Abstract

In the course of mining and processing of almost all petrographic varieties of rock raw materials for the production of building and materials, aggregates for road and railway construction, waste is generated. These are usually fine-grained fractions of these rocks that are difficult to manage and are deposited at dumps. The article presents and describes the results of the physical, chemical, and mineralogical properties of fine-grained waste from the production of amphibolite aggregate from Pilawa Gorna in Lower Silesia (S-W Poland). Such studies have not been carried out on this waste before. The tested waste is a very fine-grained dusty material (<0.100 mm) originating from the dedusting of the crushing and classification operations during the production of aggregates. Preliminary studies of the separation of the tested material using collector-less flotation and gravity separation are also presented. Detailed chemical analysis shows that most of the elements in the studied rock dust occur in abundance close to the average in the Earth’s crust. The collector-free flotation of the investigated sample allows effective separation of graphite and the part of sulfide minerals Cu, Ni, and Mo. The presented results may be the basis for further research and development of the concept of their economic use.

1. Introduction

In many branches of the rock raw material industry, especially in the case of crushed aggregates, the finest fractions of the extracted and processed material are considered waste. Such waste is typically used on a limited scale, and most often, it is deposited as useless material. This fact applies to the majority of mined rocks, magmatic, as well as metamorphic and sedimentary rocks. It is also true, especially for large rock mines in Lower Silesia, which is a region with the main rock raw material resource base in Poland. Fine-grained aggregate waste products have grain sizes smaller than 2 or 1 mm and often below 0.1 mm. They often show a high degree of liberation of mineral components, thanks to which their practical usage in the case of separation of components does not require an additional expensive grinding operation. This is true, for example, in the case of granite, basalt, and other volcanic rock wastes resulting from the production process of aggregates used in building and road construction. Granite wastes are a potential base of quartzo-feldspathic and feldspathic raw materials [1,2,3] or as an additive to concretes [4,5,6,7,8,9]. Basalt wastes are offered as an additive to concretes [10], and basalt dust is offered as a component of ceramic materials and glazes [11,12,13,14]. A very important direction in the management of rock waste is its use as natural mineral fertilizer. The largest amount of data concerns fine-grained waste generated during the production of aggregates from acidic and alkaline igneous rocks. The main examples are basalt and granite waste, as well as syenite and gabbro [15,16,17,18]. Such fertilizers may compensate for the lack of microelements in soils without the risk of overdosing substances introduced into the soil, as they are released slowly and in a long-term process [19,20,21]. These authors also described the release mechanism of Ca, Fe, K, Mg, Na, P, and Si from fine-grained rock wastes from various, both acidic and alkaline, mined igneous and volcanic rock deposits. For mineral fertilizer applications, the finer the rock material, the greater its surface-to-volume ratio and the easier it is to release nutrients into the soil. The agronomic advantages of using rock waste as a natural mineral fertilizer for the soil can reduce the negative environmental impacts of conventional agriculture [15,22,23]. The possibility to use rock powders as fertilizers in agriculture is important in the circular economy, as it offers a chance to find a practical application to large amounts of unmarketable material, which is stored in heaps and thus has a negative impact on the surrounding environment (dust emissions, releasing metals into the soil).

In the case of fine-grained rock wastes, grinding, which is the most expensive operation in the mineral processing of each raw material, is unnecessary. Therefore, the remaining cost of the potential use or further processing of such materials will result from other processing operations, such as enrichment. Fine fractions of the material usually is characterized by a high degree of liberation of individual mineral components of the rock, e.g., valuable accessory minerals. Hence, fine-grained rock wastes are becoming the subject of research as a source of critical raw materials (CRM), including rare metals [24,25,26].

Amphibolites are found in southwest Poland, in the Lower Silesia region (SW Poland). They are mined from four deposits: Ogorzelec, Pagorki Wschodnie, Pilawa Gorna, and Kluczowa. In the Pilawa Gorna and Kluczowa deposits, the main mineral is accompanied by migmatites. In Poland, amphibolite and migmatite deposits are mined in open-pit mines, and the final product consists of crushed aggregates. The Pilawa Gorna plant produces road and railway aggregates as well as aggregates used for the production of high-strength concrete [27].

The Pilawa Gorna deposit is located in the central part of the fore-Sudetic block, in the area of the Gory Sowie block formed of metamorphic rocks [28,29]. Mining operations are performed in the migmatite and amphibolite rock, which is composed mainly of migmatites (72%) and amphibolites with the addition of granitoid pegmatites [29]. The mineral composition of amphibolites is dominated by plagioclases, amphiboles (mainly hornblende), quartz, and biotite, and the mineral composition of migmatites is by quartz, amphiboles, potassium feldspar, plagioclases, and biotite. The quantitative content of hornblende in the above rocks varies, with the highest value being observed in laminated amphibolites [28]. In addition, these rocks consist of graphite, which is due to pegmatite veins and graphite shales. In some publications, the pegmatite veins which occur in the deposit are also described as a potential source of rare elements [30].

The Pilawa Gorna mine of amphibolite and migmatite aggregates is one of the largest aggregate mining and production facilities in Poland. It was established in 2007 as a greenfield-type investment operated by Dolnoslaskie Surowce Skalne (DSS sp. z o.o) [31] and is currently owned by Kampania Gornicza sp. z o.o. The deposit is mined in open-pit technology and using blasting methods. The blasted material is processed in a mobile system arranged in the excavation pit and in a stationary system located in the processing plant. The mobile plant can be adjusted to the mining and production conditions, thus facilitating the organization of the production processes. It is also in communication with the stationary system [32]. In the stationary processing plant, the mined material is first crushed and classified [33]. The products of this process include blends, broken stones, and grit used as crushed aggregates in road construction [34]. The production line in a modern processing plant is equipped with a high-efficiency dust separator which ensures a low level of dust in the products and in the production stations. The removed rock dusts are deposited in great quantities on an external heap as production waste. The mining company offers those rock dusts for sale as a component for concrete prefabricates [35].

The literature mentions the results of research into the possibility of using fine fractions of wastes from other amphibolite deposits mined in Lower Silesia. When investigating amphibolite wastes from the Ogorzelec and Wiesciszowice sites, Lubas and Wyszomirski [36] confirmed the possibility of using these materials in the production of glass-ceramics (aluminosilicate glass) and fibrous insulating materials Maliszewski et al. [37] analyzed fine fractions of amphibolites from the Pagorki Wschodnie, Ogorzelec, and Wiesciszowice sites. The authors concluded that the unmarketable amphibolite fractions from the Pagorki Wschodnie deposit could be used as a raw material in producing ceramic color glaze. They also concluded that the CaO, MgO, and K2O content combined with the low SiO2 content in the material from Pagorki Wschodnie justifies further research into recycling fine rock fractions from this deposit as components in the production of mineral fertilizers. Amphibolite dusts from the Pilawa Gorna deposit were investigated as an additive to cast concrete products (blocks etc.) [38].

The aim of this research is to present the results of detailed analyses of the chemical and mineral composition of the waste material from technological dust separation in the production processes of amphibolite-migmatite aggregate with a view to identifying the potential applications of this material. The aim of the research was also to verify numerous suggestions of rare and precious useful components present, especially in the currently mined pegmatites [29]. The second objective of the present research into waste dusts from the Pilawa Gorna plant was to perform a preliminary attempt at their gravity separation. The investigated material comprises highly hydrophobic elements, mainly graphite, which disrupts gravity separation. Therefore, the study also included preliminary flotation trials performed in order to remove this element from the feed for enrichment processes. Part of the results presented in this paper comes from [39].

2. Materials and Methods

The research was performed on a sample of fine-grained rock wastes from the production of crushed aggregates in the Pilawa Gorna mine. The mass of the sample was approximately 60 kg. The sample was divided in the universal sample splitter, and a representative sample of 1 kg was taken in order to identify the particle size distribution and the chemical composition of the feed. Further, 10 samples of 3 kg each were taken from the material. Such samples represented feed batches in the graphite flotation process.

The grain size distribution of the investigated material is shown in Table 1. The sample comprises fine particles with the content of the finest 0.025 mm fraction at nearly 42%. The presence of highly hydrophobic grains, identified as graphite, was observed already during the "wet" sieve analysis.

Table 1.

Particle size distribution of waste sample from Pilawa Gorna.

A representative sample of the material was subjected to chemical and mineralogical analyses. The chemical analyses were performed with the use of the Na2O2 − ICP + ICP/MS method in Activation Laboratories Ltd. (Actlabs) in Ancaster, ON, Canada. The total carbon content was identified with the use of the ELTRA CS-580 coal and sulfur analyzer (Eltra GmbH, Mettmann, Germany). The mineralogical analyses of the fine-grained waste sample were performed with the use of an automated MLA (Mineral Liberation Analysis, FEI, Hillsboro, OR, United States) system in the FEI laboratory in Australia. Importantly, this type of analysis does not allow the identification of graphite in a sample, and therefore both the flotation and gravity separation products were subjected to another mineralogical analysis with the use of an optical microscope in reflected light. The main objective of the mineralogical analyses was to provide the qualitative and quantitative characteristics of the ore minerals and graphite present in the samples obtained from the separation experiments. The quantitative mineralogical analyses were performed on the final products of the flotation and gravity separation processes. As the mineralization of the tested sample was very low grade, the balances do not include mineral content in the original feed.

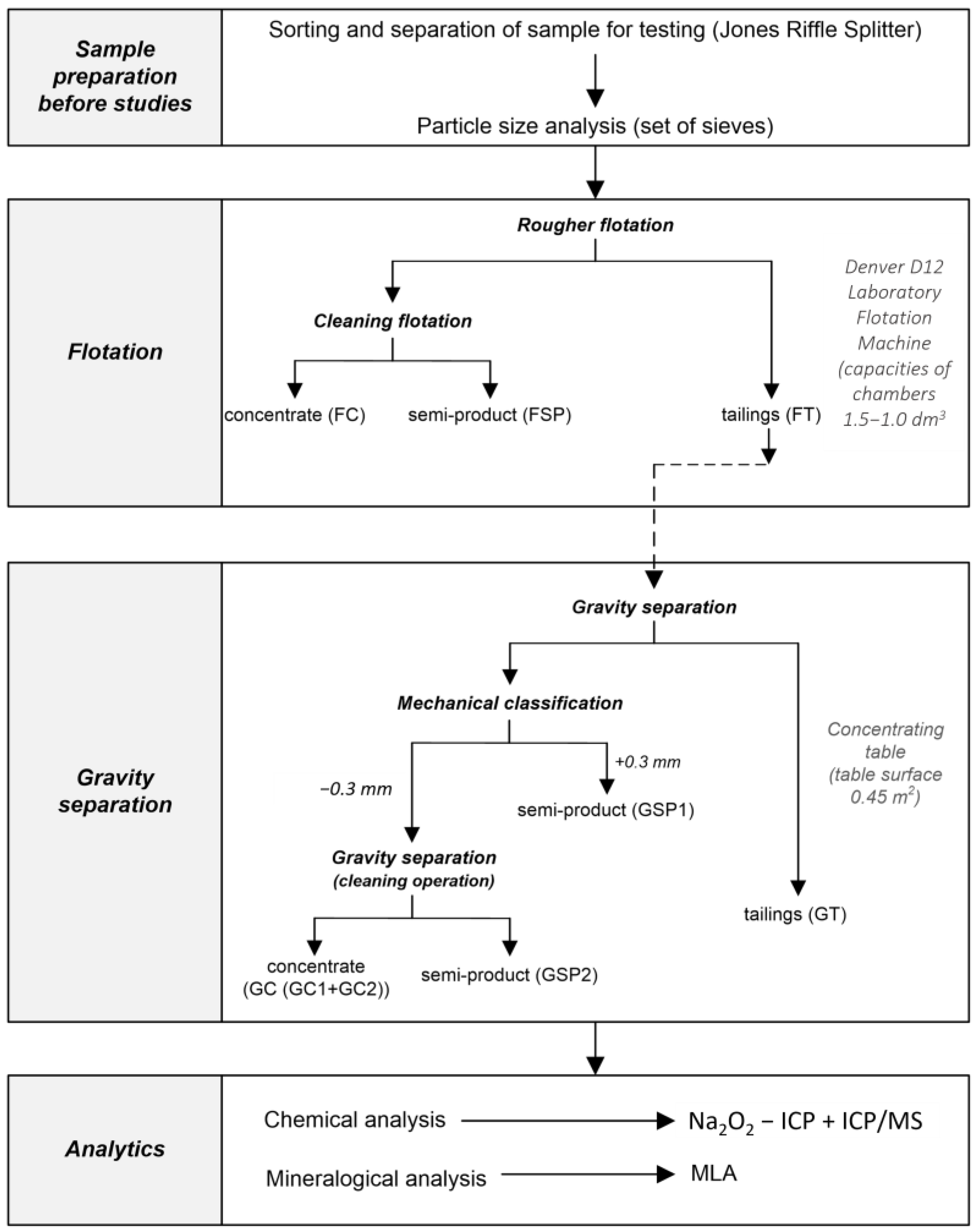

Figure 1 shows the schematic diagram of the tests. The flotation experiments were performed in a Denver D12 laboratory flotation machine provided with replaceable rotors and chambers having capacities from 1.5 to 10 dm3. The flotation operation was performed in order to separate the highly hydrophobic elements, mainly graphite, from the material. Instead of a collector, the flotation used only the MIBC (methyl isobutyl carbinol) as a frother, added at 100 g/Mg. The reagent was supplied at the beginning of rougher flotation. A total of 10 experiments were performed with 3 kg feed batches, and the collected graphite concentrate was subjected to a single cleaning operation (Figure 1). The waste from the flotation process was dressed in a multistage gravity separation operation performed on a 0.45 m2 Wilfley concentration table. The aim of this operation was to separate heavy minerals, which are typically defined as grains greater than 3.0 g/cm3 in density. The products of the gravity separation were preliminary concentrate and gravity waste. The preliminary concentrate was sieved in order to separate the +0.3 mm fraction, and the −0.3 mm fraction was subjected to a cleaning operation. The separation of the +0.3 mm fraction was aimed at providing more favorable conditions for cleaning the gravity concentrate, including the more liberated −0.3 mm grains.

Figure 1.

The scheme of research.

3. Results

Table 2 shows the results of chemical analyses performed on the investigated sample. It also presents the average scatter of assay results for the elements in the upper continental crust (UCC–down to 21 km) [40]. The last column of the table comprises the concentration coefficients of the assayed elements in relation to their average content in the UCC. These values show the concentration or dilution ratio with respect to the average values for the Earth’s crust. As can be seen in Table 2, only Se and Sr show significantly higher values of the concentration coefficient. However, these values are still far from the estimated lower limits for economically viable extraction (according to Fergusson [41]). S, Cu, Ni, Co, Cr, V, and Mn show significant concentrations in relation to the average scatter in the Earth’s crust (concentration coefficient ≥3). Ctotal, Fe, P, Ti, Zn, Ge, as well as Sn, Mo, Li, and REE + Y, show significantly lower concentrations (concentration coefficient >1). The concentration levels of the above elements are still close to the average scatter in the lithosphere and, thus, very far from the estimated lower limits for economically viable extraction [41]. The remaining element concentrations are below the average content in the UCC.

Table 2.

Chemical composition of studied waste sample from Pilawa Gorna.

Table 3 shows the mineral analysis results for the tested waste sample (feed to the main flotation). The main mineral components of the tested material include plagioclases, hornblende, quartz, and biotite, which account for nearly 88% of the entire sample. The association tests of these minerals demonstrated that they are liberated in 92–95% and that they occur mostly in mutual associations.

Table 3.

Mineral composition of studied waste sample from Pilawa Gorna.

Table 4, Table 5, Table 6 and Table 7 show the enrichment balances for selected elements, which were enriched in the collector-free flotation and in the gravity separation in relation to the content in the feed. Table 5 and Table 7 show the balances for graphite and ore minerals in the case of graphite-cleaning flotation and gravity separation.

Table 4.

The balance of collector-less flotation—analysis of the flotation of the selected chemical components.

Table 5.

The balance of cleaning flotation—analysis of the flotation of the major minerals.

Table 6.

The balance of gravity separation.

Table 7.

The balance of gravity separation (cleaning stage).

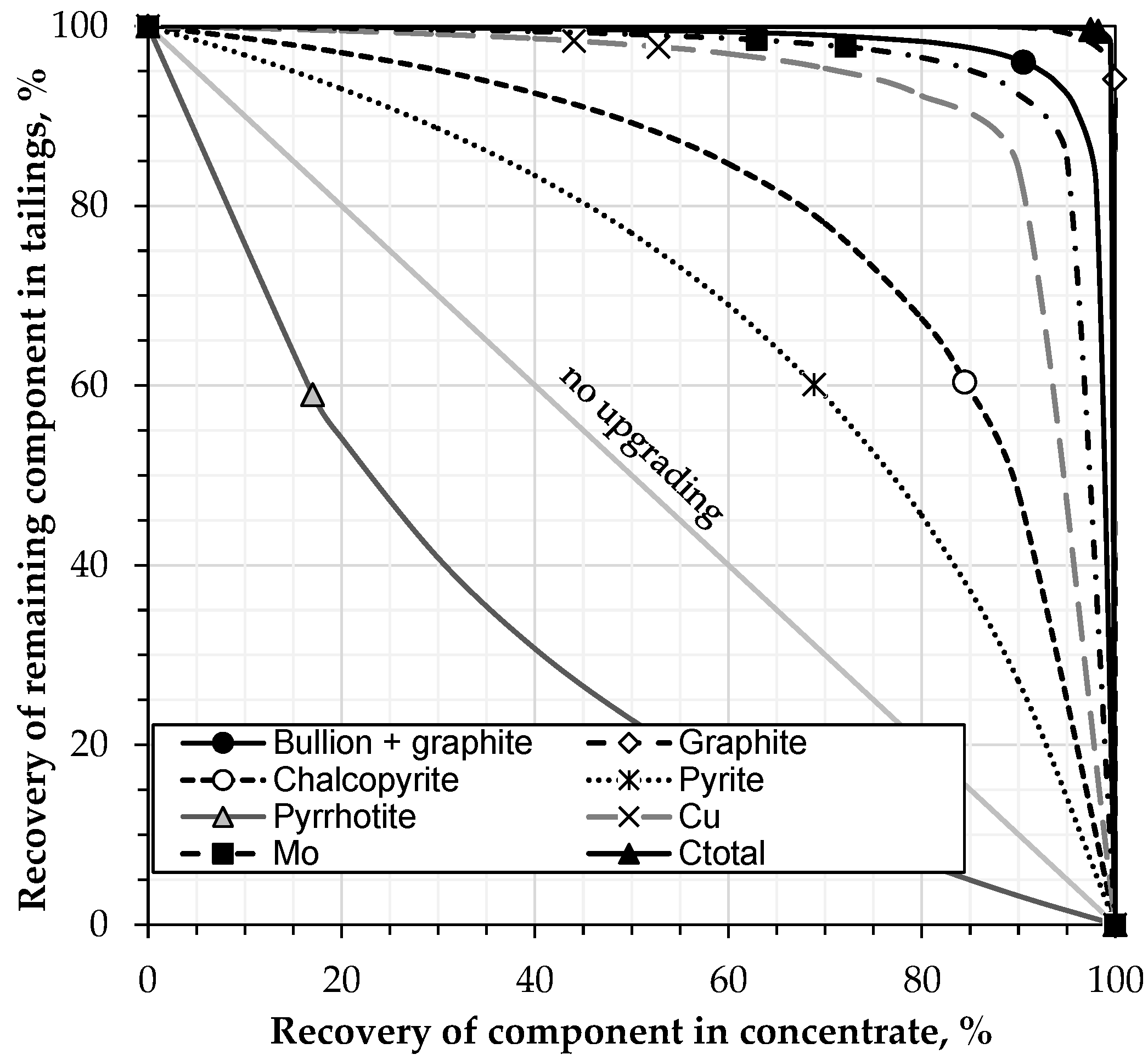

In Figure 2, the recovery-recovery upgrading curves for flotation show the flotation efficiency of selected components. Ore minerals and graphite had the highest flotation selectivity; these components concentrated in the concentrate. Based on the position of the curves relative to the no-upgrading line, it was found that pyrrhotite concentrated mostly in the cell product, while pyrite floated with the low selectivity of the upgrading process.

Figure 2.

Recovery-recovery upgrading curves for flotation of the major minerals and metals.

The purpose of the collector-free flotation procedure was mainly to isolate graphite which is an obstacle in the process of gravity separation on the concentrating table. As expected, the concentrate from the flotation process involving only the foaming agent included the easily floating graphite and sulfurous minerals, such as molybdenite and chalcopyrite. The copper and molybdenum recovery in the graphite-cleaning flotation were 44 and 63%, respectively. This assumption was confirmed in the mineral liberation analysis of the products of the graphite-cleaning flotation, the results of which are presented in Table 4. The >90% graphite concentrate from the cleaning flotation comprised almost 100% of this mineral, which after the main graphite flotation and together with ore minerals, accounted for 41.5% of the preliminary concentrate (the last row in Table 5). The cleaned concentrate also comprised the majority of chalcopyrite and pyrite, with recoveries of 84.4% and 67.3%, respectively, as well as a limited part of pyrrhotite, with a recovery of 17.0%. The cleaned concentrate also comprised molybdenite in amounts significantly below 0.1%. The “waste” from graphite flotation practically did not comprise this mineral. In the case of the remaining analyzed elements, the enrichment process practically did not produce any positive effect.

The gravity separation on the concentrating table indicates limited possibilities of effective separation of the small amounts of heavy minerals present in the feed. As indicated in the incomplete balance of the minerals in the final concentrate (Table 7), they are mainly ore minerals: pyrite and pyrrhotite, as well as small amounts of ilmenite and rutile. This fact is confirmed in the chemical balances shown in Table 6. In the main gravity concentrate (without cleaning), the recovery of Cu is approximately 10%, Ni–20%, Mn–15%, Nb + Ta–10%, Ti–15%, and ΣREE + Y–15%.

4. Conclusions

Detailed chemical analyses of the waste dust samples from the Pilawa Gorna aggregate mine indicate that the contents of the majority of rare elements are on the level of average contents in the upper lithosphere layers. Significantly high concentration coefficients are observed only in the case of Se and Sr (159 and 61, respectively). However, these values are very far from the estimated lower limits for economically viable extraction. S, Cu, Ni, Co, Cr, V, and Mn show significant concentrations in relation to the average scatter in the Earth’s crust (concentration coefficient ≥3). Ctotal, Fe, P, Ti, Zn, Ge, as well as Sn, Mo, Li, and ΣREE + Y, show significantly lower concentrations (concentration coefficient >1). The concentration levels of the above elements are still close to the average scatter in the lithosphere and, thus, very far from the estimated lower limits for economically viable extraction. The remaining element concentrations are below the average content in the UCC.

The collector-free flotation of the investigated sample allows an effective separation of the hydrophobic graphite and of the part of Cu, Ni, and Mo carriers, mainly in the form of sulfide minerals. Extensive flotation tests are expected to verify the possibilities of concentrating these metals. The gravity separation tests indicate limited possibilities of effective separation of the small amounts of heavy minerals present in the feed.

The presented results of the chemical and mineral composition tests performed for the waste from aggregate production in the Pilawa Gorna mine may be viewed as a basis for further research into its practical recycling applications.

Author Contributions

Conceptualization, A.L., M.D. and A.B.; methodology, A.L., M.D. and A.B.; software, A.L., M.D. and A.B.; validation, A.L., M.D. and A.B.; formal analysis, A.L., M.D. and A.B.; resources, A.L., M.D. and A.B.; writing—original draft preparation, A.L., M.D. and A.B.; writing—review and editing, A.L., M.D. and A.B.; visualization, A.L., M.D. and A.B.; supervision, A.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by The Polish Ministry of Education and Science Subsidy 2022 for the Department of Mining WUST, grant number 8211104160.

Data Availability Statement

Not applicable.

Acknowledgments

The authors wish to express their gratefulness to the aggregate mining plants from the Pilawa Gorna Mine for the material provided for the tests.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Torres, P.; Manjate, R.S.; Quaresma, S.; Fernandes, H.R.; Ferreira, J.M.F. Development of ceramic floor tile compositions based on quartzite and granite sludges. J. Eur. Ceram. Soc. 2007, 27, 4649–4655. [Google Scholar] [CrossRef]

- Vasic, M.V.; Mijatovic, N.; Radojevic, Z. Aplitic Granite Waste as Raw Material for the Production of Outdoor Ceramic Floor Tiles. Materials 2022, 15, 3145. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, J.Y.; Kim, Y.H.; Kim, D.; Kim, J.; Han, J.G. Evaluating the eco-compatibility of mortars with feldspar-based fine aggregate. Case Stud. Constr. Mater. 2022, 16, e00781. [Google Scholar] [CrossRef]

- Vaitkevičius, V.; Šerelis, E.; Lygutaitė, R. Production Waste of Granite Rubble Utilisation in Ultra High. J. Sustain. Archit. Civ. Eng. 2013, 2, 54–60. [Google Scholar] [CrossRef]

- Arivumangai, A.; Felixkala, T. Strength and durability properties of granite powder concrete. J. Civ. Eng. Res. 2014, 4, 1–6. [Google Scholar] [CrossRef]

- Grabiec, A.M.; Zawal, D.; Kostrzewski, W. Effect of Waste Mineral Additives on Flow Stability Over Time in Self-Compacting Concrete Mixes With Low Clinker Content. J. Ecol. Eng. 2015, 16, 206–214. [Google Scholar] [CrossRef]

- Mashaly, A.O.; Shalaby, B.N.; Rashwan, M.A. Performance of mortar and concrete incorporating granite sludge as cement replacement. Constr. Build. Mater. 2018, 169, 800–818. [Google Scholar] [CrossRef]

- Savadkoohi, M.S.; Reisi, M. Environmental protection based sustainable development by utilization of granite waste in Reactive Powder Concrete. J. Clean. Prod. 2020, 266, 121973. [Google Scholar] [CrossRef]

- Shwetha, K.G.; Kumar, C.M.; Dalawai, V.N.; Anadinni, S.B.; Sowjanya, G.V. Comparative study on strengthening of concrete using granite waste. Mater. Today Proc. 2022, 62, 5317–5322. [Google Scholar] [CrossRef]

- Dobiszewska, M.; Beycioğlu, A. Physical Properties and Microstructure of Concrete with Waste Basalt Powder Addition. Materials 2020, 13, 3503. [Google Scholar] [CrossRef] [PubMed]

- Vieira CM, F.; Soares, T.M.; Sánchez, R.; Monteiro, S.N. Incorporation of granite waste in red ceramics. Mater. Sci. Eng. A 2004, 373, 115–121. [Google Scholar] [CrossRef]

- Souza, A.J.; Pinheiro, B.C.A.; Holanda, J.N.F. Recycling of gneiss rock waste in the manufacture of vitrified floor tiles. J. Environ. Manag. 2010, 91, 685–689. [Google Scholar] [CrossRef] [PubMed]

- Cetin, S.; Marangoni, M.; Bernardo, E. Lightweight glass–ceramic tiles from the sintering of mining tailings. Ceram. Int. 2015, 41, 5294–5300. [Google Scholar] [CrossRef]

- Pazniak, A.; Barantseva, S.; Kuzmenkova, O.; Kuznetsov, D. Effect of granitic rock wastes and basalt on microstructure and properties of porcelain stoneware. Mater. Lett. 2018, 225, 122–125. [Google Scholar] [CrossRef]

- Dalmora, A.C.; Ramos, C.G.; Oliveira, M.L.S.; Teixeira, E.C.; Kautzmann, R.M.; Taffarel, S.R.; De Brum, I.A.S.; Silva, L.F.O. Chemical characterization, nano-particle mineralogy and particle size distribution of basalt dust wastes. Sci. Total Environ. 2016, 539, 560–565. [Google Scholar] [CrossRef]

- Dos Santos Teixeira, A.M.; Dos Santos Garrido, F.M.; Medeiros, M.E.; Sampaio, J.A. Effect of thermal treatments on the potassium and sodium availability in phonolite rock powder. Int. J. Miner. Process. 2015, 145, 57–65. [Google Scholar] [CrossRef]

- Ramos, C.G.; Oliveira ML, S.; Pena, M.F.; Cantillo, A.M.; Ayarza LP, L.; Korchagin, J.; Bortoluzzi, E.C. Nanoparticles generated during volcanic rock exploitation: An overview. J. Environ. Chem. Eng. 2021, 9, 106441. [Google Scholar] [CrossRef]

- Da Silva, F.J.P.; De Carvalho, A.M.X.; De Castro Borges, P.H. The gabbro dacite blend as soil remineralizer. Braz. J. Agric. Sci. 2022, 17, e1419. [Google Scholar] [CrossRef]

- Ramos, C.G.; Querol, X.; Dalmora, A.C.; De Jesus Pires, K.C.; Schneider IA, H.; Oliveira LF, S.; Kautzmann, R.M. Evaluation of the potential of volcanic rock waste from southern. Brazil as a natural soil fertilizer. J. Clean. Prod. 2017, 142, 2700–2706. [Google Scholar] [CrossRef]

- Nunes, J.M.G.; Kautzmann, R.M.; Oliveira, C. Evaluation of the natural fertilizing potential of basalt dust wastes from the mining district of Nova Prata (Brazil). J. Clean. Prod. 2014, 84, 649–656. [Google Scholar] [CrossRef]

- Plata, L.G.; Ramos, C.G.; Oliveira, M.L.S.; Oliveira, L.F.S. Release kinetics of multi-nutrients from volcanic rock mining by-products: Evidences for their use as a soil remineralizer. J. Clean. Prod. 2021, 279, 123668. [Google Scholar] [CrossRef]

- Gillman, G.P.; Burkett, D.C.; Coventry, R.J. Amending highly weathered soils with finely ground basalt rock. Appl. Geochem. 2002, 17, 987–1001. [Google Scholar] [CrossRef]

- Sikora, L.J. Effects of basaltic mineral fines on composting. Waste Manag. 2004, 24, 139–142. [Google Scholar] [CrossRef]

- Drobot, N.F.; Noskova, O.A.; Steblevskii, A.V.; Fomichev, S.V.; Krenev, V.A. Recovery of valuable components from basalt waste by sintering it with sodium carbonate. Theor. Found. Chem. Eng. 2011, 45, 769–775. [Google Scholar] [CrossRef]

- Dino, G.A.; Cavallo, A.; Rossetti, P.; Garamvölgyi, E.; Sándor, R.; Coulon, F. Towards sustainable mining: Exploiting raw materials from extractive waste facilities. Sustainability 2020, 12, 2383. [Google Scholar] [CrossRef]

- Vrbický, T.; Přikryl, R. Recovery of Some Critical Raw Materials from Processing Waste of Feldspar Ore Related to Hydrothermally Altered Granite: Laboratory-Scale Beneficiation. Minerals 2021, 11, 455. [Google Scholar] [CrossRef]

- Brzezinski, D.; Miskiewicz, W. Kamienie lamane i bloczne. In Bilans Zasobow Zloz Kopalin w Polsce wg Stanu na 31.12.2020 r; Panstwowy Instytut Geologiczny: Warszawa, Poland, 2002; pp. 106–128. [Google Scholar]

- Cymerman, Z. Rozwoj strukturalny metamorfiku sowiogorskiego w okolicy Pilawy Gornej, Sudety. Geol. Sudet. 1989, 23, 107–153. [Google Scholar]

- Pieczka, A.; Golebiowska, B.; Jelen, P.; Wlodek, A.; Szeleg, E.; Szuszkiewicz, A. Towards Zn-dominant tourmaline: A case of zn-rich fluor-elbaite and elbaite from the Julianna system at Pilawa Gorna, Lower Silesia, SW Poland. Minerals 2018, 8, 126. [Google Scholar] [CrossRef]

- Szuszkiewicz, A.; Szeleg, E.; Pieczka, A.; Ilnicki, S.; Nejbert, K.; Turniak, K.; Banach, M.; Lodzinski, M.; Rozniak, R.; Michalowski, P. The Julianna pegmatite vein system at the Pilawa Gorna Mine, Gory Sowie Block, SW Poland—preliminary data on geology and descriptive mineralogy. Geol. Q. 2013, 57, 467–484. [Google Scholar] [CrossRef]

- Galos, K. Kopalnia Pilawa Gorna nowy dostawca kruszyw naturalnych lamanych na Dolnym Ślasku. Surowce Masz. Bud. 2007, 3, 24–27. [Google Scholar]

- Gawenda, T. Analiza porownawcza mobilnych i stacjonarnych ukladow technologicznych przesiewania i kruszenia. Rocz. Ochr. Srodowiska 2013, 15, 1318–1335. [Google Scholar]

- Stefanicka, M. Mobilne i stacjonarne uklady przerobcze na przykladzie kopalni Pilawa “Gorna”. Pr. Nauk. Inst. Gor. Politech. Wroc. Stud. Mater. 2011, 132, 277–289. [Google Scholar]

- Galos, K.; Luczak, J.; Michalowski, P.; Patyk, J. Sukces w zgodzie z natur—historia powstania kopalni “Pilawa Gorna”. Pr. Nauk. Inst. Gor. Politech. Wroc. 2009, 125, 63–78. [Google Scholar]

- Kompania Gornicza SP. Z O.O. Available online: https://kompaniagornicza.pl (accessed on 21 November 2022).

- Lubas, M.; Wyszomirski, P. Niekonwencjonalne wykorzystanie amfibolitow dolnoslaskich. Mater. Ceram./Ceram. Mater. 2009, 61, 31–35. [Google Scholar]

- Maliszewski, M.; Pomorski, A.; Cichon, T. Mozliwosci wykorzystania trudno zbywalnych frakcji amfibolitu ze zloza Pagorki Wschodnie. Gor. Odkryw. 2017, 58, 4–10. [Google Scholar]

- Borowski, G.; Swiderski, T.; Ozga, M. Stone dust agglomeration for utilizing as building material. Adv. Sci. Technol. Res. J. 2017, 11, 168–174. [Google Scholar] [CrossRef]

- Luszczkiewicz, A.; Duchnowska, M.; Muszer, A. Wstepne Badania Przerobcze Pylow Skalnych z Kopalni DSS S.A. “Pilawa Gorna”; Raport nr S-005/2011; Politechnika Wroclawska, Instytut Gornictwa, Wydzial Geoinzynierii, Gornictwa I Geologii: Wroclaw, Poland, 2011. [Google Scholar]

- Wedepohl, K.H. The composition of the continental crust. Geochim. Cosmochim. Acta 1995, 59, 1217–1232. [Google Scholar] [CrossRef]

- Fergusson, J.E. Inorganic Chemistry and the Earth: Chemical Resources, Their Extraction, Use, and Environmental Impact; Pergamon Press: Sydney, Australia, 1982; 400p. [Google Scholar]

- Gruszczyk, H. Nauka o zlozach, 2nd ed.; Wydawnictwa Geologiczne: Warszawa, Poland, 1984. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).