Experimental Study on the Thickening Characteristics of Ultrafine Tailings

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Equipment

2.3. Experimental Scheme Design

2.3.1. Graduated Cylinder Sedimentation Test

2.3.2. Small-Scale Dynamic Thickening Experiment

2.3.3. Semi-Industrial Thickening Experiment

3. Results and Discussion

3.1. Graduated Cylinder Sedimentation Test

3.2. Small-Scale Dynamic Thickening Experiment

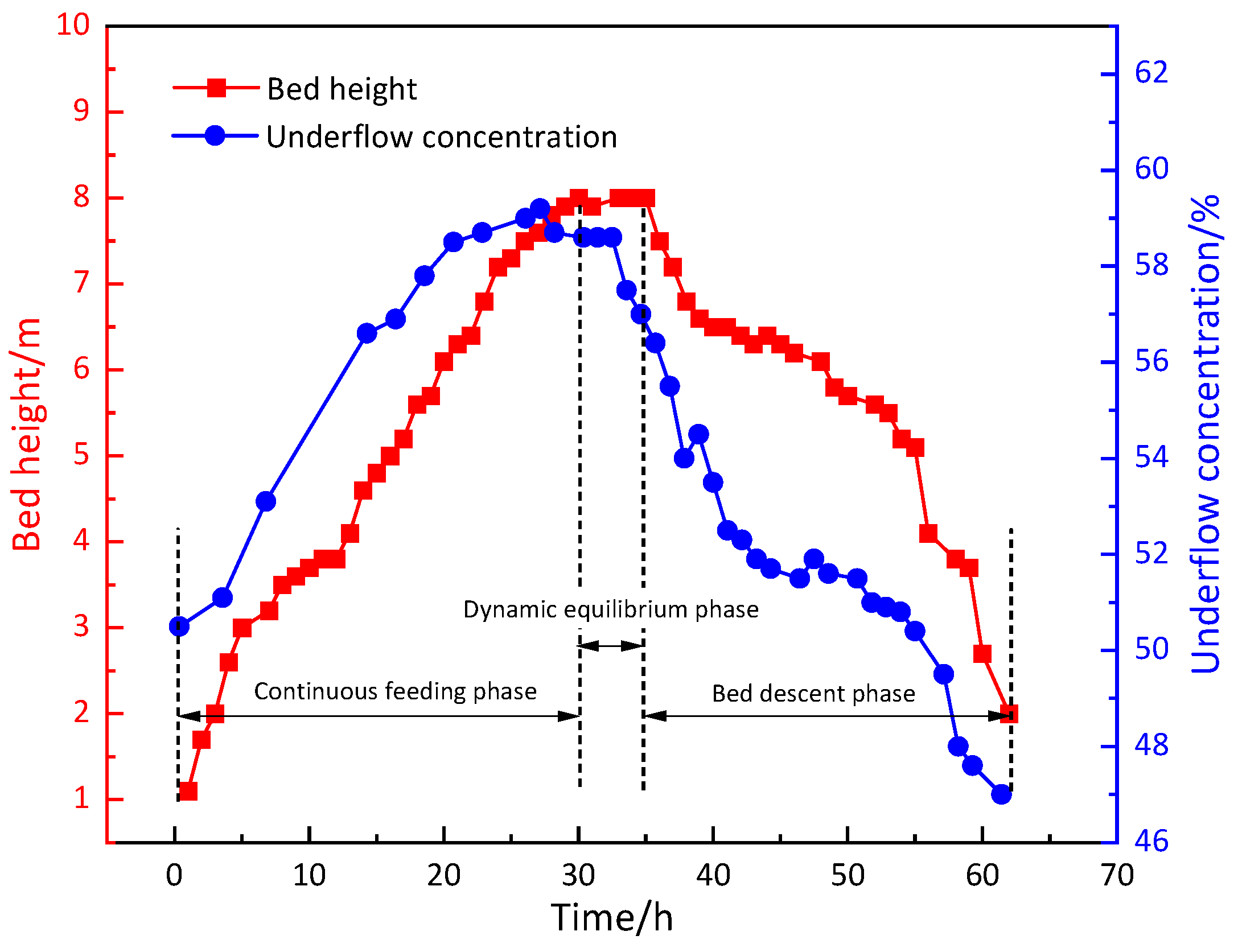

3.3. Semi-Industrial Thickening Experiment

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, P.; Cai, M. Challenges and New Insights for Exploitation of Deep Underground Metal Mineral Resources. Trans. Nonferrous Met. Soc. China 2021, 31, 3478–3505. [Google Scholar] [CrossRef]

- Ju, J.; Han, J.; Feng, C. Evaluation and Development Path of Comprehensive Utilization of Mineral Resources in China. China Min. Mag. 2024, 33, 14–25. [Google Scholar]

- Walske, M.; McWilliam, H.; Doherty, J.; Fourie, A. Influence of Curing Temperature and Stress Conditions on Mechanical Properties of Cementing Paste Backfill. Can. Geotech. J. 2016, 53, 148–161. [Google Scholar] [CrossRef]

- Al-moselly, Z.; Fall, M. Sulphate Influence on Strength Development of Cemented Paste Backfill with Superplasticizer under Field-like Curing Conditions. Constr. Build. Mater. 2024, 451, 138788. [Google Scholar] [CrossRef]

- Sari, M.; Yilmaz, E.; Kasap, T. Long-Term Ageing Characteristics of Cemented Paste Backfill: Usability of Sand as a Partial Substitute of Hazardous Tailings. J. Clean. Prod. 2023, 401, 136723. [Google Scholar] [CrossRef]

- Wang, J.; Wu, A.; Wang, M.; Ruan, Z. Experimental Investigation on Flow Behavior of Paste Slurry Transported by Gravity in Vertical Pipes. Processes 2022, 10, 1696. [Google Scholar] [CrossRef]

- Wu, A.; Ruan, Z.; Li, C.; Wang, S.; Wang, Y.; Wang, J. Numerical Study of Flocculation Settling and Thickening of Whole-Tailings in Deep Cone Thickener Using CFD Approach. J. Cent. South Univ. 2019, 26, 711–718. [Google Scholar] [CrossRef]

- Ruan, Z.; Wu, A.; Jiao, H.; Li, C.; Li, G.; Mo, Y.; Wang, H. Advances and Trends on Thickening of Full-Tailings Slurry in China. Chin. J. Nonferrous Met. 2022, 32, 286–301. [Google Scholar] [CrossRef]

- Zhang, L. Production of Bricks from Waste Materials—A Review. Constr. Build. Mater. 2013, 47, 643–655. [Google Scholar] [CrossRef]

- Ahmari, S.; Zhang, L. Production of Eco-Friendly Bricks from Copper Mine Tailings through Geopolymerization. Constr. Build. Mater. 2012, 29, 323–331. [Google Scholar] [CrossRef]

- Lemanowicz, M.; Jach, Z.; Kilian, E.; Gierczycki, A. Ultra-Fine Coal Flocculation Using Dual-Polymer Systems of Ultrasonically Conditioned and Unmodified Flocculant. Chem. Eng. J. 2011, 168, 159–169. [Google Scholar] [CrossRef]

- Wickramasinghe, S.R.; Leong, Y.K.; Mondal, S.; Liow, J.L. Influence of Cationic Flocculant Properties on the Flocculation of Yeast Suspensions. Adv. Powder Technol. 2010, 21, 374–379. [Google Scholar] [CrossRef]

- Li, C.; Chen, G.; Ruan, Z.; Hou, H. Dynamic Evolution Law of Floc Structure in Whole Process of Tailings Thickening. Chin. J. Nonferrous Met. 2023, 33, 1318–1332. [Google Scholar] [CrossRef]

- Zheng, D.; Song, W.; Tan, Y.; Cao, S.; Yang, Z.; Sun, L. Fractal and Microscopic Quantitative Characterization of Unclassified Tailings Flocs. Int. J. Miner. Metall. Mater. 2021, 28, 1429–1439. [Google Scholar] [CrossRef]

- Wang, D.; Wang, D.; Wang, K.; Yeung, A.; Liu, Q. Enhancing the Dewatering of Oil Sands Mature Fine Tailings by Coagulation-Flocculation and Pressure Filtration with Tannic Acid-Mediated Polymeric Complex Network. Sep. Purif. Technol. 2024, 335, 126194. [Google Scholar] [CrossRef]

- Motta, F.L.; Gaikwad, R.; Botha, L.; Soares, J.B.P. Quantifying the Effect of Polyacrylamide Dosage, Na+ and Ca2+ Concentrations, and Clay Particle Size on the Flocculation of Mature Fine Tailings with Robust Statistical Methods. Chemosphere 2018, 208, 263–272. [Google Scholar] [CrossRef]

- Wang, H.; Yang, Y.; Guo, J. Thickening Dehydration Performance and Flocculation Mechanism of Ultrafine Tailings Based on Dual Flocculation. J. Cent. South Univ. Sci. Technol. 2023, 54, 3597–3608. [Google Scholar] [CrossRef]

- Thompson, D.K.; Motta, F.L.; Soares, J.B.P. Investigation on the Fl Occulation of Oil Sands Mature Fi Ne Tailings with Alkoxysilanes. Miner. Eng. 2017, 111, 90–99. [Google Scholar] [CrossRef]

- Ruan, Z.; Wu, A.; Wang, Y.; Wang, Y.; Wang, J. Effect of Flocculation Sedimentation on the Yield Stress of Thickened Ultrafine Tailings Slurry. Chin. J. Eng. 2021, 43, 1276–1282. [Google Scholar]

- Wu, A.; Ruan, Z.; Wang, J.; Yin, S.; Ai, C. Optimizing the Flocculation Behavior of Ultrafine Tailings by Ultra-Flocculation. Chin. J. Eng. 2019, 41, 981–986. [Google Scholar] [CrossRef]

- Quezada, G.R.; Ramos, J.; Jeldres, R.I.; Robles, P.; Toledo, P.G. Analysis of the Flocculation Process of Fine Tailings Particles in Saltwater through a Population Balance Model. Sep. Purif. Technol. 2020, 237, 116319. [Google Scholar] [CrossRef]

- Qi, C.; Ly, H.B.; Chen, Q.; Le, T.T.; Le, V.M.; Pham, B.T. Flocculation-Dewatering Prediction of Fine Mineral Tailings Using a Hybrid Machine Learning Approach. Chemosphere 2020, 244, 125450. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.; Yang, S.; Zhang, R. Flocculation Sedimentation Test of Ultrafine Tailings Based on Turbidity of Supernatant Liquid. Gold Sci. Technol. 2022, 30, 948–957. [Google Scholar]

- Govedarica, A.; Molina Bacca, E.J.; Trifkovic, M. Structural Investigation of Tailings Flocculation and Consolidation via Quantitative 3D Dual Fluorescence/Reflectance Confocal Microscopy. J. Colloid Interface Sci. 2020, 571, 194–204. [Google Scholar] [CrossRef]

- Zou, Y.; Liu, Q.; Liu, W. Study on the Relation between Tailing Particle Size and Tailing Slurry Underflow Concentration. Adv. Civ. Eng. 2022, 5449032. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, J.; Zhang, D. Optimal Prediction Model of Flocculating Sedimentation Velocity of Unclassified Tailings. Chin. J. Nonferrous Met. 2015, 25, 793–798. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, S.; Wang, X. Influence Rules of Unit Consumptions of Flocculants on Interface Sedimentation Velocity of Unclassified Tailings Slurry. Chin. J. Nonferrous Met. 2017, 27, 318–324. [Google Scholar] [CrossRef]

- Xiao, C. Research on Intelligent Prediction Model Based on Depth Thickening Deductive Mechanism of Unclassed Tailings; Central South University: Changsha, China, 2022. [Google Scholar]

- Wang, S.; Wei, M.; Tao, T.; Song, X.; Liu, W.; Yu, H. Internal Structure Evolution Characteristics of High Concentration Unclassified Tailings Mortar Containing APAM. Chin. J. Nonferrous Met. 2022, 32, 3553–3566. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Du, Z.; Liu, X.; Wu, A. Experimental Study on the Thickening Characteristics of Ultrafine Tailings. Minerals 2025, 15, 100. https://doi.org/10.3390/min15020100

Wang J, Du Z, Liu X, Wu A. Experimental Study on the Thickening Characteristics of Ultrafine Tailings. Minerals. 2025; 15(2):100. https://doi.org/10.3390/min15020100

Chicago/Turabian StyleWang, Jiandong, Zhaolong Du, Xiaohui Liu, and Aixiang Wu. 2025. "Experimental Study on the Thickening Characteristics of Ultrafine Tailings" Minerals 15, no. 2: 100. https://doi.org/10.3390/min15020100

APA StyleWang, J., Du, Z., Liu, X., & Wu, A. (2025). Experimental Study on the Thickening Characteristics of Ultrafine Tailings. Minerals, 15(2), 100. https://doi.org/10.3390/min15020100