Characterization of Historic Lime Mortars from the Arch of San Martin to Identify the Construction Phases of the City Wall of Burgos (Spain)

Abstract

1. Introduction

2. Materials and Methods

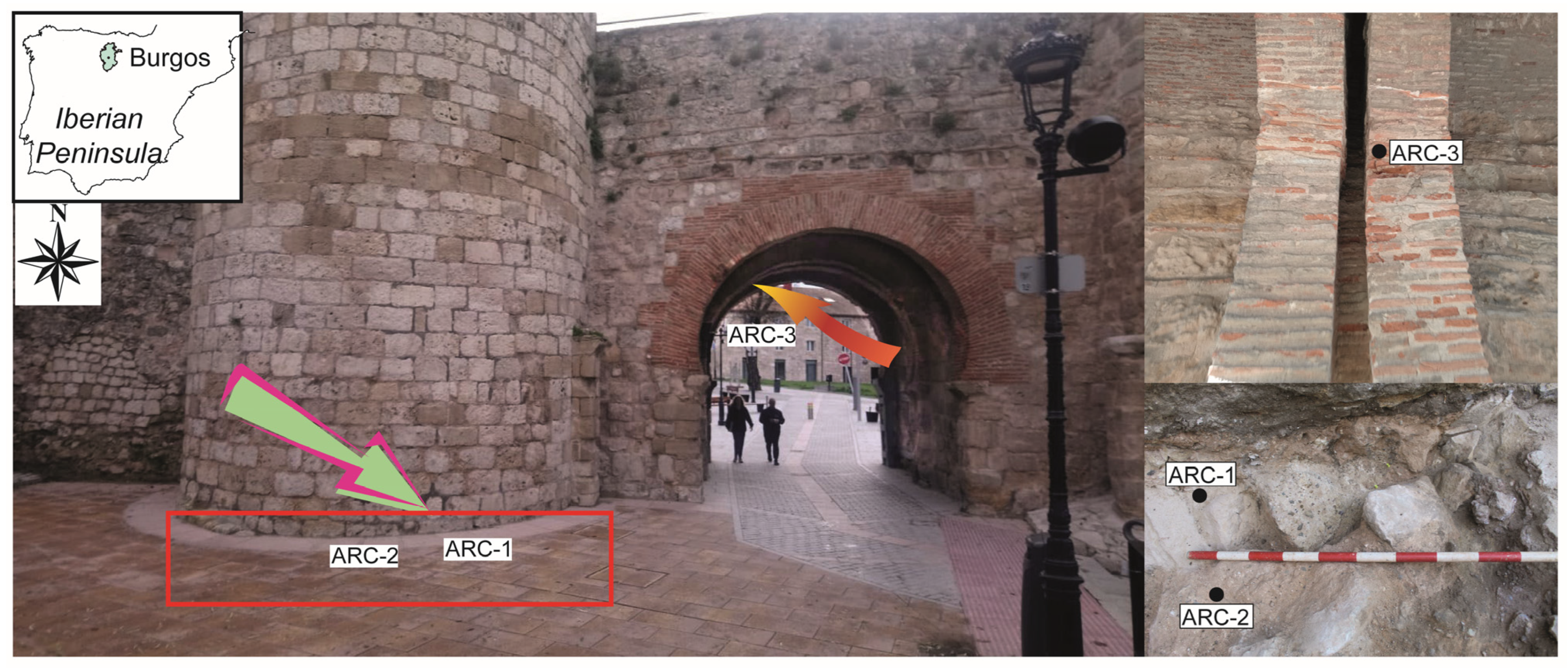

2.1. Materials

2.2. Methods

3. Results

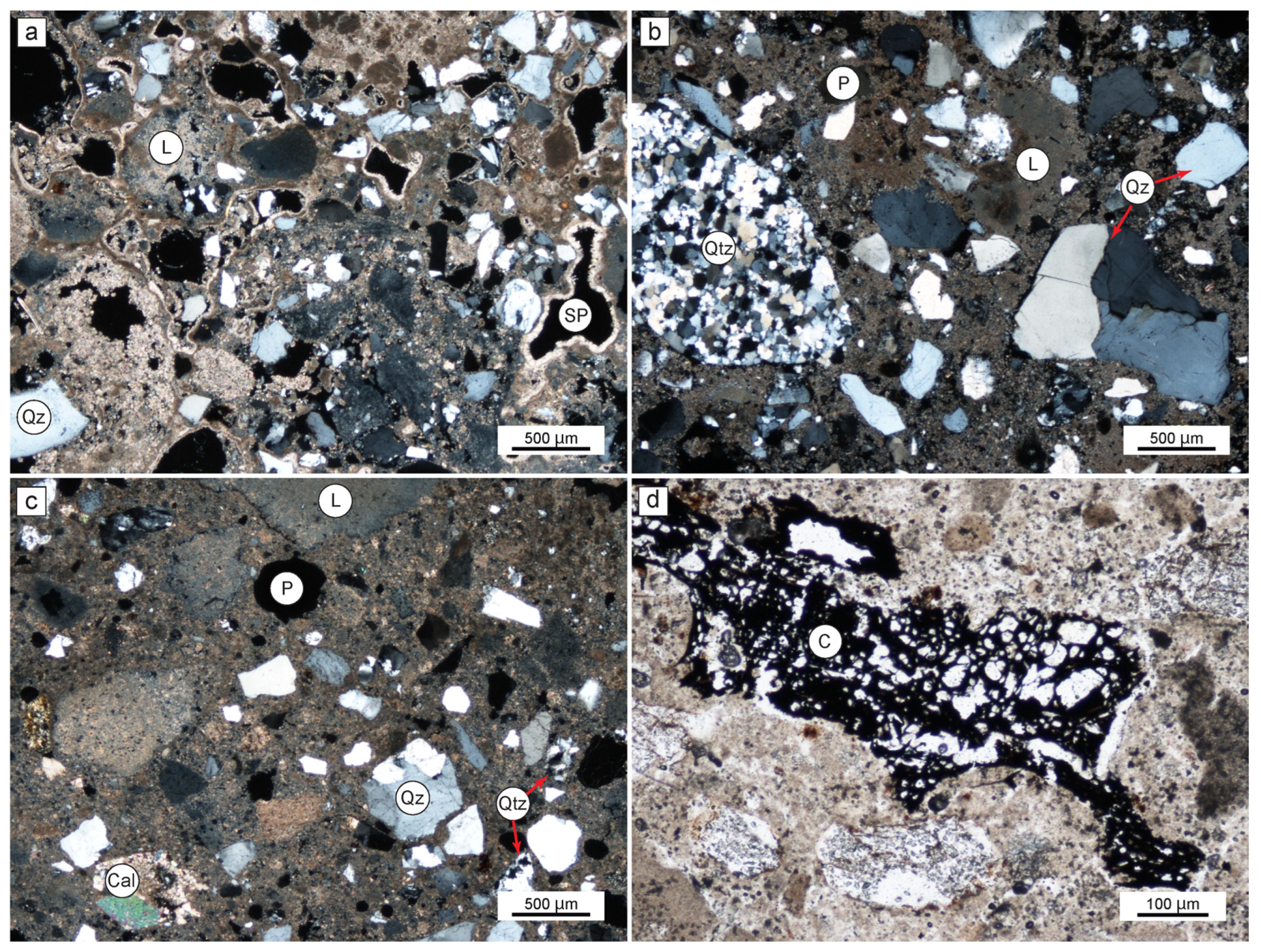

3.1. Textural Characterization

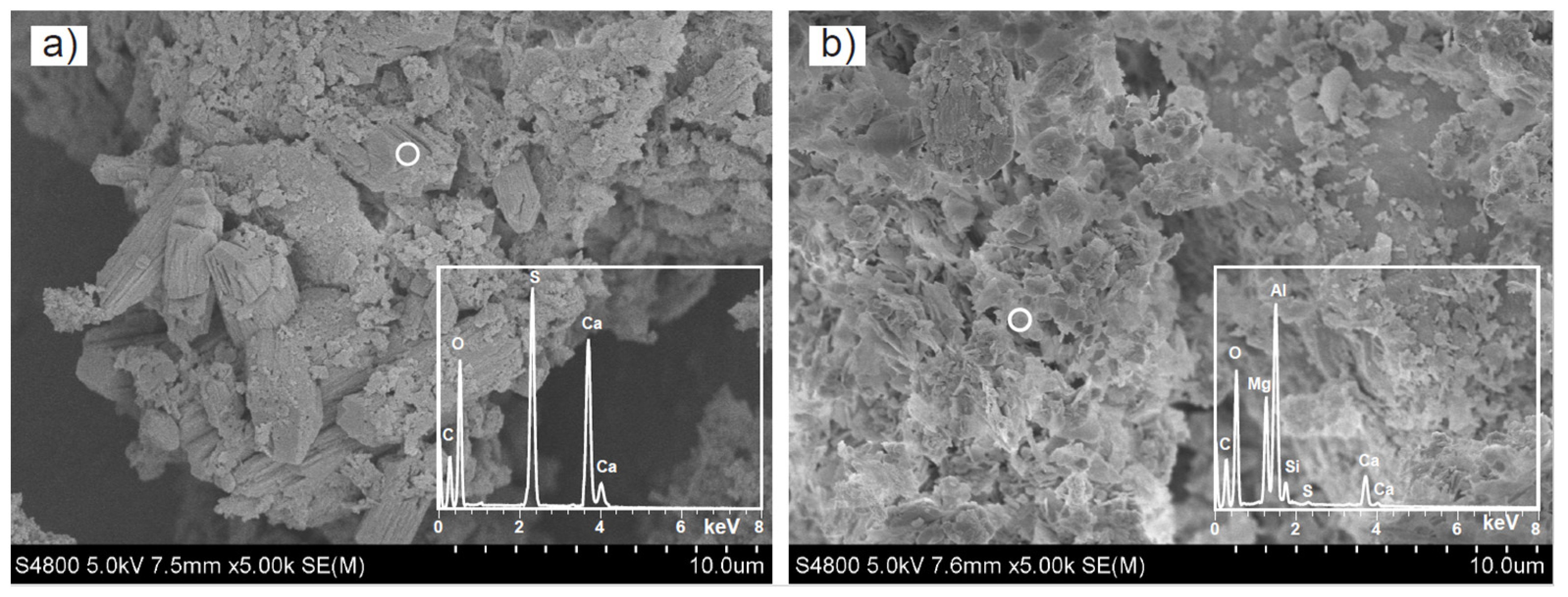

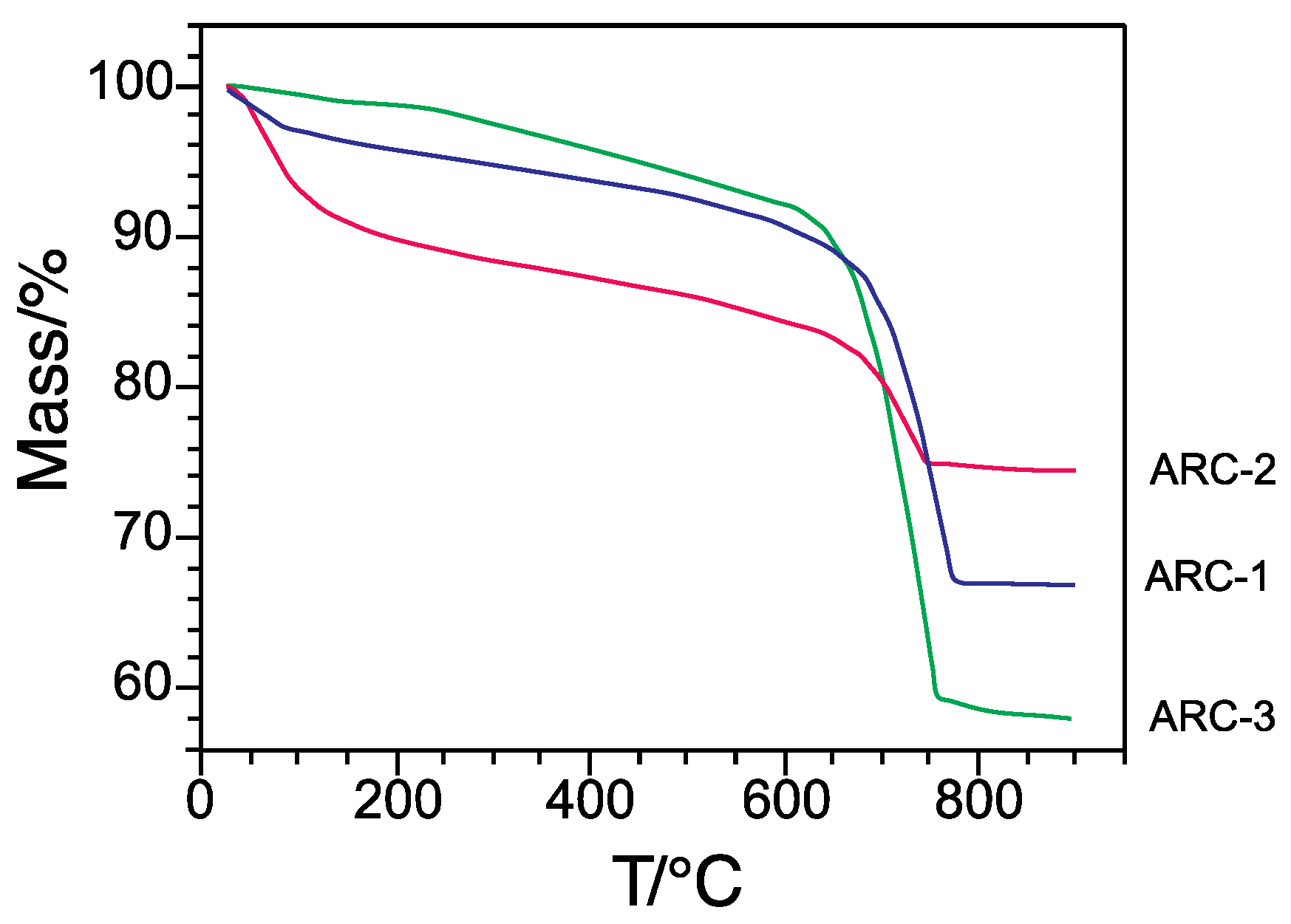

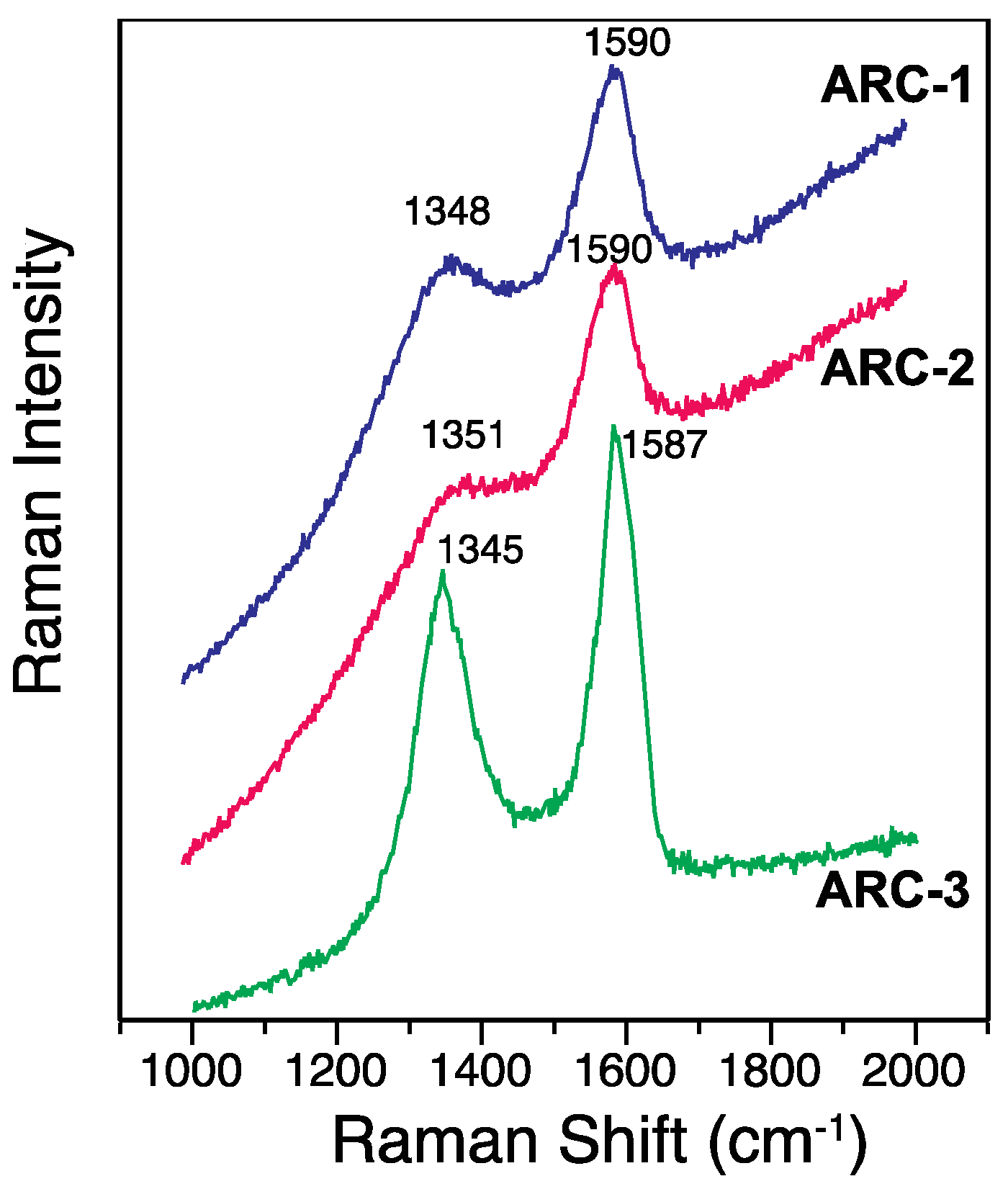

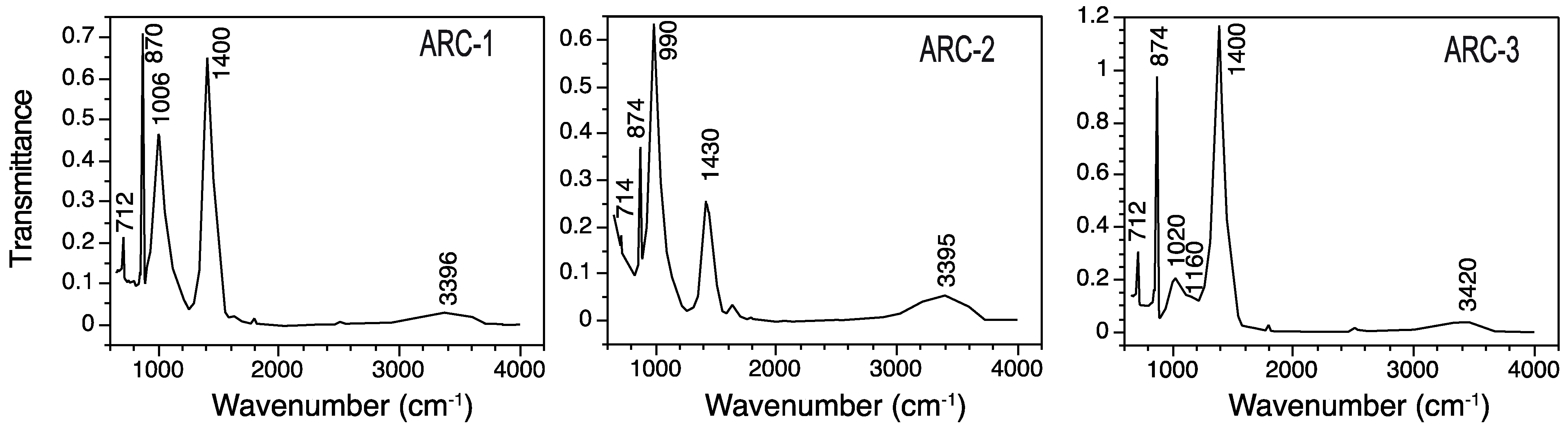

3.2. Mineralogical and Chemical Characterization

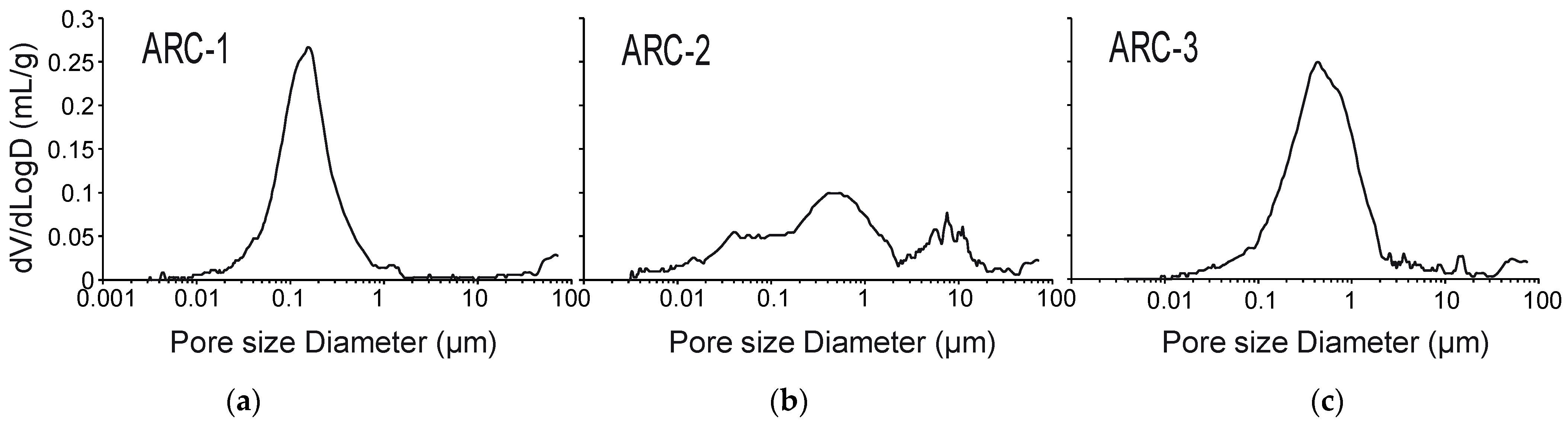

3.3. Physical Characterization

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Secco, M.; Previato, C.; Addis, A.; Zago, G.; Kamsteeg, A.; Dilaria, S.; Canovaro, C.; Artioli, G.; Bonetto, J. Mineralogical clustering of the structural mortars from the Sarno Baths, Pompeii: A tool to interpret construction techniques and relative chronologies. J. Cult. Herit. 2019, 40, 265–273. [Google Scholar] [CrossRef]

- Chiarelli, N.; Miriello, D.; Bianchi, G.; Fichera, G.; Giamello, M.; Memmi, I.T. Characterisation of ancient mortars from the S. Niccolò archaeological complex in Montieri (Tuscany–Italy). Constr. Build. Mater. 2015, 96, 442–460. [Google Scholar] [CrossRef]

- Lezzerini, M.; Raneri, S.; Pagnotta, S.; Columbu, S.; Gallello, G. Archaeometric study of mortars from the Pisa’s Cathedral Square (Italy). Measurement 2018, 126, 322–331. [Google Scholar] [CrossRef]

- Gheris, A. New dating approach based on the petrographical, mineralogical and chemical characterization of ancient lime mortar: Case study of the archaeological site of Hippo, Annaba city, Algeria. Herit. Sci. 2023, 11, 103. [Google Scholar] [CrossRef]

- Miriello, D.; Bloise, A.; Crisci, G.M.; De Luca, R.; De Nigris, B.; Martellone, A.; Osanna, M.; Pace, R.; Pecci, A.; Ruggieri, N. New compositional data on ancient mortars and plasters from Pompeii (Campania–Southern Italy): Archaeometric results and considerations about their time evolution. Mater. Charact. 2018, 146, 189–203. [Google Scholar] [CrossRef]

- Miriello, D.; Barca, D.; Bloise, A.; Ciarallo, A.; Crisci, G.M.; De Rose, T.; Gattuso, C.; Gazineo, F.; La Russa, M.F. Characterisation of archaeological mortars from Pompeii (Campania, Italy) and identification of construction phases by compositional data analysis. J. Archaeol. Sci. 2010, 37, 2207–2223. [Google Scholar] [CrossRef]

- De Luca, R.; Miriello, D.; Pecci, A.; Domínguez-Bella, S.; Bernal-Casasola, D.; Cottica, D.; Bloise, A.; Crisci, G.M. Archaeometric Study of Mortars from the Garum Shop at Pompeii, Campania, Italy. Geoarchaeology 2015, 30, 330–351. [Google Scholar] [CrossRef]

- Dilaria, S.; Previato, C.; Secco, M.; Busana, M.S.; Bonetto, J.; Cappellato, J.; Ricci, G.; Artioli, G.; Tan, P. Phasing the history of ancient buildings through PCA on mortars’ mineralogical profiles: The example of the Sarno Baths (Pompeii). Archaeometry 2022, 64, 866–882. [Google Scholar] [CrossRef]

- Carò, F.; Riccardi, M.; Mazzilli Savini, M. Characterization of plasters and mortars as a tool in archaeological studies: The case of Lardirago Castle in Pavia, Northern Italy. Archaeometry 2008, 50, 85–100. [Google Scholar] [CrossRef]

- Genestar, C.; Pons, C.; Más, A. Analytical characterisation of ancient mortars from the archaeological Roman city of Pollentia (Balearic Islands, Spain). Anal. Chim. Acta 2006, 557, 373–379. [Google Scholar] [CrossRef]

- Miriello, D.; Barca, D.; Pecci, A.; De Luca, R.; Crisci, G.M.; López Luján, L.; Barba, L. Plasters from Different Buildings of the Sacred Precinct of Tenochtitlan (Mexico City): Characterization And Provenance. Archaeometry 2015, 57, 100–127. [Google Scholar] [CrossRef]

- Alonso-Olazabal, A.; Ortega, L.A.; Zuluaga, M.C.; Ponce-Antón, G.; Jiménez Echevarría, J.; Alonso Fernández, C. Compositional characterization and chronology of roman mortars from the archaeological site of arroyo de la dehesa de velasco (Burgo de osma-ciudad de osma, Soria, Spain). Minerals 2020, 10, 393. [Google Scholar] [CrossRef]

- TC 203-RHM (Jan Erik Lindqvist). Rilem TC 203-RHM: Repair mortars for historic masonry. Testing of hardened mortars, a process of questioning and interpreting. Mater. Struct. 2009, 42, 853–865. [Google Scholar] [CrossRef]

- Anna, A.; Giuseppe, C. The water transfer properties and drying shrinkage of aerial lime-based mortars: An assessment of their quality as repair rendering materials. Environ. Earth Sci. 2014, 71, 1699–1710. [Google Scholar] [CrossRef]

- Hughes, J.J.; Cuthbert, S.J. The petrography and microstructure of medieval lime mortars from the west of Scotland: Implications for the formulation of repair and replacement mortars. Mater. Struct. 2000, 33, 594–600. [Google Scholar] [CrossRef]

- Morillas, H.; Vazquez, P.; Maguregui, M.; Marcaida, I.; Silva, L.F.O. Composition and porosity study of original and restoration materials included in a coastal historical construction. Constr. Build. Mater. 2018, 178, 384–392. [Google Scholar] [CrossRef]

- Nogueira, R.; Ferreira Pinto, A.P.; Gomes, A. Design and behavior of traditional lime-based plasters and renders. Review and critical appraisal of strengths and weaknesses. Cem. Concr. Compos. 2018, 89, 192–204. [Google Scholar] [CrossRef]

- Lanas, J.; Alvarez-Galindo, J.I. Masonry repair lime-based mortars: Factors affecting the mechanical behavior. Cem. Concr. Res. 2003, 33, 1867–1876. [Google Scholar] [CrossRef]

- Al-Bashaireh, K. Reconstructing the Chronology of the House XVII-XVIII Complex at Umm el-Jimal, East Jordan: Radiocarbon Dates of Organic Inclusions of Architectural Mortars. Radiocarbon 2014, 56, 245–256. [Google Scholar] [CrossRef]

- Al-Bashaireh, K. Radiocarbon Age Determinations of Mosaic Mortar Layers of Churches from North Jordan. Radiocarbon 2015, 57, 851–863. [Google Scholar] [CrossRef]

- Al-Bashaireh, K.; Hodgins, G.W.L. AMS 14C dating of organic inclusions of plaster and mortar from different structures at Petra-Jordan. J. Archaeol. Sci. 2011, 38, 485–491. [Google Scholar] [CrossRef]

- Nawrocka, D.M.; Michczynska, D.J.; Pazdur, A.; Czernik, J. Radiocarbon chronology of the ancient settlement in the Golan Heights area, Israel. Radiocarbon 2007, 49, 625–637. [Google Scholar] [CrossRef]

- Pachnerová Brabcová, K.; Kundrát, P.; Krofta, T.; Suchý, V.; Petrová, M.; John, D.; Kozlovcev, P.; Kotková, K.; Fialová, A.; Kubančák, J.; et al. Extensive Survey on Radiocarbon Dating of Organic Inclusions in Medieval Mortars in the Czech Republic. Radiocarbon 2023, 2023, 1–11. [Google Scholar] [CrossRef]

- Pachnerová Brabcová, K.; Kundrát, P.; Krofta, T.; Suchý, V.; Petrová, M.; Pravdíková, N.; John, D.; Kozlovcec, P.; Kotková, K.; Fialová, A.; et al. Radiocarbon Dating of Mortar Charcoals from Medieval RÝzmburk Castle, Northwestern Bohemia. Radiocarbon 2022, 65, 275–283. [Google Scholar] [CrossRef]

- Schiffer, M.B. Radiocarbon dating and the “old wood” problem: The case of the Hohokam chronology. J. Archaeol. Sci. 1986, 13, 13–30. [Google Scholar] [CrossRef]

- Berger, R. 14C Dating Mortar in Ireland. Radiocarbon 1992, 34, 880–889. [Google Scholar] [CrossRef]

- Berger, R. Radiocarbon dating of early medieval Irish monuments. In Proceedings of the Royal Irish Academy. Section C: Archaeology, Celtic Studies, History, Linguistics, Literature; Royal Irish Academy: Dublin, Ireland, 1995; pp. 159–174. [Google Scholar]

- Marzaioli, F.; Lubritto, C.; Nonni, S.; Passariello, I.; Capano, M.; Terrasi, F. Mortar radiocarbon dating: Preliminary accuracy evaluation of a novel methodology. Anal. Chem. 2011, 83, 2038–2045. [Google Scholar] [CrossRef]

- Lindroos, A.; Heinemeier, J.; Ringbom, Å.; Braskén, M.; Sveinbjörnsdóttir, Á. Mortar dating using AMS 14C and sequential dissolution: Examples from medieval, non-hydraulic lime mortars from the Åland Islands, SW Finland. Radiocarbon 2007, 49, 47–67. [Google Scholar] [CrossRef]

- Ortega, L.A.; Zuluaga, M.C.; Alonso-Olazabal, A.; Murelaga, X.; Insausti, M.; Ibañez-Etxeberria, A. Historic lime-mortar 14C dating of Santa María la real (Zarautz, Northern Spain): Extraction of suitable grain size for reliable 14C dating. Radiocarbon 2012, 54, 23–36. [Google Scholar] [CrossRef]

- Ponce-Antón, G.; Ortega, L.A.; Zuluaga, M.C.; Alonso-Olazabal, A.; Solaun, J.L. Hydrotalcite and hydrocalumite in mortar binders from the medieval castle of portilla (Álava, North Spain): Accurate mineralogical control to achieve more reliable chronological ages. Minerals 2018, 8, 326. [Google Scholar] [CrossRef]

- Pesce, G.; Quarta, G.; Calcagnile, L.; D’Elia, M.; Cavaciocchi, P.; Lastrico, C.; Guastella, R. Radiocarbon dating of lumps from aerial lime mortars and plasters: Methodological issues and results from San Nicolò of Capodimonte Church (Camogli, Genoa, Italy). Radiocarbon 2009, 51, 867–872. [Google Scholar] [CrossRef]

- Hajdas, I.; Lindroos, A.; Heinemeier, J.; Ringbom, A.; Marzaioli, F.; Terrasi, F.; Passariello, I.; Capano, M.; Artioli, G.; Addis, A.; et al. Preparation and Dating of Mortar Samples-Mortar Dating Inter-Comparison Study (MODIS). Radiocarbon 2017, 59, 1845–1858. [Google Scholar] [CrossRef]

- Addis, A.; Secco, M.; Marzaioli, F.; Artioli, G.; Arnau, A.C.; Passariello, I.; Terrasi, F.; Brogiolo, G.P. Selecting the Most Reliable 14C Dating Material Inside Mortars: The Origin of the Padua Cathedral. Radiocarbon 2019, 61, 375–393. [Google Scholar] [CrossRef]

- Warner, R.B. A Proposed Adjustment for the ‘Old-Wood Effect’. In Proceedings of the 2nd Symposium of 14C & Archaeology; Mook, W., Waterbolk, H., Eds.; European Science Foundation (ESF): Groningen, The Netherlands, 1987; pp. 159–172. [Google Scholar]

- Caroselli, M.; Hajdas, I.; Cassitti, P. The Dating of Dolomitic Mortars with Uncertain Chronology from MÜstair Monastery: Sample Characterization and Combined Interpretation of Results. Radiocarbon 2023, 2023, 1–13. [Google Scholar] [CrossRef]

- Ricci, G.; Secco, M.; Addis, A.; Pistilli, A.; Preto, N.; Brogiolo, G.P.; Arnau, A.C.; Marzaioli, F.; Passariello, I.; Terrasi, F.; et al. Integrated multi-analytical screening approach for reliable radiocarbon dating of ancient mortars. Sci. Rep. 2022, 12, 3339. [Google Scholar] [CrossRef] [PubMed]

- Marzaioli, F.; Nonni, S.; Passariello, I.; Capano, M.; Ricci, P.; Lubritto, C.; De Cesare, N.; Eramo, G.; Quirós Castillo, J.A.; Terrasi, F. Accelerator mass spectrometry 14C dating of lime mortars: Methodological aspects and field study applications at CIRCE (Italy). Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2013, 294, 246–251. [Google Scholar] [CrossRef]

- Folk, R.L.; Valastro, S. Successful technique for dating of lime mortar by carbon-14. J. Field Archaeol. 1976, 3, 203–208. [Google Scholar] [CrossRef]

- Nawrocka, D.; Czernik, J.; Goslar, T. 14C dating of carbonate mortars from polish and Israeli sites. Radiocarbon 2009, 51, 857–866. [Google Scholar] [CrossRef]

- Heinemeier, J.; Ringbom, Å.; Lindroos, A.; Sveinbjörnsdóttir, Á.E. Successful AMS 14C dating of non-hydraulic lime mortars from the medieval churches of the Åland Islands, Finland. Radiocarbon 2010, 52, 171–204. [Google Scholar] [CrossRef]

- Folk, R.L. A comparison chart for visual percentage estimation. J. Sediment. Res. 1951, 21, 32–33. [Google Scholar]

- López, A.; Guzmán, G.A.; Di Sarli, A.R. Color stability in mortars and concretes. Part 1: Study on architectural mortars. Constr. Build. Mater. 2016, 120, 617–622. [Google Scholar] [CrossRef]

- Schueremans, L.; Cizer, Ö.; Janssens, E.; Serré, G.; Balen, K.V. Characterization of repair mortars for the assessment of their compatibility in restoration projects: Research and practice. Constr. Build. Mater. 2011, 25, 4338–4350. [Google Scholar] [CrossRef]

- UNE-EN 15886:2011; Conservation of Cultural Property. Test Methods. Colour Measurement of Surfaces: Madrid, Spain, 2011.

- Sadezky, A.; Muckenhuber, H.; Grothe, H.; Niessner, R.; Pöschl, U. Raman microspectroscopy of soot and related carbonaceous materials: Spectral analysis and structural information. Carbon 2005, 43, 1731–1742. [Google Scholar] [CrossRef]

- Pawlyta, M.; Rouzaud, J.N.; Duber, S. Raman microspectroscopy characterization of carbon blacks: Spectral analysis and structural information. Carbon 2015, 84, 479–490. [Google Scholar] [CrossRef]

- Bernard, E.; Nguyen, H.; Kawashima, S.; Lothenbach, B.; Manzano, H.; Provis, J.; Scott, A.; Unluer, C.; Winnefeld, F.; Kinnunen, P. MgO-based cements—Current status and opportunities. RILEM Tech. Lett. 2023, 8, 65–78. [Google Scholar] [CrossRef]

- Dilaria, S.; Secco, M.; Bonetto, J.; Ricci, G.; Artioli, G. Making Ancient Mortars Hydraulic. How to Parametrize Type and Crystallinity of Reaction Products in Different Recipes. In Conservation and Restoration of Historic Mortars and Masonry Structures; Springer: Cham, Switzerland, 2023; pp. 36–52. [Google Scholar]

- Papayianni, I.; Stefanidou, M. Strength–porosity relationships in lime–pozzolan mortars. Constr. Build. Mater. 2006, 20, 700–705. [Google Scholar] [CrossRef]

- Thomson, M.; Lindqvist, J.; Elsen, J.; Groot, C. 2.5 Porosity of Mortars. In Characterisation of Old Mortars with Respect to their Repair; Final Report of RILEM TC 167-COM; Groot, C., Ashall, G., Hughes, J., Eds.; RILEM Publications SARL: Champs-sur-Marne, France, 2004; Volume 28, pp. 77–106. [Google Scholar]

- Ponce-Antón, G.; Zuluaga, M.C.; Ortega, L.A.; Agirre Mauleon, J. Petrographic and Chemical–Mineralogical Characterization of Mortars from the Cistern at Amaiur Castle (Navarre, Spain). Minerals 2020, 10, 311. [Google Scholar] [CrossRef]

- Shafer, J.; Hilsdorf, H. Ancient and new lime mortars—The correlation between their composition, structure and mechanical properties. In Proceedings of the International Congress on Conservation of Stone and Other Materials, E & FN Spon, Paris, France, 29 June–1 July 1993; pp. 605–612. [Google Scholar]

- Papayianni, I.; Stefanidou, M. The evolution of porosity in lime based mortars. In Proceedings of the 8th Euroseminar on Microscopy Applied to Building Materials, Athens, Greece, 4–7 September 2001; pp. 4–7. [Google Scholar]

- Silva, A.S.; Gameiro, A.; Grilo, J.; Veiga, R.; Velosa, A. Long-term behavior of lime–metakaolin pastes at ambient temperature and humid curing condition. Appl. Clay Sci. 2014, 88–89, 49–55. [Google Scholar] [CrossRef]

- Bernard, E.; Lothenbach, B.; Cau-Dit-Coumes, C.; Chlique, C.; Dauzères, A.; Pochard, I. Magnesium and calcium silicate hydrates, Part I: Investigation of the possible magnesium incorporation in calcium silicate hydrate (C-S-H) and of the calcium in magnesium silicate hydrate (M-S-H). Appl. Geochem. 2018, 89, 229–242. [Google Scholar] [CrossRef]

- Nawrocka, D.; Michniewicz, J.; Pawlyta, J.; Pazdur, A. Application of radiocarbon method for dating of lime mortars. Geochronometria 2005, 24, 109–115. [Google Scholar]

| Sample | SU | Structure | Broad Age Range |

|---|---|---|---|

| ARC-1 | UE213 | Foundation of the circular cube | 11th century |

| ARC-2 | UE210 | Quadrangular foundation, covering the circular cube foundation | First half of the 13th century |

| ARC-3 | - | Intrados of the Mudejar arch | Second half of the 13th century |

| Sample | Calcite | Quartz | K-Feldspar | Phyllosilicates | Other Phases |

|---|---|---|---|---|---|

| ARC-1 BF | ** | **** | tr | ||

| ARC-2 BF | * | **** | tr | ||

| ARC-3 BF | **** | **** | tr | tr | tr (gypsum) |

| Binder | |||||

| ARC-1 < 20 μm | **** | * | tr | ||

| ARC-2 < 20 μm | **** | * | * | tr (dolomite) tr (amesite) | |

| ARC-3 < 20 μm | **** | tr | |||

| ARC-1 < 2 μm | **** | tr | tr | ||

| ARC-2 < 2 μm | **** | tr | * | tr (amesite) | |

| ARC-3 < 2 μm | **** | tr (gypsum) |

| SiO2 | Al2O3 | Fe2O3 | MgO | CaO | K2O | TiO2 | P2O5 | SO3 | LOI | Total | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ARC-1 BF | 55.48 | 0.98 | 0.28 | 0.41 | 19.33 | 0.44 | 0.08 | 0.18 | 0.31 | 20.03 | 97.52 |

| ARC-2 BF | 74.35 | 1.97 | 0.48 | 1.31 | 7.22 | 0.56 | 0.18 | 0.05 | 0.13 | 10.2 | 96.45 |

| ARC-3 BF | 29.9 | 0.88 | 0.29 | 0.47 | 35.67 | 0.34 | 0.08 | 0.06 | 0.8 | 28.94 | 97.43 |

| ARC1 < 20 µm | 13.77 | 4.4 | 1.41 | 2.49 | 35.17 | 0.91 | 0.18 | 0.41 | 0.49 | 39.67 | 98.9 |

| ARC2 < 20 µm | 23.2 | 4.22 | 1.31 | 7.44 | 25.47 | 0.74 | 0.14 | 0.28 | 0.82 | 35.33 | 98.95 |

| ARC3 < 20 µm | 3.23 | 0.96 | 0.4 | 0.82 | 44.26 | 0.23 | 0.04 | 0.09 | 0.29 | 48.98 | 99.3 |

| ARC-1 < 2 µm | 1.53 | 0.54 | 0.34 | 0.30 | 53.64 | 0.14 | 0.12 | 0.14 | 0.49 | 42.15 | 99.39 |

| ARC-2 < 2 µm | 2.52 | 0.57 | 0.23 | 0.84 | 52.76 | 0.12 | 0.21 | 0.23 | 0.20 | 41.46 | 99.15 |

| ARC-3 < 2 µm | 0.52 | 0.30 | 0.14 | 0.28 | 54.78 | 0.07 | 0.05 | 0.11 | 0.89 | 43.04 | 100.19 |

| Sample | L* | a* | b* | C* | H |

|---|---|---|---|---|---|

| ARC-1 | 81.14 | 3.08 | 7.83 | 8.41 | 68.53 |

| ARC-2 | 80.45 | 3.81 | 10.85 | 11.50 | 70.66 |

| ARC-3 | 84.50 | 1.54 | 8.77 | 8.90 | 80.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ponce-Antón, G.; Zuluaga, M.C.; Ortega, L.Á.; Jiménez Echevarría, J.; Alonso Fernández, C. Characterization of Historic Lime Mortars from the Arch of San Martin to Identify the Construction Phases of the City Wall of Burgos (Spain). Minerals 2024, 14, 147. https://doi.org/10.3390/min14020147

Ponce-Antón G, Zuluaga MC, Ortega LÁ, Jiménez Echevarría J, Alonso Fernández C. Characterization of Historic Lime Mortars from the Arch of San Martin to Identify the Construction Phases of the City Wall of Burgos (Spain). Minerals. 2024; 14(2):147. https://doi.org/10.3390/min14020147

Chicago/Turabian StylePonce-Antón, Graciela, Maria Cruz Zuluaga, Luis Ángel Ortega, Javier Jiménez Echevarría, and Carmen Alonso Fernández. 2024. "Characterization of Historic Lime Mortars from the Arch of San Martin to Identify the Construction Phases of the City Wall of Burgos (Spain)" Minerals 14, no. 2: 147. https://doi.org/10.3390/min14020147

APA StylePonce-Antón, G., Zuluaga, M. C., Ortega, L. Á., Jiménez Echevarría, J., & Alonso Fernández, C. (2024). Characterization of Historic Lime Mortars from the Arch of San Martin to Identify the Construction Phases of the City Wall of Burgos (Spain). Minerals, 14(2), 147. https://doi.org/10.3390/min14020147