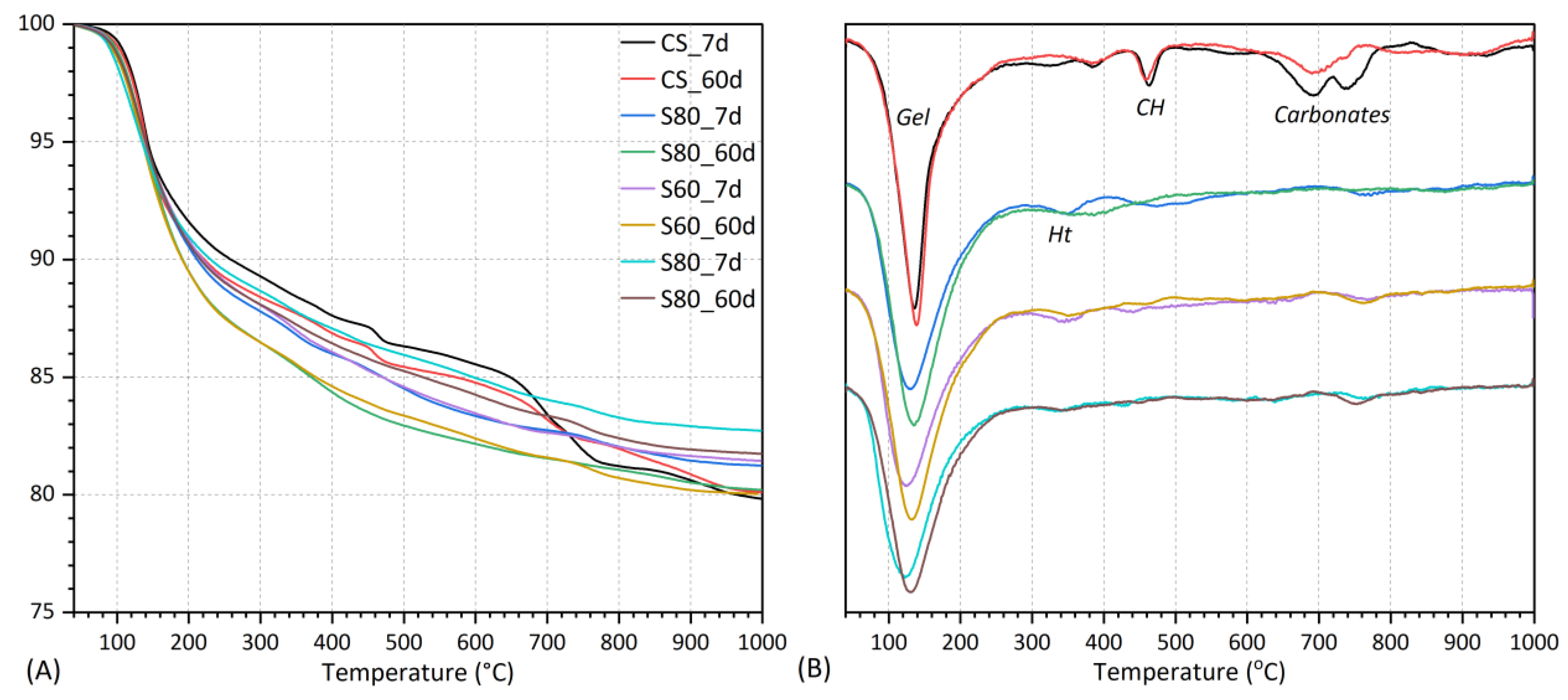

3.1.2. TGA

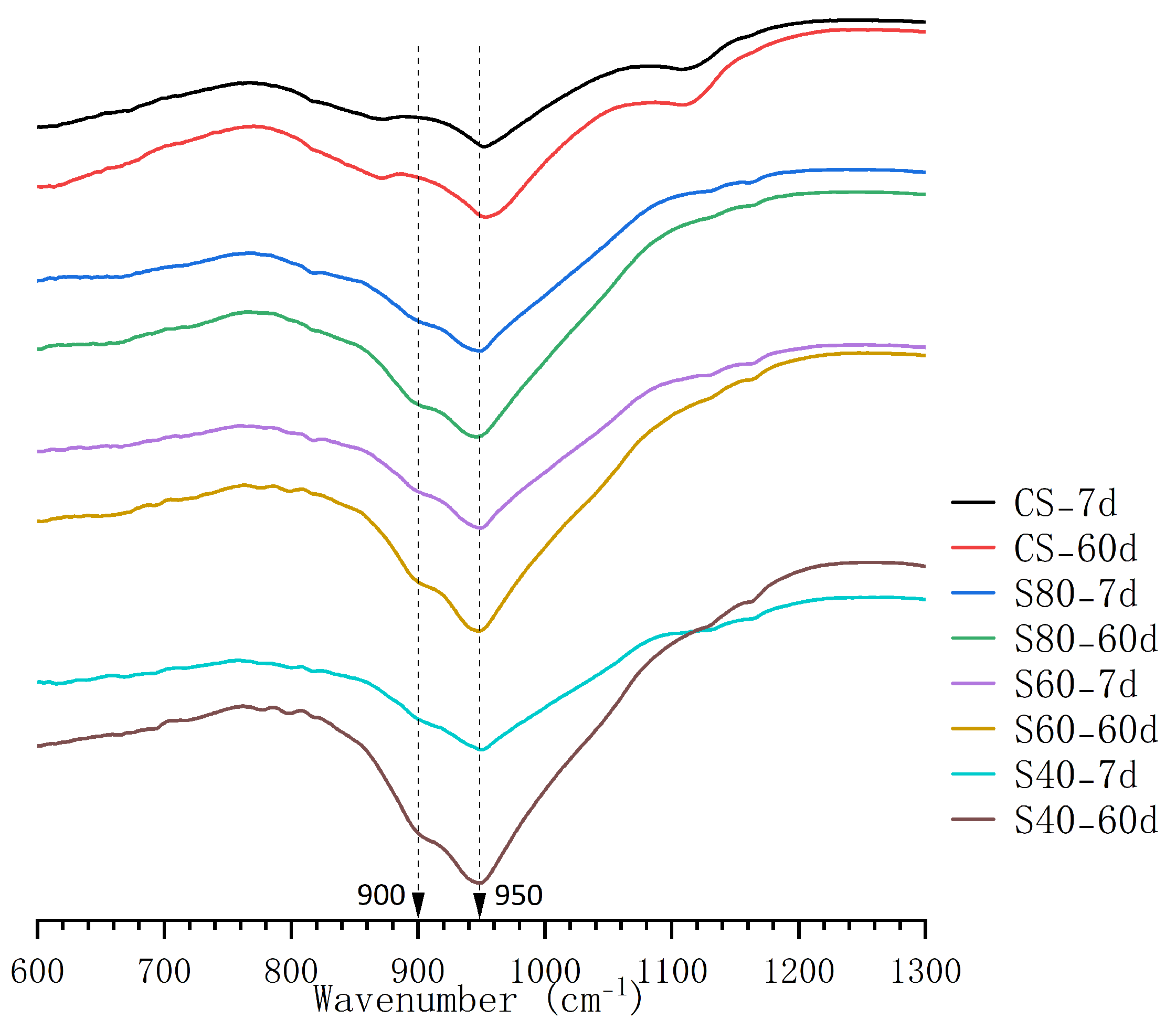

3.1.3. FTIR

3.2. Characterizations of CPB

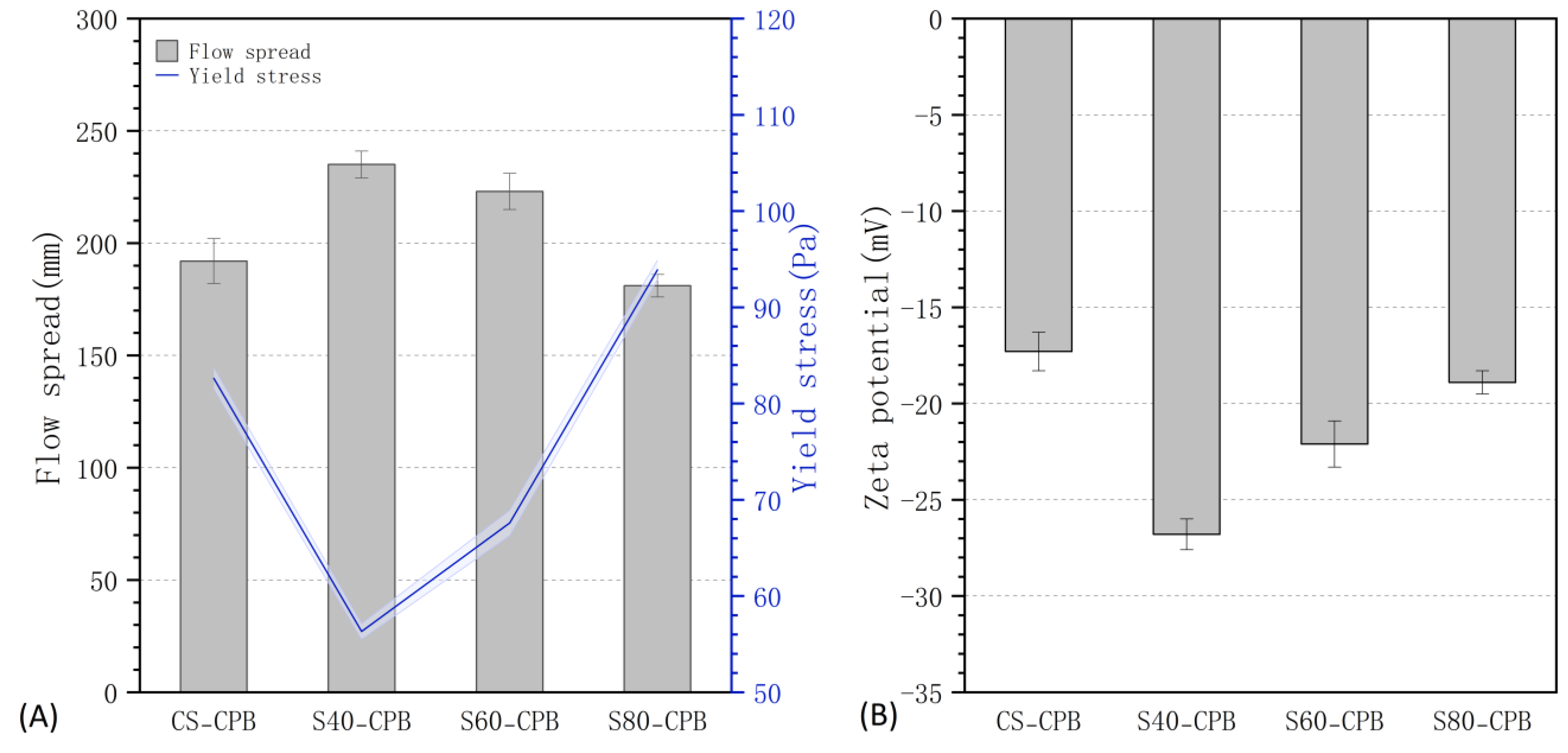

3.2.1. Flow Spread and Yield Stress

3.2.2. UCS

3.2.3. Microstructure

4. Conclusions

- The hydration products of the alkali-activated slag–wood biomass ash system were dominated by disordered gels, without forming crystalline phases such as ettringite or hydrotalcite. However, the Si–O bond vibration peak (950 cm−1) in these gels exhibited a polymerization degree comparable to those in cement-based systems. WBFA reduced the Ca/Si ratio, facilitating the formation of bridging sites (900 cm−1) within the gel matrix and thereby enhancing microstructural densification.

- Increasing slag content (with reduced WBFA proportion) decreased the flow spread of CPB while elevating yield stress. This behavior arises from slag hydration products forming dense network structures, which increase internal friction within the slurry. Concurrently, higher slag proportions reduced particle surface zeta potential, weakening electrostatic repulsion and enhancing particle aggregation, further diminishing fluidity.

- Inert components in WBFA (e.g., quartz) suppressed early hydration reactions, but long-term strength was compensated by sustained slag hydration. High-WBFA CPB (e.g., S40-CPB) exhibited a 3-day compressive strength of only 0.88 MPa, significantly lower than cement-based CPB (CS-CPB: 1.46 MPa), primarily due to WBFA diluting reactive components and retarding slag hydration. However, after 28 days, high-slag systems (e.g., S80-CPB) achieved a strength of 4.11 MPa, comparable to CS-CPB (4.16 MPa), demonstrating that long-term hydration products from slag effectively offset WBFA’s inhibitory effects.

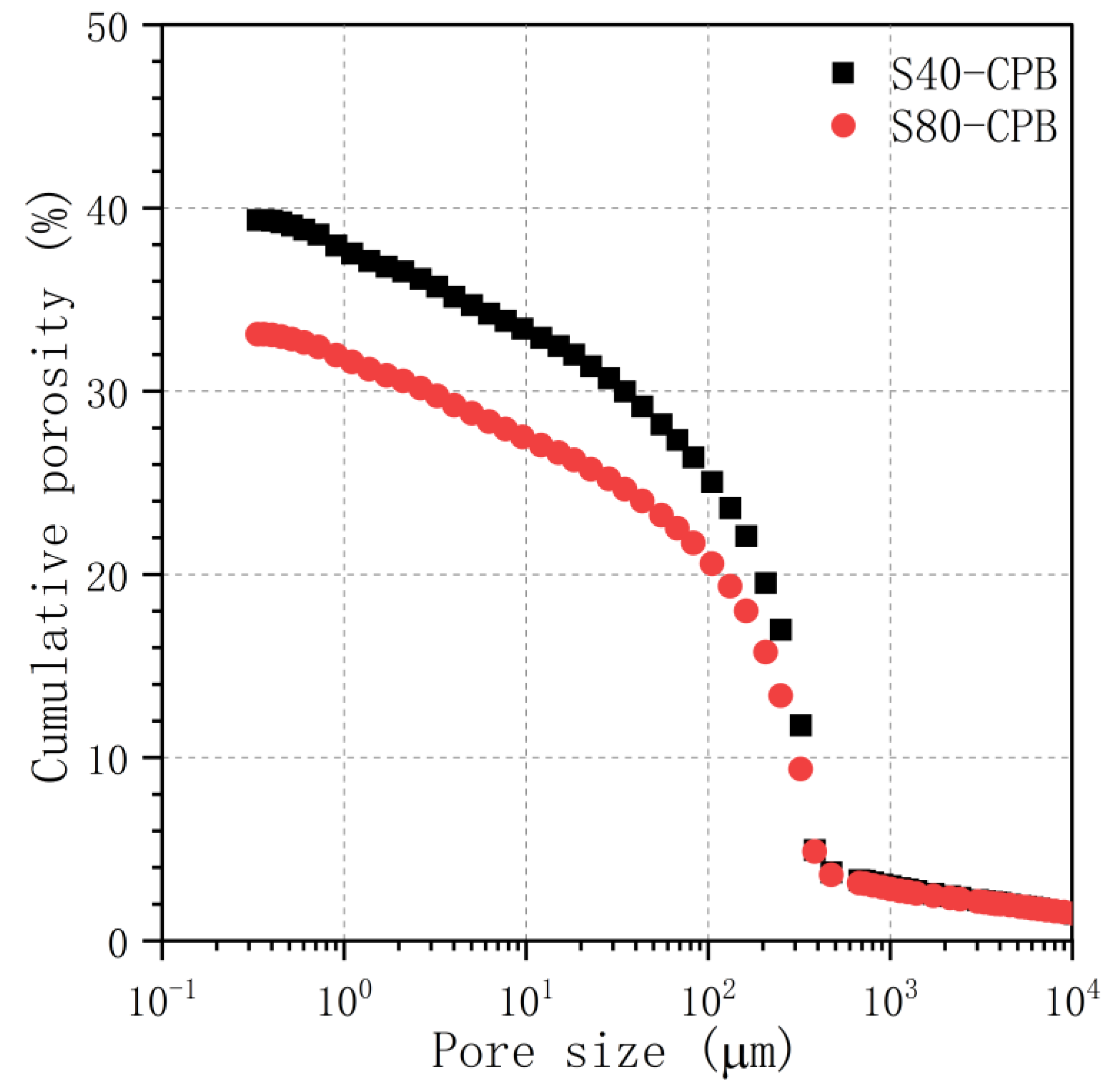

- High-slag S80-CPB, enriched with hydration products, formed tightly interconnected networks and exhibited significantly lower porosity than high-WBFA S40-CPB, particularly showing uniform densification in the micropore range. In contrast, S40-CPB’s loose structure and unreacted WBFA particles resulted in elevated porosity, compromising mechanical strength. These findings highlight that optimizing slag-to-WBFA ratios to regulate microstructure is critical for enhancing CPB performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hu, S.; Qiu, J.; Zhang, Q.; Guo, Z.; Liu, C. Quantitative Analysis of Yield Stress and Its Evolution in Fiber-Reinforced Cemented Paste Backfill. Minerals 2025, 15, 81. [Google Scholar] [CrossRef]

- Ghirian, A.; Fall, M. Coupled Behavior of Cemented Paste Backfill at Early Ages. Geotech. Geol. Eng. 2015, 33, 1141–1166. [Google Scholar] [CrossRef]

- Guo, Z.; Qiu, J.; Pel, L.; Zhao, Y.; Zhu, Q.; Kwek, J.W.; Zhang, L.; Jiang, H.; Yang, J.; Qu, Z. A Contribution to Understanding the Rheological Measurement, Yielding Mechanism and Structural Evolution of Fresh Cemented Paste Backfill. Cem. Concr. Compos. 2023, 143, 105221. [Google Scholar] [CrossRef]

- Zhu, K.; Wang, H.; Zhao, X.; Luo, G.; Dai, K.; Hu, Q.; Liu, Y.; Liu, B.; Miao, Y.; Liu, J.; et al. Effects of Superfine Cement on Fluidity, Strength, and Pore Structure of Superfine Tailings Cemented Paste Backfill. Minerals 2024, 15, 24. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, H.; Luo, G.; Dai, K.; Hu, Q.; Jin, J.; Liu, Y.; Liu, B.; Miao, Y.; Zhu, K.; et al. Study on the Rheological and Thixotropic Properties of Fiber-Reinforced Cemented Paste Backfill Containing Blast Furnace Slag. Minerals 2024, 14, 964. [Google Scholar] [CrossRef]

- Al-Moselly, Z.; Fall, M. Multiphysical Testing of Strength Development of Cemented Paste Backfill Containing Superplasticizer. Cem. Concr. Compos. 2024, 154, 105772. [Google Scholar] [CrossRef]

- Zhao, Y.; Guo, Y.; Feng, G.; Li, C.; Xie, W.; Zhang, C. Study on Strength and Deformation Characteristics of Cemented Gangue Backfill Body under the Coupling Action of Load and Salt Erosion. Constr. Build. Mater. 2022, 342, 128003. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z.; Wu, A.; Wang, L.; Na, Q.; Cao, C.; Yang, G. Experimental Research and Numerical Simulation of the Multi-Field Performance of Cemented Paste Backfill: Review and Future Perspectives. Int. J. Miner. Metall. Mater. 2023, 30, 193–208. [Google Scholar] [CrossRef]

- Li, Y.; Yao, N.; Ye, Y.; Guan, W.; Wu, M.; Chen, G. Study on the Leaching of Harmful Elements and Pore Characteristics of Phosphogypsum-Based Cemented Paste Backfill under Multi-Field Coupling Interaction. Environ. Earth Sci. 2024, 83, 512. [Google Scholar] [CrossRef]

- Sagade, A.; Fall, M. Study of Fresh Properties of Cemented Paste Backfill Material with Ternary Cement Blends. Constr. Build. Mater. 2024, 411, 134287. [Google Scholar] [CrossRef]

- Yang, L.; Jia, H.; Wu, A.; Jiao, H.; Chen, X.; Kou, Y.; Dong, M. Particle Aggregation and Breakage Kinetics in Cemented Paste Backfill. Int. J. Miner. Metall. Mater. 2024, 31, 1965–1974. [Google Scholar] [CrossRef]

- Siame, M.C.; Zvarivadza, T.; Edjeou, W.; Simate, I.N.; Lusambo, E. Integrating Process Re-Engineering Models in Cement Production to Improve Energy Efficiency. Appl. Sci. 2024, 14, 8850. [Google Scholar] [CrossRef]

- Miller, S.A.; Juenger, M.; Kurtis, K.E.; Weiss, J. Cement and Alternatives in the Anthropocene. Annu. Rev. Environ. Resour. 2024, 49, 309–335. [Google Scholar] [CrossRef]

- Sarangi, S.; Suganya, O.M. A Comprehensive Review of the Physical and Mechanical Characteristics of Agricultural By-Products as Cementitious Alternatives in the Production of Sustainable Concrete. Mater. Today Sustain. 2024, 100882. [Google Scholar] [CrossRef]

- Liang, X.; Li, Z.; Dong, H.; Ye, G. A Review on the Characteristics of Wood Biomass Fly Ash and Their Influences on the Valorization in Cementitious Materials. J. Build. Eng. 2024, 27, 110927. [Google Scholar] [CrossRef]

- Odzijewicz, J.I.; Wołejko, E.; Wydro, U.; Wasil, M.; Jabłońska-Trypuć, A. Utilization of Ashes from Biomass Combustion. Energies 2022, 15, 9653. [Google Scholar] [CrossRef]

- Silvestro, L.; Scolaro, T.P.; Ruviaro, A.S.; dos Santos Lima, G.T.; Gleize, P.J.P.; Pelisser, F. Use of Biomass Wood Ash to Produce Sustainable Geopolymeric Pastes. Constr. Build. Mater. 2023, 370, 130641. [Google Scholar] [CrossRef]

- Gabrijel, I.; Skazlić, M.; Štirmer, N. Long-Term Behavior of Concrete Containing Wood Biomass Fly Ash. Appl. Sci. 2022, 12, 12859. [Google Scholar] [CrossRef]

- Olatoyan, O.J.; Kareem, M.A.; Adebanjo, A.U.; Olawale, S.O.A.; Alao, K.T. Potential Use of Biomass Ash as a Sustainable Alternative for Fly Ash in Concrete Production: A Review. Hybrid Adv. 2023, 4, 100076. [Google Scholar] [CrossRef]

- Carević, I.; Štirmer, N.; Trkmić, M.; Kostanić Jurić, K. Leaching Characteristics of Wood Biomass Fly Ash Cement Composites. Appl. Sci. 2020, 10, 8704. [Google Scholar] [CrossRef]

- De Rossi, A.; Simão, L.; Ribeiro, M.J.; Hotza, D.; Moreira, R. Study of Cure Conditions Effect on the Properties of Wood Biomass Fly Ash Geopolymers. J. Mater. Res. Technol. 2020, 9, 7518–7528. [Google Scholar] [CrossRef]

- Rajamma, R.; Senff, L.; Ribeiro, M.J.; Labrincha, J.A.; Ball, R.J.; Allen, G.C.; Ferreira, V.M. Biomass Fly Ash Effect on Fresh and Hardened State Properties of Cement Based Materials. Compos. Part B Eng. 2015, 77, 1–9. [Google Scholar] [CrossRef]

- Teixeira, E.R.; Camões, A.; Branco, F.G. Synergetic Effect of Biomass Fly Ash on Improvement of High-Volume Coal Fly Ash Concrete Properties. Constr. Build. Mater. 2022, 314, 125680. [Google Scholar] [CrossRef]

- Berra, M.; Mangialardi, T.; Paolini, A.E. Reuse of Woody Biomass Fly Ash in Cement-Based Materials. Constr. Build. Mater. 2015, 76, 286–296. [Google Scholar] [CrossRef]

- Oyejobi, D.O.; Firoozi, A.A.; Fernandez, D.B.; Avudaiappan, S. Integrating Circular Economy Principles into Concrete Technology: Enhancing Sustainability through Industrial Waste Utilization. Results Eng. 2024, 24, 102846. [Google Scholar] [CrossRef]

- Khalil, A.K.A.; Bouaziz, I.; Jaber, L.; Abushawish, A.; Almanassra, I.W.; Abdelkareem, M.A.; Atieh, M.A. Fly Ash as Zero Cost Material for Water Treatment Applications: A State of the Art Review. Sep. Purif. Technol. 2024, 354, 129104. [Google Scholar] [CrossRef]

- Prasittisopin, L. Power Plant Waste (Fly Ash, Bottom Ash, Biomass Ash) Management for Promoting Circular Economy in Sustainable Construction: Emerging Economy Context. Smart Sustain. Built Environ. 2024; ahead-of-print. [Google Scholar]

- Rolka, E.; Wyszkowski, M.; Żołnowski, A.C.; Skorwider-Namiotko, A. Role of Woody Biomass Ash Material in Immobilization of Cadmium, Lead and Zinc in Soil. Materials 2024, 17, 2206. [Google Scholar] [CrossRef]

- Du, Y.; Pundienė, I.; Pranckevičienė, J.; Kligys, M.; Girskas, G.; Korjakins, A. A Review of Biomass Wood Ash in Alkali-Activated Materials: Treatment, Application, and Outlook. J. Compos. Sci. 2024, 8, 161. [Google Scholar] [CrossRef]

- Maier, D.; Manea, D.L.; Tămaș-Gavrea, D.-R.; Țiriac, A.; Costin, P. Wood—Cement Composites: A Sustainable Approach for Mitigating Environmental Impact in Construction. J. Compos. Sci. 2024, 8, 474. [Google Scholar] [CrossRef]

- Yu, Z.; Kong, W.; Ji, Z.; Wang, Y. Impact of Virgin and Recycled Polymer Fibers on the Rheological Properties of Cemented Paste Backfill. Sci. Rep. 2024, 14, 17783. [Google Scholar] [CrossRef]

- Guo, Z.; Qiu, J.; Kirichek, A.; Zhou, H.; Liu, C.; Yang, L. Recycling Waste Tyre Polymer for Production of Fibre Reinforced Cemented Tailings Backfill in Green Mining. Sci. Total Environ. 2024, 908, 168320. [Google Scholar] [CrossRef] [PubMed]

- Fall, M.; Benzaazoua, M.; Ouellet, S. Experimental Characterization of the Influence of Tailings Fineness and Density on the Quality of Cemented Paste Backfill. Miner. Eng. 2005, 18, 41–44. [Google Scholar] [CrossRef]

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. One-Part Alkali-Activated Materials: A Review. Cem. Concr. Res. 2018, 103, 21–34. [Google Scholar] [CrossRef]

- Liu, C.; Liang, X.; Chen, Y.; Li, Z.; Ye, G. Degradation of Alkali-Activated Slag Subjected to Water Immersion. Cem. Concr. Compos. 2023, 142, 105157. [Google Scholar] [CrossRef]

- Liu, C.; Wu, H.; Li, Z.; Shi, H.; Ye, G. Effect of Curing Condition on Mechanical Properties and Durability of Alkali-Activated Slag Mortar. Constr. Build. Mater. 2024, 439, 137376. [Google Scholar] [CrossRef]

- Guo, Z.; Qiu, J.; Jiang, H.; Xing, J.; Sun, X.; Ma, Z. Flowability of Ultrafine-Tailings Cemented Paste Backfill Incorporating Superplasticizer: Insight from Water Film Thickness Theory. Powder Technol. 2021, 381, 509–517. [Google Scholar] [CrossRef]

- Qiu, J.; Guo, Z.; Yang, L.; Jiang, H.; Zhao, Y. Effect of Tailings Fineness on Flow, Strength, Ultrasonic and Microstructure Characteristics of Cemented Paste Backfill. Constr. Build. Mater. 2020, 263, 120645. [Google Scholar] [CrossRef]

- Guo, Z.; Sun, X.; Zhang, X.; Qiu, J.; Jiang, H.; Zhao, Y.; Wu, P.; Zhang, Q. Effect of Superplasticizer on Rheology and Thixotropy of Superfine-Tailings Cemented Paste Backfill: Experiment and Modelling. Constr. Build. Mater. 2022, 316, 125693. [Google Scholar] [CrossRef]

- Qu, Z.; Yu, Q.; Ong, G.P.; Cardinaels, R.; Ke, L.; Long, Y.; Geng, G. 3D Printing Concrete Containing Thermal Responsive Gelatin: Towards Cold Environment Applications. Cem. Concr. Compos. 2023, 140, 105029. [Google Scholar] [CrossRef]

- Jiang, H.; Qi, Z.; Yilmaz, E.; Han, J.; Qiu, J.; Dong, C. Effectiveness of Alkali-Activated Slag as Alternative Binder on Workability and Early Age Compressive Strength of Cemented Paste Backfills. Constr. Build. Mater. 2019, 218, 689–700. [Google Scholar] [CrossRef]

- Jiang, H.; Fall, M. Yield Stress and Strength of Saline Cemented Tailings in Sub-Zero Environments: Portland Cement Paste Backfill. Int. J. Miner. Process. 2017, 160, 68–75. [Google Scholar] [CrossRef]

- Xiu, Z.; Wang, S.; Ji, Y.; Wang, F.; Ren, F.; Nguyen, V.-T. Loading Rate Effect on the Uniaxial Compressive Strength (UCS) Behavior of Cemented Paste Backfill (CPB). Constr. Build. Mater. 2021, 271, 121526. [Google Scholar] [CrossRef]

- Scrivener, K.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2016; Volume 540. [Google Scholar]

- Fořt, J.; Šál, J.; Ševčík, R.; Doleželová, M.; Keppert, M.; Jerman, M.; Záleská, M.; Stehel, V.; Černý, R. Biomass Fly Ash as an Alternative to Coal Fly Ash in Blended Cements: Functional Aspects. Constr. Build. Mater. 2021, 271, 121544. [Google Scholar] [CrossRef]

- Aydin, S.; Baradan, B. Effect of Activator Type and Content on Properties of Alkali-Activated Slag Mortars. Compos. Part B Eng. 2014, 57, 166–172. [Google Scholar] [CrossRef]

- Wang, S.-D.; Scrivener, K.L. Hydration Products of Alkali Activated Slag Cement. Cem. Concr. Res. 1995, 25, 561–571. [Google Scholar] [CrossRef]

- Alarcon-Ruiz, L.; Platret, G.; Massieu, E.; Ehrlacher, A. The Use of Thermal Analysis in Assessing the Effect of Temperature on a Cement Paste. Cem. Concr. Res. 2005, 35, 609–613. [Google Scholar] [CrossRef]

- Taylor, H.F.W. Cement Chemistry; Thomas Telford: London, UK, 1997; Volume 2. [Google Scholar]

- Liu, C.; Zhang, Y.; Liang, M.; Li, Z.; Ye, G. Underwater Carbonation of Alkali-Activated Slag Pastes. Constr. Build. Mater. 2024, 445, 137967. [Google Scholar] [CrossRef]

- Liu, C.; Li, Z.; Nie, S.; Skibsted, J.; Ye, G. Structural Evolution of Calcium Sodium Aluminosilicate Hydrate (C-(N-) ASH) Gels Induced by Water Exposure: The Impact of Na Leaching. Cem. Concr. Res. 2024, 178, 107432. [Google Scholar] [CrossRef]

- Liu, C.; Li, Z.; Ye, G. Mechanisms of Efflorescence of Alkali-Activated Slag. Cem. Concr. Compos. 2025, 155, 105811. [Google Scholar] [CrossRef]

- Vidmer, A.; Sclauzero, G.; Pasquarello, A. Infrared Spectra of Jennite and Tobermorite from First-Principles. Cem. Concr. Res. 2014, 60, 11–23. [Google Scholar] [CrossRef]

- Yu, P.; Kirkpatrick, R.J.; Poe, B.; McMillan, P.F.; Cong, X. Structure of Calcium Silicate Hydrate (C-S-H): Near-, Mid-, and Far-Infrared Spectroscopy. J. Am. Ceram. Soc. 1999, 82, 742–748. [Google Scholar] [CrossRef]

- Guo, Z.; Qiu, J.; Huang, D.; Liu, K.; Kirichek, A.; Liu, C.; Chen, B.; Zhao, Y.; Qu, Z. Rheology of Flexible Fiber-Reinforced Cement Pastes: Maximum Packing Fraction Determination and Structural Build-up Analysis. Compos. Struct. 2025, 352, 118662. [Google Scholar] [CrossRef]

- Sohn, I.; Min, D.J. A Review of the Relationship between Viscosity and the Structure of Calcium-Silicate-Based Slags in Ironmaking. Steel Res. Int. 2012, 83, 611–630. [Google Scholar] [CrossRef]

- Li, H.; Chen, J.; Peng, C.; Min, F.; Song, S. Salt Coagulation or Flocculation? In Situ Zeta Potential Study on Ion Correlation and Slime Coating with the Presence of Clay: A Case of Coal Slurry Aggregation. Environ. Res. 2020, 189, 109875. [Google Scholar] [CrossRef]

- Elakneswaran, Y.; Nawa, T.; Kurumisawa, K. Zeta Potential Study of Paste Blends with Slag. Cem. Concr. Compos. 2009, 31, 72–76. [Google Scholar] [CrossRef]

- Mahfoud, E.; Maherzi, W.; Ndiaye, K.; Benzerzour, M.; Aggoun, S.; Abriak, N.-E. Mechanical and Microstructural Properties of Just Add Water Geopolymer Cement Comprised of Thermo-Mechanicalsynthesis Sediments-Fly Ash Mix. Constr. Build. Mater. 2023, 400, 132626. [Google Scholar] [CrossRef]

- Mahfoud, E.; Maherzi, W.; Ndiaye, K.; Abriak, N.-E.; Aggoun, S.; Benzerzour, M. One-Part Geopolymer Based on Micronized Sediments and Fly Ash Mix: Mechanical, Microstructural and Leaching Assessment. J. Build. Eng. 2024, 96, 110426. [Google Scholar] [CrossRef]

- Meng, W.; Lunkad, P.; Kumar, A.; Khayat, K. Influence of Silica Fume and Polycarboxylate Ether Dispersant on Hydration Mechanisms of Cement. J. Phys. Chem. C 2016, 120, 26814–26823. [Google Scholar] [CrossRef]

- Zhao, J.; Li, Z.; Zhu, H.; Liu, Q.; Liu, J. Dissolution-Precipitation Hydration Mechanism of Steel Slag Based on Ion Exchange of a Layered Alkali-Activator. Constr. Build. Mater. 2024, 411, 134795. [Google Scholar] [CrossRef]

- Li, G.; Liu, P.; Chao, S.; Zhang, X.; Li, J.; Zhang, Y.; Duan, Y. The Mineral Phase Evolution Characteristics and Hydration Activity Enhancement Mechanism of Steel Slag under NaOH Alkaline Excitation. J. Alloys Compd. 2024, 978, 173524. [Google Scholar] [CrossRef]

- Liang, X. Valorization of Wood Biomass Fly Ash for the Development of Sustainable Low-Carbon Cementitious Materials. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2024. [Google Scholar]

- Bouchikhi, A.; Mamindy-Pajany, Y.; Maherzi, W.; Albert-Mercier, C.; El-Moueden, H.; Benzerzour, M.; Peys, A.; Abriak, N.-E. Use of Residual Waste Glass in an Alkali-Activated Binder—Structural Characterization, Environmental Leaching Behavior and Comparison of Reactivity. J. Build. Eng. 2021, 34, 101903. [Google Scholar] [CrossRef]

| CaO | SiO2 | Al2O3 | MgO | Fe2O3 | Na2O | K2O | SO3 | Others | |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 64.5 | 20.1 | 5.4 | - | 3.2 | 0.6 | - | 2.9 | 3.3 |

| Slag | 40.2 | 33.8 | 13.6 | 8.4 | 0.4 | 0.2 | 0.5 | 1.5 | 1.4 |

| WBFA | 17.2 | 50.9 | 12.5 | 3.2 | 7.7 | 1.7 | 0.8 | 3.8 | 2.2 |

| Cement | Slag | WBFA | Na2SiO3∙5H2O | Water | |

|---|---|---|---|---|---|

| CS | 30 | 70 | 0 | 0 | 40 |

| S80 | 0 | 80 | 20 | 34 | 40 |

| S60 | 0 | 60 | 40 | 34 | 40 |

| S40 | 0 | 40 | 60 | 34 | 40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, K.; Wang, H.; Dong, L.; Zhao, X.; Jin, J.; Liu, Y.; Liu, J.; Lv, D. One-Part Alkali-Activated Wood Biomass Binders for Cemented Paste Backfill. Minerals 2025, 15, 273. https://doi.org/10.3390/min15030273

Zhu K, Wang H, Dong L, Zhao X, Jin J, Liu Y, Liu J, Lv D. One-Part Alkali-Activated Wood Biomass Binders for Cemented Paste Backfill. Minerals. 2025; 15(3):273. https://doi.org/10.3390/min15030273

Chicago/Turabian StyleZhu, Kunlei, Haijun Wang, Lu Dong, Xulin Zhao, Junchao Jin, Yang Liu, Jianbo Liu, and Dingchao Lv. 2025. "One-Part Alkali-Activated Wood Biomass Binders for Cemented Paste Backfill" Minerals 15, no. 3: 273. https://doi.org/10.3390/min15030273

APA StyleZhu, K., Wang, H., Dong, L., Zhao, X., Jin, J., Liu, Y., Liu, J., & Lv, D. (2025). One-Part Alkali-Activated Wood Biomass Binders for Cemented Paste Backfill. Minerals, 15(3), 273. https://doi.org/10.3390/min15030273