Application of Alumina Nanofibers as Adsorbents for the Removal of Mercury (II) and Lead (II) from Aqueous Solutions

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Synthesis and Characterisation of Adsorbent (Al2O3–NH–NH2 Nanofiber)

2.3. Heavy Metal Adsorption

2.4. Heavy Metal Adsorption with Varying pH Values

2.5. Adsorption Kinetics and Adsorption Capacities

2.6. Nanosorbent Selectivity

2.7. Desorption

3. Results and Discussion

3.1. Characterisation of Alumina Nanofibers

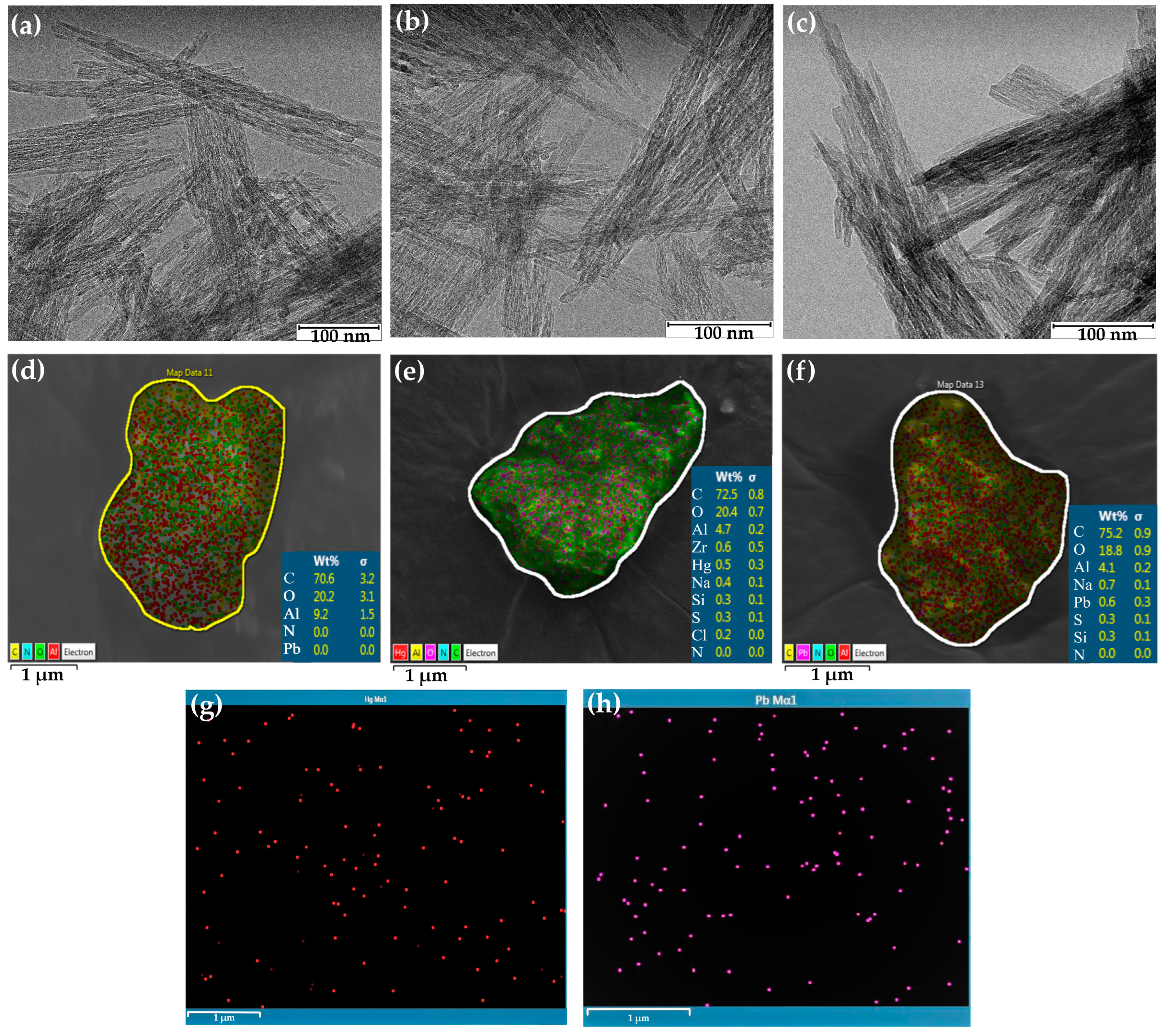

3.1.1. Morphology Analysis Using TEM and SEM–EDS

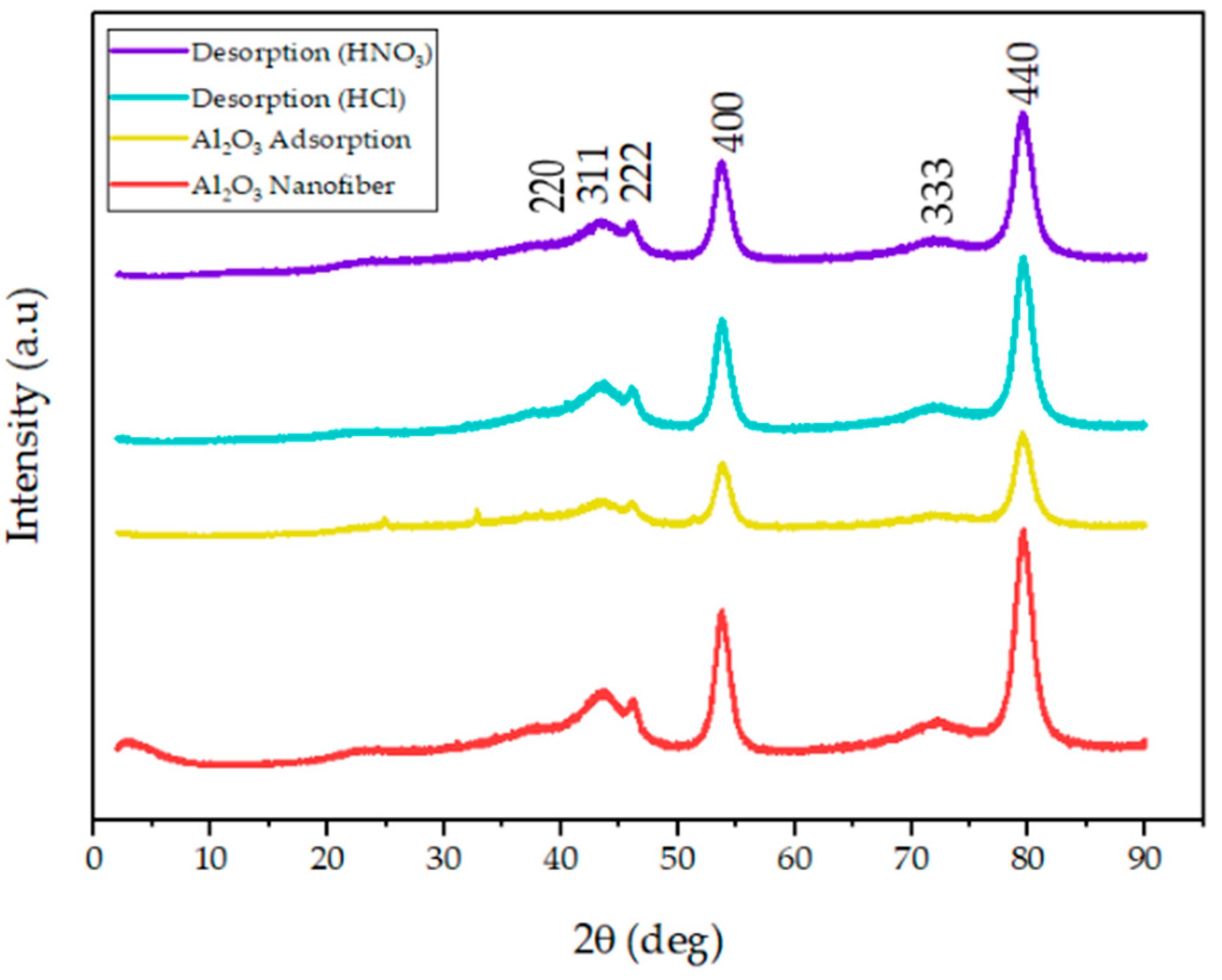

3.1.2. Structural Analysis Using XRD

3.1.3. XPS Analysis

3.2. Adsorption Studies of Alumina Nanofibers

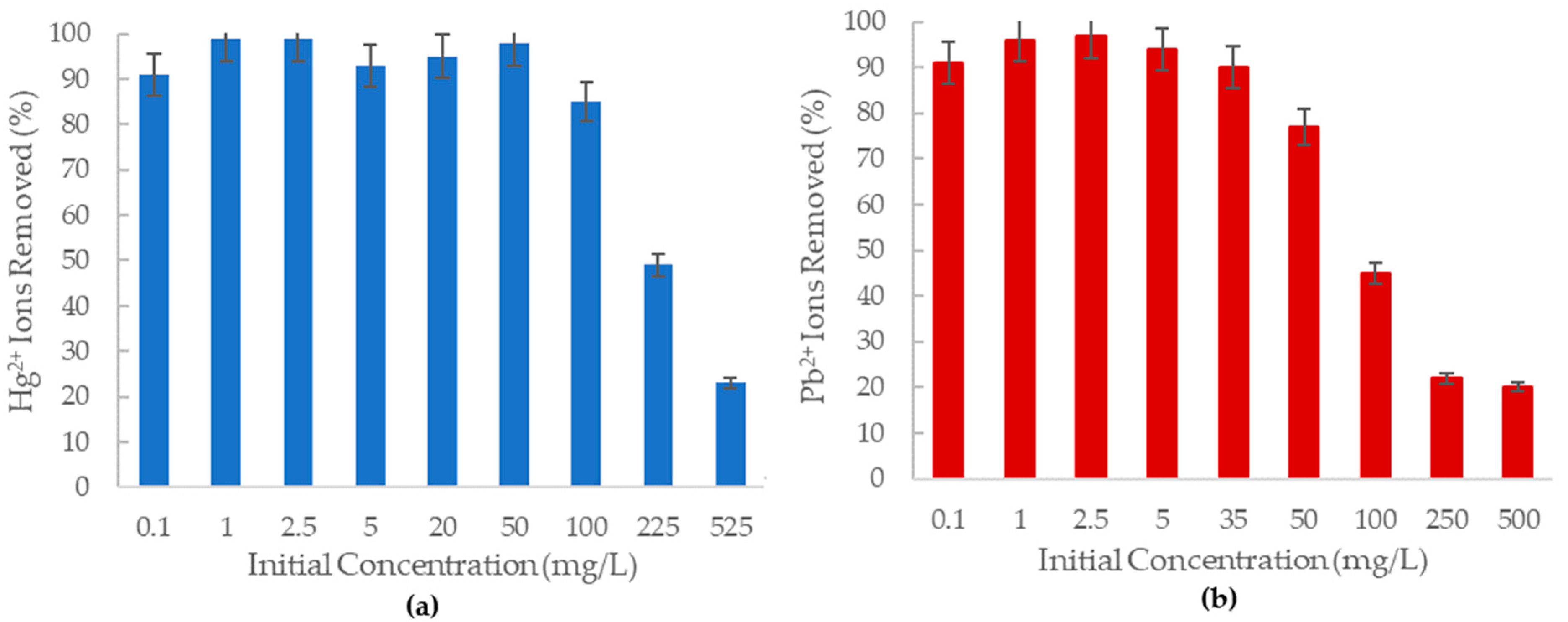

3.2.1. Effect of Initial Concentration on Adsorption Removal Percentage

3.2.2. Effect of pH on Adsorption Removal Percentage

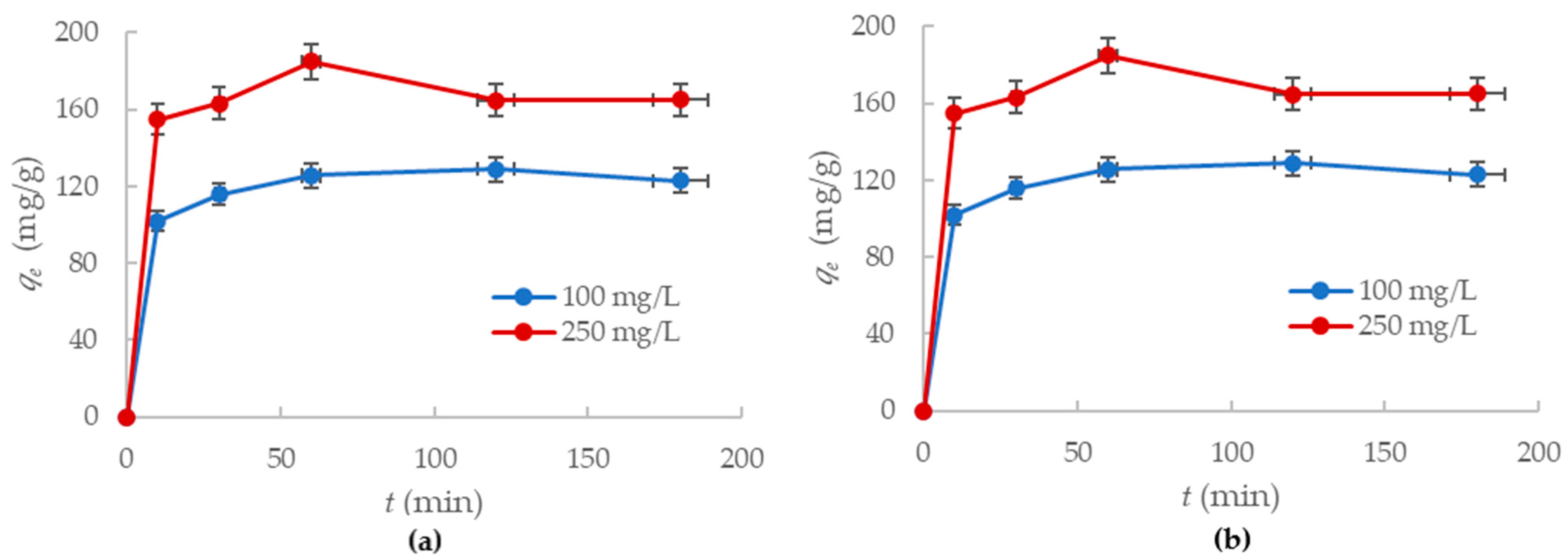

3.3. Adsorption Kinetics

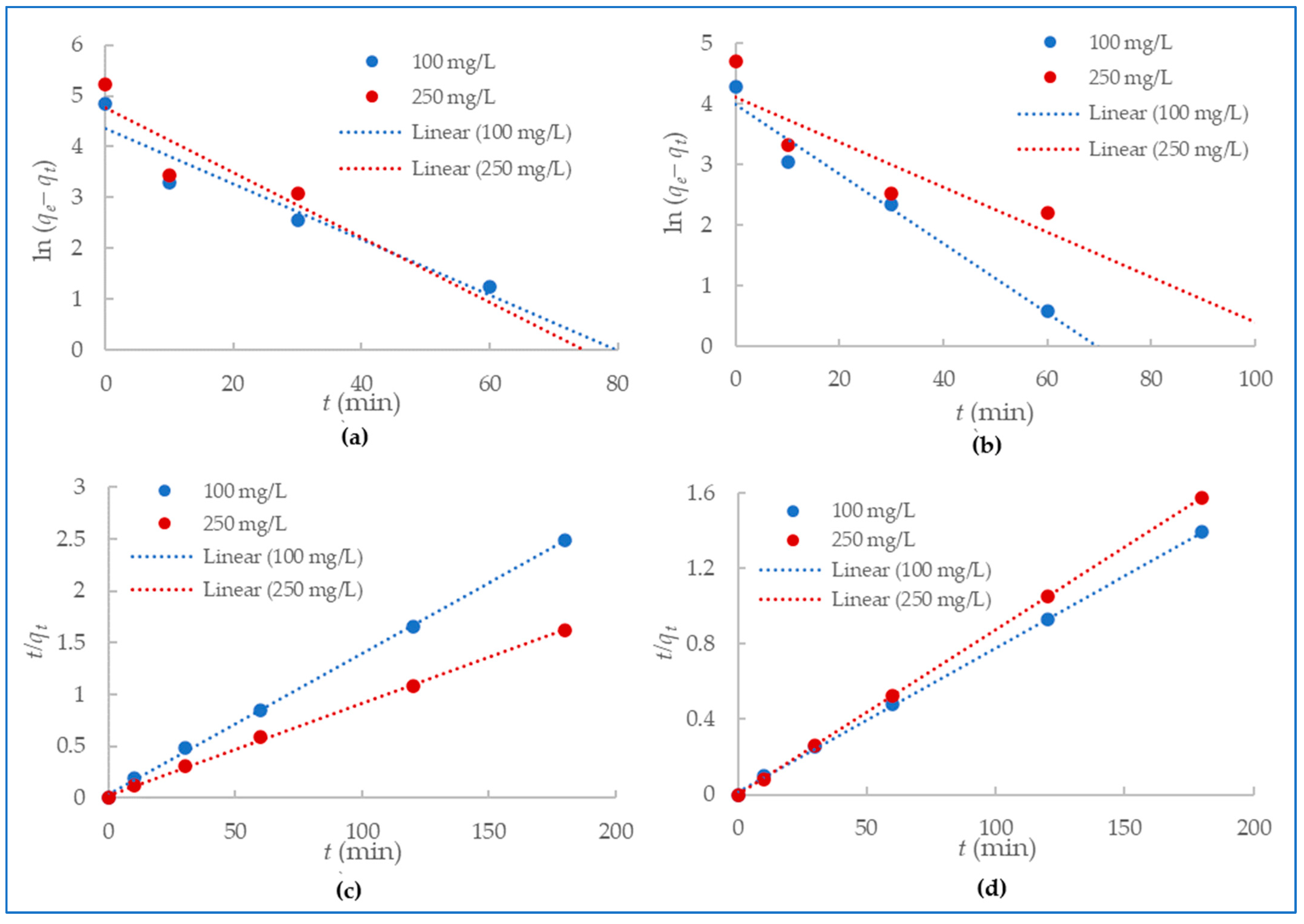

Pseudo-First-Order and Pseudo-Second-Order Kinetic Modeling

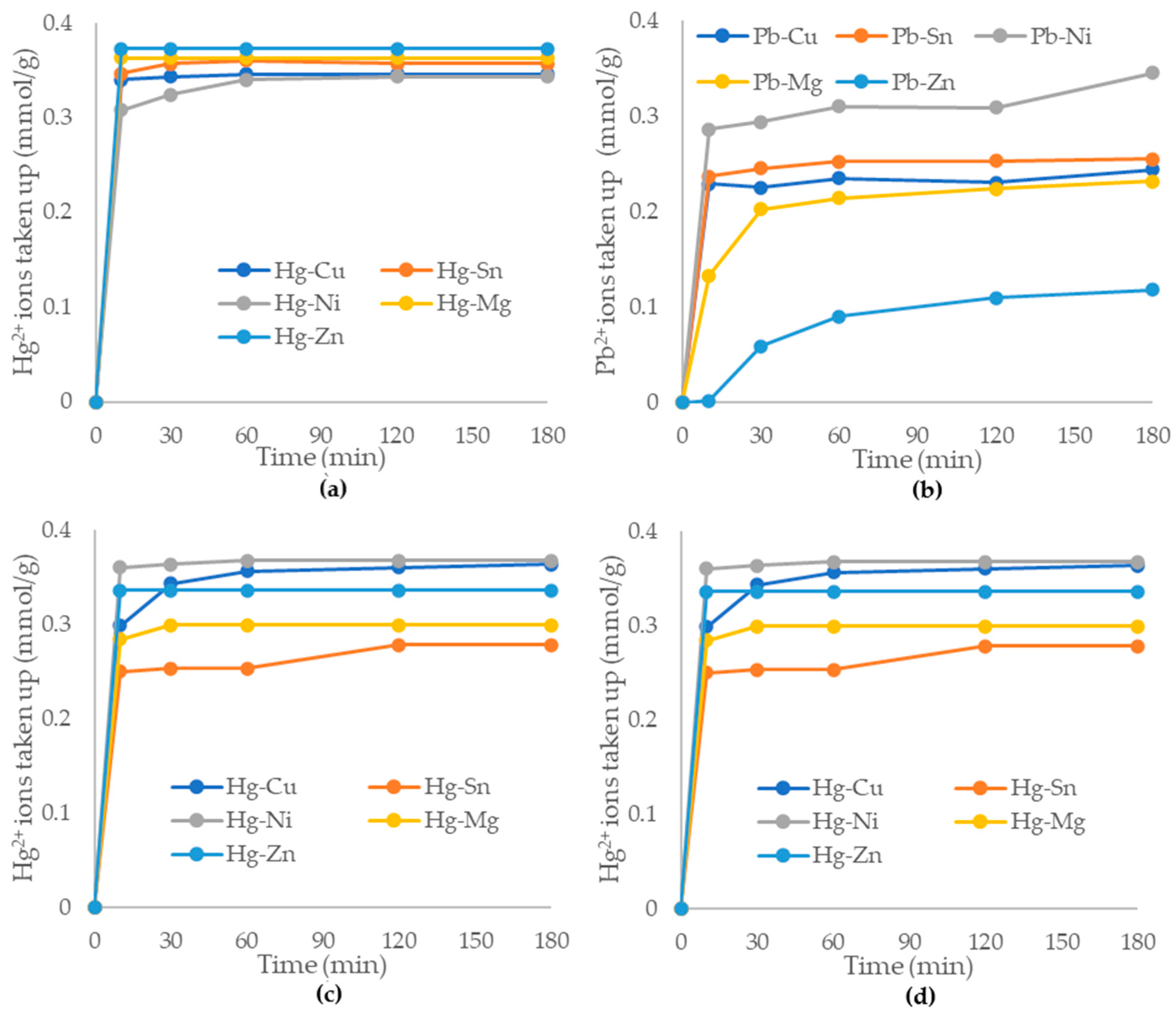

3.4. Selectivity of the Alumina Nanofiber to Hg2+ and Pb2+ Ions

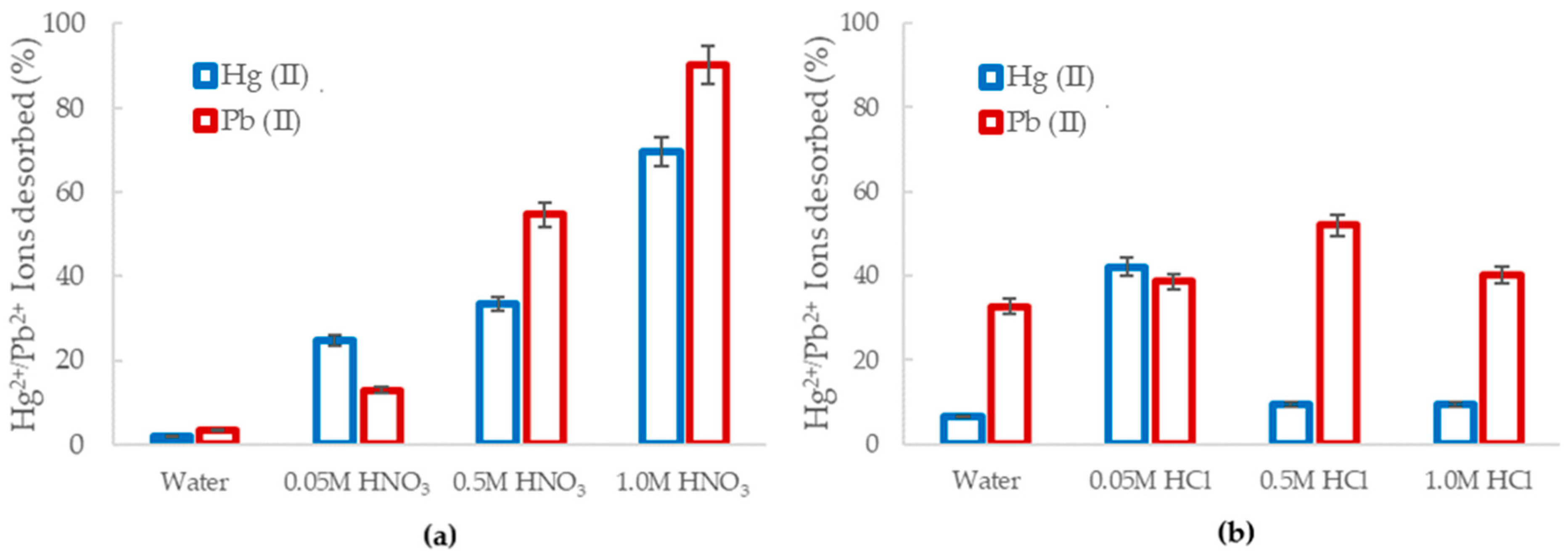

3.5. Desorption Studies

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chowdhury, S.; Mazumder, M.A.J.; Al-Attas, O.; Husain, T. Heavy metals in drinking water: Occurrences, implications, and future needs in developing countries. Sci. Total Environ. 2016, 569–570, 476–488. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization. Guidelines for Drinking-Water Quality; World Health Organization: Geneva, Switzerland, 2017. [Google Scholar]

- World Health Organization. Lead in Drinking-water. In Background Document for Development of WHO Guidelines for Drinking-Water Quality; World Health Organization: Geneva, Switzerland, 2016; p. 27. [Google Scholar]

- World Health Organization. Mercury in Drinking-water. In Background Document for Development of WHO Guidelines for Drinking-Water Quality; World Health Organization: Geneva, Switzerland, 2005; p. 18. [Google Scholar]

- School, W.S. Mercury Contamination of Aquatic Environments; USGS: Reston, VA, USA, 2018. [Google Scholar]

- Saleh, T.S.; Badawi, A.K.; Salama, R.S.; Mostafa, M.M.M. Design and development of novel composites containing nickel ferrites supported on activated carbon derived from agricultural wastes and its application in water remediation. Materials 2023, 16, 2170. [Google Scholar] [CrossRef] [PubMed]

- Qu, X.; Alvarez, P.J.; Li, Q. Applications of nanotechnology in water and wastewater treatment. Water Res. 2013, 47, 3931–3946. [Google Scholar] [CrossRef] [PubMed]

- Kurniawan, T.A.; Lo, W.-H.; Liang, X.; Goh, H.H.; Othman, M.H.D.; Chong, K.-K.; Mohyuddin, A.; Kern, A.O.; Chew, K.W. Heavy Metal Removal from Aqueous Solutions Using Biomaterials and/or Functional Composites: Recent Advances and the Way Forward in Wastewater Treatment Using Digitalization. J. Compos. Sci. 2023, 7, 84. [Google Scholar] [CrossRef]

- Alyüz, B.; Veli, S. Kinetics and equilibrium studies for the removal of nickel and zinc from aqueous solutions by ion exchange resins. J. Hazard. Mater. 2009, 167, 482–488. [Google Scholar] [CrossRef]

- Panizza, M. Importance of electrode material in the electrochemical treatment of wastewater containing organic pollutants. In Electrochemistry for the Environment; Springer: New York, NY, USA, 2010; pp. 25–54. [Google Scholar]

- Hamza, M.F.; Mira, H.; Khalafalla, M.S.; Wang, J.; Wei, Y.; Yin, X.; Ning, S.; Althumayri, K.; Fouda, A. Photocatalytic Performance of Functionalized Biopolymer for Neodymium (III) Sorption and the Recovery from Leachate Solution. Catalysts 2023, 13, 672. [Google Scholar] [CrossRef]

- Benettayeb, A.; Haddou, B. New biosorbents based on the seeds, leaves and husks powder of Moringa oleifera for the effective removal of various toxic pollutants. Int. J. Environ. Anal. Chem. 2021, 1–26. [Google Scholar] [CrossRef]

- Dasgupta, N.; Ranjan, S.; Mundekkad, D.; Ramalingam, C.; Shanker, R.; Kumar, A. Nanotechnology in agro-food: From field to plate. Food Res. Int. 2015, 69, 381–400. [Google Scholar] [CrossRef]

- Mahapatra, A.; Mishra, B.; Hota, G. Studies on electrospun alumina nanofibers for the removal of chromium (VI) and fluoride toxic ions from an aqueous system. Ind. Eng. Chem. Res. 2013, 52, 1554–1561. [Google Scholar] [CrossRef]

- Tian, Y.; Wu, M.; Liu, R.; Li, Y.; Wang, D.; Tan, J.; Wu, R.; Huang, Y. Electrospun membrane of cellulose acetate for heavy metal ion adsorption in water treatment. Carbohydr. Polym. 2011, 83, 743–748. [Google Scholar] [CrossRef]

- Fouda-Mbanga, B.; Prabakaran, E.; Pillay, K. Synthesis and characterization of CDs/Al2O3 nanofibers nanocomposite for Pb2+ ions adsorption and reuse for latent fingerprint detection. Arab. J. Chem. 2020, 13, 6762–6781. [Google Scholar] [CrossRef]

- Saleh, T.A. Isotherm, kinetic, and thermodynamic studies on Hg (II) adsorption from aqueous solution by silica-multiwall carbon nanotubes. Environ. Sci. Pollut. Res. 2015, 22, 16721–16731. [Google Scholar] [CrossRef] [PubMed]

- Rahimi, S.; Moattari, R.M.; Rajabi, L.; Derakhshan, A.A.; Keyhani, M. Iron oxide/hydroxide (α, γ-FeOOH) nanoparticles as high potential adsorbents for lead removal from polluted aquatic media. J. Ind. Eng. Chem. 2015, 23, 33–43. [Google Scholar] [CrossRef]

- De Canck, E.; Lapeire, L.; De Clercq, J.; Verpoort, F.; Van Der Voort, P. New ultrastable mesoporous adsorbent for the removal of mercury ions. Langmuir 2010, 26, 10076–10083. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, D.; Zhao, L.; Lu, X.; Zhang, P.; He, S.; Hu, G.; Tang, X. Synthesis of a thiacalix [4] arenetetrasulfonate-functionalized reduced graphene oxide adsorbent for the removal of lead (II) and cadmium (II) from aqueous solutions. RSC Adv. 2016, 6, 113352–113365. [Google Scholar] [CrossRef]

- Abbas, K.; Znad, H.; Awual, M.R. A ligand anchored conjugate adsorbent for effective mercury (II) detection and removal from aqueous media. Chem. Eng. J. 2018, 334, 432–443. [Google Scholar] [CrossRef]

- Huang, Z.-H.; Zheng, X.; Lv, W.; Wang, M.; Yang, Q.-H.; Kang, F. Adsorption of lead (II) ions from aqueous solution on low-temperature exfoliated graphene nanosheets. Langmuir 2011, 27, 7558–7562. [Google Scholar] [CrossRef]

- Partana, C.; Salim, A. Structure and dynamics of Hg2+ in aqueous solution: An Ab Initio QM/MM molecular dynamics study. J. Phys. Conf. Ser. 2019, 1156, 012012. [Google Scholar] [CrossRef]

- Almetwally, A.A.; El-Sakhawy, M.; Elshakankery, M.; Kasem, M. Technology of nano-fibers: Production techniques and properties-Critical review. J. Text. Assoc. 2017, 78, 5–14. [Google Scholar]

- Yang, D.; Paul, B.; Xu, W.; Yuan, Y.; Liu, E.; Ke, X.; Wellard, R.M.; Guo, C.; Xu, Y.; Sun, Y. Alumina nanofibers grafted with functional groups: A new design in efficient sorbents for removal of toxic contaminants from water. Water Res. 2010, 44, 741–750. [Google Scholar] [CrossRef]

- Golshaei, R.; Shemirani, F.; Davudabadi Farahani, M. Synthesis of sulfur nanoparticles-loaded alumina as a low-cost sorbent for the preconcentration of nickel from real samples. Sep. Sci. Technol. 2017, 52, 2523–2531. [Google Scholar] [CrossRef]

- Huang, Y.; Keller, A.A.; Cervantes-Avilés, P.; Nelson, J. Fast multielement quantification of nanoparticles in wastewater and sludge using single-particle ICP-MS. ACS EST Water 2020, 1, 205–213. [Google Scholar] [CrossRef]

- Paranjpe, K.Y. Alpha, Beta and Gamma alumina as catalyst. Pharma Innov. J. 2017, 6, 236–238. [Google Scholar]

- Gebald, C.; Wurzbacher, J.A.; Tingaut, P.; Zimmermann, T.; Steinfeld, A. Amine-based nanofibrillated cellulose as adsorbent for CO2 capture from air. Environ. Sci. Technol. 2011, 45, 9101–9108. [Google Scholar] [CrossRef] [PubMed]

- Gelles, T.; Lawson, S.; Rownaghi, A.A.; Rezaei, F. Recent advances in development of amine functionalized adsorbents for CO2 capture. Adsorption 2020, 26, 5–50. [Google Scholar] [CrossRef]

- Baaloudj, O.; Nasrallah, N.; Kenfoud, H.; Bourkeb, K.W.; Badawi, A.K. Polyaniline/Bi12TiO20 Hybrid System for Cefixime Removal by Combining Adsorption and Photocatalytic Degradation. ChemEngineering 2023, 7, 4. [Google Scholar] [CrossRef]

- Lagergren, S.K. About the theory of so-called adsorption of soluble substances. Sven. Vetenskapsakad. Handingarl 1898, 24, 1–39. [Google Scholar]

- Ho, Y.-S.; McKay, G. Pseudo-second order model for sorption processes. Process Biochem. 1999, 34, 451–465. [Google Scholar] [CrossRef]

- Riaz, S.; Sajid-ur-Rehman; Abutalib, M.; Naseem, S. Structural, Optical, and Dielectric Properties of Aluminum Oxide Nanofibers Synthesized by a Lower-Temperature Sol–Gel Approach. Electron. Mater. 2016, 45, 5185–5197. [Google Scholar] [CrossRef]

- Yang, J.; Frost, R.L. Synthesis and characterization of boehmite nanofibers. Res. Lett. Inorg. Chem. 2008, 2008, 602198. [Google Scholar] [CrossRef]

- Sifontes, Á.B.; Gutierrez, B.; Mónaco, A.; Yanez, A.; Díaz, Y.; Méndez, F.J.; Llovera, L.; Cañizales, E.; Brito, J.L. Preparation of functionalized porous nano-γ-Al2O3 powders employing colophony extract. Biotechnol. Rep. 2014, 4, 21–29. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Zhang, W. Evaluating the adsorption of Shanghai silty clay to Cd (II), Pb (II), As (V), and Cr (VI): Kinetic, equilibrium, and thermodynamic studies. Environ. Monit. Assess. 2021, 193, 1–23. [Google Scholar] [CrossRef] [PubMed]

- Behra, P.; Bonnissel-Gissinger, P.; Alnot, M.; Revel, R.; Ehrhardt, J.J. XPS and XAS study of the sorption of Hg (II) onto pyrite. Langmuir 2001, 17, 3970–3979. [Google Scholar] [CrossRef]

- Biesinger, M.C. X-ray Photoelectron Spectroscopy (XPS) Reference Pages. 2009–2021. Available online: http://www.xpsfitting.com/2015/11/mercury.html (accessed on 28 November 2022).

- Biesinger, M.C. X-ray Photoelectron Spectroscopy (XPS) Reference Pages. 2009–2021. Available online: http://www.xpsfitting.com/search/label/Lead (accessed on 28 November 2022).

- Santos, M.D.; da Silva Júnior, F.M.R.; Zurdo, D.V.; Baisch, P.R.M.; Muccillo-Baisch, A.L.; Madrid, Y. Selenium and mercury concentration in drinking water and food samples from a coal mining area in Brazil. Environ. Sci. Pollut. Res. 2019, 26, 15510–15517. [Google Scholar] [CrossRef] [PubMed]

- Leenhouts, D. SCIENCING. Difference in Properties of Main Group & Transition Metals. 2018. Available online: https://sciencing.com/difference-between-halogen-halide-5650203.html (accessed on 17 January 2023).

- Bao, S.; Li, K.; Ning, P.; Peng, J.; Jin, X.; Tang, L. Highly effective removal of mercury and lead ions from wastewater by mercaptoamine-functionalised silica-coated magnetic nano-adsorbents: Behaviours and mechanisms. Appl. Surf. Sci. 2017, 393, 457–466. [Google Scholar] [CrossRef]

- Esposito, A.; Pagnanelli, F.; Vegliò, F. pH-related equilibria models for biosorption in single metal systems. Chem. Eng. Sci. 2002, 57, 307–313. [Google Scholar] [CrossRef]

- Kennepohl, D.; Farmer, S.; Reusch, W.; Soderberg, T. LibreTexts Chemistry. Acidity and Basicity of Amines. 2020. Available online: https://chem.libretexts.org/Bookshelves/Organic_Chemistry/Map%3A_Organic_Chemistry_(Vollhardt_and_Schore)/21%3A_Amines_and_Their_Derivatives/21.04%3A_Acidity__and__Basicity__of_Amines (accessed on 20 January 2023).

- Dahman, Y. Nanotechnology and Functional Materials for Engineers; Elsevier: Toronto, ON, Canada, 2017. [Google Scholar]

- Boudrahem, F.; Aissani-Benissad, F.; Soualah, A. Adsorption of lead (II) from aqueous solution by using leaves of date trees as an adsorbent. J. Chem. Eng. Data 2011, 56, 1804–1812. [Google Scholar] [CrossRef]

- Ugrina, M.; Čeru, T.; Nuić, I.; Trgo, M. Comparative Study of Mercury(II) Removal from Aqueous Solutions onto Natural and Iron-Modified Clinoptilolite Rich Zeolite. Processes 2020, 8, 1523. [Google Scholar] [CrossRef]

- Giraldo, L.; Moreno-Piraján, J. Pb2+ adsorption from aqueous solutions on activated carbons obtained from lignocellulosic residues. Braz. J. Chem. Eng. 2008, 25, 143–151. [Google Scholar] [CrossRef]

- Ji, C.; Ren, Y.; Yu, H.; Hua, M.; Lv, L.; Zhang, W. Highly efficient and selective Hg (II) removal from water by thiol-functionalized MOF-808: Kinetic and mechanism study. Chem. Eng. J. 2022, 430, 132960. [Google Scholar] [CrossRef]

- Shahzad, W.; Badawi, A.K.; Rehan, Z.A.; Khan, A.M.; Khan, R.A.; Shah, F.; Ali, S.; Ismail, B. Enhanced visible light photocatalytic performance of Sr0.3(Ba, Mn)0.7ZrO3 perovskites anchored on graphene oxide. Ceram. Int. 2022, 48, 24979–24988. [Google Scholar] [CrossRef]

- Sahoo, T.R.; Prelot, B. Adsorption Processes for the Removal of Contaminants from Wastewater: The Perspective Role of Nanomaterials and Nanotechnology. In Nanomaterials for the Detection and Removal of Wastewater Pollutants; Elsevier: Amsterdam, The Netherlands, 2020; pp. 161–222. [Google Scholar]

- Yoder, C. Metallic, Covalent and Ionic Radii(r)*. Wired Chemist: 2022. Available online: https://www.wiredchemist.com/chemistry/data/metallic-radii (accessed on 7 February 2023).

- Reactivity Series. BYJU’S, 2022. Available online: https://byjus.com/chemistry/reactivity-series/ (accessed on 7 February 2023).

- Vo, T.S.; Hossain, M.M.; Jeong, H.M.; Kim, K. Heavy metal removal applications using adsorptive membranes. Nano Converg. 2020, 7, 36. [Google Scholar] [CrossRef] [PubMed]

- Fiol, N.; de la Torre, F.; Demeyere, P.; Florido, A.; Villaescusa, I. Vegetable waste-based sensors for metal ion determination. Sens. Actuators B Chem. 2007, 122, 187–194. [Google Scholar] [CrossRef]

- Easley, R.A.; Byrne, R.H. The ionic strength dependence of lead (II) carbonate complexation in perchlorate media. Geochim. Cosmochim. Acta 2011, 75, 5638–5647. [Google Scholar] [CrossRef]

- Karapinar, H.S.; Kilicel, F.; Ozel, F.; Sarilmaz, A. Fast and effective removal of Pb (II), Cu (II) and Ni (II) ions from aqueous solutions with TiO2 nanofibers: Synthesis, adsorption-desorption process and kinetic studies. Int. J. Environ. Anal. Chem. 2021, 1–21. [Google Scholar] [CrossRef]

| Mercury (II) | Lead (II) | ||||||

|---|---|---|---|---|---|---|---|

| Adsorbent | Adsorption Capacity (mg/g) | Removal % (50 mg/L) | References | Adsorbent | Adsorption Capacity (mg/g) | Removal % (50 mg/L) | References |

| Fe2O3–Al2O3 | 63.69 | 89 | [14] | Fe2O3–Al2O3 | 23.75 | 52 | [14] |

| Cellulose acetate membrane | 20 | - | [15] | CDs/Al2O3 | 177.83 | 99.7 | [16] |

| Silica multi-walled nanotubes | 59.28 | 80 | [17] | Lepidocrocite nanoparticles | 160 | 67 | [18] |

| Ethene bridged mesoporous organosilica | 64 | 60 | [19] | Thiacalix[4]arenetetrasulfonate-graphene oxide | 230 | - | [20] |

| Mesoporous conjugate adsorbent | 172.61 | - | [21] | Graphene nanosheets | 35.46 | 30 | [22] |

| Amine-functionalized alumina nanofiber | 165 | 98 | This work | Amine-functionalized alumina nanofiber | 111 | 77 | This work |

| Metals | Initial Concentration (mg/L) | qe, Experimental (mg/g) | Pseudo-First-Order | Pseudo-Second-Order | ||||

|---|---|---|---|---|---|---|---|---|

| k1 (1/min) | qe, Calculated (mg/g) | R2 | k2 (g/mg/min) | qe, Calculated (mg/g) | R2 | |||

| Hg2+ | 100 | 129 | 5.45 × 10−2 | 18.38 | 0.9183 | 7.7 × 10−3 | 129.87 | 0.9997 |

| 250 | 165 | 6.36 × 10−2 | 25.72 | 0.7181 | 8.8 × 10−3 | 113.63 | 1 | |

| Pb2+ | 100 | 72 | 5.73 × 10−2 | 17.45 | 0.9672 | 1.36 × 10−2 | 73.53 | 0.9993 |

| 250 | 111 | 3.71 × 10−2 | 26.95 | 0.7732 | 8.9 × 10−3 | 112.36 | 0.9991 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Houston, R.L.; Waclawik, E.R.; Sarina, S. Application of Alumina Nanofibers as Adsorbents for the Removal of Mercury (II) and Lead (II) from Aqueous Solutions. Minerals 2023, 13, 654. https://doi.org/10.3390/min13050654

Houston RL, Waclawik ER, Sarina S. Application of Alumina Nanofibers as Adsorbents for the Removal of Mercury (II) and Lead (II) from Aqueous Solutions. Minerals. 2023; 13(5):654. https://doi.org/10.3390/min13050654

Chicago/Turabian StyleHouston, Rebecca L., Eric R. Waclawik, and Sarina Sarina. 2023. "Application of Alumina Nanofibers as Adsorbents for the Removal of Mercury (II) and Lead (II) from Aqueous Solutions" Minerals 13, no. 5: 654. https://doi.org/10.3390/min13050654

APA StyleHouston, R. L., Waclawik, E. R., & Sarina, S. (2023). Application of Alumina Nanofibers as Adsorbents for the Removal of Mercury (II) and Lead (II) from Aqueous Solutions. Minerals, 13(5), 654. https://doi.org/10.3390/min13050654