Treatment of Waters Having Different Ionic Composition and pH with Natural Zeolites from Bulgaria

Abstract

1. Introduction

2. Materials and Methods

| Sample Name | Sample Type | Place of Sampling and Description |

|---|---|---|

| BP | Zeolitized tuff (cream-white color) | Samples were collected from the Beli Plast quarry, located to the north of Beli Plast village, 20 km N-NE away from Kardzhali town (Figure 1). The clinoptilolitized pyroclastics belong to the first Early Oligocene acid phase. The samples (~8 kg) were provided by the chief geologist of the quarry operated by Imerys Minerals Bulgaria JSC. |

| GB | Zeolitized tuff (pale green color) | Samples (~7 kg) were collected from an outcrop located 750 m southeast of the Golobradovo village, 45 km E away from Kardzhali town (Figure 1). The clinoptilolitized pyroclastics belong to the first Early Oligocene acid phase. |

| dw | Ultrapure water | Produced by Thermo ScientificTM BarnsteadTM Smart2PureTM water purification system. |

| tw | Tap/drinking water | Drinking water supplied from the Iskar reservoir, Sofia. |

| mw | Mineral water | Mineral water from springs in the SW area of Sofia with a temperature of 19 °C. Its lithology is related to Late Cretaceous andesitic rocks [42,43]. |

| zmw | Spring water | Spring water, known as “zeolite” water, is water from a borehole with a depth of 170 m, located 500 m NW from the Beli Plast zeolitized tuff quarry. The source lithology is presumed to be Eocene-Early Oligocene volcanic and pyroclastic rocks [44]. |

| trn1w | Mine water | Water taken from the mining area of Troyanovo North mine, Maritsa East, lignite basin. It is formed by precipitation (rain, snow) draining into ditches and other low areas in the open-pit mine and interacts with the organic and mineral matter (coal and clay partings). |

| BPdw | Water leachate | Water leachate produced by the treatment of ultrapure water with Beli Plast zeolitized tuffs. |

| GBdw | Water leachate | Water leachate produced by the treatment of ultrapure water with Golobradovo zeolitized tuffs. |

| BPtw | Water leachate | Water leachate produced by the treatment of tap water with Beli Plast zeolitized tuffs. |

| BPmw | Water leachate | Water leachate produced by the treatment of mineral spring water from the SW area of Sofia with Beli Plast zeolitized tuffs. |

| BPtrn1w | Water leachate | Water leachate produced by the treatment of mine water from the Maritsa East lignite basin with Beli Plast zeolitized tuffs. |

| GBtrn1w | Water leachate | Water leachate produced by the treatment of mine water from the Maritsa East lignite basin with Golobradovo zeolitized tuffs. |

3. Results

3.1. Mineralogy

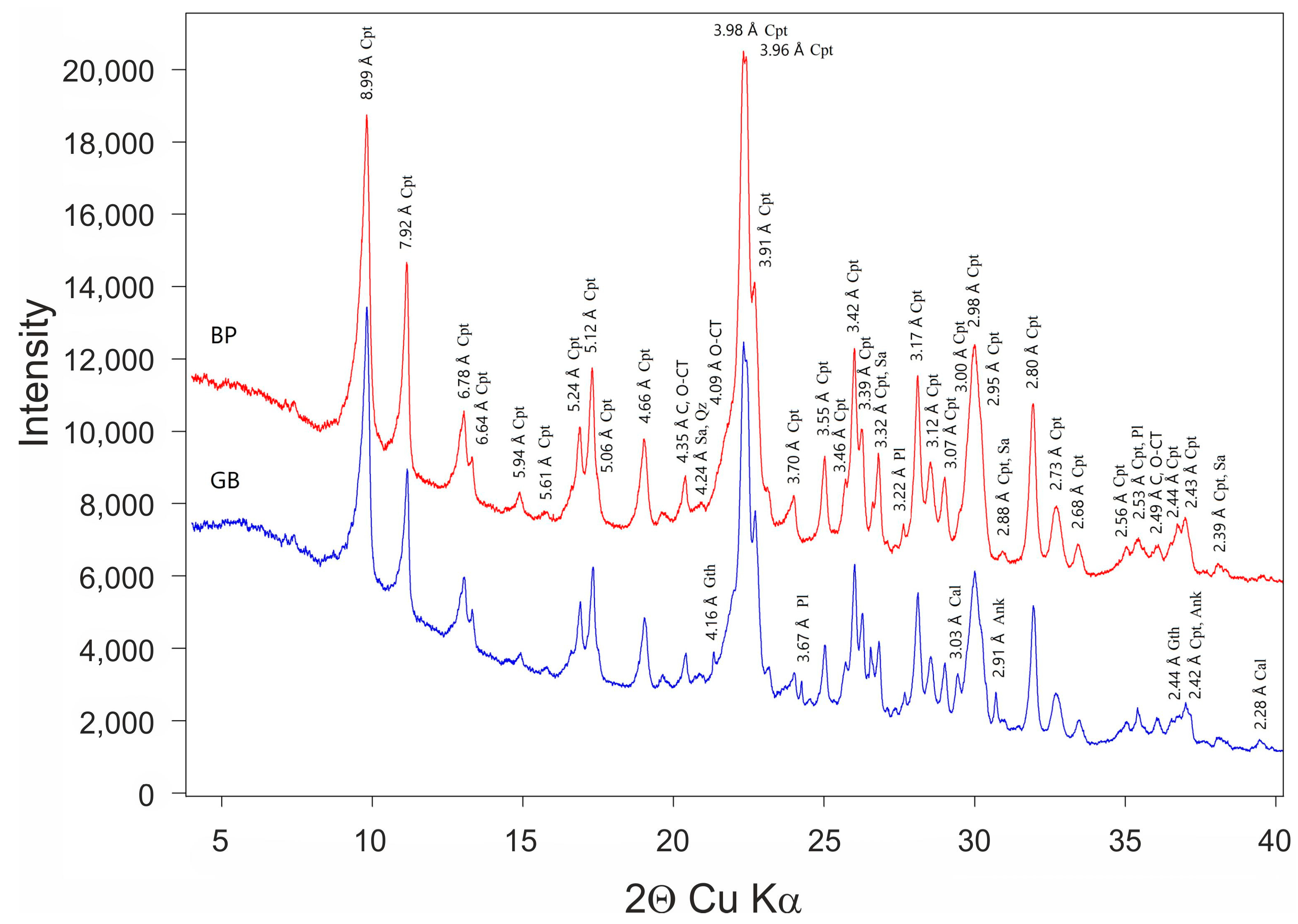

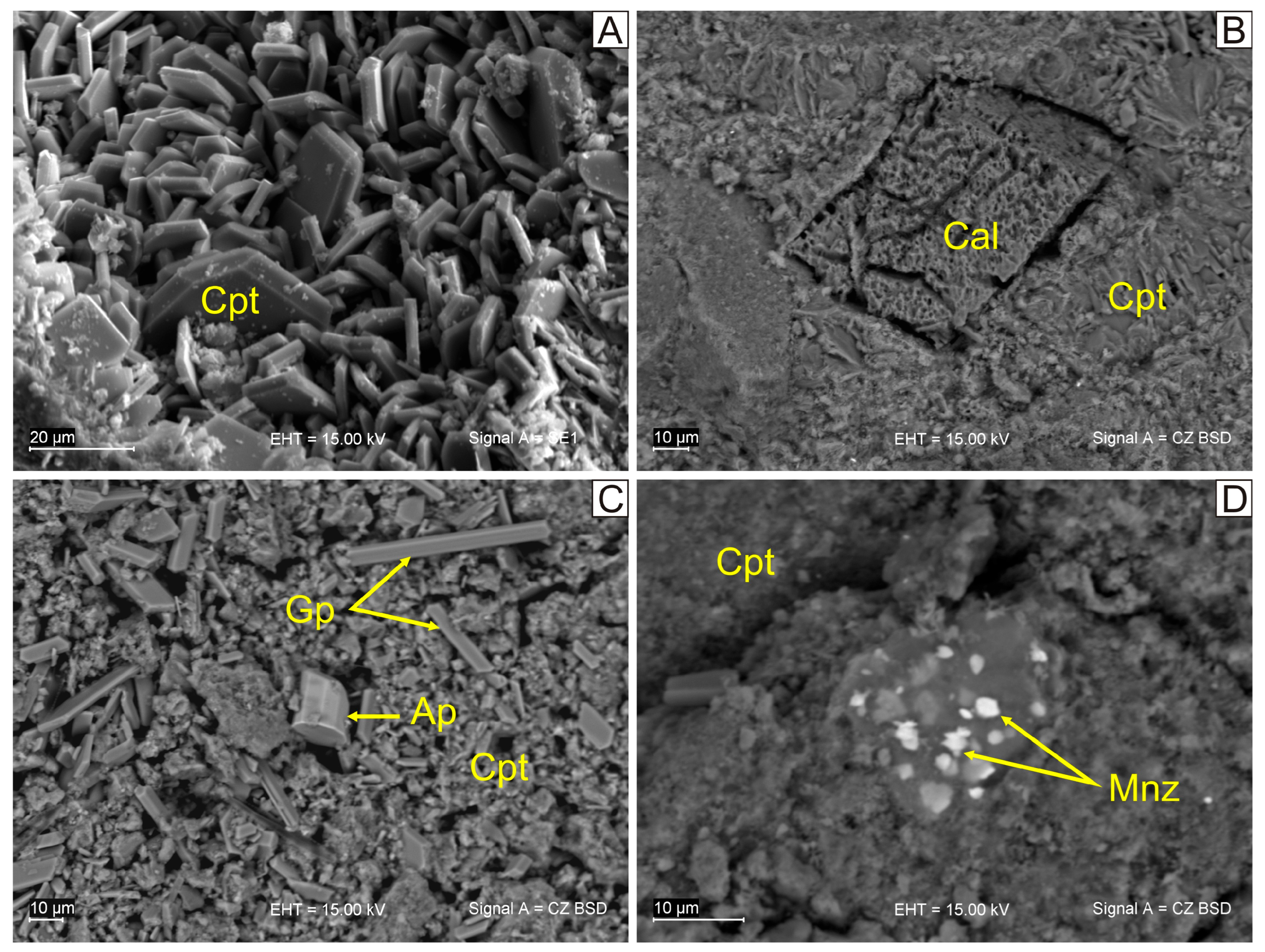

3.1.1. Mineral Composition of Zeolitized Tuffs

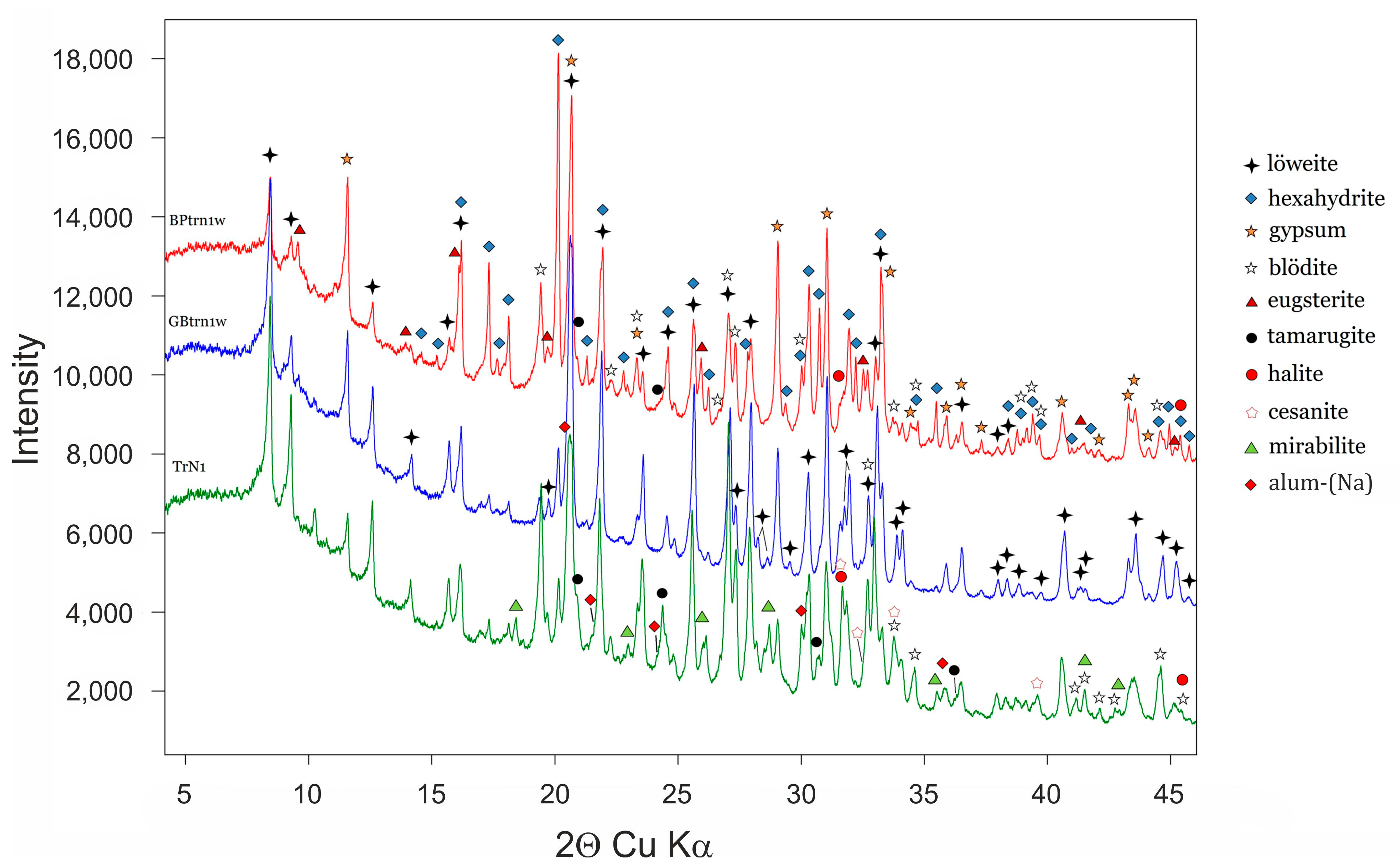

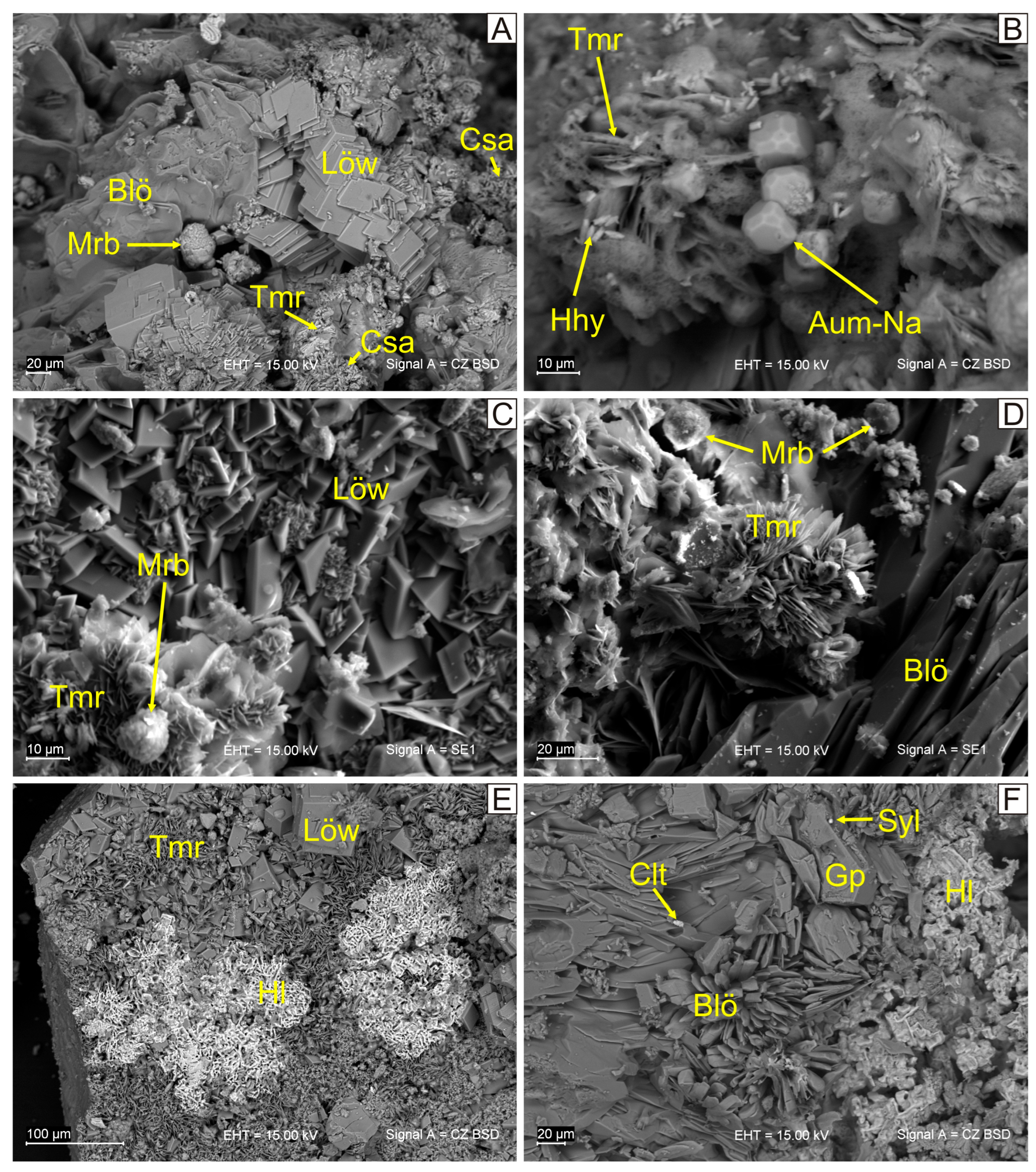

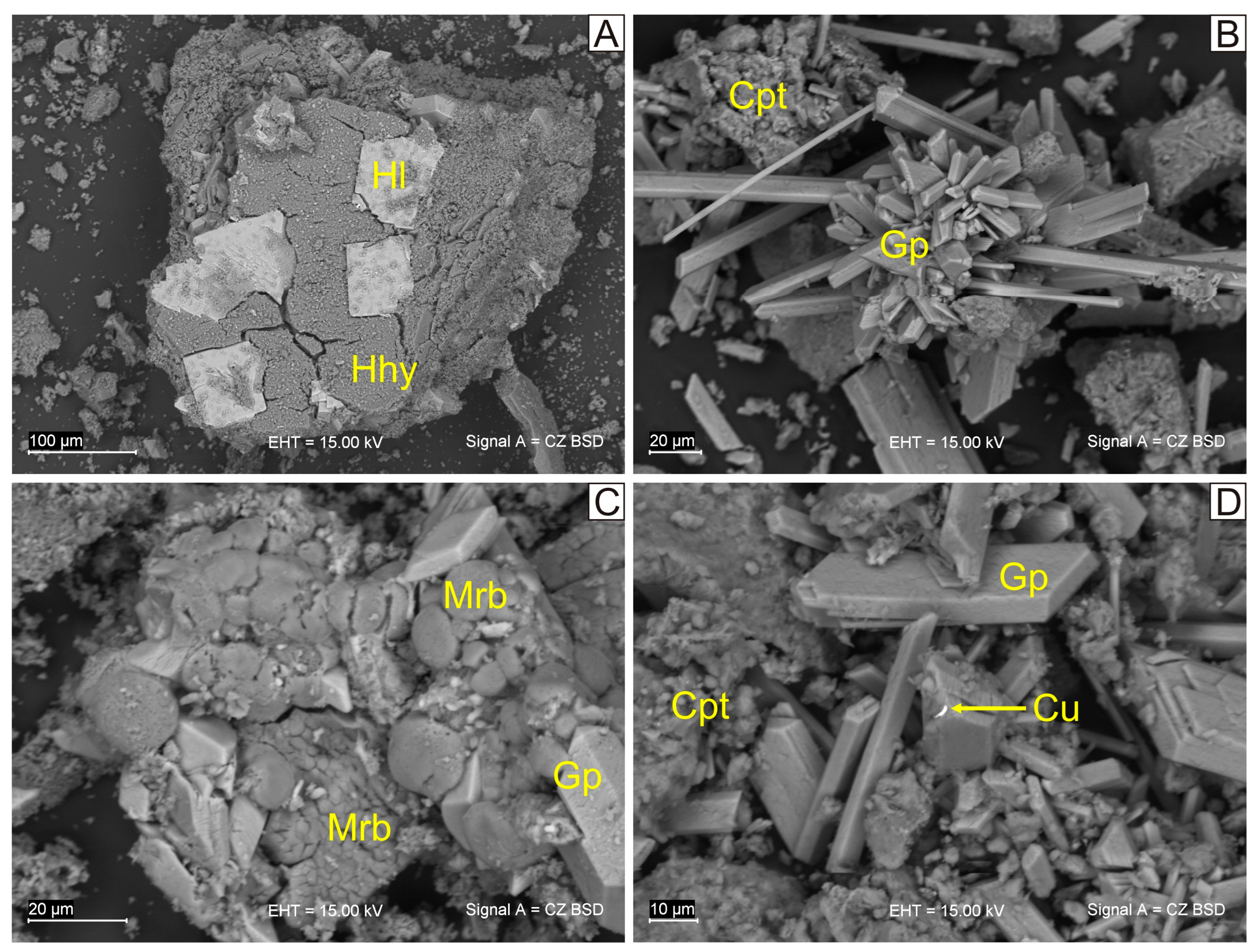

3.1.2. Mineral Composition of Dry Residues

3.2. Geochemistry

3.2.1. Chemical Composition of Zeolitized Tuffs

3.2.2. Chemical Composition of Waters Used for Treatment

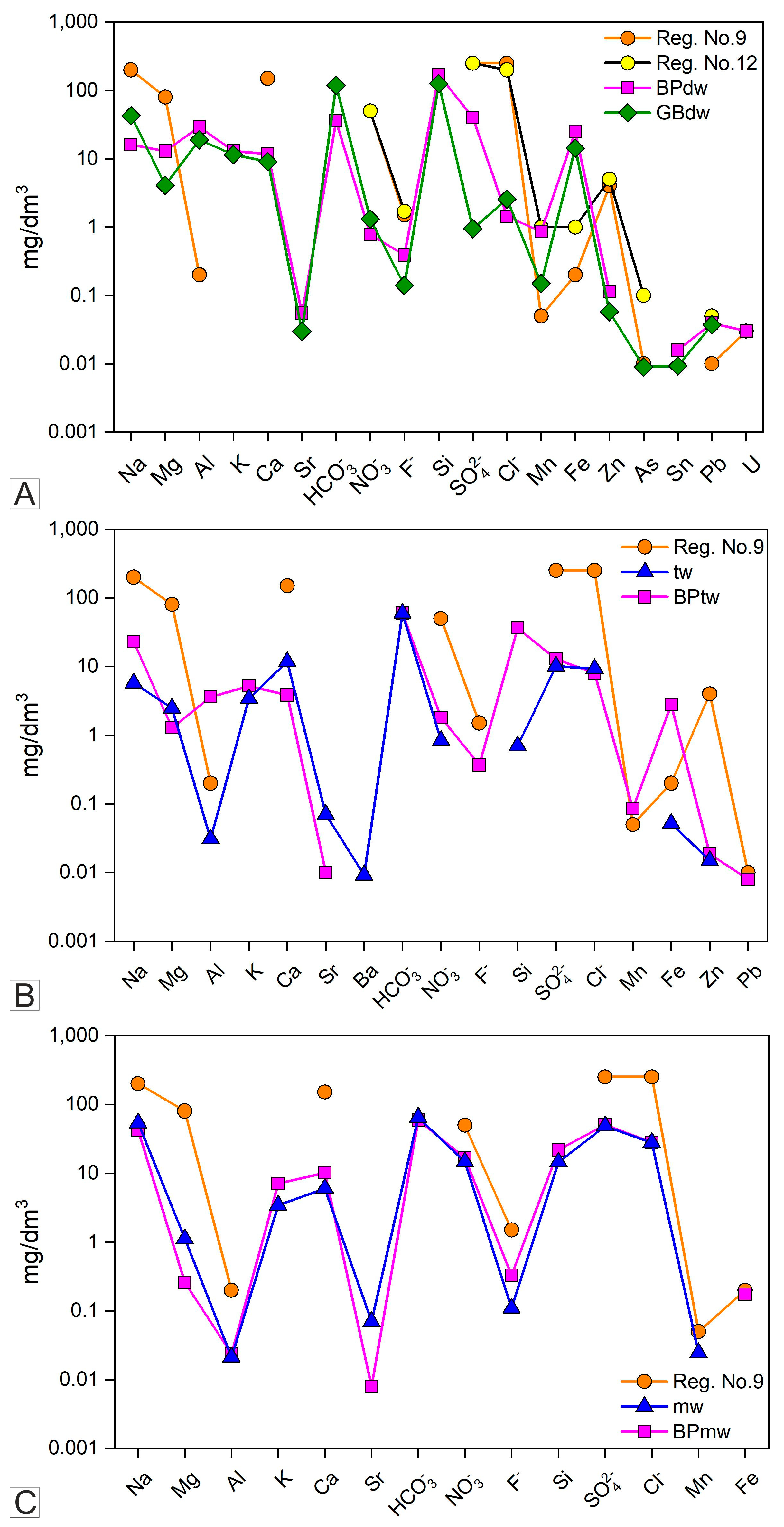

3.2.3. Chemical Composition of Water Leachates (Treated Waters)

4. Discussion

4.1. Natural Zeolites as Desorbents in Ultrapure Water

4.2. Natural Zeolites as Sorbents for Drinking Water Purification and Quality Improvement at Home

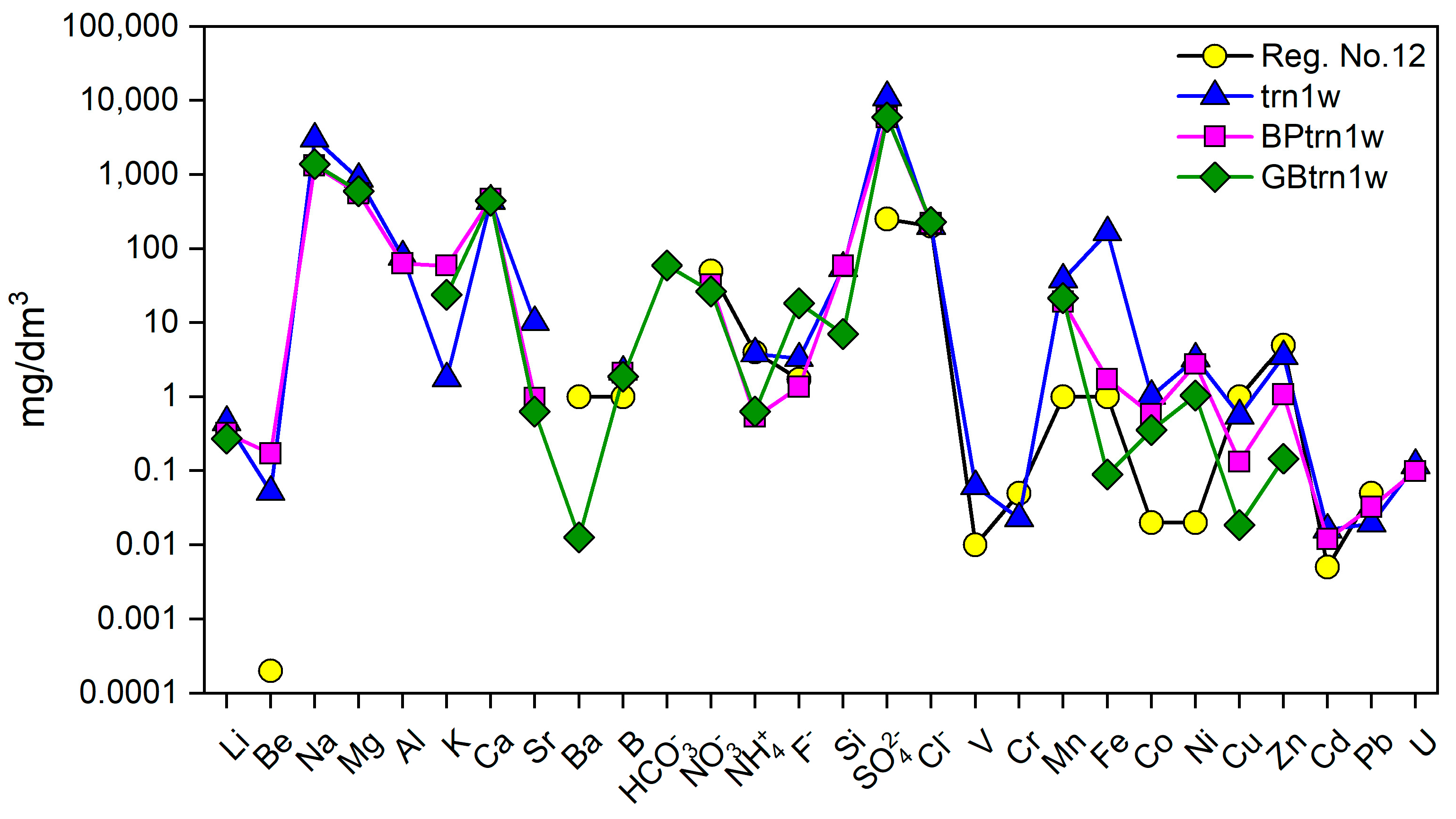

4.3. Natural Zeolites for Coal Mine Water Treatment

4.4. Ion Incorporation in Newly Formed Minerals

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bish, D.L.; Ming, D.W. Natural Zeolites: Occurrence, Properties, Applications; Review in Mineralogy and Geochemistry; Mineralogical Society of America, Walter de Gruyter GmbH & Co KG: Washington, DC, USA, 2001; Volume 45, 654p. [Google Scholar]

- Corma, A.; Martinez, A. Zeolites in refining and petrochemistry. Stud. Surf. Sci. Catal. 2005, 157, 337–366. [Google Scholar] [CrossRef]

- Yeritsyan, H.; Sahakyan, A.; Harutyunyan, V.; Nikoghosyan, S.; Hakhverdyan, E.; Grigoryan, N.; Hovhannisyan, A.; Atoyan, V.; Keheyan, Y.; Rhodes, C. Radiation-modified natural zeolites for cleaning liquid nuclear waste (irradiation against radioactivity). Sci. Rep. 2013, 3, 2900. [Google Scholar] [CrossRef]

- Colella, C. A critical reconsideration of biomedical and veterinary applications of natural zeolites. Clay Miner. 2011, 46, 295–309. [Google Scholar] [CrossRef]

- Camacho, L.M.; Deng, S.; Parra, R.R. Uranium removal from groundwater by natural clinoptilolite zeolite: Effect of pH and initial feed concentration. J. Hazard. Mater. 2010, 175, 393–398. [Google Scholar] [CrossRef]

- Dyer, A.; Hriljac, J.; Evans, N.; Stokes, I.; Rand, P.; Kellet, S.; Harjula, R.; Moller, T.; Maher, Z.; Heatlie-Branson, R.; et al. The use of columns of the zeolite clinoptilolite in the remediation of aqueous nuclear waste streams. J. Radioanal. Nucl. Chem. 2018, 318, 2473–2491. [Google Scholar] [CrossRef]

- Ahuja, S. (Ed.) Chemistry and Water: The Science behind Sustaining the World’s Most Crucial Resource; Elsevier: Amsterdam, The Netherlands, 2017; 670p. [Google Scholar] [CrossRef]

- Abu Shmeis, R.M. Water chemistry and microbiology. Compr. Anal. Chem. 2018, 81, 1–56. [Google Scholar] [CrossRef]

- Yargeau, V. 17-Water and wastewater treatment: Chemical processes. In Metropolitan Sustainability: Understanding and Improving the Urban Environment; Zeman, F., Ed.; Woodhead Publishing: Sawston, UK, 2012; pp. 390–405. [Google Scholar] [CrossRef]

- Kallo, D. Applications of natural zeolites in water and wastewater treatment. Rev. Mineral. Geochem. 2001, 45, 519–550. [Google Scholar] [CrossRef]

- Chen, X.; Yu, L.; Zou, S.; Xiao, L.; Fan, J. Zeolite cotton in tube: A simple robust household water treatment filter for heavy metal removal. Sci. Rep. 2020, 10, 4719. [Google Scholar] [CrossRef]

- Mohapatra, M.; Anand, S.; Mishra, B.K.; Giles, D.; Singh, P. Review of fluoride removal from drinking water. J. Environ. Manag. 2009, 91, 67–77. [Google Scholar] [CrossRef]

- Ebsa, D.G. Defluoridation of drinking water by modified natural zeolite with cationic surfactant, in the case of Ziway town, Ethiopia. Clean. Eng. Technol. 2023, 12, 100596. [Google Scholar] [CrossRef]

- Tankersley, K.B.; Dunning, N.P.; Carr, C.; Lentz, D.; Scarborough, V.I. Zeolite water purification at Tikal, an ancient Maya city in Guatemala. Sci. Rep. 2020, 10, 18021. [Google Scholar] [CrossRef]

- The European Commission, Commission Implementing Regulation (EU) No 651/2013 of 9 July 2013 Concerning the Authorization of Clinoptilolite of Sedimentary Origin as a Feed Additive for All Animal Species and Amending Regulation (EC) No 1810/2005, Official J of the EU, 1–3. Available online: https://eur-lex.europa.eu/eli/reg_impl/2013/651/oj (accessed on 10 December 2023).

- The European Commission, Commission Regulation (EU) No 744/2012 of 16 August 2012 amending Annexes I and II to Directive 2002/32/EC of the European Parliament and of the Council as Regards Maximum Levels for Arsenic, Fluorine, Lead, Mercury, Endosulfan, Dioxins, Ambrosia spp., Diclazuril and Lasalocid A Sodium and Action Thresholds for Dioxins. Official J of the EU, 1–8. Available online: https://eur-lex.europa.eu/eli/reg/2012/744/oj (accessed on 10 December 2023).

- Aleksiev, B. Clinoptilolite des Rhodopes du nordest. C. R. Acad. Bulg. Sci. 1968, 21, 1093–1095. [Google Scholar]

- Kirov, G. Zeolites in sedimentary rocks from Bulgaria. Ann. Univ. Sofia Fac. Géol. Géogr. 1974, 66, 171–184, (In Bulgarian with an English abstract). [Google Scholar]

- Aleksiev, B.; Djourova, E.G. On the origin of zeolite rocks. C. R. Acad. Bulg. Sci. 1975, 28, 517–520. [Google Scholar]

- Aleksiev, B.; Djourova, E.G. Zeolitic rocks in the area between the villages Golobradovo and Moriantzi. Ann. Univ. Sofia, Fac. Géol. Géogr. 1982, 76, 3–15, (In Bulgarian with an English abstract). [Google Scholar]

- Djourova, E.; Aleksiev, B. Zeolitic rocks deposits of economic value in North-Eastern Rhodopes. Ann. Univ. Sofia, Fac. Géol. Géogr. 1984, 78, 256–263, (in Bulgarian with an English abstract). [Google Scholar]

- Raynov, N.; Popov, N.; Yanev, Y.; Petrova, P.; Popova, T.; Hristova, V.; Atanasova, R.; Zankarska, R. Geological, mineralogical and technological characteristics of zeolitized (clinoptilolitized) tuff deposits in the Eastern Rhodopes, Bulgaria. In Natural Zeolites—Sofia’95; Kirov, G., Filizova, L., Petrov, O., Eds.; Pensoft Publishers Sofia: Moscow, Russia, 1997; pp. 263–275. [Google Scholar]

- Yanev, Y.; Innocenti, F.; Manetti, P.; Serri, G. Upper Eocene-Oligocene collision-related volcanism in Eastern Rhodopes (Bulgaria)–Western Thrace (Greece): Petrogenetic affinity and geodynamic significance. Acta Vulcanol. 1998, 10, 279–291. [Google Scholar]

- Yanev, Y. Petrology of the Eastern Rhodopes Paleogene acid volcanics, Bulgaria. Acta Vulcanol. 1998, 10, 265–278. [Google Scholar]

- Marchev, P.; Raicheva, R.; Filipov, P.; Jicha, B.; Spikings, R.; Ivanova, R.; Bachmann, O.; Guillong, M.; Okay, A. 40Ar/39Ar and U-Pb age correlations of the large Rupelian Rhodope Massif eruptions with airfall tuffs in SE, S and Central Europe. Rev. Bulg. Geol. Soc. 2023, 84, 117–120. [Google Scholar] [CrossRef]

- Yanev, Y.; Cochemé, J.-J.; Ivanova, R.; Grauby, O.; Burlet, E.; Pravchanska, R. Zeolites and zeolitization of acid pyroclastic rocks from paroxysmal Paleogene volcanism, Eastern Rhodopes, Bulgaria. N. Jb. Miner. Abh. 2006, 182, 265–283. [Google Scholar] [CrossRef]

- Kirov, G.; Šamajova, E.; Nedialkov, R.; Stanimirova, T. Alteration processes and products of acid pyroclastic rocks in Bulgaria and Slovakia. Clay Miner. 2011, 46, 279–294. [Google Scholar] [CrossRef]

- Ivanova, R.; Dimitrova, D.; Sergeeva, I.; Yossifova, M.; Vlahov, A. Trace element geochemistry of altered pyroclastic deposits from the Eastern Rhodopes (SE Bulgaria). Rev. Bulg. Geol. Soc. 2023, 84, 109–112. [Google Scholar] [CrossRef]

- Tzvetanova, Y.; Tacheva, E.; Dimowa, L.; Tsvetanova, L.; Nikolov, A. Trace elements in the clinoptilolite tuffs from four Bulgarian deposits, Eastern Rhodopes. Rev. Bulg. Geol. Soc. 2023, 84, 51–55. [Google Scholar] [CrossRef]

- Petrov, O.E.; Karamaneva, T.A.; Kirov, G.N. Cation distribution in clinoptilolite structure: Natural samples. C. R. Acad. Bulg. Sci. 1984, 37, 785–788. [Google Scholar]

- Dimowa, L.; Petrova, N.; Tzvetanova, Y.; Petrov, O.; Piroeva, I. Structural features and thermal behavior of ion-exchanged clinoptilolite from Beli Plast deposit (Bulgaria). Minerals 2022, 12, 1576. [Google Scholar] [CrossRef]

- Popov, N.; Popova, Y.; Rubio, J.; Taffarel, S.R. Use of natural and modified zeolites from Bulgarian and Chilian deposits to improve adsorption of heavy metals from aqueous solutions. Geochem. Mineral. Petrol. 2012, 49, 83–93. [Google Scholar]

- Lilkov, V.; Rostovsky, I.; Petrov, O. Physical and mechanical characteristics of cement mortars and concretes with addition of clinoptilolite from Beli Plast deposit (Bulgaria), silica fume and fly ash. Clay Miner. 2011, 46, 213–223. [Google Scholar] [CrossRef]

- Filcheva, E.; Chakalov, K. Soil fertility management with zeolite amendments. I. Effect of zeolite on the carbon sequestration. A Review. In Agricultural Practices and Policies for Carbon Sequestration in Soil; Kimble, J., Lal, R., Follet, R., Eds.; Lewis Publishers, CRC Press LLC: Boca Raton, FL, USA, 2002; Chapter 20; pp. 223–228. [Google Scholar]

- Chakalov, K.; Popova, T.; Filcheva, E. Soil fertility management with zeolite amendments. II. Zeolite effect on the maintaining the soil Eh. In Agricultural Practices and Policies for Carbon Sequestration in Soil; Kimble, J., Lal, R., Follet, R., Eds.; Lewis Publishers, CRC Press LLC: Boca Raton, FL, USA, 2002; Chapter 21; pp. 229–235. [Google Scholar]

- Beltcheva, M.; Metcheva, R.; Topashka-Ancheva, M.; Popov, N.; Teodorova, S.; Heredia-Rojas, J.A.; Rodriguez de la Fuente, A.O.; Rodríguez-Flores, L.E. Zeolites versus lead toxicity. J. Bioequiv. Availab. 2014, 6, 223–240. [Google Scholar] [CrossRef]

- Topashka-Ancheva, M.; Beltcheva, M.; Metcheva, R.; Heredia-Rojas, J.A.; Rodriguez de la Fuente, A.O.; Gerasimova, T.; Rodríguez-Flores, L.E.; Teodorova, S. Modified natural clinoptilolite detoxifies small mammal’s organism loaded with lead II. Genetic, cell, and physiological effects. Biol. Trace Elem. Res. 2012, 147, 206–216. [Google Scholar] [CrossRef]

- Nikolov, A.; Rostovsky, I.; Nugteren, H. Geopolymer materials based on natural zeolite. Case Stud. Constr. Mater. 2017, 6, 198–205. [Google Scholar] [CrossRef]

- Lihareva, N.; Dimowa, L.; Petrov, O.; Tzvetanova, Y. Evaluation of Bulgarian clinoptilolite as ion-exchanger for Cs+ removal from water solutions. J. Radioanal. Nucl. Chem. 2018, 316, 37–47. [Google Scholar] [CrossRef]

- Match!–Phase Analysis using Powder Diffraction, Crystal Impact–Dr. H. Putz & Dr. K. Brandenburg GbR, Kreuzherrenstr. 102, 53227 Bonn, Germany. Available online: https://www.crystalimpact.de/match (accessed on 10 December 2023).

- Guillong, M.; Meier, D.L.; Allan, M.M.; Heinrich, C.A.; Yardley, B.W.D. Appendix A6: SILLS: A MATLAB-based program for the reduction of laser ablation ICP-MS data of homogeneous materials and inclusions. In Laser Ablation ICP–MS in the Earth Sciences: Current Practices and Outstanding Issues; Sylvester, P., Ed.; Short Course 40; Mineralogical Association of Canada: Vancouver, BC, Canada, 2008; pp. 328–333. [Google Scholar]

- Petrov, P.; Martinov, S.; Limonadov, K.; Straka, Y. Hydrogeological Study on Mineral Waters in Bulgaria; Tehnika: Sofia, Bulgaria, 1970; 196p. [Google Scholar]

- Hristov, V.; Valtchev, S.; Trayanova, M.; Atanassova, R.; Benderev, A. Mineral water bottling in Bulgaria. Geol. Balc. 2023, 52, 53–64. [Google Scholar] [CrossRef]

- Yordanov, B.; Sarov, S.; Georgiev, S.; Valkov, V.; Balkanska, E.; Grozdev, V.; Marinova, R.; Markov, N. Explanatory Note to the Geological Map of the Republic of Bulgaria Scale 1:50000 Map Sheet K-35-75-G (Nikolovo); Ministry of Environment and Water: Sofia, Bulgaria, 2008; pp. 1–92. [Google Scholar]

- Rudnick, R.L.; Gao, S. Composition of the continental crust. In Treatise on Geochemistry, 2nd ed.; Holland, H.D., Turekian, K.K., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 1–64. [Google Scholar]

- Taylor, S.R.; McLennan, S.M. The Continental Crust: Its Composition and Evolution; Blackwell: Oxford, UK, 1985; 312p. [Google Scholar]

- Ministry of Health; Ministry of Development and Public Works; Ministry of Environment and Water. Regulation No. 9/16.03.2001 on the quality of water intended for human consumption. State Gaz. 2014, 102, 44–51. (In Bulgarian) [Google Scholar]

- Ministry of Health; Ministry of Development and Public Works; Ministry of Environment and Water. Regulation No. 12/18.06.2002 on quality requirements of surface water intended for drinking and household water supply. State Gaz. 2002, 63, 42–51. (In Bulgarian) [Google Scholar]

- Bowen, H.J.M. Trace Elements in Biochemistry; Academic Press: Cambridge, MA, USA, 1966; 241p. [Google Scholar]

- Djurova, E.; Stefanova, I.; Gradev, G. Geological, mineralogical and ion exchange characteristics of zeolite rocks from Bulgaria. J. Radioanal. Nucl. Chem. 1989, 130, 425–432. [Google Scholar] [CrossRef]

- Yossifova, M.; Dimitrova, D.; Ivanova, R.; Tzvetanova, Y.; Lyutov, G.; Sergeeva, I. Mineral and chemical composition of selected clinoptilolite tuffs and migration of elements in acidic aqueous media. C. R. Acad. Bulg. Sci. 2021, 74, 1012–1023. [Google Scholar] [CrossRef]

- Margeta, K.; Zabukovec Logar, N.; Šiljeg, M.; Farkaš, A. Natural zeolites in water treatment—How effective is their use. In Water Treatment; Elshorbagy, W., Chowdhury, R., Eds.; IntechOpen: Rijeka, Croatia, 2013; pp. 81–112. [Google Scholar] [CrossRef]

- Rožić, M.; Cerjan-Stefanović, Š.; Kurajica, S.; Rožmarić Maěefat, M.; Margeta, K.; Farkaš, A. Decationization and dealumination of clinoptilolite tuff and ammonium exchange on acid-modified tuff. J. Colloid Interface Sci. 2005, 284, 48–56. [Google Scholar] [CrossRef] [PubMed]

- Groen, J.C.; Mouljin, J.A.; Pérez-Ramírez, J. Desilication: On the controlled generation of mesoporosity in MFI zeolites. J. Mater. Chem. 2006, 16, 2121–2131. [Google Scholar] [CrossRef]

- Silaghi, M.-C.; Chizallet, C.; Raybaud, P. Challenges on molecular aspects of dealumination and desilication of zeolites. Microporous Mesoporous Mater. 2014, 191, 82–96. [Google Scholar] [CrossRef]

- Wojciechowska, K. The influence of desilication/dealumination processes on the physicochemical properties of clinoptilolite. Clay Miner. 2019, 54, 111–119. [Google Scholar] [CrossRef]

- Perelman, A.I. Geochemistry, 2nd ed.; Vysshaya Shkola: Moscow, Russia, 1989; 528p. [Google Scholar]

- Ilieva, A.; Mihailova, B.; Tsintsov, Z.; Petrov, O. Structural state of microcrystalline opals: A Raman spectroscopic study. Am. Mineral. 2007, 92, 1325–1333. [Google Scholar] [CrossRef]

- Marchev, P. Personal Communication; Geological Institute, Bulgarian Academy of Sciences: Sofia, Bulgaria, 2024. [Google Scholar]

- Pulido, A.; Corma, A.; Sastre, G. Computational study of location and role of fluoride in zeolite structures. J. Phys. Chem. B 2006, 110, 23951–23961. [Google Scholar] [CrossRef] [PubMed]

- Fischer, M. Fluoride anions in all-silica zeolites: Studying preferred fluoride sites and dynamic disorder with density functional theory calculations. J. Phys. Chem. C 2021, 125, 8825–8839. [Google Scholar] [CrossRef]

- Ivanova, R.; Popov, N.; Yanev, Y.; Popova, T.; Machiels, L. Mineralogy of zeolitized pyroclastics from Golobradovo deposit, (East Rhodopes) and their application for industrial waste water treatment. In Proceedings of the Zeolite 2010—8th International Conference of the Occurrence Properties, and Utilization of Natural Zeolites, Sofia, Bulgaria, 10–18 July 2010; pp. 115–116. [Google Scholar]

- Filippidis, A.; Kantiranis, N. Experimental neutralization of lake and stream water from N. Greece using domestic HEU-type rich natural zeolitic material. Desalination 2007, 213, 47–55. [Google Scholar] [CrossRef]

- Cincotti, A.; Mameli, A.; Locci, A.M.; Orru, R.; Cao, G. Heavy Metals Uptake by Sardinian Natural Zeolites: Experiment and Modeling. Ind. Eng. Chem. Res. 2006, 45, 1074–1084. [Google Scholar] [CrossRef]

- Kumar, L.; Kaur, R.; Sharma, J. The efficiency of zeolites in water treatment for combating ammonia—Anexperimental study on Yamuna River water & treated sewage effluents. Innorg. Chem. Commun. 2021, 134, 108978. [Google Scholar] [CrossRef]

- Filippidis, A.; Tziritis, E.; Kantiranis, N.; Tzamos, E.; Gamaletsos, P.; Papastergios, G.; Filippidis, S. Application of Hellenic natural zeolites in Thessaloniki industrial area wastewater treatment. Desalin. Water Treat. 2016, 57, 19702–19712. [Google Scholar] [CrossRef]

- Krestou, A.; Xenidis, A.; Panias, D. Mechanism of aqueous uranium (VI) uptake by natural zeolitic tuff. Miner. Eng. 2003, 16, 1363–1370. [Google Scholar] [CrossRef]

- Inan, S.; Hiçsönmez, U. Adsorption Studies of Radionuclides by Turkish Minerals: A Review. J. Turkish Chem. Soc. Sect. Chem. 2022, 9, 579–600. [Google Scholar] [CrossRef]

- Abd-Elaziz, A.; Haggag, E.S.; Soliman, K.G.; Atress, M.S. Studies on the uranium removal from aqueous solution of contaminated soil using natural zeolite. Egypt. J. Chem. 2023, 66, 73–88. [Google Scholar] [CrossRef]

- Rahmani, A.; Nouri, J.; Kamal Ghadiri, S.; Mahvi, A.H.; Zae, M.R. Adsorption of fluoride from water by Al3+ and Fe3+ pretreated natural Iranian zeolites. Int. J. Environ. Res. 2010, 4, 607–614. [Google Scholar] [CrossRef]

- Ghomashi, P.; Chakri, A.; Kazemeini, M.; Yousefi, T. Removal of fluoride from wastewater by natural and modified nano clinoptilolite zeolite. J. Water Environ. Nanotechnol. 2020, 5, 270–282. [Google Scholar] [CrossRef]

| Mineral | Zeolitized Tuffs | Fine-grained Material of Zeolitized Tuffs After Treatment | ||||

|---|---|---|---|---|---|---|

| BP | GB | BPdw | GBdw | BPtw | BPmw | |

| Clinoptilolite | M (90) | M (78) | M (45) | M (59) | M (67) | M (78) |

| Plagioclase | m (1) | m (2.8) | ||||

| Sanidine | m (2) | M (3.3) | ||||

| Quartz | m (1) | m (1.6) | m (1.3) | |||

| Opal-Cristobalite-Tridymite (O-CT) | M (6.4) | M (7.6) | M (16.4) | M (12) | M (15.7) | M (9.2) |

| Mica (Celadonite) | M (3.1) | M (7) | M (13.7) | |||

| Montmorillonite | a | a | M (32) | M (10.3) | ||

| Goethite | a | m (1) | ||||

| Calcite | m (1.7) | |||||

| Ankerite | a | |||||

| Monazite * | a | a | a | |||

| Apatite * | a | |||||

| Mineral | Water | Water Leachates | |

|---|---|---|---|

| TrN1 | BPtrn1w | GBtrn1w | |

| Löweite Na12Mg7(SO4)13·15H2O | M (36.3) | M (16.9) | M (52) |

| Blödite Na2Mg(SO4)2·4H2O | M (29.3) | M (12.2) | m (7.7) |

| Alum-(Na) NaAl(SO4)2·12H2O | M (1.9) | m (1.4) | |

| Tamarugite NaAl(SO4)2·6H2O | M (8.5) | M (3.1) | |

| Cesanite Na3Ca2(SO4)3OH | M (3.4) | M (4.5) | |

| Eugsterite Na4Ca(SO4)3·2H2O | M (10.1) | ||

| Glauberite Na2Ca(SO4)2 | M (3.7) | ||

| Hexahydrite MgSO4·6H2O | M (4.4) | M (36.3) | M (14.8) |

| Mirabilite Na2SO4·10H2O | M (3.5) | ||

| Gypsum CaSO4·2H2O | M (7.6) | M (19.6) | M (16) |

| Celestine SrSO4 * | a | ||

| Halite NaCl | m (1.4) | a (0.3) | m (1.2) |

| Sylvite KCl * | a | ||

| Cu phase * | a | ||

| Elements | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ref./Sample | Na % | Mg % | Al % | K % | Ca % | Rb | Sr | Y | Zr | Nb | Cs | Ba | La | Ce | Pr | Nd | Sm | Eu |

| UCC | 2.42 | 1.50 | 8.15 | 2.32 | 2.56 | 84 | 320 | 21 | 193 | 12 | 4.9 | 624 | 31 | 63 | 7.1 | 27 | 4.7 | 1.0 |

| BP (mean) | 0.62 | 0.40 | 6.45 | 2.70 | 1.89 | 259 | 243 | 13.6 | 94.5 | 22.6 | 26.2 | 21.5 | 16.5 | 31.2 | 2.9 | 9.0 | 1.4 | 0.22 |

| BP (SD) | 1.3 | 4.7 | 0.5 | 1.4 | 0.8 | 0.4 | 1.1 | 0.5 | 0.8 | 0.2 | 0.3 | 0.2 | 0.01 a | |||||

| GB (mean) | 1.13 | 0.57 | 6.35 | 1.79 | 2.78 | 203 | 161 | 14.6 | 105.7 | 21.3 | 24.8 | 57.3 | 29.4 | 55.5 | 5.3 | 16.3 | 2.3 | 0.25 |

| GB (SD) | 5.4 | 1.8 | 0.3 | 0.9 | 0.8 | 0.8 | 3.3 | 0.7 | 0.8 | 0.1 | 1.3 | 0.4 | 0.02 a | |||||

| Elements | ||||||||||||||||||

| Ref./Sample | Gd | Tb | Dy | Ho | Er | Tm | Yb | Lu | Hf | Ta | W | Si % | P | S | Sc | Ti | V | Cr |

| UCC | 4.0 | 0.7 | 3.9 | 0.83 | 2.3 | 0.30 | 2.0 | 0.31 | 5.3 | 0.9 | 1.9 | 31.1 | 200 | 621 | 14.0 | 3800 | 97 | 92 |

| BP (mean) | 1.4 | 0.3 | 2.2 | 0.40 | 1.4 | 0.28 | 2.1 | 0.27 | 3.4 | 1.3 | <0.4 | 30.74 | 318 | 2516 | 3.96 | 640 | 9.4 | 36.8 |

| BP (SD) | 0.3 | 0.02 | 0.06 | 0.02 | 0.2 | 0.05 | 0.2 | 0.03 | 0.2 | 0.1 | 43.9 | 276 | 0.4 | 13.1 | 0.7 | 5.8 | ||

| GB (mean) | 2.4 | 0.3 | 2.4 | 0.56 | 1.5 | 0.22 | 1.5 | 0.29 | 3.6 | 1.3 | 3.1 | 30.08 | 386 | 1603 | 4.02 | 762 | 12.9 | 34.7 |

| GB (SD) | 0.8 | 0.03 | 0.4 | 0.06 | 0.3 | 0.02 | 0.2 | 0.04 | 0.4 | 0.1 | 1.0 | 40 | 273 | 0.4 | 17.1 | 0.8 | 7.6 | |

| Elements | ||||||||||||||||||

| Ref./Sample | Mn | Fe % | Co | Ni | Cu | Zn | Ga | As | In | Sn | Tl | Pb | Bi | Th | U | Ag | LOI % | |

| UCC | 19000 | 3.91 | 17.3 | 47 | 28 | 67 | 17.5 | 4.8 | 0.056 | 2.1 | 0.9 | 17 | 0.16 | 10.5 | 2.7 | 0.053 | ||

| BP (mean) | 207 | 0.55 | <0.5 | 5.4 | 10.4 | 37.9 | 16.5 | 3.7 | 0.17 | 5.8 | 0.8 | 38 | 0.67 | 24.5 | 13.6 | 0.94 | 13.13 | |

| BP (SD) | 6.0 | 1.2 a | 1.9 | 6.4 | 1.1 | 0.3 a | 0.02 | 0.6 | 0.04 | 0.8 | 0.05 | 0.6 | 0.2 | 0.2 a | ||||

| GB (mean) | 349 | 0.60 | 0.9 | 5.7 | 12.2 | 36.4 | 14.2 | <3.9 | <0.21 | 6.6 | 0.6 | 57 | 0.65 | 24.7 | 9.1 | <0.76 | 14.09 | |

| GB (SD) | 8.8 | 0.3 a | 0.3 a | 1.9 | 2.4 | 0.9 | 0.5 | 0.1 | 1.3 | 0.07 | 1.2 | 0.4 | ||||||

| Regulations | Waters | Leachates | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Elements/Ions | [47] | [48] | [49] | tw | mw | zmw | trn1w | BPdw | GBdw | BPtw | BPmw | BPtrn1w | GBtrn1w |

| Lithophile | |||||||||||||

| Li | 0.0011 | <0.05 | <0.05 | <0.05 | 0.45 | <0.05 | <0.05 | <0.05 | <0.05 | 0.32 | 0.27 | ||

| Be | 0.0002 | 0.001 | <0.01 | <0.01 | <0.01 | 0.052 | <0.01 | <0.01 | <0.01 | <0.01 | 0.17 | <0.01 | |

| Na | 200 | 6.30 | 5.80 | 54.23 | 127 | 3029 | 16.05 | 42.7 | 22.9 | 42.4 | 1320 | 1386 | |

| Mg | 80 | 4.10 | 2.47 | 1.12 | 0.21 | 876 | 12.99 | 4.10 | 1.28 | 0.26 | 554 | 600 | |

| Al | 0.2 | 0.24 | 0.031 | 0.021 | <0.05 | 77.8 | 29.26 | 19.0 | 3.62 | 0.024 | 63 | <0.01 | |

| K | 2.30 | 3.43 | 3.42 | 0.55 | 1.76 | 13.02 | 11.5 | 5.23 | 7.10 | 59 | 24 | ||

| Ca | 150 | 15.00 | 11.8 | 6.04 | 1.09 | 441 | 11.73 | 9.10 | 3.84 | 10.3 | 465 | 444 | |

| Sr | 0.08 | 0.070 | 0.07 | 0.023 | 10.25 | 0.055 | 0.03 | 0.01 | 0.008 | 0.955 | 0.632 | ||

| Ba | 1.0 | 0.054 | 0.009 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | 0.013 | |

| Non-metals | |||||||||||||

| B | 1.0 | 1.0 | 0.0130 | <0.05 | <0.05 | 0.20 | 2.18 | <0.05 | <0.05 | <0.05 | <0.05 | 2.08 | 1.88 |

| C | 11.00 | 11.7 | 12.9 | 45.8 | <bdl | 7.03 | 23.43 | 11.75 | 11.71 | <bdl | 11.71 | ||

| HCO3− | 59.5 | 65.4 | 184.1 | <10.0 | 35.7 | 119 | 59.7 | 59.5 | <10.0 | 59.50 | |||

| CO32− | <10.0 | <10.0 | 48.02 | <10.0 | <10.0 | <10.0 | <10.0 | <10.0 | <10.0 | <10.0 | |||

| N | 0.23 | 0.19 | 3.33 | 0.08 | 2.98 | 0.18 | 0.30 | 0.41 | 3.78 | 7.84 | 6.48 | ||

| NO3− | 50 | 50.0 | 0.84 | 14.77 | 0.35 | nd | 0.78 | 1.32 | 1.80 | 16.76 | 33.0 | 26.53 | |

| NH4+ | 0.5 | 4.0 | <0.01 | <0.01 | <0.01 | 3.84 | <0.01 | <0.01 | <0.01 | <0.01 | 0.53 | 0.63 | |

| F- | 1.5 | 1.7 | 0.09 | <0.1 | 0.11 | 1.10 | 3.30 | 0.39 | 0.14 | 0.37 | 0.33 | 1.35 | 18.31 |

| Si | 6.50 | 0.70 | 14.65 | 18.66 | 54.71 | 168.9 | 125.7 | 36.35 | 21.98 | 58.76 | 7.07 | ||

| S | 3.70 | 3.39 | 16.31 | 7.16 | 3685 | 13.4 | 0.32 | 4.31 | 16.98 | 1965 | 1988 | ||

| SO42− | 250 | 250 | 10.13 | 48.78 | 21.40 | 11018 | 40.07 | 0.95 | 12.90 | 50.78 | 5874 | 5944 | |

| Cl- | 250 | 200 | 7.80 | 9.37 | 28.01 | 11.08 | 200 | 1.43 | 2.57 | 7.99 | 28.07 | 221 | 230 |

| Siderophile | |||||||||||||

| V | 0.01 | 0.0010 | <0.01 | <0.01 | <0.01 | 0.062 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | |

| Cr | 0.05 | 0.05 | 0.0002 | <0.01 | <0.01 | <0.01 | 0.023 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

| Mn | 0.05 | 1.0 | 0.0120 | <0.01 | 0.025 | <0.01 | 38.26 | 0.861 | 0.149 | 0.085 | <0.01 | 19.23 | 21.69 |

| Fe | 0.20 | 1.0 | 0.67 | 0.052 | <0.005 | <0.005 | 167 | 25.25 | 14.31 | 2.79 | 0.175 | 1.71 | 0.089 |

| Co | 0.02 | 0.0009 | <0.01 | <0.01 | <0.01 | 0.001 | <0.01 | <0.01 | <0.01 | <0.01 | 0.576 | 0.353 | |

| Ni | 0.02 | 0.02 | 0.01 | <0.01 | <0.01 | <0.01 | 3.27 | <0.01 | <0.01 | <0.01 | <0.01 | 2.75 | 1.04 |

| Chalcophile | |||||||||||||

| Cu | 2.0 | 1.0 | 0.01 | <0.01 | <0.01 | 0.019 | 0.557 | <0.01 | <0.01 | <0.01 | <0.01 | 0.132 | 0.019 |

| Zn | 4.0 | 5.0 | 0.01 | 0.015 | <0.01 | <0.01 | 3.52 | 0.114 | 0.058 | 0.019 | <0.01 | 1.07 | 0.146 |

| As | 0.01 | 0.10 | 0.0004 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | 0.009 | <0.01 | <0.01 | <0.01 | <0.01 |

| Cd | 0.01 | 0.005 | 0.08 | <0.01 | <0.01 | <0.01 | 0.016 | <0.01 | <0.01 | <0.01 | <0.01 | 0.012 | <0.01 |

| Sn | 0.00004 | <0.01 | <0.01 | <0.01 | <0.01 | 0.016 | 0.009 | <0.01 | <0.01 | <0.01 | <0.01 | ||

| Pb | 0.01 | 0.05 | 0.005 | <0.01 | <0.01 | <0.01 | 0.019 | 0.039 | 0.037 | 0.008 | <0.01 | 0.032 | <0.01 |

| Radioactive | |||||||||||||

| U | 0.03 | 0.03 * | 0.001 | <0.01 | <0.01 | <0.01 | 0.119 | 0.030 | <0.01 | <0.01 | <0.01 | 0.098 | <0.01 |

| Others | |||||||||||||

| pH | 6.5–9.5 | 5.5–9.0 | 7.64 | 9.55 | 8.85 | 2.87 | 7.63 | 7.39 | 7.72 | 7.66 | 3.40 | 7.34 | |

| Dry residue (mg/dm3) | 84 | 178 | 200 | 13650 | 44 | 84 | 56 | 152 | 7830 | 8010 | |||

| EC (µS/cm) | 2000 | 1000 | 112 | 279 | 500 | 14470 | 137 | 191 | 138 | 282 | 8730 | 9170 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yossifova, M.; Dimitrova, D.; Tacheva, E.; Sergeeva, I.; Ivanova, R. Treatment of Waters Having Different Ionic Composition and pH with Natural Zeolites from Bulgaria. Minerals 2024, 14, 245. https://doi.org/10.3390/min14030245

Yossifova M, Dimitrova D, Tacheva E, Sergeeva I, Ivanova R. Treatment of Waters Having Different Ionic Composition and pH with Natural Zeolites from Bulgaria. Minerals. 2024; 14(3):245. https://doi.org/10.3390/min14030245

Chicago/Turabian StyleYossifova, Mariana, Dimitrina Dimitrova, Elena Tacheva, Ivanina Sergeeva, and Rositsa Ivanova. 2024. "Treatment of Waters Having Different Ionic Composition and pH with Natural Zeolites from Bulgaria" Minerals 14, no. 3: 245. https://doi.org/10.3390/min14030245

APA StyleYossifova, M., Dimitrova, D., Tacheva, E., Sergeeva, I., & Ivanova, R. (2024). Treatment of Waters Having Different Ionic Composition and pH with Natural Zeolites from Bulgaria. Minerals, 14(3), 245. https://doi.org/10.3390/min14030245