A Review of Tailings Dam Safety Monitoring Guidelines and Systems

Abstract

1. Introduction

- (1)

- The use of tailings material or waste rock for embankment construction;

- (2)

- A linear relationship between the dam height and the amount of wastewater deposited along with tailings that needs to be managed;

- (3)

- Minimum regulations are provided in the dam design standards;

- (4)

- The high monitoring cost when the dam is active and post-reclamation, throughout and after the active life of the mine ends.

2. Background

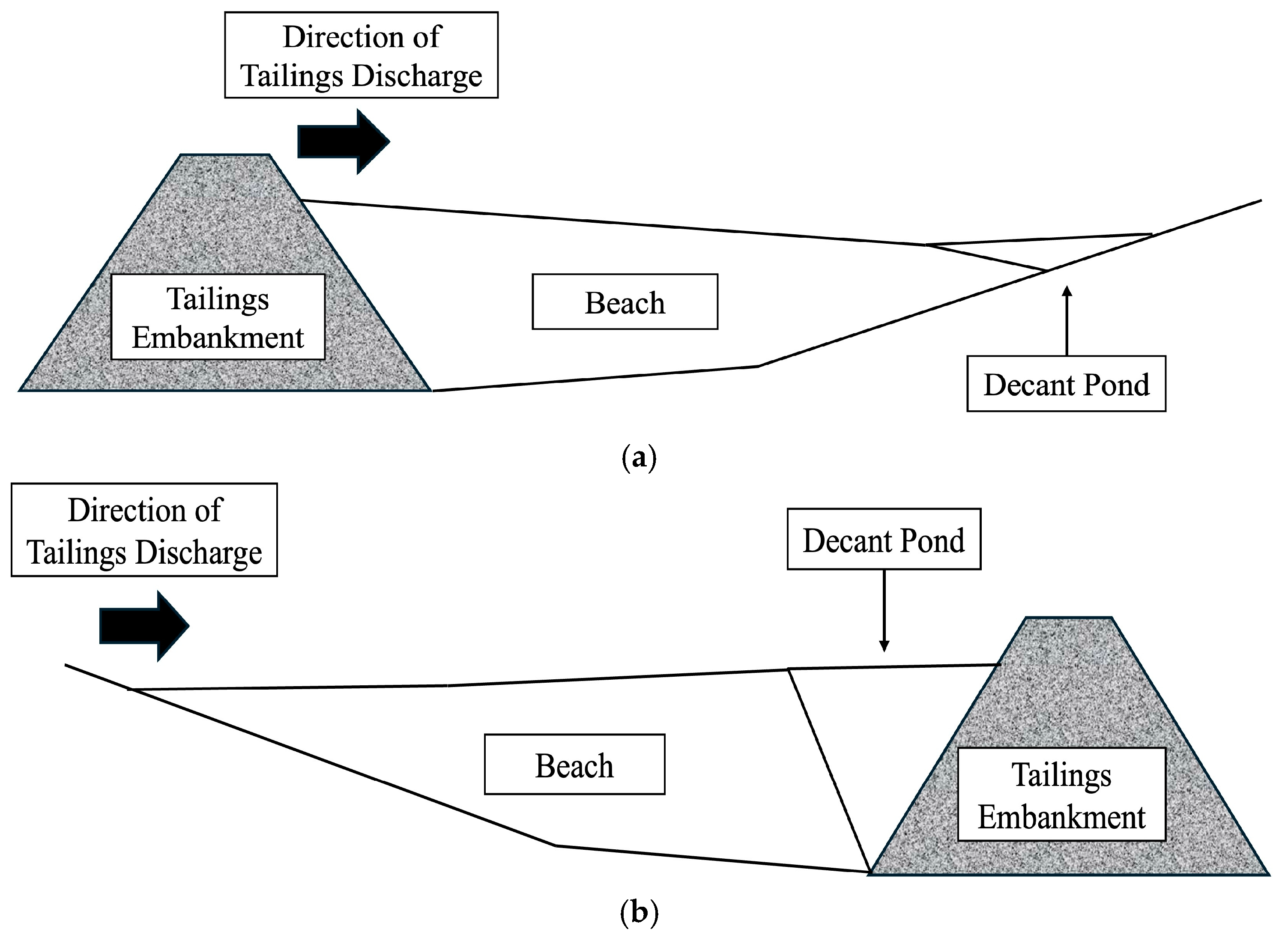

2.1. Tailings Disposal

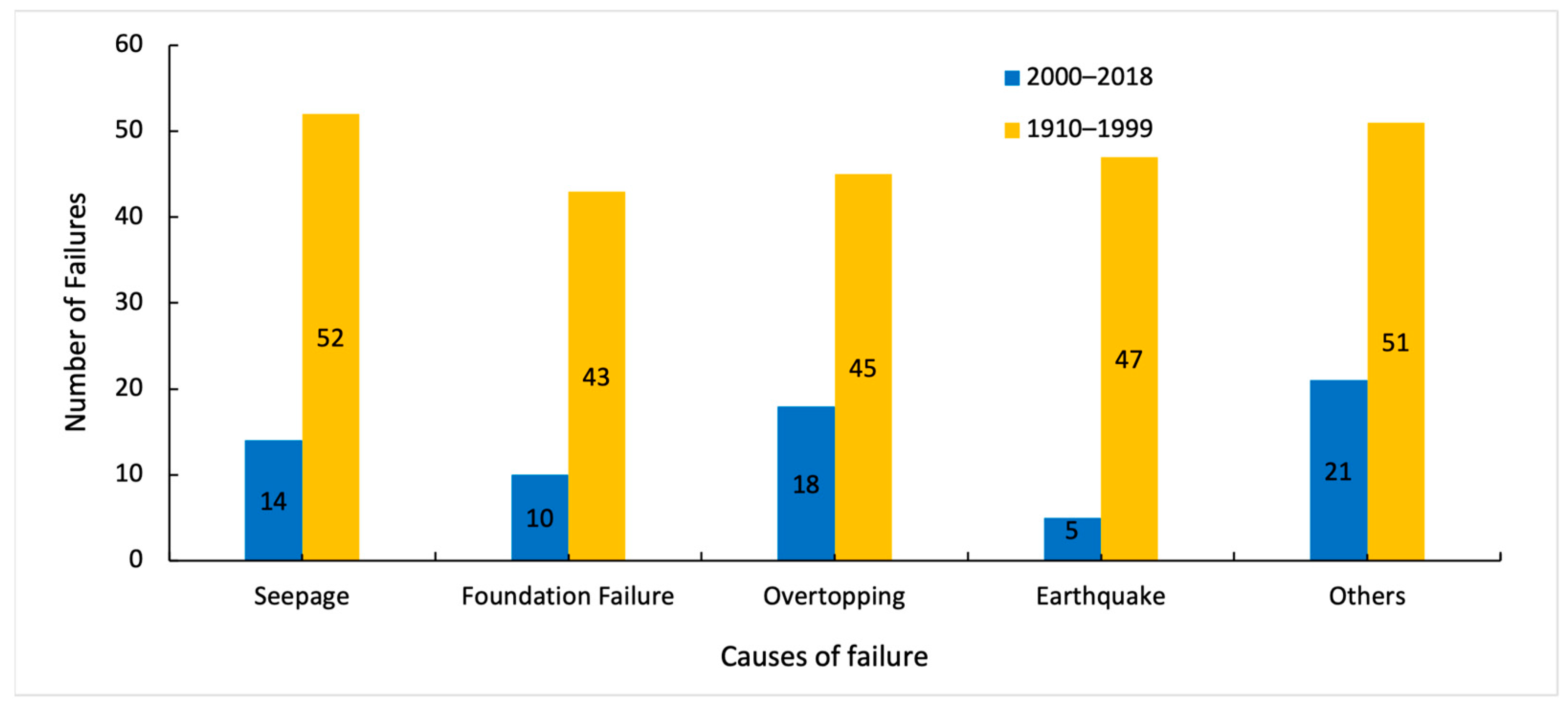

2.2. Tailings Failures

3. Existing Guidelines and Standards for Tailings Dam Management

3.1. Mining Association of Canada (MAC)

- Pond level and freeboard;

- Deformation (bulges, cracks, sinkholes, etc.);

- A new or expanding area of erosion;

- Piping or unexpected water movement;

- New seeps formation, changes in seeps, or changes in seepage characteristics;

- Spigot or material discharge instrument and pump condition;

- Possible leakage of water lines from the decant pump;

- Condition of water reclamation infrastructure;

- New or change in wildlife activity;

- New or changes in vegetation;

- Condition of the ground instruments.

3.2. Canadian Dam Association (CDA)

- (1)

- Leakage;

- (2)

- Erosion;

- (3)

- Sinkholes;

- (4)

- Boils;

- (5)

- Seepage;

- (6)

- Slope slumping or sliding;

- (7)

- Settlement;

- (8)

- Displacements or cracking of structural component;

- (9)

- Clogging of drains and relief wells.

3.3. International Commission on Large Dams (ICOLD)

- (1)

- Seepage;

- (2)

- Displacements and deformations;

- (3)

- Cracking;

- (4)

- Erosion, weathering, and clogging.

3.4. Australian National Committee on Large Dams (ANCOLD)

- (1)

- Overtopping;

- (2)

- Burrowing;

- (3)

- Flora attack (root penetration);

- (4)

- Flora colonies;

- (5)

- Erosion;

- (6)

- Cracks;

- (7)

- Sinkholes;

- (8)

- Subsidence;

- (9)

- Piping;

- (10)

- Seepage;

- (11)

- Movement;

- (12)

- Misalignment;

- (13)

- Deformation;

- (14)

- Settlement;

- (15)

- Freeboard levels;

- (16)

- Beach width;

- (17)

- Pond location;

- (18)

- Storage capacities.

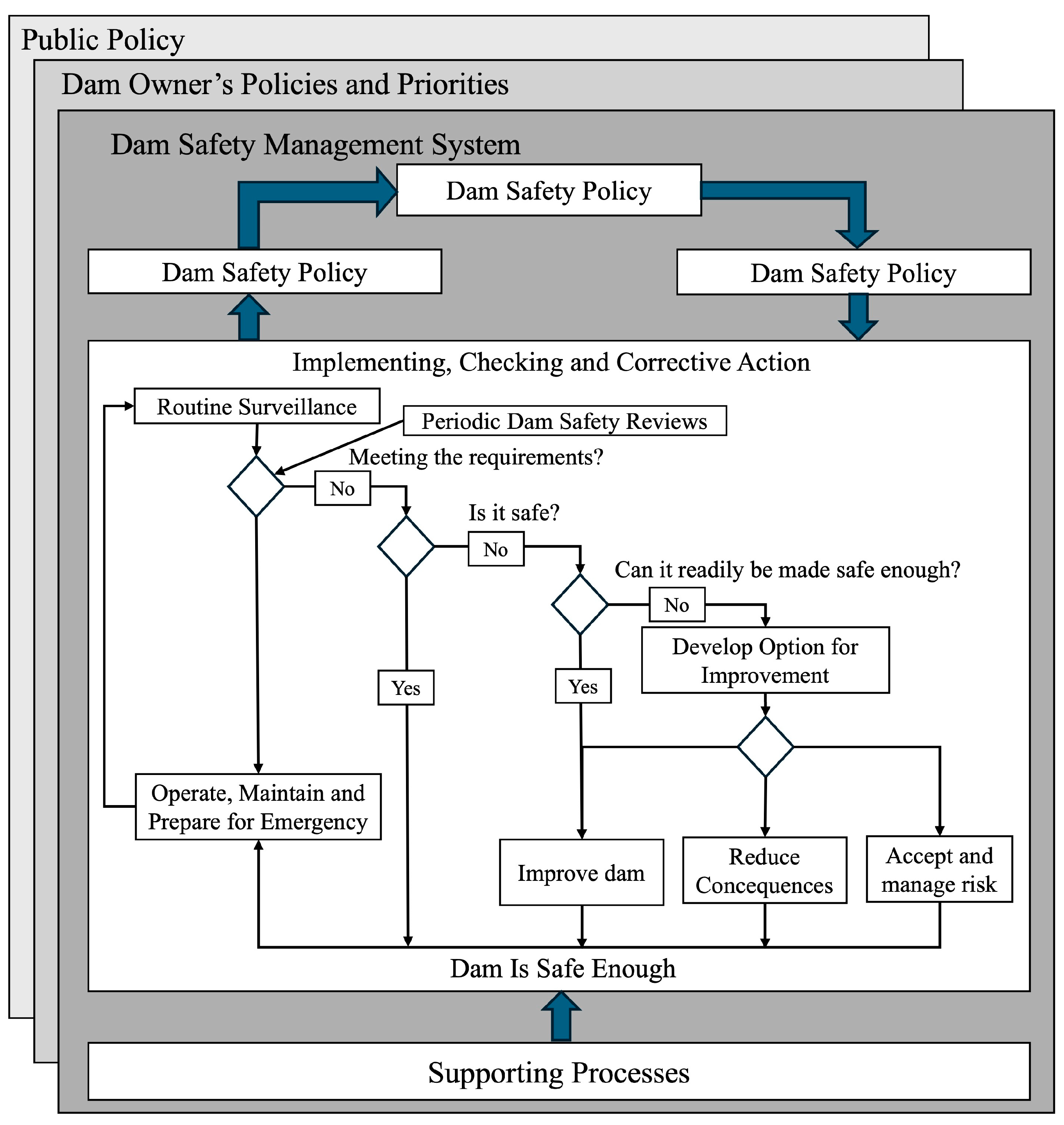

3.5. Dam Safety Management Guideline

- (1)

- Investigation;

- (2)

- Design and Construction Documentation;

- (3)

- Standard Operating Procedures;

- (4)

- Operation and Maintenance;

- (5)

- Inspection and Evaluation Reports;

- (6)

- Dam Safety Review Reports;

- (7)

- Emergency Action Plan;

- (8)

- Emergency Event Reports.

3.6. United Nations Economic Commission for Europe (UNECE)

3.7. South Africa National Standard (SANS 10286)

- (1)

- Continual management: Emphasized for on-going processes;

- (2)

- The minimization of waste and the impacts of waste: Reduce waste production and its footprint;

- (3)

- Precautionary principle: Use a conservative risk analysis;

- (4)

- Internalization of costs: Cost description should be true to all levels of risk;

- (5)

- Assessment of the full cycle of implications: Waste management should be considered throughout the whole mine cycle, even after closure.

3.8. International Organization for Standardization (ISO)

- (a)

- Specification of specialized mining equipment for surface and underground operations;

- (b)

- Best practices in the presentation of mine survey plans and drawings;

- (c)

- Mineral reserve calculation methods;

- (d)

- Management of mine reclamation;

- (e)

- Design of structures for the mining industry;

- (f)

- Special refuge/rescue chambers;

- (g)

- Shaft boring machines.

- (1)

- ISO 9000:2015—Fundamentals and vocabulary;

- (2)

- ISO 9001:2015—Quality management systems—Requirements;

- (3)

- ISO 9004:2018—Quality of an organization—Guidance to achieve sustained success.

- (1)

- ISO 14001:2015—Requirements with guidance for use;

- (2)

- ISO 14002-1:2019—Guidelines for using ISO 14001 to address environmental aspects and conditions within an environmental topic area—Part 1: General;

- (3)

- ISO 14004:2016—General guidelines on implementation;

- (4)

- ISO 14005:2019—Guidelines for a flexible approach to phased implementation;

- (5)

- ISO 14006:2020—Guidelines for incorporating eco-design;

- (6)

- ISO 14007:2019—Guidelines for determining environmental costs and benefits;

- (7)

- ISO 14008:2019—Monetary valuation of environmental impacts and related environmental aspects.

- (a)

- The timing of monitoring and measurement is coordinated with the need for analysis and evaluation results;

- (b)

- The results of monitoring and measurement are reliable, reproducible, and traceable;

- (c)

- The analysis and evaluation are reliable and reproducible and enable the organization to report trends.

- ISO 31000:2018—Principles and guidelines on implementation;

- ISO/IEC 31013:2009—Risk management—Risk assessment techniques;

- ISO Guide 73:2009—Risk management—Vocabulary.

- (a)

- Avoiding the risk by deciding not to start or continue with the activity that gives rise to the risk;

- (b)

- Taking or increasing the risk to pursue an opportunity;

- (c)

- Removing the risk sources;

- (d)

- Changing the likelihood;

- (e)

- Changing the consequences;

- (f)

- Sharing the risk with another party or parties;

- (g)

- Retaining the risk by informed decision.

3.9. Global Industry Standard on Tailings Management

- Establishing policies, systems, and accountabilities to support the safety and integrity of the tailings facility, creating systems, rules, and accountability measures to support the tailings facility’s integrity and safety. A policy for the safe management of tailings facilities, emergency readiness, and failure recovery must be adopted and published by the Board of Directors. Choose one or more Responsible Executives who will be directly responsible to the CEO for the safety of the tailings facilities and the program for training tailings management personnel. The Responsible Executives are also in charge of preventing or lessening the effects of a tailings plant failure on society and the environment.

- Choose an engineering company with knowledge and experience in the planning and building stages. Additionally, the company must designate a senior engineer with the required qualifications to serve as the Engineer of Record (EOR), who must be accepted by the operator. In the alternative, the operator may name an inside engineer to act as the EOR; in this case, the EOR may assign the design to a company but must remain intimately knowledgeable. Use a written agreement outlining the EOR’s authority, function, and duties for the duration of the tailings facility’s life to give them more influence. Also, the Responsible Executive will determine the EOR, and if it changes, a thorough plan must be made for the transfer of all data, information, knowledge, and experience.

- At least every three years, and more frequently whenever there is a substantial shift in the social, environmental, or regional economic context of the tailings facility, risk assessments with a qualified multidisciplinary team must be revised. To ensure the efficacy of the management systems, a frequent evaluation of the tailing management system and the elements of the environmental and social management system must be performed. The Responsible Executive, Board of Directors, and those affected by the initiative must also be informed of the results. A review must be carried out at least every three years for TSFs designated as having high, very high, or extreme implications.

- Every member of the staff working on any aspect of the tailings plant needs to be informed about the steps they must take to prevent failure. Putting in place procedures that take into account the knowledge that comes from workers’ experience in planning, designing, and operating; encouraging cross-functional cooperation to efficiently share data and knowledge; and praising, rewarding, and shielding from retaliation staff members and contractors who report issues or spot opportunities for bettering tailings facility management. Recognizing and putting into practice lessons learned from relevant external incident reports or internal event reports that concentrate on organizational and human elements.

- The Responsible Executive must establish a formal, private, and documented procedure for gathering, looking into, and quickly responding to employee or contractor complaints that jeopardize the integrity of the tailings facility. Also, the operator is prohibited from firing, treating unfairly, or taking any other adverse action against a whistleblower.

3.10. European Commission: Best Available Techniques Reference Document for the Management of Waste from Extractive Industries

3.10.1. Generic BATs

- (a)

- Organizational and Corporate Management System (O&CMS): Includes quality assurance and control, mass balances, and risk management during the planning phase. It must be updated during the operational period, and it must adapt to the particulars of the closure phase;

- (b)

- Environmental Management System (EMS): Asks for the creation of an environmental policy that covers ongoing improvements in operators’ management of extractive waste. It must be updated during the operational period, and it must adapt to the particulars of the closure phase.

- (a)

- Initial extractive waste characterization examining the traits of representative extractive waste samples in accordance with EN criteria. Use an ISO, national, or other international standard if EN standards are not available for certain parameters;

- (b)

- Review and verification of the extractive waste characteristics based on the environmental risk and impact assessment and the initial characterization.

3.10.2. Risk-Specific BATs

- (a)

- Investigation of the supporting strata’s geotechnical characteristics;

- (b)

- Choosing the right materials for a dam based on the suitability of materials for the specific geotechnical and environmental conditions;

- (c)

- Geotechnical analysis of ponds and dams, taking into account every mechanism that could have a detrimental impact on the full or partial structural stability of dams and ponds, e.g., seismic conditions;

- (d)

- Geotechnical analysis of heaps, addressing every mechanism that could have a harmful effect on the full or partial structural stability of heaps.

3.11. Limitations

4. Tailings Dam Stability Monitoring Indicators and Systems

4.1. Visual Indicators

4.1.1. Vegetation

4.1.2. Decant Pond

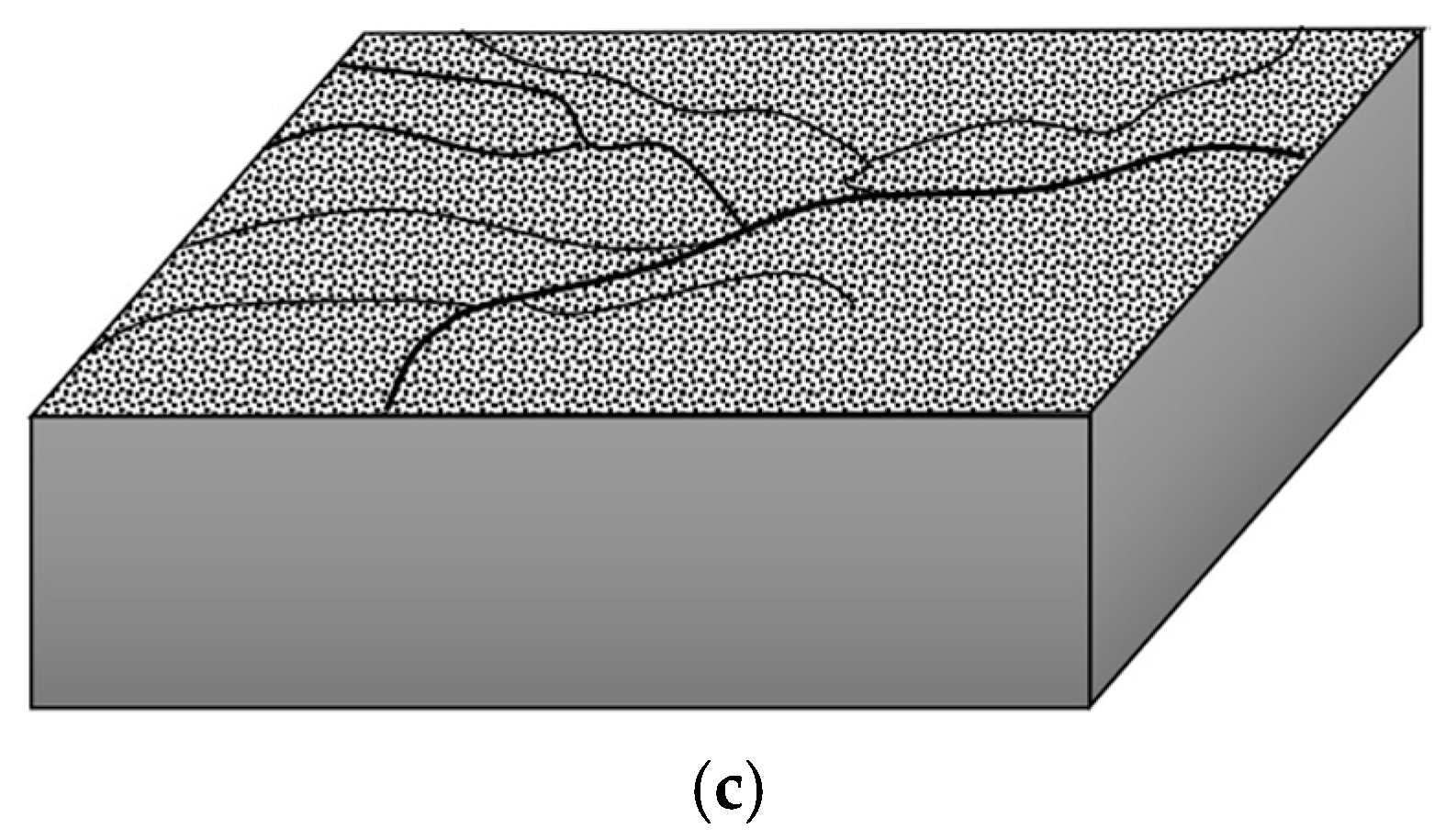

4.1.3. Deformation and Displacement

4.1.4. Seepage or Leakage

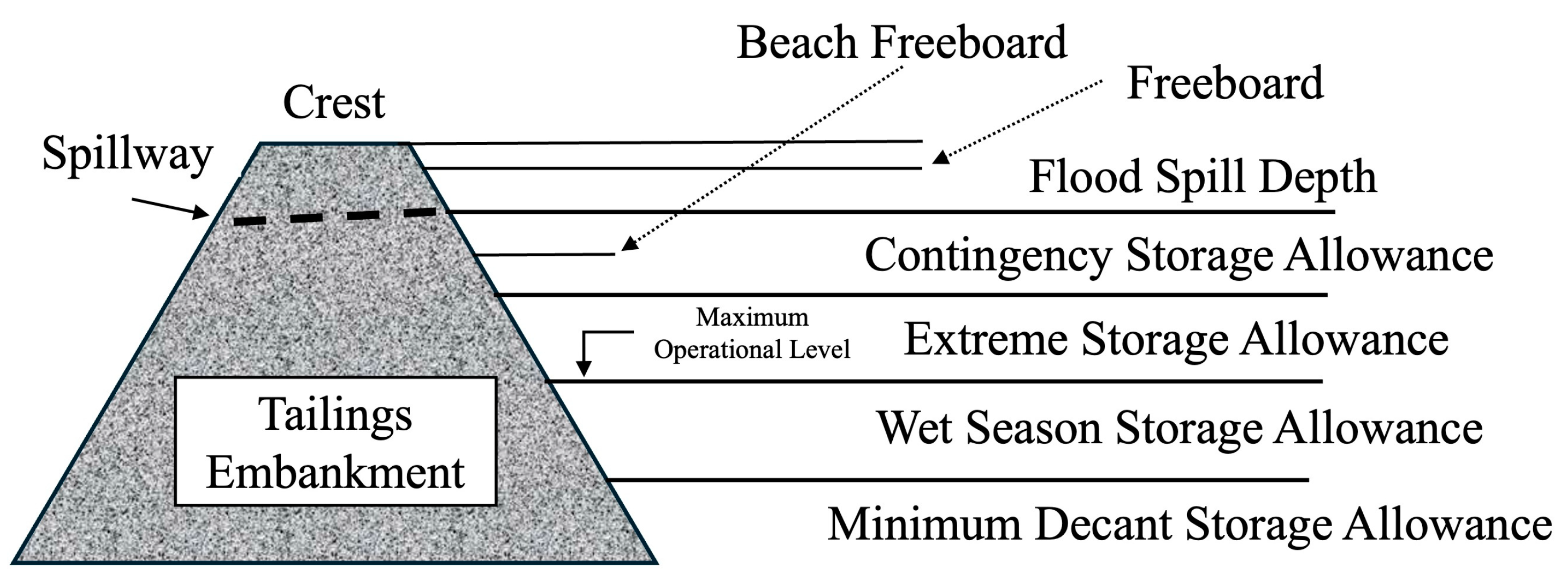

4.1.5. Freeboard

- Minimum decant storage allowance: The minimum amount of water expected to be held within the dam to achieve the required discharge condition;

- Wet season storage allowance: The water volume allowed during the wet season that includes input from rainfall and water from processing;

- Operational freeboard: The distance between the crest and the top of the tailings material;

- Maximum operating level: The highest extent where the water level can rise under normal conditions before activation of the site’s emergency plan.

4.1.6. Beach Width and Distance

4.1.7. Erosion

4.2. Monitoring Systems

- Comparison between the actual and design performance to identify deviations;

- Detection of changes in performance or the development of hazardous conditions;

- Confirmation that reservoir operations are following the dam safety requirements;

- Confirmation of adequate maintenance is being carried out.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- CDA. Dam Safety Guidelines 2007, 2013rd ed.; Canadian Dam Association: Ontario, ON, Canada, 2013.

- ICOLD. A Guide To Tailings Dams and Impoundments—Design, Construction, Use, and Rehabilitiation, 106th ed.; International Commission on Large Dams: Paris, France, 1996. [Google Scholar]

- Vick, S.G. Planning, Design, and Analysis of Tailings Dams; BiTech Publishers Ltd.: Vancouver, BC, Canada, 1990; ISBN 0921095120. [Google Scholar]

- Fell, R.; Macgregor, P.; Stapledon, D. Engineering of Embankment Dams; A. A, Balkema: Rotterdam, The Netherlands, 1992. [Google Scholar]

- ICOLD. Tailings Dams: Risk of Dangerous Occurrences: Lessons Learnt from Practical Experiences (No. 121); International Commission on Large Dams: Paris, France, 2001. [Google Scholar]

- WISE Uranium Project: Chronology of Major Tailings Dam Failures. Available online: https://www.wise-uranium.org (accessed on 4 March 2024).

- Lyu, Z.; Chai, J.; Xu, Z.; Qin, Y.; Cao, J. A Comprehensive Review on Reasons for Tailings Dam Failures Based on Case History. Adv. Civ. Eng. 2019, 2019, 4159306. [Google Scholar] [CrossRef]

- Clarkson, L.; Williams, D. Critical Review of Tailings Dam Monitoring Best Practice. Int. J. Min. Reclam. Environ. 2020, 34, 119–148. [Google Scholar] [CrossRef]

- FEMA. Federal Guidelines for Dam Safety; U.S. Department of Homeland Security Federal Emergency Management Agency: Washington, DC, USA, 2004.

- Armstrong, M.; Petter, R.; Petter, C. Why Have so Many Tailings Dams Failed in Recent Years? Resour. Policy 2019, 63, 101412. [Google Scholar] [CrossRef]

- Jeong, Y.; Kim, K. A Case Study: Determination of the Optimal Tailings Beach Distance as a Guideline for Safe Water Management in an Upstream TSF. Min. Metall. Explor. 2020, 37, 141–151. [Google Scholar] [CrossRef]

- Slingerland, N.; Sommerville, A.; O’Leary, D.; Beier, N.A. Identification and Quantification of Erosion on a Sand Tailings Dam. Geosyst. Eng. 2018, 23, 131–145. [Google Scholar] [CrossRef]

- Dixon-Hardy, B.W.; Engels, J.M. Guidelines and Recommendations for the Safe Operation of Tailings Management Facilities. Environ. Eng. Sci. 2007, 24, 625–637. [Google Scholar] [CrossRef]

- Mirabeau, T.; Citron, Q.A.; Cédex, P.; Ce, F. Case Studies on Tailings Management; UNEP/Earthprint: Nairobi, Kenya, 1998. [Google Scholar]

- The Church of England. Investor Mining & Tailings Safety Initiative Disclosure; Church of England: Westminster, UK, 2019. [Google Scholar]

- Franks, D.M.; Stringer, M.; Torres-Cruz, L.A.; Baker, E.; Valenta, R.; Thygesen, K.; Matthews, A.; Howchin, J.; Barrie, S. Tailings Facility Disclosures Reveal Stability Risks. Sci. Rep. 2021, 11, 5353. [Google Scholar] [CrossRef] [PubMed]

- USACE. National Inventory of Dams—Interactive Maps & Charts; United States Army Corps of Engineers: Washington, DC, USA, 2019.

- MAC. A Guide to the Management of Tailings Facilities, 3rd ed.; MAC: Ontario, ON, Canada, 2017. [Google Scholar]

- MAC. Developing an Operation, Maintenance and Surveillance Manual for the Post-Closure Management of Tailings Facilities, 2nd ed.; MAC: Ontario, ON, Canada, 2019. [Google Scholar]

- ICOLD. Tailings Dams and Environment Review and Recommendations, 103rd ed.; International Commission on Large Dams: Paris, France, 1996. [Google Scholar]

- ICOLD. Monitoring of Tailings Dams Bulletin 104—Review and Recommendations; International Commission on Large Dams: Paris, France, 1996. [Google Scholar]

- ICOLD. Tailings Dam Design—Technology Update, 181st ed.; International Commission on Large Dams: Paris, France, 2019. [Google Scholar]

- ICOLD. Automated Dam Monitoring Systems—Guidelines and Case Histories Bulletin 118; International Commission on Large Dams: Paris, France, 2000. [Google Scholar]

- ICOLD. Dam Surveillance Guide (Gide de La Surveillance), 158th ed.; International Commission on Large Dams: Paris, France, 2018. [Google Scholar]

- ANCOLD. Guidelines on Tailings Dams Planning, Design, Construction, Operation and Closure; Australian National Committee on Large Dams: Hobart, Australia, 2019. [Google Scholar]

- DRDMW. Dam Safety Management Guideline Version 3; Department of Regional Development, Manufacturing and Water, Queensland Government: Brisbane, Astralia, 2024.

- United Nations Economic Commission for Europe. Safety Guidelines and Good Practices for Tailings Management Facilities; United Nations Economic Commission for Europe: New York, NY, USA; Geneva, Switzerland, 2014. [Google Scholar]

- SABS. SANS 10286 Code of Practice for Mine Residue Deposits; South African Bureau of Standards: Pretoria, South Africa, 1998. [Google Scholar]

- Global Industry Standard on Tailings Management. August 2020. Available online: https://globaltailingsreview.org/global-industry-standard/ (accessed on 4 March 2024).

- Schimmer, R. Pecora 17-The Future of Land Imaging…Going Operational A Remote Sensing and Gis Method for Detecting Land Surface Areas Covered by Copper Mill Tailings; University of Connecticut: Storrs, CT, USA, 2008. [Google Scholar]

- Johnson, A.; Martin, P.; Burkhalter, C.; Lutes, K. New Remote Sensing Systems for Improved Planning and Management of Mine Tailings Storage Facilities. In Proceedings of the Tailings and Mine Waste 2016, Keystone, CO, USA, 2–5 October 2016. [Google Scholar]

- Lumbroso, D.; McElroy, C.; Goff, C.; Collell, M.R.; Petkovsek, G.; Wetton, M. The Potential to Reduce the Risks Posed by Tailings Dams Using Satellite-Based Information. Int. J. Disaster Risk Reduct. 2019, 38, 101209. [Google Scholar] [CrossRef]

- Mainali, G.; Nordlund, E.; Knutsson, S.; Thunehed, H. Tailings Dams Monitoring in Swedish Mines Using Self-Potential and Electrical Resistivity Methods. Electron. J. Geotech. Eng. 2015, 20, 5859–5875. [Google Scholar]

- Li, Q.M.; Wang, Y.H.; Li, G. Tailings Dam Breach Disaster On-Line Monitoring Method and System Realization. Procedia Eng. 2011, 26, 1674–1681. [Google Scholar] [CrossRef]

- Bashir, S.; Atif, J.; Bibi, I.; Niaz, A. Soil and Water Conservation; University of Agriculture: Faisalabad, Pakistan, 2017. [Google Scholar]

- Lupo, J.; Scharnhorst, V.J. Tailings Disposal and Management; Society for Mining, Metallurgy & Exploration: Englewood, CO, USA, 2019. [Google Scholar]

- Nasategay, F. Detection and Monitoring of Tailings Dam Surface Erosion Using UAV and Machine Learning. Master’s Thesis, The University of Nevada, Reno, NY, USA, 2020. [Google Scholar]

- Adriaan Basson, J.; Broekman, A.; Willem Jacobsz, S. TD-DAQ: A Low-Cost Data Acquisition System Monitoring the Unsaturated Pore Pressure Regime in Tailings Dams. HardwareX 2021, 10, 221. [Google Scholar] [CrossRef]

- Dong, L.; Shu, W.; Sun, D.; Li, X.; Zhang, L. Pre-Alarm System Based on Real-Time Monitoring and Numerical Simulation Using Internet of Things and Cloud Computing for Tailings Dam in Mines. IEEE Access 2017, 5, 21080–21089. [Google Scholar] [CrossRef]

- Dong, K.; Yang, D.; Yan, J.; Sheng, J.; Mi, Z.; Lu, X.; Peng, X. Anomaly Identification of Monitoring Data and Safety Evaluation Method of Tailings Dam. Front. Earth Sci. 2022, 10, 1016458. [Google Scholar] [CrossRef]

- Du, Z.; Ge, L.; Ng, A.H.M.; Zhu, Q.; Horgan, F.G.; Zhang, Q. Risk Assessment for Tailings Dams in Brumadinho of Brazil Using InSAR Time Series Approach. Sci. Total Environ. 2020, 717, 137125. [Google Scholar] [CrossRef] [PubMed]

- Duan, H.; Li, Y.; Jiang, H.; Li, Q.; Jiang, W.; Tian, Y.; Zhang, J. Retrospective Monitoring of Slope Failure Event of Tailings Dam Using InSAR Time-Series Observations. Nat. Hazards 2023, 117, 2375–2391. [Google Scholar] [CrossRef]

- Gama, F.F.; Paradella, W.R.; Mura, J.C.; de Oliveira, C.G. Advanced DINSAR Analysis on Dam Stability Monitoring: A Case Study in the Germano Mining Complex (Mariana, Brazil) with SBAS and PSI Techniques. Remote Sens. Appl. Soc. Environ. 2019, 16, 100267. [Google Scholar] [CrossRef]

- Hu, J.; Liu, X. Design and Implementation of Tailings Dam Security Monitoring System. Procedia Eng. 2011, 26, 1914–1921. [Google Scholar] [CrossRef]

- Lumbroso, D.; Collell, M.R.; Petkovsek, G.; Davison, M.; Liu, Y.; Goff, C.; Wetton, M. DAMSAT: An Eye in the Sky for Monitoring Tailings Dams. Mine Water Environ. 2021, 40, 113–127. [Google Scholar] [CrossRef]

- Nie, W.; Luo, M.; Wang, Y.; Li, R. 3D Visualization Monitoring and Early Warning System of a Tailings Dam—Gold Copper Mine Tailings Dam in Zijinshan, Fujian, China. Front. Earth Sci. 2022, 10, 800924. [Google Scholar] [CrossRef]

- Ouellet, S.M.; Dettmer, J.; Olivier, G.; DeWit, T.; Lato, M. Advanced Monitoring of Tailings Dam Performance Using Seismic Noise and Stress Models. Commun. Earth Environ. 2022, 3, 301. [Google Scholar] [CrossRef]

- Rauhala, A.; Tuomela, A.; Davids, C.; Rossi, P.M. UAV Remote Sensing Surveillance of a Mine Tailings Impoundment in Sub-Arctic Conditions. Remote Sens. 2017, 9, 1318. [Google Scholar] [CrossRef]

- Song, D.; Guanjun, W.; Bin, L. Influence of Control Point Number on UAV Low-Altitude Photogrammetry and Its Application: A Case Study in Subsidence Monitoring of a Tailing Dam Area in Northwestern China. Chin. J. Geol. Hazard Control. 2021, 32, 113–120. [Google Scholar] [CrossRef]

- Zwissler, B.; Oommen, T.; Vitton, S.; Seagren, E.A. Thermal Remote Sensing for Moisture Content Monitoring of Mine Tailings: Laboratory Study. Environ. Eng. Geosci. 2017, 23, 299–312. [Google Scholar] [CrossRef]

| Category | Visual Parameters |

|---|---|

| Tailings Surface | Slurry flow rate and density Size and position of the decant ponds Reservoir level and freeboard requirements Tailings transport conditions Beach slopes Persistent vortex (whirlpool) in the reservoir |

| Ancillary Infrastructure | Decant facility integrity and access Cracking in any concrete structure Erosion in roadways and access routes Return water storage capacity and infrastructure Condition of gates, fencing, and signage Pump and pipeline systems condition Vegetation clogging drainage ditches Discharge tunnel or conduit condition, seeps, and cracks |

| Emergency Preparedness | Status of the leak detection system Performance of automatic flow measurement Status of fault alarms |

| Seepage Flow | Trench flow efficiency Density and flow rate of slurry New development or changes in seepage areas The color of seepage water Quantity, location, and clarity of flowing water |

| Instrumentation | Water levels in permanent monitoring stations Condition of monitoring instruments and data reading quality |

| Embankment/Berms | Cracking Bulging at the toe of slope Weeping Piping Sloughing Subsidence at the crest or downstream embankment Sinkholes at upstream face of the dam New vegetation or changes in quantity Surface erosion of any type Wave erosion on the upstream embankment |

| Miscellaneous | Animal burrows |

| Classification | Amount |

|---|---|

| Total Number Contacted | 721 |

| Overall Number of Responders | 341 |

| Responders Declared no TSF | 188 |

| Responders with Full TSF Disclosures | 114 |

| Total Number of Disclosures (Partial Included) | 153 |

| No Response | 183 |

| No Response but No TSF Confirmed | 197 |

| Dam Section | Changes Inspected |

|---|---|

| Downstream face | Seepage water surfacing Cracks, local settlements Erosion (development of gulling) Vegetation Animal burrows |

| Dam crest | Cracks, local settlements Erosion Vegetation Animal burrows Road condition |

| Upstream face (accessible section only) | Vortex formation on the water surface Cracks, local deformations, local slides Bulging of surface sealing elements Damages in the surface sealing element Displacement or riprap Vegetation Animal burrows |

| Author(s) and Year | Article Title | Case Study Location | Monitoring Method | Parameters Monitored | Description of Work | Scale of Study |

|---|---|---|---|---|---|---|

| Adriaan Basson et al., 2021 [38] | TD-DAQ: A Low-Cost Data Acquisition System Monitoring the Unsaturated Pore Pressure Regime in Tailings Dams | South Africa | Hardware TD-DAQ | Negative pore pressure, moisture content, and temperature | This paper describes the construction, experimentation, and verification of a data acquisition system for measurements of the unsaturated pore pressure regime in tailings dams over extended periods of time. The data are saved and delivered in wireless networks. | Full TSF |

| Dong et al., 2017 [39] | Pre-Alarm System Based on Real-Time Monitoring and Numerical Simulation Using Internet of Things and Cloud Computing for Tailings Dam in Mines | China | Piezometers, extensometer, transducer, strain gauge | Hydrostatic pressure, dry beach length, internal deformation, stress monitoring, horizontal displacement | A pre-alarm system for tailings using cloud computing to calculate the limit state equation, phreatic line, and a numerical simulation based on instrumentation data, with output including three pre-alarm levels, safety factors, and reliability scores. | Full TSF |

| Dong et al., 2022 [40] | Anomaly Identification of Monitoring Data and Safety Evaluation Method of Tailings Dam | China | Seepage field | Depth of saturation line | Cloud computing and artificial neural networks (ANNs) were utilized to identify outliers in seepage monitoring data. A real-time safety assessment was performed based on the relationship between the depth of the saturation line and the safety factor. | Full TSF |

| Du et al., 2020 [41] | Risk Assessment for Tailings Dams in Brumadinho of Brazil Using InSAR Time Series Approach | Brazil | InSAR images | Ground displacement | A new method that allows for selecting more accurate pixels from InSAR images to create time series and acquire ground displacement in synthetic and real data in tailings dams. | Full TSF |

| Duan et al., 2023 [42] | Retrospective Monitoring of Slope Failure Event of Tailings Dam Using InSAR Time-Series Observations | China | InSAR time series | Deformation rates | The surface deformation map of the tailings dam before a failure event was obtained using the InSAR time-series method. A GPU-assisted InSAR processing method was applied to 91 images from 2019 to 2022. Rainfall was found to significantly influence tailings pond deformation, with a delayed peak deformation rate of about one month compared to the maximum rainfall. | Full TSF |

| Gama et al., 2019 [43] | Advanced DINSAR Analysis on Dam Stability Monitoring: A Case Study in Germano Mining Complex (Mariana, Brazil) with SBAS and PSI Techniques | Brazil | Advanced differential SAR interferometry | Deformation | The feasibility of a satellite imaging system in tailings dam monitoring was studied. The SBAS technique showed the best deformation detection capability. The use of satellite data provided a cheaper rate compared to the installation of full ground movement equipment, especially for small companies located in developing countries. | Full TSF |

| Hu & Liu, 2011 [44] | Design and Implementation of Tailings Dam Security Monitoring Systems | China | Sensors, GPS, video surveillance | Saturation line, water level, internal horizontal and vertical displacements, and surface displacement | The authors created a software to automate streamlining data acquisition, presentation, and alert systems. One shortcoming of their research is the lack of result analysis to see the accuracy of these data compared to manual data. | Full TSF |

| Jeong & Kim, 2020 [11] | A Case Study: Determination of the Optimal Tailings Beach Distance as a Guideline for Safe Water Management in an Upstream TSF | USA | UAV | Beach distance | A digital model was created using drone data. This study found an optimal safe beach distance to maintain the factor of safety requirements (FoS = 2.0). The model is valid for the geometry it is created for, hence constant updates are required. | Full TSF in a computer simulation |

| Li et al., 2011 [34] | Tailings Dam Breach Disaster On-Line Monitoring Method and System Realization | China | GPS, vibrating wire sensors | Displacement and saturation line | This study proposed a method of creating an on-line monitoring system using GPS to detect displacement and vibrating wire sensors to find the saturation line. The data were gathered in situ through ground instruments and transferred as an optical signal to the data monitoring and alert center. No numerical results were given since this was a proposed method only. | Full TSF |

| Lumbroso et al., 2021 [45] | DAMSAT: An Eye in the Sky for Monitoring Tailings Dams | Peru | InSAR, GNSS | Ground displacement | A new system that uses earth observation technology for modules of visualization, movement detection, hydrometeorological forecasting, emergency planning, and leaching detection. | Full TSF |

| Lumbroso et al., 2019 [32] | The Potential to Reduce Risk Posed by Tailings Dams Using Satellite-Based Information | Peru | Satellite information | Displacement, deformation | The need for a low-cost and efficient monitoring system for developing countries and small mining operations drove the development of this system. Software using satellite images for tailings dam monitoring was presented, which was in testing stages at mines in Peru with acceptable performance. | Full TSF |

| Mainali et al., 2015 [33] | Tailings Dam Monitoring in Swedish Mines Using Self-Potential and Electrical Resistivity Methods | Sweden | Geoelectrical: self-potential (SP), electrical resistivity | Seepage on wall | Geophysical methods were used for tailings dam monitoring. These methods showed great success in detecting potential seepage in embankments. | Full TSF |

| Nie et al., 2022 [46] | 3D Visualization Monitoring and Early Warning System of a Tailings Dam | China | GIS | Phreatic line changes | Geographic Information System (GIS) and autoregressive integrated moving average model were utilized to predict deformation and phreatic line changes in the tailings dam. | Full TSF |

| Ouellet et al., 2022 [47] | Advanced Monitoring of Tailings Dam Performance Using Seismic Noise and Stress Models | Canada | Geophones array | Soil stiffness | Ambient noise interferometry (ANI) was utilized to monitor performance of an active tailings dam, combining it with recordings of pond levels and shear wave velocity profiles. Fluctuations in seismic velocity were found to be strongly associated with changes in water levels in a nearby tailings dam. | Full TSF |

| Rauhala et al., 2017 [48] | UAV Remote Sensing Surveillance of a Mine Tailings Impoundment in Sub-Arctic Conditions | Finland | UAV | Surface displacement | Four measurement campaigns were performed in a sub-Arctic environment when the mine was temporarily inactive during the summer. Stable areas around the perimeter were used as ground control points. Detected displacements were related to a combination of tailings settlement, erosion, and possible consolidation of an underlying peat layer. | Full TSF |

| Slingerland et al., 2018 [12] | Identification and Quantification of Erosion on a Sand Tailings Dam | Canada | LiDAR, aerial photos | Erosion | The objectives were to investigate the tailings erodibility of the site, obtain a better understanding of future design based on the current state, and test the possibility of sourcing LiDAR and aerial photos to identify and quantify erosion signs after reclamation. An in situ assessment was performed on rills and gullies appearance on site. The study showed that both water and wind erosion were present. The authors evaluated the applicability of LiDAR and aerial photography models to identify, classify, quantify, and determine the causes of erosion. The digital stereo aerial photography was found to be superior in most assessments but limited when quantifying erosion. | Full TSF |

| Song et al., 2021 [49] | Influence of Control Point Number on UAV Low-Altitude Photogrammetry and its Application | China | Photogrammetry | Surface subsidence | A surface subsidence map of the tailings dam was obtained using a high-precision mapping method based on low-altitude aerial photogrammetry. To analyze the subsidence of the study area, the elevation differences values of corresponding points from the digital elevation model were extracted. | Full TSF |

| Zwissler et al., 2017 [50] | Thermal Remote Sensing for Moisture Content Monitoring of Mine Tailings: Laboratory Study | USA | Thermal remote sensor | Moisture content | Variables measured are mass, penetration depth, spectral reflectance, atmospheric temperature, humidity, and thermal emissivity. The recorded gravimetric moisture content and penetration depth plot show an exponential relationship with a different coefficient for each site. Regression models were created where sample temperature and atmospheric humidity were found to be the most significant parameters. | Laboratory-scale tests |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zare, M.; Nasategay, F.; Gomez, J.A.; Moayedi Far, A.; Sattarvand, J. A Review of Tailings Dam Safety Monitoring Guidelines and Systems. Minerals 2024, 14, 551. https://doi.org/10.3390/min14060551

Zare M, Nasategay F, Gomez JA, Moayedi Far A, Sattarvand J. A Review of Tailings Dam Safety Monitoring Guidelines and Systems. Minerals. 2024; 14(6):551. https://doi.org/10.3390/min14060551

Chicago/Turabian StyleZare, Masoud, Florida Nasategay, Jose A. Gomez, Arsham Moayedi Far, and Javad Sattarvand. 2024. "A Review of Tailings Dam Safety Monitoring Guidelines and Systems" Minerals 14, no. 6: 551. https://doi.org/10.3390/min14060551

APA StyleZare, M., Nasategay, F., Gomez, J. A., Moayedi Far, A., & Sattarvand, J. (2024). A Review of Tailings Dam Safety Monitoring Guidelines and Systems. Minerals, 14(6), 551. https://doi.org/10.3390/min14060551