Rheological Properties of Aluminium Oxide Nanoparticle-Modified Cemented Paste Tailings Materials

Abstract

1. Introduction

2. Experimental Approach

2.1. Specimen Preparation and Materials

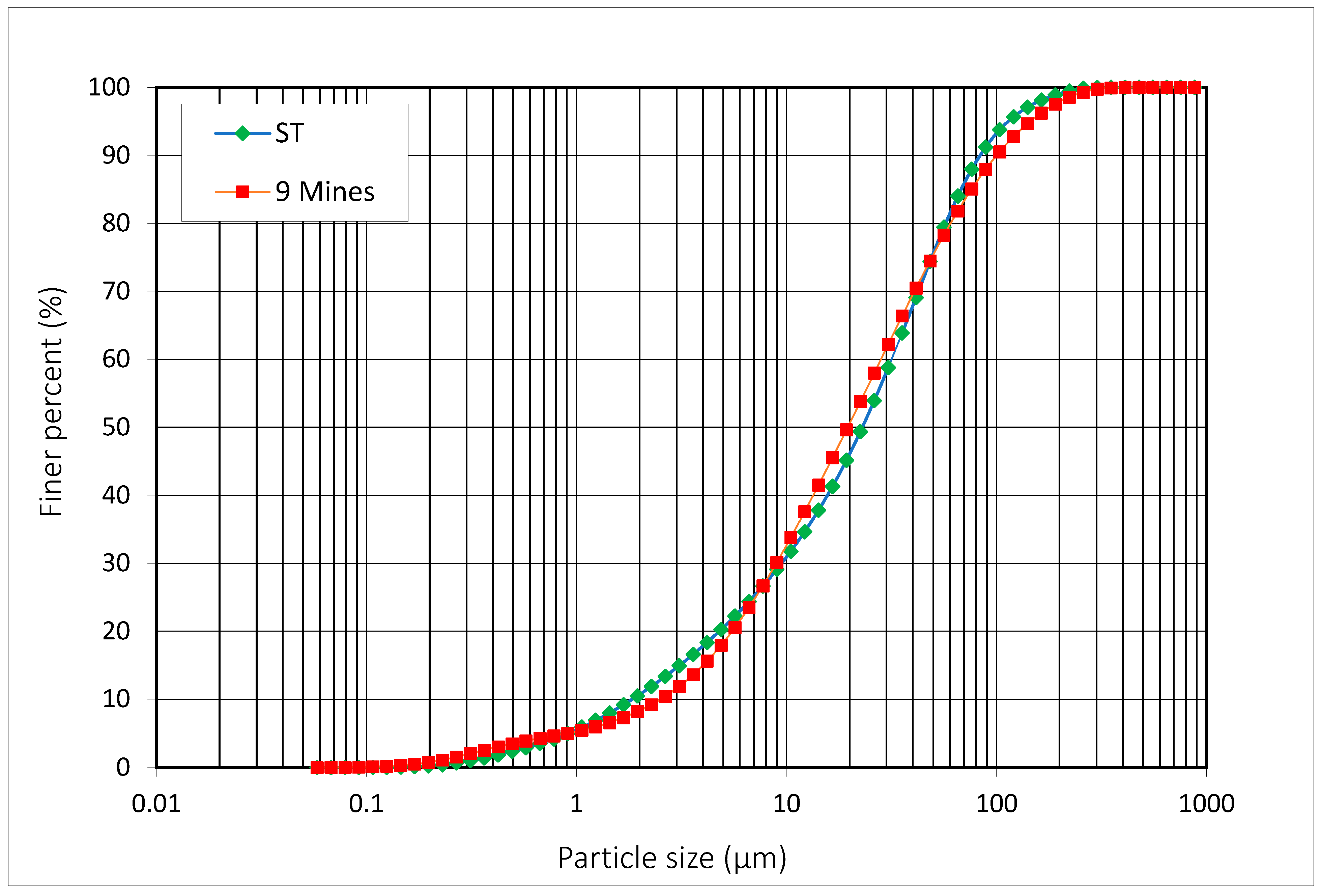

2.1.1. Tailings

2.1.2. Binders and Water

2.1.3. Nano-Aluminium Oxide

2.1.4. Superplasticizer

2.2. Specimen Preparation

2.3. Methods of Testing and Analysis

2.3.1. Viscosity Test

2.3.2. Vane Shear Test

2.3.3. Microstructural Analysis

2.3.4. pH and Zeta Potential (ZP) Measurements

2.3.5. Electrical Conductivity Monitoring

3. Results and Discussion

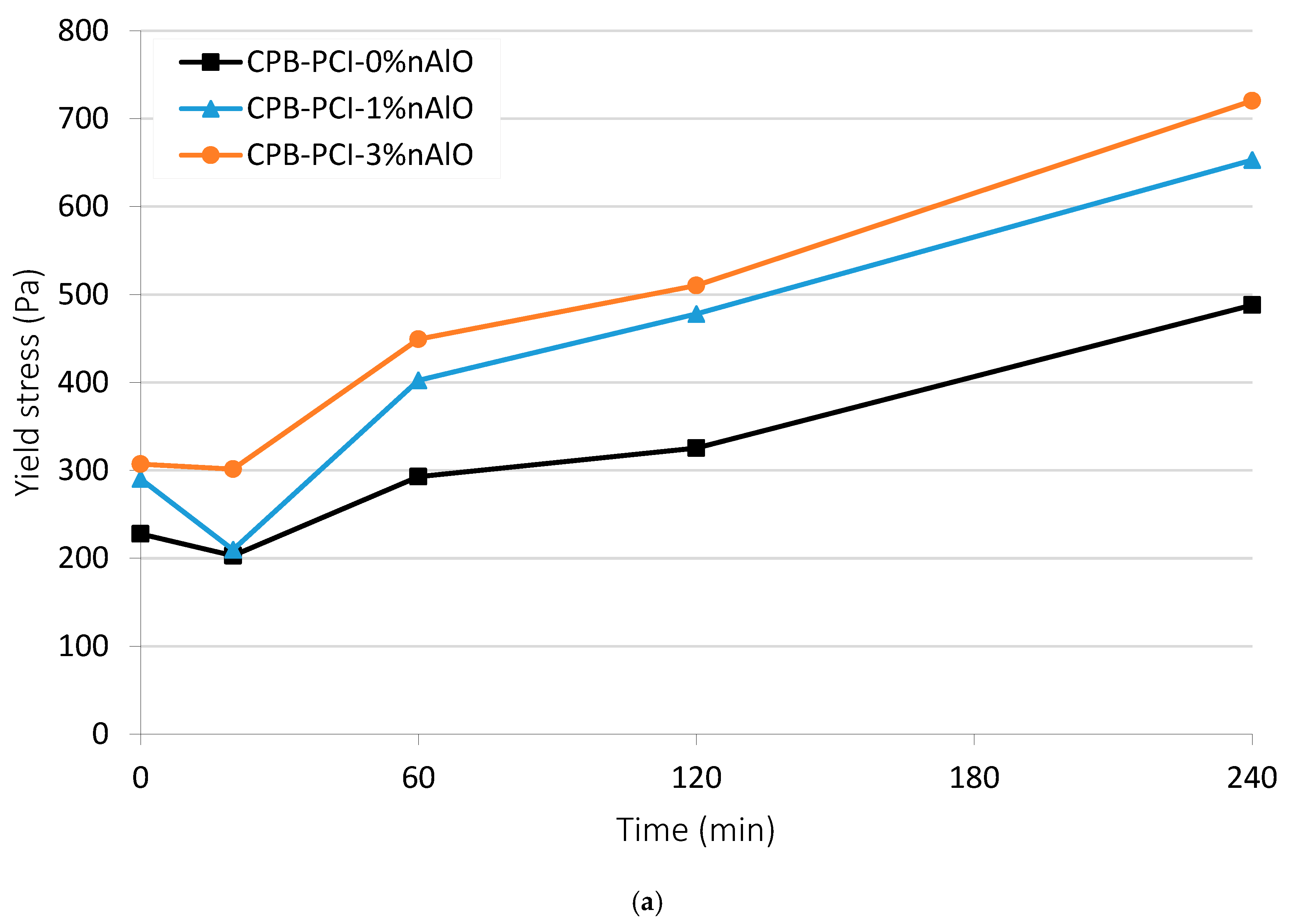

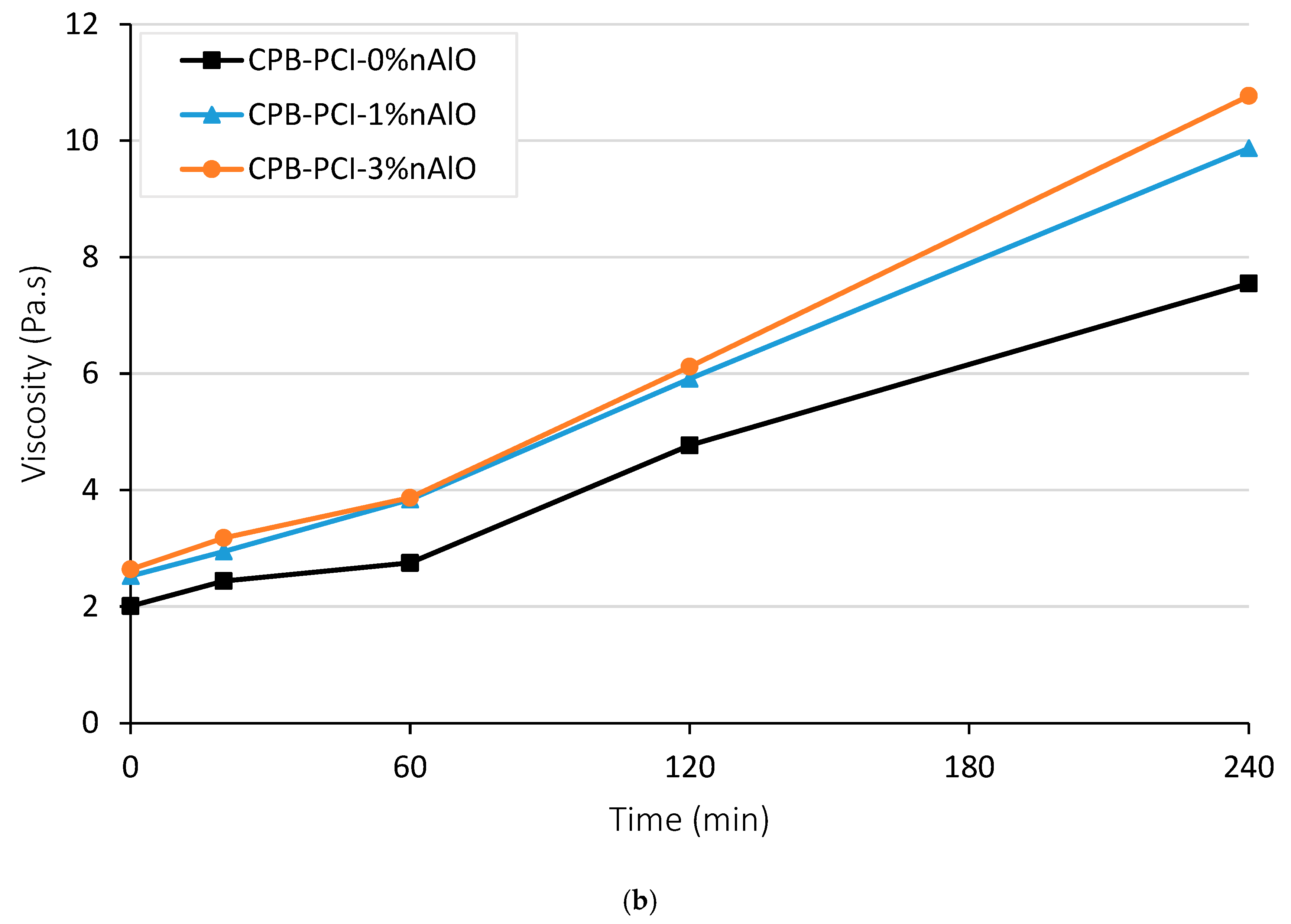

3.1. Influence of Nano-Aluminium Oxide (nAlO) on the Rheological Properties of CPB Made of Portland Cement

- nAlO filler effect: It is well known that nanoparticles are effective in partially filling the empty spaces in a cementitious material, which causes the microstructure to become denser [42]. This finally increases the yield stress and viscosity of the backfill material by increasing the frictional resistance between the particles and the solid volume fraction in the CPB material (ref. [18,40]).

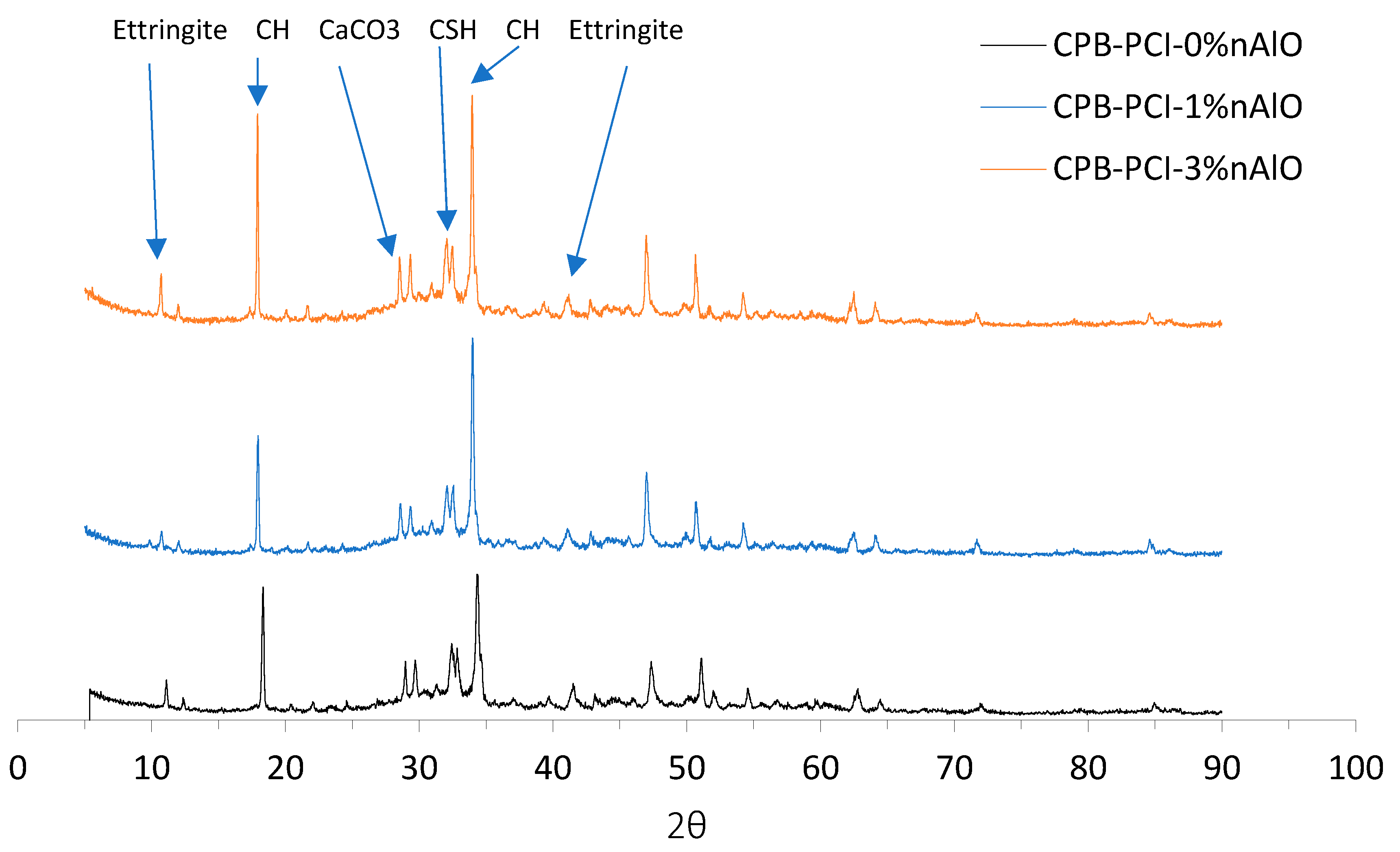

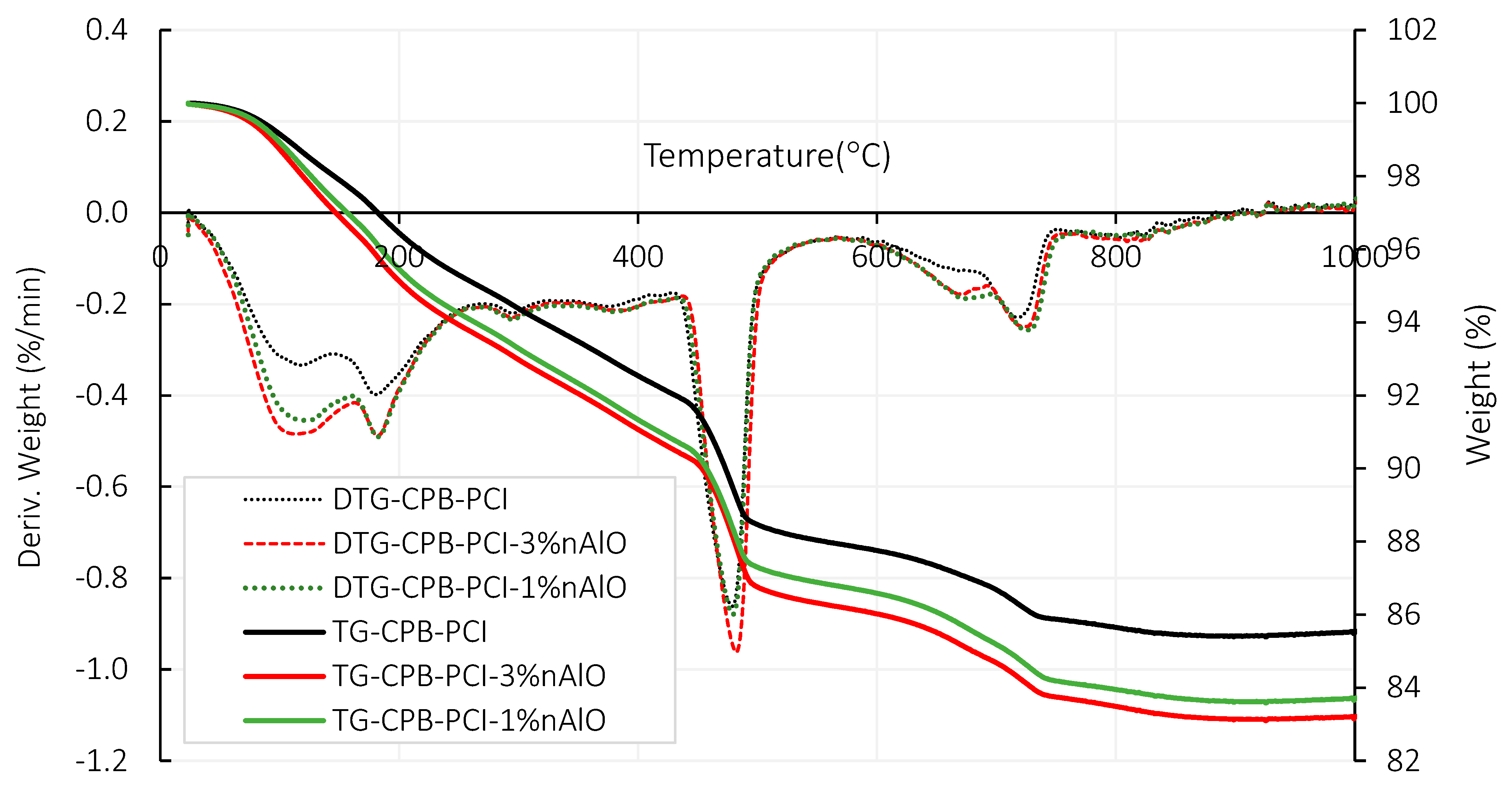

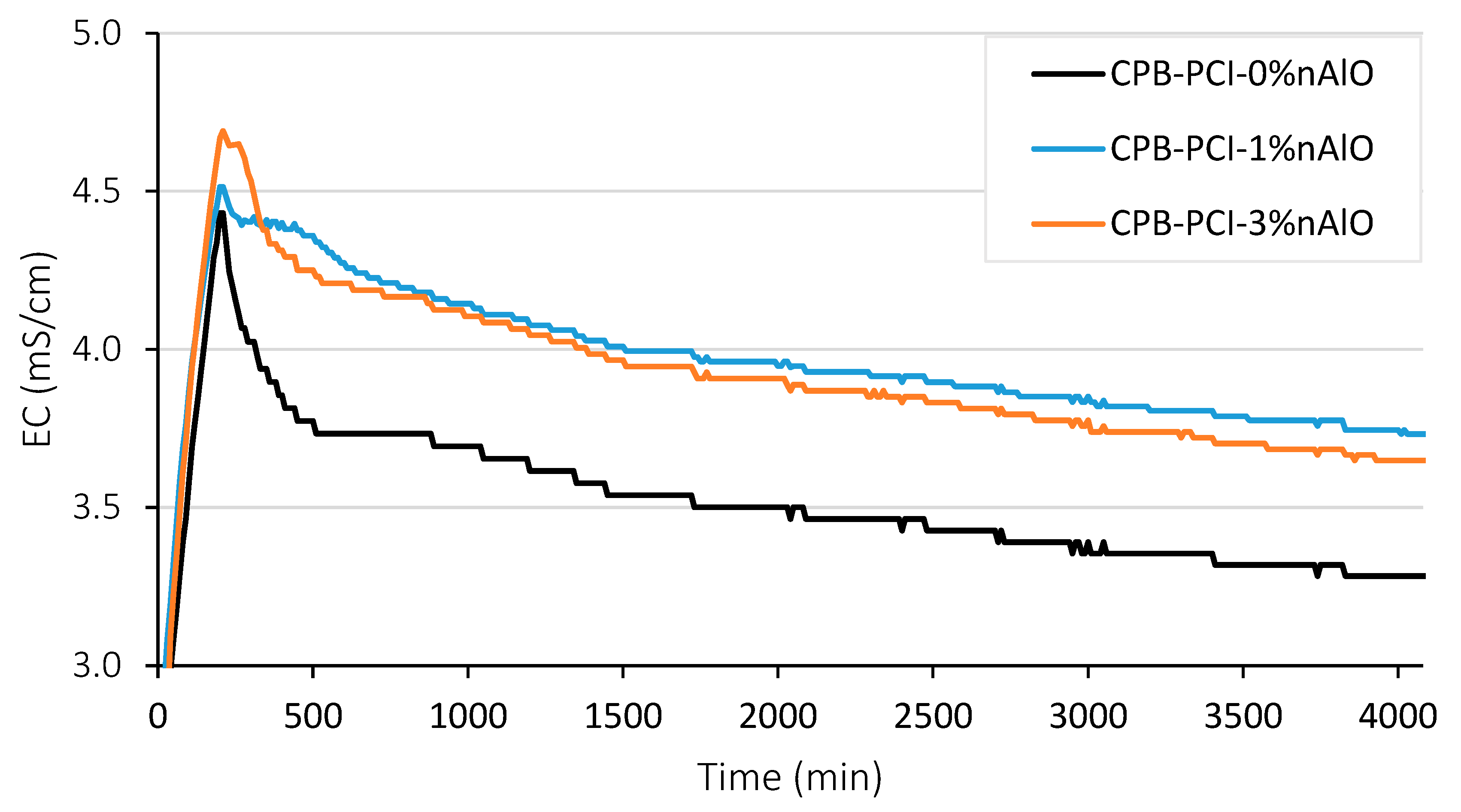

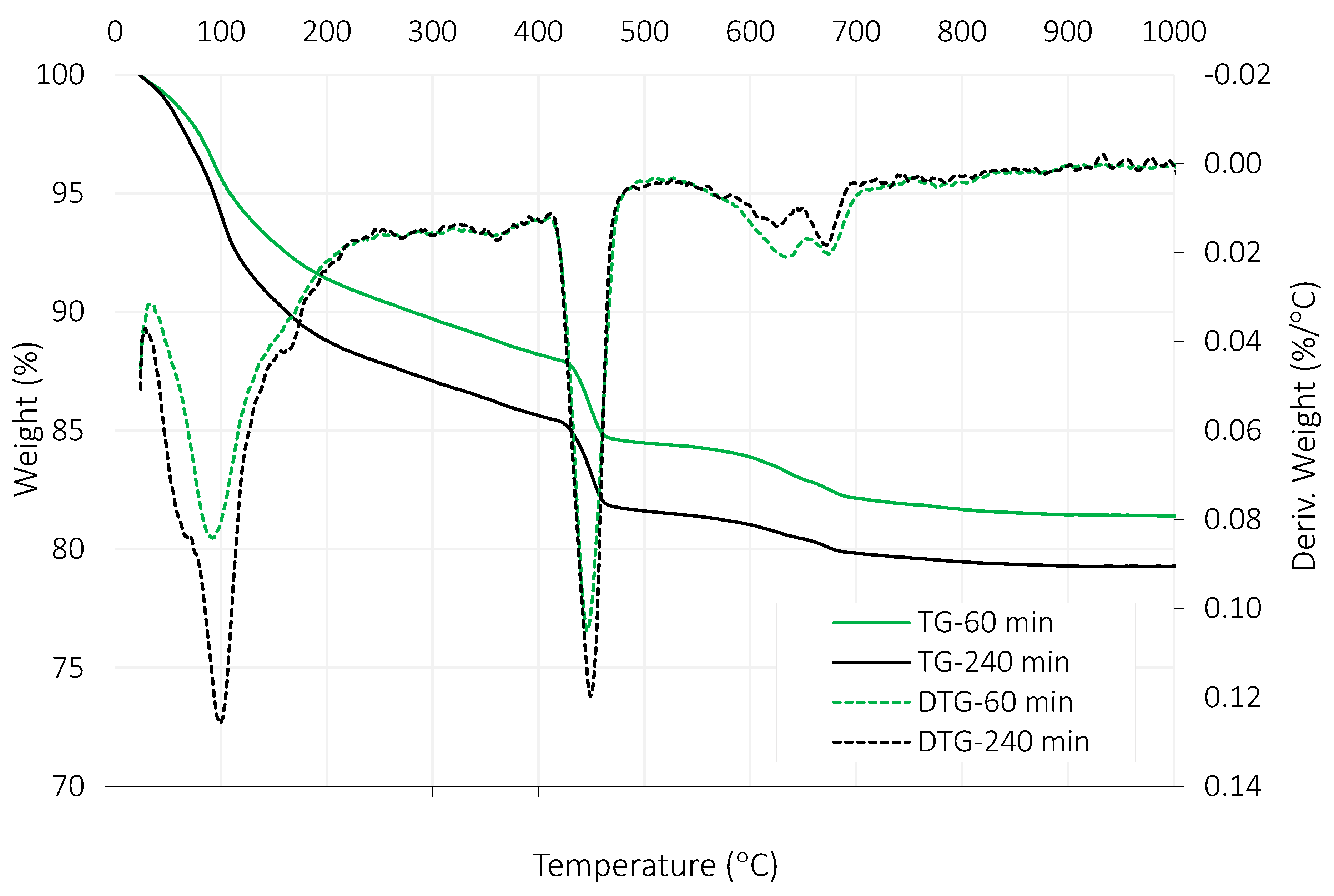

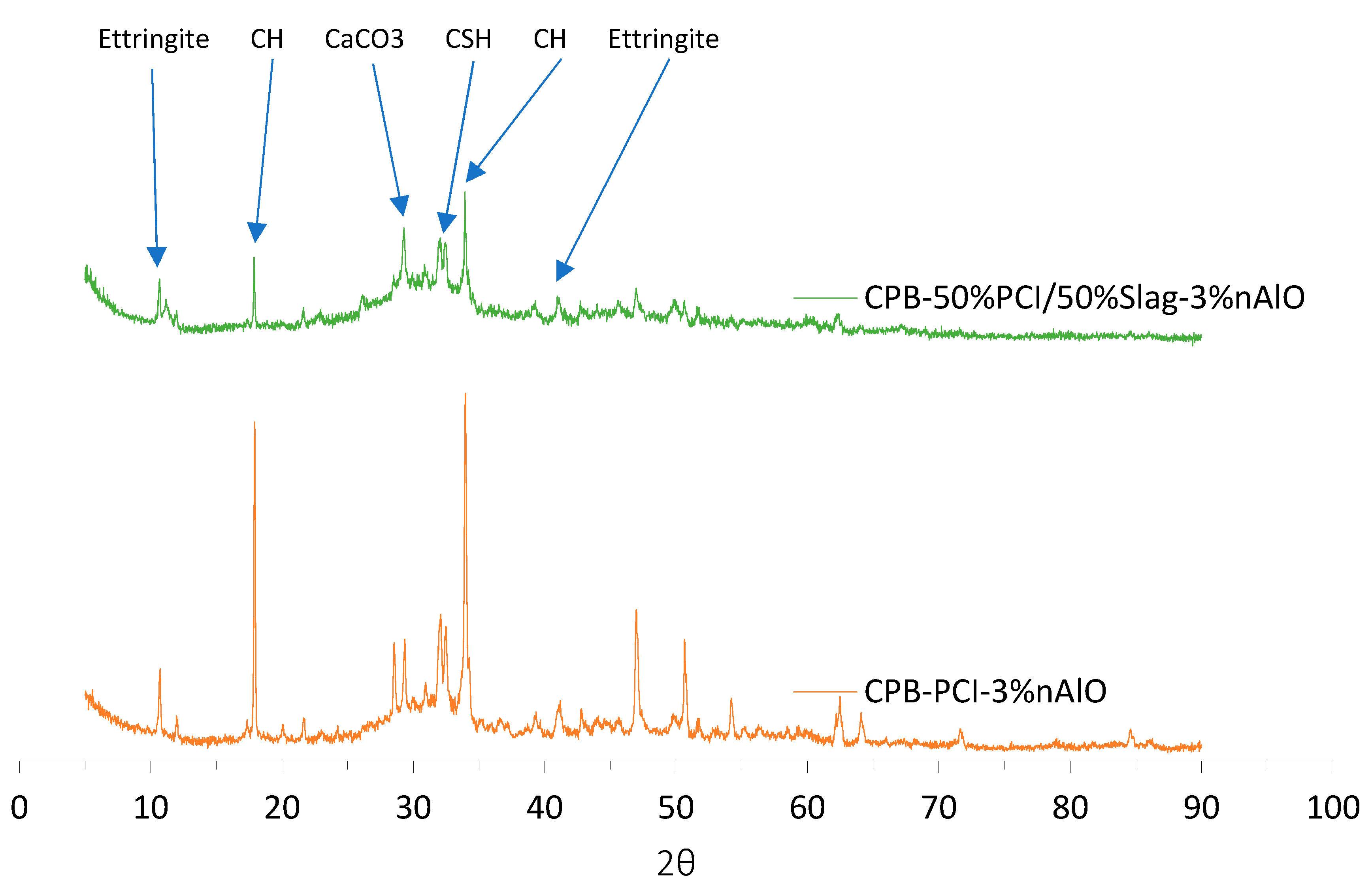

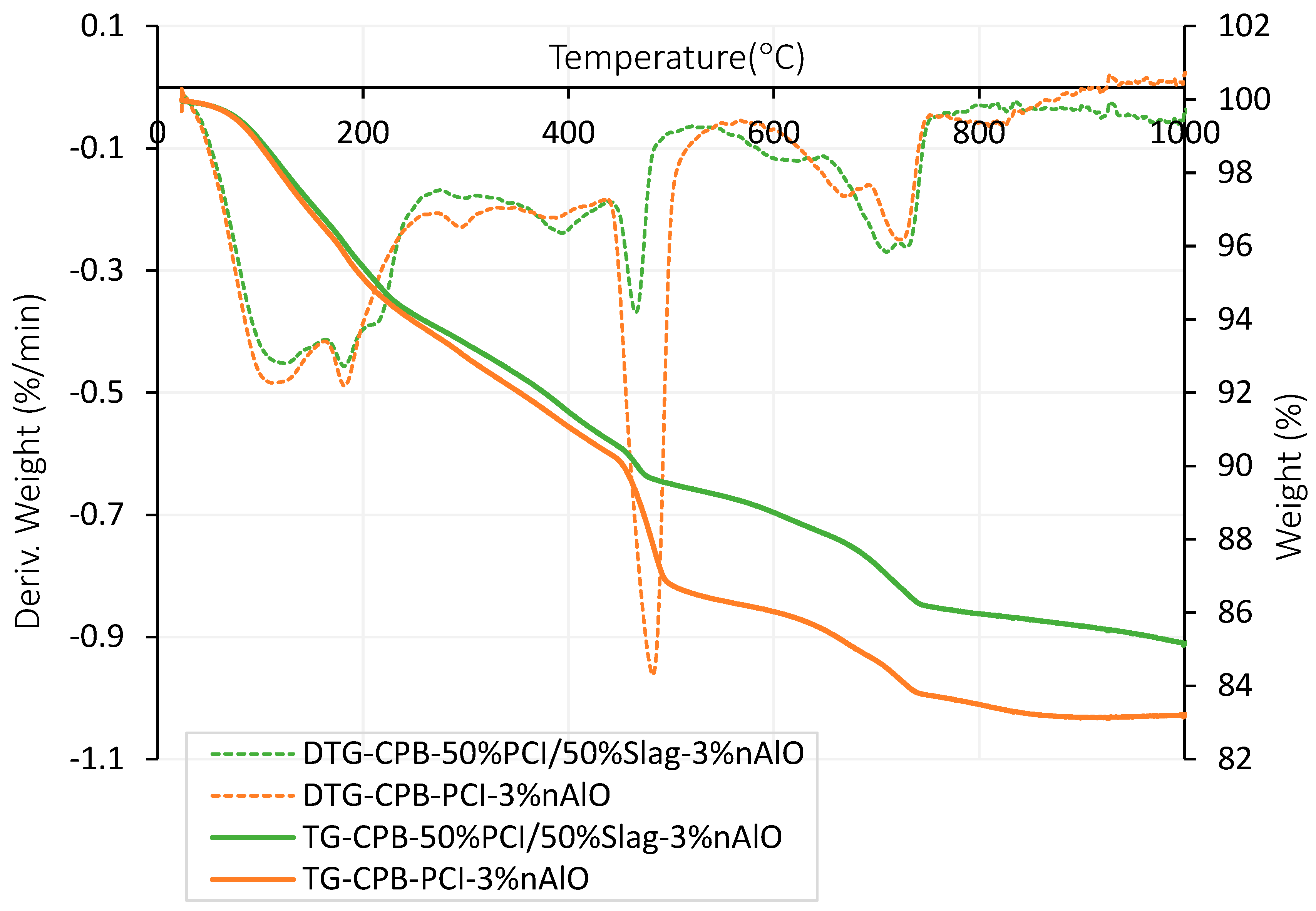

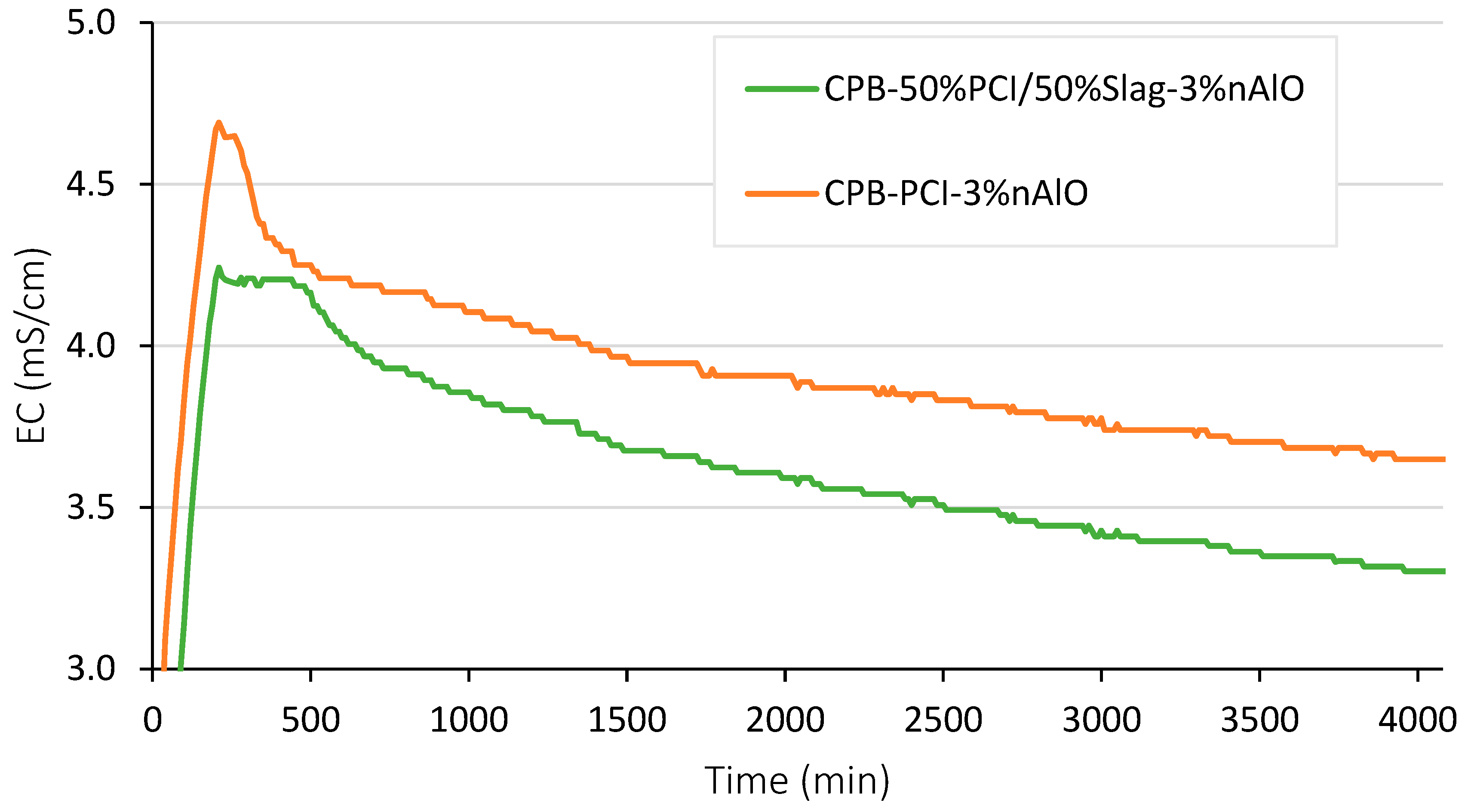

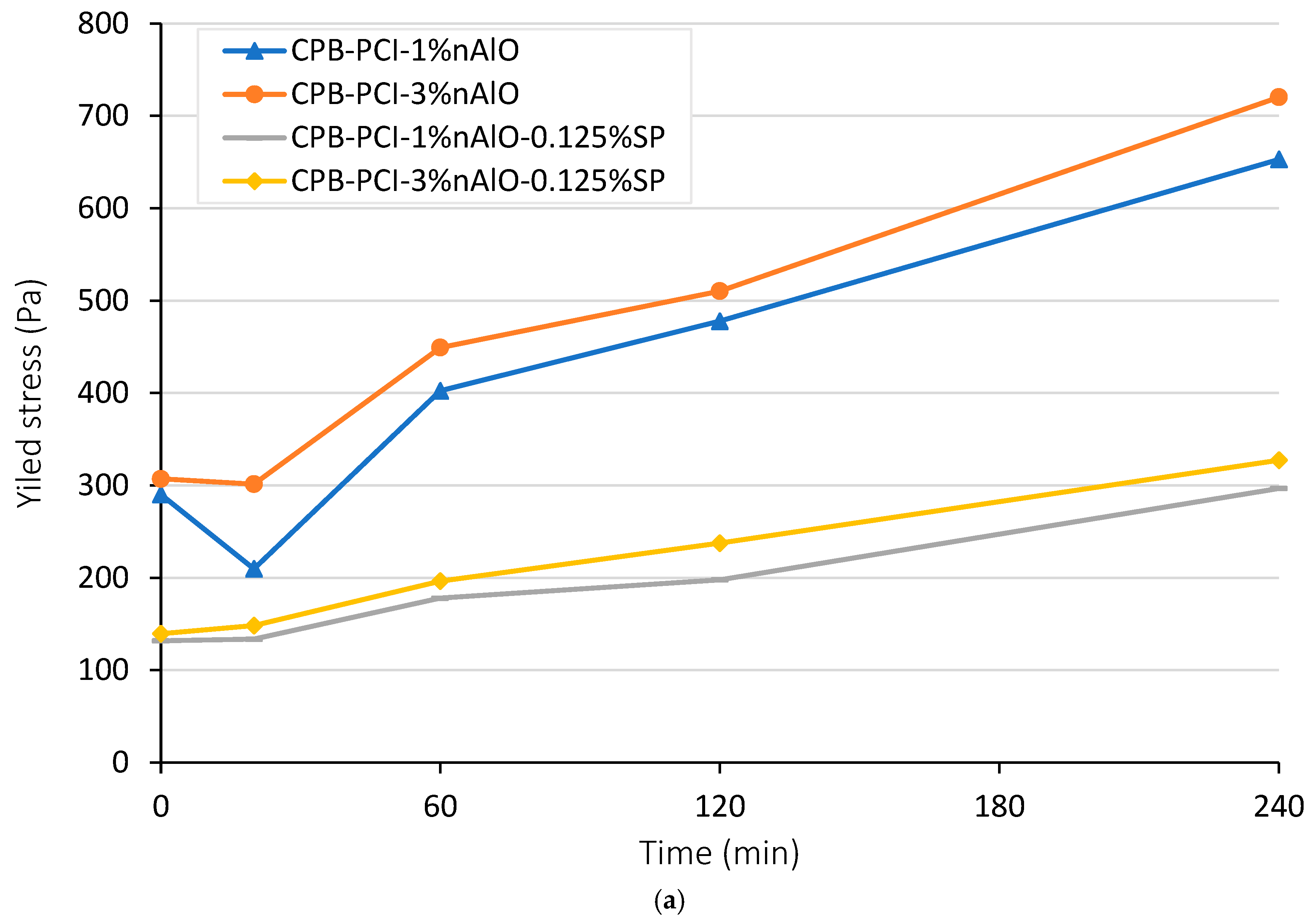

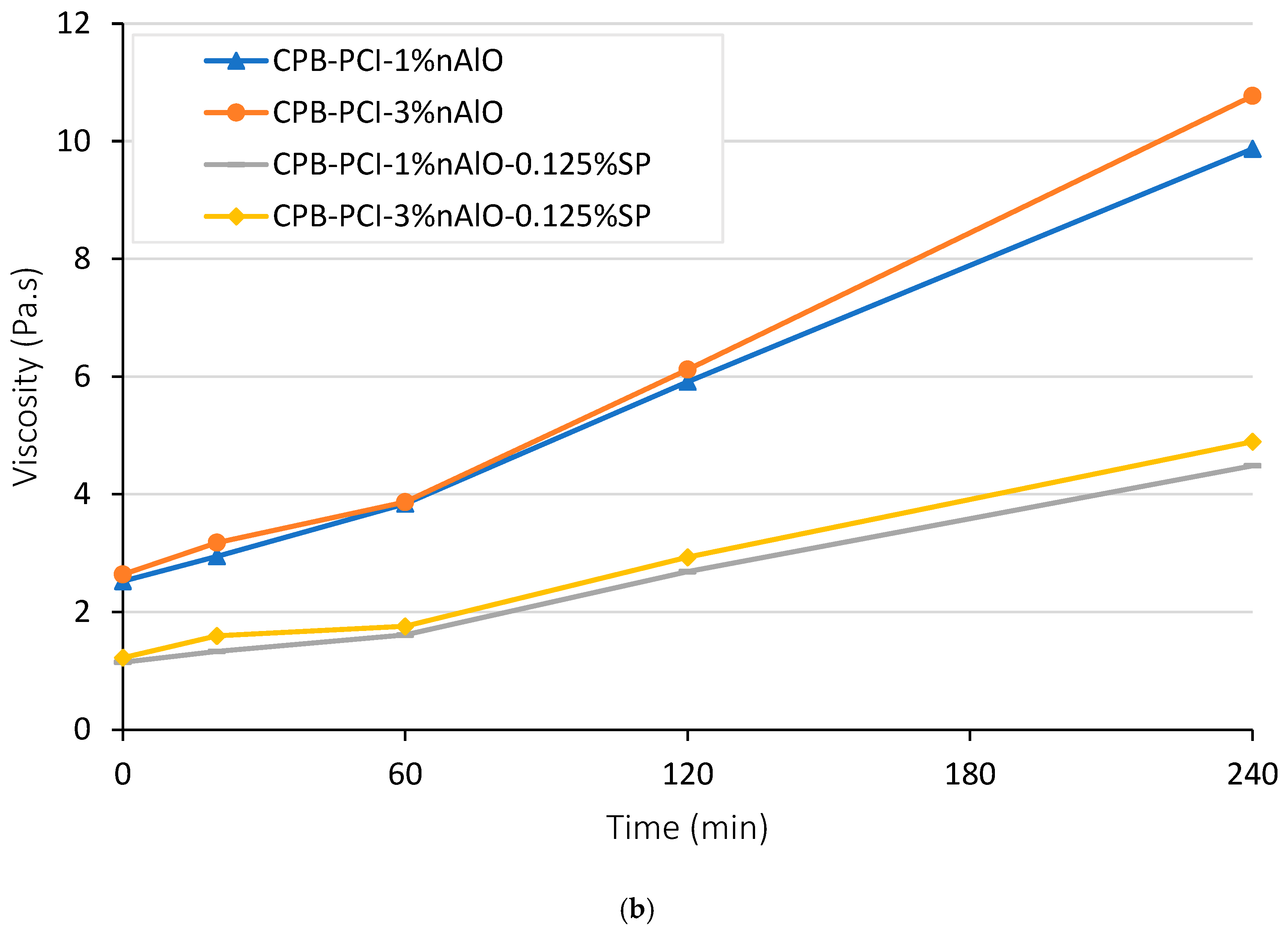

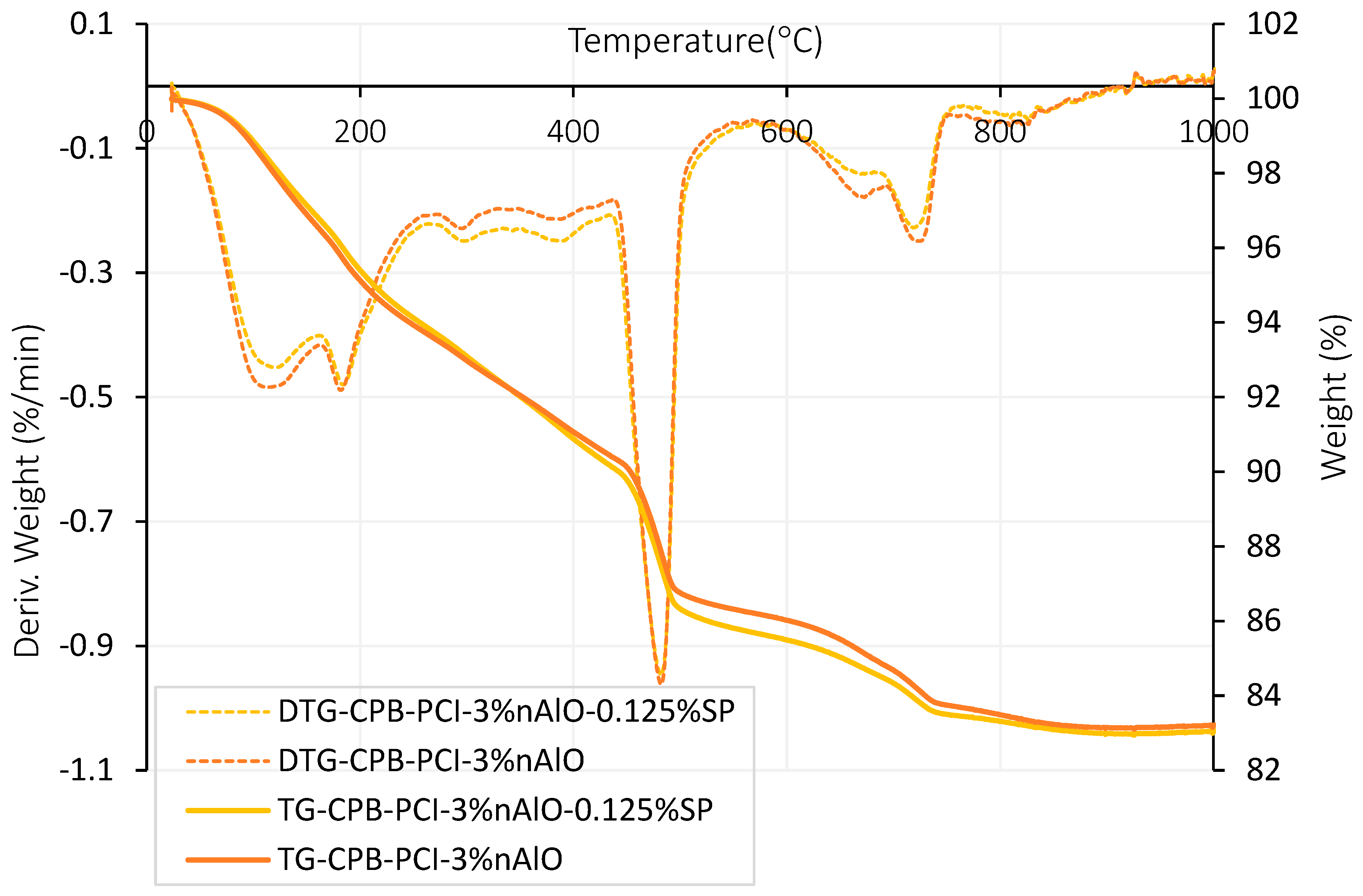

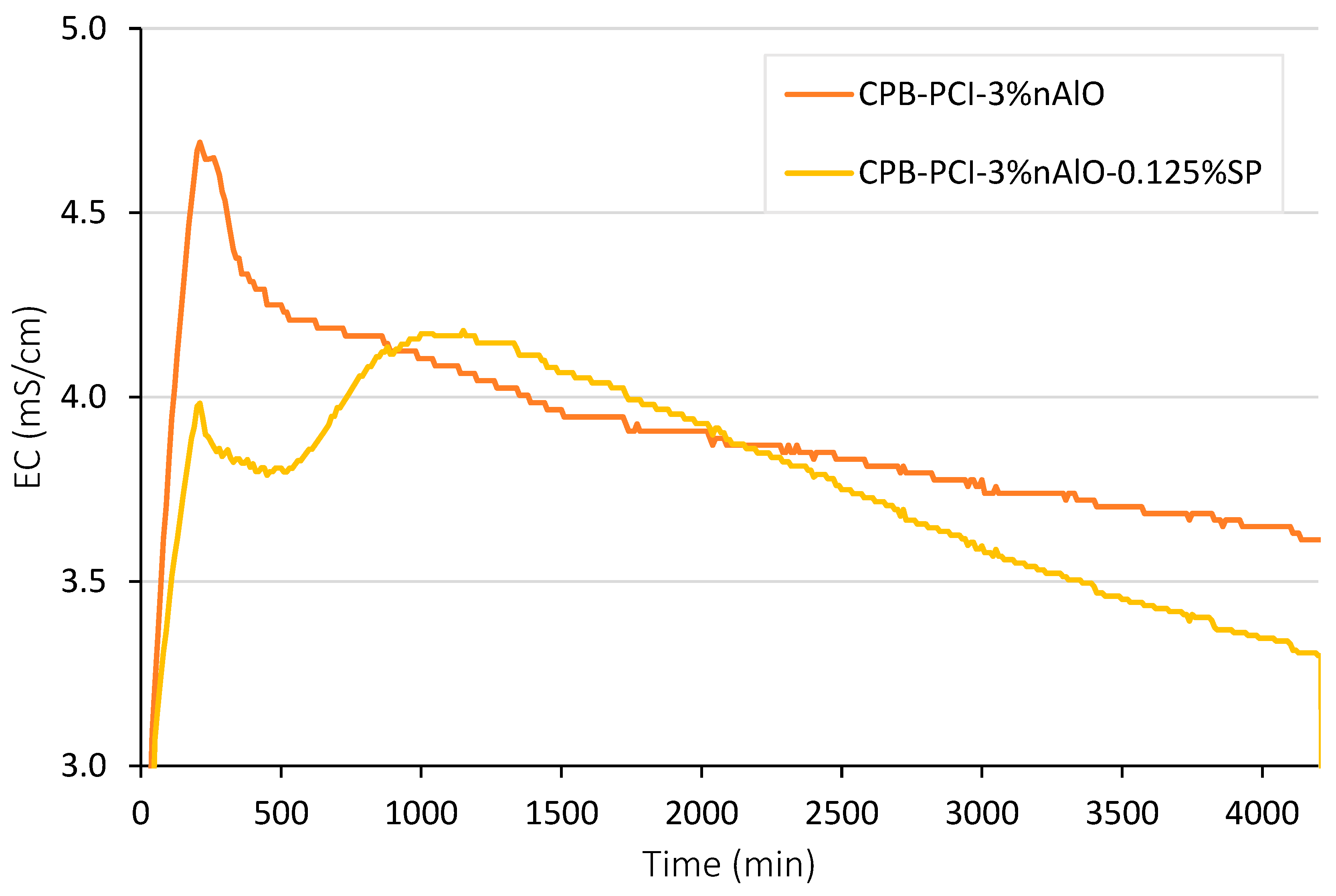

- Enhancement of the cement hydration by nAlO: The extremely small dimensions of nAlO particles (see Table 3) provide an extensive number of nucleation sites, helping the formation of numerous hydration products, notably C-S-H. These nucleation sites play an essential role in enhancing and intensifying the hydration process of essential cement compounds. The sample containing nAlO has a greater amount of hydration products, according to the XRD data (Figure 4). For instance, the sample containing nAlO has a greater CH intensity than the one containing no nAlO. In fact, the sample with nanoparticles (nAlO) had a greater CH intensity at 18 and 34° 2-theta than the sample without nAlO. This observation highlights the effect of nAlO on cement hydration by implying a higher production of CH in specimens with that addition. This conclusion about the inclusion of nAlO particles producing additional hydration products is also consistent with the findings of TG/DTG studies performed on cement pastes that were 2 h old and had varying nAlO concentrations (0%, 1%, and 3%), as shown in Figure 5. According to these findings, the cement paste that has been treated with nAlO shows the strongest endothermic peaks and weight loss between 100° and 180 °C. These indicators point to a higher yield stress and viscosity level due to an enhanced production of hydration products. The agreement with the results of the EC monitoring of CPB samples with different percentages of nAlO, shown in Figure 6, gives further support to this explanation. This graph shows that the curves initially show increasing tendencies, which can be attributed to the cement’s breakdown phase. Aluminate, potassium, calcium aluminium oxide ions, and other types of ions were released when water was added to the cement, causing the cement’s ions to dissolve. The paste’s electrical conductivity was improved by these liberated and mobile ions [57,58]. CH, C-S-H, and ettringite were among the hydrates that filled the capillary holes as another hydration reaction occurred. As a result, EC decreased as a result of the decline in ion mobility and concentration [59]. As shown in Figure 6, the EC for the nAlO-containing samples was higher than that of the nAlO-free samples during the early stage (up to 2 h or 120 min). Furthermore, the addition of nAlO resulted in a noticeable shift of the EC peaks to shorter hydration periods, indicating faster hydration reaction rates. In fact, the specimens containing 3%, 1%, and 0% nAlO had conductivity peaks at 3.7 h (200 min), 3.6 h (220 min), and 4.0 h (240 min), respectively. This also aligns with the observation that the slopes of the 3%-nAlO and 1%-nAlO samples prior to the EC peak were steeper than those of the control sample, suggesting an acceleration in cement hydration within the chloride-containing samples. In fact, the slope preceding the EC curve’s peak correlates with the rate of the hydration reaction; a sharper slope signifies a quicker hydration process [50]. This early-stage fast acceleration of cement hydration is consistent with yield stress and viscosity observations shown in Figure 2.

- nAlO-induced increase in water demand: The water requirement of the CPB mixture to attain appropriate flowability was directly impacted by the addition of nAlO to the CPB. The well-established fact is that nanoparticles raise the need for water [60,61]. Because of the nanoparticles’ large surface area (>40 m2/g), which adsorbs free water on their surface, there is a higher water demand when they are present. Greater surface area to be wetted results from finer particles. As a result, more water is needed to keep the CPB’s workability or flowability at a respectable level [62].

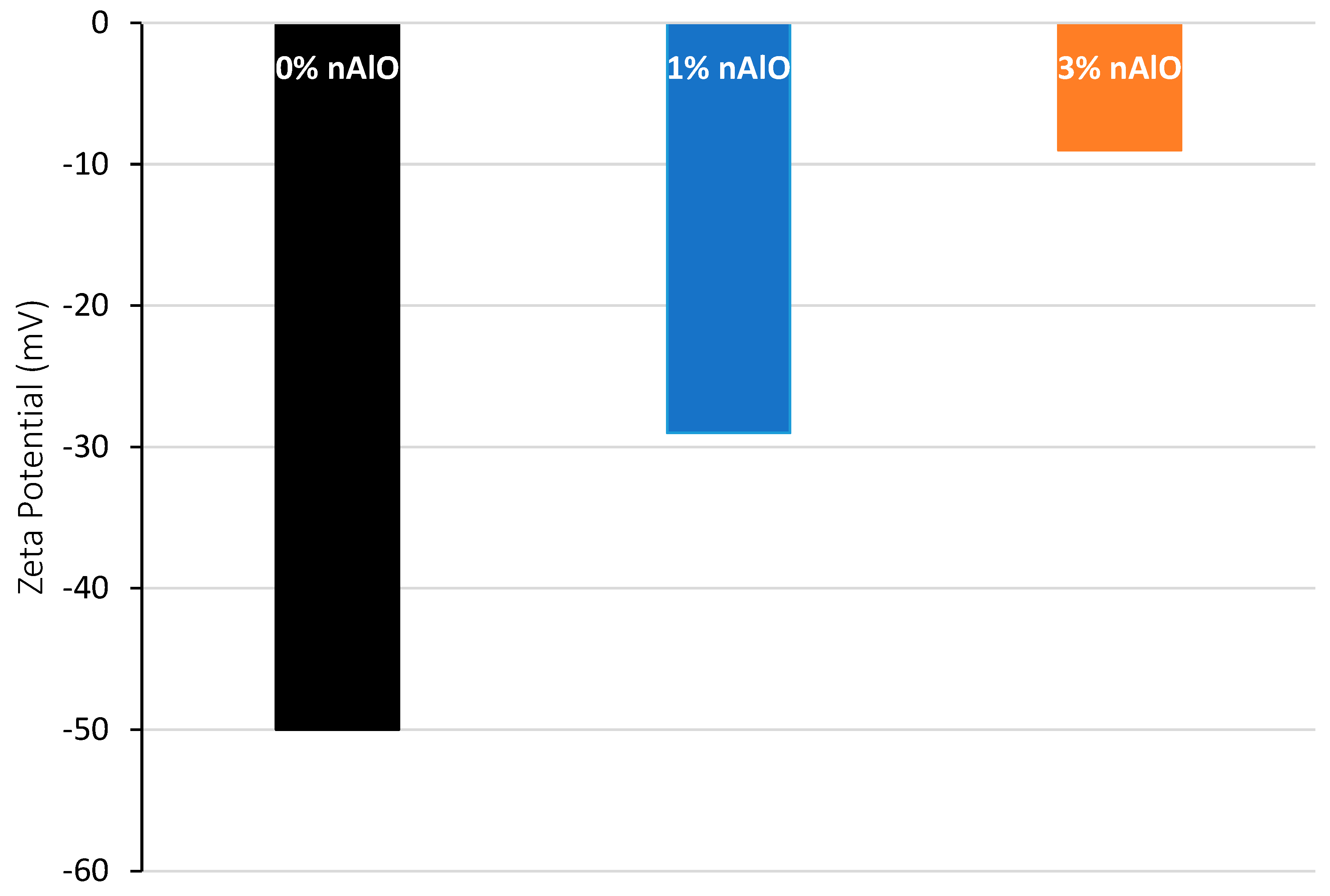

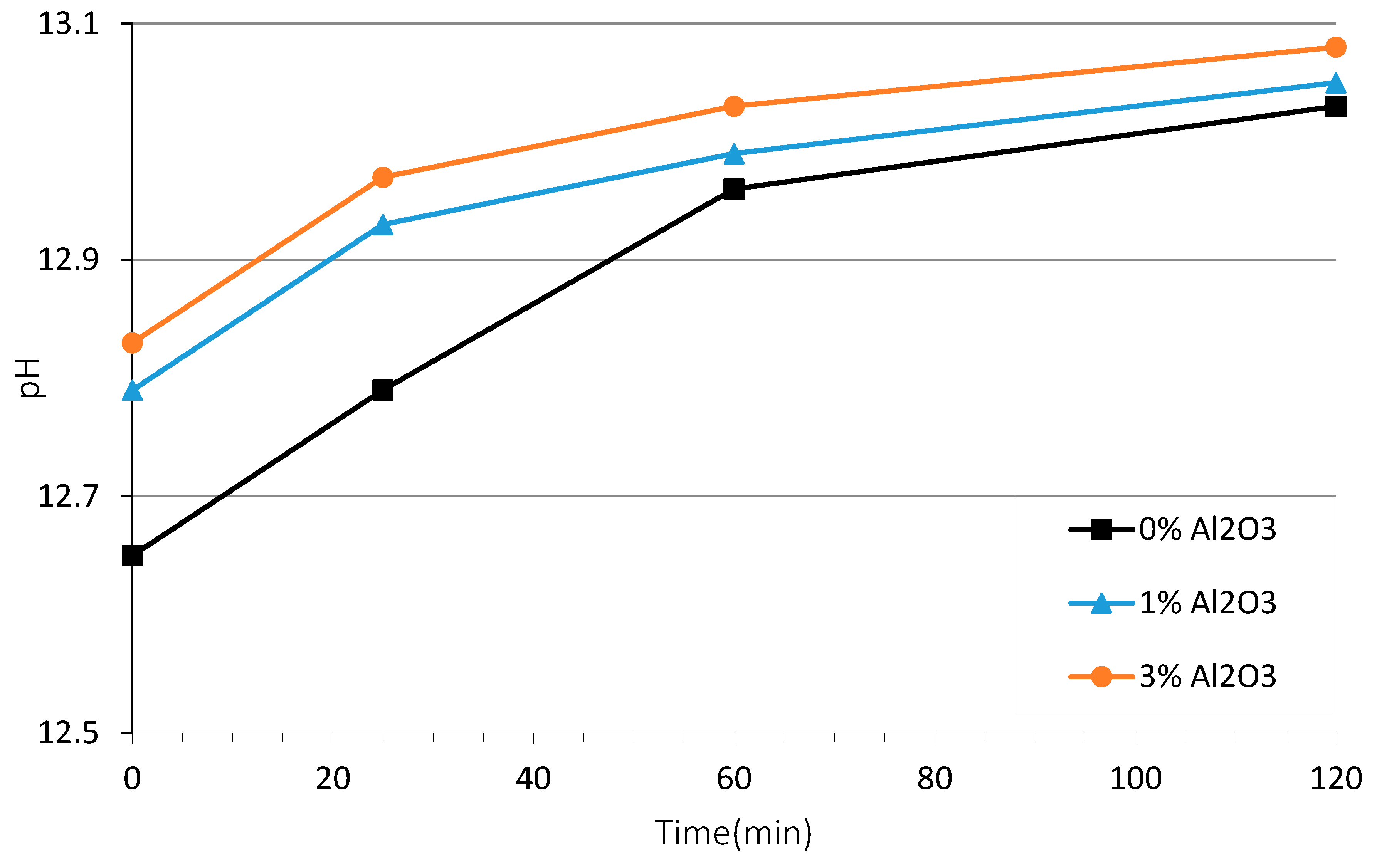

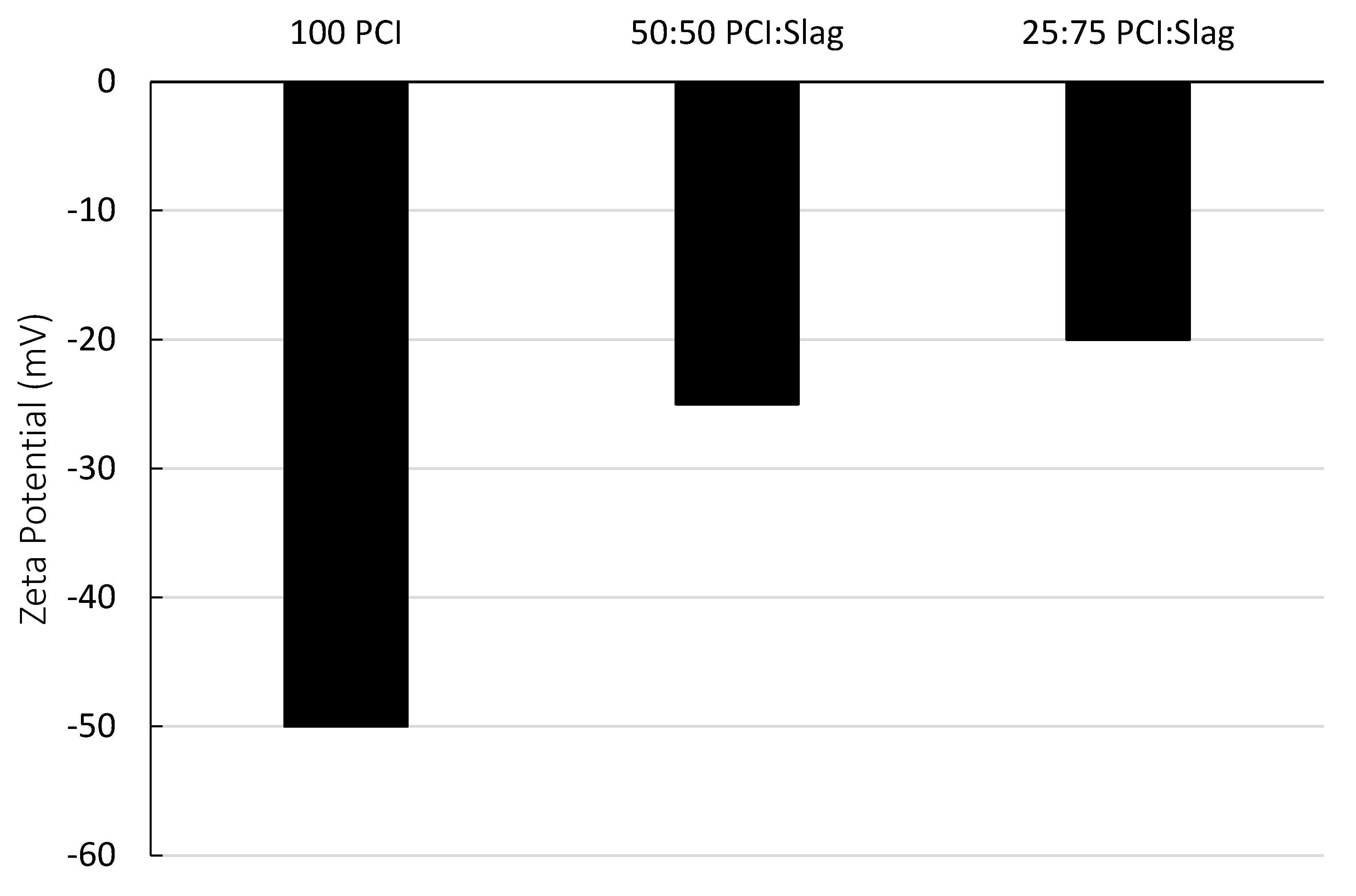

- Enhanced flocculation or agglomeration of the paste owing to nAlO particles: The tendency for flocculation or agglomeration after adding nAlO particles is consistent with the results of zeta potential (ZP) measurements made on the CPBs with different concentrations of nAlO particles (Figure 7). Higher ZP magnitudes are linked to stronger electrostatic repulsion between charged particles, which leads to improved dispersion. ZP determination is a technique used to evaluate the surface charge and potential stability of suspended particles. The electrostatic surface charge, or ZP, determines how much repulsion or attraction there is between colloidal particles [57]. As a result, ZP may be used to identify the nAlO particle dispersal process in the alkaline Portland cement paste environment (Figure 7). The pH trend over time for PCI-CPB samples containing 0% and 3% nAlO is shown in Figure 8. In all CPB samples, the creation of Ca(OH)2 as a result of cement hydration creates an alkaline state (high pH). The pH values of the specimens containing 0% and 3% nAlO were 12.79 and 12.97, respectively, following a 25-min curing period. Moreover, pH levels rose to 13.03 and 13.08 for samples containing 0% and 3% nAlO, respectively, after two hours of ageing. Figure 8 shows that the pH of CPB with 3% nAlO is higher than the pH of CPB without nAlO. This is consistent with the theory that nAlO particles improve cement compound hydration, which releases more alkali ions into CPB pore water and raises pH. The ZP measurement findings for CPB with 100% PCI, including 1% and 3% nAlO, are shown in Figure 7 beside the control sample. When the nAlO % rises, the ZP of the CPB falls, suggesting that there is a stronger electronic double-layer repulsive force when nAlO is absent. Altered rheology and increased water demand are caused by reduced repulsion and low ZP, which is congruent with the outcomes of yield stress and viscosity, as was previously discussed [14].

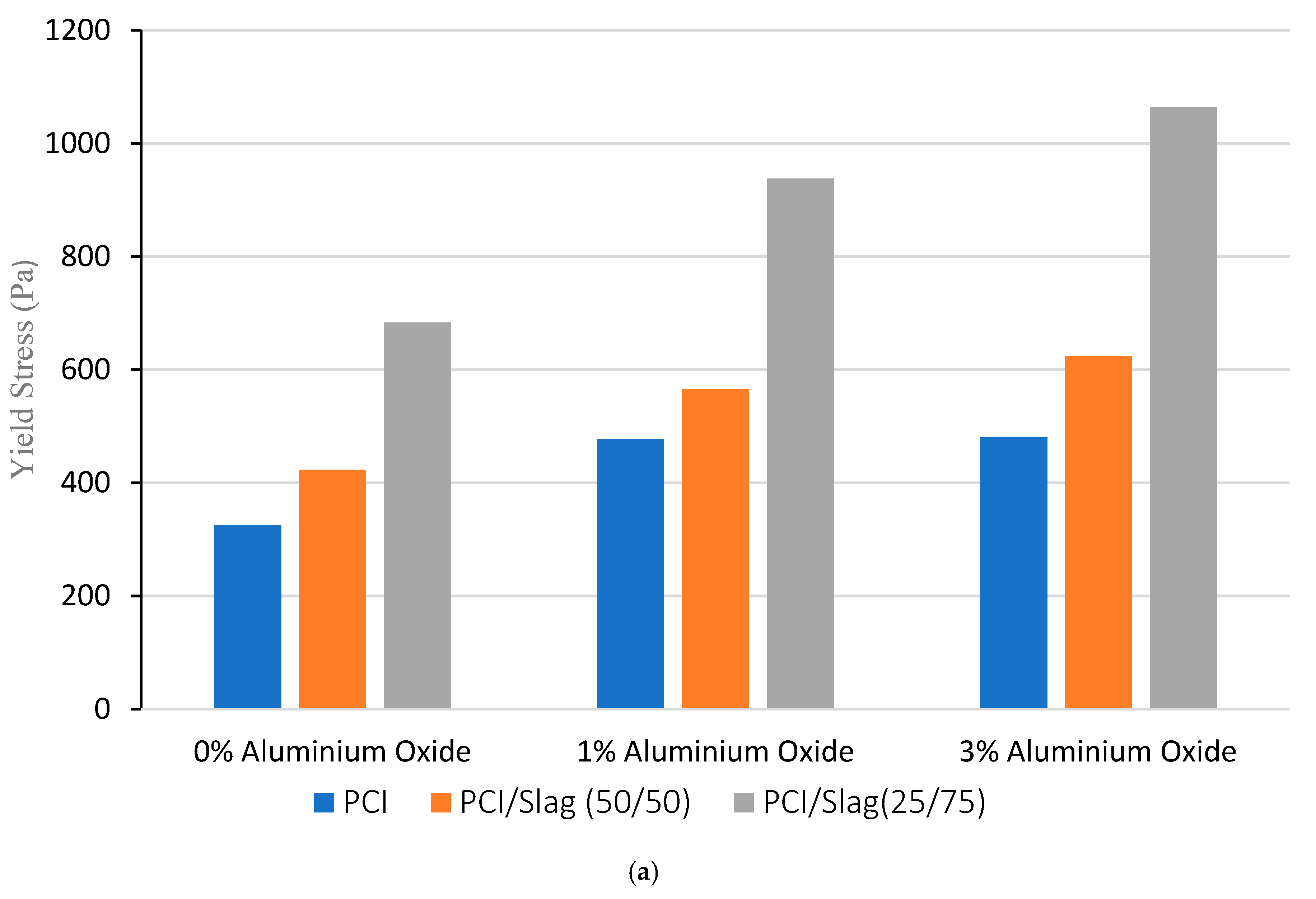

3.2. Influence of Nano-Aluminium Oxide (nAlO) on the Rheological Properties of CPB with Slag

3.3. Impact of Superplasticizer on the Rheological Properties of CPB with nAlO

4. Conclusions

- Adding nAlO particles or adjusting their dosage modifies CPB flowability by increasing yield stress and viscosity. This occurs due to (i) the filler effect of nAlO, (ii) its catalytic impact on cement hydration, (iii) increased water demand, and (iv) nAlO-induced flocculation or agglomeration of CPB particles.

- The influence of nAlO particles on rheology intensifies with longer curing or transport time due to increased hydration product formation and enhanced particle flocculation.

- The binder type in CPB preparation influences how nAlO affects flowability. As nAlO content increases, the yield stress of PCI-based CPB rises more gradually than in PCI/Slag (25/75) and PCI/Slag (50/50) samples. Thus, nAlO has a stronger impact on CPB with PCI/Slag binders over extended transport times. This is due to friction effects from multivalent cations between nAlO particles and the denser particle packing, which raises the solid volume fraction and enhances particle interactions, as explained by the Krieger–Dougherty model.

- Compared to PCI-CPB, Slag-CPB samples exhibited lower viscosity but higher yield stress. Higher binder concentration in Slag-CPB reduced both due to improved free water bleeding, despite the same water-to-cement ratio. However, increased Slag content reduced Slag-CPB flowability.

- Adding a superplasticizer to CPB with nAlO enhances flowability by increasing electrostatic repulsion between particles, with its effect becoming more pronounced at higher nAlO content.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cui, L.; Fall, M. Multiphysics modeling and simulation of strength development and distribution in cemented tailings backfill structures. Int. J. Concr. Struct. Mater. 2018, 12, 25. [Google Scholar] [CrossRef]

- Cui, L.; Fall, M. Multiphysics model for consolidation behavior of cemented paste backfill. Int. J. Geomech. 2017, 17, 04016077. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, Y.; Zuo, X.; Hong, M. Time-dependent rheological and mechanical properties of silica fume modified cemented tailings backfill in low temperature environment. Cem. Concr. Compos. 2020, 114, 103804. [Google Scholar] [CrossRef]

- Bull, A.A.; Fall, M. Curing temperature dependency of the release of arsenic from cemented paste backfill made with Portland cement. J. Environ. Manag. 2020, 269, 110772. [Google Scholar] [CrossRef]

- Qiu, J.; Guo, Z.; Yang, L.; Jiang, H.; Zhao, Y. Effects of packing density and water film thickness on the fluidity behaviour of cemented paste backfill. Powder Technol. 2020, 359, 27–35. [Google Scholar] [CrossRef]

- Aldhafeeri, A.; Fall, M. Sulphate induced changes in the reactivity of cemented tailings backfill. Int. J. Miner. Process. 2017, 166, 13–23. [Google Scholar] [CrossRef]

- Colangelo, F.; Forcina, A.; Farina, I.; Petrillo, A. Life Cycle Assessment (LCA) of Different Kinds of Concrete Containing Waste for Sustainable Construction. Buildings 2018, 8, 70. [Google Scholar] [CrossRef]

- Fang, K.; Cui, L.; Fall, M. A coupled chemo-elastic cohesive zone model for backfill-rock interface. Comput. Geotech. 2020, 125, 103666. [Google Scholar] [CrossRef]

- Al-Moselly, Z.; Fall, M.; Haruna, S. Further insight into the strength development of cemented paste backfill materials containing polycarboxylate ether-based superplasticizer. J. Build. Eng. 2022, 47, 103859. [Google Scholar] [CrossRef]

- Simon, D.; Grabinsky, M. Apparent yield stress measurement in cemented paste backfill. Int. J. Min. Reclam. Environ. 2013, 27, 231–256. [Google Scholar] [CrossRef]

- Taylor, H.F. The Chemistry of Cements; 1, 2. Print; Academic Press: London, UK, 1972. [Google Scholar]

- Wu, D.; Fall, M.; Cai, S. Numerical modelling of thermally and hydraulically coupled processes in hydrating cemented tailings backfill columns. Int. J. Min. Reclam. Environ. 2014, 28, 173–199. [Google Scholar] [CrossRef]

- Xiapeng, P.; Fall, M.; Haruna, S. Sulphate induced changes of rheological properties of cemented paste backfill. Miner. Eng. 2019, 141, 105849. [Google Scholar] [CrossRef]

- Lavergne, F.; Belhadi, R.; Carriat, J.; Ben Fraj, A. Effect of nano-silica particles on the hydration, the rheology and the strength development of a blended cement paste. Cem. Concr. Compos. 2019, 95, 42–55. [Google Scholar] [CrossRef]

- Zhang, M.H.; Islam, J. Use of nano-silica to reduce setting time and increase early strength of concretes with high volumes of fly ash or slag. Constr. Build. Mater. 2012, 29, 573–580. [Google Scholar] [CrossRef]

- Justnes, H.; Vikan, H.V. Viscosity of Cement Slurries as a Function of Solids Content. 2005. Available online: https://api.semanticscholar.org/CorpusID:89612352 (accessed on 12 February 2024).

- Bentz, D.P.; Ferraris, C.F.; Galler, M.A.; Hansen, A.S.; Guynn, J.M. Influence of particle size distributions on yield stress and viscosity of cement–fly ash pastes. Cem. Concr. Res. 2012, 42, 404–409. [Google Scholar] [CrossRef]

- Li, Z.; Ohkubo, T.; Tanigawa, Y. Theoretical Analysis of Time-Dependence and Thixotropy of Fluidity for High Fluidity Concrete. J. Mater. Civ. Eng. 2004, 16, 247–256. [Google Scholar] [CrossRef]

- Chin, C.-J.; Yiacoumi, S.; Tsouris, C. Probing DLVO Forces Using Interparticle Magnetic Forces: Transition from Secondary-Minimum to Primary-Minimum Aggregation. Langmuir 2001, 17, 6065–6071. [Google Scholar] [CrossRef]

- Fornes, J.A. Secondary minimum analysis in the DLVO-theory. Colloid Polym. Sci. 1985, 263, 1004–1007. [Google Scholar] [CrossRef]

- Chen, J.; Kou, S.; Poon, C. Hydration and properties of nano-TiO2 blended cement composites. Cem. Concr. Compos. 2012, 34, 642–649. [Google Scholar] [CrossRef]

- Land, G.; Stephan, D. The influence of nano-silica on the hydration of ordinary Portland cement. J. Mater. Sci. 2012, 47, 1011–1017. [Google Scholar] [CrossRef]

- Li, Z.; Wang, H.; He, S.; Lu, Y.; Wang, M. Investigations on the preparation and mechanical properties of the nano-alumina reinforced cement composite. Mater. Lett. 2006, 60, 356–359. [Google Scholar] [CrossRef]

- Oltulu, M.; Şahin, R. Pore structure analysis of hardened cement mortars containing silica fume and different nano-powders. Constr. Build. Mater. 2014, 53, 658–664. [Google Scholar] [CrossRef]

- Quercia, G.; Spiesz, P.; Hüsken, G.; Brouwers, H.J.H. SCC modification by use of amorphous nano-silica. Cem. Concr. Compos. 2014, 45, 69–81. [Google Scholar] [CrossRef]

- Said, A.M.; Zeidan, M.S.; Bassuoni, M.T.; Tian, Y. Properties of concrete incorporating nano-silica. Constr. Build. Mater. 2012, 36, 838–844. [Google Scholar] [CrossRef]

- Senff, L.; Hotza, D.; Lucas, S.; Ferreira, V.M.; Labrincha, J.A. Effect of nano-SiO2 and nano-TiO2 addition on the rheological behavior and the hardened properties of cement mortars. Mater. Sci. Eng. A 2012, 532, 354–361. [Google Scholar] [CrossRef]

- Zhang, M.; Li, H. Pore structure and chloride permeability of concrete containing nano-particles for pavement. Constr. Build. Mater. 2011, 25, 608–616. [Google Scholar] [CrossRef]

- Bharathan, B.; McGuinness, M.; Kuhar, S.; Kermani, M.; Hassani, F.P.; Sasmito, A.P. Pressure loss and friction factor in non-Newtonian mine paste backfill: Modelling, loop test and mine field data. Powder Technol. 2019, 344, 443–453. [Google Scholar] [CrossRef]

- Yang, L.; Yilmaz, E.; Li, J.; Liu, H.; Jiang, H. Effect of superplasticizer type and dosage on fluidity and strength behavior of cemented tailings backfill with different solid contents. Constr. Build. Mater. 2018, 187, 290–298. [Google Scholar] [CrossRef]

- Wu, D.; Fall, M.; Cai, S.J. Coupling temperature, cement hydration and rheological behaviour of fresh cemented paste backfill. Miner. Eng. 2013, 42, 76–87. [Google Scholar] [CrossRef]

- Yang, M. Interparticle Potential and Sedimentation Behavior of Cement Suspensions Review and Results from Paste. Adv. Cem. Based Mater. 1997, 5, 1–7. [Google Scholar] [CrossRef]

- Yilmaz, E. Cemented coal fly ash backfill for mechanized underground coal mine application: Evaluating fresh and hardened properties. Keynote Address. In Proceedings of the 2024 International Conference on Green Intelligent Mining for Thick Coal Seam, Beijing, China, 22–24 November 2024. [Google Scholar]

- Hanehara, S.; Yamada, K. Rheology and early age properties of cement systems. Cem. Concr. Res. 2008, 38, 175–195. [Google Scholar] [CrossRef]

- ASTM C494/C494M; Standard Specification for Chemical Admixture for Concrete. ASTM International: West Conshohocken, PA, USA, 2004.

- Haruna, S.; Fall, M. Time- and temperature-dependent rheological properties of cemented paste backfill that contains superplasticizer. Powder Technol. 2020, 360, 731–740. [Google Scholar] [CrossRef]

- “Brookfield”. Available online: https://pim-resources.coleparmer.com/instruction-manual/98945-xx.pdf (accessed on 14 January 2024).

- ASTM; Standard Test Method for Laboratory Miniature Vane Shear Test for Saturated Fine-Grained Clayey Soil. American Society for Testing and Materials: West Conshohocken, PA, USA, 2016.

- Clogston, J.D.; Patri, A.K. Zeta Potential Measurement. In Characterization of Nanoparticles Intended for Drug Delivery; McNeil, S.E., Ed.; Humana Press: Totowa, NJ, USA, 2011; pp. 63–70. [Google Scholar] [CrossRef]

- Roshani, A.; Fall, M. Rheological properties of cemented paste backfill with nano-silica: Link to curing temperature. Cem. Concr. Compos. 2020, 114, 103785. [Google Scholar] [CrossRef]

- Zhou, Y.; Fall, M.; Haruna, S. Flow ability of cemented paste backfill with chloride-free antifreeze additives in sub-zero environments. Cem. Concr. Compos. 2022, 126, 104359. [Google Scholar] [CrossRef]

- Taylor, H.F. Cement Chemistry; Thomas Telford: London, UK, 1997; Volume 2. [Google Scholar]

- American Society for Testing and Materials. Cement, Concrete and Aggregates; American Society for Testing and Materials: West Conshohocken, PA, USA, 1979. [Google Scholar]

- Sha, W.; O’Neill, E.A.; Guo, Z. Differential scanning calorimetry study of ordinary Portland cement. Cem. Concr. Res. 1999, 29, 1487–1489. [Google Scholar] [CrossRef]

- Sari, M.; Yilmaz, E.; Kasap, T. Long-term ageing characteristics of cemented paste backfill: Usability of sand as a partial substitute of hazardous tailings. J. Clean. Prod. 2023, 401, 136723. [Google Scholar] [CrossRef]

- Pane, I.; Hansen, W. Investigation of blended cement hydration by isothermal calorimetry and thermal analysis. Cem. Concr. Res. 2005, 35, 1155–1164. [Google Scholar] [CrossRef]

- Zhou, Q.; Glasser, F.P. Thermal stability and decomposition mechanisms of ettringite at< 120 C. Cem. Concr. Res. 2001, 31, 1333–1339. [Google Scholar]

- Nonnet, E.; Lequeux, N.; Boch, P. Elastic properties of high alumina cement castables from room temperature to 1600 C. J. Eur. Ceram. Soc. 1999, 19, 1575–1583. [Google Scholar] [CrossRef]

- Xiao, B.; Fall, M.; Roshani, A. Towards Understanding the Rheological Properties of Slag-Cemented Paste Backfill. Int. J. Min. Reclam. Environ. 2021, 35, 268–290. [Google Scholar] [CrossRef]

- Zhou, Y.; Fall, M. Investigation on rheological properties of cemented pastefill with chloride-bearing antifreeze additives in sub-zero environments. Cold Reg. Sci. Technol. 2022, 196, 103506. [Google Scholar] [CrossRef]

- Berkmen, Y.M.; Lande, A. Chest roentgenography as a window to the diagnosis of Takayasu’s arteritis. Am. J. Roentgenol. 1975, 125, 842–846. [Google Scholar] [CrossRef] [PubMed]

- Akbar, E.; Yaakob, Z.; Kamarudin, S.K.; Ismail, M.; Salimon, J. Characteristic and composition of Jatropha curcas oil seed from Malaysia and its potential as biodiesel feedstock feedstock. Eur. J. Sci. Res. 2009, 29, 396–403. [Google Scholar]

- Cai, Y.; Hou, P.; Duan, C.; Zhang, R.; Zhou, Z.; Cheng, X.; Shah, S. The use of tetraethyl orthosilicate silane (TEOS) for surface-treatment of hardened cement-based materials: A comparison study with normal treatment agents. Constr. Build. Mater. 2016, 117, 144–151. [Google Scholar] [CrossRef]

- Björnström, J.; Martinelli, A.; Matic, A.; Börjesson, L.; Panas, I. Accelerating effects of colloidal nano-silica for beneficial calcium–silicate–hydrate formation in cement. Chem. Phys. Lett. 2004, 392, 242–248. [Google Scholar] [CrossRef]

- Sargam, Y.; Wang, K. Hydration kinetics and activation energy of cement pastes containing various nanoparticles. Compos. Part B Eng. 2021, 216, 108836. [Google Scholar] [CrossRef]

- Carette, G.; Chevrier, A.B.R.L.; Malhotra, V.M. Mechanical Properties of Concrete Incorporating High Volumes of Fly Ash From Sources in the U.S. Mater. J. 1993, 90, 535–544. [Google Scholar] [CrossRef]

- Roshani, A.; Fall, M. Flow ability of cemented pastefill material that contains nano-silica particles. Powder Technol. 2020, 373, 289–300. [Google Scholar] [CrossRef]

- Wei, X. Study on hydration of Portland cement with fly ash using electrical measurement. Mater. Struct. 2005, 38, 411–417. [Google Scholar] [CrossRef]

- McCarter, W.J.; Starrs, G.; Chrisp, T.M. Electrical conductivity, diffusion, and permeability of Portland cement-based mortars. Cem. Concr. Res. 2000, 30, 1395–1400. [Google Scholar] [CrossRef]

- Madani, H.; Bagheri, A.; Parhizkar, T. The pozzolanic reactivity of monodispersed nanosilica hydrosols and their influence on the hydration characteristics of Portland cement. Cem. Concr. Res. 2012, 42, 1563–1570. [Google Scholar] [CrossRef]

- Qing, Y.; Zenan, Z.; Deyu, K.; Rongshen, C. Influence of nano-SiO2 addition on properties of hardened cement paste as compared with silica fume. Constr. Build. Mater. 2007, 21, 539–545. [Google Scholar] [CrossRef]

- Fall, M.; Benzaazoua, M.; Ouellet, S. Experimental characterization of the influence of tailings fineness and density on the quality of cemented paste backfill. Miner. Eng. 2005, 18, 41–44. [Google Scholar] [CrossRef]

- Krieger, I.M.; Dougherty, T.J. A Mechanism for Non-Newtonian Flow in Suspensions of Rigid Spheres. Trans. Soc. Rheol. 1959, 3, 137–152. [Google Scholar] [CrossRef]

- Panchal, S.; Deb, D.; Sreenivas, T. Variability in rheology of cemented paste backfill with hydration age, binder and superplasticizer dosages. Adv. Powder Technol. 2018, 29, 2211–2220. [Google Scholar] [CrossRef]

- Manmohan, D.; Mehta, P.K. Influence of pozzolanic, slag, and chemical admixtures on pore size distribution and permeability of hardened cement pastes. Cem. Concr. Aggreg. 1981, 3, 63–67. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Uygunoğlu, T.; Hocaoğlu, İ. Electrical conductivity of setting cement paste with different mineral admixtures. Constr. Build. Mater. 2012, 28, 414–420. [Google Scholar] [CrossRef]

- Di, W.U.; Cai, S.; Huang, G. Coupled effect of cement hydration and temperature on rheological properties of fresh cemented tailings backfill slurry. Trans. Nonferrous Met. Soc. China 2014, 24, 2954–2963. [Google Scholar]

- Deng, X.J.; Klein, B.; Zhang, J.X.; Hallbom, D.; De Wit, B. Time-dependent rheological behaviour of cemented backfill mixture. Int. J. Min. Reclam. Environ. 2018, 32, 145–162. [Google Scholar] [CrossRef]

- Kocaba, V.; Gallucci, E.; Scrivener, K.L. Methods for determination of degree of reaction of slag in blended cement pastes. Cem. Concr. Res. 2012, 42, 511–525. [Google Scholar] [CrossRef]

- Fall, M.; Célestin, J.C.; Pokharel, M.; Touré, M. A contribution to understanding the effects of curing temperature on the mechanical properties of mine cemented tailings backfill. Eng. Geol. 2010, 114, 397–413. [Google Scholar] [CrossRef]

- Gomes, C.E.M.; Ferreira, O.P.; Fernandes, M.R. Influence of vinyl acetate-versatic vinylester copolymer on the microstructural characteristics of cement pastes. Mater. Res. 2005, 8, 51–56. [Google Scholar] [CrossRef]

- He, X.F.; Miao, C.W.; Wu, Y.H.; Cao, X.X.; Liu, D. Thermal Reaction Kinetics of Fly Ash Cement Paste at the Age of 28 Days. Appl. Mech. Mater. 2014, 668, 91–94. [Google Scholar] [CrossRef]

- Pereira, P.; Evangelista, L.; De Brito, J. The effect of superplasticisers on the workability and compressive strength of concrete made with fine recycled concrete aggregates. Constr. Build. Mater. 2012, 28, 722–729. [Google Scholar] [CrossRef]

- Plank, J.; Vlad, D.; Brandl, A.; Chatziagorastou, P. Colloidal chemistry examination of the steric effect of polycarboxylate superplasticizers. Cem. Int. 2005, 3, 100–110. [Google Scholar]

- Huynh, L.; Beattie, D.A.; Fornasiero, D.; Ralston, J. Effect of polyphosphate and naphthalene sulfonate formaldehyde condensate on the rheological properties of dewatered tailings and cemented paste backfill. Miner. Eng. 2006, 19, 28–36. [Google Scholar] [CrossRef]

- Dhers, S.; Guggenberger, R.; Freimut, D.; Fataei, S.; Schwesig, P.; Martic, Z. Impact of Admixtures on Environmental Footprint, Rheological and Mechanical Properties of LC3 Cemented Paste Backfill Systems. Minerals 2023, 13, 1552. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, H.; Taheri, A.; Deng, J.; Ke, B. Effects of Superplasticizer on the Hydration, Consistency, and Strength Development of Cemented Paste Backfill. Minerals 2018, 8, 381. [Google Scholar] [CrossRef]

- Cavusoglu, I. Superplasticizer Dosage Effect on Strength, Microstructure and Permeability Enhancement of Cementitious Paste Fills. Minerals 2024, 14, 1242. [Google Scholar] [CrossRef]

- Cavusoglu, I. Slag Substitution Effect on Features of Alkali-Free Accelerator-Reinforced Cemented Paste Backfill. Minerals 2025, 15, 135. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Y.; Cao, C.; Wang, H. Effect of Curing Temperature under Deep Mining Conditions on the Mechanical Properties of Cemented Paste Backfill. Minerals 2023, 13, 383. [Google Scholar] [CrossRef]

- Feng, Y.; Li, F.; Qi, W.; Ren, Q.; Qi, W.; Duan, G.; Zheng, K.; Han, Y.; Pang, H. Mechanical Properties and Microstructure of Iron Tailings Cemented Paste Backfills Using Carbide Slag-Activated Ground Granulated Blast-Furnace Slag as Alternative Binder. Minerals 2022, 12, 1549. [Google Scholar] [CrossRef]

| Element | Gs | D10 (μm) | D30 (μm) | D50 (μm) | D60 (μm) | Ss (cm2/g) |

|---|---|---|---|---|---|---|

| ST | 2.7 | 1.9 | 9.0 | 22.5 | 31.5 | 3600 |

| An average of 9 mines | – | 1.8 | 9.1 | 20.0 | 30.8 | – |

| Na2O | MgO | Al2O3 | SiO2 | K2O | CaO | TiO2 | MnO | Fe2O3 | Relative Density | Specific Surface Area (cm2/g) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PCI | 0.34 | 2.58 | 4.81 | 20.38 | 0.96 | 62.70 | 0.23 | 0.05 | 3.61 | 3.2 | 1300 |

| Slag | 0.28 | 11.78 | 10.60 | 35.57 | 0.48 | 39.21 | 0.47 | 0.30 | 0.62 | 2.8 | 2100 |

| Form | Nanopowder |

|---|---|

| Particle size | <50 nm (TEM) |

| Surface area | >40 m2/g (BET) |

| Molecular Weight | 101.96 |

| Colour | White |

| Sample Name | Nano-Al2O3 (a) (%) | Binder (%) | Binder Type | w/b | Superplasticizer (%) |

|---|---|---|---|---|---|

| CPB-PCI-0%nAlO | 0 | 4.5 | PCI | 7.8 | 0 |

| CPB-PCI-1%nAlO | 1 | 4.5 | PCI | 7.8 | 0 |

| CPB-PCI-3%nAlO | 3 | 4.5 | PCI | 7.8 | 0 |

| CPB-PCI 1%nAlO-SP | 1 | 4.5 | PCI | 7.8 | 0.125 |

| CPB-PCI 3%nAlO-SP | 3 | 4.5 | PCI | 7.8 | 0.125 |

| CPB-50%PCI/50%Slag 0%nAlO | 0 | 4.5 | PCI/Slag (50/50) (b) | 7.8 | 0 |

| CPB-50%PCI/50%Slag 1%nAlO | 1 | 4.5 | PCI/Slag (50/50) | 7.8 | 0 |

| CPB-50%PCI/50%Slag 3%nAlO | 3 | 4.5 | PCI/Slag (50/50) | 7.8 | 0 |

| CPB-25%PCI/75%Slag 0%nAlO | 0 | 4.5 | PCI/Slag (25/75) | 7.8 | 0 |

| CPB-25%PCI/75%Slag 1%nAlOCPB | 1 | 4.5 | PCI/Slag (25/75) | 7.8 | 0 |

| CPB-25%PCI/75%Slag 3%nAlOCPB | 3 | 4.5 | PCI/Slag (25/75) | 7.8 | 0 |

| Sample Nomenclature | Binder Content (%) | PCI in the Binder (%) | Slag in the Binder (%) | SP (%) | Tailing Type | Ratio | Mixing Water | Nanop Content (%) | Nanop Type | Curing Time (h) |

|---|---|---|---|---|---|---|---|---|---|---|

| CPB-PCI 0 | - | 100 | 0 | 0 | none | 1 | DW | 0 | none | 2 |

| CPB-PCI 1 | - | 100 | 0 | 0 | none | 1 | DW | 1 | nAlO | 2 |

| CPB-PCI 3 | - | 100 | 0 | 0 | none | 1 | DW | 3 | nAlO | 2 |

| CPB-PCI/Slag 3 | - | 50 | 50 | 0 | none | 1 | DW | 3 | nAlO | 2 |

| CPB-PCI 3-SP | - | 100 | 0 | 0.125 | none | 1 | DW | 3 | nAlO | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaviani, R.; Fall, M. Rheological Properties of Aluminium Oxide Nanoparticle-Modified Cemented Paste Tailings Materials. Minerals 2025, 15, 246. https://doi.org/10.3390/min15030246

Kaviani R, Fall M. Rheological Properties of Aluminium Oxide Nanoparticle-Modified Cemented Paste Tailings Materials. Minerals. 2025; 15(3):246. https://doi.org/10.3390/min15030246

Chicago/Turabian StyleKaviani, Raouf, and Mamadou Fall. 2025. "Rheological Properties of Aluminium Oxide Nanoparticle-Modified Cemented Paste Tailings Materials" Minerals 15, no. 3: 246. https://doi.org/10.3390/min15030246

APA StyleKaviani, R., & Fall, M. (2025). Rheological Properties of Aluminium Oxide Nanoparticle-Modified Cemented Paste Tailings Materials. Minerals, 15(3), 246. https://doi.org/10.3390/min15030246