Ce and Nd Extraction by Cationic Exchange, Using Bentonite, Diatomite, and Eggshell—Preliminary Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

Characterization

2.2. Experimental Procedure

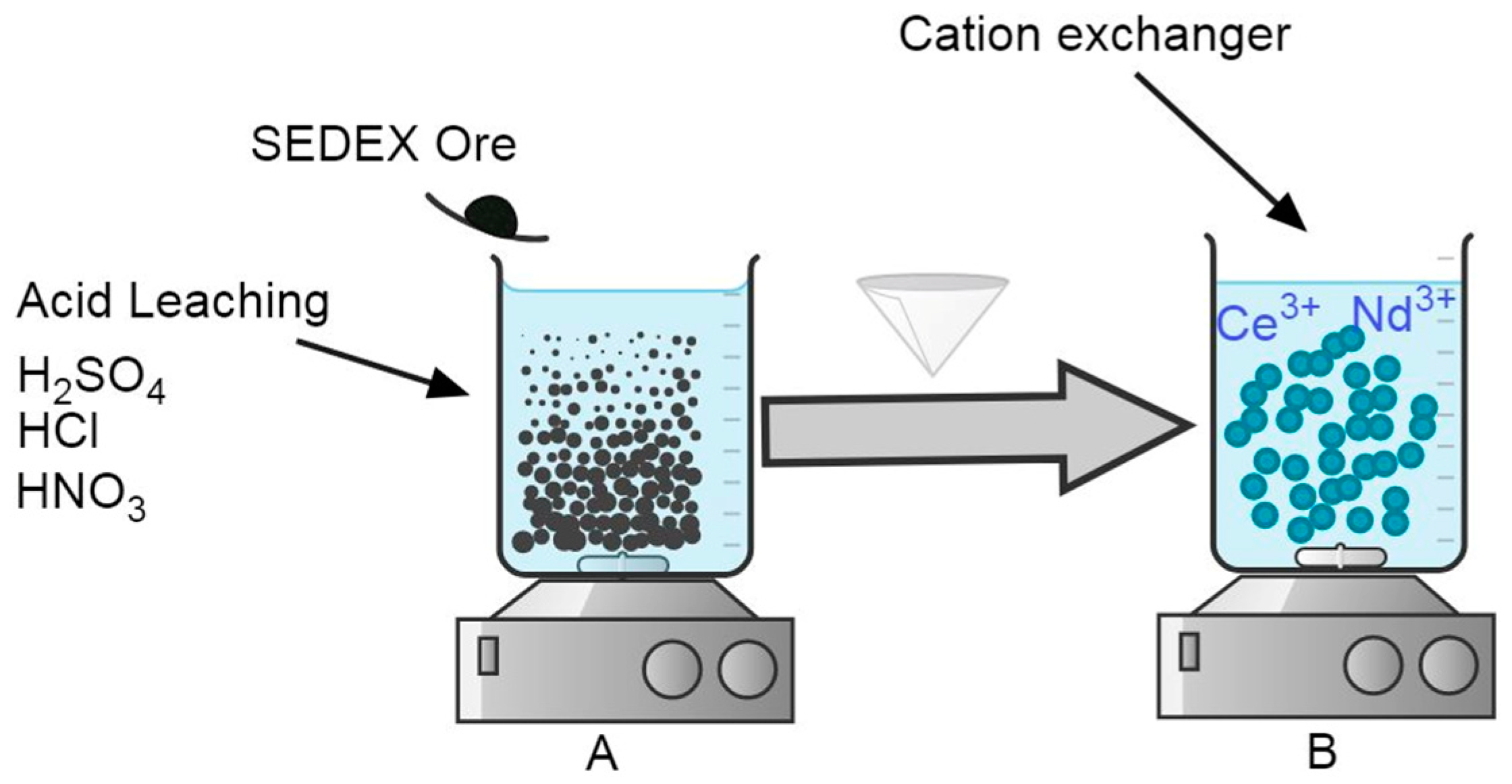

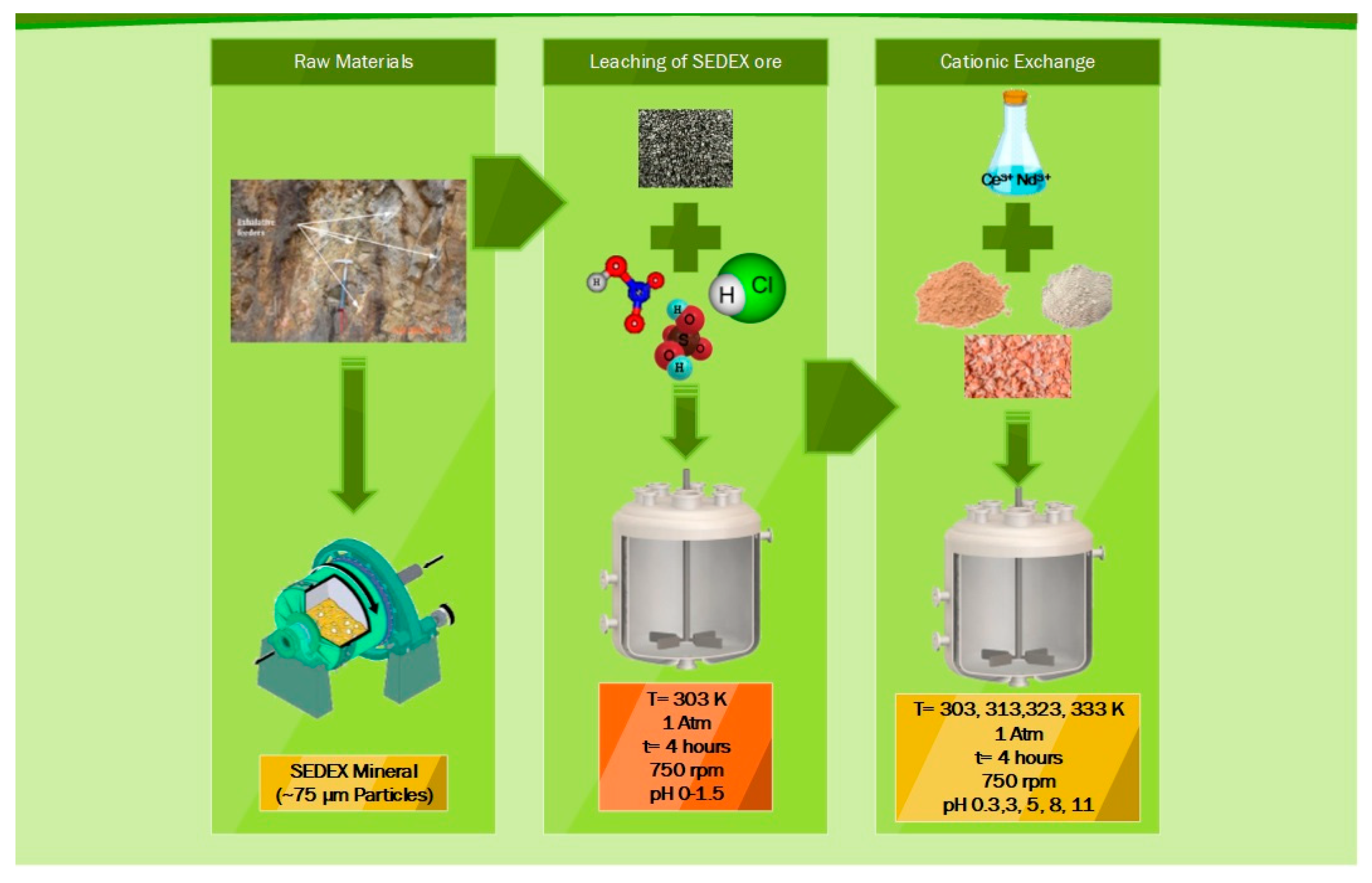

Leaching of Mineral and Cationic Exchange

3. Results

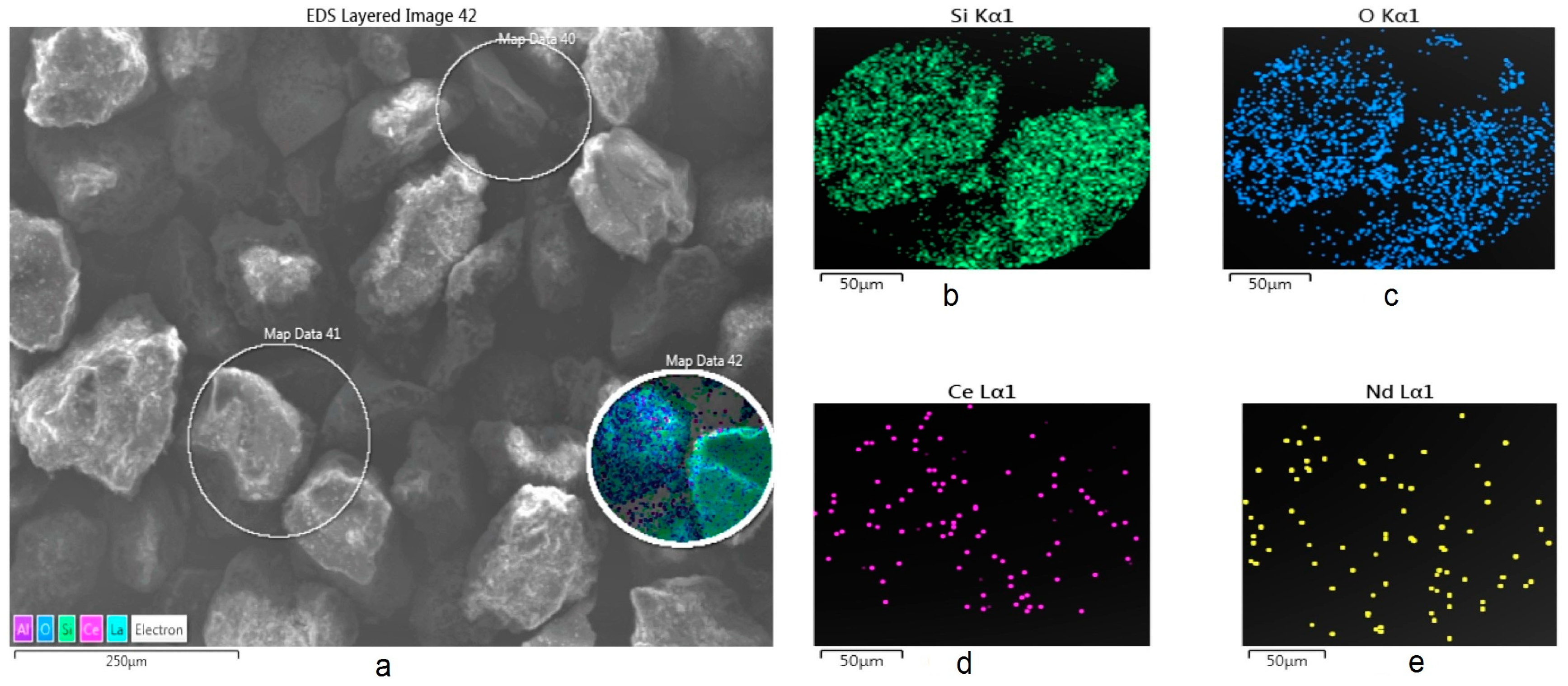

3.1. Characterization of SEDEX-Type Ore

3.2. Acid Leaching of the SEDEX Ore Mineral for Ce and Nd Extraction

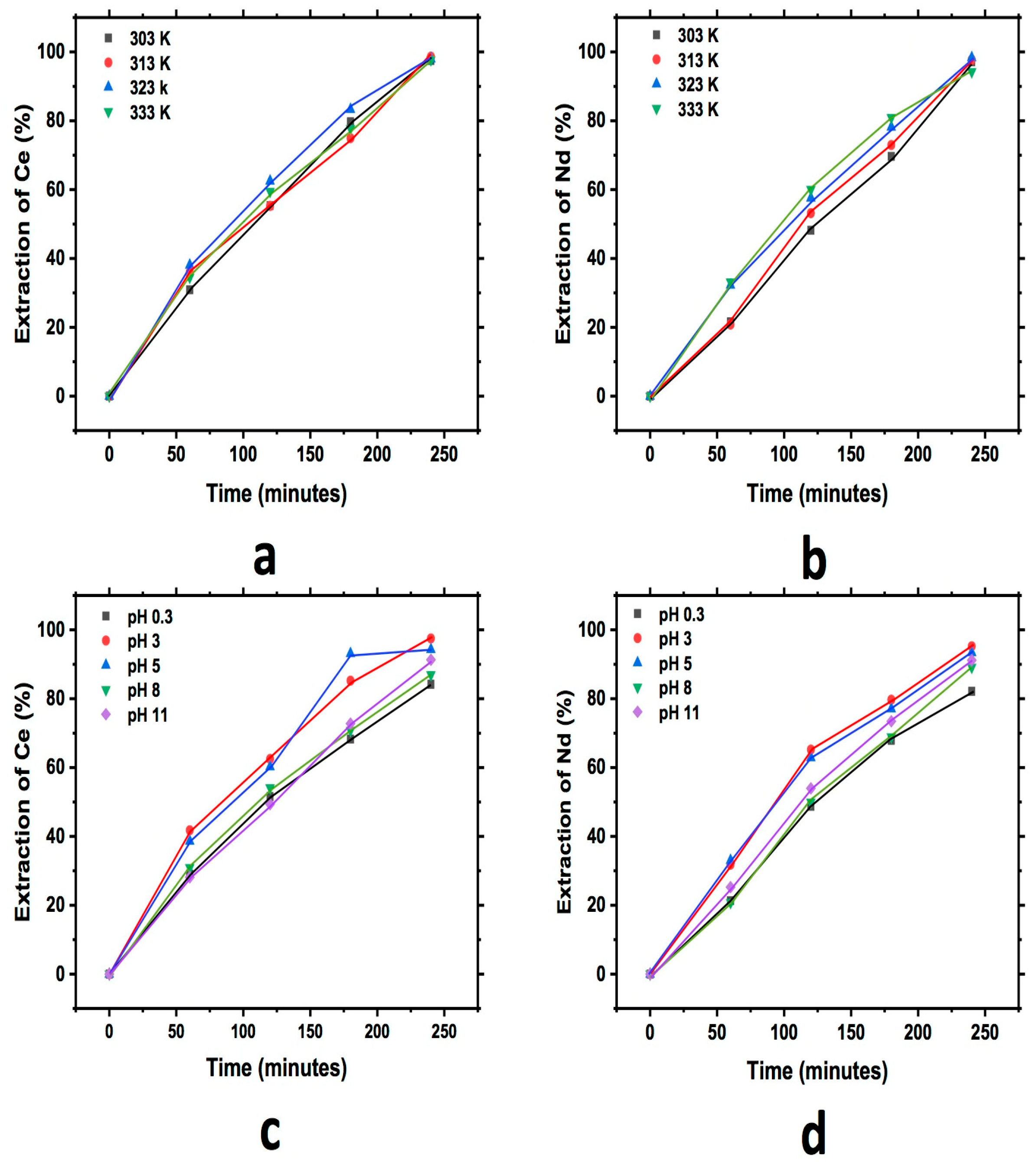

3.3. Cationic Exchange

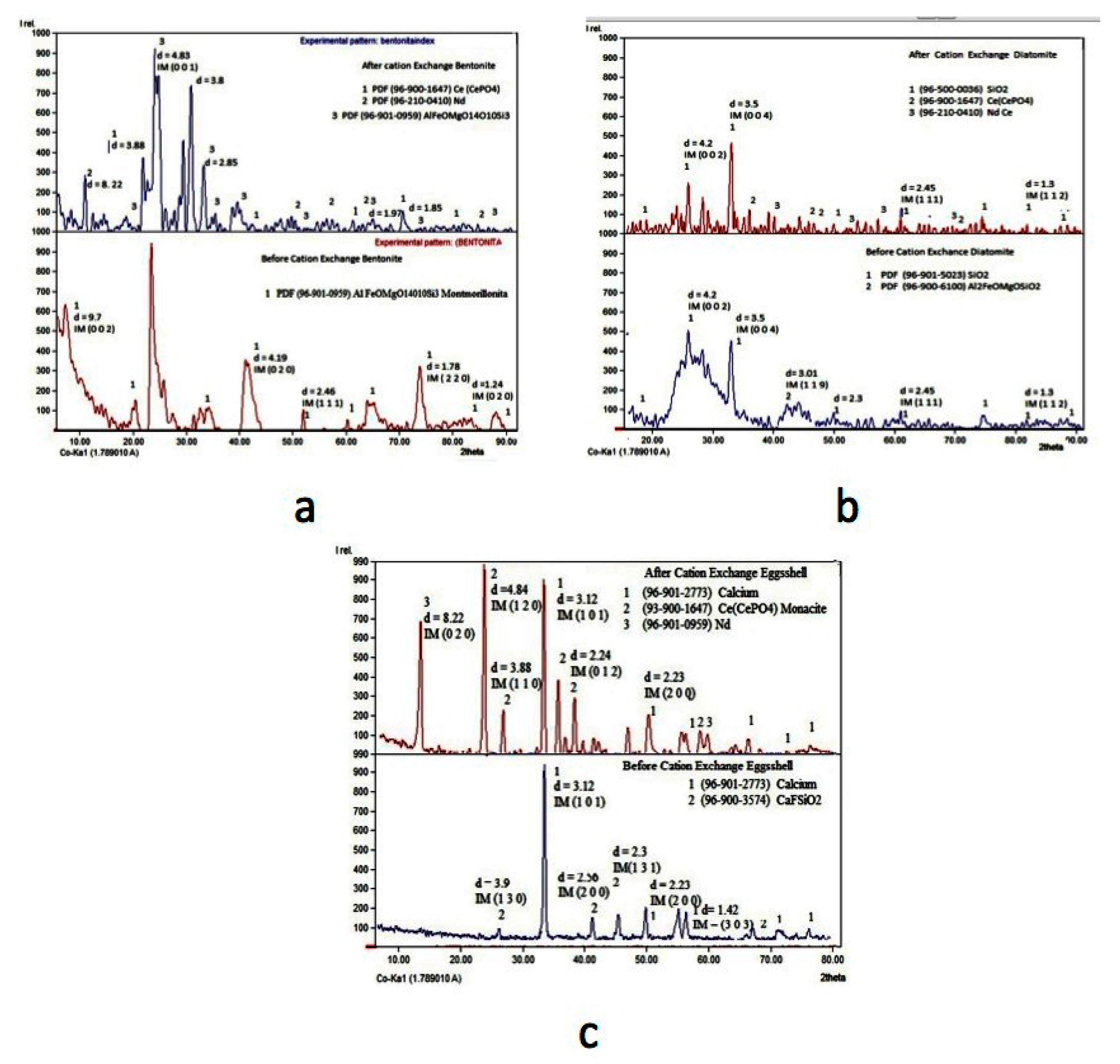

3.3.1. Bentonite

3.3.2. Diatomite

3.3.3. Eggshell

3.3.4. Efficiency of the Cationic Exchange

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Daly, J.C.K. Mongolia’s rare earth reserves draw foreign investor interest. Centr. Asia-Cauc. Anal. 2011, 13, 6–8. [Google Scholar]

- USGS (U.S. Geological Survey). Mineral Commodity Summaries (2018–2022e) [R/LO]. Available online: https://pubs..usgs.gov/periodicals/mcs2023/msc2023-rare-earths.pdf (accessed on 15 May 2023).

- Kim, R.; Cho, H.; Han, K.N.; Kim, K.; Mun, M. Optimization of acid leaching of rare-earth elements from mongolian apatite-based ore. Minerals 2016, 6, 63. [Google Scholar] [CrossRef]

- Sadri, F.; Nazari, A.M.; Ghahreman, A. A review on the cracking, baking and leaching processes of rare earth element concentrates. J. Rare Earths 2017, 35, 739–752. [Google Scholar] [CrossRef]

- Rodriguez-Figueroa, G.M. Geochemistry of Trace Elements, Major Elements and Rare Earth Elements, in the Marine Sediments of the Mining District of Santa Rosalía, B.C.S; Instituto Politecnico Nacional: Mexico City, Mexico, 2004. [Google Scholar]

- Campa Uranga, M.F.; Torres de León, R.; Iriondo, A.; Premo, W.R. Caracterización geológica de los ensambles metamórficos de Taxco y Taxco el Viejo, Guerrero (In Spanish), México. Boletín La Soc. Geológica Mex. 2012, 64, 369–385. [Google Scholar] [CrossRef]

- Badillo, A.L.; Flores, K.; Esquivel, C.; Duran, J.C.; Noé, P. Organic Geochemistry applied to Middle Jurassic sedimentary rocks in the Aztlan outcrop in Huhuetla, Hidalgo (Mexico): Paleoenvironmental implications. XXII Congr. Nac. Geoquimica 2012, 18, 181. [Google Scholar]

- Cerecedo-Sáenz, E.; Rodríguez-Lugo, V.; Hernández-Ávila, J.; Mendoza-Anaya, D.; Reyes-Valderrama, M.I.; Moreno-Pérez, E.; Salinas-Rodríguez, E. Mineralization of Rare Earths, Platinum and Gold in a Sedimentary Deposit, Found Using an Indirect Method of Exploration. Asp. Min. Miner. Sci. 2018, 1, 1–9. [Google Scholar] [CrossRef]

- Lee, J.C.; Kurniawan; Hong, H.J.; Chung, K.W.; Kim, S. Separation of platinum, palladium and rhodium from aqueous solutions using ion exchange resin: A review. Sep. Purif. Technol. 2020, 246, 116896. [Google Scholar] [CrossRef]

- Walls, D.; Walker, J.M. Protein Chromatography. Protein Chromatogr. 2017, 1485, 423. [Google Scholar] [CrossRef]

- Jungbauer, A.; Hahn, R. Chapter 22 Ion-Exchange Chromatography. In Methods in Enzymology; Elsevier Inc.: Amsterdam, The Netherlands, 2009; Volume 463, pp. 349–371. [Google Scholar]

- Virolainen, S.; Wesselborg, T.; Kaukinen, A.; Sainio, T. Removal of iron, aluminium, manganese and copper from leach solutions of lithium-ion battery waste using ion exchange. Hydrometallurgy 2021, 202, 105602. [Google Scholar] [CrossRef]

- Hammache, Z.; Bensaadi, S.; Berbar, Y.; Audebrand, N.; Szymczyk, A.; Amara, A. Recovery of rare earths elements from electronic waste by diffusion dialysis. Separ. Pufic. Tech. 2021, 254, 117641. [Google Scholar] [CrossRef]

- Hermassi, M.; Granados, M.; Valderrama, C.; Skoglund, N.; Ayora, C.; Cortina, J.L. Impact of functional group types in ion exchange resins on rare earths elements recovery fromtreated acid mine waters. J. Clean. Prod. 2022, 379 Pt 2, 134742. [Google Scholar] [CrossRef]

- Alshameri, A.; He, H.; Xin, C.; Zhu, J.; Xinghu, W.; Zhu, R.; Wang, H. Understanding the role of natural clay minerals as effective adsorbents and alternative source of rare earth elements: Adsorption operative parameters. Hydrometallurgy 2019, 185, 149–161. [Google Scholar] [CrossRef]

- Avdibegović, D.; Zhang, W.; Xu, J.; Regadío, M.; Koivula, R.; Binnemans, K. Selective ion-exchange separation of scandium(III) over iron(III) by crystalline A-zirconium phosphate platelets under acidic conditions. Sep. Purif. Technol. 2019, 215, 81–90. [Google Scholar] [CrossRef]

- Swain, N.; Mishra, S. A review on the recovery and separation of rare earths and transition metals from secondary resources. J. Clean. Prod. 2019, 220, 884–898. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, L.; Yan, Y.; Chen, J.; Dai, J.; Dai, X. Separation of adjacent heavy rare earth Lutetium (III) and Ytterbium (III) by task-specific ionic liquid Cyphos IL 104 embedded polymer inclusion membrane. J. Memb. Sci. 2020, 610, 118263. [Google Scholar] [CrossRef]

- Shu, Q.; Khayambashi, A.; Wang, X.; Wei, Y. Studies on adsorption of rare earth elements from nitric acid solution with macroporous silica-based bis(2-ethylhexyl)phosphoric acid impregnated polymeric adsorbent. Adsorpt. Sci. Technol. 2018, 36, 1049–1065. [Google Scholar] [CrossRef]

- Khawassek, Y.M.; Eliwa, A.A.; Haggag, E.S.A.; Omar, S.A.; Abdel-Wahab, S.M. Adsorption of rare earth elements by strong acid cation exchange resin thermodynamics, characteristics and kinetics. SN Appl. Sci. 2019, 1, 51. [Google Scholar] [CrossRef]

- Bohác, P.; Delaverhe, L.; Zervas, E.; Königer, F.; Schuhmann, R.; Emmerich, K. Cation exchange capacity of bentonite in a saline environment. Appl. Geochem. 2019, 100, 407–413. [Google Scholar] [CrossRef]

- da Costa, T.B.; da Silva, M.G.C.; Vieira, M.G.A. Recovery of rare-earth metals from aqueous solutions by bio/adsorption using non-conventional materials: A review with recent studies and promising approaches in column applications. J. Rare Earths 2020, 38, 339–355. [Google Scholar] [CrossRef]

- Cristiani, C.; Bellotto, M.; Dotelli, G.; Latorrata, S.; Ramis, G.; Stampino, P.G.; Zubiani, E.M.I.; Finocchio, E. Rare earths (La, y, and nd) adsorption behaviour towards mineral clays and organoclays: Monoionic and trionic solutions. Minerals 2021, 11, 30. [Google Scholar] [CrossRef]

- Iannicelli-Zubiani, E.M.; Cristiani, C.; Dotelli, G.; Gallo Stampino, P.; Pelosato, R.; Mesto, E.; Schingaro, E.; Lacalamita, M. Use of natural clays as sorbent materials for rare earth ions: Materials characterization and set up of the operative parameters. Waste Manag. 2015, 46, 546–556. [Google Scholar] [CrossRef] [PubMed]

- Anastopoulos, I.; Bhatnagar, A.; Lima, E.C. Adsorption of rare earth metals: A review of recent literature. J. Mol. Liq. 2016, 221, 954–962. [Google Scholar] [CrossRef]

- Freiherr, G. Conventional x-ray still tops in vascular imaging. Diagn. Imaging 1994, 16, 33–34, 37, 39. [Google Scholar]

- Cheng, Y.; Tao, J.; Jiao, Y.; Guo, Q.; Li, C. Influence of diatomite and mineral powder on thermal oxidative ageing properties of asphalt. Adv. Mater. Sci. Eng. 2015, 2015, 947834. [Google Scholar] [CrossRef]

- Al-Degs, Y.; Khraisheh, M.A.M.; Tutunji, M.F. Sorption of lead ions on diatomite and manganese oxides modified diatomite. Water Res. 2001, 35, 3724–3728. [Google Scholar] [CrossRef] [PubMed]

- Chojnacka, K. Biosorption of Cr(III) ions by eggshells. J. Hazard. Mater. 2005, 121, 167–173. [Google Scholar] [CrossRef]

- Van Der Watt, J.G.; Waanders, F.B. Leaching of rare earth elements from bentonite clay. J. S. Afr. Inst. Min. Metall. 2012, 112, 281–285. [Google Scholar]

- Chegrouche, S.; Mellah, A.; Telmoune, S. Removal of lanthanum from aqueous solutions by natural bentonite. Water Res. 1997, 31, 1733–1737. [Google Scholar] [CrossRef]

- Aagaard, P. Rare earth elements adsorption on clay minerals. Bull. Groupe Français Argiles 1974, 26, 193–199. [Google Scholar] [CrossRef]

- Sheng, G.; Hu, J.; Wang, X. Sorption properties of Th(IV) on the raw diatomite-Effects of contact time, pH, ionic strength and temperature. Appl. Radiat. Isot. 2008, 66, 1313–1320. [Google Scholar] [CrossRef]

- Hernandez-Avila, J.; Serrano-Mejía, E.O.; Salinas-Rodríguez, E.; Cerecedo-Sáenz, E.; Isabel Reyes-Valderrama, M.; del Pilar Gutiérrez-Amador, M.; Rodríguez-Lugo, V. Use of Porous no Metallic Minerals to Remove Heavy Metals, Precious Metals and Rare Earths, by Cationic Exchange. In Trace Metals in the Environment-New Approaches and Recent Advances; IntechOpen: London, UK, 2021; Chapter 11; pp. 1–18. [Google Scholar] [CrossRef]

- Roldán-Contreras, E.; Salinas-Rodríguez, E.; Hernández-Ávila, J.; Cerecedo-Sáenz, E.; Rodríguez-Lugo, V.; Jeldres, R.I.; Toro, N. Leaching of Silver and Gold Contained in a Sedimentary Ore, Using Sodium Thiosulfate; A Preliminary Kinetic Study. Metals 2020, 10, 159. [Google Scholar] [CrossRef]

- Cerecedo-Sáenz, E.; Salinas-Rodríguez, E.; Amador-Ortega, C.A.; del Pilar Gutiérrez-Amador, M.; Sánchez-Trujillo, M.G.; Hernández-Ávila, J. Recuperación de Tierras Raras Mediante Intercambio Catiónico, Usando bentonita Natural: Estudio Preliminar (In Spanish). Pädi 2019, 7, 98–103. [Google Scholar] [CrossRef]

- Hernández-Ávila, J.; Salinas-Rodríguez, E.; Cerecedo-Sáenz, E.; Reyes-Valderrama, M.I.; Arenas-Flores, A.; Román-Gutiérrez, A.D.; Rodríguez-Lugo, V. Diatoms and Their Capability for Heavy Metal Removal by Cationic Exchange. Metals 2017, 7, 169. [Google Scholar] [CrossRef]

- Echeverry-Vargas, L.; Rojas-Reyes, N.R.; Ocampo-Carmona, L.M. Recovery of light rare earths elements, cerium, lanthanum, and neodymium from alluvial gold mining waste from the Bagre-Nechí mining district in Colombia using acid leaching, oxalate precipitation and calcination. Hydrometallurgy 2023, 216, 106009. [Google Scholar] [CrossRef]

- Xie, C.; Xiao, Y.; He, C.; Lui, W.-S.; Tang, Y.-T.; Wang, S.; van der Ent, A.; Morel, J.L.; Simonnot, M.-O.; Qiu, R.-L. Selective recoveryof rare earths elements and value-added chemicals from de Dicranopteris linearis bio-ore produced by agromining using green fractionation. J. Hazard. Mater. 2023, 443, 130253. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Wu, Y.; Xie, Z.; Li, Y.; Tang, W.; Yu, J. Calcium Hydroxide recycled from waste eggshell resources for the effective recovery of flouride from wastwater. RSC Adv. 2022, 12, 28264–28278. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Experimental Condition |

|---|---|

| Acid concentration | H2SO4, HCl or HNO3 (1 M) |

| Volume (L) | 0.5 |

| Sample weight (g) | 30.0 |

| Temperature (K) | 303 |

| Stirring system | Magnetic |

| Stirring rate (RPM) | 750 |

| Reaction time (Hour) | 4 |

| Pressure | Atmospheric (open) |

| Parameter | Experimental Condition |

|---|---|

| Volume (L) | 0.5 |

| Exchanger (B, D, or E) weight (g) | 30.0 |

| Temperature (K) | 303, 313, 323 and 333 |

| pH | 0.3, 3, 5, 8 and 11 |

| Stirring system | Magnetic |

| Stirring rate (RPM) | 750 |

| Reaction time (Hour) | 4 |

| Pressure | Atmospheric (open) |

| Elements | Leaching Media | |||

|---|---|---|---|---|

| H2SO4 | HCl | HNO3 | ||

| Ce (ppm) | Before Leaching | 131.7 | 134.2 | 134.2 |

| After Leaching | 3.3 | 4.8 | 10.8 | |

| Nd (ppm) | Before Leaching | 91.3 | 93.5 | 89.6 |

| After Leaching | 3.9 | 6.1 | 12.2 | |

| Efficiency (%) | 97.6 (Ce) | 96.4 (Ce) | 92.0 (Ce) | |

| 95.7 (Nd) | 93.5 (Nd) | 86.4 (Nd) | ||

| Exchanger | BET Specific Surface Area (m2/g) |

|---|---|

| Diatomite | 22.53 |

| Bentonite | 18.31 |

| Eggshell | 2.75 |

| Ce and Nd Content (in ppm) | ||

|---|---|---|

| Mineral | Ce | Nd |

| Leachate | 128.4 | 87.4 |

| Bentonite | 0 | 0 |

| Diatomite | 0 | 0 |

| Eggshell | 0 | 0 |

| Cationic Exchange Efficiency (%) | |||||

|---|---|---|---|---|---|

| Exchanger-Element | pH 0.3 | pH 3 | pH 5 | pH 8 | pH 11 |

| Diatomite-Ce | 82.86 | 98.13 | 94.58 | 87.19 | 90.51 |

| Diatomite-Nd | 87.21 | 97.34 | 95.67 | 91.14 | 93.38 |

| Bentonite-Ce | 84.20 | 97.51 | 94.30 | 86.97 | 91.32 |

| Bentonite-Nd | 82.16 | 95.24 | 93.44 | 89.14 | 91.19 |

| Eggshell-Ce | 84.00 | 93.25 | 97.18 | 86.96 | 91.03 |

| Eggshell-Nd | 81.57 | 92.82 | 94.87 | 86.78 | 90.39 |

| Cationic Exchange Efficiency (%) | ||||

|---|---|---|---|---|

| Exchanger-Element | 303 K | 313 K | 323 K | 333 K |

| Diatomite-Ce | 98.13 | 99.02 | 99.06 | 98.84 |

| Diatomite-Nd | 97.15 | 97.84 | 99.07 | 96.39 |

| Bentonite-Ce | 97.49 | 98.63 | 97.96 | 97.74 |

| Bentonite-Nd | 97.17 | 97.75 | 98.36 | 94.24 |

| Eggshell-Ce | 97.41 | 99.11 | 97.64 | 97.25 |

| Eggshell-Nd | 94.83 | 95.85 | 98.36 | 94.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salinas Rodríguez, E.; Cárdenas-Reyes, E.A.; Barrientos-Hernández, F.R.; Flores-Badillo, J.; Gutiérrez-Amador, M.P.; Sánchez-Castillo, A.; Acevedo-Sandoval, O.A.; Cerecedo-Sáenz, E.; Hernández-Ávila, J. Ce and Nd Extraction by Cationic Exchange, Using Bentonite, Diatomite, and Eggshell—Preliminary Study. Minerals 2023, 13, 735. https://doi.org/10.3390/min13060735

Salinas Rodríguez E, Cárdenas-Reyes EA, Barrientos-Hernández FR, Flores-Badillo J, Gutiérrez-Amador MP, Sánchez-Castillo A, Acevedo-Sandoval OA, Cerecedo-Sáenz E, Hernández-Ávila J. Ce and Nd Extraction by Cationic Exchange, Using Bentonite, Diatomite, and Eggshell—Preliminary Study. Minerals. 2023; 13(6):735. https://doi.org/10.3390/min13060735

Chicago/Turabian StyleSalinas Rodríguez, Eleazar, Edgar A. Cárdenas-Reyes, Francisco R. Barrientos-Hernández, Javier Flores-Badillo, M. P. Gutiérrez-Amador, Ariadna Sánchez-Castillo, Otilio A. Acevedo-Sandoval, Eduardo Cerecedo-Sáenz, and Juan Hernández-Ávila. 2023. "Ce and Nd Extraction by Cationic Exchange, Using Bentonite, Diatomite, and Eggshell—Preliminary Study" Minerals 13, no. 6: 735. https://doi.org/10.3390/min13060735

APA StyleSalinas Rodríguez, E., Cárdenas-Reyes, E. A., Barrientos-Hernández, F. R., Flores-Badillo, J., Gutiérrez-Amador, M. P., Sánchez-Castillo, A., Acevedo-Sandoval, O. A., Cerecedo-Sáenz, E., & Hernández-Ávila, J. (2023). Ce and Nd Extraction by Cationic Exchange, Using Bentonite, Diatomite, and Eggshell—Preliminary Study. Minerals, 13(6), 735. https://doi.org/10.3390/min13060735