Application of Jigging Beneficiation for Processing of Waste from Post-Mining Heaps for Circular Economy Purposes

Abstract

1. Introduction

- The presence of hot zones at the surface or shallow depths;

- The emission of harmful gases (e.g., CO, CO2);

- Exceedances of groundwater acidity levels and concentrations of pollutants (chlorides and sulfates) in surface waters;

- Ground movements due to material loss from combustion or excavation activities;

Comprehensive Processing of Coal Mine Waste Heaps

2. Materials and Methods

2.1. Laboratory Stand

- A laboratory jig model;

- A working (pulsating) air blower;

- A control air compressor;

- An electronic control system.

2.2. Laboratory Research

- Grain size class 10–30 mm–4 cm (representing 20% of the total thickness of the layer);

- Grain size class 3–10 mm–7 cm (representing 35% of the total thickness of the layer);

- Grain size class 3–30 mm–5.5 cm (representing 27.5% of the total thickness of the layer).

- The size of the working sieve opening: s = 1.5 mm and s = 2.5 mm;

- Gravitational enrichment time: t = 30 s and t = 60 s, which corresponded to the unit load of 33 t/h/m2 and 16.5 t/h/m2, respectively;

- Pulsation cycle frequency: f = 40 min−1, f = 60 min−1 and f = 80 min-1;

- Process water supply flow rate: Q = 4.5 m3/h.

3. Results

- Density analysis in heavy liquids (based on zinc chloride) with densities of 1.3, 1.4, 1.5, 1.6, 1.7, and 1.8 g/cm3 according to PN-G-04559:1997 [44];

- Determination of ash content in the obtained density fractions (<1.3; 1.3–1.4; 1.4–1.5; 1.5–1.6; 1.6–1.7; 1.7–1.8, and >1.8 g/cm3) according to PN-ISO 1171:2002 [45].

3.1. Quantitative and Qualitative Parameters of Separation Products

3.1.1. Grain Class 10–30 mm

3.1.2. Grain Class 3–10 mm

3.1.3. Grain Class 3–30 mm

3.2. Separation Accuracy Parameters

4. Discussion

- Of low density, consisting mostly of grains of the combustible fraction;

- Of high density, consisting mostly of grains of the mineral fraction.

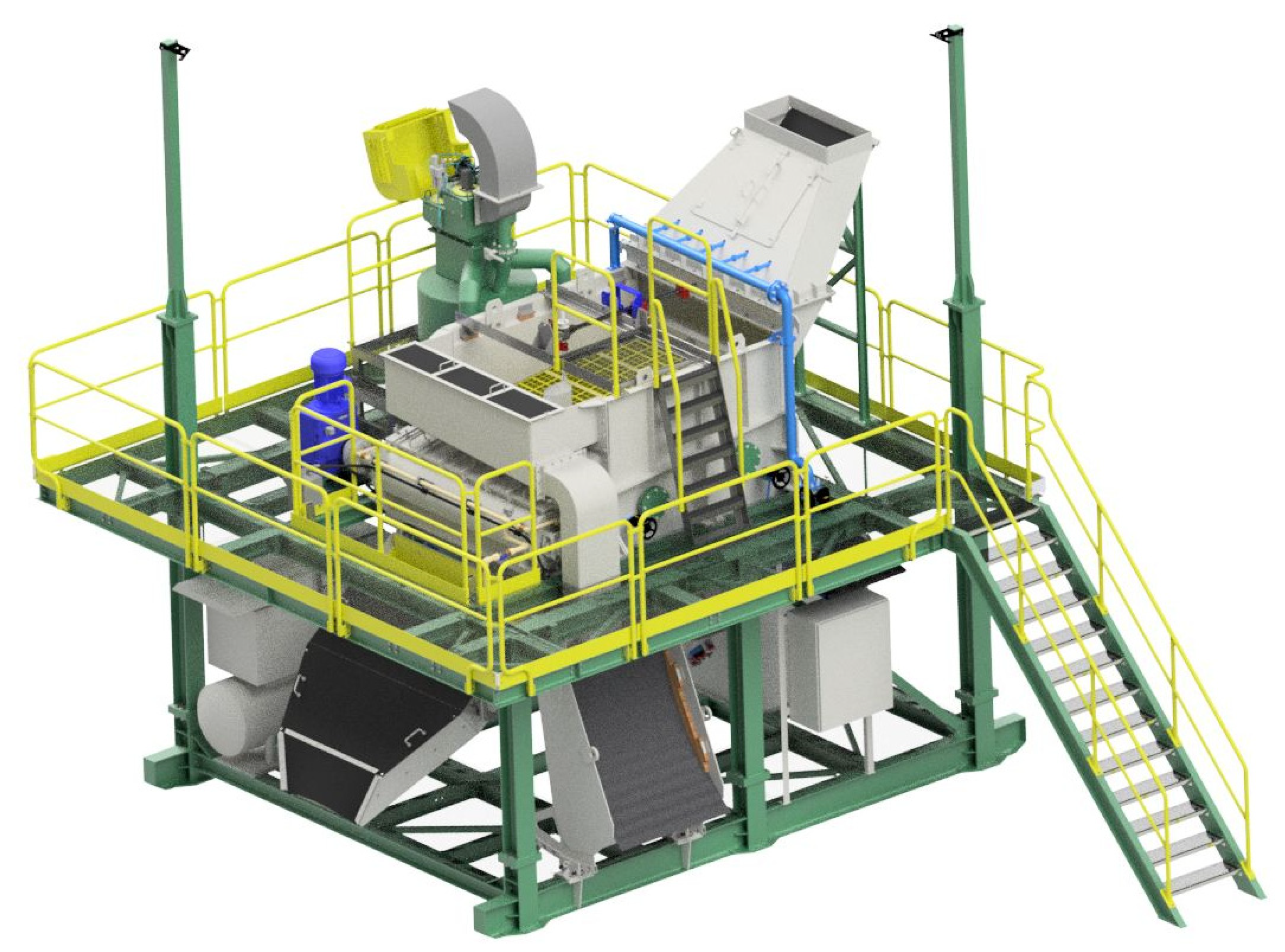

5. A New Solution for Industrial Separation of Mine Waste

5.1. Input Data for Design

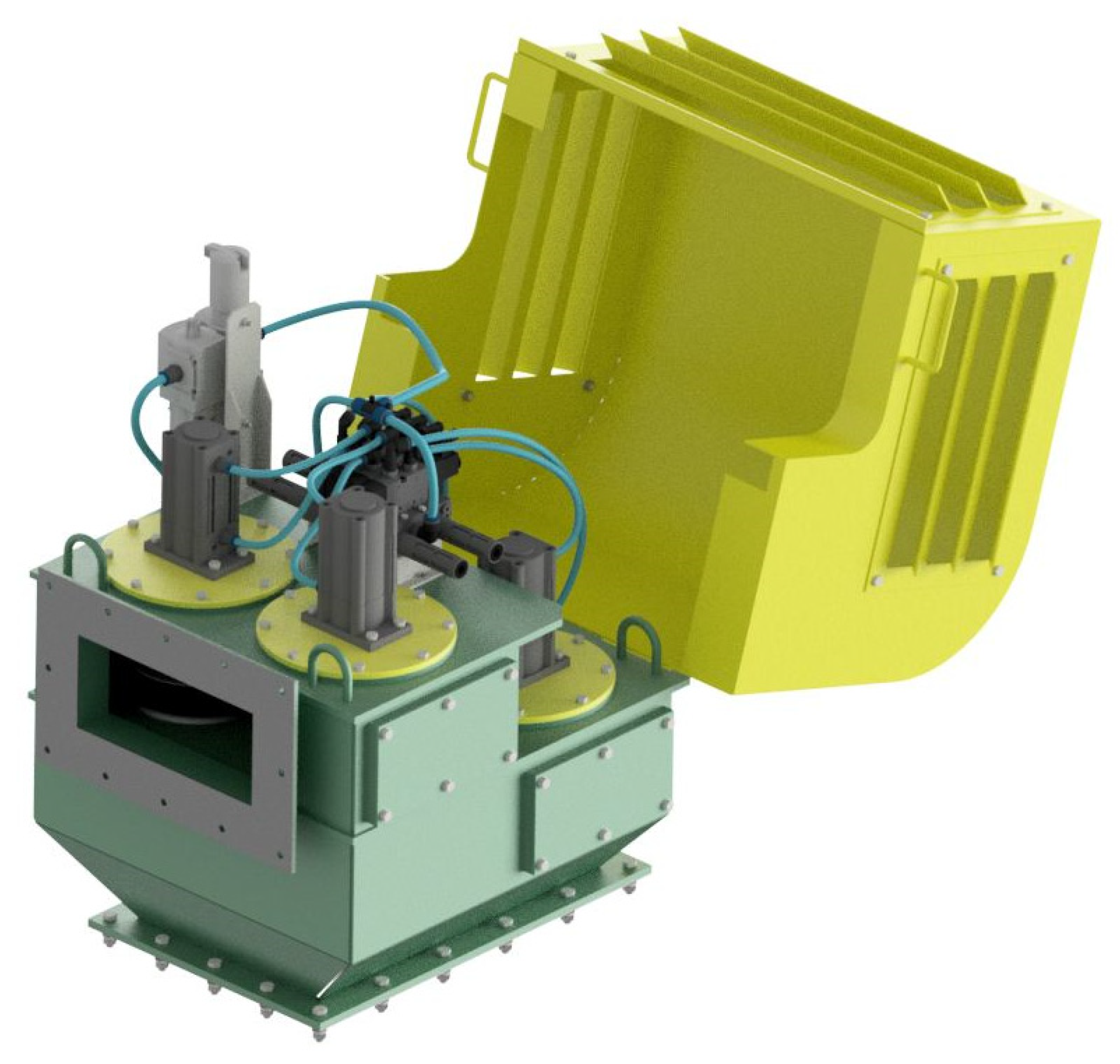

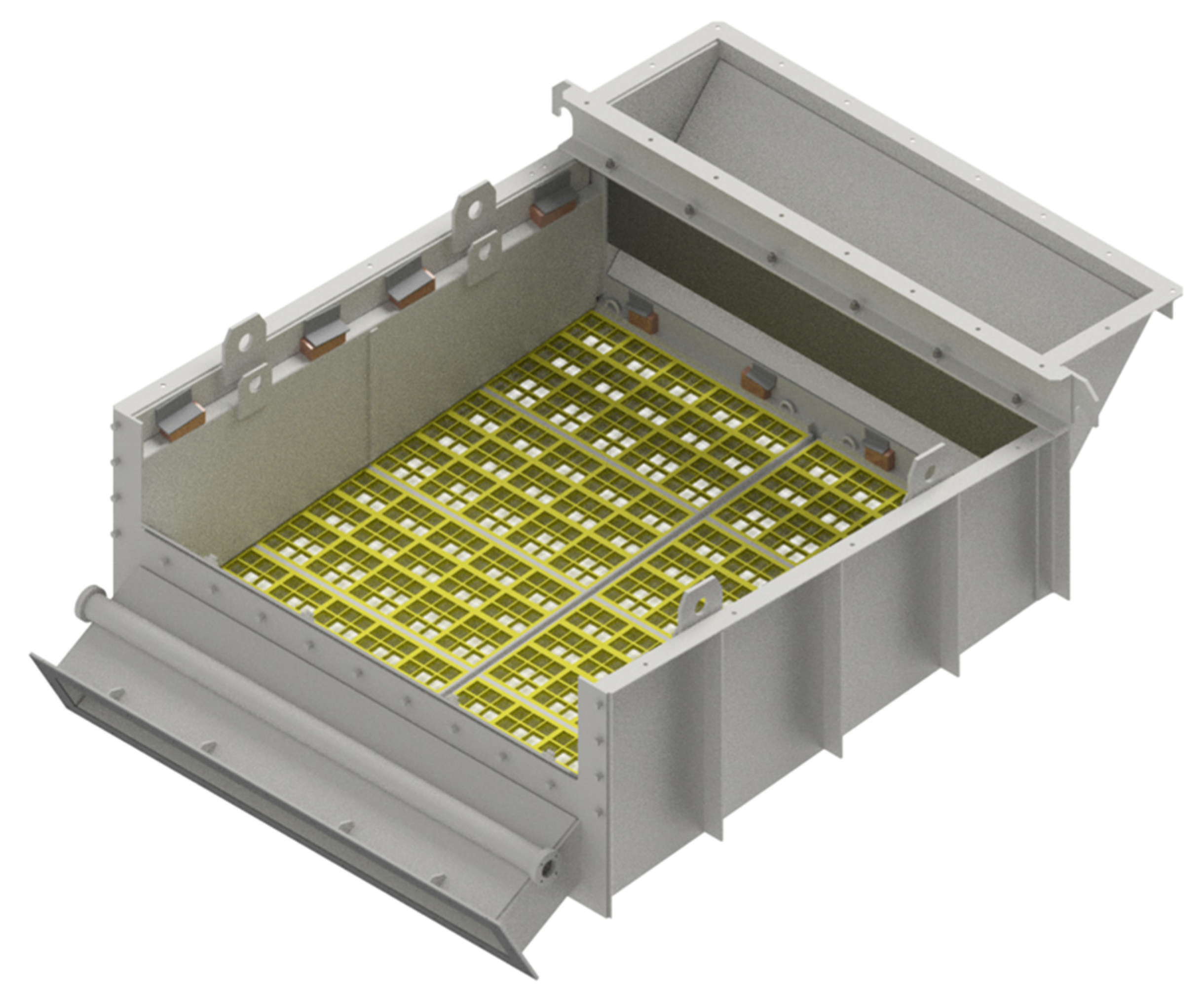

5.2. New Pulsating Jig for Coal-Mining Waste Separation

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bonczyk, M.; Rubin, J. The application of coal mining waste to the production of construction ceramics: Radiological and mechanical aspects. Mater. Constr. 2022, 72, e300. [Google Scholar] [CrossRef]

- Murzyn, P.; Pyzalski, M. Characteristis and assessment of the suitability of coal-rich mining waste in the production of ceramic building materials. Multidisc. J. Waste Resour. Resid. 2018, 1, 30–37. [Google Scholar] [CrossRef]

- Osborne, D. Chapter 4: Coal wastes: Handling, pollution, impacts, and utilization. In The Coal Handbook Towards Cleaner Coal Utilization; Woodhead Publishing: Cambridge, UK, 2023; pp. 97–163. [Google Scholar]

- Fecko, P.; Tora, B.; Tod, M. Coal waste: Handling, pollution impacts and utilization. In The Coal Handbook: Towards Cleaner Production: Volume 2: Coal Utilisation; Osborne, D.G., Ed.; Woodhead Publishing: Cambridge, UK, 2013. [Google Scholar]

- Available online: https://www.pgi.gov.pl/surowce/energetyczne/wegiel-kamienny.html (accessed on 29 August 2025).

- Available online: https://energetyka24.com/gornictwo/wiadomosci/wydobycie-wegla-w-polsce-rekordowo-niskie-arp-publikuje-wyniki-za-2024-rok?utm_source=chatgpt.com (accessed on 29 August 2025).

- Gawor, Ł. Coal mining waste dumps as secondary deposits—Examples from the Upper Silesian Coal Basin and the Lublin Coal Basin. Geol. Geophys. Environ. 2014, 40, 285–289. [Google Scholar] [CrossRef]

- Mills, S. The Use of Coal-Derived Wastes as a Source of Energy; Report number CCC/288; IEA Clean Coal Centre: London, UK, 2018. [Google Scholar]

- Zabezpieczenie i Zagospodarowanie Zwałowisk Pogórniczych. Informacja o Wynikach Kontroli NIK (Securing and Managing Post-Mining Waste Heaps. Information on the Audit Results of the Supreme Audit Office (NIK). LKA.430.003.2018. Nr. Ewid. 158/2018/P/18/067/LKA; 2019. Available online: https://www.nik.gov.pl/kontrole/P/18/067/ (accessed on 6 August 2025).

- Zástěrová, P.; Marschalko, M.; Niemiec, D.; Durďák, J.; Bulko, R.; Vlček, J. Analysis of Possibilities of Reclamation Waste Dumps after Coal Mining. Procedia Earth Planet. Sci. 2015, 15, 656–662. [Google Scholar] [CrossRef]

- Yu, J.; Meng, F.; Li, X.; Tahmasebi, A. Power generation from coal gangue in China: Current status and development. Adv. Mater. Res. 2012, 550–553, 443–446. [Google Scholar] [CrossRef]

- Skarżyńska, K.M. Reuse of coal mining wastes in civil engineering—Part 1: Properties of minestone. Waste Manag. 1995, 15, 3–42. [Google Scholar] [CrossRef]

- Bian, Z.; Dong, J.; Lei, S.; Leng, H.; Mu, S.; Wang, H. The impact of disposal and treatment of coal mining wastes on environment and farmland. Environ. Geol. 2009, 58, 625–634. [Google Scholar] [CrossRef]

- Różański, Z. Fire hazard in coal waste dumps—Selected aspects of the environmental impact. IOP Conf. Ser. Earth Environ. Sci. 2018, 174, 012013. [Google Scholar] [CrossRef]

- Pactwa, K.; Woźniak, J.; Dudek, M. Coal mining waste in Poland in reference to circular economy principles. Fuel 2020, 270, 117493. [Google Scholar] [CrossRef]

- Monjoie, A.; Schroeder, C. Instabilités de versants de terrils en relation avec l’autocombustion des schistes etcharbons résiduels. Rev. Fr. Géotech. 2001, 95/96, 91–102. [Google Scholar] [CrossRef]

- Gogola, K.; Rogala, T.; Magdziarczyk, M.; Smoliński, A. The mechanisms of endogenous fires occurring in extractive waste dumping facilities. Sustainability 2020, 12, 2856. [Google Scholar] [CrossRef]

- Szczepańska-Plewa, J.; Stefaniak, S.; Twardowska, I. Coal mining waste management and its impact on the groundwater chemical status exemplified in the Upper Silesia Coal Basin (Poland). Biul. Państw. Inst. Geol. 2010, 441, 157–166. [Google Scholar]

- Różański, Z.; Wrona, P.; Pach, G.; Niewiadomski, A.P.; Markowska, M.; Wrana, A.; Frączek, R.; Balcarczyk, L.; Vaquero Quintana, G.; de Paz Ruiz, D. Influence of water erosion on fire hazards in a coal waste dump—A case study. Sci. Total Environ. 2022, 834, 155350. [Google Scholar] [CrossRef]

- Capasso, I.; Lirer, S.; Flora, A.; Ferone, C.; Cioffi, R.; Caputo, D.; Liguori, B. Reuse of mining waste as aggregates in fly ash-based geopolymers. J. Clean. Prod. 2019, 220, 65–73. [Google Scholar] [CrossRef]

- Moradikhou, A.B.; Safehian, M.; Golafshani, E.M. High-strength geopolymer concrete based on coal washing waste. Constr. Build. Mater. 2023, 362, 129675. [Google Scholar] [CrossRef]

- Subashi De Silva, G.H.M.J.; Hansamali, E. Eco-friendly fired clay bricks incorporated with porcelain ceramic sludge. Constr. Build. Mater 2019, 228, 116754. [Google Scholar] [CrossRef]

- Kusiorowski, R.; Zaremba, T.; Piotrowski, J. The potential use of cement-asbestos waste in the ceramic masses destined for sintered wall clay brick manufacture. Ceram. Int. 2014, 40, 11995–12002. [Google Scholar] [CrossRef]

- Luo, L.; Li, K.; Fu, W.; Liu, C.; Yang, S. Preparation, characteristics and mechanisms of the composite sintered bricks produced from shale, sewage sludge, coal gangue powder and iron ore tailings. Constr. Build. Mater. 2020, 232, 117250. [Google Scholar] [CrossRef]

- Stolboushkin, A.Y.; Ivanov, A.I.; Fomina, O.A. Use of coal-mining and processing wastes in production of bricks and fuel for their burning. Procedia Eng. 2016, 150, 1496–1502. [Google Scholar] [CrossRef]

- Kusin, F.M.; Munirah, S.N.; Hasan, S.; Hassim, M.A.; Molahid, V.L.M. Mineral carbonation of sedimentary mine waste for carbon sequestration and potential reutilization as cementitious material. Environ. Sci. Pollut. Res. 2020, 27, 12767–12780. [Google Scholar] [CrossRef]

- Rubin, J.A. The Influence of Material and Technological Factors on Radon Exhalation from Concrete with a Cement Matrix; Monograph; Publishing House of the Silesian University of Technology: Gliwice, Poland, 2019; ISBN 978-83-7880-620-2. [Google Scholar]

- Li, L.; Long, G.; Bai, C.; Ma, K.; Wang, M.; Zhang, S. Utilization of Coal Gangue Aggregate for Railway Roadbed Construction in Practice. Sustainability 2020, 12, 4583. [Google Scholar] [CrossRef]

- Amaral Filho, J.R.; Schneider, I.A.H.; de Brum, I.A.S.; Sampaio, C.H.; Miltzarek, G.; Schneider, C. Characterization of a coal tailing deposit for integrated mine waste management in the Brazilian coal field of Santa Catarina. Rev. Esc. Minas 2013, 66, 347–353. [Google Scholar] [CrossRef]

- Zhao, H.; Chang, J.; Miao, Z.; Kang, H.; Ji, J.; Luan, Y.; Lu, Z.; Guo, Y. Application of coal-based solid waste artificial soil in the restoration of saline alkali land-taking the saline alkali land restoration of the Emao River in China as an example. Heliyon 2024, 10, e37095. [Google Scholar] [CrossRef]

- Santos, C.R.; Amaral, J.R. Use of Coal Waste as Fine Aggregates in Concrete Paving Blocks. Geomaterials 2013, 3, 54–59. [Google Scholar] [CrossRef]

- H2GEO—New Technology for Hydrogen and Geopolymer Composites Production. Available online: https://h2geo.komag.eu/ (accessed on 10 July 2025).

- Woodruff, D. Dense Medium Baths and Drum Separators a Re-evaluation of Their Role in Modern Coal Preparation Plants. In XVIII International Coal Preparation Congress Volume 1; Litvinenko, V., Ed.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 169–174. [Google Scholar] [CrossRef]

- Amini, S.H.; Honaker, R.; Noble, A. Performance evaluation of a dense-medium cyclone using alternative silica-based media. Powder Technol. 2016, 297, 392–400. [Google Scholar] [CrossRef]

- Napier-Munn, T. The dense medium cyclone—Past, present and future. Miner. Eng. 2018, 116, 107–113. [Google Scholar] [CrossRef]

- Matusiak, P.; Kowol, D. Use of state-of-the-art jigs of KOMAG type for a beneficiation of coking coal. Min. Mach. 2020, 1, 46–55. [Google Scholar] [CrossRef]

- Kowol, D.; Matusiak, P. Improving the quality of hard coal products using the state-of-the-art KOMAG solutions in a pulsating jig nod. IOP Conf. Ser. Mater. Sci. Eng. 2019, 641, 012004. [Google Scholar] [CrossRef]

- Kumar, S.; Venugopal, R. Coal cleaning using jig and response surface approach for determination of quality of clean coal. Int. J. Coal Prep. Util. 2020, 40, 107–115. [Google Scholar] [CrossRef]

- Matusiak, P.; Kowol, D. State-of-the-art pulsating jigs of KOMAG type. IOP Conf. Ser. Mater. Sci. Eng. 2019, 545, 012008. [Google Scholar] [CrossRef]

- Kowol, D.; Matusiak, P. Use of a jig beneficiation process for obtaining mineral raw materials. IOP Conf. Ser. Mater. Sci. Eng. 2019, 545, 012006. [Google Scholar] [CrossRef]

- Kowol, D.; Matusiak, P. Technology of fine coal grains recovery from the mining waste deposits. IOP Conf. Ser. Mater. Sci. Eng. 2018, 427, 012025. [Google Scholar] [CrossRef]

- Kowol, D.; Matusiak, P.; Prostański, D.; Baron, R.; Friebe, P.; Lutyński, M.; Kołodziej, K. Recovery of Valuable Raw Materials Using KOMAG Jig Beneficiation Laboratory Studies and Industrial Implementations. Minerals 2025, 15, 943. [Google Scholar] [CrossRef]

- Results of Laboratory Tests of Mine Wastes of Jig Beneficiation. Available online: https://h2geo.komag.eu/wp-content/uploads/2025/03/H2GEO_D_3_1_Results_of_laboratory_tests_of_mine_wastes.pdf (accessed on 10 July 2025).

- PN-G-04559:1997; Węgiel Kamienny i Brunatny—Metoda Analizy Gęstościowej (Hard Coal and Lignite—Density Analysis Method). Polish Committee for Standardization: Warszawa, Poland, 1997.

- PN-ISO 1171:2002; Paliwa Stałe. Oznaczanie Zawartości Popiołu (Solid Fuels. Determination of Ash Content). Polish Committee for Standardization: Warszawa, Poland, 2002.

- PN-G-07020:1997; Przeróbka Mechaniczna Węgla Kamiennego—Określone Skuteczności Procesów Wzbogacania Grawitacyjnego (Mechanical Processing of Hard Coal—Specified Efficiencies of Gravity Beneficiation Processes). Polish Committee for Standardization: Warszawa, Poland, 1997.

- Midilli, A.; Kucuk, H.; Topal, M.E.; Akbulut, U.; Dincer, I. A comprehensive review on hydrogen production from coal gasification: Challenges and Opportunities. Int. J. Hydrogen Energy 2021, 46, 25385–25412. [Google Scholar] [CrossRef]

- Almutairi, A.L.; Tayeh, B.A.; Adesina, A.; Isleem, H.F.; Zeyad, A.M. Potential applications of geopolymer concrete in construction: A review. Case Stud. Constr. Mater. 2021, 15, e00733. [Google Scholar] [CrossRef]

- Figiela, B.; Bąk, A.; Hebda, M.; Korniejenko, K. Eco-friendly production of foamed geopolymers based on mine waste. J. Achiev. Mater. Manuf. Eng. 2023, 121, 341–349. [Google Scholar] [CrossRef]

- Tasiopoulou, T.; Katsourinis, D.; Giannopoulos, D.; Founti, M. Production-Process Simulation and Life-Cycle Assessment of Metakaolin as Supplementary Cementitious Material. Eng 2023, 4, 761–779. [Google Scholar] [CrossRef]

| Density Fraction | Feed 10–30 mm | Feed 3–10 mm | Feed 3–30 mm | |||

|---|---|---|---|---|---|---|

| Share | Ash Content, A a | Share | Ash Content, A a | Share | Ash Content, A a | |

| g/cm3 | % | % | % | % | % | % |

| <1.5 | 5.7 | 8.5 | 12.9 | 9.9 | 9.9 | 9.6 |

| 1.5–1.8 | 5.3 | 38.4 | 6.2 | 38.5 | 5.5 | 38.0 |

| >1.8 | 89.0 | 83.0 | 80.9 | 79.7 | 84.6 | 82.9 |

| Sum | 100.0 | 100.0 | 100.0 | |||

| Average | 76.4 | 68.2 | 73.2 | |||

| Grain Class | Feed 10–30 mm | Feed 3–10 mm | Feed 3–30 mm |

|---|---|---|---|

| mm | % | % | % |

| 20–30 | 42.7 | 0.0 | 19.5 |

| 16–20 | 17.6 | 0.0 | 8.1 |

| 10–16 | 39.7 | 0.0 | 21.3 |

| 6–10 | 0.0 | 63.7 | 31.9 |

| 3–6 | 0.0 | 36.3 | 19.2 |

| Sum | 100.0 | 100.0 | 100.0 |

| A | B | C | D | E | A | B | C | D | E |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 10–30 | 1.5 | 40 | 60 | 13 | 10–30 | 1.5 | 80 | 60 |

| 2 | 3–10 | 1.5 | 40 | 60 | 14 | 3–10 | 1.5 | 80 | 60 |

| 3 | 3–30 | 1.5 | 40 | 60 | 15 | 3–30 | 1.5 | 80 | 60 |

| 4 | 10–30 | 1.5 | 40 | 30 | 16 | 10–30 | 2.5 | 40 | 60 |

| 5 | 3–10 | 1.5 | 40 | 30 | 17 | 3–10 | 2.5 | 40 | 60 |

| 6 | 3–30 | 1.5 | 40 | 30 | 18 | 3–30 | 2.5 | 40 | 60 |

| 7 | 10–30 | 1.5 | 60 | 60 | 19 | 10–30 | 2.5 | 60 | 60 |

| 8 | 3–10 | 1.5 | 60 | 60 | 20 | 3–10 | 2.5 | 60 | 60 |

| 9 | 3–30 | 1.5 | 60 | 60 | 21 | 3–30 | 2.5 | 60 | 60 |

| 10 | 10–30 | 1.5 | 60 | 30 | 22 | 10–30 | 2.5 | 60 | 30 |

| 11 | 3–10 | 1.5 | 60 | 30 | 23 | 3–10 | 2.5 | 60 | 30 |

| 12 | 3–30 | 1.5 | 60 | 30 | 24 | 3–30 | 2.5 | 60 | 30 |

| Duration of the Pulsation Cycle Phase, ms | Pulsation Frequency, min−1 | ||

|---|---|---|---|

| 40 | 60 | 80 | |

| Inlet | 345 | 230 | 173 |

| Interval | 375 | 250 | 188 |

| Outlet | 345 | 230 | 173 |

| Interval | 435 | 290 | 216 |

| Test Number | Carbon-Bearing Product | Mineral Product | ||

|---|---|---|---|---|

| Product Mass Yield | Average Ash Content, A a | Product Mass Yield | Average Ash Content, A a | |

| % | % | % | % | |

| Grain class 10–30 mm | ||||

| 1 | 20.39 | 49.07 | 79.61 | 83.38 |

| 4 | 20.22 | 55.26 | 79.78 | 81.67 |

| 7 | 20.19 | 49.55 | 79.81 | 83.26 |

| 10 | 20.31 | 56.52 | 79.69 | 81.28 |

| 13 | 20.05 | 52.12 | 79.95 | 82.27 |

| 16 | 20.30 | 49.11 | 79.70 | 83.44 |

| 19 | 20.18 | 48.50 | 79.82 | 83.47 |

| 22 | 20.54 | 55.22 | 79.46 | 82.06 |

| Grain class 3–10 mm | ||||

| 2 | 29.36 | 40.63 | 70.64 | 79.81 |

| 5 | 29.54 | 46.96 | 70.46 | 76.56 |

| 8 | 29.31 | 40.66 | 70.69 | 79.93 |

| 11 | 29.69 | 46.53 | 70.31 | 76.69 |

| 14 | 29.53 | 42.87 | 70.47 | 78.50 |

| 17 | 29.45 | 40.57 | 70.55 | 79.83 |

| 20 | 29.54 | 40.38 | 70.46 | 80.07 |

| 23 | 29.19 | 46.09 | 70.81 | 76.55 |

| Grain class 3–30 mm | ||||

| 3 | 27.39 | 44.80 | 72.61 | 84.12 |

| 6 | 27.76 | 50.17 | 72.24 | 81.79 |

| 9 | 27.68 | 44.38 | 72.32 | 84.14 |

| 12 | 27.73 | 48.85 | 72.27 | 82.28 |

| 15 | 27.62 | 46.25 | 72.38 | 83.35 |

| 18 | 27.43 | 44.40 | 72.57 | 84.15 |

| 21 | 27.58 | 43.67 | 72.42 | 84.26 |

| 24 | 27.60 | 47.86 | 72.40 | 82.34 |

| Grain Class 10–30 mm | ||||||||

|---|---|---|---|---|---|---|---|---|

| Parameter | Test number | |||||||

| 1 | 4 | 7 | 10 | 13 | 16 | 19 | 22 | |

| Separation Density D50, g/cm3 | 2.130 | 1.975 | 2.070 | 2.040 | 2.080 | 2.115 | 2.145 | 1.970 |

| Probable Error Ep, g/cm3 | 0.245 | 0.498 | 0.273 | 0.535 | 0.365 | 0.258 | 0.235 | 0.453 |

| Imperfection, I | 0.217 | 0.510 | 0.255 | 0.514 | 0.338 | 0.231 | 0.205 | 0.466 |

| Grain Class 3–10 mm | ||||||||

| Parameter | Test number | |||||||

| 2 | 5 | 8 | 11 | 14 | 17 | 20 | 23 | |

| Separation Density D50, g/cm3 | 2.180 | 2.025 | 2.150 | 2.075 | 2.020 | 2.205 | 2.220 | 1.910 |

| Probable Error Ep, g/cm3 | 0.255 | 0.515 | 0.273 | 0.510 | 0.340 | 0.215 | 0.195 | 0.493 |

| Imperfection, I | 0.216 | 0.502 | 0.237 | 0.474 | 0.333 | 0.178 | 0.160 | 0.541 |

| Grain Class 3–30 mm | ||||||||

| Parameter | Test number | |||||||

| 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 | |

| Separation Density D50, g/cm3 | 2.190 | 1.990 | 2.210 | 2.060 | 2.125 | 2.210 | 2.220 | 2.140 |

| Probable Error Ep, g/cm3 | 0.193 | 0.300 | 0.173 | 0.305 | 0.258 | 0.173 | 0.160 | 0.268 |

| Imperfection, I | 0.162 | 0.303 | 0.143 | 0.288 | 0.229 | 0.143 | 0.131 | 0.235 |

| Assebly/ Unit | Previous Design | Current Design | Advantages |

|---|---|---|---|

| Gravel receiver | “Granupack” sealing system | A labyrinth seal and a flushing system have been added. | The additional protection safeguards the receiver plates from wear by removing fine particles transported by the scraper, thereby contributing to an extended service life. |

| Pulsation valve | Pulsation valve supply and discharge manifold | Valve islands | The solution facilitates assembly and maintenance, while also significantly enhancing the precision of valve adjustments. |

| Working trough | Mounting of screen decks using a wedge system | Use of a longitudinal bar along the screen deck, enabling clamping of the screen deck. | The new screen deck mounting system is simpler, faster, and more durable, resulting in higher operational efficiency and reduced downtime. |

| Air supply manifold | Tall manifold tank, above the pulsation jig | Lowered collector tank, to the height of the pulsation jig. | Improved access to the pulsation valves, facilitating their adjustment and maintenance. |

| Maintenance platform | Full-width platform over the working trough | Lowered platform over half of the working trough | Improved access to the float sensor for easier adjustment and maintenance. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kowol, D.; Matusiak, P.; Baron, R.; Friebe, P.; Jendrysik, S.; Bigda, J.; Czardybon, A.; Ignasiak, K. Application of Jigging Beneficiation for Processing of Waste from Post-Mining Heaps for Circular Economy Purposes. Minerals 2025, 15, 1108. https://doi.org/10.3390/min15111108

Kowol D, Matusiak P, Baron R, Friebe P, Jendrysik S, Bigda J, Czardybon A, Ignasiak K. Application of Jigging Beneficiation for Processing of Waste from Post-Mining Heaps for Circular Economy Purposes. Minerals. 2025; 15(11):1108. https://doi.org/10.3390/min15111108

Chicago/Turabian StyleKowol, Daniel, Piotr Matusiak, Rafał Baron, Paweł Friebe, Sebastian Jendrysik, Joanna Bigda, Agata Czardybon, and Karina Ignasiak. 2025. "Application of Jigging Beneficiation for Processing of Waste from Post-Mining Heaps for Circular Economy Purposes" Minerals 15, no. 11: 1108. https://doi.org/10.3390/min15111108

APA StyleKowol, D., Matusiak, P., Baron, R., Friebe, P., Jendrysik, S., Bigda, J., Czardybon, A., & Ignasiak, K. (2025). Application of Jigging Beneficiation for Processing of Waste from Post-Mining Heaps for Circular Economy Purposes. Minerals, 15(11), 1108. https://doi.org/10.3390/min15111108