Dynamic Mechanical Properties and Mesoscopic Characteristics of Cemented Tailings Backfill Under Cyclic Dynamic Loading

Abstract

1. Introduction

2. Materials and Method

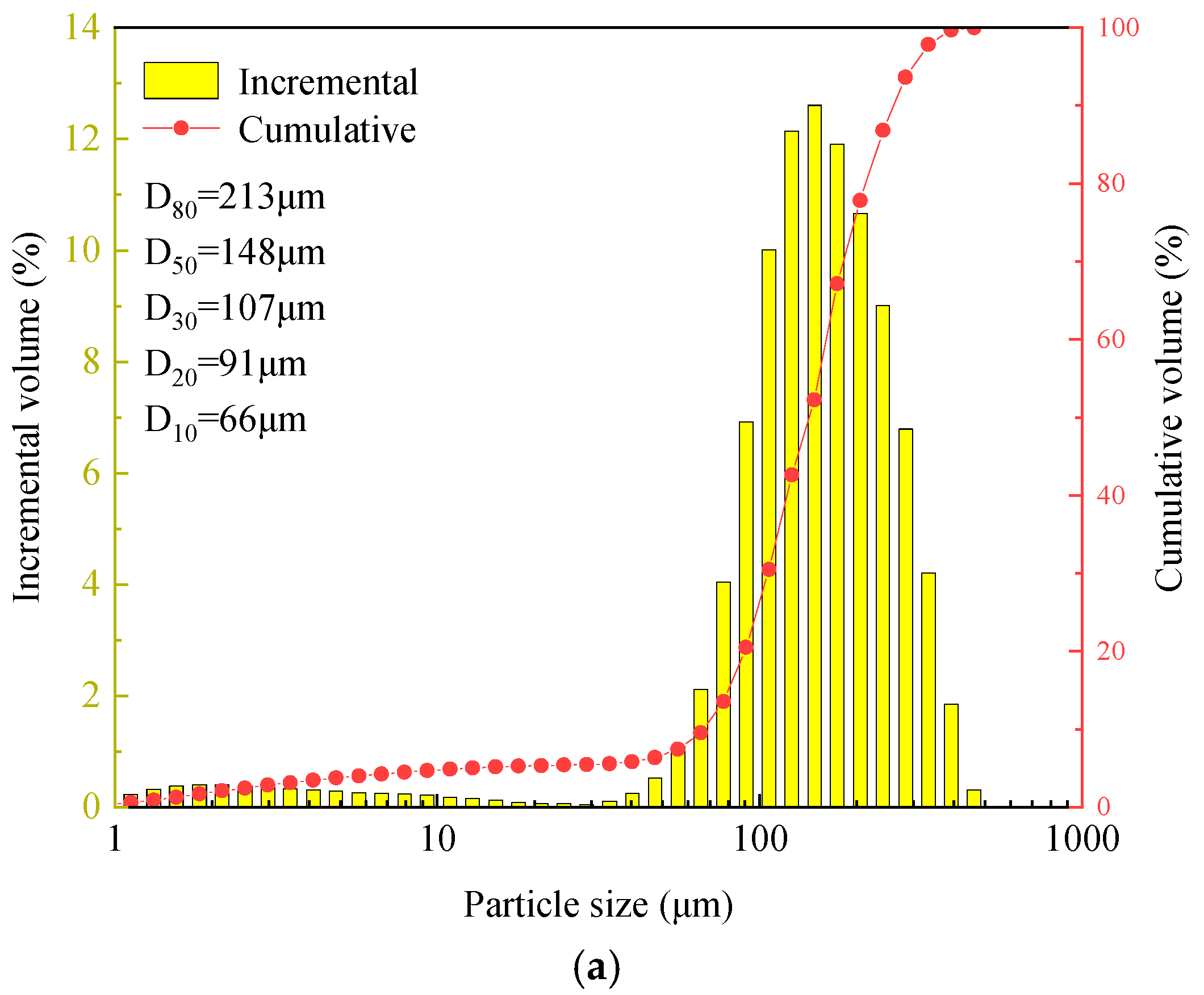

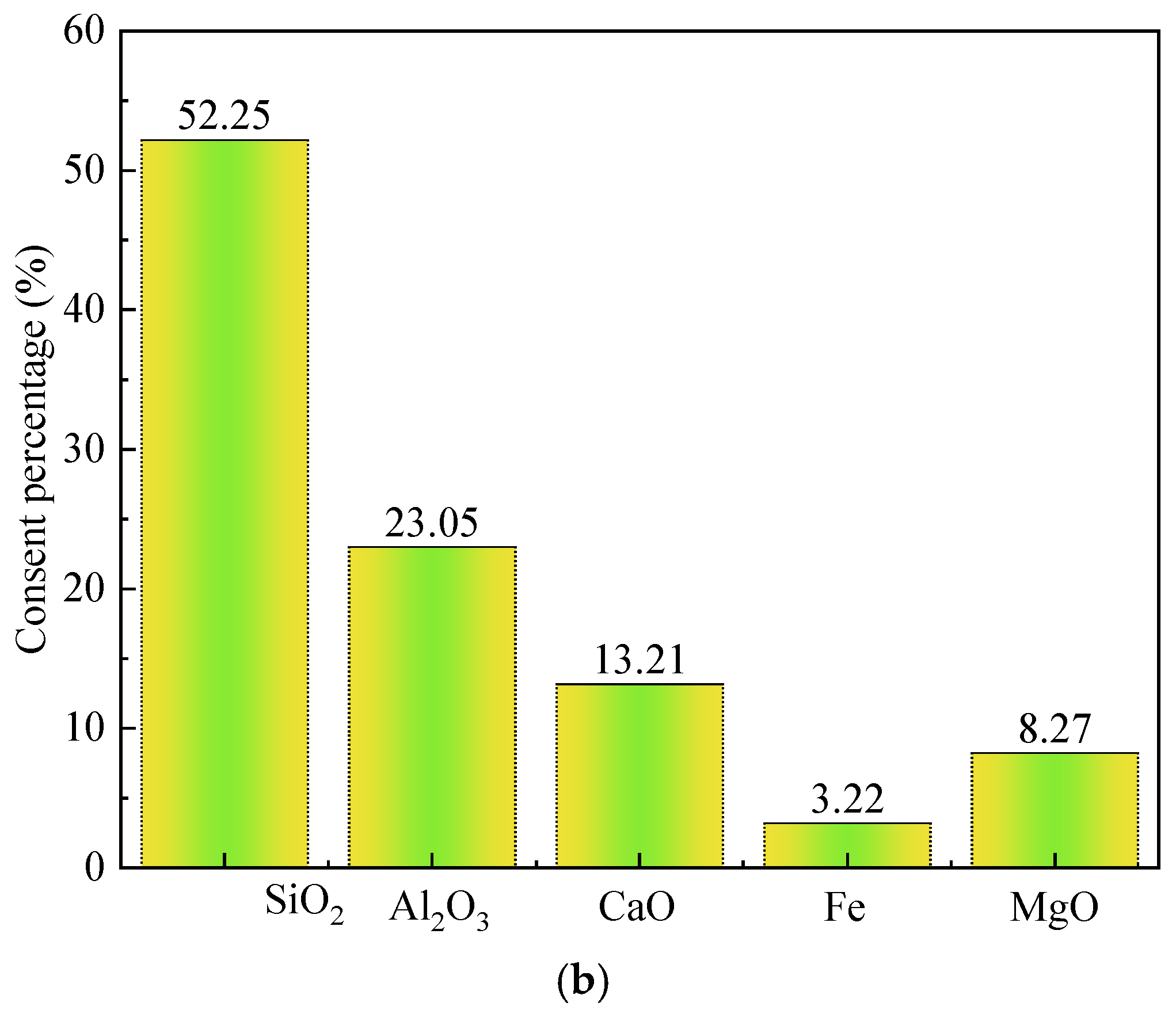

2.1. Experimental Materials

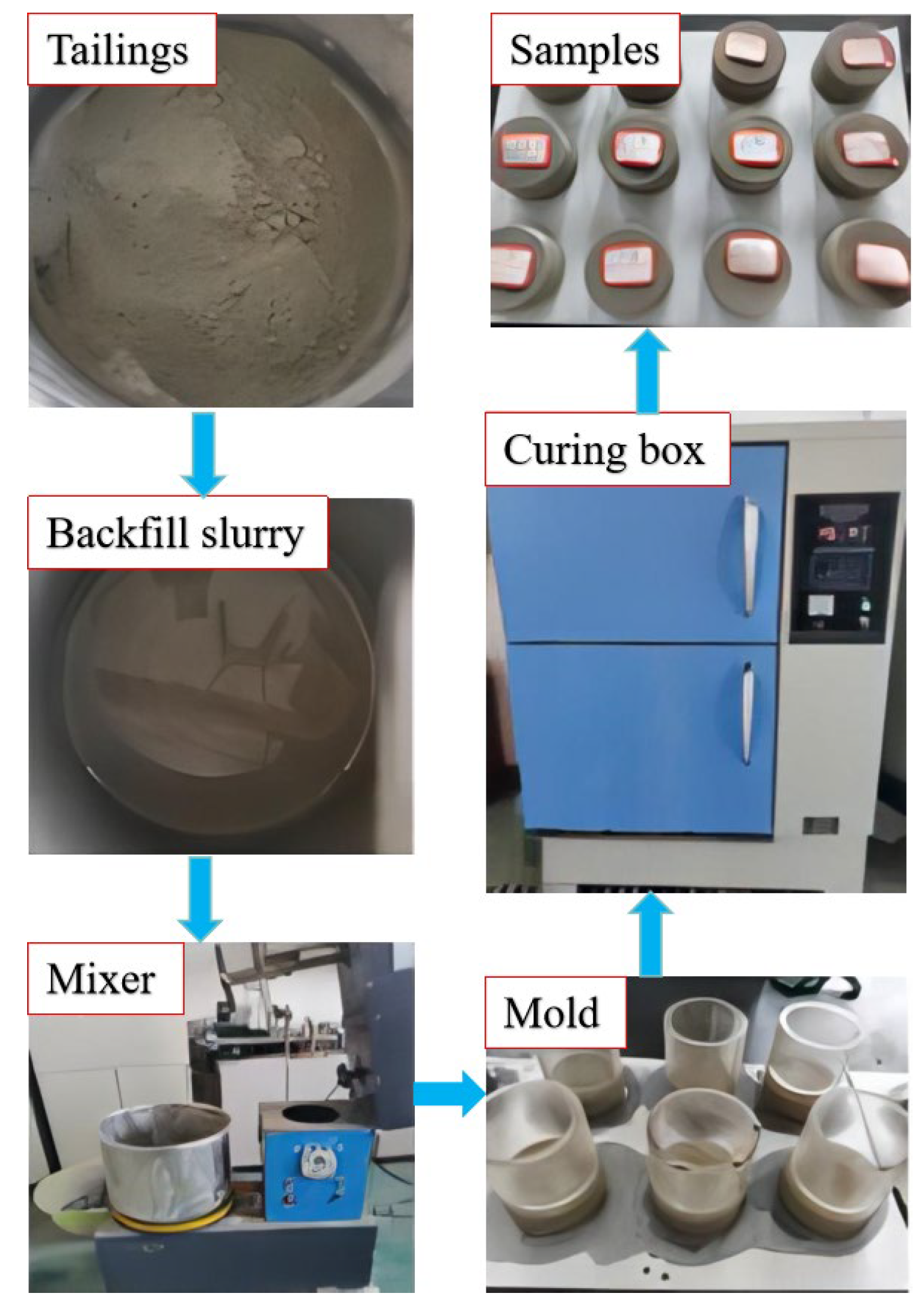

2.2. Specimen Preparation

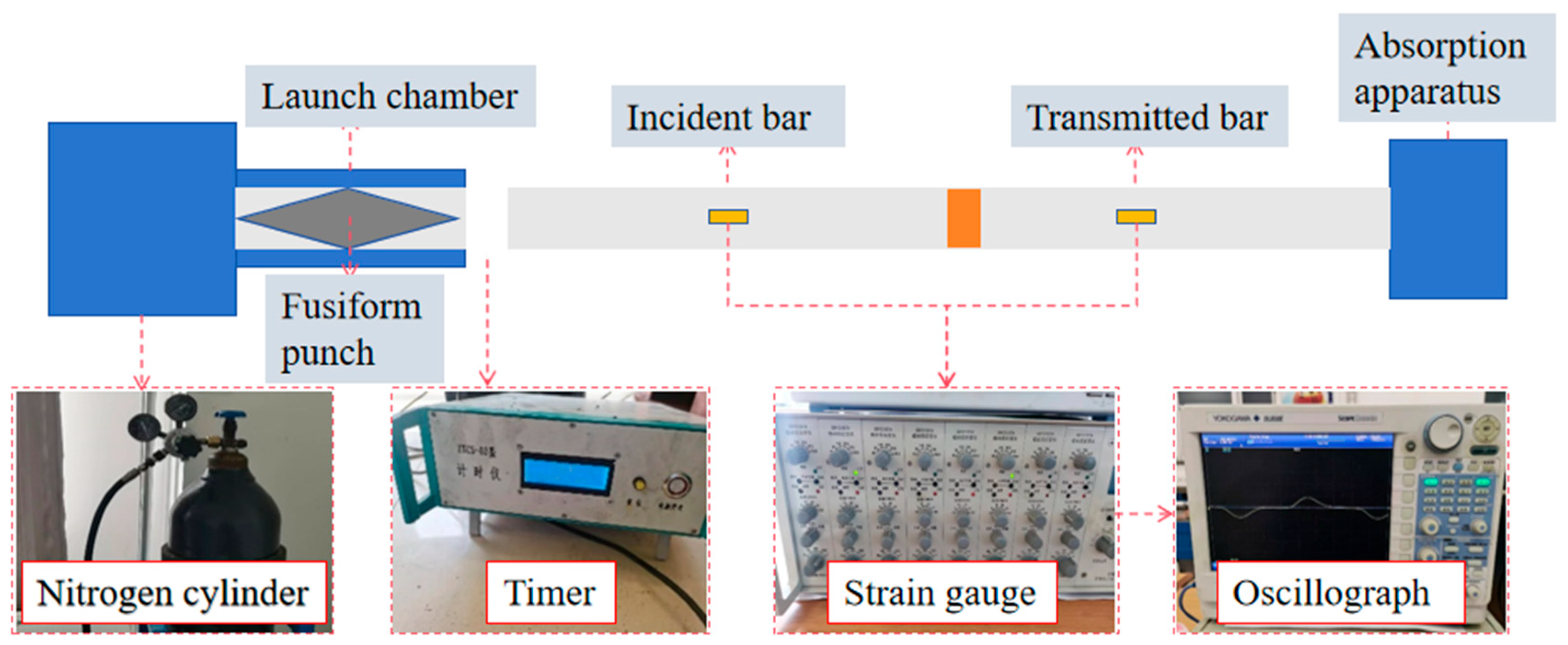

2.3. Testing Equipment

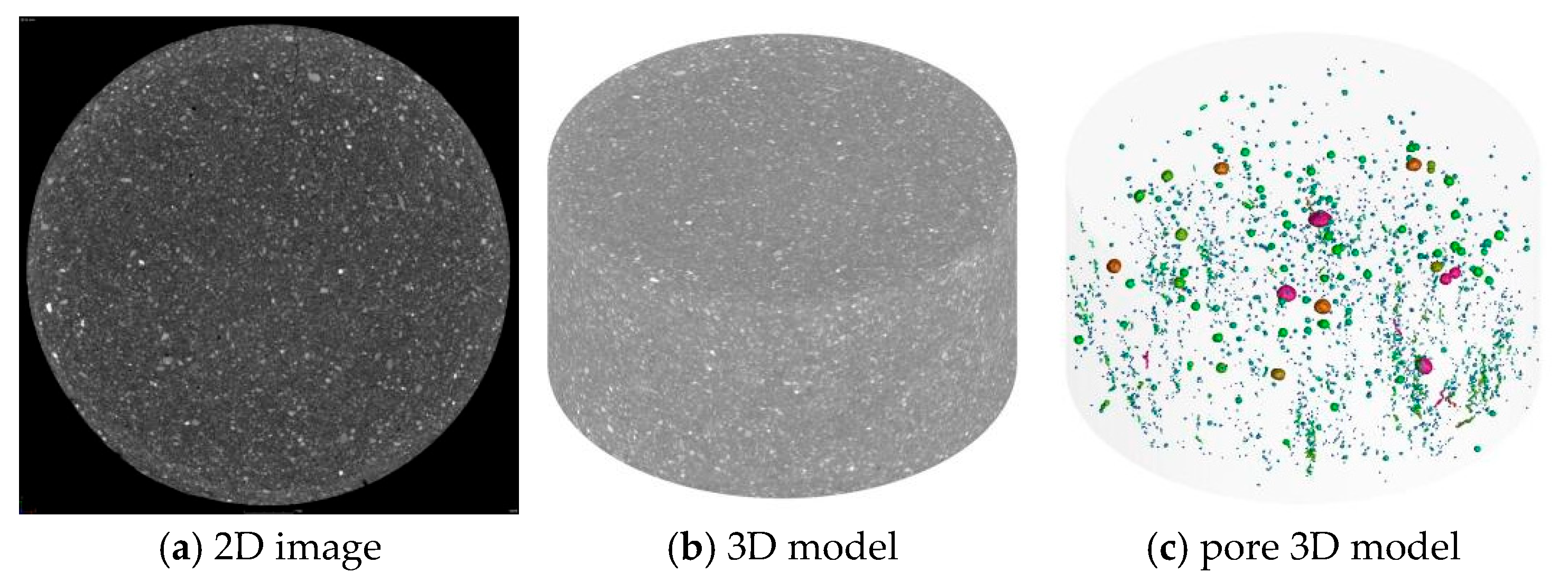

2.4. Three-Dimensional Reconstruction

3. Result and Discussion

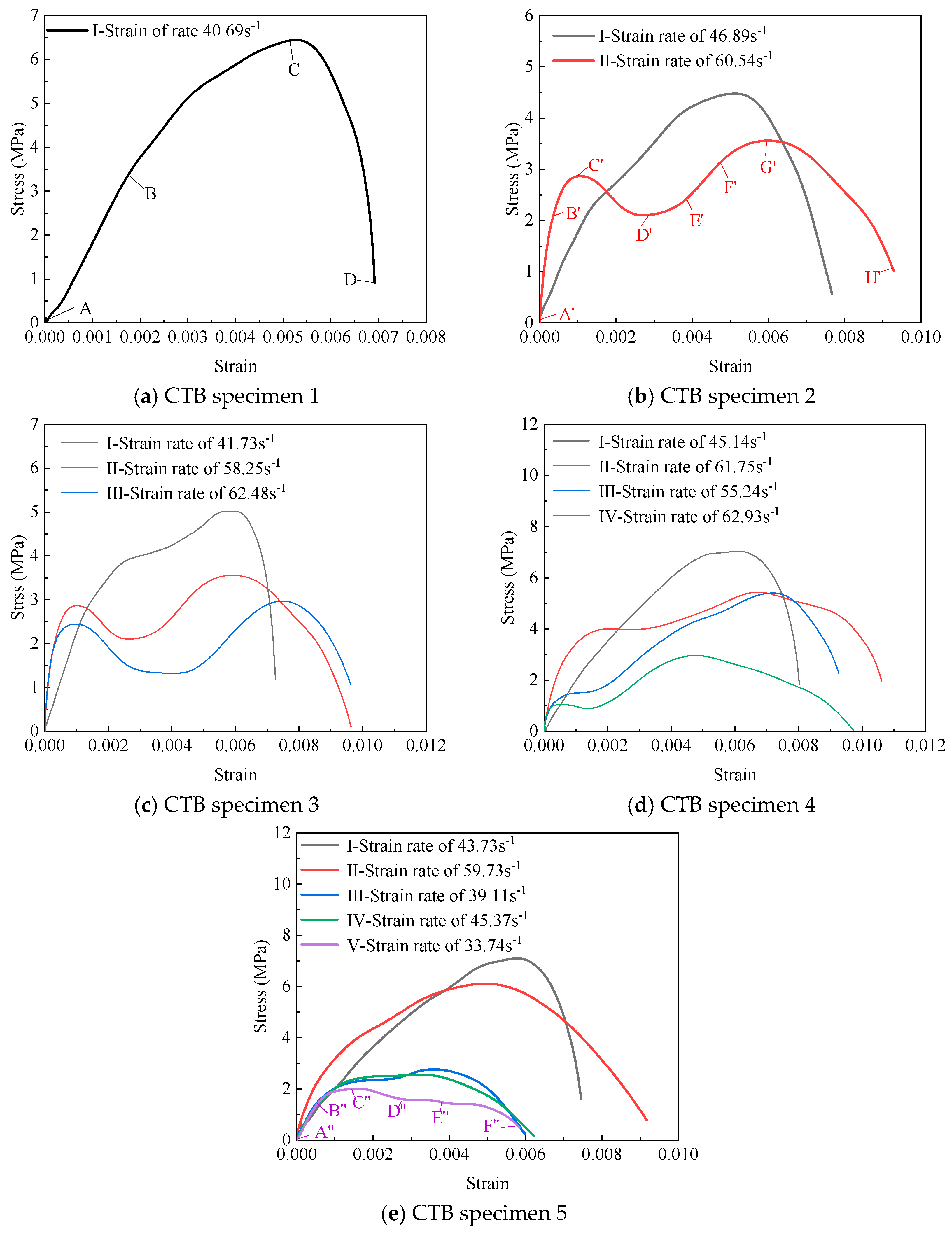

3.1. Stress–Strain Characteristics

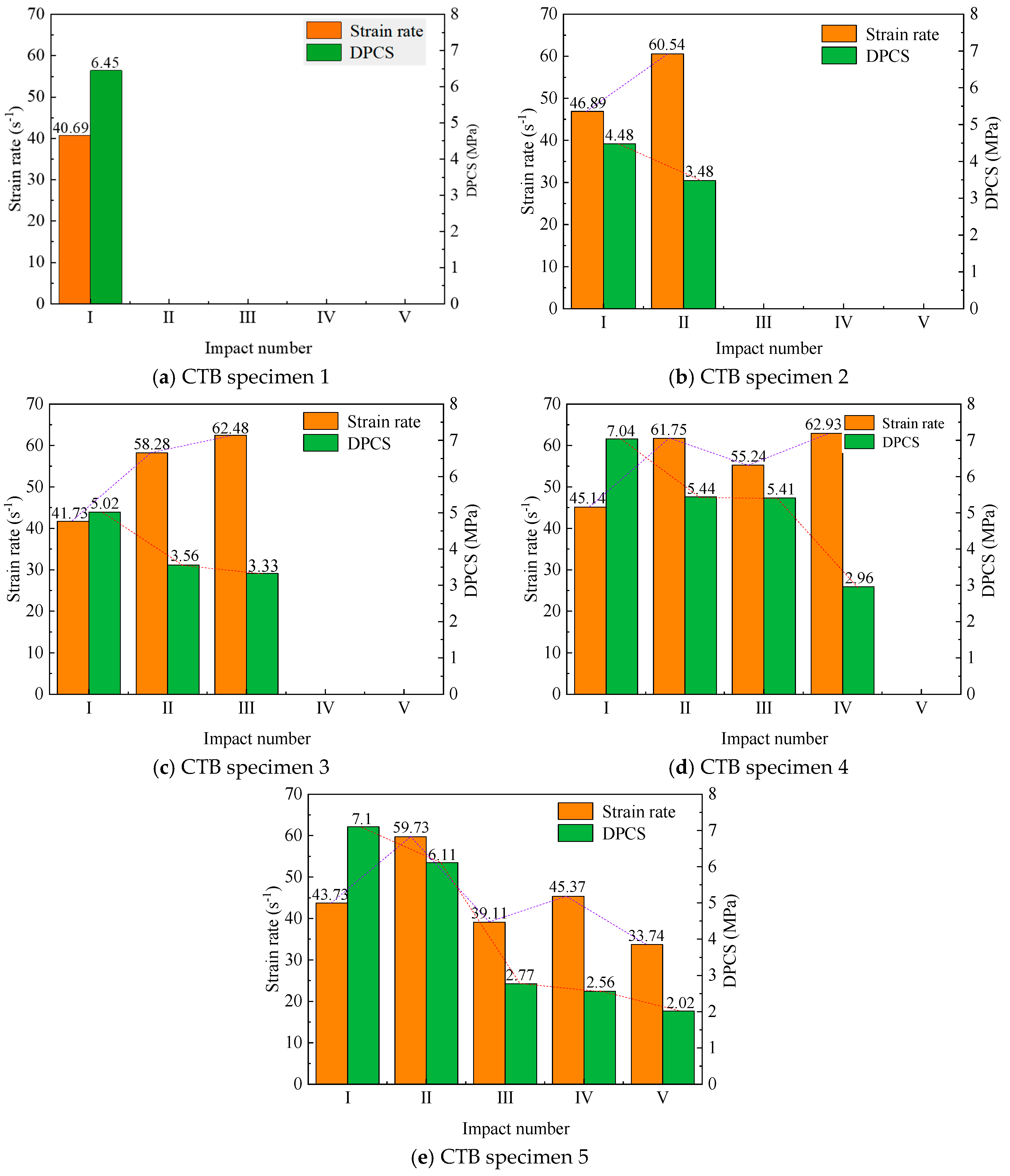

3.2. Variation Characteristics of DPCS and Elastic Modulus

3.3. Energy Evolution Characteristics

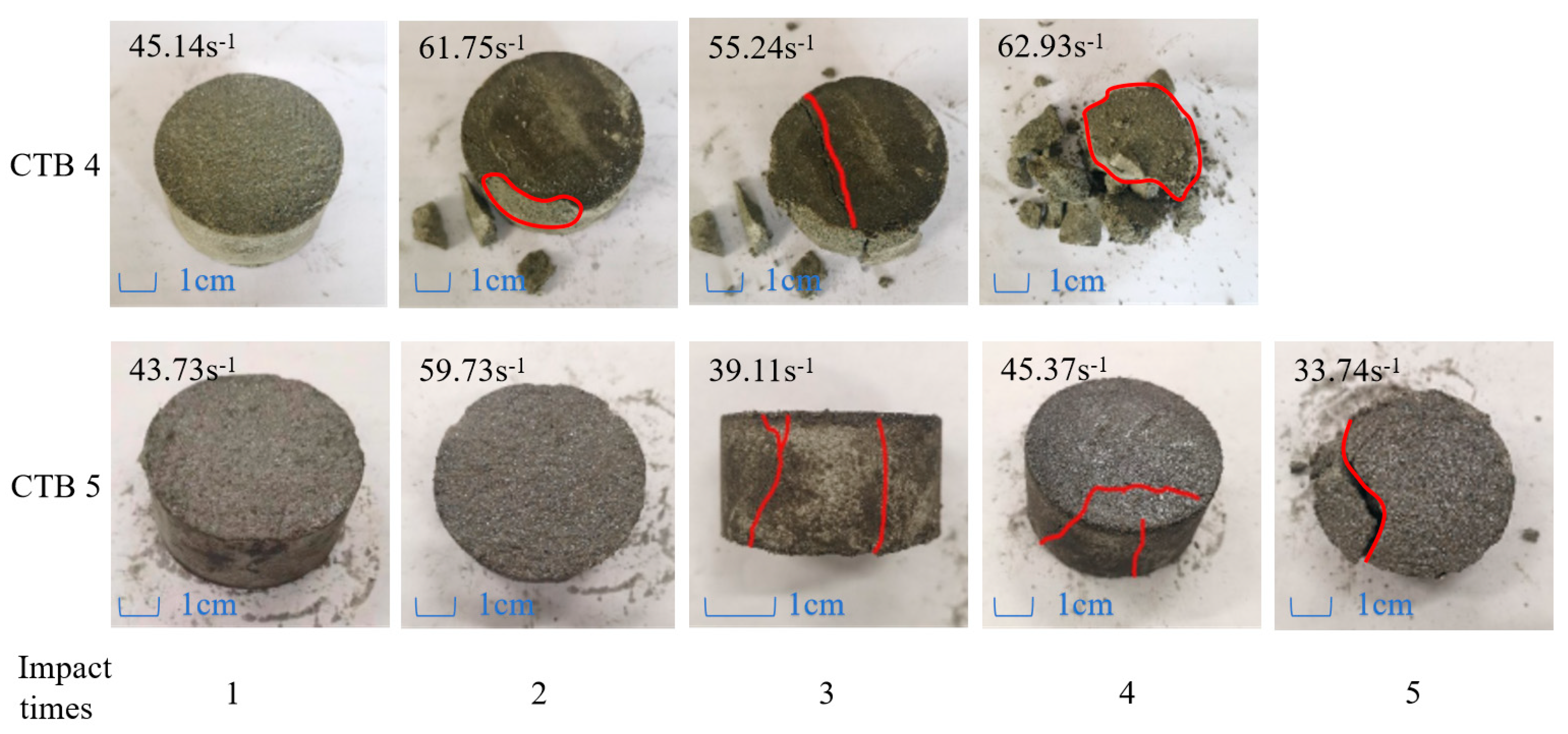

3.4. Failure Modes

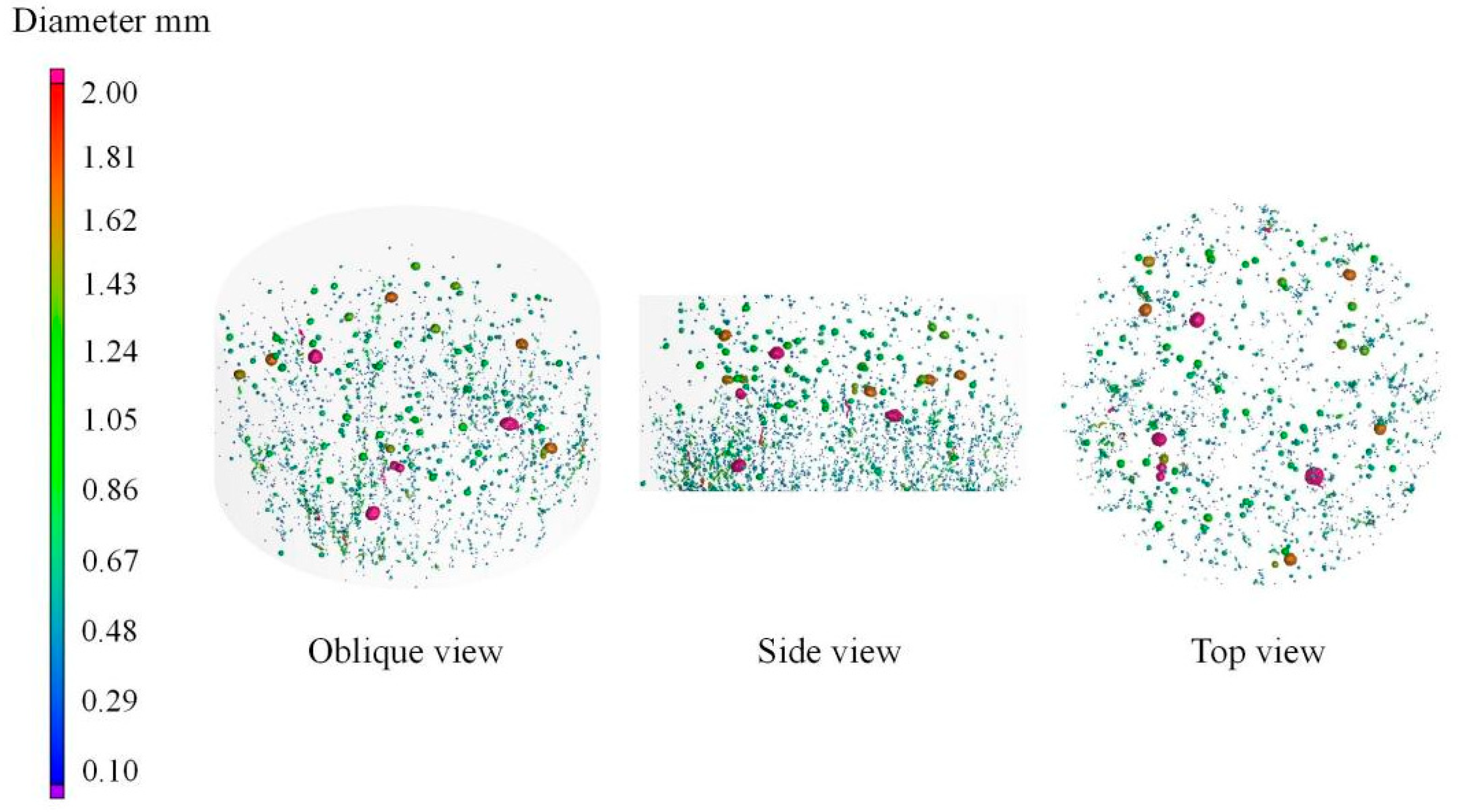

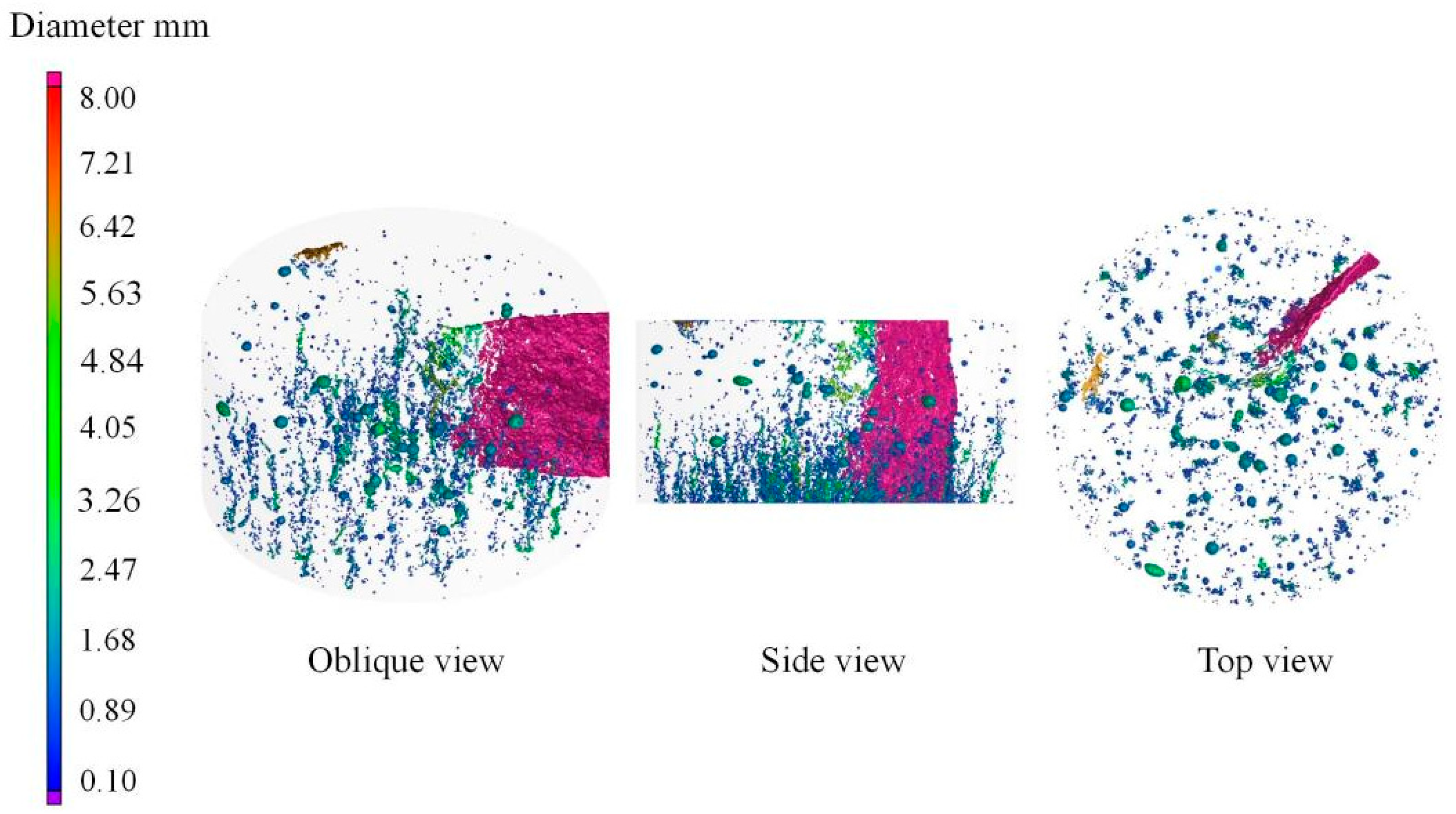

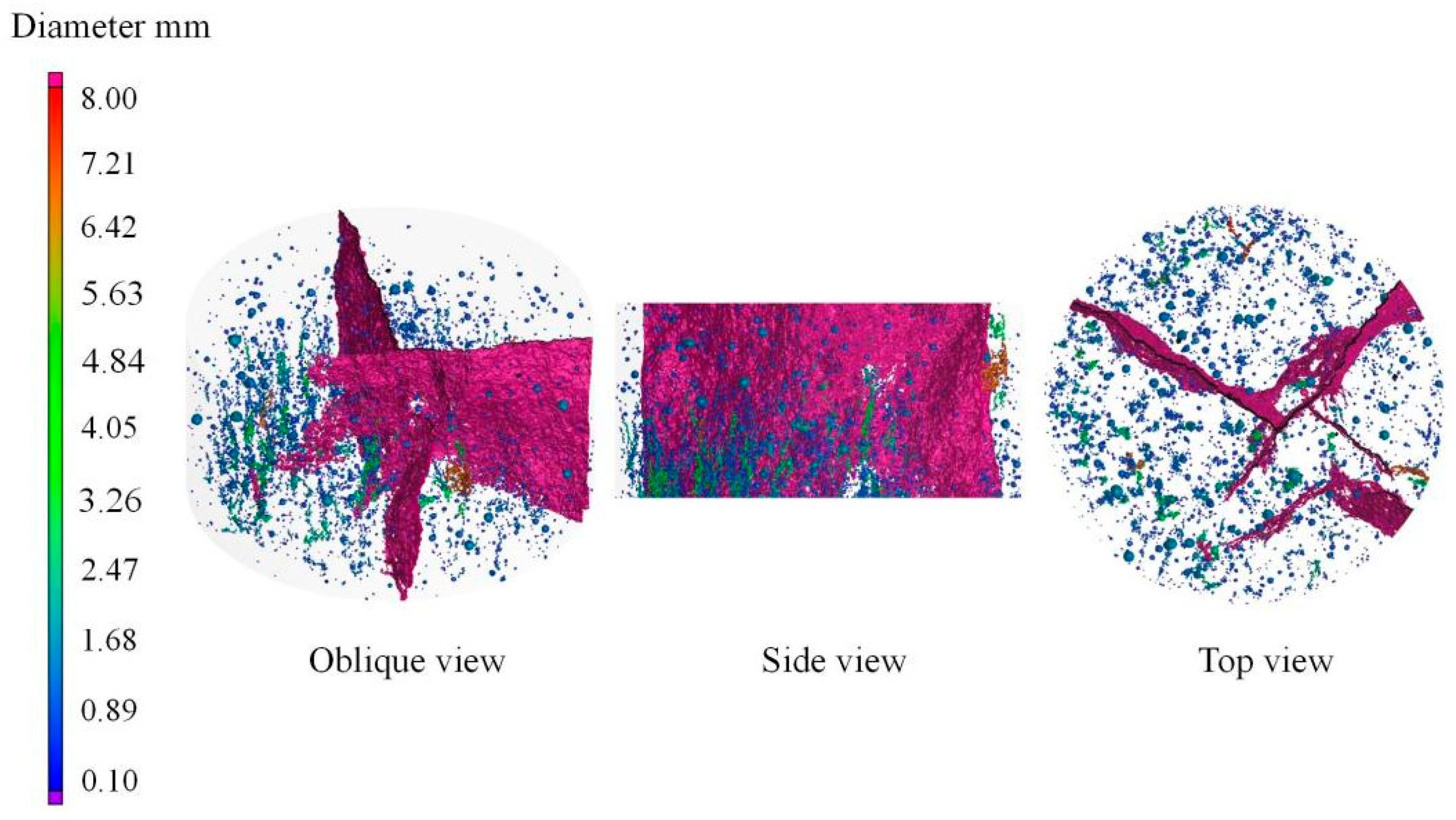

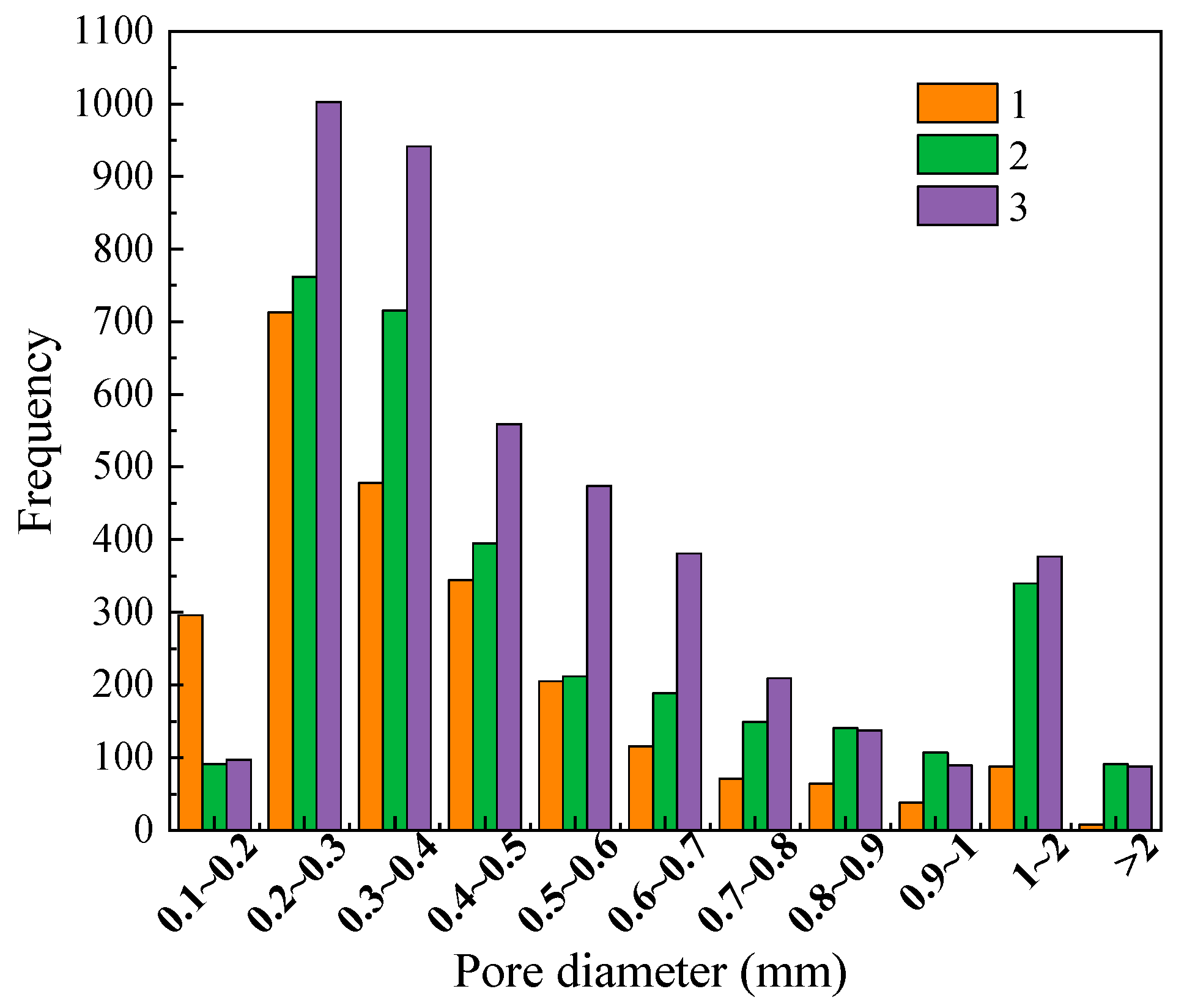

3.5. Mesoscopic Characteristics

4. Conclusions

- (1)

- Cyclic dynamic loading significantly degrades the mechanical properties of CTB. As the number of impacts increases, the dynamic peak compressive strength (DPCS) exhibits a consistent decline. This reduction is attributed to the accumulation of internal damage through the initiation and propagation of microcracks. Although partial crack compaction occurs during cyclic loading, it is insufficient to counteract the overall damage accumulation. The strain rate also plays a critical role: higher strain rates result in a slower decline in DPCS, suggesting that controlled blasting energy release could mitigate strength loss. These findings underscore the importance of considering cumulative damage in the design and assessment of backfill structures subjected to repeated dynamic disturbances.

- (2)

- Energy absorption capacity decreases with increasing impact cycles, reflecting internal damage evolution. The energy absorption rate of CTB specimens declines progressively under cyclic impacts, indicating reduced capacity to dissipate energy through microcrack formation and propagation. The absorbed energy is primarily consumed by crack expansion and coalescence, leading to a decrease in overall structural integrity. As damage accumulates, less energy is required to cause failure, highlighting the vulnerability of CTB under repeated loading. This energy-based analysis provides a valuable perspective for evaluating the long-term stability and failure thresholds of backfill materials in dynamic mining environments.

- (3)

- Mesoscopic characteristics reveal the evolution of internal damage under cyclic loading. CT scans and 3D reconstructions show that cyclic impacts cause microcracks to initiate predominantly at the specimen edges and gradually propagate and interconnect, forming macroscopic fracture networks. Pore size distribution analysis indicates that large pores increase with impact cycles, while small pores decrease due to compaction. This mesoscopic behavior explains the macroscopic mechanical response, including the bimodal stress–strain curves observed under high strain rates. The study demonstrates that mesostructural analysis is essential for understanding the damage mechanisms and improving the durability of CTB under cyclic dynamic loads.

- (4)

- This study has some limitations. Future work should focus on refining the experimental apparatus to achieve consistently lower strain rates, enabling the investigation of CTB’s dynamic properties and mesoscopic characteristics under such conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Safari, A.; Tennant, C.; Gholampour, A.; Palmer, J.; Taheri, A. Effect of mixing water temperature on the thermal and microstructural evolution of cemented paste backfill in underground mining. Minerals 2025, 15, 887. [Google Scholar] [CrossRef]

- Li, J.X.; Sun, W.; Li, Q.Q.; Chen, S.; Yuan, M.L.; Xia, H. Influence of layered angle on dynamic characteristics of backfill under impact loading. Minerals 2022, 12, 511. [Google Scholar] [CrossRef]

- Wu, A.X.; Ruan, Z.E.; Wang, J.D. Rheological behavior of paste in metal mines. Int. J. Miner. Metall. Mater. 2022, 29, 717–726. [Google Scholar] [CrossRef]

- Zhang, N.; Yuan, L.; Han, C.; Xue, J.; Kan, J. Stability and deformation of surrounding rock in pillarless gob-side entry retaining. Saf. Sci. 2012, 50, 593–599. [Google Scholar] [CrossRef]

- Zou, S.Z.; Guo, W.H.; Wang, S.; Gao, Y.T.; Qian, L.Y.; Zhou, Y. Investigation of the dynamic mechanical properties and damage mechanisms of fiberreinforced cemented tailing backfill under triaxial split-Hopkinson pressure bar testing. J. Mater. Res. Technol. 2023, 27, 105–121. [Google Scholar] [CrossRef]

- Yu, H.; Zahidi, I. Spatial and temporal variation of vegetation cover in the main mining area of Qibaoshan Town, China:potential impacts from mining damage, solid waste discharge and land reclamation. Sci. Total Environ. 2023, 859, 160392. [Google Scholar] [CrossRef]

- Pappu, A.; Saxena, M.; Asolekar, S.R. Solid wastes generation in India and their recycling potential in building materials. Build. Environ. 2007, 42, 2311–2320. [Google Scholar] [CrossRef]

- Wang, J.D.; Jiang, G.; Wu, A.; Wang, Y.; Yin, S.; Wang, Y. Rheological behavior of a novel quick-setting binder under resting and mixing and its relations to hydration and microstructure. Constr. Build. Mater. 2022, 357, 129313. [Google Scholar] [CrossRef]

- Gao, T.; Sun, W.; Li, Z.Y.; Fan, K.; Jiang, M.G.; Cheng, H.Y. Study on shear characteristics and failure mechanism of inclined layered backfill in mining solid waste utilization. Minerals 2022, 12, 1540. [Google Scholar] [CrossRef]

- Hou, Y.Q.; Yin, S.H.; Yang, S.X.; Chen, X.; Du, H.H. Mechanical properties, damage evolution and energy dissipation of cemented tailings backfill under impact loading. J. Build. Eng. 2023, 66, 105912. [Google Scholar] [CrossRef]

- Song, B.F.; Li, H.Y.; An, R.; Zhang, X.W.; Zhou, Z.F. Experimental study on the strength and damage characteristics of cement–fly ash–slag–gangue cemented backfill. Buildings 2024, 14, 1411. [Google Scholar] [CrossRef]

- Kalisz, S.; Kibort, K.; Mioduska, J.; Lieder, M.; Malachowska, A. Waste management in the mining industry of metals ores, coal, oil and natural gas—A review. J. Environ. Manag. 2022, 304, 114239. [Google Scholar] [CrossRef]

- Chen, X.; Shi, X.; Zhou, J.; Li, E.; Qiu, P.; Gou, Y. High strain rate compressive strength behavior of cemented paste backfill using split Hopkinson pressure bar. Int. J. Mining Sci. Technol. 2021, 31, 387–399. [Google Scholar] [CrossRef]

- Tan, Y.Y.; Davide, E.; Zhou, Y.C.; Song, W.D.; Meng, X. Long-term mechanical behavior and characteristics of cemented tailings backfill through impact loading. Int. J. Miner. Metall. Mater. 2020, 27, 140–151. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Gan, D.Q.; Gan, Z. Dynamic regimes of cemented backfill at early-age. J. Cent. South Univ. 2021, 28, 2079–2090. [Google Scholar] [CrossRef]

- Tan, Y.Y.; Yu, X.; Elmo, D.; Xu, L.H.; Song, W.D. Experimental study on dynamic mechanical property of cemented tailings backfill under SHPB impact loading. Int. J. Miner. Metall. Mater. 2019, 26, 404–416. [Google Scholar] [CrossRef]

- Lyu, H.Y.; Chen, Y.L.; Pu, H.; Ju, F.; Zhang, K.; Li, Q.; Wu, P. Dynamic properties and fragmentation mechanism of cemented tailings backfill with various particle size distributions of aggregates. Constr. Build. Mater. 2023, 366, 130084. [Google Scholar] [CrossRef]

- Cao, S.; Yilmaz, E.; Song, W.D. Dynamic response of cement-tailings matrix composites under SHPB compression load. Constr. Build. Mater. 2018, 186, 892–903. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Wang, X.M.; Wei, C.; Zhang, Q. Dynamic mechanical properties and instability behavior of layered backfill under intermediate strain rates. Trans. Nonferrous Met. Soc. Chin. 2017, 27, 1608–1617. [Google Scholar] [CrossRef]

- Han, L.; Liu, J.X. Experimental study on mechanical properties of cemented backfill under dynamic loading. Eng. Blast. 2021, 27, 35–41. [Google Scholar]

- Wu, Z.K.; Jin, A.B.; Chen, S.J. Study on cemented tailing backfill dynamic characteristics and its blasting response simulation. Met. Mine 2020, 7, 25–32. [Google Scholar]

- Li, J.; Cao, S.; Yilmaz, E.; Liu, Y. Compressive fatigue behavior and failure evolution of additive fiber-reinforced cemented tailings composites. Int. J. Miner. Metall. Mater. 2022, 29, 345–355. [Google Scholar] [CrossRef]

- Huang, Z.; Cao, S.; Yilmaz, E. Investigation on the flexural strength, failure pattern and microstructural characteristics of combined fibers reinforced cemented tailings backfill. Constr. Build. Mater. 2021, 300, 124005. [Google Scholar] [CrossRef]

- Libos, I.L.S.; Cui, L.; Liu, X. Effect of curing temperature on time-dependent shear behavior and properties of polypropylene fiber-reinforced cemented paste backfill. Constr. Build. Mater. 2021, 311, 125302. [Google Scholar] [CrossRef]

- Jia, H.; Yan, B.; Yilmaz, E.; Chen, Q. A large goaf group treatment by means of mine backfill technology. Adv. Civ. Eng. 2021, 2021, 3737145. [Google Scholar] [CrossRef]

- Song, X.P.; Hao, Y.X.; Wang, S.; Zhang, L.; Liu, H.B.; Yong, F.W.; Dong, Z.L.; Yuan, Q. Dynamic mechanical response and damage evolution of cemented tailings backfill with alkalized rice straw under SHPB cycle impact load. Constr. Build. Mater. 2022, 327, 127009. [Google Scholar] [CrossRef]

- Tan, Y.; Wang, J.; Song, W.; Xu, L.; Cao, S. Experimental study on mechanical properties of cemented tailings backfill under cycle dynamic loading test. J. Min. Saf. Eng. 2019, 36, 184–192. [Google Scholar]

- Shu, R.H.; Xu, G.; Huang, L.J.H. Dynamic compressive properties of heat-treated and pre-stressed cement mortar specimen subjected to cyclic impact loading. Case Stud. Therm. Eng. 2024, 57, 104362. [Google Scholar] [CrossRef]

- Liao, H.; Fang, Y.; Yao, Z.G.; Yu, T.; Luo, H.; Zhu, N.B.; Wang, Y.H.; Li, M.K. Effects of fiber and rubber materials on the dynamic mechanical behaviors and damage evolution of shotcrete under cyclic impact load. J. Build. Eng. 2023, 73, 106763. [Google Scholar] [CrossRef]

- Zheng, D.; Song, W.D.; Cao, S.; Li, J.J. Dynamical mechanical properties and microstructure characteristics of cemented tailings backfill considering coupled strain rates and confining pressures effects. Constr. Build. Mater. 2022, 320, 126321. [Google Scholar] [CrossRef]

- Cao, S.; Xue, G.; Yilmaz, E.; Yin, Z.; Yang, F. Utilizing concrete pillars as an environmental mining practice in underground mines. J. Clean. Prod. 2021, 278, 123433. [Google Scholar] [CrossRef]

- Cao, S.; Yilmaz, E.; Yin, Z.; Xue, G.; Song, W.; Sun, L. CT scanning of internal crack mechanism and strength behavior of cement-fiber-tailings matrix composites. Cem. Concr. Compos. 2021, 116, 103865. [Google Scholar] [CrossRef]

- Safari, A.; Taheri, A.; Karakus, M. Mechanical and microstructural behavior of cemented paste backfill under cyclic loading. Minerals 2025, 15, 123. [Google Scholar] [CrossRef]

- Liu, W.Z.; Guo, Z.P.; Wang, C.; Niu, S.W. Physico-mechanical and microstructure properties of cemented coal Gangue-Fly ash backfill effects of curing temperature. Construct. Build. Mater. 2021, 299, 124011. [Google Scholar] [CrossRef]

- Wang, D.L.; Na, Q.; Liu, Y.K.; Feng, Y.; Zhang, Q.L.; Chen, Q.S. Hydration process and fluoride solidification mechanism of multi-source solid waste-based phosphogypsum cemented paste backfill under CaO modification. Cement Concr. Comp. 2024, 154, 105804. [Google Scholar] [CrossRef]

- Dai, F.; Huang, S.; Xia, K.W.; Tan, Z.Y. Some fundamental issues in dynamic compression and tension tests of rocks using split Hopkinson pressure bar. Rock Mech. Rock Eng. 2010, 43, 657. [Google Scholar] [CrossRef]

- Liu, W.; Wang, G.; Han, D.; Xu, H.; Chu, X. Accurate characterization of coal pore and fissure structure based on CT 3D reconstruction and NMR. J. Nat. Gas Sci. Eng. 2021, 96, 104242. [Google Scholar] [CrossRef]

| CTB Number | Energy Reflectance Rate (%) | Energy Transmittance Rate (%) | Energy Absorption Rate (%) |

|---|---|---|---|

| 1-1 | 70.28 | 2.43 | 27.29 |

| 2-1 | 69.74 | 0.28 | 29.98 |

| 2-2 | 73.71 | 0.83 | 25.46 |

| 3-1 | 69.31 | 1.04 | 29.65 |

| 3-2 | 75.97 | 1.57 | 22.46 |

| 3-3 | 77.99 | 0.91 | 21.1 |

| 4-1 | 64.52 | 1.52 | 33.96 |

| 4-2 | 73.84 | 0.98 | 25.18 |

| 4-3 | 84.23 | 0.39 | 15.38 |

| 4-4 | 81.74 | 0.5 | 17.76 |

| 5-1 | 59.97 | 1.25 | 38.78 |

| 5-2 | 72.01 | 0.21 | 27.78 |

| 5-3 | 79.59 | 0.18 | 20.23 |

| 5-4 | 81.85 | 0.12 | 18.03 |

| 5-5 | 77.2 | 1.14 | 21.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, R.; Yang, X.; Liu, C.; Cui, J.; Liu, Z.; Zhang, Y.; Zhang, Y. Dynamic Mechanical Properties and Mesoscopic Characteristics of Cemented Tailings Backfill Under Cyclic Dynamic Loading. Minerals 2025, 15, 1140. https://doi.org/10.3390/min15111140

Yin R, Yang X, Liu C, Cui J, Liu Z, Zhang Y, Zhang Y. Dynamic Mechanical Properties and Mesoscopic Characteristics of Cemented Tailings Backfill Under Cyclic Dynamic Loading. Minerals. 2025; 15(11):1140. https://doi.org/10.3390/min15111140

Chicago/Turabian StyleYin, Ruhai, Xi Yang, Chengbo Liu, Jiuyun Cui, Zhiyi Liu, Yuxi Zhang, and Yunpeng Zhang. 2025. "Dynamic Mechanical Properties and Mesoscopic Characteristics of Cemented Tailings Backfill Under Cyclic Dynamic Loading" Minerals 15, no. 11: 1140. https://doi.org/10.3390/min15111140

APA StyleYin, R., Yang, X., Liu, C., Cui, J., Liu, Z., Zhang, Y., & Zhang, Y. (2025). Dynamic Mechanical Properties and Mesoscopic Characteristics of Cemented Tailings Backfill Under Cyclic Dynamic Loading. Minerals, 15(11), 1140. https://doi.org/10.3390/min15111140