Re-Mining of Waste Rock Dumps from a Closed Lead–Zinc Mine—Characterisation of the Residuals

Abstract

:1. Introduction

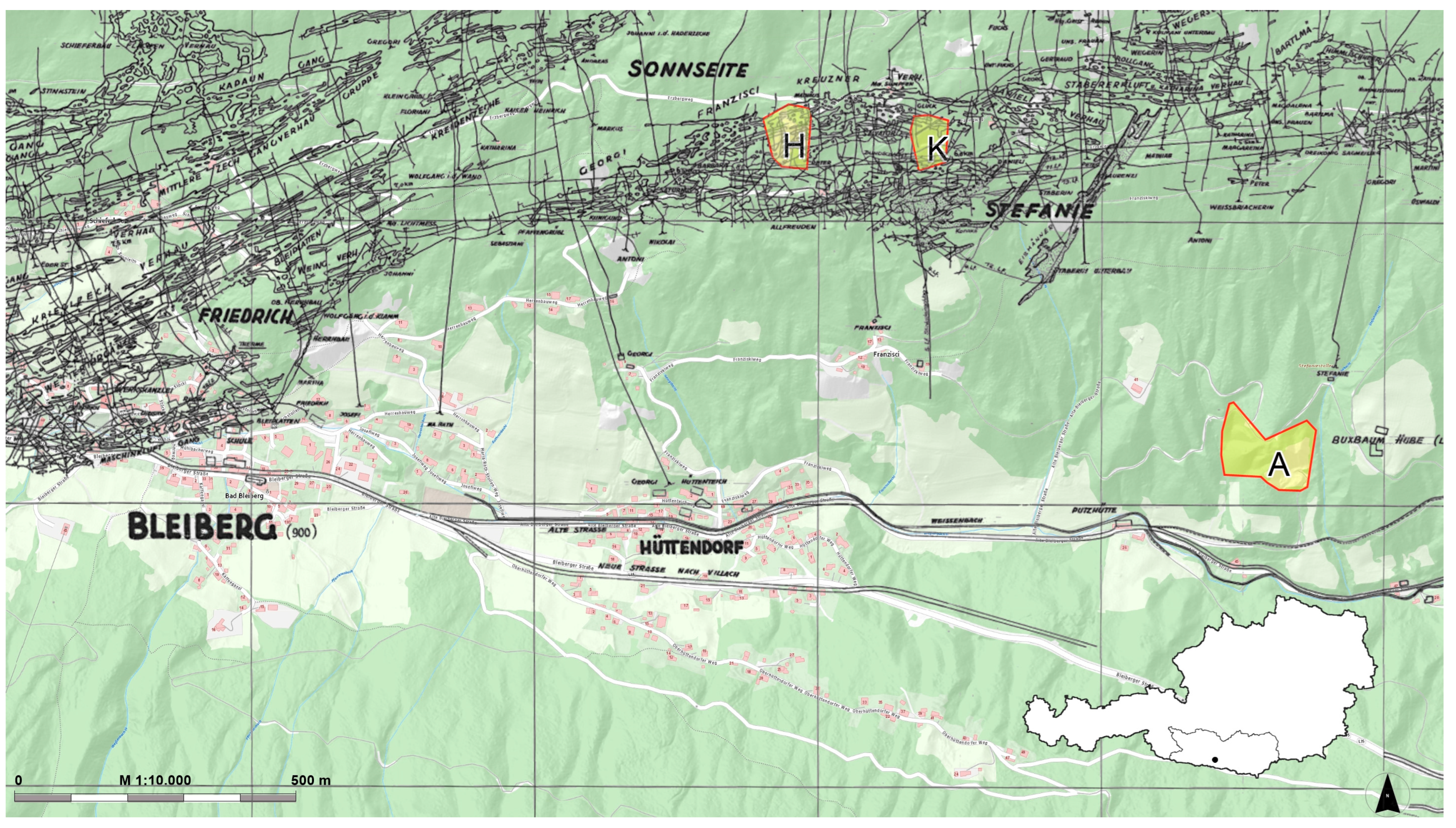

2. Motivation

3. Material and Methods

3.1. Mineralogy

3.2. Waste Rock Dumps—Past and Present Investigations

3.3. Sampling

3.3.1. Stage One: Pre-Sampling

3.3.2. Stage Two: Sampling

3.4. Laboratory Studies and Equipment

3.4.1. Sample Material

3.4.2. Fractional Analysis—Sink–Float Analysis

4. Laboratory Sorting Trials—Pre-Concentration

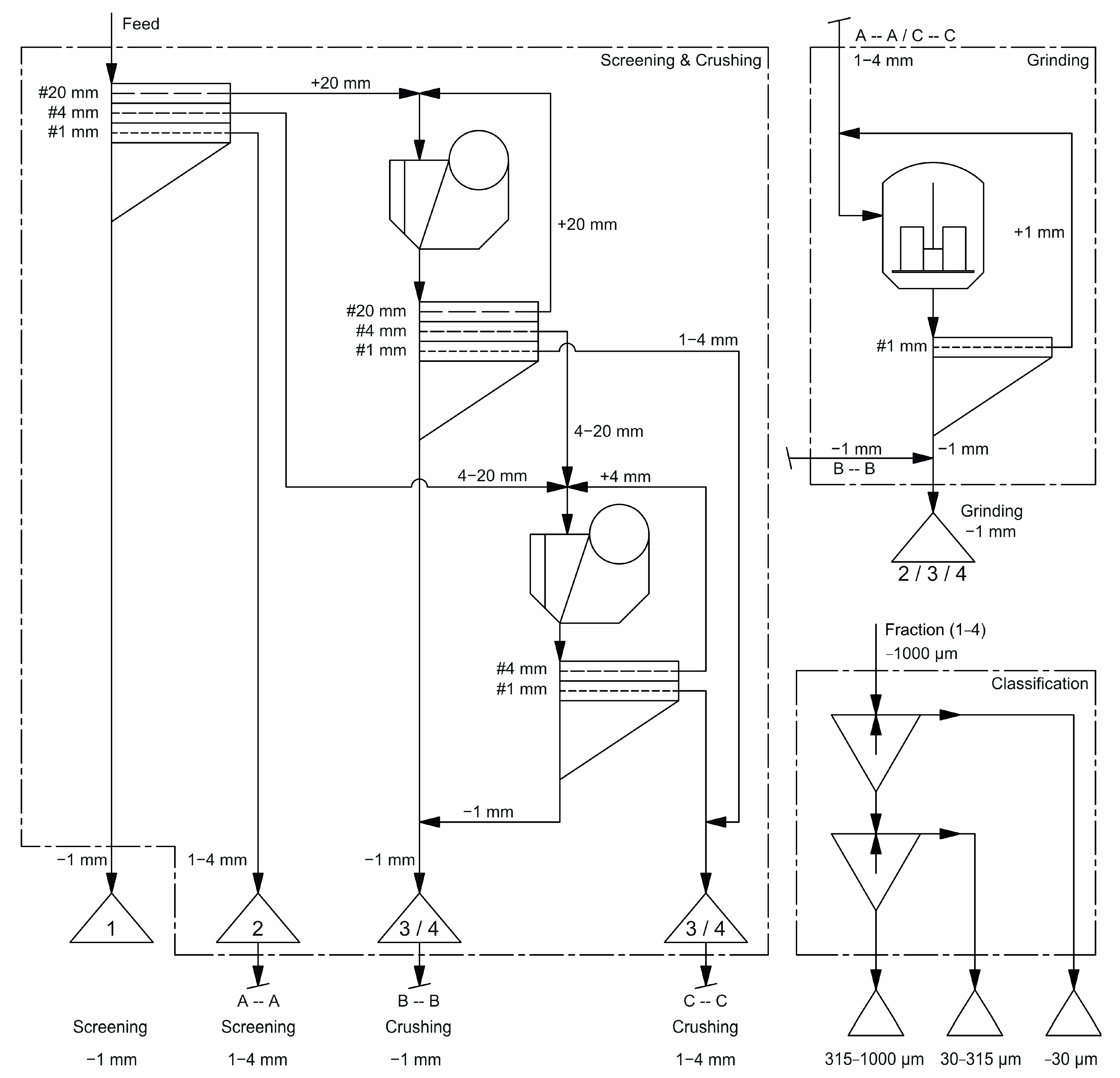

4.1. Screening, Comminution, and Classification

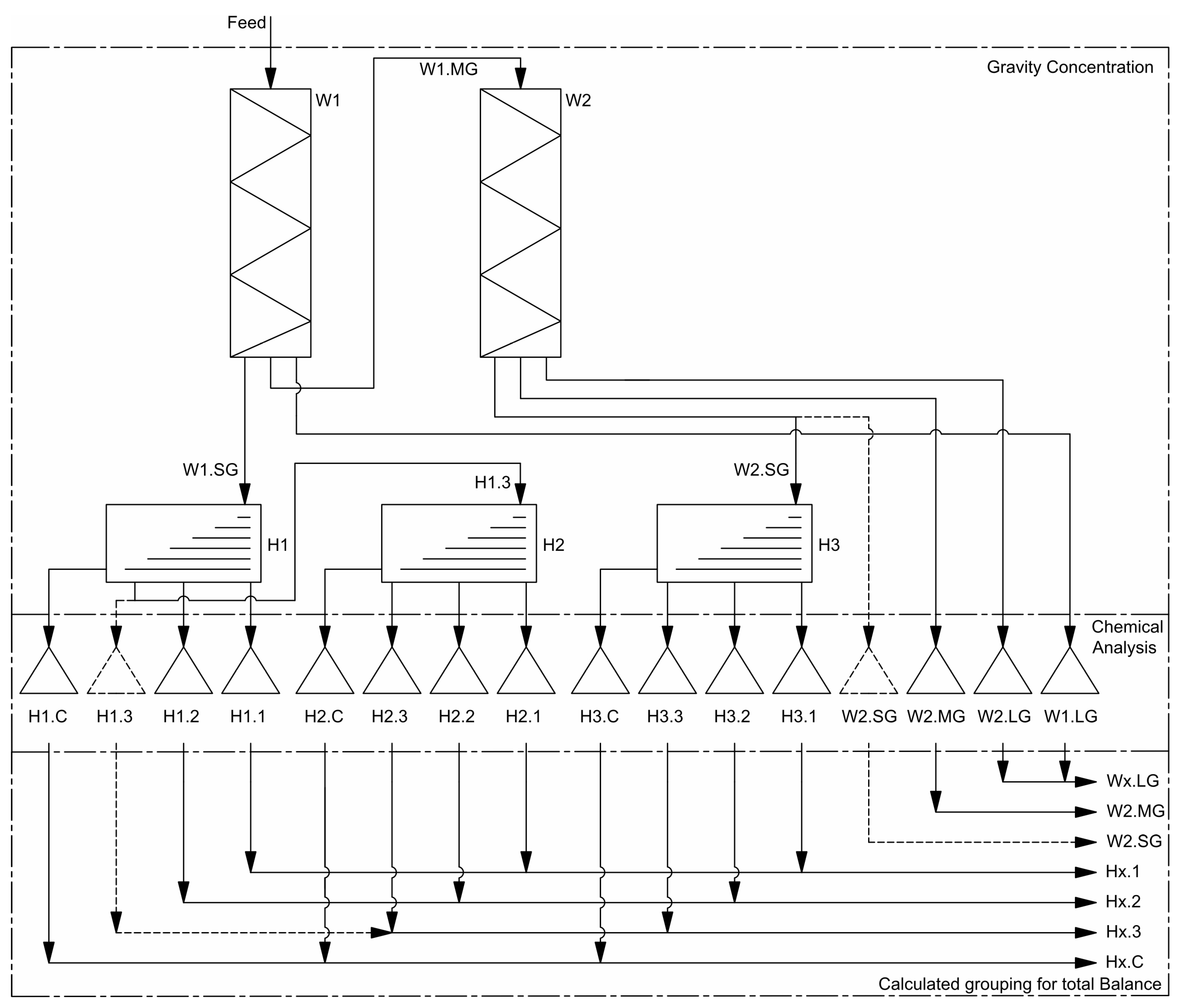

4.2. Gravity Concentration Trials

4.3. Methodology of Chemical Analysis

5. Theory/Calculation

6. Results and Discussion

6.1. Chemical Analysis of Pre-Sampling

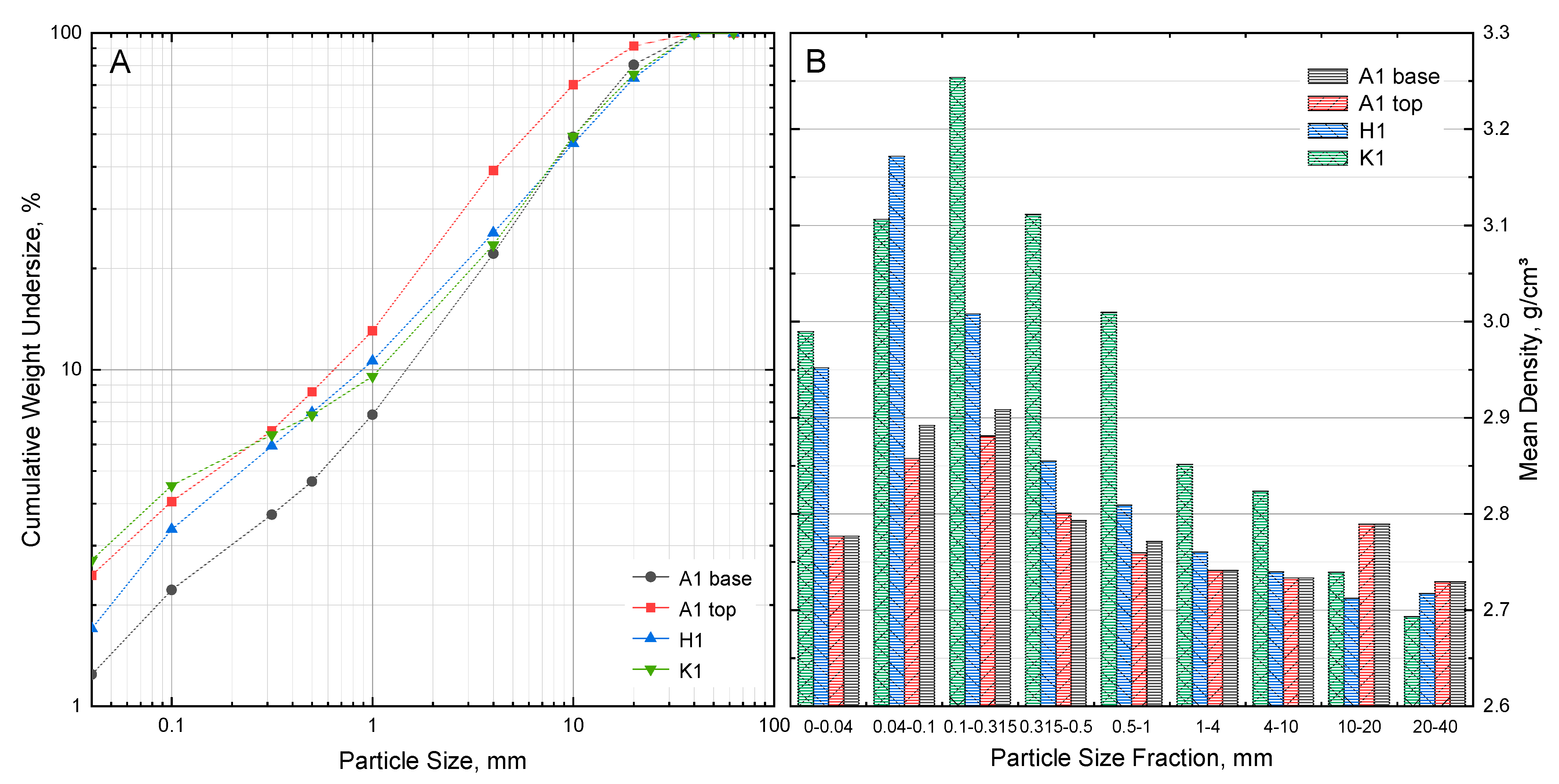

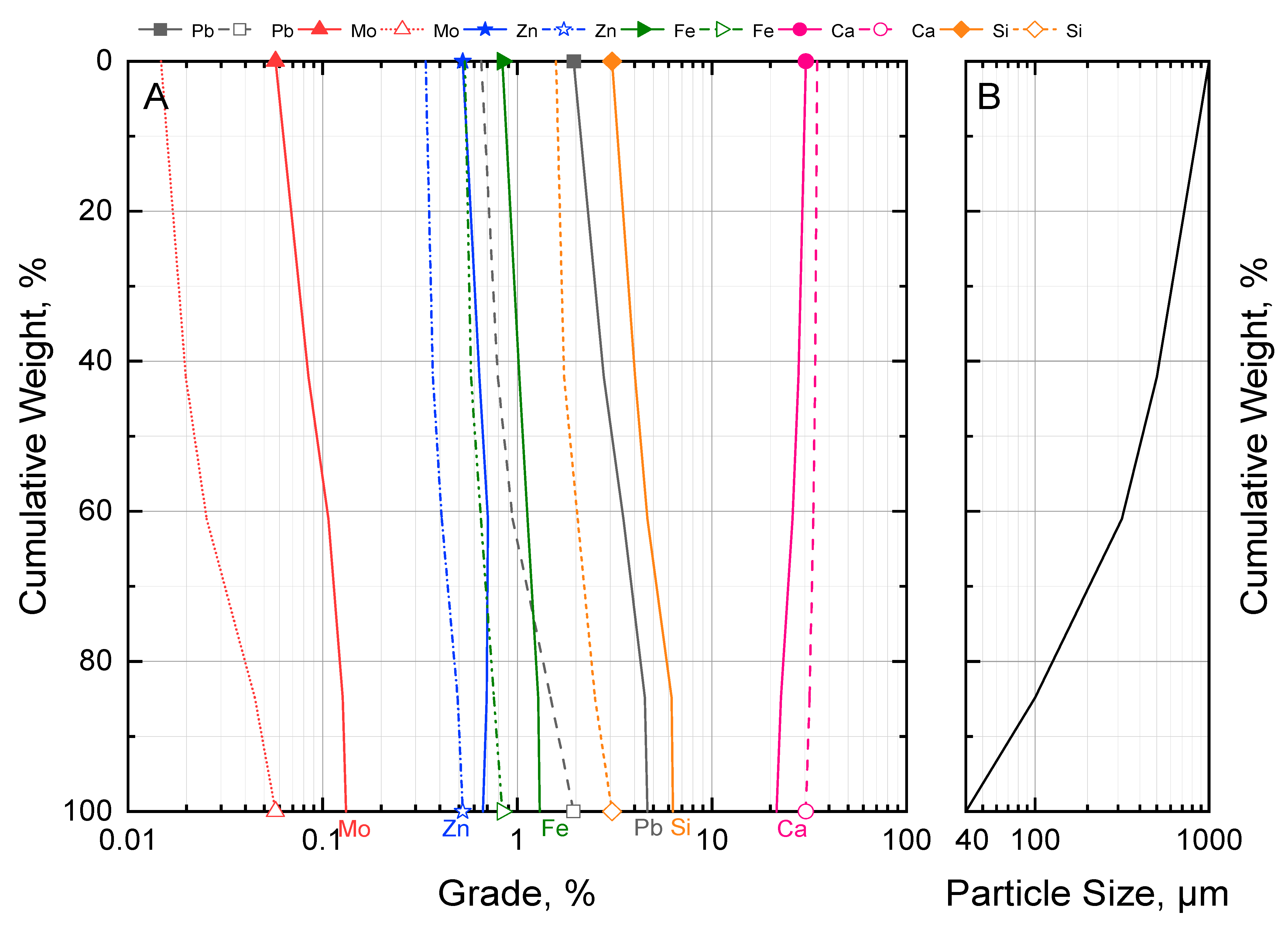

6.2. Particle Size Distribution and Mean Densities

6.3. Sink–Float Analysis

6.4. Evaluation of the Sink–Float Analysis

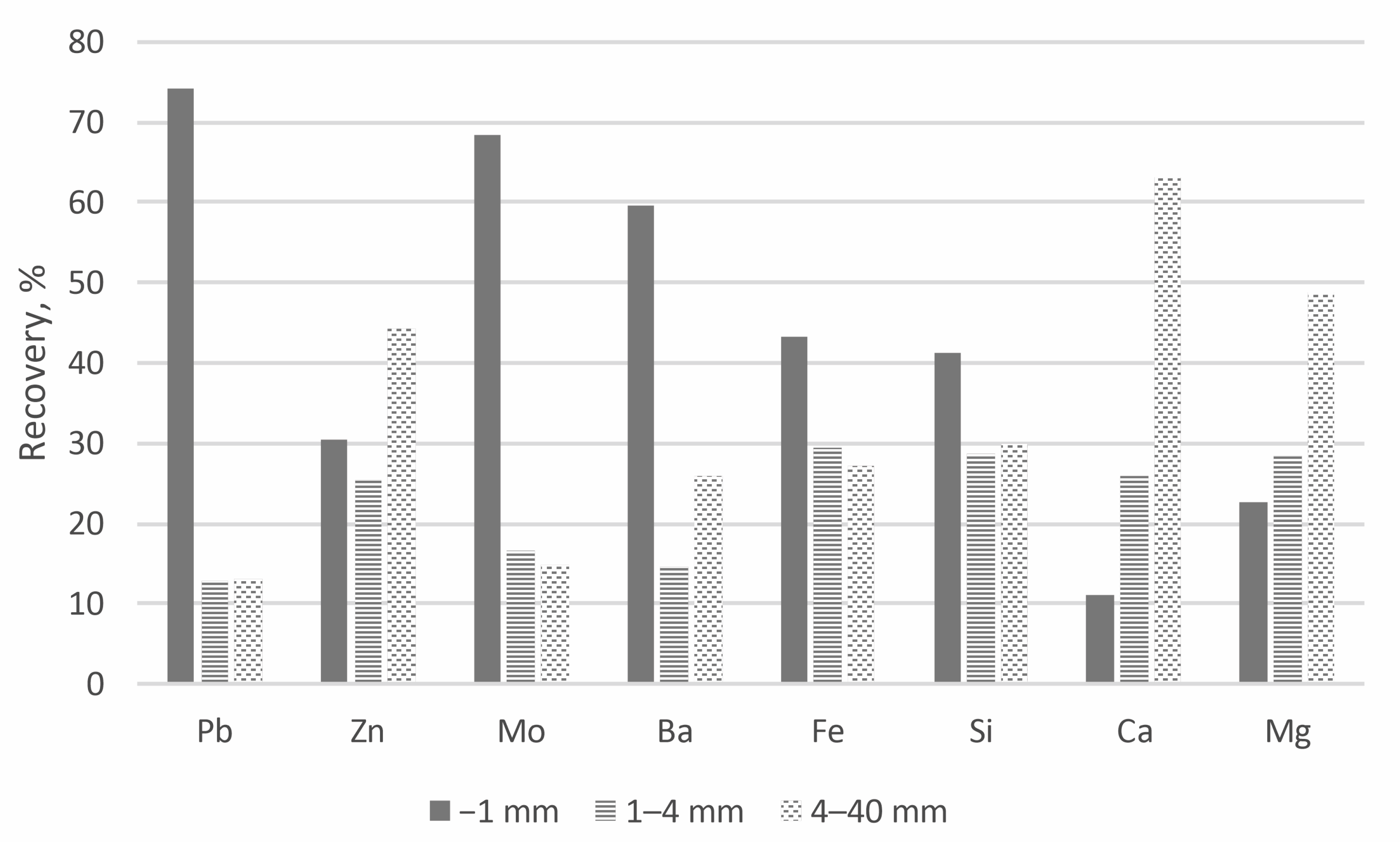

6.5. Evaluation of the Laboratory Sorting Trials

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jicha, H.L. Alpine lead-zinc ores of Europe. Econ. Geol. 1951, 46, 707–730. [Google Scholar] [CrossRef]

- Schneider, H.J. Facies Differentiation and Controlling Factors for the Depositional Lead-Zinc Concentration in the Ladinian Geosyncline of the Eastern Alps. Dev. Sedimentol. 1964, 2, 29–45. [Google Scholar] [CrossRef]

- Maucher, A.; Schneider, H.-J. The Alpine Lead-Zinc Ores. In Genesis of Stratiform Lead-Zinc-Barite-Fluorite Deposits (Mississippi Valley Type Deposits); Society of Economic Geologists: Littleton, CO, USA, 1967; Volume 3, pp. 71–89. [Google Scholar]

- Brigo, L.; Kostelka, L.; Omenetto, P.; Schneider, H.-J.; Schroll, E.; Schulz, O. Comparative Reflections on Four Alpine Pb-Zn Deposits. In Time- and Strata-Bound Ore Deposits; Springer: Berlin/Heidelberg, Germany, 1977; pp. 273–293. [Google Scholar] [CrossRef]

- Cerny, I. Die karbonatgebundenen Blei-Zink-Lagerstätten des alpinen und außeralpinen Mesozoikums. Die Bedeutung ihrer Geologie, Stratigraphie und Faziesgebundenheit für Prospektion und Bewertung [The Carbonate-bonded Lead-Zinc Deposits of the Alpine and extra-Alpine Mesozoic]. The Significance of their Geology, Stratigraphy and Facies-binding for Prospecting and Evaluation. Arch. Lagerstättenforsch. Geol. Bundesanst. 1989, 11, 104–113. [Google Scholar]

- Schroll, E. Mineralisation der Blei-Zink-Lagerstätte Bleiberg-Kreuth (Kärnten) [Mineralisation of the Bleiberg-Kreuth Lead-Zinc Deposit (Carinthia)]. Aufschluss. Z. Freunde Mineral. Geol. 1984, 35, 339–350. [Google Scholar]

- Cerny, I.; Schroll, E. Heimische Vorräte an Spezialmetallen (Ga, In, Tl, Ge, Se, Te und Cd) [Domestic Reserves of Special Metals (Ga, In, Tl, Ge, Se, Te and Cd)]. Arch. Lagerstättenforsch. Geol. Bundesanst. 1995, 18, 5–33. [Google Scholar]

- Schroll, E. Über Minerale und Spurenelemente, Vererzung und Entstehung der Blei-Zink-Lagerstätte Bleiberg-Kreuth/Kärnten in Osterreich [About Minerals and Trace Elements, Mineralization and Genesis of the Lead-Zinc Deposit Bleiberg-Kreuth/Carinthia in Austria]. Mitt. Osterr. Mineral. Ges.-Sonderh. 1953, 7, 73. [Google Scholar]

- Zeloth, T. Zwischen Staat und Markt Geschichte der Bleiberger Bergwerks Union und ihrer Vorläuferbetriebe [Between State and Market History of the Bleiberger Bergwerks Union and its predecessor companies]. Verl. Kärntner Landesarch. 2004, 1, 15–31. [Google Scholar]

- Schroll, E. Neues zur Genese der Blei-Zink Lagerstätte Bleiberg [News on the Genesis of the Bleiberg Lead-Zinc Deposit]. Carinthia II-tl. 2 2006, 196, 483–500. [Google Scholar]

- Schroll, E. Über die Anreicherung von Mo und V in der Hutzone der Pb-Zn-Lagerstätte Bleiberg-Kreuth [On the Enrichment of Mo and V in the Alteration Zone of the Bleiberg-Kreuth Pb-Zn Deposit]. Verh. Geol. Bundesanst. 1949, 139, 138–157. [Google Scholar]

- Marousek, L.; Öfner, W.; Flachberger, H. Zu Fragen der Charakterisierung und Aufarbeitung metallhaltiger Rest- und Kreislaufstoffe aus aufbereitungstechnischer Sicht – Vorstellung eines Dissertationsvorhabens [Characterization and Processing of Metal Bearing By-products in Consideration of Mineral Processing Aspects]. BHM Berg-Und Hüttenmännische Mon. 2020, 165, 598–607. [Google Scholar] [CrossRef]

- Schroll, E. Blei-Zink-Lagerstätte Bleiberg: Die Geschichte ihrer Erforschung [Bleiberg Lead-Zinc Deposit: The History of its Exploration]. Carinthia II-Sonderhefte 2008, 62, 1–286. [Google Scholar]

- Scherer, J. Blei-Zink-Haldenbeprobung, Bleiberger Sonnseite [Lead-Zinc Dump Sampling, Bleiberger Sonnseite]; Montanuniversität Leoben: Leoben, Austria, 1979. [Google Scholar]

- Jedlicka, K. Haldenerzgewinnung und -verarbeitung beim Bergbau Bleiberg/Kreuth der Bleiberger Bergwerksunion AG [Waste Rock Ore Mining and Processing at the Bleiberg/Kreuth Mine of Bleiberger Bergwerksunion AG]. BHM Berg-Und Hüttenmännische Mon. 1983, 128, 477–483. [Google Scholar]

- Land Kärnten. KAGIS. 2022. Available online: https://kagis.ktn.gv.at/ (accessed on 1 November 2022).

- Bergmännischer Kulturverein Bad Bleiberg. Der Weg des Erzes [The Way of the Ore]. 2022. Available online: https://www.bergbauverein-bad-bleiberg.at/der-weg-des-erzes/ (accessed on 1 November 2022).

- ISO 3310-1:2016; Test Sieves-Technical Requirements and Testing—Part 1: Test Sieves of Metal Wire Cloth. Beuth Verlag: Berlin, Germany, 2017. [CrossRef]

- Wills, B.A.; Finch, J.A. Chapter 11—Dense Medium Separation (DMS). In Wills’ Mineral Processing Technology, 8th ed.; Wills, B.A., Finch, J.A., Eds.; Butterworth-Heinemann: Boston, MA, USA, 2016; pp. 245–264. [Google Scholar]

- TC-Tungsten Compounds. Sodium Polytungstate at a Glance: Facts + Advantages. 2020. Available online: https://www.heavy-liquid.com/en/faq/ (accessed on 25 August 2021).

- Steiner, H.J. Probenahmetheorie für die Probenahmepraxis [Applied Sampling Theory]. BHM Berg-Und Hüttenmännische Mon. 1999, 144, 224–229. [Google Scholar]

- Böhm, A. Gutstrominvariante zur Auslegung inkrementaler Probenahmeeinrichtungen—Hintergrund und Einsatzbeispiele [Bulk Stream Invariants for Designing Incremental Sampling Devices—Basics and Examples]. BHM Berg-Und Hüttenmännische Mon. 2012, 157, 236–243. [Google Scholar] [CrossRef]

- Gy, P. Sampling of heterogeneous and dynamic material systems: Theories of heterogeneity, sampling, and homogenizing. Data Handl. Sci. Technol. 1992, 10, 56–102. [Google Scholar]

- Visman, J.; Parkinson, J. Part 1: Sampling. In Coal Preparation, 5th ed.; Leonard, J.W., III, Hardinge, B.C., Eds.; Society for Mining, Metallurgy, and Exploration, Inc.: Baltimore, MD, USA, 1991; pp. 866–876. [Google Scholar]

- Wills, B.A.; Finch, J.A. Chapter 3—Sampling, Control, and Mass Balancing. In Wills’ Mineral Processing Technology, 8th ed.; Wills, B.A., Finch, J.A., Eds.; Butterworth-Heinemann: Boston, MA, USA, 2016; pp. 41–90. [Google Scholar]

- Schubert, H. (Ed.) Handbuch der Mechanischen Verfahrenstechnik [Handbook of Mechanical Process Engineering], 1st ed.; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2003; pp. 622–626. [Google Scholar]

| Nr. | Dump | Sample | Fraction | Treatment On-Site |

|---|---|---|---|---|

| mm | ||||

| 1 | Altstefanie, A | A1 top | −40 | screened |

| 2 | A1 top | +40 | screened and crushed | |

| 3 | A1 base | −40 | screened | |

| 4 | A1 base | +40 | screened and crushed | |

| 5 | Matthäus, H | H1 | −40 | screened |

| 6 | H2 | +40 | screened and crushed | |

| 7 | Glück, K | K1 | −40 | screened |

| 8 | K2 | +40 | screened and crushed |

| Sample | Index | Original Fraction | Description |

|---|---|---|---|

| A1 top −40 mm | 1 | −1 mm | uncrushed sample—used as present on waste dumps |

| 2 | 1–4 mm | ground in lab | |

| 3 | 4–40 mm | crushed and ground in lab | |

| A1 top +40 mm | 4 | +40 mm | pre-crushed on-site, and crushed and ground in lab |

| Device | Settings |

|---|---|

| Spiral (Krebs, five turns, height 2.05 m, diameter 630 mm) | Feed pulp, 15% solids by weight Water flow rate, 816 L/h Splitter angle 0° |

| Shaking Table (Krupp K 1794 250 mm × 500 mm) | Feed pulp, 22% solids by volume Wash water 200 L/h Strokes per minute: 280, Length 10–12 mm Table slope, feed-to-tailings discharge: 5°; feed-to-concentrate discharge: 1° |

| Dump | Fraction | Pb | Zn | Mo | Ba | Fe | Cd | Cu | Mn | Ge | As |

|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | % | % | % | % | % | ppm | ppm | ppm | ppm | ppm | |

| Altstefanie, A | 1–4 | 0.24 | 0.24 | 0.02 | 0.31 | 0.81 | 34 | 259 | 96 | 1.40 | 11 |

| 0.5–1 | 0.70 | 0.29 | 0.04 | 0.40 | 1.04 | 37 | 207 | 113 | 1.61 | 12 | |

| −0.5 | 2.36 | 0.77 | 0.10 | 1.76 | 1.77 | 47 | 258 | 173 | 3.03 | 25 | |

| Matthäus, H | 1–4 | 0.88 | 0.77 | 0.20 | 0.05 | 0.64 | 87 | 289 | 118 | 1.42 | 18 |

| 0.5–1 | 2.24 | 1.56 | 0.28 | 0.04 | 1.21 | 127 | 272 | 128 | 3.91 | 42 | |

| −0.5 | 9.47 | 2.91 | 1.06 | 0.27 | 2.17 | 168 | 317 | 241 | 7.66 | 92 | |

| Glück, K | 0.5–1 | 1.22 | 6.84 | 0.14 | 2.88 | 0.56 | 239 | 187 | 123 | 2.91 | 18 |

| −0.5 | 4.18 | 7.84 | 0.65 | 5.93 | 0.85 | 247 | 315 | 153 | 3.49 | 43 |

| Particle Size | Weight | Deviation | Inhomogeneity |

|---|---|---|---|

| mm | % | %-pts | kg%2 |

| 40 | - | - | |

| 20 | 8.47 | 1.03 | 23.08 |

| 10 | 21.30 | 0.51 | 5.70 |

| 4 | 31.17 | 0.23 | 1.11 |

| 1 | 26.02 | 0.18 | 0.71 |

| 0.5 | 4.47 | 0.18 | 0.70 |

| 0.315 | 2.00 | 0.18 | 0.70 |

| 0.1 | 2.52 | 0.18 | 0.70 |

| 0.04 | 1.61 | 0.18 | 0.70 |

| 0 | 0 | - | - |

| Specific Gravity Fraction, g/cm3 | Weight, % | Mean Density, g/cm3 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Size Fraction, µm | Size Fraction, µm | ||||||||

| 500–1000 | 315–500 | 100–315 | 40–100 | 500–1000 | 315–500 | 100–315 | 40–100 | ||

| A1 top | −2.67 | 7.7 | 11.9 | 11.5 | 17.8 | 2.71 | 2.68 | 2.67 | 2.64 |

| 2.67–3 | 89.1 | 82.8 | 76.0 | 66.0 | 2.73 | 2.73 | 2.74 | 2.76 | |

| +3.0 | 3.2 | 5.2 | 12.5 | 16.2 | 4.28 | 4.39 | 4.39 | 4.73 | |

| Total | 100.0 | 100.0 | 100.0 | 100.0 | 2.76 | 2.78 | 2.86 | 2.93 | |

| A1 base | −2.67 | 11.7 | 6.6 | 10.2 | 20.9 | 2.69 | 2.68 | 2.67 | 2.63 |

| 2.67–3 | 84.8 | 88.2 | 77.5 | 63.0 | 2.73 | 2.73 | 2.74 | 2.77 | |

| +3.0 | 3.4 | 5.2 | 12.3 | 16.2 | 4.29 | 4.35 | 4.63 | 4.86 | |

| Total | 100.0 | 100.0 | 100.0 | 100.0 | 2.76 | 2.78 | 2.87 | 2.94 | |

| K1 | −2.67 | 14.7 | 10.8 | 5.1 | 10.3 | 2.76 | 2.77 | 2.77 | 2.37 |

| 2.67–3 | 62.0 | 56.3 | 50.0 | 45.4 | 2.76 | 2.77 | 2.80 | 2.83 | |

| +3.0 | 23.2 | 32.8 | 45.0 | 44.3 | 3.99 | 3.99 | 3.99 | 3.95 | |

| Total | 100.0 | 100.0 | 100.0 | 100.0 | 2.97 | 3.08 | 3.23 | 3.16 | |

| H1 | −2.67 | 11.8 | 11.8 | 8.6 | 7.9 | 2.74 | 2.75 | 2.73 | 2.38 |

| 2.67–3 | 80.8 | 76.9 | 68.4 | 59.0 | 2.74 | 2.75 | 2.76 | 2.77 | |

| +3.0 | 7.4 | 11.3 | 23.0 | 33.1 | 4.05 | 4.21 | 4.40 | 5.24 | |

| Total | 100.0 | 100.0 | 100.0 | 100.0 | 2.81 | 2.87 | 3.02 | 3.23 | |

| Sp.G. Fraction | Sp.G. g/cm3 | Mass Yield % | Grade % | Recovery % | Grade ppm | Recovery % | Grade % | Recovery % | Grade % | Recovery % |

|---|---|---|---|---|---|---|---|---|---|---|

| Pb | Mo | Zn | Fe | |||||||

| −2.67 | 2.67 | 10.95 | 0.19 | 1.04 | 34 | 0.65 | 0.20 | 4.26 | 2.38 | 31.07 |

| 2.67–3.0 | 2.73 | 81.27 | 0.15 | 6.35 | 13 | 1.87 | 0.12 | 19.02 | 0.26 | 25.05 |

| +3.0 | 4.47 | 7.78 | 23.15 | 92.61 | 7164 | 97.48 | 5.17 | 76.72 | 4.72 | 43.88 |

| Total | 2.81 | 100.00 | 1.95 | 100.00 | 572 | 100.00 | 0.52 | 100.00 | 0.84 | 100.00 |

| Ba | Ca | Mg | Si | |||||||

| −2.67 | 2.67 | 10.95 | 0.03 | 0.25 | 9.94 | 3.58 | 1.13 | 6.53 | 21.59 | 77.08 |

| 2.67–3.0 | 2.73 | 81.27 | 0.04 | 2.23 | 35.51 | 95.03 | 2.12 | 91.24 | 0.69 | 18.19 |

| +3.0 | 4.47 | 7.78 | 17.17 | 97.52 | 5.41 | 1.39 | 0.54 | 2.22 | 1.89 | 4.73 |

| Total | 2.81 | 100.00 | 1.37 | 100.00 | 30.37 | 100.00 | 1.89 | 100.00 | 3.07 | 100.00 |

| Original Fraction | Mass Yield, % | Grade, % | Recovery, % | ||||||

| Screening | Pb | Zn | Mo, ppm | Ba | Pb | Zn | Mo | Ba | |

| −1 mm | 13.04 | 0.93 | 0.56 | 790 | 1.59 | 74.10 | 30.38 | 68.34 | 59.59 |

| 1–4 mm | 26.02 | 0.08 | 0.24 | 97 | 0.20 | 12.80 | 25.34 | 16.67 | 14.59 |

| 4–40 mm | 60.94 | 0.04 | 0.18 | 37 | 0.15 | 13.10 | 44.28 | 14.99 | 25.82 |

| Total −40 mm | 100.00 | 0.16 | 0.24 | 151 | 0.35 | 100.00 | 100.00 | 100.00 | 100.00 |

| +40 mm | 100.00 | 0.03 | 0.20 | 19 | 0.09 | 100.00 | 100.00 | 100.00 | 100.00 |

| Fe | Si | Ca | Mg | Fe | Si | Ca | Mg | ||

| −1 mm | 13.04 | 1.01 | 3.85 | 29.67 | 1.99 | 43.39 | 41.38 | 10.98 | 22.71 |

| 1–4 mm | 26.02 | 0.34 | 1.34 | 35.06 | 1.25 | 29.49 | 28.67 | 25.88 | 28.48 |

| 4–40 mm | 60.94 | 0.13 | 0.60 | 36.53 | 0.91 | 27.11 | 29.95 | 63.15 | 48.81 |

| Total −40 mm | 100.00 | 0.30 | 1.21 | 35.26 | 1.14 | 100.00 | 100.00 | 100.00 | 100.00 |

| +40 mm | 100.00 | 0.13 | 0.56 | 35.70 | 1.46 | 100.00 | 100.00 | 100.00 | 100.00 |

| Mass, % | Grades, % | Recovery, % | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Screening | Sorting | Pb | Zn | Mo | Pb | Zn | Mo | |||||

| Index | j | l | l | jl | l | jl | l | jl | ||||

| Original fraction | Mass | Product | Mass | Sorting product | Sorting product | Fraction total | Sorting product | Fraction total | Sorting product | Fraction total | ||

| −1 mm | 13.04 | Wx.LG | 21.04 | 0.18 | 0.39 | 0.013 | 4.14 | 3.07 | 14.52 | 4.41 | 3.46 | 2.37 |

| W2.MG | 59.71 | 0.13 | 0.39 | 0.027 | 8.56 | 6.35 | 41.40 | 12.58 | 20.28 | 13.86 | ||

| W2.SG | 0.00 | 0.00 | 0.00 | 0.000 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | ||

| Hx.1 | 2.51 | 0.31 | 0.54 | 0.031 | 0.83 | 0.62 | 2.39 | 0.73 | 0.99 | 0.67 | ||

| Hx.2 | 3.05 | 0.17 | 0.42 | 0.018 | 0.56 | 0.42 | 2.26 | 0.69 | 0.69 | 0.47 | ||

| Hx.3 | 11.62 | 0.78 | 1.59 | 0.162 | 9.74 | 7.22 | 32.89 | 9.99 | 23.81 | 16.28 | ||

| Hx.C | 2.07 | 34.08 | 1.78 | 1.934 | 76.16 | 56.43 | 6.54 | 1.99 | 50.76 | 34.69 | ||

| Total | 100.00 | 0.93 | 0.56 | 0.079 | 100.00 | 74.10 | 100.00 | 30.38 | 100.00 | 68.34 | ||

| 1–4 mm | 26.02 | Wx.LG | 27.69 | 0.06 | 0.12 | 0.005 | 19.61 | 2.51 | 14.06 | 3.56 | 12.91 | 2.15 |

| W2.MG | 59.32 | 0.03 | 0.17 | 0.004 | 23.38 | 2.99 | 43.30 | 10.97 | 24.06 | 4.01 | ||

| W2.SG | 4.59 | 0.07 | 0.39 | 0.006 | 4.27 | 0.55 | 7.53 | 1.91 | 2.88 | 0.48 | ||

| Hx.1 | 0.36 | 0.34 | 1.75 | 0.044 | 1.53 | 0.20 | 2.71 | 0.69 | 1.67 | 0.28 | ||

| Hx.2 | 0.53 | 0.11 | 0.37 | 0.012 | 0.72 | 0.09 | 0.85 | 0.21 | 0.65 | 0.11 | ||

| Hx.3 | 6.68 | 0.17 | 0.51 | 0.032 | 14.24 | 1.82 | 14.40 | 3.65 | 22.03 | 3.67 | ||

| Hx.C | 0.82 | 3.56 | 4.94 | 0.423 | 36.25 | 4.64 | 17.16 | 4.35 | 35.80 | 5.97 | ||

| Total | 100.00 | 0.08 | 0.24 | 0.010 | 100.00 | 12.80 | 100.00 | 25.34 | 100.00 | 16.67 | ||

| 4–40 mm | 60.94 | Wx.LG | 29.66 | 0.02 | 0.08 | 0.002 | 19.15 | 2.51 | 13.60 | 6.02 | 13.58 | 2.04 |

| W2.MG | 55.42 | 0.03 | 0.13 | 0.002 | 40.87 | 5.36 | 42.54 | 18.83 | 24.98 | 3.74 | ||

| W2.SG | 2.42 | 0.00 | 0.23 | 0.000 | 0.18 | 0.02 | 3.19 | 1.41 | 0.00 | 0.00 | ||

| Hx.1 | 1.00 | 0.08 | 0.48 | 0.007 | 2.34 | 0.31 | 2.74 | 1.21 | 2.00 | 0.30 | ||

| Hx.2 | 1.08 | 0.05 | 0.25 | 0.004 | 1.38 | 0.18 | 1.54 | 0.68 | 1.14 | 0.17 | ||

| Hx.3 | 9.00 | 0.04 | 0.21 | 0.004 | 10.81 | 1.42 | 10.98 | 4.86 | 8.83 | 1.32 | ||

| Hx.C | 1.42 | 0.63 | 3.15 | 0.129 | 25.28 | 3.31 | 25.42 | 11.26 | 49.47 | 7.42 | ||

| Total | 100.00 | 0.04 | 0.18 | 0.004 | 100.00 | 13.10 | 100.00 | 44.28 | 100.00 | 14.99 | ||

| Total −40 mm | 100.00 | Wx.LG | 28.03 | 0.05 | 0.12 | 0.004 | 8.09 | 8.09 | 13.99 | 13.99 | 6.55 | 6.55 |

| W2.MG | 56.99 | 0.04 | 0.18 | 0.006 | 14.69 | 14.69 | 42.38 | 42.38 | 21.62 | 21.62 | ||

| W2.SG | 2.67 | 0.03 | 0.30 | 0.003 | 0.57 | 0.57 | 3.32 | 3.32 | 0.48 | 0.48 | ||

| Hx.1 | 1.03 | 0.18 | 0.61 | 0.018 | 1.12 | 1.12 | 2.62 | 2.62 | 1.25 | 1.25 | ||

| Hx.2 | 1.19 | 0.09 | 0.32 | 0.009 | 0.69 | 0.69 | 1.58 | 1.58 | 0.75 | 0.75 | ||

| Hx.3 | 8.74 | 0.20 | 0.51 | 0.037 | 10.46 | 10.46 | 18.50 | 18.50 | 21.27 | 21.27 | ||

| Hx.C | 1.35 | 7.80 | 3.16 | 0.538 | 64.39 | 64.39 | 17.59 | 17.59 | 48.08 | 48.08 | ||

| Total | 100.00 | 0.16 | 0.24 | 0.015 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | ||

| +40 mm | 100.00 | Wx.LG | 27.73 | 0.02 | 0.13 | 0.001 | 13.76 | 13.76 | 17.60 | 17.60 | 14.81 | 14.81 |

| W2.MG | 58.13 | 0.04 | 0.16 | 0.001 | 64.69 | 64.69 | 45.48 | 45.48 | 19.57 | 19.57 | ||

| W2.SG | 4.21 | 0.04 | 0.52 | 0.007 | 5.54 | 5.54 | 10.83 | 10.83 | 15.91 | 15.91 | ||

| Hx.1 | 0.52 | 0.06 | 0.73 | 0.003 | 0.90 | 0.90 | 1.86 | 1.86 | 0.87 | 0.87 | ||

| Hx.2 | 0.76 | 0.04 | 0.32 | 0.003 | 1.05 | 1.05 | 1.18 | 1.18 | 1.19 | 1.19 | ||

| Hx.3 | 7.96 | 0.03 | 0.32 | 0.004 | 8.48 | 8.48 | 12.54 | 12.54 | 15.70 | 15.70 | ||

| Hx.C | 0.70 | 0.26 | 3.06 | 0.089 | 5.57 | 5.57 | 10.51 | 10.51 | 31.96 | 31.96 | ||

| Total | 100.00 | 0.03 | 0.20 | 0.002 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | ||

| Mass, % | Grades, % | Recovery, % | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Screening | Sorting | Pb | Zn | Mo | Pb | Zn | Mo | |||||

| Index | j | l | l | jl | l | jl | l | jl | ||||

| Original fraction | Mass | Product | Mass | Sorting product | Sorting product | Fraction total | Sorting product | Fraction total | Sorting product | Fraction total | ||

| −1 mm | 13.04 | Wx.LG | 21.04 | 0.18 | 0.39 | 0.013 | 4.14 | 3.07 | 14.5 | 4.41 | 3.46 | 2.37 |

| W2.MG | 59.71 | 0.13 | 0.39 | 0.027 | 8.56 | 6.35 | 41.40 | 12.58 | 20.28 | 13.86 | ||

| Wx.SG | 19.25 | 4.21 | 1.29 | 0.313 | 87.30 | 64.69 | 44.08 | 13.39 | 76.26 | 52.12 | ||

| Total | 100.00 | 0.93 | 0.56 | 0.079 | 100.00 | 74.10 | 100.00 | 30.38 | 100.00 | 68.34 | ||

| 1–4 mm | 26.02 | Wx.LG | 27.69 | 0.06 | 0.12 | 0.005 | 19.61 | 2.51 | 14.06 | 3.56 | 12.91 | 2.15 |

| W2.MG | 59.32 | 0.03 | 0.17 | 0.004 | 23.38 | 2.99 | 43.30 | 10.97 | 24.06 | 4.01 | ||

| Wx.SG | 12.98 | 0.35 | 0.77 | 0.047 | 57.00 | 7.29 | 42.64 | 10.81 | 63.03 | 10.51 | ||

| Total | 100.00 | 0.08 | 0.24 | 0.010 | 100.00 | 12.80 | 100.00 | 25.34 | 100.00 | 16.67 | ||

| 4–40 mm | 60.94 | Wx.LG | 29.66 | 0.02 | 0.08 | 0.002 | 19.15 | 2.51 | 13.60 | 6.02 | 13.58 | 2.04 |

| W2.MG | 55.42 | 0.03 | 0.13 | 0.002 | 40.87 | 5.36 | 42.54 | 18.83 | 24.98 | 3.74 | ||

| Wx.SG | 14.92 | 0.09 | 0.52 | 0.015 | 39.99 | 5.24 | 43.87 | 19.42 | 61.43 | 9.21 | ||

| Total | 100.00 | 0.04 | 0.18 | 0.004 | 100.00 | 13.10 | 100.00 | 44.28 | 100.00 | 14.99 | ||

| Total −40 mm | 100.00 | Wx.LG | 28.03 | 0.05 | 0.12 | 0.004 | 8.09 | 8.09 | 13.99 | 13.99 | 6.55 | 6.55 |

| W2.MG | 56.99 | 0.04 | 0.18 | 0.006 | 14.69 | 14.69 | 42.38 | 42.38 | 21.62 | 21.62 | ||

| Wx.SG | 14.98 | 0.84 | 0.70 | 0.072 | 77.22 | 77.22 | 43.62 | 43.62 | 71.83 | 71.83 | ||

| Total | 100.00 | 0.16 | 0.24 | 0.015 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maroušek, L.; Dollinger, S.; Elmer, S.; Öfner, W.; Nussbacher, H.; Melcher, F.; Flachberger, H. Re-Mining of Waste Rock Dumps from a Closed Lead–Zinc Mine—Characterisation of the Residuals. Minerals 2023, 13, 361. https://doi.org/10.3390/min13030361

Maroušek L, Dollinger S, Elmer S, Öfner W, Nussbacher H, Melcher F, Flachberger H. Re-Mining of Waste Rock Dumps from a Closed Lead–Zinc Mine—Characterisation of the Residuals. Minerals. 2023; 13(3):361. https://doi.org/10.3390/min13030361

Chicago/Turabian StyleMaroušek, Lukas, Sabrina Dollinger, Simone Elmer, Wolfgang Öfner, Hanspeter Nussbacher, Frank Melcher, and Helmut Flachberger. 2023. "Re-Mining of Waste Rock Dumps from a Closed Lead–Zinc Mine—Characterisation of the Residuals" Minerals 13, no. 3: 361. https://doi.org/10.3390/min13030361

APA StyleMaroušek, L., Dollinger, S., Elmer, S., Öfner, W., Nussbacher, H., Melcher, F., & Flachberger, H. (2023). Re-Mining of Waste Rock Dumps from a Closed Lead–Zinc Mine—Characterisation of the Residuals. Minerals, 13(3), 361. https://doi.org/10.3390/min13030361