Abstract

The grinding process plays a crucial role in the floatability of mineral. The present study proposes a scheme to assist in the flotation separation of galena and pyrite by optimizing the choice of grinding media. The effects of grinding media (cast iron balls, steel balls containing 18% chromium, and steel balls containing 12% chromium) on the pulp properties and hydrophilicity of galena and pyrite were evaluated using grinding tests, micro-flotation tests, X-ray photoelectron spectroscopy, and adsorption capacity analyses. The results showed significant differences in the pH, potential, and dissolved oxygen content of the galena or pyrite pulp with different grinding media, resulting in significant differences in the flotation behavior of galena and pyrite. The use of cast iron balls in the grinding process was more favorable for the flotation separation of galena and pyrite. The pyrite surfaces adsorbed less butyl xanthate when cast iron balls were used as grinding media due to the presence of more hydrophilic hydroxyl iron. Therefore, cast iron balls as grinding media are favorable for broadening the surface hydrophilic differences between galena and pyrite.

1. Introduction

Lead, mainly extracted from galena, is extensively used in the chemical, pharmaceutical, and construction industries. Galena is often associated with abundant pyrite and non-metallic minerals [1]. As a result of continuous mining, lead-bearing deposits contain an increasing proportion of pyrite and a decreasing proportion of galena. Pyrite has similar surface properties to galena, and their separation by flotation has been a great challenge [2]. The higher the pyrite content, the lower the economic value of the galena concentrate. In addition, the pyrite accompanying the galena entering the lead smelting system will pollute the environment due to the release of more sulfur dioxide [3]. Thus, the selective separation of galena and pyrite becomes a necessary prerequisite for the economic, clean, and efficient extraction of lead.

Flotation is the method preferred for the separation of galena and pyrite [4]. The separation of minerals via the process of flotation depends on the difference in the hydrophilicity of the different mineral surfaces [5]. Grinding is an important operation prior to flotation for the adequate liberation of minerals and the reduction in grain size [6]. Along with the reduction in grain size, the minerals are exposed to more fresh surfaces during grinding. Thus, grinding inevitably leads to a variation in the hydrophilicity of the mineral [7,8]. This suggests that improving the grinding conditions may be able to amplify the differences in hydrophilicity between different minerals, and thus effectively achieve their flotation separation. Ke et al. [9] demonstrated that there is a galvanic interaction between the grinding media and the sulfide minerals because of the semiconducting nature of the sulfide minerals. During grinding, electrons will be transferred from the active material with a lower rest potential to the noble material with a higher rest potential [10]. The rest potential of common iron-based grinding media is generally lower than that of common sulfide minerals (pyrite, chalcopyrite, galena, and sphalerite, etc.) [11,12]. Therefore, iron-bearing media often assume the role of an anode during grinding, which results in the release of ferrous ions [13]. These ferrous ions will gradually be converted into hydroxyl iron complexes and coat the surface of the mineral, which inevitably changes the hydrophilicity of the mineral [14]. Peng and Grano [15] identified that the hydroxyl iron complexes originating from the grinding media are an important factor for the flotation separation of galena and chalcopyrite. Kinal et al. [16] demonstrated that a moderate amount of iron hydroxide, generated by the corrosive reaction of the grinding media, contributes to the depression of sphalerite, without altering the floatability of galena. Li and Iwasaki [17] reported that inert grinding media, such as ceramics and zirconia, were beneficial to the recovery of sulfide minerals but detrimental to the separation of different sulfide minerals. In industrial practice, Greet et al. [18] reported that metal debris, generated during grinding, has a potential influence on downstream flotation. The increase in metallic debris can significantly alter the chemistry of the pulp [19]. Apparently, the chemical substances released by the galvanic interaction between the grinding media and the mineral play an important role in the hydrophobicity of the mineral.

The strength of the galvanic interaction depends on the difference in the rest potential between the grinding media and the sulfide mineral [20]. Therefore, the variation in the grinding media will inevitably cause changes in the pulp properties and hydrophilicity of the minerals. Jacques et al. [21] concluded that high-chromium media are more beneficial than forged steel media for the flotation separation of chalcopyrite and pyrite due to the more optimal pulp chemistry that can be obtained with high-chromium media. For the flotation system of galena and pyrite, Peng et al. [22] investigated the effect of atmosphere (nitrogen, air, and oxygen) during grinding with different media on the floatability of minerals. However, almost no studies have been reported on the effect of different grinding media (chromium containing media, iron media, and other media) on the pulp properties (pH, potential, and dissolved oxygen) of galena and pyrite. The effect of grinding media on the hydrophilic substances on the surface of galena and pyrite has also been rarely reported. In this study, an effective scheme is proposed to assist the flotation separation of galena and pyrite by optimizing the choice of grinding media. The effects of three grinding media, cast iron balls, steel balls containing 18% chromium, and steel balls containing 12% chromium, on the pH, potential, and dissolved oxygen content of galena and pyrite pulp were investigated. The effect of the grinding media on the floatability of galena and pyrite was investigated using micro-flotation tests with different collector dosages and pHs. The effect of the grinding media on the hydrophilicity of the mineral surface was evaluated using X-ray photoelectron spectroscopy (XPS) and adsorption capacity analyses. Overall, this study can provide novel insights into improving the flotation separation of galena and pyrite.

2. Materials and Methods

2.1. Materials

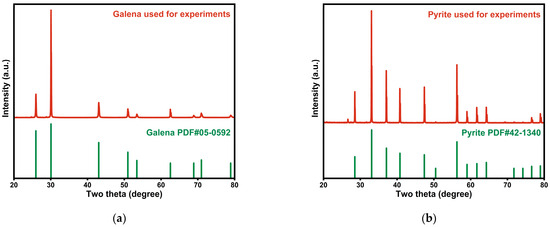

Pure galena and pyrite were collected from the Guangdong Province, China, which were crushed to 50–100 mm by a jaw crusher with a ceramic liner. The XRD patterns of the collected mineral samples are shown in Figure 1. The galena (PDF#05-0592) and pyrite (PDF#42-1430) correspond to their respective standard cards, proving that there were no other impurities in the samples.

Figure 1.

XRD pattern of the samples used for the experiment: (a) galena and (b) pyrite.

Butyl xanthate (BX) and terpineol oil were employed as a collector and frother during flotation, respectively, and sodium hydroxide (NaOH) and hydrochloric acid (HCl) were used to adjust the pulp pH. All reagents were purchased from Sinopharm group, China, and were analytically pure. The water consumed in the tests was deionized water with a resistivity of 18.20 MΩ.

Stainless steel tanks with zirconia liners were used for the grinding tests. The media filled in the ball-grinding tank were classified as cast iron balls (CIB), steel balls containing 18% chromium (CSB18%), and steel balls containing 12% chromium (CSB12%). It should be noted that the chromium was homogenously distributed in the chromium-containing steel ball body. The diameters of the grinding media were classified into three sizes, 15, 10, and 5 mm. The number of media was 2, 10, and 50, respectively, in the order of volume from largest to smallest. The grinding equipment and materials were purchased from Changsha Miqi Instrument Equipment Co., Ltd., Changsha, China.

2.2. Testing of Pulp Properties

A mineral sample of 30 g and 60 mL of deionized water were taken into a ball-grinding tank filled with the media. The ball-grinding tank was fixed in the planetary ball grinder, and then the grind speed and time were set. At the end of the grinding, the pulp was quickly removed and fixed to 100 mL, then the pH, potential, and dissolved oxygen of the pulp were determined using a pH meter (PHB-4, Inesa, Shanghai, China). All the grinding tests were repeated three times for averaging.

2.3. Micro-flotation Tests

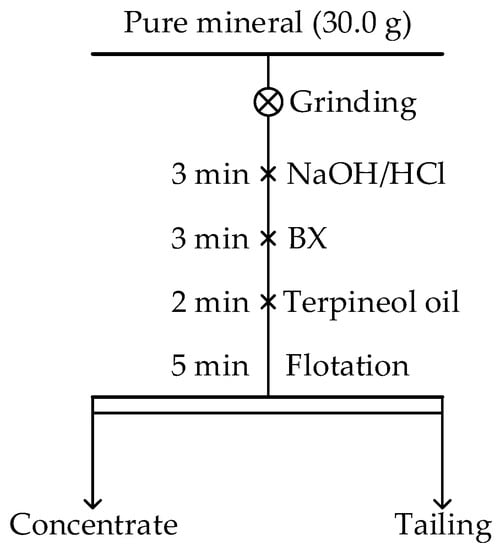

The flotation behavior of the pure minerals was studied utilizing an XFG-1600 flotation machine (Exploring Machinery Plant, Changchun, China). In total, 100 mL of pulp containing 30 g of the ground mineral was placed in the flotation cell, after which, the chemical environment of the pulp was adjusted and the flotation was performed according to the flowsheet shown in Figure 2.

Figure 2.

Flowsheet of micro-flotation tests.

For the binary mixed-mineral flotation system, both galena and pyrite had masses of 15 g. The flotation concentrates and tailings were dried and assayed for the recovery calculated by Equation (1). All the flotation tests were validated twice to minimize errors.

where is the concentrate recovery of the desired element (%), and are the masses of the concentrate and tailing (g), respectively, and and represent the grades of the desired elements in the concentrate and tailing (%), respectively.

2.4. X-ray Photoelectron Spectroscopy Analysis

A total of 30 g of galena or pyrite was freeze-dried after 5 min of ball grinding with different media. Two grams was separated from the dried sample for an XPS analysis. The XPS spectra of the galena or pyrite were obtained using a K-Alpha 1063 spectrometer (Thermo Scientific Co., Waltham, MA, USA) at ambient temperature. The XPS fine spectra were fitted by the Thermo Avantage version 5.96 software (Thermo Scientific Co., Waltham, MA, USA).

2.5. Testing of Adsorption Capacity

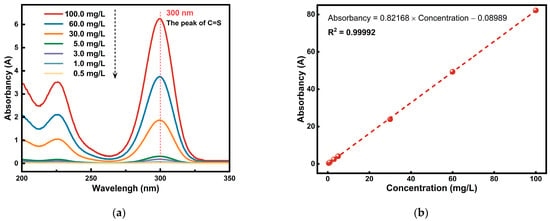

UV–visible spectrophotometry (UV-vis; T6, Pgeneral, Beijing, China) was used to detect the concentration of residual BX in the pulp. Figure 3 shows that the degree of fit of the linear equation between the BX concentration and absorbance was as high as 0.99992, indicating that the determination of the BX concentration using UV-vis was plausible. After adjusting the chemical environment of the pulp according to the procedure shown in Figure 2, a 10 mL suspension was collected from the flotation cell. The suspension was centrifuged and then used to detect the BX concentrations. The adsorption capacity of the minerals for BX was calculated by Equation (2). Adsorption experiments with the same conditions were performed at least three times to minimize errors.

where (mg/g) is the adsorption capacity of the BX on the surface of the galena or pyrite, (L) is the volume of the pulp suspension, (g) refers to the mass of the galena or pyrite, and (mg/L) and (mg/L) are the BX concentrations before and after adsorption, respectively.

Figure 3.

Linear fit between the concentration and absorbance of BX, (a) UV-vis spectroscopy of different concentrations of the BX and (b) linear relationship.

3. Results and Discussion

3.1. Effect of Grinding Media on Pulp Properties

3.1.1. Effect of Grinding Media on pH

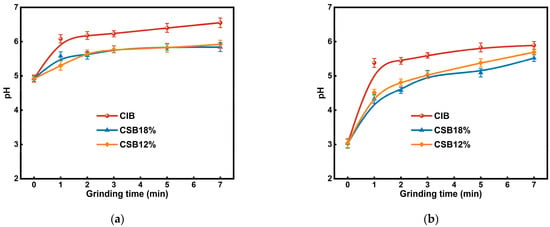

Figure 4 shows the effect of grinding time on the pH of the pulp for different grinding media. After grinding with CIB, CSB18%, or CSB12%, the pulp pHs of both galena and pyrite increased gradually with the grinding time. CSB18% and CSB12% as grinding media caused a similar increase in the pulp pH, while CIB as grinding media caused a greater increase in the pulp pH. The galvanic interaction between the minerals and the grinding media was the main trigger for the increase in the pulp pH during the grinding process [23]. Galena and pyrite always assume the role of cathodes in galvanic interactions because of their higher potentials compared to CIB, CSB18%, and CSB12%. The dissolved oxygen (DO) in the pulp was converted into hydroxide ion at the cathode [11], thereby causing an increase in the pulp pH. Compared to CSB18% and CSB12%, CIB is more susceptible to abrasion and corrosion; thus, a stronger galvanic interaction occurred between the CIB and the mineral, which, in turn, caused a greater pH increment.

Figure 4.

Variation of pulp pH with grinding time: (a) galena and (b) pyrite.

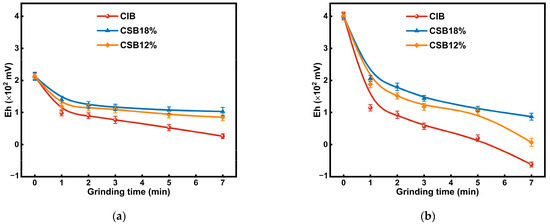

3.1.2. Effect of Grinding Media on Potential

Figure 5 illustrates the effect of the grinding time on the pulp potential for different grinding media. Both the galena and pyrite pulp potentials gradually decreased with an increasing grinding time for different grinding media. For the same mineral at the same grinding time, the pulp potential decreased in the order of CSB18% > CSB12% > CIB. Zhang et al. [24] demonstrated that the CIBs were more susceptible to wear than the chromium-containing steel balls during grinding, which could have resulted in the release of more iron ions from the CIBs. More ferrous ions inevitably induced a greater reduction in the pulp potential. In addition, the reduction in the pulp potential was more significant for pyrite compared to galena with the same grinding media at the same grinding time. When CIBs were employed as the grinding media, the maximum drop in the pulp potential was obtained at 7 min of grinding, with 187 mV and 463 mV reductions relative to the initial values in the galena and pyrite, respectively. This may be attributed to the fact that the grinding media were more susceptible to wear as they collided with the pyrite, because pyrite (6.5) has a higher Mohs hardness than galena (2.5). Moreover, the rest potential of pyrite (445 mV) was higher than that of galena (172 mV) [25], which suggests a more intense galvanic interaction between the pyrite and the grinding media. A more wearable and stronger galvanic interaction inevitably induced the release of more ferrous ions from the grinding process and thus exhibited a lower pulp potential.

Figure 5.

Variation of pulp potential with grinding time: (a) galena and (b) pyrite.

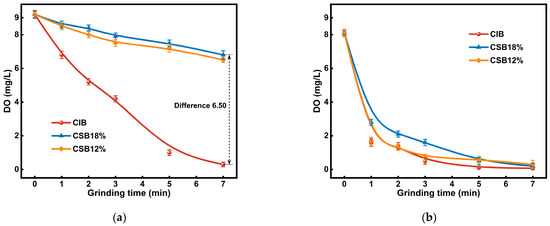

3.1.3. Effect of Grinding Media on Dissolved Oxygen

Figure 6 depicts the effect of grinding time on the DO content of the pulp with different grinding media. The DO content decreased progressively with an increasing grinding time, which may be attributed to the enhanced oxidation of the mineral or grinding media. For galena, CSB18% and CSB12% induced comparable reductions in DO content, whereas CIB caused a significant reduction in DO content. This was related to the fact that the CIBs were more susceptible to abrasion during grinding than CSB18% and CSB12%. Zhao et al. [26] reported that the iron filings generated by the abrasion of the CIBs would be transformed into ferrous or ferric ions, which would inevitably consume more dissolved oxygen. For pyrite, the DO content was similar with different grinding media, which is explained by the fact that pyrite was the dominant substance releasing ferrous ions during grinding [27].

Figure 6.

Variation of dissolved oxygen content of the pulp with grinding time: (a) galena and (b) pyrite.

3.2. Effect of Grinding Media on Mineral Floatability

The pH and potential of pulp can affect the type of ions dissolved or coated on a mineral surface, which, in turn, may change the hydrophilicity of the mineral surface [28]. In addition, variations in DO can lead to variations in the hydrophilicity of the mineral surface. Excessive levels of DO in the pulp would aggravate the oxidation of the surface of sulfide minerals, while too low of a level of DO is not conducive to the adsorption of BX on the surfaces of minerals [29,30]. The results of Section 3.1. revealed that the pH, potential, and DO content of the pulp could vary significantly with the type of grinding media. Therefore, the variation in the grinding media would inevitably lead to a change in the hydrophilicity of the mineral surface and may amplify the differences in the floatability of different minerals. This section investigates the effect of the type of grinding media on the floatability of minerals in a single mineral system of galena and pyrite.

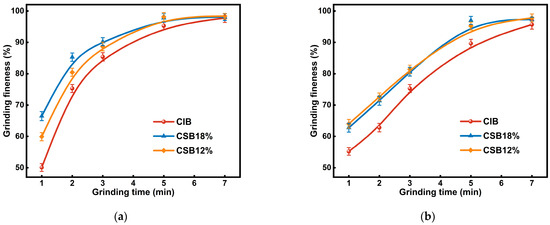

3.2.1. Effect of Grinding Media on Grinding Fineness

Considering that the studied minerals are all liberated pure minerals, particle size becomes an important factor affecting the floatability of the minerals. Particle sizes that are too coarse or too fine are not conducive to particles adhering to the bubble [31]. Figure 7 displays the effect of grinding time on the fineness of the galena and pyrite with particle sizes of 50–100 mm under different grinding media. The grinding fineness is expressed as a proportion of the mass of particles with a particle size of less than 0.074 mm. The fineness of the galena and pyrite gradually increased with the grinding time with the different grinding media. Particularly, a higher fineness could be achieved with the chromium-containing steel balls as the grinding media than with the CIBs at the same grinding time, which can be attributed to the higher hardness of the chromium-containing steel balls compared to the CIBs [32]. Moreover, the fineness of the galena was higher than that of pyrite under the same grinding conditions, which can be attributed to the lower Mohs hardness of the former. At a grinding time of 5 min, the fineness of the galena and pyrite was more than 90% with the different grinding media. A longer grinding time (7 min) may result in too fine a mineral particle to be favorable for flotation. Thus, the optimal grinding time adopted for the subsequent experiments was determined to be 5 min.

Figure 7.

Variation of grinding fineness with grinding time: (a) galena and (b) pyrite.

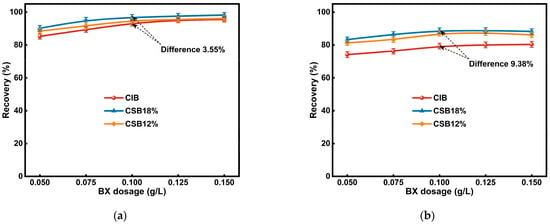

3.2.2. Effect of Grinding Media on Recovery at Different BX Dosages

Figure 8 illustrates the effect of the BX dosage on the single mineral recoveries of the galena and pyrite with different grinding media. The recovery of galena and pyrite showed the trend of a slight increase followed by stabilization with an increasing BX dosage. Maximum recovery was achieved with a BX dosage of 0.10 g/L with a different grinding media. At the same BX dosage and with different grinding media, the recovery of galena and pyrite decreased in the order of CSB18% > CSB12% > CIB. The more abrasive nature of the CIBs and the stronger galvanic interaction between the CIBs and the mineral may account for this phenomenon [33]. Interestingly, the reduction in the recovery of pyrite was much greater than that of galena when using CIBs as the grinding media. This phenomenon may be attributed to the lower rest potential of pyrite inducing a stronger galvanic interaction [23]. Apparently, the alteration in the grinding media contributed to an amplification of the differences in mineral floatability, which provided the potential for the flotation separation of galena and pyrite.

Figure 8.

Variation of recovery of (a) galena and (b) pyrite with BX dosage at different grinding media under the following experimental conditions: grinding time 5 min and natural pH.

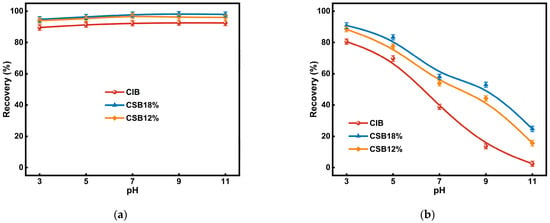

3.2.3. Effect of Grinding Media on Recovery at Different pH

Figure 9 shows the effect of the pH on the single mineral recovery of galena and pyrite with different grinding media. For galena, the pH had no significant effect on the recovery with the same grinding media, while the recovery obtained with CIS as the grinding media was slightly lower (about 5%) than that of CSB18% and CSB12% under the same pH. For pyrite, an increase in the pH resulted in a significant decrease in recovery. This trend of pyrite floatability variation with pH was similar to previous studies [34]. The recovery of pyrite decreased in the order of CSB18% > CSB12% > CIB with different grinding media at the same pH, indicating that utilizing CIBs for grinding was more conducive to the depression of pyrite. The recovery of pyrite obtained using CIB grinding was 22.30% lower than that obtained using CSB18% grinding at pH = 11, while the corresponding difference in the recovery of galena was only 5.40%. Apparently, the reduction in the recovery of pyrite induced by the CIBs was considerably greater than the reduction in the recovery of galena at the same pH, demonstrating that CIBs as a grinding media could amplify the difference in floatability between galena and pyrite.

Figure 9.

Variation of recovery (a) galena and (b) pyrite with pH at different grinding media under the following experimental conditions: grinding time 5 min and BX dosage 0.10 g/L.

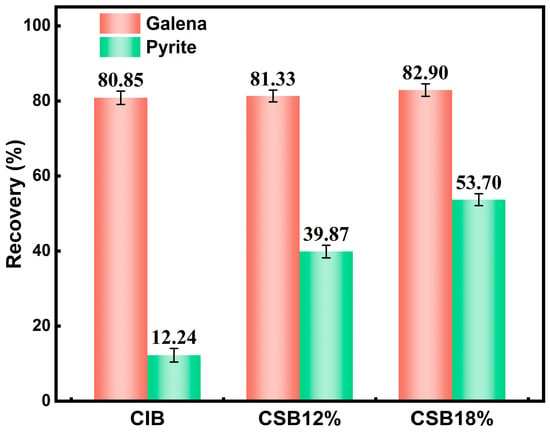

3.3. Effect of Grinding Media on Flotation Separation of Binary Mixed Mineral

Figure 10 shows the recovery of the galena and pyrite obtained using three different grinding media in a binary mixed-mineral flotation system. The recovery of galena showed a slightly increasing trend as the grinding media were CIB, CSB12%, and CSB18% in sequence. This indicated that the effect of grinding media on the floatability of galena is relatively weak in binary mixed-mineral systems. The recoveries of pyrite were 53.70%, 39.87%, and 12.24% when using CSB18%, CSB12%, and CIB as the grinding media, respectively. This variation trend is evidence that CIBs are more favorable for increasing the hydrophilicity of pyrite in binary mixed-mineral systems. The trend of variation in the galena and pyrite recovery caused by the variation in the grinding media was similar to the study by Peng et al. [22]. However, there is also a slight difference between Peng et al.’s study and the present one. Peng et al. concluded that chromium-containing steel balls caused a significant increase in the recovery of both galena and pyrite relative to mild steel balls. The current study indicated that the chromium-containing steel balls primarily induced a significant increase in the pyrite recovery relative to the CIBs, with a slight increase in galena recovery. A similar trend of recovery variation may be attributed to the fact that the chromium-containing steel balls released less iron oxides than the CIBs and mild steel balls. The difference in the magnitude of recovery variation may be ascribed to the flotation pulp pH being maintained at 9 in Peng et al.’s study and at 11 in this one. Differences in the composition and strength of the CIBs and mild steel balls could also be another reason for the difference in the magnitude of the recovery variation. Considering that oxygen reduction in the pulp is more likely to occur on the surface of pyrite than on that of galena [35], it is possible that more iron hydroxyl complexes are attached to the surface of pyrite. Therefore, it is reasonable that CIBs, which are more capable of releasing iron ions, would be more effective at reducing the floatability of pyrite.

Figure 10.

Effect of grinding media on recovery of galena and pyrite by flotation in a binary mixed-mineral system under the following experimental conditions: grinding time 5 min, BX dosage 0.10 g/L, and pH = 11.

When CIBs were used as the grinding media, the difference in the recovery between galena and pyrite reached 68.61%, demonstrating that an effective separation of the two minerals was achieved. Notably, the recovery of galena from the binary mixed-mineral system was lower than that from single mineral systems under the same flotation conditions, while pyrite showed the opposite trend. This may be attributed to the presence of a galvanic interaction between galena and pyrite. Qin et al. [36] demonstrated that the galvanic interaction between galena and pyrite can increase the floatability of pyrite, but deteriorate the floatability of galena. Overall, flotation tests on both single and mixed minerals support the fact that varying the type of grinding media improves the separation of galena and pyrite by flotation.

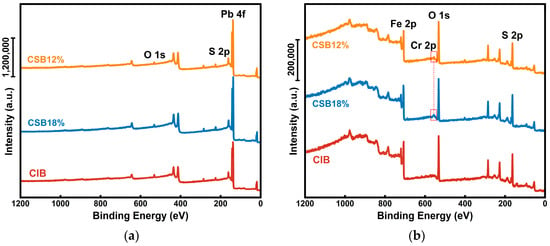

3.4. Variation of Valence States of Elements on Mineral Surfaces with Three Grinding Media

Figure 11 exhibits the XPS spectra of the galena and pyrite after grinding with the three media, and the corresponding surface elemental compositions are shown in Table 1 and Table 2. For galena, the percentages of O and Fe on the surfaces after grinding with the CIBs were significantly higher than when using the chromium-containing steel balls. The higher percentage of O proved that CIBs as grinding media are more likely to cause galena oxidation, which rationally explains the lower galena recovery achieved when the CIBs were used as the grinding media under the same conditions. The higher Fe percentage meant that CIB abrasion produced more ferric or ferrous ions, which was responsible for the higher pH (Figure 4a) and lower potential (Figure 5a) and DO content (Figure 6a) of the galena pulp when grinding with the CIBs. For pyrite, the O percentage after grinding with the CIBs was significantly higher than that after grinding with the chromium-containing steel balls. The higher O percentage indicated that pyrite was more readily oxidized during collision with the CIBs, which rationally explains the lower pulp potential (Figure 5b) and lower recovery (Figure 10) of the pyrite when CIBs acted as the grinding media. In addition, the XPS spectrum of the pyrite ground by the chromium-containing steel balls showed a weak Cr 2p peak, and Table 2 also shows that the surface of the pyrite ground by CSB18% and CSB12% contained 0.57% and 0.66% of Cr, respectively. However, no Cr 2p peak was observed in the XPS spectrum of the galena. This phenomenon is attributed to the fact that pyrite is harder than galena, and is more likely to cause the wear of chromium-containing steel balls.

Figure 11.

Wide-scan survey of minerals after grinding with different media: (a) galena; (b) pyrite.

Table 1.

Elemental normalized percentage of galena surface after ball grinding with different media.

Table 2.

Elemental normalized percentage of pyrite surface after ball grinding with different media.

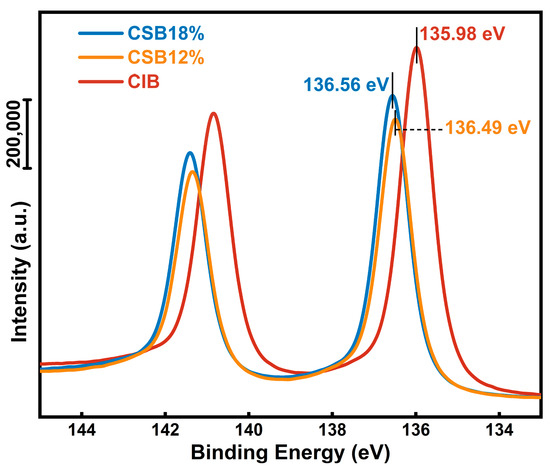

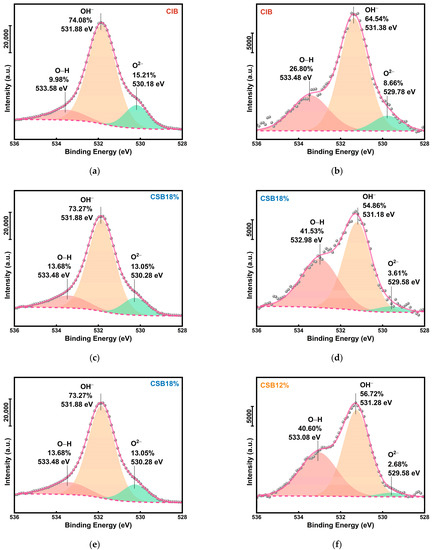

Figure 12 shows the Pb 4f spectrum of galena after grinding with the three media. The Pb 4f7/2 peaks in galena ground by CSB18%, CSB12%, and CIB appeared at binding energies of 136.56, 136.49, and 135.98 eV, respectively. Compared to the CSB18% and CSB12%, the CIBs induced a significant negative shift in the Pb 4f7/2 peak of the galena, confirming that the surface of the galena was more oxidized after grinding with the CIBs (https://srdata.nist.gov/xps/, last updated: 15 September 2012, accessed on: 13 September 2023). Figure 13 shows the O 1s spectra of galena and pyrite after grinding with the three media. The peaks at 533.58, 533.48, 532.98, and 533.08 eV are attributed to the O–H of adsorbed H2O, the peaks discovered at 531.88, 531.38, 531.18, and 531.28 eV represent the hydroxyls (OH−) in the mineral surface hydroxide, and the peaks at 530.18, 530.28, 529.78, and 529.58 eV belong to the lattice oxygen (O2−) in the metal oxide [37]. When CSB18% and CSB12% were used as grinding media, the distributions of O on the galena and pyrite surfaces were relatively close to each other. However, the distribution rate of O in OH− and O2− increased significantly after the galena and pyrite were ground by the CIBs. Meanwhile, the increment in the distribution of O in the OH− and O2− of the pyrite was much higher than that of galena when the CIBs were used as the grinding media. This phenomenon illustrates that the use of CIBs during grinding can exacerbate the oxidation of pyrite, whereas galena is only weakly oxidized. This difference in the degree of oxidation was the primary reason why galena and pyrite exhibited different trends in recovery under different grinding media.

Fe ⇌ Fe2+ + 2e−

1/2O2 + H2O + 2e− ⇌ 2OH−

1/2O2 + 2Fe2+ ⇌ 2Fe3+ + O2−

Fe3+ + 3OH− ⇌ Fe(OH)3

2Fe3+ + O2− + 4OH− ⇌ 2FeOOH + H2O

Figure 12.

High-resolution XPS spectrum of Pb 4f of galena.

Figure 13.

High-resolution XPS spectra of O 1s of (a,c,e) galena and (b,d,f) pyrite after grinding three media.

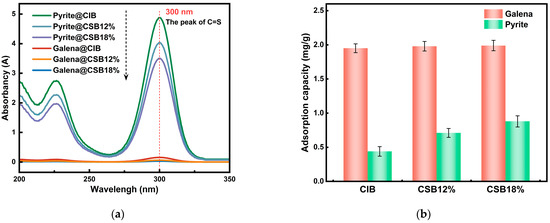

Pozzo [38] reported that the rest potential of pyrite (445 mV) in deionized water was higher than that of galena (172 mV), while the rest potential of steel and iron balls was even lower (usually below −200 mV). Thus, in a single-mineral grinding system, a galvanic interaction always occurs with the grinding media as the anode and the mineral as the cathode. The grinding media release ferrous ion ((Equation (2)), while the DO close to the minerals is reduced to OH− ((Equation (3)) [13]. The production of OH− is the dominant cause of the increase in the pulp pH and the decrease in the DO content during grinding. The generated Fe2+ will be oxidized and converted into iron hydroxides ((Equations (4)–(7)) [39]. The hydroxyl iron complexes tend to adhere to mineral surfaces and make minerals hydrophilic, which may hinder the adsorption of collectors (as shown in Figure 14). Considering that pyrite has a higher rest potential than galena, and that CIBs are more wearable than chromium containing steel balls, the galvanic interaction between the CIB and pyrite would be more likely to occur. Therefore, when CIBs are used as grinding media, the surface of pyrite has higher percentages of OH− and O2−, which effectively amplifies the difference in hydrophilicity between galena and pyrite. The different contents of the hydroxyl iron complexes on the surfaces of galena and pyrite inevitably affect the adsorption of the collector.

Figure 14.

Adsorption capacity of collector on mineral surface under different grinding media: (a) UV–Vis spectra of solutions after adsorption and (b) differences in adsorption capacity.

3.5. Variation of BX Adsorption Capacity with Three Grinding Media

Figure 14a shows the UV spectra of the pulp supernatants of the galena and pyrite after grinding with different media. The main characteristic peak of the maximum absorbance at 300 nm is attributed to the presence of C=S in the BX molecular structure [40]. The absorbance of the pulp supernatant of pyrite was significantly higher than that of galena, indicating that less BX was adsorbed onto the pyrite surface. For the same mineral with different grinding media, the absorbance of the pulp supernatant decreased sequentially in the order of CIB > CSB12% > CSB18%, indicating that CIBs as the grinding media were more detrimental to the adsorption of BX. Figure 14b gives the adsorption capacity of BX for galena and pyrite with different grinding media, which confirms that the difference in the absorption capacity of BX for galena and pyrite was greatest (1.51 mg/g) when using CIBs as the grinding media. This result echoes the results of the binary mixed-ore flotation (Figure 10) and the XPS analyses (Figure 13), which, together, firmly support the fact that selecting suitable grinding media can enhance the selective separation of galena and pyrite.

4. Conclusions

In this study, it was proposed to aid in broadening the hydrophilicity of the surfaces of galena and pyrite by varying the type of grinding media. The effects of CIS, CSB18%, and CSB12% on the pulp properties and hydrophilicity of galena and pyrite were investigated using grinding tests, micro-flotation tests, XPS, and adsorption capacity analyses. The following conclusions are drawn.

- For galena and pyrite, the pH of the pulp increased with grinding time, while the potential and dissolved oxygen content of the pulp decreased with grinding time. Under the same grinding conditions, CIBs as the grinding media resulted in a higher pH and lower potential and DO content of the pulp.

- The floatation systems of both single mineral and binary mixed mineral confirmed that CIBs as grinding media are more beneficial for expanding the floatability of galena and pyrite. In the binary mixed-mineral flotation system, the recovery of pyrite with CIBs as the grinding media was lower than that with chromium-containing steel balls as the grinding media by approximately 30%.

- The XPS analysis showed that the variation in the grinding media did not have a significant effect on the oxidation of the galena surface, whereas the hydrophilic hydroxyl iron content of the pyrite surface increased significantly when CIBs were used as the grinding media. Therefore, the use of CIBs during grinding is more effective in expanding the surface hydrophilicity of galena and pyrite. The difference between the amount adsorbed BX of galena and pyrite also reached its maximum when CIBs were used as the grinding media.

Author Contributions

Conceptualization, R.L., W.S. and Y.H.; methodology, Q.Z., R.L. and J.L.; software, Q.Z.; validation, Q.Z., R.L. and J.L.; investigation, Q.Z. and J.L.; resources, R.L., W.S. and Y.H.; data curation, Q.Z. and J.L.; writing—original draft preparation, Q.Z. and J.L.; writing—review and editing, Q.Z. and J.L.; supervision, R.L., W.S. and Y.H.; project administration, R.L.; funding acquisition, R.L., W.S. and Y.H. All authors have read and agreed to the published version of the manuscript.

Funding

The authors acknowledge financial support from the National Natural Science Foundation of China (Grant No. 91962223 and 52174272) and the Fundamental Research Funds for the Central Universities of Central South University (Grant No. 2022ZZTS0425).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhou, Z.; Wang, C.; Ma, B.; Zhang, B.; Liu, D.; Xiong, H.; Deng, Y.; Xu, B. Separation of lead sulfide from galena concentrate via two-step vacuum distillation. Vacuum 2023, 213, 112155. [Google Scholar] [CrossRef]

- Pan, Z.; Liu, Z.; Xiong, J.; Li, J.; Wei, Q.; Zhang, Z.; Jiao, F.; Qin, W. Application and depression mechanism of sodium sulfite on galena-pyrite mixed concentrate flotation separation: Huize Lead-Zinc Mine, China, as an example. Miner. Eng. 2022, 185, 107696. [Google Scholar] [CrossRef]

- Song, W.; Zhou, J.; Wang, B.; Li, S.; Han, J. New insight into investigation of reduction of desulfurization ash by pyrite for clean generation SO2. J. Clean. Prod. 2020, 253, 120026. [Google Scholar] [CrossRef]

- Feng, B.; Zhang, W.; Guo, Y.; Wang, T.; Luo, G.; Wang, H.; He, G. The flotation separation of galena and pyrite using serpentine as depressant. Powder Technol. 2019, 342, 486–490. [Google Scholar] [CrossRef]

- Kyzas, G.Z.; Lazaridis, N.K.; Matis, K.A. Chapter 2—Flotation: Recent innovations in an interesting and effective separation process. In Interface Science and Technology; Kyzas, G.Z., Mitropoulos, A.C., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; Volume 30, pp. 15–42. [Google Scholar]

- Li, C.; Gao, Z. Effect of grinding media on the surface property and flotation behavior of scheelite particles. Powder Technol. 2017, 322, 386–392. [Google Scholar] [CrossRef]

- Corin, K.C.; Song, Z.G.; Wiese, J.G.; O’Connor, C.T. Effect of using different grinding media on the flotation of a base metal sulphide ore. Miner. Eng. 2018, 126, 24–27. [Google Scholar] [CrossRef]

- Ding, W.; Bao, S.; Zhang, Y.; Xiao, J. Efficient Selective Extraction of Scandium from Red Mud. Miner. Process. Extr. Metall. Rev. 2023, 44, 304–312. [Google Scholar] [CrossRef]

- Ke, B.; Li, Y.; Chen, J.; Zhao, C.; Chen, Y. DFT study on the galvanic interaction between pyrite (100) and galena (100) surfaces. Appl. Surf. Sci. 2016, 367, 270–276. [Google Scholar] [CrossRef]

- Kaur, J.; Schoonen, M.A. Non-linear hydroxyl radical formation rate in dispersions containing mixtures of pyrite and chalcopyrite particles. Geochim. Cosmochim. Acta 2017, 206, 364–378. [Google Scholar] [CrossRef]

- Aikawa, K.; Ito, M.; Segawa, T.; Jeon, S.; Park, I.; Tabelin, C.B.; Hiroyoshi, N. Depression of lead-activated sphalerite by pyrite via galvanic interactions: Implications to the selective flotation of complex sulfide ores. Miner. Eng. 2020, 152, 106367. [Google Scholar] [CrossRef]

- Azizi, A.; Shafaei, S.Z.; Noaparast, M.; Karamoozian, M. The effect of pH, solid content, water chemistry and ore mineralogy on the galvanic interactions between chalcopyrite and pyrite and steel balls. Front. Chem. Sci. Eng. 2013, 7, 464–471. [Google Scholar] [CrossRef]

- Chenje, T.W.; Simbi, D.J.; Navara, E. The role of corrosive wear during laboratory milling. Miner. Eng. 2003, 16, 619–624. [Google Scholar] [CrossRef]

- Bruckard, W.J.; Sparrow, G.J.; Woodcock, J.T. A review of the effects of the grinding environment on the flotation of copper sulphides. Int. J. Miner. Process. 2011, 100, 1–13. [Google Scholar] [CrossRef]

- Peng, Y.; Grano, S. Effect of iron contamination from grinding media on the flotation of sulphide minerals of different particle size. Int. J. Miner. Process. 2010, 97, 1–6. [Google Scholar] [CrossRef]

- Kinal, J.; Greet, C.; Goode, I. Effect of grinding media on zinc depression in a lead cleaner circuit. Miner. Eng. 2009, 22, 759–765. [Google Scholar] [CrossRef]

- Li, X.; Iwasaki, I. Effect of cathodic polarization on the floatability of chalcopyrite in the absence of oxygen. Min. Metall. Explor. 1992, 9, 1–6. [Google Scholar] [CrossRef]

- Greet, C.J.; Small, G.L.; Steinier, P.; Grano, S.R. The Magotteaux Mill®: Investigating the effect of grinding media on pulp chemistry and flotation performance. Miner. Eng. 2004, 17, 891–896. [Google Scholar] [CrossRef]

- Asamoah, R.K.; Baawuah, E.; Greet, C.; Skinner, W. Characterisation of Metal Debris in Grinding and Flotation Circuits. Miner. Eng. 2021, 171, 107074. [Google Scholar] [CrossRef]

- Zhang, X.; Han, Y.; Kawatra, S.K. Effects of Grinding Media on Grinding Products and Flotation Performance of Sulfide Ores. Miner. Process. Extr. Metall. Rev. 2021, 42, 172–183. [Google Scholar] [CrossRef]

- Jacques, S.; Greet, C.J.; Bastin, D. Oxidative weathering of a copper sulphide ore and its influence on pulp chemistry and flotation. Miner. Eng. 2016, 99, 52–59. [Google Scholar] [CrossRef]

- Peng, Y.; Grano, S.; Fornasiero, D.; Ralston, J. Control of grinding conditions in the flotation of galena and its separation from pyrite. Int. J. Miner. Process. 2003, 70, 67–82. [Google Scholar] [CrossRef]

- Wang, X.; Qin, W.; Jiao, F.; Wu, J. The influence of galvanic interaction on the dissolution and surface composition of galena and pyrite in flotation system. Miner. Eng. 2020, 156, 106525. [Google Scholar] [CrossRef]

- Zhang, X.; Han, Y.; Sun, M.; Li, W.; Li, Y.; He, J. Insight into the effects of grinding media on the flotation kinetics of chalcopyrite. Adv. Powder Technol. 2022, 33, 103860. [Google Scholar] [CrossRef]

- Li, Z.; Heping, L.; Liping, X. Galvanic interaction between galena and pyrite in an open system. Chin. J. Geochem. 2006, 25, 230–237. [Google Scholar] [CrossRef]

- Zhao, Q.; Yang, H.; Tong, L.; Jin, R.; Ma, P. Understanding the effect of grinding media on the adsorption mechanism of cyanide to chalcopyrite surface by ToF–SIMS, XPS, contact angle, zeta potential and flotation. Colloids Surf. A: Physicochem. Eng. Asp. 2022, 644, 128799. [Google Scholar] [CrossRef]

- Zhang, X.; Han, Y.; Gao, P.; Li, Y.; Sun, Y. Effects of particle size and ferric hydroxo complex produced by different grinding media on the flotation kinetics of pyrite. Powder Technol. 2020, 360, 1028–1036. [Google Scholar] [CrossRef]

- López Valdivieso, A.; Sánchez López, A.A.; Ojeda Escamilla, C.; Fuerstenau, M.C. Flotation and depression control of arsenopyrite through pH and pulp redox potential using xanthate as the collector. Int. J. Miner. Process. 2006, 81, 27–34. [Google Scholar] [CrossRef]

- Xu, S.; Zanin, M.; Skinner, W.; Brito e Abreu, S. Surface chemistry of oxidised pyrite during grinding: ToF-SIMS and XPS surface analysis. Miner. Eng. 2021, 170, 106992. [Google Scholar] [CrossRef]

- Qin, W.; Wang, X.; Ma, L.; Jiao, F.; Liu, R.; Yang, C.; Gao, K. Electrochemical characteristics and collectorless flotation behavior of galena: With and without the presence of pyrite. Miner. Eng. 2015, 74, 99–104. [Google Scholar] [CrossRef]

- Luttrell, G.; Yoon, R.-H. A hydrodynamic model for bubble—Particle attachment. J. Colloid Interface Sci. 1992, 154, 129–137. [Google Scholar] [CrossRef]

- Ali, Y.; Garcia-Mendoza, C.D.; Gates, J.D. Effects of ‘impact’ and abrasive particle size on the performance of white cast irons relative to low-alloy steels in laboratory ball mills. Wear 2019, 426–427, 83–100. [Google Scholar] [CrossRef]

- Sun, W.; Sun, C.; Liu, R.-q.; Cao, X.-f.; Tao, H.-b. Electrochemical behavior of galena and jamesonite flotation in high alkaline pulp. Trans. Nonferrous Met. Soc. China 2016, 26, 551–556. [Google Scholar] [CrossRef]

- Shen, Z.; Wen, S.; Han, G.; Zhou, Y.; Bai, X.; Feng, Q. Selective depression mechanism of locust bean gum in the flotation separation of chalcopyrite from pyrite in a low-alkalinity media. Miner. Eng. 2021, 170, 107044. [Google Scholar] [CrossRef]

- Ahlberg, E.; Elfström Broo, A. Oxygen reduction at sulphide minerals. 2. A rotating ring disc electrode (RRDE) study at galena and pyrite in the presence of xanthate. Int. J. Miner. Process. 1996, 47, 33–47. [Google Scholar] [CrossRef]

- Qin, W.-q.; Wang, X.-j.; Ma, L.-y.; Jiao, F.; Liu, R.-z.; Gao, K. Effects of galvanic interaction between galena and pyrite on their flotation in the presence of butyl xanthate. Trans. Nonferrous Met. Soc. China 2015, 25, 3111–3118. [Google Scholar] [CrossRef]

- Zhai, Q.; Liu, R.; Wang, C.; Wen, X.; Li, X.; Sun, W. A novel scheme for the utilization of Cu slag flotation tailings in preparing internal electrolysis materials to degrade printing and dyeing wastewater. J. Hazard. Mater. 2022, 424, 127537. [Google Scholar] [CrossRef] [PubMed]

- Pozzo, R.L. Electrochemical Interactions Between Sulfide Minerals and Grinding Media and Their Effects on Flotation and Media Wear. Ph.D. Thesis, University of Minnesota, Minneapolis, MN, USA, 1987. [Google Scholar]

- Chen, Z.; Xia, L.; Hart, B.; Chi, R.; Yu, J. Influence of ball mill medium and size on properties of copper-zinc ore pulp and mineral surface. Chin. J. Nonferrous Met. 2017, 8, 1701–1707. [Google Scholar] [CrossRef]

- Ozturk, Y. Electrochemical advanced oxidation for removal of xanthate from flotation process water. Miner. Eng. 2023, 202, 108308. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).