The Adjustment for Entrainment Behavior of Kaolinite in Coal Flotation

Abstract

1. Introduction

2. Experimental

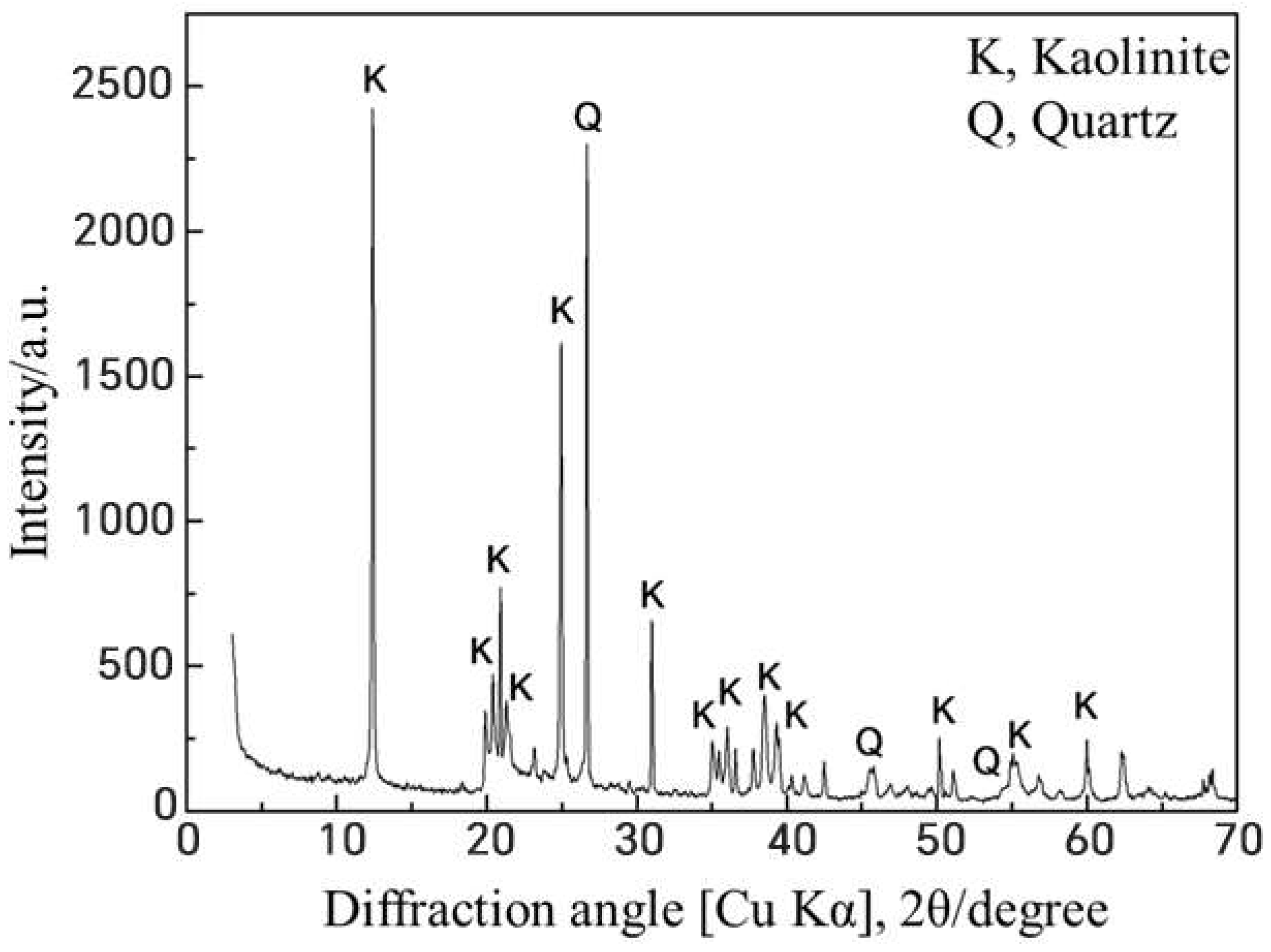

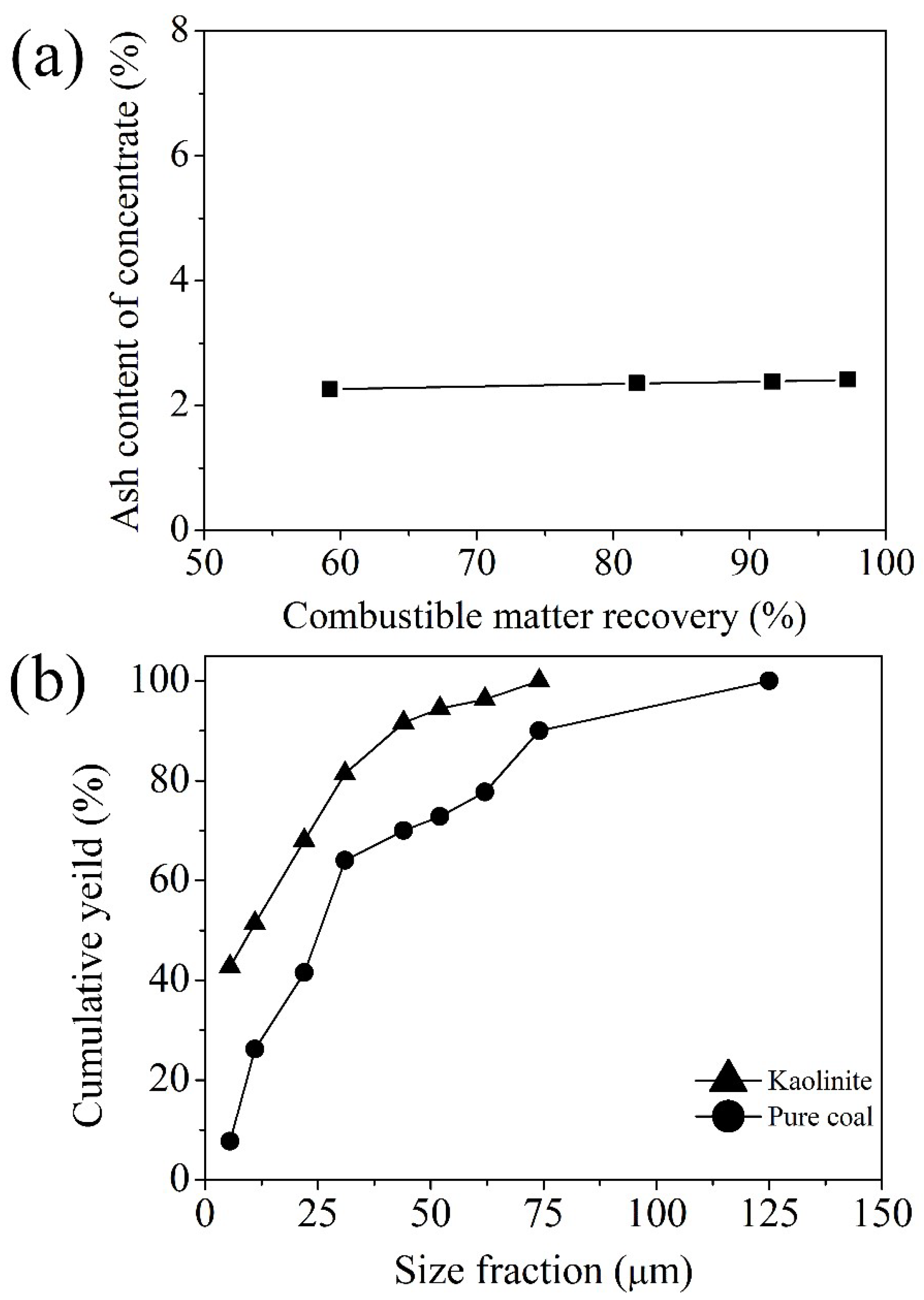

2.1. Materials

2.2. Experimental Procedure

- eg, the degree of entrainment of kaolinite;

- Rs, the recovery of kaolinite in a certain period;

- Rw, the recovery of water in a certain period;

- m(c,i), the amount of kaolinite in concentrate in a certain period, g;

- m(f,i), the amount of kaolinite in feed pulp in a certain period, g;

- m(c,w), the amount of water in concentrate in a certain period, g;

- m(f,w), the amount of water in feed pulp in a certain period, g.

- Ec, the combustible recovery of concentrate, %;

- γc, the yield of concentrate, %;

- Ac, the ash content of concentrate, %;

- Af, the ash content of feed, %.

3. Results and Discussion

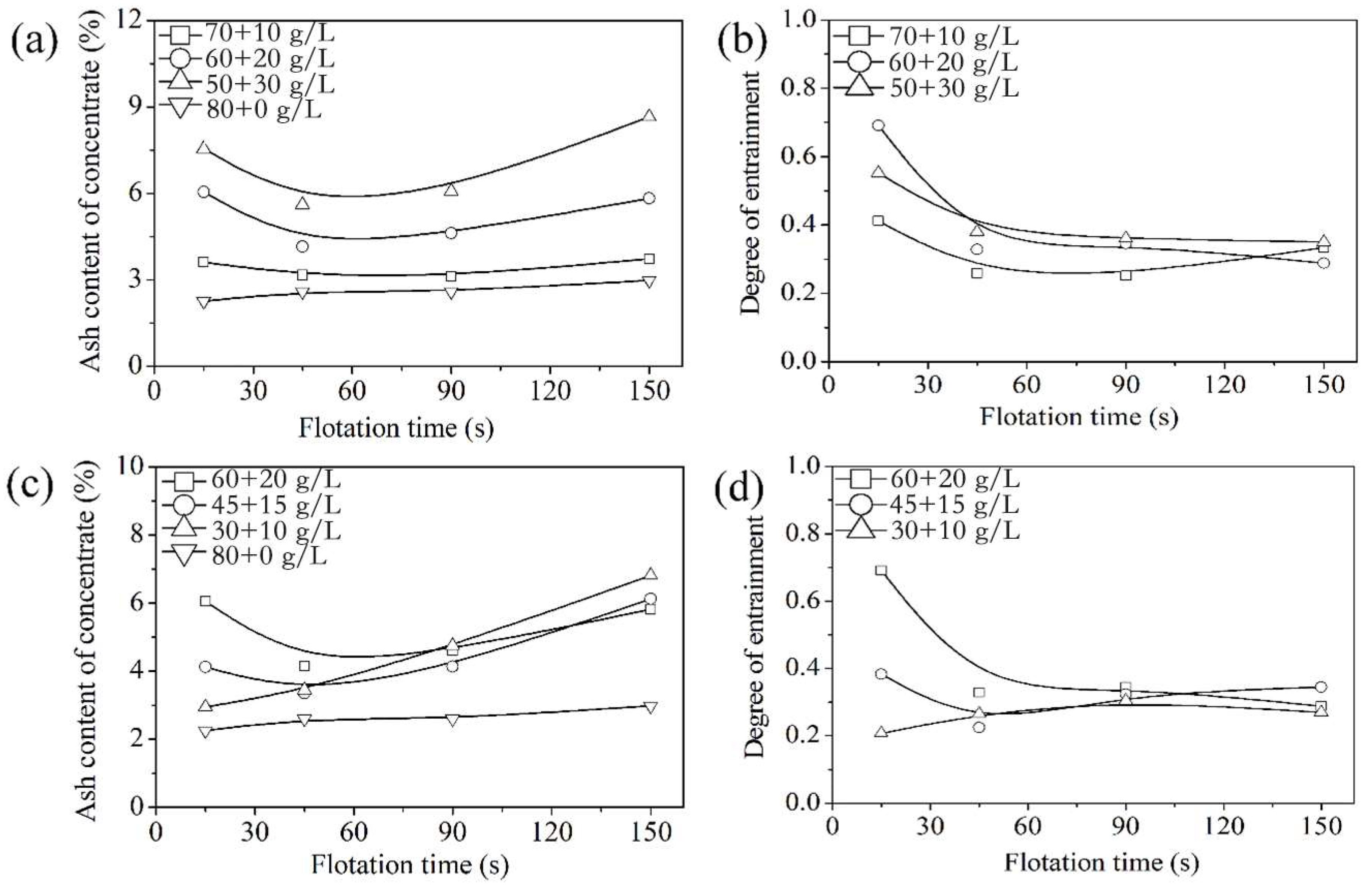

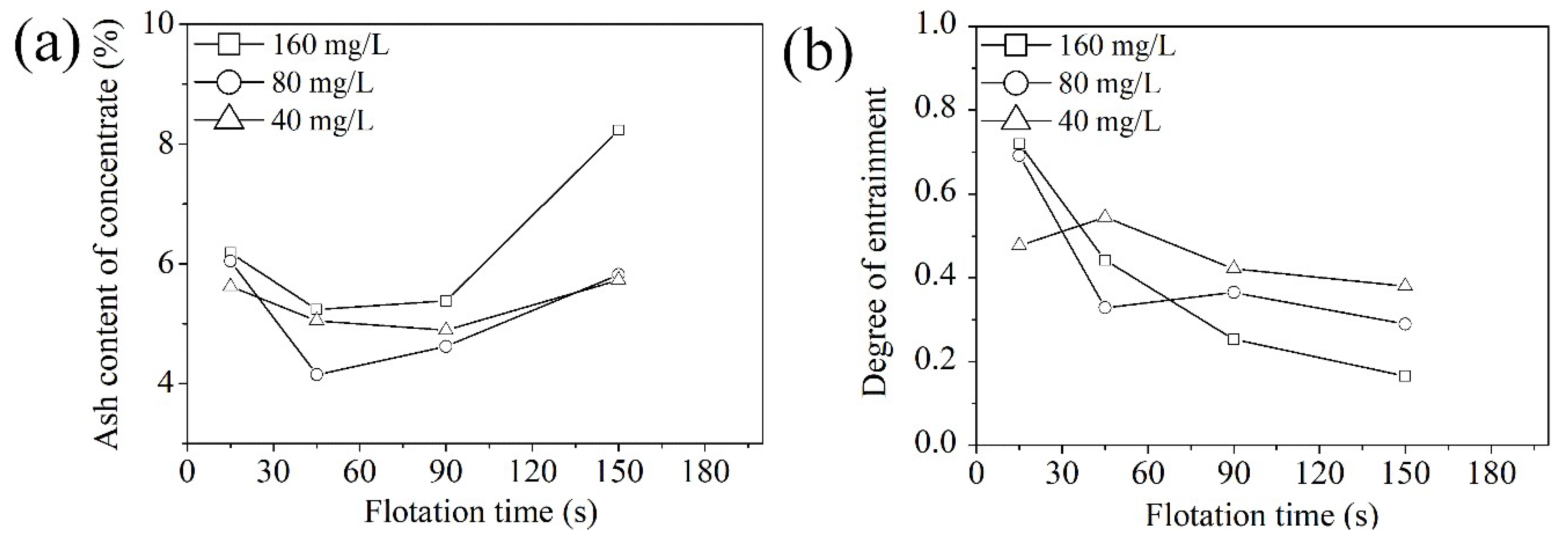

3.1. Effect of Kaolinite Concentration on Entrainment

3.2. Effect of Frother Concentration on Entrainment

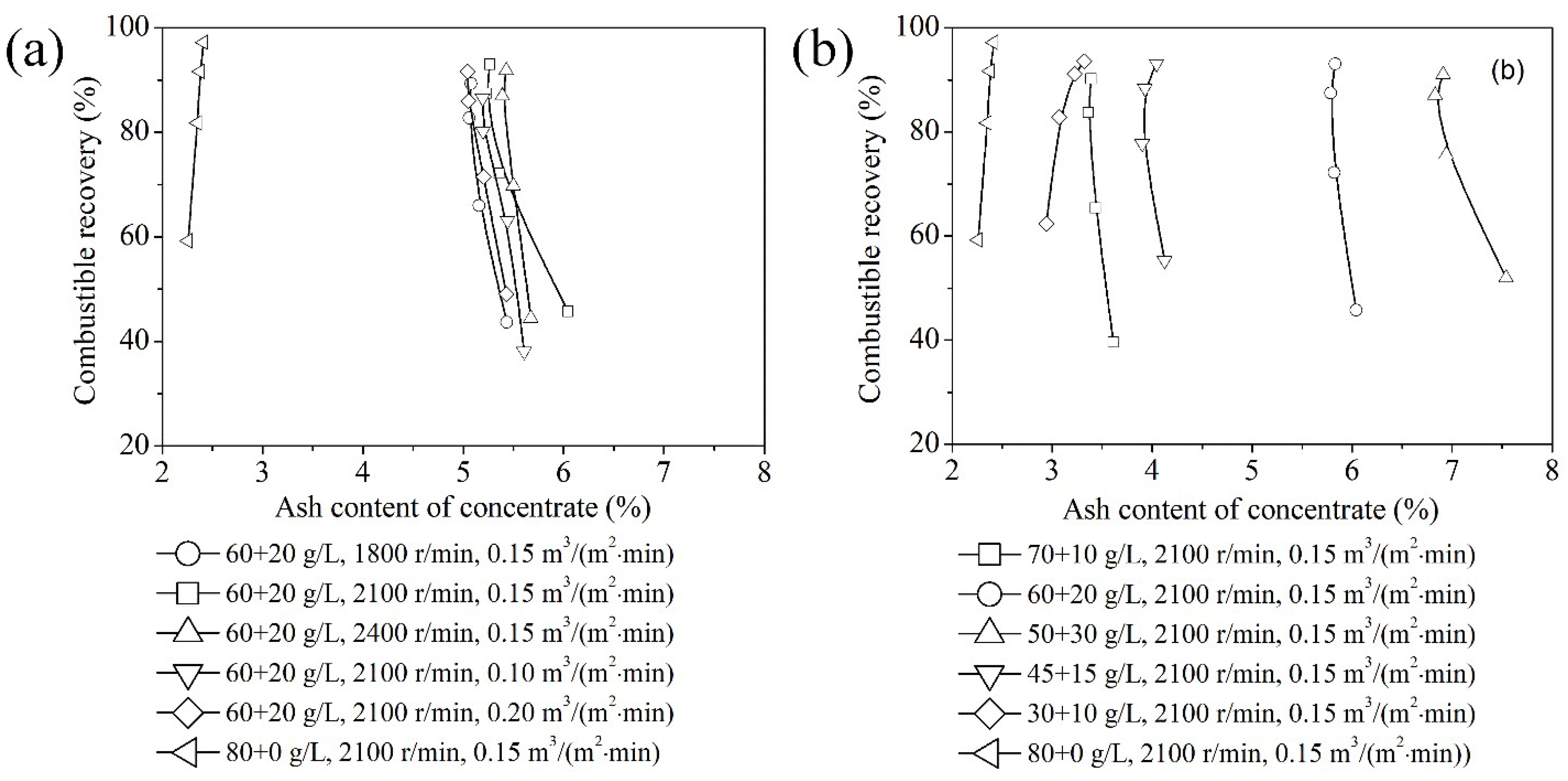

3.3. Effects of Aeration Rate and Impeller Speed on the Flotation Performance

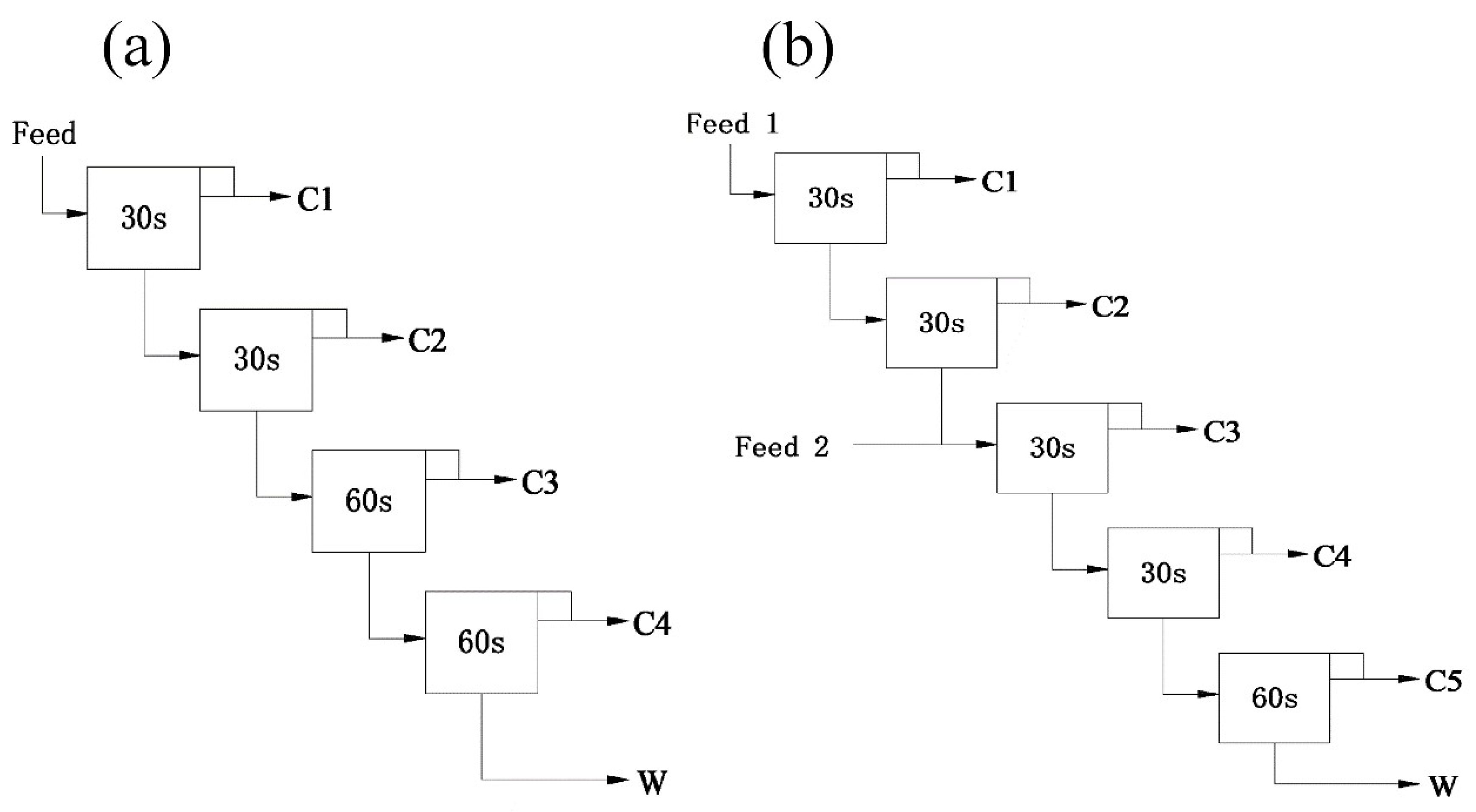

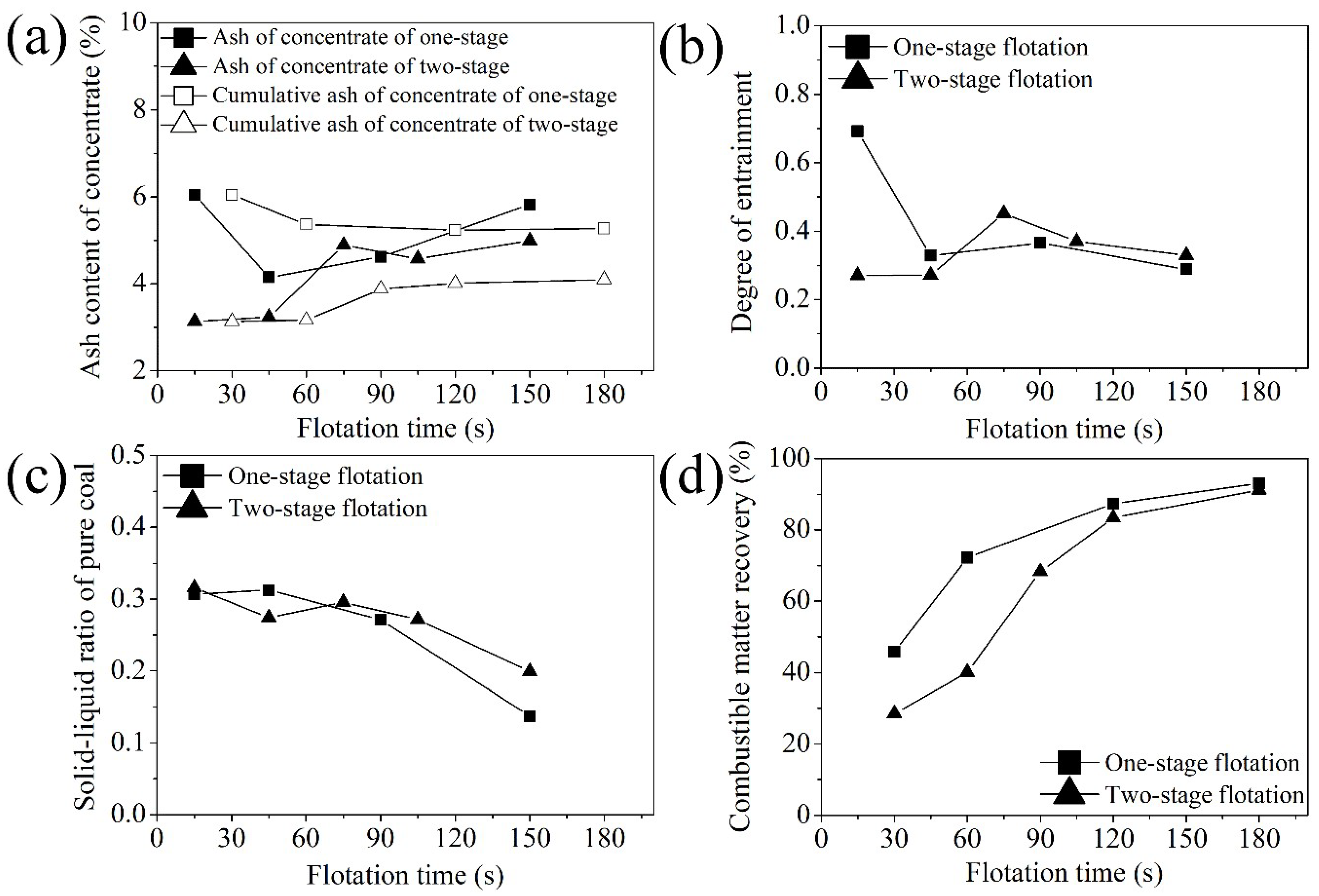

3.4. Two-Stage Flotation Process

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, N.; Chen, X.; Peng, Y. The interaction between kaolinite and saline water in affecting the microstructure, rheology and settling of coal flotation products. Powder Technol. 2020, 372, 76–83. [Google Scholar] [CrossRef]

- Jaiswal, S.; Tripathy, S.K.; Banerjee, P. An overview of reverse flotation process for coal. Int. J. Miner. Process. 2015, 134, 97–110. [Google Scholar] [CrossRef]

- Tian, Q.; Zhang, Y.; Li, G.; Wang, Y. Application of carboxylic acid in low-rank coal flotation. Int. J. Coal Prep. Util. 2019, 39, 44–53. [Google Scholar] [CrossRef]

- Han, R.; Zhou, A.; Zhang, N.; Li, Z.; Cheng, M.; Chen, X.; Nan, T. Effective separation of coal gasification fine slag: Role of classification and ultrasonication in enhancing flotation. Int. J. Min. Sci. Technol. 2024, 34, 867–880. [Google Scholar] [CrossRef]

- Zhang, N.; Ruan, S.; Fu, N.; Han, R.; Zhou, A.; Li, Z.; Yu, Y.; Wang, H. Composition and structural properties of coal gasification fine slag and its classified products—A case study. Int. J. Coal Prep. Util. 2024, 1–22. [Google Scholar] [CrossRef]

- Zheng, X.; Franzidis, J.; Johnson, N. An evaluation of different models of water recovery in flotation. Miner. Eng. 2006, 19, 871–882. [Google Scholar] [CrossRef]

- Zheng, X.; Johnson, N.; Franzidis, J.-P. Modelling of entrainment in industrial flotation cells: Water recovery and degree of entrainment. Miner. Eng. 2006, 19, 1191–1203. [Google Scholar] [CrossRef]

- Kirjavainen, V. Review and analysis of factors controlling the mechanical flotation of gangue minerals. Int. J. Miner. Process. 1996, 46, 21–34. [Google Scholar] [CrossRef]

- Ross, V. Flotation and entrainment of particles during batch flotation tests. Miner. Eng. 1990, 3, 245–256. [Google Scholar] [CrossRef]

- Guangyuan, X.; Ling, W.; Zeshen, O.; Xiupeng, Z.; Wuping, W. Research on fine coal classified flotation flow sheet. J. China Univ. Min. Technol. 2003, 34, 756–760. [Google Scholar]

- Yu, Y.; Ma, L.; Zhang, Z.-L.; Wang, L.-Y.; Yao, L.-Y. Mechanism of entrainment and slime coating on coal flotation. J. China Coal Soc. 2015, 40, 652–658. [Google Scholar]

- Zhu, Z.; Yin, W.; Yang, B.; Fu, Y.; Xue, J. Reduction of the slime contamination on fine coking coal by using the reverse-and-direct flotation process. Colloids Surf. Physicochem. Eng. Asp. 2019, 579, 123681. [Google Scholar] [CrossRef]

- Amelunxen, P.; LaDouceur, R.; Amelunxen, R.; Young, C. A phenomenological model of entrainment and froth recovery for interpreting laboratory flotation kinetics tests. Miner. Eng. 2018, 125, 60–65. [Google Scholar] [CrossRef]

- Wang, L.; Runge, K.; Peng, Y.; Vos, C. An empirical model for the degree of entrainment in froth flotation based on particle size and density. Miner. Eng. 2016, 98, 187–193. [Google Scholar] [CrossRef]

- Szyszka, D. Critical Coalescence Concentration (CCC) for surfactants in aqueous solutions. Minerals 2018, 8, 431. [Google Scholar] [CrossRef]

- Chen, T.; Zhao, Y.; Li, H.; Song, S. Effects of colloidal montmorillonite particles on froth flotation of graphite, galena and fluorite. Physicochem. Probl. Miner. Pro. 2017, 53. [Google Scholar] [CrossRef]

- Wang, G.; Bai, X.; Wu, C.; Li, W.; Liu, K.; Kiani, A. Recent advances in the beneficiation of ultrafine coal particles. Fuel Process. Technol. 2018, 178, 104–125. [Google Scholar] [CrossRef]

- Wang, B.; Peng, Y. The behaviour of mineral matter in fine coal flotation using saline water. Fuel 2013, 109, 309–315. [Google Scholar] [CrossRef]

- Liu, D.; Peng, Y. Reducing the entrainment of clay minerals in flotation using tap and saline water. Powder Technol. 2014, 253, 216–222. [Google Scholar] [CrossRef]

- Mileva, E.; Nikolov, L. Entrapment efficiencies of hydrodynamic boundary layers on rising bubbles. J. Colloid Interface Sci. 2003, 265, 310–319. [Google Scholar] [CrossRef]

- Wang, L.; Peng, Y.; Runge, K.; Bradshaw, D. A review of entrainment: Mechanisms, contributing factors and modelling in flotation. Miner. Eng. 2015, 70, 77–91. [Google Scholar] [CrossRef]

- Wang, L.; Peng, Y.; Runge, K. Entrainment in froth flotation: The degree of entrainment and its contributing factors. Powder Technol. 2016, 288, 202–211. [Google Scholar] [CrossRef]

- Kursun, H. Effect of Fine Particles’ Entrainment on Conventional and Column Flotation. Part. Sci. Technol. 2014, 32, 251–256. [Google Scholar] [CrossRef]

- Akdemir, Ü.; Sönmez, İ. Investigation of coal and ash recovery and entrainment in flotation. Fuel Process. Technol. 2003, 82, 1–9. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Sun, F.; Gui, X. Revisiting the enhanced selectivity in low-rank coal flotation by composite collector comprising kerosene and sorbitan mono oleate. Powder Technol. 2023, 428, 118799. [Google Scholar] [CrossRef]

- Wang, L.; Peng, Y.; Runge, K. The mechanism responsible for the effect of frothers on the degree of entrainment in laboratory batch flotation. Miner. Eng. 2017, 100, 124–131. [Google Scholar] [CrossRef]

- Jera, T.M.; Bhondayi, C. A Review on Froth Washing in Flotation. Minerals 2022, 12, 1462. [Google Scholar] [CrossRef]

- Mesa, D.; Morrison, A.J.; Brito-Parada, P.R. The effect of impeller-stator design on bubble size: Implications for froth stability and flotation performance. Miner. Eng. 2020, 157, 106533. [Google Scholar] [CrossRef]

- Tabosa, E.; Runge, K.; Holtham, P. The effect of cell hydrodynamics on flotation performance. Int. J. Miner. Process. 2016, 156, 99–107. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, G.; Wang, M.; Liu, D. The Critical Role of Pulp Density on Flotation Separation of Nickel-Copper Sulfide from Fine Serpentine. Minerals 2018, 8, 317. [Google Scholar] [CrossRef]

- Ni, C.; Ma, G.; Xia, W.; Peng, Y.; Jie, S.; Xie, G. Influence of Inclined Plates in the Froth Zone on the Flotation Performance of a Flotation Column. Int. J. Coal Prep. Util. 2017, 39, 132–144. [Google Scholar] [CrossRef]

- Gong, J.; Peng, Y.; Bouajila, A.; Ourriban, M.; Yeung, A.; Liu, Q. Reducing quartz gangue entrainment in sulphide ore flotation by high molecular weight polyethylene oxide. Int. J. Miner. Process. 2010, 97, 44–51. [Google Scholar] [CrossRef]

- Wang, C.; Sun, C.; Liu, Q. Entrainment of Gangue Minerals in Froth Flotation: Mechanisms, Models, Controlling Factors, and Abatement Techniques—A Review. Min. Metall. Explor. 2020, 38, 673–692. [Google Scholar] [CrossRef]

- Kim, M.; You, K.; Kim, K.; Jeon, Y.-W. Study of the effect of airflow rate and agitation speed on entrainment of ash particles in bottom ash flotation. Physicochem. Probl. Miner. Process. 2024, 60, 187835. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, H.; Zhu, J.; Tang, J.; Huang, D.; Shao, S. Optimizing oxidized coal flotation through pH adjustment and inorganic salt ion. Int. J. Coal Prep. Util. 2019, 42, 715–723. [Google Scholar] [CrossRef]

- Gupta, A.K.; Banerjee, P.; Mishra, A.; Satish, P. Effect of alcohol and polyglycol ether frothers on foam stability, bubble size and coal flotation. Int. J. Miner. Process. 2007, 82, 126–137. [Google Scholar] [CrossRef]

- Shi, Q.; Zhu, H.; Shen, T.; Qin, Z.; Zhu, J.; Gao, L.; Ou, Z.; Zhang, Y.; Pan, G. Effect of frother on bubble entraining particles in coal flotation. Energy 2024, 288, 129711. [Google Scholar] [CrossRef]

- Hoang, D.H.; Heitkam, S.; Kupka, N.; Hassanzadeh, A.; Peuker, U.A.; Rudolph, M. Froth properties and entrainment in lab-scale flotation: A case of carbonaceous sedimentary phosphate ore. Chem. Eng. Res. Des. 2019, 142, 100–110. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Gu, W.; Zhang, H.; Tian, Q.; Wang, H.; Zhou, Y.; Liu, Z. The Adjustment for Entrainment Behavior of Kaolinite in Coal Flotation. Minerals 2025, 15, 147. https://doi.org/10.3390/min15020147

Liu C, Gu W, Zhang H, Tian Q, Wang H, Zhou Y, Liu Z. The Adjustment for Entrainment Behavior of Kaolinite in Coal Flotation. Minerals. 2025; 15(2):147. https://doi.org/10.3390/min15020147

Chicago/Turabian StyleLiu, Chengyong, Wenzhe Gu, Haijun Zhang, Quanzhi Tian, Hainan Wang, Yuejin Zhou, and Zhicheng Liu. 2025. "The Adjustment for Entrainment Behavior of Kaolinite in Coal Flotation" Minerals 15, no. 2: 147. https://doi.org/10.3390/min15020147

APA StyleLiu, C., Gu, W., Zhang, H., Tian, Q., Wang, H., Zhou, Y., & Liu, Z. (2025). The Adjustment for Entrainment Behavior of Kaolinite in Coal Flotation. Minerals, 15(2), 147. https://doi.org/10.3390/min15020147