Abstract

This research undertakes a comparative study between compacted phosphate-based (CPG) and alkaline-based (CAG) geopolymeric materials. The obtained materials underwent comprehensive evaluation through mechanical, physical, and chemical analyses. CPG exhibited superior mechanical strength, demonstrating an exponential growth with curing age in contrast to CAG. Both materials exhibited stable density over time, with CPG displaying a notably higher density attributed to its enhanced reactivity in an acidic medium. Dimensional variations revealed stable dimensions for CPG and subtle shrinkage for CAG, potentially associated with an observed efflorescence phenomenon. Visual assessments during water immersion highlighted the enhanced stability of CPG. Chemical analyses confirmed the persistence of mineralogical phases, such as quartz and illite, and the emergence of an amorphous geopolymeric network in both CPG and CAG samples. CPG materials featured aluminum phosphate phases, reinforcing structural integrity, while CAG materials exhibited sodium carbonate phases, introducing impurities, elucidating the superior performance of CPG over CAG. For the formation kinetics, CPG exhibited a faster reaction time than CAG, as evidenced by the evolution of pH, densification rate, and FTIR band over curing time.

1. Introduction

The area of geopolymerization has undergone noteworthy advancements in recent years, with researchers increasingly focusing on customizing the properties of these materials to meet specific application requirements [1,2,3]. Geopolymeric materials are inorganic polymers formed from the chemical reaction between a source of alumina and silica with either an alkaline or acidic activator. Traditionally, after mixing the reagents, the resulting paste would be poured into molds and cured at temperatures ranging from 25 °C to 100 °C, according to Davidovits [4]. Recently, another elaboration approach has been introduced. As part of this approach, geopolymeric materials are obtained through a mechanical compaction process that applies uniform pressure to the starting mixture. This method involves placing the geopolymeric paste into a mold and compressing it at a specific pressure and for a specific duration to ensure uniform density and reduce porosity [5,6,7]. Utilizing this compaction process enhances material properties such as increased densification, accelerated reaction kinetics due to particle proximity, and reduced water demand in the forming process, all of which minimize porosity.

According to this elaboration approach, the resulting geopolymers are known as cold-compacted geopolymeric materials, which exhibit attractive properties [6,7]. This type of geopolymer represents a novel development in the field of construction materials, offering a relatively ecofriendly and economical material compared to traditional building materials like earth bricks, Portland cement, and conventionally heated geopolymers [8]. These materials are characterized by several advantages, including higher mechanical strength, robust durability in water immersion, and important dimensional stability [5,6,7]. These benefits encourage further investigation and development of these materials.

Traditionally, geopolymeric materials subjected to heating can be produced through two primary routes: the acidic route and the alkaline route [4]. The acidic route is characterized by its reliance on a low pH environment, involving the incorporation of aluminosilicate precursors like metakaolin or fly ash. Powerful acidic activators, such as phosphoric acid, drive an efficient geopolymerization process [9]. This route is well-suited for applications requiring rapid structural development, such as construction projects with stringent timelines [10]. In contrast, the alkaline route uses highly alkaline activators, typically sodium or potassium hydroxide, in reaction with aluminosilicate precursors [4]. Traditionally, this route yields geopolymeric materials known for exceptional long-term durability, resistance to chemical degradation, and overall structural stability [4,11]. Geopolymeric materials from the alkaline route find applicability in scenarios prioritizing longevity and resistance to harsh environmental conditions, such as in infrastructural projects exposed to aggressive chemical agents or marine environments [4].

Similar to heated geopolymeric materials, both acidic and alkaline routes are viable for the compacted geopolymeric materials elaboration. The existing literature predominantly explores the alkaline route, employing geopolymeric materials as stabilizers in compacted building materials. For instance, Sore et al. [12] investigated the stabilization of compressed earth blocks (CEBs) using a geopolymer binder derived from a mixture of metakaolin and sodium hydroxide solution. The principal matrix of the bricks comprised laterite. Results indicated a significant enhancement in mechanical performance and thermal properties, with CEBs stabilized using 20% geopolymer achieving the highest compressive strength of 8.9 MPa. Other studies have investigated volcanic ash as a reliable aluminosilicate source for geopolymer production as a stabilizer of compressed earth bricks (CEBs), as observed in works such as [13]. However, some other works have explored the acidic route, using also geopolymeric materials as stabilizers in compacted building materials. For example, Mimboe et al. [14] explored mud brick stabilization using calcined laterite activated with phosphoric acid. They obtained compressed earth bricks with a dry compressive strength of up to 38 MPa. Regarding the comparison between the two distinct routes, some studies have delved into this area. For instance, Kamwa et al. [15] conducted research comparing two geopolymer binder systems created under alkaline and acidic conditions for stabilizing compressed lateritic earth bricks (CEBs), utilizing natural pozzolan as the aluminosilicate precursor. Various CEBs were prepared, incorporating different proportions of natural pozzolan at 5%, 10%, 15%, and 20%. The findings revealed that, in the acidic environment, mechanical performance exhibited a significant increase, with higher pozzolan content and a slight improvement with longer curing times. Conversely, in the alkaline environment, performance decreased for samples with 0% to 10% pozzolan and remained constant for samples with 15% to 20% pozzolan after a 14-day curing period.

This study aims to conduct a comprehensive comparative analysis of compacted geopolymeric materials synthesized via both alkaline and acidic routes. The primary focus is on evaluating the properties of the materials, identifying the different geopolymeric phases formed, and understanding the formation reaction kinetics. In the context of compacted geopolymeric materials, most research has concentrated on the alkaline-based route or has treated compacted acidic-based geopolymers merely as stabilizers in minimal proportions. This study is novel in considering compacted acidic-based geopolymeric materials as the principal material for elaboration and comparing them directly with their alkaline counterparts. Such a comparative analysis is crucial, as it goes beyond surface-level properties to delve into the formation kinetics, providing deeper insights into how different synthesis routes affect the final material properties. These findings are essential for making informed decisions about the most suitable geopolymeric production routes tailored to specific construction needs. This research also highlights the novelty of studying compacted geopolymeric materials, which represent a new direction in materials construction, diverging from the traditional focus on heated geopolymers. By exploring the largely uncharted territory of acidic-based compacted geopolymers, this study offers significant contributions to the understanding of material synthesis, performance, and potential applications in the construction industry.

2. Materials and Methods

2.1. Materials

In this study, the aluminosilicate precursor used was natural clay from the Medenine region in the south of Tunisia (Medenine clay MC). To gain a comprehensive understanding of the chemical composition inherent to this precursor, X-ray fluorescence analysis was employed. Detailed results are presented in Table 1.The examination of these results shed light on the mineralogical composition of the selected aluminosilicate precursor. Notably, SiO2 and Al2O3 were identified as the primary essential oxides. The Si/Al molar ratio was about 4.3, which probably indicates the presence of free silica and/or minerals of 2:1 clay type as illite, the latter supported by the presence of potassium oxide (K2O) with a content of 6.07 wt%. In addition, the high oxide content of iron (Fe2O3 = 8.72 wt%) may suggest the presence of hematite. Finally, this clay contained calcium oxide (CaO = 3.94 wt%) which reflects the presence of calcite.

Table 1.

Chemical composition of the Medenine clay (MC), as determined via X-ray fluorescence analyses.

To enhance the reactivity of this reagent, the Medenine clay underwent calcination at 750 °C for a duration of 3 h in a static bed oven, following a protocol proposed in literature [16]. On the other hand, Table 2 presents the Atterberg limits of Medenine clay (MC). The plasticity index, indicating the range of moisture content over which the clay exhibits plastic behavior, was determined to be 44.31. This high plasticity index (plasticity index ≥ 17) [17] justifies the choice and use of MC clay in the development of compacted geopolymeric materials in this study. This high plasticity index, which persisted even after the calcination of the clay, resulted from the presence of illite in the used MC. Illite is known for its good plasticity and resistance to degradation, even after heating at 750 °C. The high plasticity of MC enhances its workability and binding properties, both of which are essential for achieving uniform compaction and improved mechanical strength. Previous studies [17] have demonstrated that clays with higher plasticity indices are more effective in producing geopolymers with superior mechanical properties and durability. These characteristics facilitate the molding and compaction process, resulting in a denser and more homogeneous material. Therefore, the high plasticity index of MC was a key factor in its selection for this research.

Table 2.

Results of the Medenine clay (MC) plasticity.

2.2. Methods

For the acidic route, a commercial 85% phosphoric acid solution (H3PO4) provided by the Scharlau Chemie S.A. company, located in Sentmenat, Barcelona, Spain, was utilized as the activator. The phosphoric acid was dissolved in distilled water to prepare a 14 mol/L solution, aligning with the protocol defined by Kamwa et al. [13]. Conversely, the alkaline solution was prepared using NaOH pellets with a purity level of 99%.The NaOH solution, with a concentration of 14 M, was created by dissolving caustic soda flakes in distilled water. It was allowed to equilibrate at room temperature for 24 h before application to ensure the complete dilution of the caustic soda flakes.

To elaborate compacted phosphate-based geopolymeric (CPG) materials, a precise volume of the prepared phosphoric acid solution was added to the aluminosilicate precursor, maintaining a P/Al molar ratio equal to 1, as the optimal P/Al molar ratio suggested in the literature [16]. This specific ratio is critical for achieving the desired chemical reactions and mechanical properties of the geopolymer. The solid/liquid mass ratio was set to 3.33, as this ratio ensures the necessary workability of the mixture, ensuring it can be easily molded and compacted. However, for compacted alkaline-based geopolymeric (CAG) materials, the solid/liquid mass ratio must be significantly higher to achieve a similar workability. In this case, the ratio was approximately 8.75. The substantial difference in the solid/liquid ratios between the acidic and alkaline routes is due to the differing chemical interactions and physical properties of the materials involved. The higher ratio for the alkaline-based geopolymer ensures that the mixture maintains sufficient fluidity for effective compaction and proper formation of the geopolymeric network.

In the two cases, the obtained mixture was manually homogenized for 1 min and then poured into a cylindrical stainless-steel mold (diameter 30 mm and height of 60 mm). Based on insights extracted from existing literature, a pressing force up to 60 MPa, with a rate of 0.2 mm/min, was meticulously applied to the compaction process.

The piston used in this compaction process featured a cylindrical piston made from durable materials with a polished surface finish, precise guidance and load application systems, and control over the compression rate, ensuring uniform compaction of the materials with monitored pressure application.

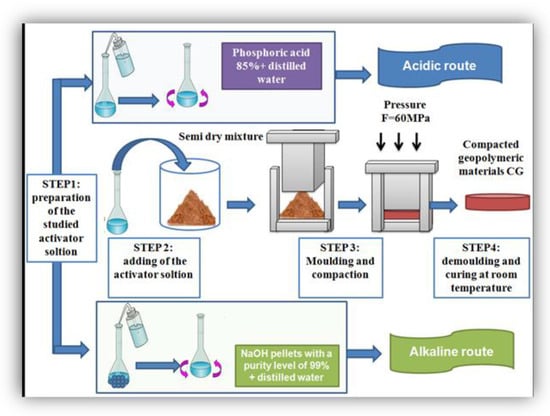

Demolded cylindrical samples with dimensions of 30 mm in diameter and 6 mm in height were obtained, they were immediately wrapped in plastic film to prevent moisture loss, and then they were cured at room temperature for varying durations as specified for each technique.The previous protocol is summarized in Figure 1.

Figure 1.

Elaboration protocol for acidic and alkaline routes.

In our study, the Atterberg limits were determined following ASTM standards D4318 [18]. For the liquid limit test, a soil sample was prepared by air-drying and sieving to remove any large particles. The soil was then mixed with distilled water to form a paste. A groove was made in the paste using a standardized tool, and the number of blows needed to close the groove was recorded. This process was repeated five times to ensure accuracy and consistency. In the plastic limit test, a plastic paste was formed by adding water to the soil sample until it reached a plastic consistency. A thread of the paste was then rolled between the fingers on a flat surface until it broke at a diameter of 3.2 mm. The moisture content at this point was recorded as the plastic limit.

Subsequently, the plasticity index was calculated by subtracting the plastic limit from the liquid limit. All procedures were conducted in accordance with ASTM standards to ensure the uniformity and reliability of the results.

The mechanical strength of the investigated materials was evaluated. In this testing procedure, a cylindrical specimen was carefully prepared with a diameter-to-height ratio close to 4:1 to ensure optimal testing conditions, according to the literature [19]. Thus, cylindrical geopolymeric samples, with dimensions of 30mm in diameter and 6 mm in height, underwent testing using a LLOYD LR 50K Plus device with compressive test units (manufactured by Lloyd Instruments Ltd., located in Bognor Regis, West Sussex, UK). The ends of the specimen were ground flat and parallel to ensure uniform loading during testing. The mechanical strength values presented in this study are the averages derived from five measurements conducted under uniform conditions. A rate of 0.2 mm/min was consistently employed during the testing process.

The apparent density of the geopolymeric materials was calculated using the formula: density = mass/apparent volume. The sample mass was determined using a digital scale, while its apparent volume was calculated using the formula: V = π r2h, where “r” and “h” represent, respectively, the radius and the height of the cylindrical geopolymeric sample. The values presented in this study are the averages derived from three measurements conducted under uniform conditions.

To assess dimensional variations, a 150 mm/6-inch digital vernier caliper (manufactured by Mitutoyo Corporation, headquartered in Takatsu-ku, Kawasaki, Kanagawa, Japan) was employed. Measurements were taken throughout the maturation period, providing valuable insights into the dimensional stability of geopolymeric materials. The values presented in this study are the averages derived from five measurements conducted under uniform conditions.

The mineralogical composition of the specimens was investigated through X-ray diffraction (XRD) utilizing a BRUKER-AXS-D8 advance powder diffractometer (Bruker, Billerica, MA, USA), with Cu Ka radiation (λka = 1.5418 Å). The analytical range spanned from 5° to 70° (2θ) at a rate of 1°/min.

The chemical composition of the specimens was comprehensively analyzed through a PerkinElmer Spectrum BX spectrophotometer, used for Fourier transform infrared spectroscopy (FTIR) in transmittance mode (manufactured by PerkinElmer, Inc., located in Waltham, MA, USA). The wavenumber range covered extended from 4000 cm−1 to 450 cm−1.

The pH value of the solution resulting from the immersion of geopolymer samples in distilled water for 24 h was determined. Additionally, the acidic or alkaline character of the studied materials was assessed by measuring the pH of the solution obtained from immerging the geopolymer paste in a fixed water volume. The mixture was thoroughly agitated to ensure uniform distribution of the material in the water. After allowing time for equilibration, the pH of the resulting suspension was measured using an Apera Apera pH meter from the 820 series (located in Columbus, OH, USA). This pH meter has a resolution of 0.1/0.01/0.001 pH, 0.1 mV, and 0.1°C, and an accuracy of ±0.002 pH, ±0.03% F.S., and ±0.4 °C. The device features an automatic five-point calibration and is equipped with a LabSen 211 electrode (KDG022) and a temperature probe (KDG039).

The densification rate of the acquired materials was assessed at different curing ages using a glass pycnometer of 50 mL. This involved weighing dry samples and immersing them in the pycnometer filled with a known volume of liquid. By measuring the volume of liquid displaced by the sample, the volume and thus the density of the sample were determined. Repeating this process at various curing ages allowed for the evaluation of how the material’s density changed over time, providing insights into its compaction and solidity as it cured. The values presented in this study are the averages derived from three measurements conducted under uniform conditions.

3. Results

3.1. Effect on the Compacted Geopolymers (CG) Properties

3.1.1. Mechanical Strength

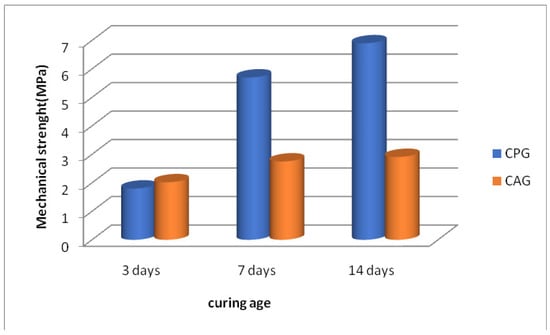

Figure 2 depicts the evolution of mechanical strength in the compacted geopolymeric (CG) materials elaborated through the two investigated routes across their curing age. Regardless of the activator’s nature, the mechanical strength of the materials exhibited exponential growth as the curing age increased, a phenomenon attributed to the time required for the completion of the polycondensation processes [20]. In fact, with the evaporation of unreacted water, the structure gains strength.

Figure 2.

Evolution of compacted geopolymeric materials mechanical strength over their curing age.

Notably, the acidic route outperformed the alkaline route, demonstrating twice the mechanical strength after a 7-day curing age and three times greater mechanical strength after a 14-day curing age. This superiority can be attributed to the presence of phosphate aluminum compounds, which reinforce the compacted phosphate-based geopolymeric materials, thereby enhancing their mechanical strength [20,21]. Furthermore, this difference may be attributed to the increased stability of the bonds formed through acid activation compared to those formed through alkaline activation at room temperature [15]. Indeed, in open air, a carbonation reaction occurs between free Na+ and atmospheric CO2, leading to efflorescence within the material and posing a potential threat to the strength of compacted alkaline-based geopolymeric (CAG) materials [22,23].

3.1.2. Density

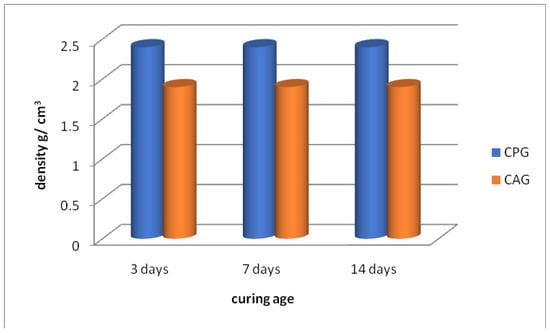

Figure 3 illustrates the evolution of density in the compacted geopolymeric materials throughout their curing age. Notably, irrespective of the activator’s nature, the density of both studied materials remained consistent during the initial three days of curing and exhibited no significant changes thereafter. This observation underscores the stability of compacted geopolymeric materials, highlighting a key advantage for industrial applications.

Figure 3.

Evolution of compacted geopolymeric materials density throughout their curing age.

The compaction process plays a pivotal role in achieving this stability by facilitating the densification of precursor particles. By starting the material elaboration with a compaction process, porosity is effectively minimized, contributing to a denser and more homogeneous structure. This early densification is instrumental in establishing a robust and enduring framework from the onset of material formation.

However, it is noteworthy that the density of CPG materials (2.4 g/cm3) was found to be higher than that of CAG materials (1.9 g/cm3). This difference can be attributed to the higher reactivity of the aluminosilicate precursor in an acidic medium compared to an alkaline solution. The introduction of a phosphoric acid solution leads to a more extensive dissolution of the aluminosilicate phases than the alkaline solution [24]. Moreover, during polycondensation in an acidic medium, the formed binder establishes robust bonds with the fines present in the material, resulting in increased density [15].

3.1.3. Dimensional Variation (Shrinkage)

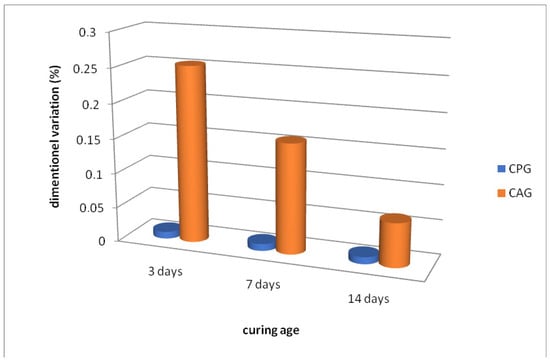

Figure 4 depicts the dimensional variation observed in compacted geopolymeric materials, elaborated through the two investigated routes, over their curing age. The results indicate that compacted phosphate-based geopolymeric (CPG) materials maintained stable dimensions throughout the maturation process (0.05%). Conversely, compacted alkaline-based geopolymeric (CAG) materials exhibited a subtle shrinkage that diminished with the advancing of the curing age, decreasing from 0.25% on day3 to 0.08% on day14. This means that there was a significant shrinkage initially, followed by swelling, ultimately resulting in a minor shrinkage.

Figure 4.

Compacted geopolymeric materials dimensional variation over their curing age.

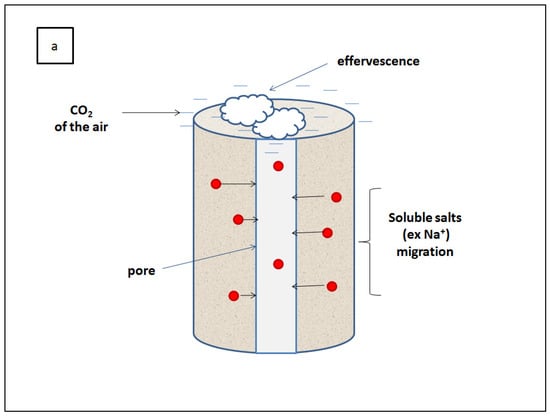

The observed result, particularly in geopolymers obtained through the alkaline route, can be attributed to the efflorescence phenomenon. Efflorescence is commonly associated with the migration of soluble salts toward the surface of porous materials, like concrete or masonry [22,23]. Upon reaction with atmospheric carbon dioxide, these salts can lead to the formation of visible, white, powdery deposits, as depicted in Figure 5. This reaction can be described by the following Equations (1) and (2):

CO2 (g) + 2OH− (aq) → CO32− (aq) + H2O

2Na+ (aq) + CO32− (aq) + H2O → Na2CO3.H2O (sd)

Figure 5.

Efflorescence phenomenon on the sample surfaces. (a) Schematic representation, (b) real aspect.

The formation of Na2CO3·H2O due to efflorescence may explain the observed dimensional variation in the alkaline route, a phenomenon that did not occur in the acidic route thanks to the absence of soluble alkaline salts. The decrease in dimensional variation with increased geopolymer age suggests that the efflorescence effect may diminish as the material matures, and soluble salts become more integrated into the developing geopolymeric network and more consumed.

3.1.4. Durability

Table 3 presents various findings related to the durability of the studied geopolymeric materials following immersion in to water. It includes photographs of geopolymeric specimens prepared via the two different routes, illustrating their appearances before, during, and after a 24 h immersion in distilled water. Additionally, the table presents the pH of the immersion water, the material mass loss after immersion, and the drop of mechanical strength.

Table 3.

Durability of compacted geopolymeric materials under water exposure (geopolymers aged 14 days, 24 h of immersion in distilled water).

Notably, there was no apparent visual distinction between the CPG and CAG samples before water immersion, as they exhibited similar colors and structures. However, following water immersion, compacted geopolymeric materials obtained through the acidic route displayed clearer water than those obtained through the alkaline one. This phenomenon can be attributed to their improved stability in water. The result was a slightly brick-red coloration of the water after immersion, attributed to the release of fine unreacted particles in the started aluminosilicate precursor, mainly the iron and aluminum ones. The dissolution of these elements from the solid phase explains the observed coloration. Specifically, with acidic activation, aluminum and iron are likely to undergo more reaction with the activator precursor (aluminum and iron phosphate units) and become more integrated into the geopolymeric network, thereby contributing to the material’s enhanced durability.

This phenomenon was further corroborated by the pH of the resulting immersion water. Specifically, in the case of the CPG material, no significant pH variation was observed. For instance, if we began with distilled water with a pH of 7 and the obtained pH was 6.12, the pH variation was only 0.88. Conversely, a more significant pH variation was observed in the case of the CAG material. In fact, if we started with distilled water with a pH of 7 and the obtained pH was 9.97, we observed a pH variation of 2.97. This indicates that material dissolution and structural destruction were more pronounced in association with the alkaline route.

Another result confirmed this finding, that is, the material mass loss after immersion. Specifically, the CPG material experienced only a 0.45% loss of its starting mass, whereas the CAG material lost about 13.64% of its starting mass. These results underscore the greater durability of CPG compared to CAG and highlight the robustness of its structure.

These observations were further confirmed by the drop in mechanical strength after 24 h of water immersion. Specifically, the CPG material exhibited only a 5.1% decrease in its initial mechanical strength, whereas the CAG material showed an almost 16.2% decrease. This highlights the superior mechanical stability of geopolymers produced via the acidic route compared to those produced via the alkaline route.

The primary reason for this superior stability lies in the microstructural differences between the two types of geopolymers. The higher density of the CPG samples, as previously discussed, plays a crucial role in limiting water penetration during immersion. This is because the dense structure of CPG samples reduces the size and connectivity of pores and the spaces between compacted particles which act as pathways for water ingress. In contrast, the CAG samples, with their relatively lower density, have a more porous structure that allows water to infiltrate more easily, leading to a greater reduction in mechanical strength.

Moreover, the chemical composition of the acidic route geopolymers contributes to their enhanced durability. The acidic synthesis process may promote the formation of a more cross-linked and compact matrix which enhances resistance to water-induced degradation. This denser and more cohesive matrix is less susceptible to the disruptive effects of water immersion, thereby maintaining its mechanical integrity.

These findings underscore the importance of considering the synthesis route in the development of geopolymers, especially for applications where exposure to water is likely. The enhanced durability and mechanical stability of acidic route geopolymers make them a preferable choice for such environments, offering greater longevity and reliability.

3.2. Effect on the Compacted Geopolymers (CG) Composition

3.2.1. Mineralogical Composition

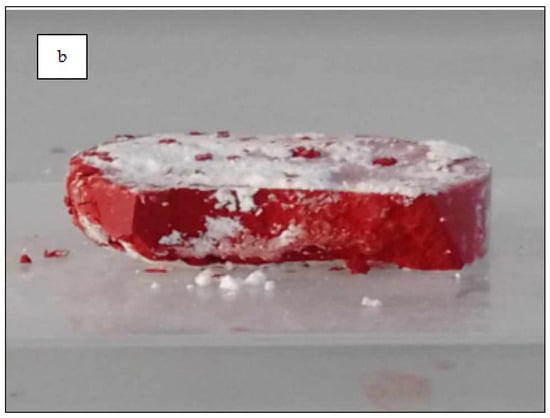

Figure 6 displays X-ray diffractograms of the calcined Medenine clay and compacted geopolymeric sample (aged 14 days) under investigation. The analysis of the calcined Medenine clay diffractogram revealed characteristic peaks of quartz, illite, and muscovite, indicating the persistence of these minerals post-calcination at 750 °C. This aligns with existing literature [16,20,21]. Following the two different routes of geopolymerization, the characteristic peaks of quartz, illite, and muscovite persisted, reflecting their inertness to both alkaline and acidic activators, as supported by other studies [20,21,24,25].

Figure 6.

X-ray diffractograms of the calcined Medenine clay and compacted geopolymeric sample (aged 14 days). With: M: muscovite (00-007-0032 ), I: illite (00-009-0343),Q: quartz (00-046-1045), P: aluminum phosphate(01-075-1072) and N: natrite: sodium carbonate (00-037-0451).

Upon examination of the geopolymeric diffractograms of both CPG and CAG samples, a weak amorphous phase emerged, evidenced by a diffuse halo pattern between 20° and 35° (2θ). This amorphous phase confirmed the geopolymerization phenomenon, highlighting the development of a novel amorphous geopolymeric network irrespective of the activator type.

In the compacted phosphate-based geopolymeric material diffractogram, the formation of aluminum phosphate phases was observed, leading to an increase in the length of certain quartz peaks (e.g., peak at 2θ = 27°). In fact, this compound exhibited an isostructure with quartz, causing an overlap in characteristic quartz peaks and an increase in their length.

Conversely, in the compacted alkaline geopolymeric material diffractogram, new peaks of natrite appeared, indicating the formation of sodium carbonate due to the efflorescence phenomenon [13].

In summary, both compacted phosphate-based and alkaline-based geopolymeric samples exhibited geopolymeric networks containing quartz, illite, and muscovite as inert compounds vis-a-vis the two activators. However, geopolymeric materials obtained through the acidic route were characterized by the presence of aluminum phosphate phases, reinforcing the structure. In contrast, geopolymeric materials obtained through the alkaline route showed the presence of sodium carbonate phases, introducing impurities into the structure. This explains the superior performance of the compacted phosphate-based geopolymeric material compared to the compacted alkaline-based geopolymeric one.

3.2.2. Chemical Composition

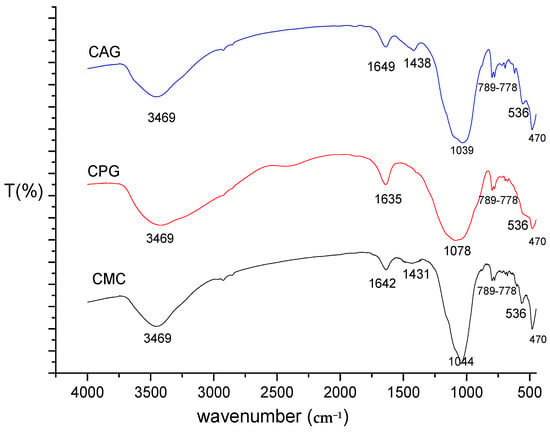

Figure 7 illustrates the infrared spectra of the calcined aluminosilicate precursor (Medenine clay) CMC and the compacted geopolymeric materials obtained through both acidic and alkaline activation and aged 14 days.

Figure 7.

Infrared spectra of the calcined Medenine clay and the compacted geopolymeric materials obtained through both acidic and alkaline activation and aged 14 days.

Upon examination, a distinct, broad band around 3469 cm−1 was observed in all spectra, attributed to the OH group characteristic of illite and residual kaolinite [26], as identified through XRD analysis. Remarkably, this band remained consistent regardless of the activation route, providing evidence that illite and muscovite remain unreacted during the geopolymerization process, irrespective of the chosen activator. After geopolymerization, this broad band can also include bands attributed to O–H stretching bands belonging to the geopolymer network [26,27,28].

The second observed band was around 1635 cm−1 and 1649 cm−1 for the compacted phosphate-based geopolymeric sample and compacted alkaline-based geopolymeric sample, respectively. These bands were attributed to the vibration of O–H of water molecules present in the geopolymeric network [27,28].

Another band located at 1431 cm−1 in the calcined Medenine clay spectra was observed. This band was generally attributed to residual C–O bonds characteristic of calcium carbonate, which undergo decarbonation at 750 °C [28]. With the acidic activation, this band disappeared totally due to the reaction between calcium carbonate and phosphate, as expressed in the reaction:

CaCO3 (s) + HPO42− (aq) → CaHPO4 (s) + CO2(g) + H2O (L)

However, with alkaline activation, this band persisted and shifted toward 1438 cm−1, attributed to the carbonate group characteristic of sodium carbonate resulting from efflorescence reaction [15].

The bond characteristic of the asymmetric stretching vibrations of Si–O–T (T= Si or Al) located at 1044 cm−1 in the starting calcined Medenine clay shifted to 1078 cm−1 wavenumber for the compacted phosphate-based geopolymeric (CPG) sample, confirming the insertion of PO units into the new geopolymeric network [20]. However, for the compacted alkaline-based geopolymeric (CAG) sample, this band nearly persisted in the same position (1039 cm−1) because, in this case, the new chemical network was formed almost with the same units as the starting precursor.

Interestingly, the doublet of quartz [26,27,28,29] and the characteristic band of Al VI–O–Si in illite [26,27,28,29], located at approximately 789 cm−1, 778 cm−1, and 536 cm−1, respectively, and evident in the calcined Medenine clay spectrum, remained unchanged following the geopolymerization process using various routes. This aligns with XRD observations and indicates the resistance of these compounds to phosphoric acid, regardless of the applied activator type.

Additionally, the band situated around 470 cm−1 in the calcined clay FTIR spectrum, attributed to Si–O type bonds, remained virtually unaltered post-geopolymerization using either alkaline or acidic activation. Si–O–Si bonds exhibited greater robustness compared to Al–O–Al and Al–O–Si bonds due to their relatively covalent nature, making them less susceptible to acid- and alkaline-based attacks [30].

3.3. Effect on the Geopolymerization Kinetics

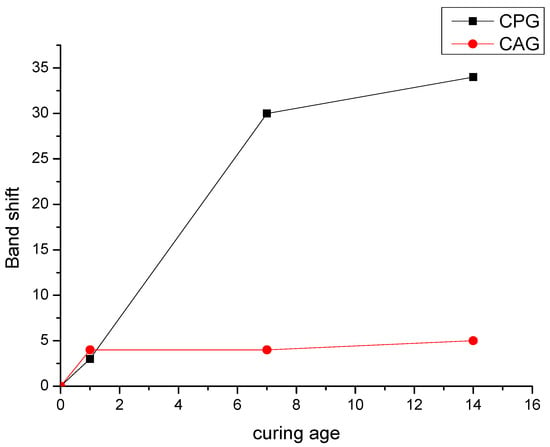

3.3.1. Evolution of Infrared Bands with Respect to Curing Time

The examination of the literature pertaining to the study of geopolymeric materials, particularly through Fourier transform infrared (FTIR) spectroscopy, revealed a significant insight into the reactivity rates of these materials [20]. The key focus was on the shift in the broad band between 1100 cm−1 and 1000 cm−1 in the FTIR spectrum of geopolymeric materials, serving as a crucial indicator of reactivity. This shift, whether toward higher wavenumbers in the case of acidic activation or lower wavenumbers in the case of alkaline activation, reflected the formation of new geopolymeric structures. The evolution of this FTIR band shift over the curing time of compacted geopolymeric materials activated through both acidic and alkaline routes is presented in Figure 8. Notably, the findings highlight remarkable differences in reactivity rates between the two activation routes. Initially, the alkaline route demonstrated higher reactivity in the early stages of geopolymerization, explaining the superior mechanical performance of CAG compared to CPG at the 3-day mark. However, as the geopolymerization progressed, the acidic route outpaced the alkaline route by becoming seven times faster. Intriguingly, for CAG materials, the geopolymerization phenomenon was achieved within the first 3 days, with a subsequent slow kinetic of formation. In contrast, CPG materials exhibited continuous geopolymerization even after 14 days of curing, with a consistently more significant kinetic compared to the alkaline route. This nuanced understanding underscores the critical role of activation route selection and observation time in influencing the reactivity and kinetics of geopolymerization, thereby impacting the mechanical properties of the resulting materials.

Figure 8.

Evolution of FTIR band (located between 1100 cm−1 and 1000 cm−1) shift over the curing age of compacted geopolymeric materials activated through both acidic and alkaline routes.

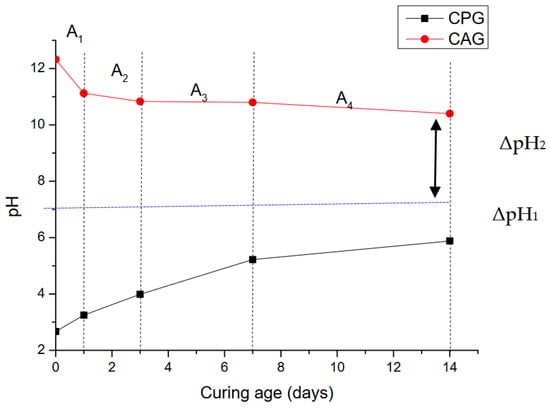

3.3.2. Evolution of pH with Respect to Curing Time

Figure 9 illustrates the pH evolution of the investigated materials throughout the curing age. The results revealed that the rate of pH variation (increase for CPG materials and decrease for CAG materials) was nearly identical for both studied routes only during the initial day of curing, as evidenced by the similar slopes of the curves in area A1. However, subsequently, the CPG material exhibited a more rapid increase in pH compared to the decrease observed in the CAG material, as indicated by the slopes of their respective curves in other areas (A2, A3, and A4).

Figure 9.

Evolution of pH over the curing age of compacted geopolymeric materials activated through both acidic and alkaline routes.

This observed trend aligns with the kinetics observed in the evolution of FTIR bands over curing time. Initially, the alkaline route demonstrated a similar or slightly faster reaction relative to the acidic route. However, as the curing process progressed, the acidic geopolymerization surpassed the alkaline geopolymerization in terms of both rapidity and effectiveness. It is noteworthy that CPG materials displayed their maximum reactivity and progress during the first 3 days to 7 days of curing.This observation further clarifies the superior performance of CPG materials compared to CAG materials, attributed to the more substantial effective chemical bonding and structure formation during curing.

Furthermore, a notable advantage of the CPG material over the CAG material was the final pH value reached after 14 days of curing. Industrial applications often prefer materials with a pH closer to neutral (around 7) for safety during production and use. In this regard, the difference between the final material pH and neutral pH, denoted as ΔpH, was found to be lower for the acidic activation compared to the alkaline activation (ΔpH1 = 1.5 < ΔpH2 = 3.9). This discrepancy represents a significant and desirable advantage [31].

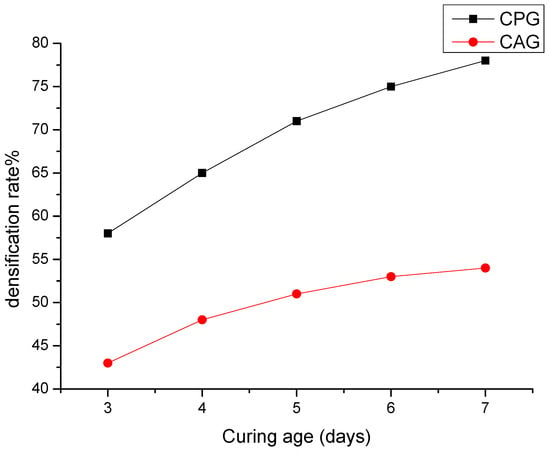

3.3.3. Densification Rate

Figure 10 illustrates the evolution of the densification rate for both investigated materials throughout the curing age, specifically from the third to the seventh day of curing, corresponding to the period demonstrating the maximum progress in geopolymerization with the latest techniques. The results underscore a denser microstructure in the case of CPG compared to CAG, irrespective of the curing duration, justifying CPG better mechanical performance and durability, as previously discussed.

Figure 10.

Evolution of the densification rate over the curing age of compacted geopolymeric materials activated through both acidic and alkaline routes.

Initially, the CPG materials exhibited a densification rate of around 57%, whereas the CAG materials showed a densification rate of approximately 42%, despite both being subjected to the same pressure of 60 MPa. This indicates that the acidic route demonstrated a superior pressing ability, possibly due to its heightened plasticity, which is crucial for subsequent applications, especially in the field of civil engineering. Moreover, this implies that the CPG materials can attain the same densification rate as CAG materials (42%), but with significantly lower pressure requirements, leading to more cost-effective products and decreased energy consumption. This pattern persisted, with CPG achieving a densification rate of 78% after 7 days of curing, while CAG only reached 57%.

In terms of the kinetics of geopolymerization, CPG demonstrated a faster reaction, as evidenced by the steeper slope of its corresponding curve. Moreover, the densification rate increased exponentially, as demonstrated by the curve’s trajectory for each sample. This trend aligns with findings in the literature [20].

Expanding on these observations, the higher densification rate observed in association with CPG materials can be attributed to several factors. Firstly, the specific composition and activation route of CPG materials may facilitate more efficient chemical bonding and structure formation during curing, leading to a denser microstructure. Additionally, the faster reaction kinetics observed in CPG materials indicates a more rapid progression of geopolymerization, further contributing to the densification process. Overall, these factors collectively resulted in the enhanced densification observed in CPG materials compared to CAG materials, highlighting their superior performance in terms of microstructural development.

4. Conclusions

In conclusion, this study addresses a gap in the literature by providing a comprehensive comparative analysis of compacted geopolymeric materials elaborated via alkaline and acidic routes. Unlike previous studies that primarily investigated only compacted alkaline-based geopolymeric materials or compacted acidic-based geopolymers used solely as stabilizers, our research considers the acidic compacted geopolymers as the primary studied reaction product. Through our analysis, we highlight the merits and constraints of each approach.

Our findings reveal that compacted phosphate-based geopolymers (CPG) exhibited superior mechanical strength (three times greater after a 14-day curing period) and higher density (more than 20% higher), due to enhanced reactivity of the acidic medium, compared to compacted alkaline-based geopolymers (CAG), which maintained constant density. Dimensional stability tests indicated that CPG retained stable dimensions, while CAG experienced slight shrinkage, likely due to efflorescence. Visual assessments further highlighted CPG's improved stability before, during, and after water immersion. Chemical analyses confirmed the persistence of mineralogical phases such as quartz and illite in both types, with the formation of an amorphous geopolymeric network. CPG contained aluminum phosphate phases that reinforced structural integrity, whereas CAG contained sodium carbonate phases, considered to be impurities which reduce performance. Additionally, CPG demonstrated faster reaction kinetics than CAG, evidenced by trends in pH, densification rate, and FTIR band evolutions over curing time.

These findings provide valuable insights into the synthesis, characterization, and performance of compacted geopolymeric materials, suggesting that CPG materials have superior properties and potential applications in various industries.

Author Contributions

Conceptualization, M.Z., M.I. and S.B.; methodology, M.Z. and M.I.; software, S.B.; validation, M.Z. and M.I.; formal analysis, M.Z.; investigation, M.Z.; writing—original draft preparation, M.Z.; writing—review and editing, S.B.; supervision, S.B.; project administration, S.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request. Due to privacy and ethical restrictions, the data are not publicly available.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Xie, T.; Visintin, P.; Zhao, X.; Gravina, R. Mix design and mechanical properties of geopolymer and alkali activated concrete: Review of the state-of-the-art and the development of a new unified approach. Constr. Build. Mater. 2020, 256, 119380. [Google Scholar] [CrossRef]

- Wu, Y.; Lu, B.; Bai, T.; Wang, H.; Du, F.; Zhang, Y.; Cai, L.; Jiang, C.; Wang, W. Geopolymer, green alkali activated cementitious material: Synthesis, applications and challenges. Constr. Build. Mater. 2019, 224, 930–949. [Google Scholar] [CrossRef]

- Srividya, T.; Kannan Rajkumar, P.R.; Sivasakthi, M.; Sujitha, A.; Jeyalakshmi, R. A state-of-the-art on development of geopolymer concrete and its field applications. Case Stud. Constr. Mater. 2022, 16, e00812. [Google Scholar]

- Davidovits, J. Properties of geopolymer cements. In Proceedings of the First International Conference on Alkaline Cements and Concretes, Scientific Research Institute on Binders and Materials, Kiev, Ukraine, 11–14 October 1994; Volume 1, pp. 131–149. [Google Scholar]

- Mango-Itulamya, L.A.; Fagel, N. Study of parameters influencing the compressive strength of Compressed Earth Blocks. J. Phys. Conf. Ser. 2022, 2368, 012004. [Google Scholar] [CrossRef]

- Güllü, H.; Agha, A.A. The rheological, fresh and strength effects of cold-bonded geopolymer made with metakaolin and slag for grouting. Constr. Build. Mater. 2021, 274, 122091. [Google Scholar] [CrossRef]

- Patel, Y.J.; Shah, N. Development of self-compacting geopolymer concrete as a sustainable construction material. Sustain. Environ. Res. 2018, 28, 412–421. [Google Scholar] [CrossRef]

- Sambucci, M.; Sibai, A.; Valente, M. Recent advances in geopolymer technology. A potential eco-friendly solution in the construction materials industry: A review. J. Compos. Sci. 2021, 5, 109. [Google Scholar] [CrossRef]

- Krishna, R.S.; Mishra, J.; Zribi, M.; Adeniyi, F.; Saha, S.; Baklouti, S.; Shaikh, F.U.A.; Gökçe, H.S. A review on developments of environmentally friendly geopolymer technology. Materialia 2021, 20, 101212. [Google Scholar] [CrossRef]

- Zribi, M.; Baklouti, S. Phosphate-based geopolymers: A critical review. Polym. Bull. 2022, 79, 6827–6855. [Google Scholar] [CrossRef]

- Ryu, G.S.; Lee, Y.B.; Koh, K.T.; Chung, Y.S. The mechanical properties of fly ash-based geopolymer concrete with alkaline activators. Constr. Build. Mater. 2013, 47, 409–418. [Google Scholar] [CrossRef]

- Sore, S.O.; Messan, A.; Prud’Homme, E.; Escadeillas, G.; Tsobnang, F. Stabilization of compressed earth blocks (CEBs) by geopolymer binder based on local materials from Burkina Faso. Constr. Build. Mater. 2018, 165, 333–345. [Google Scholar] [CrossRef]

- Kamwa, R.A.T.; Tome, S.; Chongouang, J.; Eguekeng, I.; Spieß, A.; Fetzer, M.N.; Elie, K.; Janiak, C.; Etoh, M.A. Stabilization of compressed Earth blocks (CEB) by pozzolana based phosphate geopolymer binder: Physico-mechanical and microstructural investigations. Clean. Mater. 2022, 4, 100062. [Google Scholar] [CrossRef]

- Mimboe, A.G.; Abo, M.T.; Djobo, J.N.Y.; Tome, S.; Kaze, R.C.; Deutou, J.G.N. Lateritic soil based-compressed earth bricks stabilized with phosphate binder. J. Build. Eng. 2020, 31, 101465. [Google Scholar] [CrossRef]

- Kamwa, R.A.T.; Noumbissie, L.T.; Tome, S.; Idriss, E.; Nemaleu, J.G.D.; Tommes, B.; Woschko, D.; Janiak, C.; Etoh, M.A. A comparative study of compressed lateritic earth bricks stabilized with natural pozzolan-based geopolymer binders synthesized in acidic and alkaline conditions. Constr. Build. Mater. 2023, 400, 132652. [Google Scholar] [CrossRef]

- Zribi, M.; Samet, B.; Baklouti, S. Mechanical, microstructural and structural investigation of phosphate-based geopolymers with respect to P/Al molar ratio. J. Solid State Chem. 2020, 281, 121025. [Google Scholar] [CrossRef]

- Roy, S.; Bhalla, S.K. Role of geotechnical properties of soil on civil engineering structures. Resour. Environ. 2017, 7, 103–109. [Google Scholar]

- ASTM D4318-17e1; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2017.

- Li, D.; Wong, L.N.Y. The Brazilian disc test for rock mechanics applications: Review and new insights. Rock Mech. Rock Eng. 2013, 46, 269–287. [Google Scholar] [CrossRef]

- Zribi, M.; Baklouti, S. Investigation of Phosphate based geopolymers formation mechanism. J. Non-Cryst. Solids 2021, 562, 120777. [Google Scholar] [CrossRef]

- Tchakouté, H.K.; Rüscher, C.H. Mechanical and microstructural properties of metakaolin-based geopolymer cements from sodium waterglass and phosphoric acid solution as hardeners: A comparative study. Appl. Clay Sci. 2017, 140, 81–87. [Google Scholar] [CrossRef]

- Pouhet, R.; Cyr, M. Carbonation in the pore solution of metakaolin-based geopolymer. Cem. Concr. Res. 2016, 88, 227–235. [Google Scholar] [CrossRef]

- Longhi, M.A.; Zhang, Z.; Rodríguez, E.D.; Kirchheim, A.P.; Wang, H. Efflorescence of alkali-activated cements (geopolymers) and the impacts on material structures: A critical analysis. Front. Mater. 2019, 6, 89. [Google Scholar] [CrossRef]

- Zribi, M.; Samet, B.; Baklouti, S. Structural characterization of phosphate-based geopolymer. In Advances in Materials, Mechanics and Manufacturing, Proceedings of the Second International Conference on Advanced Materials, Mechanics and Manufacturing (A3M’2018), Hammamet, Tunisia, 17–19 December 2018; Springer International Publishing: Cham, Switzerland, 2020; pp. 36–42. [Google Scholar]

- Zribi, M.; Samet, B.; Baklouti, S. Effect of curing temperature on the synthesis, structure and mechanical properties of phosphate-based geopolymers. J. Non-Cryst. Solids 2019, 511, 62–67. [Google Scholar] [CrossRef]

- Louati, S.; Baklouti, S.; Samet, B. Geopolymers based on phosphoric acid and illito-kaolinitic clay. Adv. Mater. Sci. Eng. 2016, 2016, 1–7. [Google Scholar] [CrossRef]

- Yusuf, M.O. Bond characterization in cementitious material binders using Fourier-transform infrared spectroscopy. Appl. Sci. 2023, 13, 3353. [Google Scholar] [CrossRef]

- Derouiche, R.; Zribi, M.; Baklouti, S. Study of Carbonated Clay-Based Phosphate Geopolymer: Effect of Calcite and Calcination Temperature. Minerals 2023, 13, 284. [Google Scholar] [CrossRef]

- Tchakoute, H.K.; Rüscher, C.H.; Djobo, J.Y.; Kenne, B.B.D.; Njopwouo, D. Influence of gibbsite and quartz in kaolin on the properties of metakaolin-based geopolymer cements. Appl. Clay Sci. 2015, 107, 188–194. [Google Scholar] [CrossRef]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; Mallicoat, S.W.; Kriven, W.M.; Van Deventer, J.S. Understanding the relationship between geopolymer composition, microstructure and mechanical properties. Colloids Surf. A Physicochem. Eng. Asp. 2005, 269, 47–58. [Google Scholar] [CrossRef]

- Davidovits, J. Environmentally driven geopolymer cement applications. In Proceedings of the 2002 Geopolymer Conference, Melbourne, Australia, 28–29 October 2002. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).