Characteristics and Controlling Factors of Particle Crushing in Volcaniclastic Sediments under Compaction: The Quaternary Pyroclastic Deposits of Hongtu Hill, Changbaishan Area, Northeastern China

Abstract

:1. Introduction

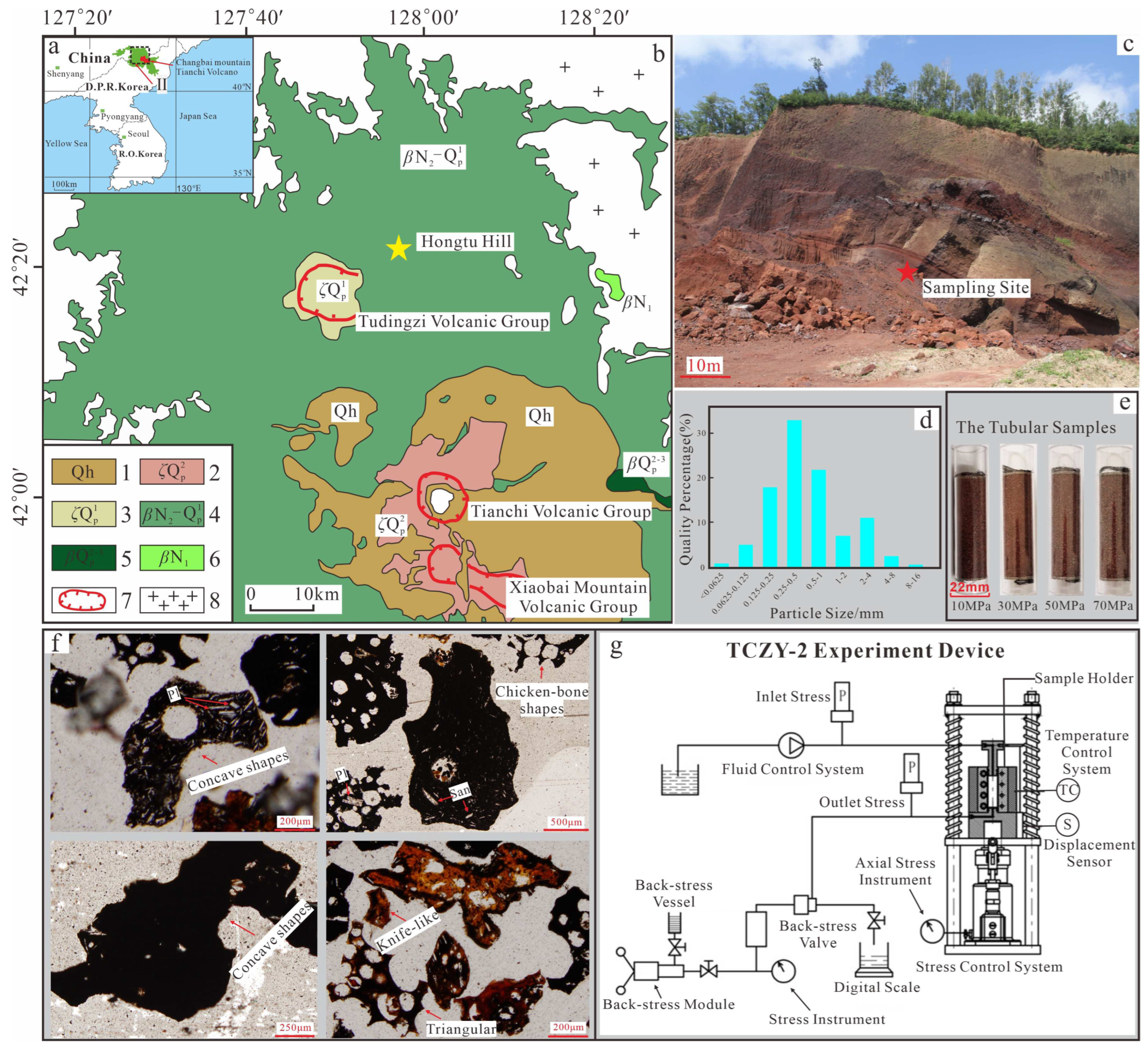

2. Geologic Setting and Samples

3. Methods

3.1. Experimental Mechanical Compaction

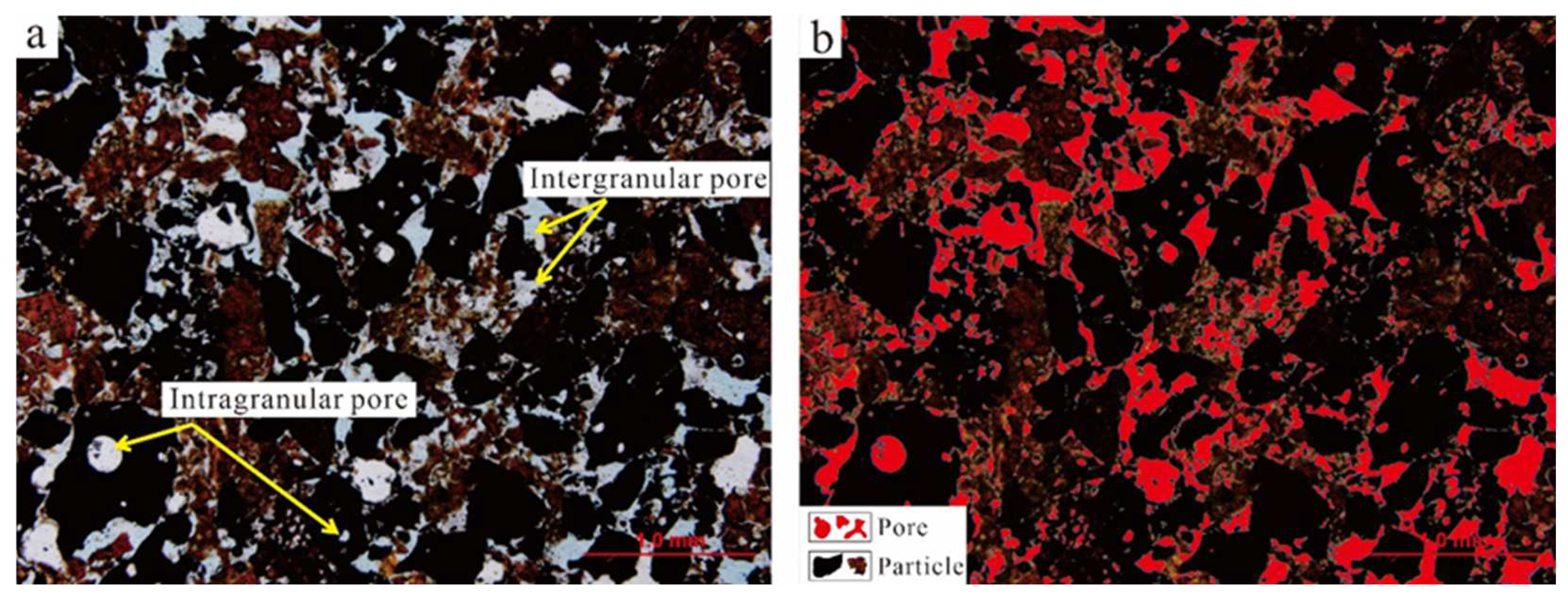

3.2. Image Surface Porosity

3.3. Particle Size Analysis

4. Results

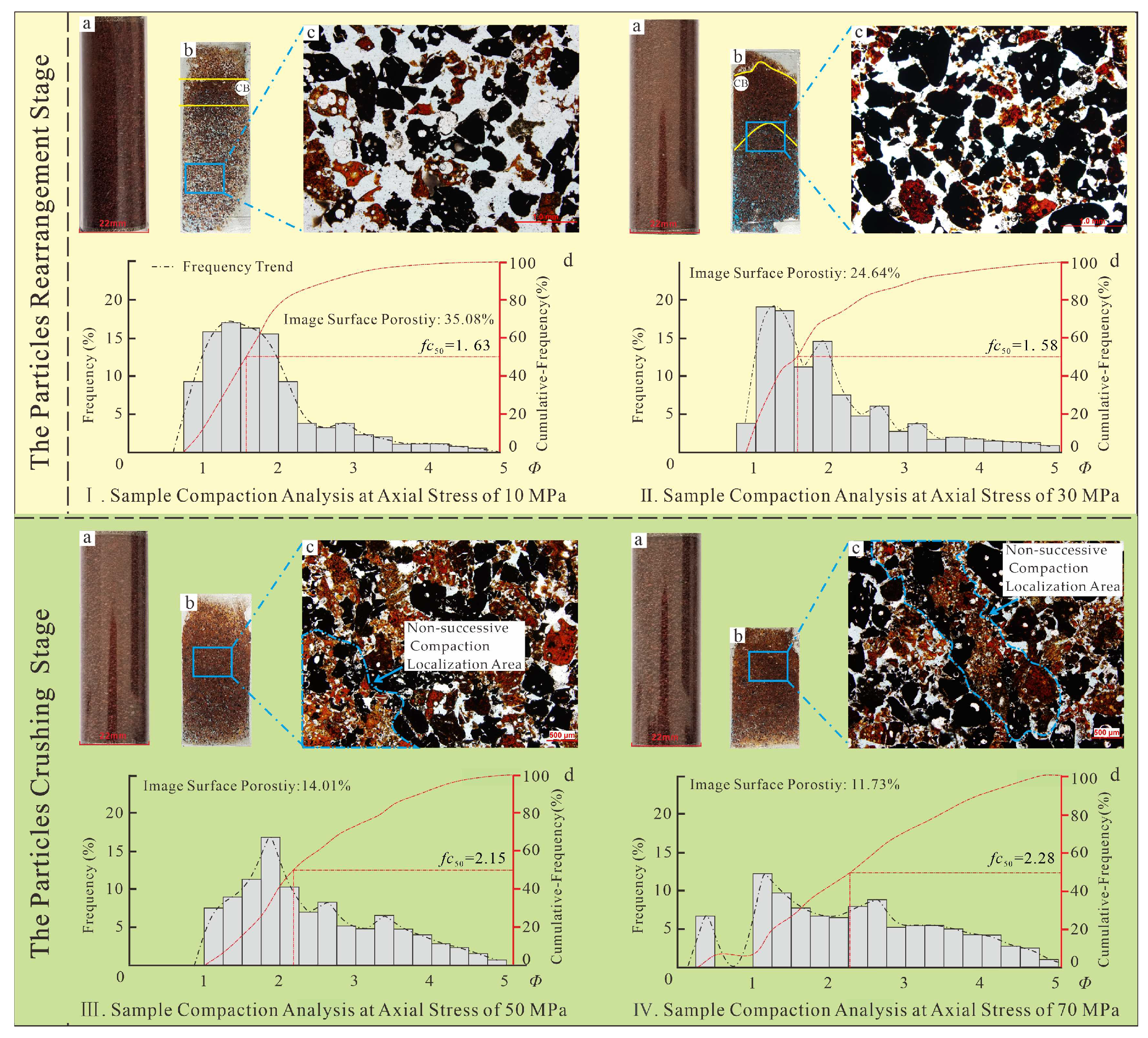

4.1. Effective Porosity and Image Surface Porosity

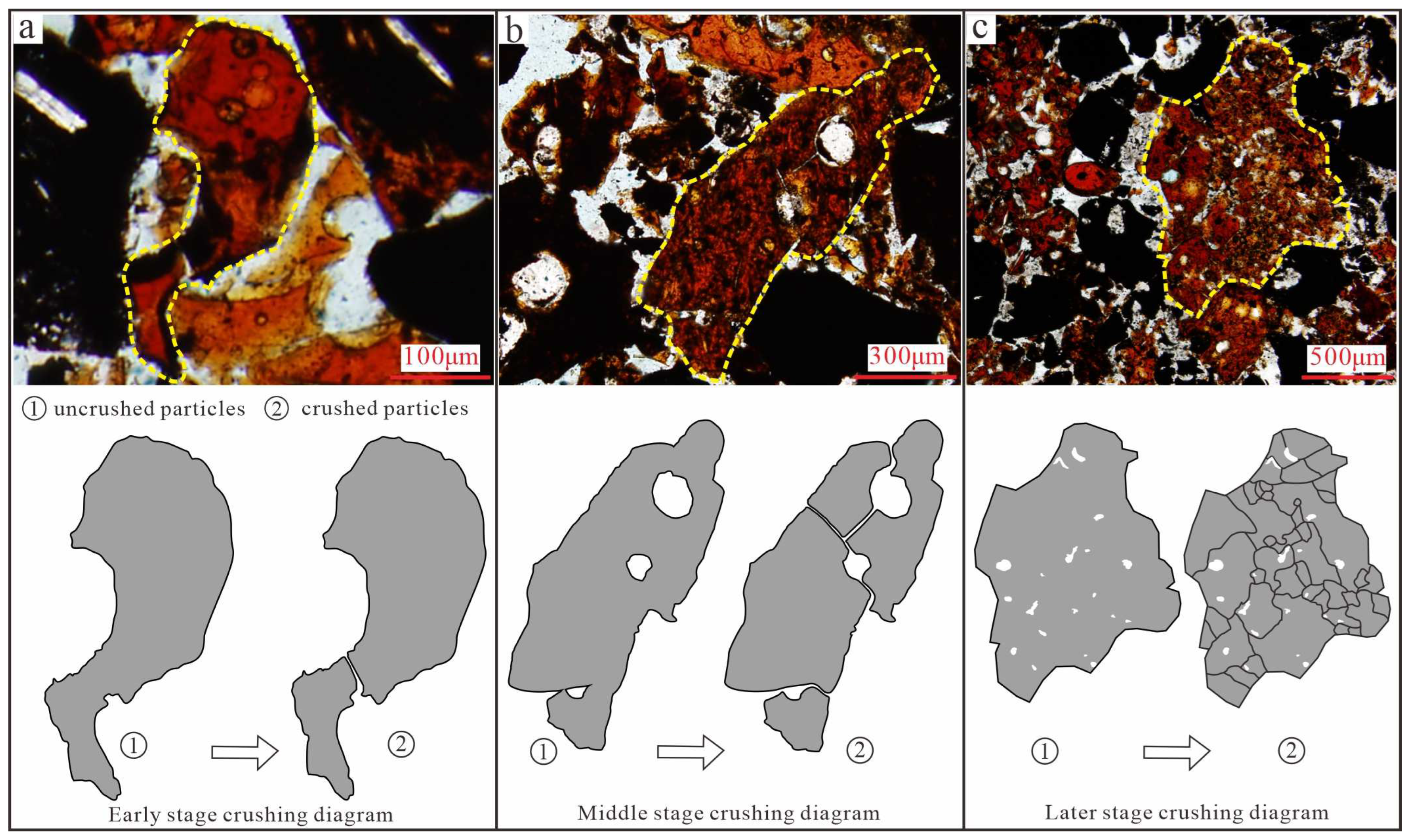

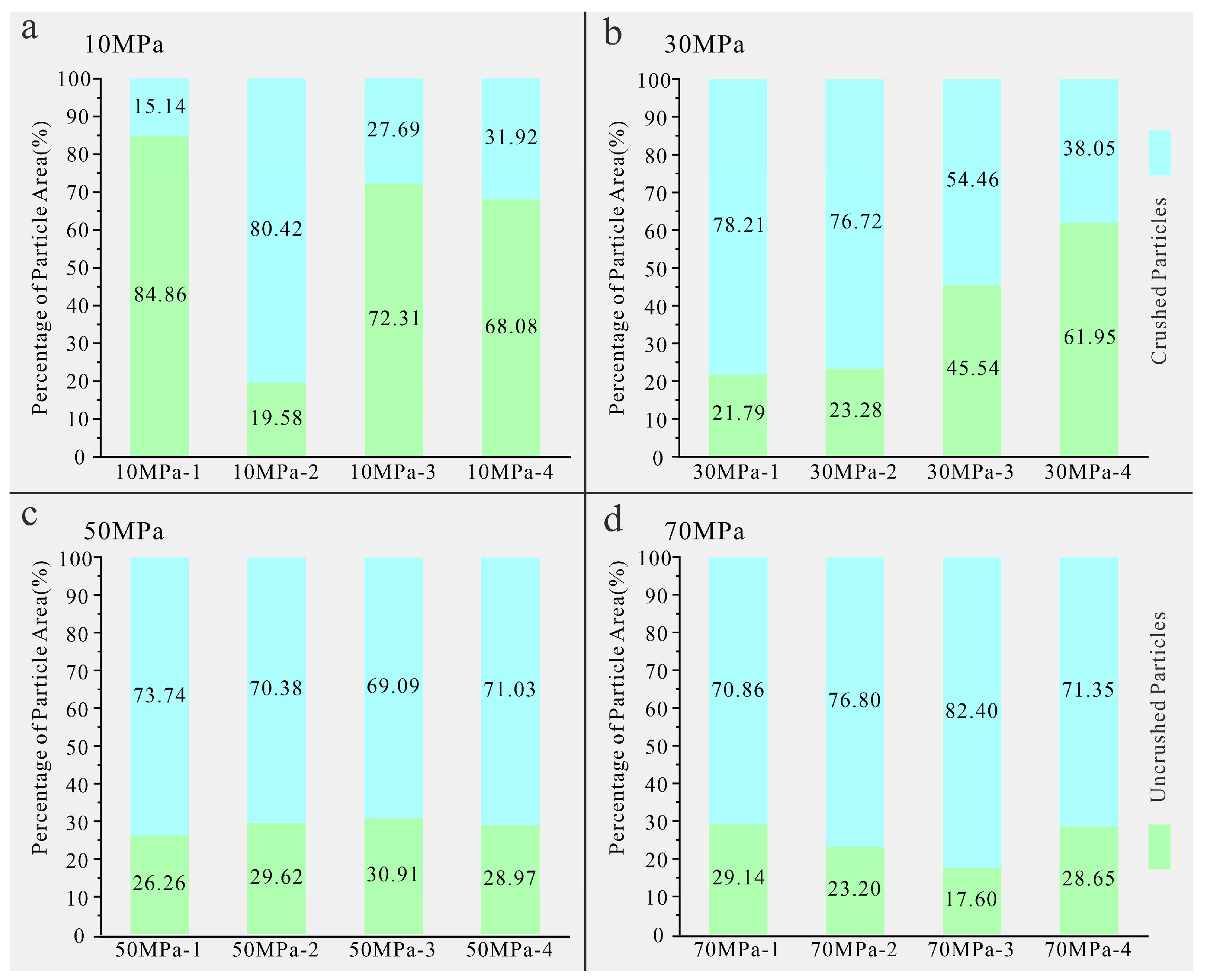

4.2. Characteristics of Particle Crushing

4.3. Localized Compaction Deformation

5. Discussion

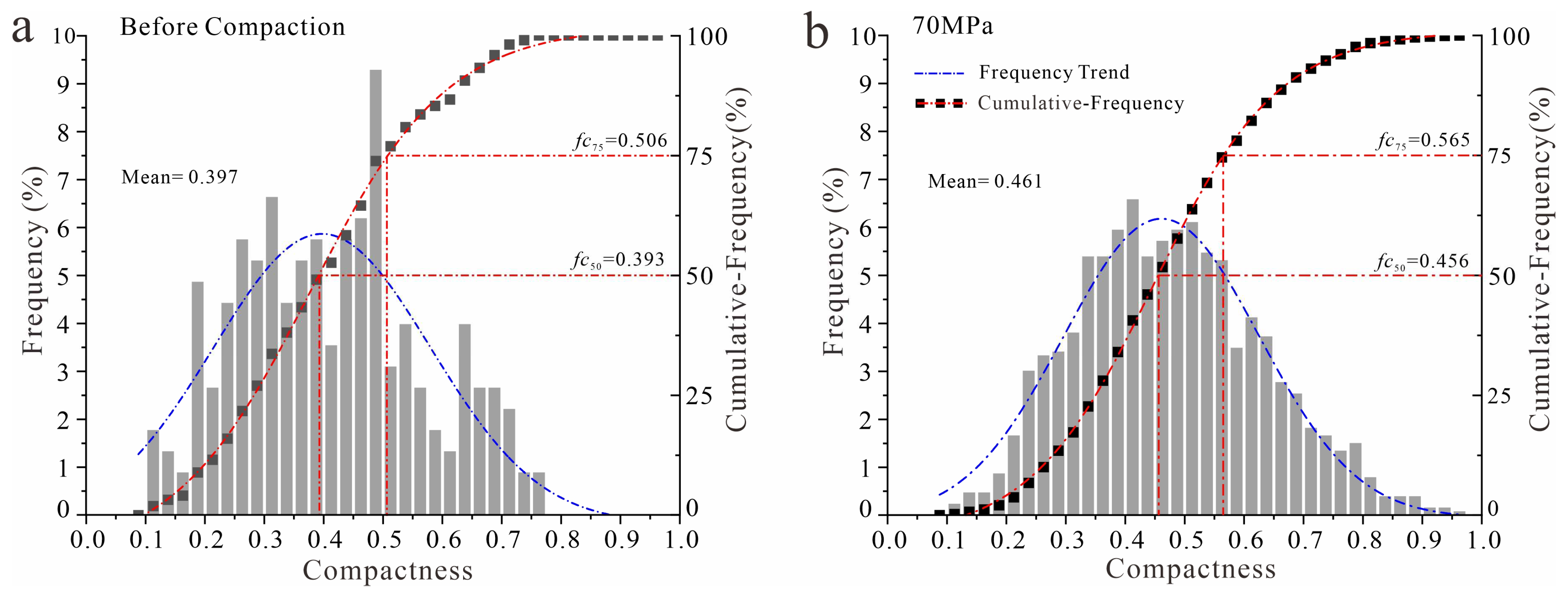

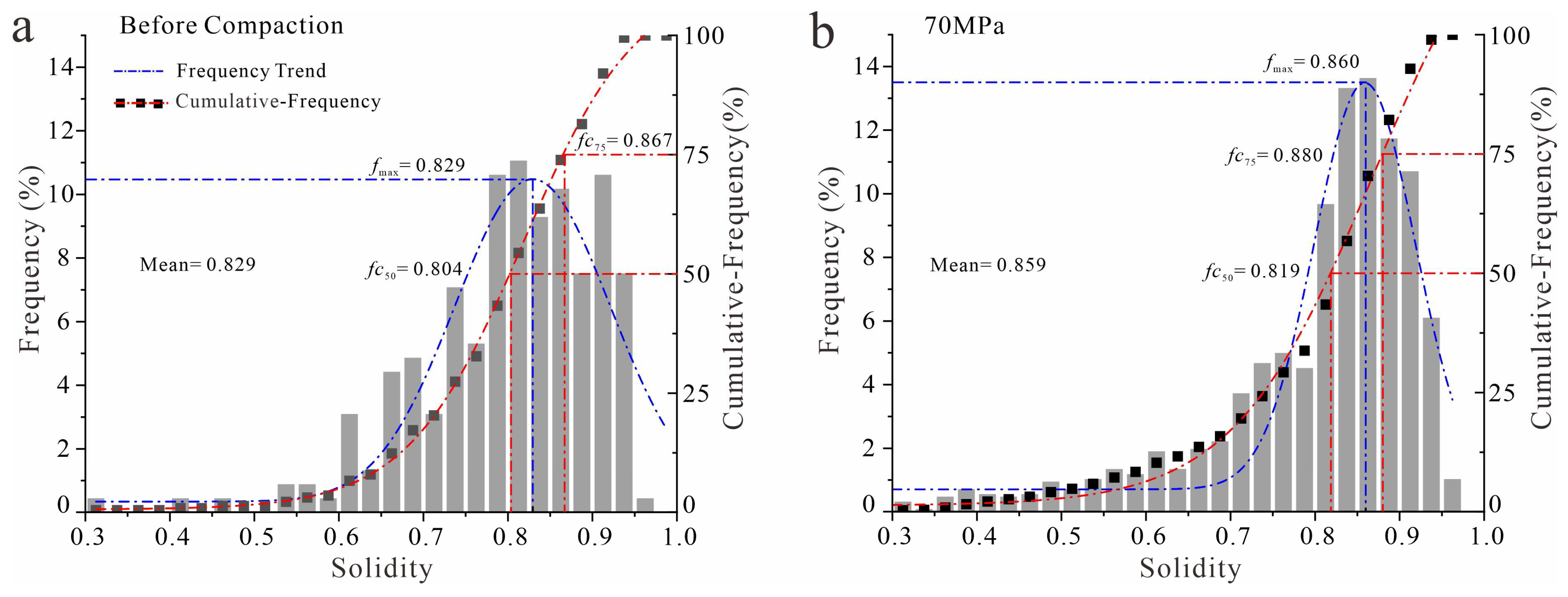

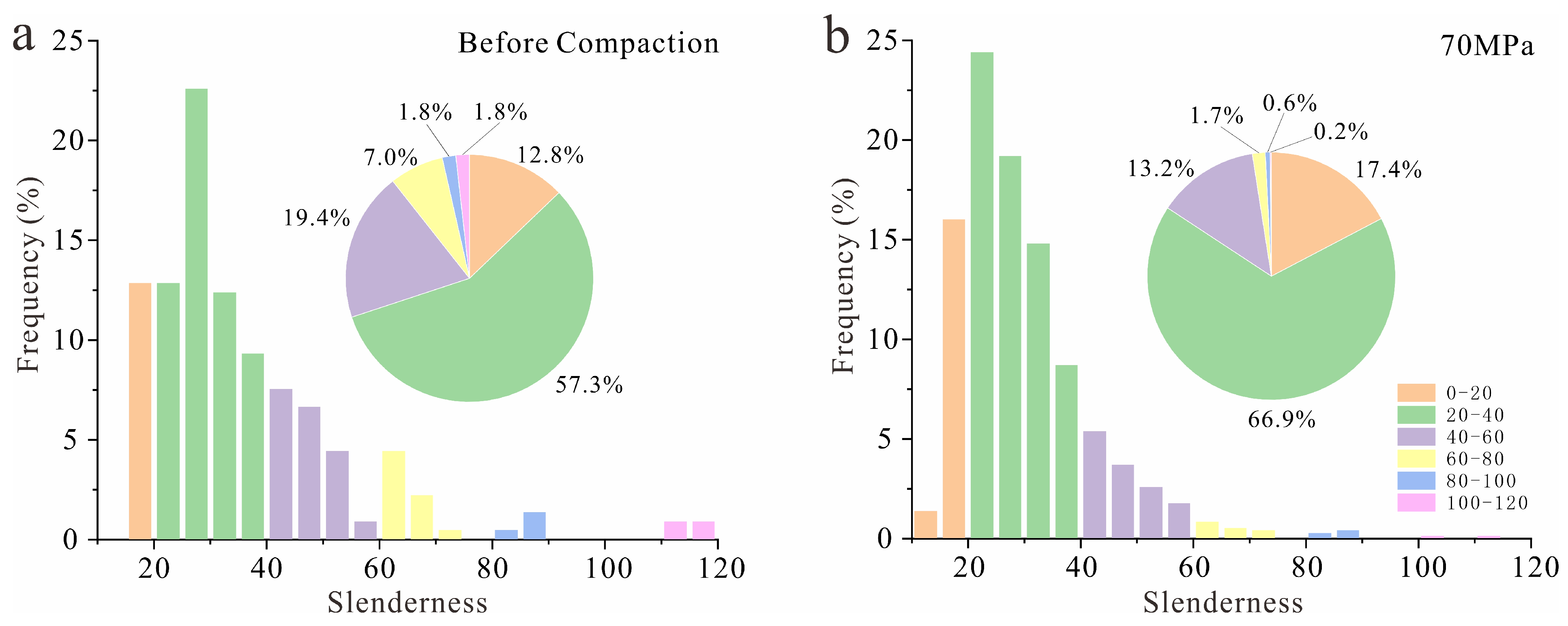

5.1. Relationships between Compactness, Solidity, and Slenderness and Particle Crushing

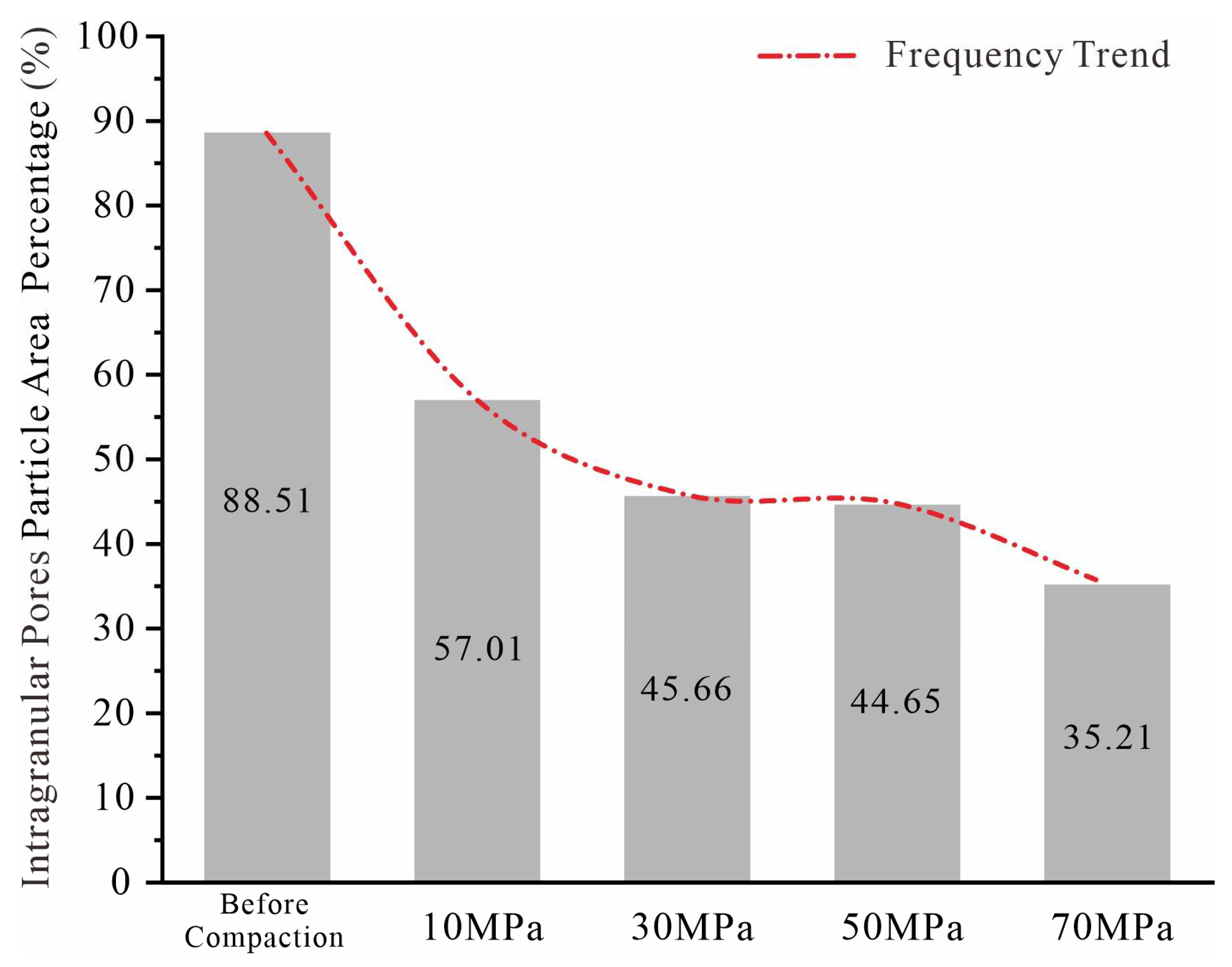

5.2. Relationship between Intragranular Pores in Scoria and Particle Crushing

5.3. Relationship between Scoria Type and Particle Crushing

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sruoga, P.; Rubinstein, N.; Hinterwimmer, G. Porosity and permeability in volcanic rocks: A case study on the Serie Tobifera, South Patagonia, Argentina. J. Volcanol. Geotherm. Res. 2004, 132, 31–43. [Google Scholar] [CrossRef]

- Tang, H.F.; Kong, T.; Liu, X.; Yang, D.; Huo, H.Y.; Huang, Y.L. Characteristics and formation mechanisms of high quality reservoir of volcaniclastic sedimentary rocks of Early Cretaceous in Songliao Basin. Acta Pet. Sin. 2016, 37, 631–643. [Google Scholar]

- Tang, H.F.; Tian, Z.W.; Gao, Y.F.; Dai, X.J. Review of volcanic reservoir geology in China. Earth Sci. Rev. 2022, 232, 104158. [Google Scholar] [CrossRef]

- Wen, L.; Li, Y.; Yi, H.Y.; Liu, X.; Zhang, B.J.; Qiu, Y.G.; Zhou, G.; Zhang, X.H. Lithofacies and reservoir characteristics of Permian volcanic rocks in the Sichuan Basin. Nat. Gas Ind. 2019, 39, 17–27. [Google Scholar] [CrossRef]

- Yuan, X.G.; Li, W.F.; Dong, H.; Wang, T.; Zhang, B.L.; Li, S. Characteristics and controlling factors of Permian volcanic reservoirs in Kebai Area. Fault-Block Oil Gas Field 2015, 22, 445–449. [Google Scholar]

- Wang, P.J.; Chen, S.M. Cretaceous volcanic reservoirs and their exploration in the Songliao Basin, northeast China. AAPG Bull. 2015, 99, 499–523. [Google Scholar] [CrossRef]

- Ji, Y.L. Geology of Oil and Gas Reservoirs, 2nd ed.; China University of Petroleum Press: Qingdao, China, 2015. [Google Scholar]

- Mohamed, A.K.; Ibrahim, M.H.; Alaa, M.S. Petrography, diagenesis and reservoir characteristics of the Pre-Cenomanian sandstone, Sheikh Attia area, East Central Sinai, Egypt. J. Afr. Earth Sci. 2014, 96, 122–138. [Google Scholar]

- Fisher, Q.J.; Casey, M.; Clennell, M.B.; Knipe, R.J. Mechanical compaction of deeply buried sandstones of the North Sea. Mar. Pet. Geol. 1999, 16, 605–618. [Google Scholar] [CrossRef]

- Marcussen, O.; Thyberg, B.I.; Peltonen, C.; Jahren, J.; Bjrlykke, K.; Faleide, J.I. Physical properties of Cenozoic mudstones from the northern North Sea: Impact of clay mineralogy on compaction trends. AAPG Bull. 2009, 93, 127–150. [Google Scholar] [CrossRef]

- Peltonen, C.; Marcussen, Ø.; Bjørlykke, K.; Jahren, J. Mineralogical control on mudstone compaction: A study of Late Cretaceous to Early Tertiary mudstones of the Vring and Mre basins, Norwegian Sea. Pet. Geosci. 2008, 14, 127–138. [Google Scholar] [CrossRef]

- Chester, J.S.; Lenz, S.C.; Chester, F.M.; Lang, R.A. Mechanisms of compaction of quartz sand at diagenetic conditions. Earth Planet. Sci. Lett. 2004, 220, 435–451. [Google Scholar] [CrossRef]

- Chuhan, F.A.; Kjeldstad, A.; Bjørlykke, K.; Høeg, K. Experimental compression of loose sands: Relevance to porosity reduction during burial in sedimentary basins. Can. Geotech. J. 2003, 45, 995–1011. [Google Scholar] [CrossRef]

- Fawad, M.; Mondol, N.H.; Jahren, J.; Bjorlykke, K. Mechanical compaction and ultrasonic velocity of sands with different texture and mineralogical composition. Geophys. Prospect. 2011, 59, 697–720. [Google Scholar] [CrossRef]

- Hou, G.F.; Ji, Y.L.; Wu, H.; Li, L.L.; Wang, Y.S.; Wang, W. Quantitative characterization of factors influencing the physical properties of clastic reservoirs by physical simulation. Geol. Sci. Technol. Inf. 2017, 36, 153–159. [Google Scholar]

- Lander, R.H.; Walderhaug, O. Predicting porosity through simulating sandstone compaction and quartz cementation. AAPG Bull. 1999, 83, 433–449. [Google Scholar]

- Zhuo, X.Z.; Zhang, L.Y.; Chen, X.S.; Zhang, J.J.; Yang, J.L.; Li, Y.C. Influence of the Argillaceous Matrix on Pore Evolution Model of the Deep Reservoir in Well Kun-2, Qaidam Basin. Geol. Rev. 2015, 61, 1447–1457. [Google Scholar]

- Liu, G.Y.; Jin, Z.J.; Zhang, L.P. Experimental study on the simulation of compaction of clastic rock formation. Acta Sedimentol. Sin. 2006, 24, 407–413. [Google Scholar]

- Liu, G.Y.; Liu, Y.; Zhang, L.P. Effect of compaction on the physical properties of sandstone reservoirs. J. Xi’an Shiyou Univ. Nat. Sci. Ed. 2006, 21, 24–28+41+112. [Google Scholar]

- Cao, Y.C.; Xi, K.L.; Wang, J.; Yuan, G.H.; Yang, T. Preliminary Discussion of Simulation Experiments on the Mechanical Compaction and Physical Property Evolution of Sandstones. Geoscience 2011, 25, 1152–1158. [Google Scholar]

- Couvreur, J.F.; Vervoort, A.; King, M.S.; Lousberg, E.; Thimus, J.F. Successive cracking steps of a limestone highlighted by ultrasonic wave propagation. Geophys. Prospect. 2001, 49, 71–78. [Google Scholar] [CrossRef]

- Vajdova, V.; Baud, P.; Wong, T.F. Compaction, dilatancy, and failure in porous carbonate rocks. J. Geophys. Res. Solid Earth 2004, 109, 1–16. [Google Scholar] [CrossRef]

- Croizé, D.; Bjorlykke, K.; Jahren, J.; Renard, F. Experimental mechanical and chemical compaction of carbonate sand. J. Geophys. Res. Solid Earth 2010, 115, B11204. [Google Scholar] [CrossRef]

- Croizé, D.; Ehrenberg, S.N.; BjøRlykke, K.; Renard, F.O.; Jahren, J. Petrophysical properties of bioclastic platform carbonates: Implications for porosity controls during burial. Mar. Pet. Geol. 2010, 27, 1765–1774. [Google Scholar] [CrossRef]

- Croizé, D.; Renard, F.; Gratier, J.P. Compaction and Porosity Reduction in Carbonates: A Review of Observations, Theory, and Experiments. Adv. Geophys. 2013, 54, 181–238. [Google Scholar]

- Mondol, N.H.; BjøRlykke, K.; Jahren, J.; HøEg, K. Experimental mechanical compaction of clay mineral aggregates—Changes in physical properties of mudstones during burial. Mar. Pet. Geol. 2007, 24, 289–311. [Google Scholar] [CrossRef]

- Zanella, A.; Cobbold, P.R.; Le Carlier de Veslud, C. Physical modelling of chemical compaction, overpressure development, hydraulic fracturing and thrust detachments in organic-rich source rock. Mar. Pet. Geol. 2014, 55, 262–274. [Google Scholar] [CrossRef]

- Liu, P.C.; Yi, J.; Shan, X.L.; Wu, C.Z.; Gao, F.H.; Guo, J.N.; Li, J.H.; Wang, W.; Ventura, G. Modelling the Post-Caldera Plumbing System of Changbaishan Volcano (China) from Integrated Geochemical, Isotopic, Geobarometry, and Geophysical Data. Lithos 2023, 454–455, 107287. [Google Scholar] [CrossRef]

- Zhang, M.L.; Guo, Z.F.; Liu, J.Q.; Liu, G.M.; Zhang, L.H.; Lei, M.; Zhao, W.B.; Ma, L.; Vincenzo, V.; Guido, V. The intraplate Changbaishan volcanic field (China/North Korea): A review on eruptive history, magma genesis, geodynamic significance, recent dynamics and potential hazards. Earth Sci. Rev. 2018, 187, 19–52. [Google Scholar] [CrossRef]

- Wei, H.Q.; Liu, G.M.; Gil, J. Review of eruptive activity at Tianchi volcano.Changbaishan, Northeast China: Implications for possible future eruptions. Bull. Volcanol. 2013, 75, 706. [Google Scholar] [CrossRef]

- Pan, B.; De Silva, S.L.; Xu, J.D.; Chen, Z.; Miggins, D.P.; Wei, H. The VEI-7 Milennium eruption, Changbaishan-Tianchi volcano, China/DPRK: New field, petrologicaland chemical constraints on stratigraphy, volcanology, and magma dynamics. J. Volcanol. Geotherm. Res. 2017, 343, 45–59. [Google Scholar] [CrossRef]

- Qian, C.; Cui, T.R.; Jiang, B.; Li, L.C.; Chen, H.J.; Qin, T.; Tang, Z.; Si, Q.L.; Lu, L. A study on the characteristics of late cenozoic volcanic terrain in Changbaishan Mountain and its geological application. Quat. Sci. 2014, 34, 312–324. [Google Scholar]

- Roduit, N. JMicroVision: Un Logiciel D’analyse D’images Pétrographiques Polyvalent. Ph.D. Thesis, University of Geneva, Geneva, Switzerland, 2007. [Google Scholar]

- Ji, Y.L.; Wu, H.; Wang, Y.S.; Zhou, Y.; Wang, W.; Hou, G.F.; Zhang, Y.L. Application of physical simulation to study the physical evolution characteristics of clastic reservoirs: An example of the Paleocene Shahejie Formation in the Shengli Oil Region. Geol. J. Chin. Univ. 2017, 23, 657–669. [Google Scholar]

- Selley, R.C. Porosity gradients in North Sea oil-bearing sandstones. J. Geol. Soc. 1978, 135, 119–132. [Google Scholar] [CrossRef]

- Fossen, H.; Schultz, R.A.; Torabi, A. Conditions and implications for compaction band formation in the Navajo Sandstone, Utah. J. Struct. Geol. 2011, 33, 1477–1490. [Google Scholar] [CrossRef]

- Haimson, B.C.; Klaetsch, A.R. Compaction bands and the formation of slot-shaped breakouts in St. Peter sandstone. Geol. Soc. Publ. 2007, 284, 89–105. [Google Scholar] [CrossRef]

- Mollema, P.N.; Antonellini, M.A. Compaction bands: A structural analog for anti-mode I cracks in aeolian sandstone. Tectonophysics 1996, 267, 209–228. [Google Scholar] [CrossRef]

- Baud, P.; Klein, E.; Wong, T.F. Compaction localization in porous sandstones: Spatial evolution of damage and acoustic emission activity. J. Struct. Geol. 2004, 26, 603–624. [Google Scholar] [CrossRef]

- Fortin, J.; Stanchits, S.; Dresen, G.; Guéguen, Y. Acoustic emission and velocities associated with the formation of compaction bands in sandstone. J. Geophys. Res. Solid Earth 2006, 111, B10203. [Google Scholar] [CrossRef]

- Holcomb, D.; Rudnicki, J.W.; Issen, K.A.; Sternlof, K. Compaction localization in the Earth and the laboratory: State of the research and research directions. Acta Geotech. 2007, 2, 1–15. [Google Scholar] [CrossRef]

- Abdallah, Y.; Sulem, J.; Bornert, M.; Ghabezloo, S.; Stefanou, I. Compaction Banding in High-Porosity Carbonate Rocks: 1. Experimental Observations; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2021. [Google Scholar]

- Adelinet, M.; Fortin, J.; Schubnel, A.; Guéguen, Y. Deformation modes in an Icelandic basalt: From brittle failure to localized deformation bands. J. Volcanol. Geotherm. Res. 2013, 255, 15–25. [Google Scholar] [CrossRef]

- Baud, P.; Schubnel, A.; Heap, M.; Rolland, A. Inelastic Compaction in High-Porosity Limestone Monitored Using Acoustic Emissions. J. Geophys. Res. Solid Earth 2017, 122, 9989–10008. [Google Scholar] [CrossRef]

- Cilona, A.; Faulkner, D.R.; Tondi, E.; Agosta, F.; Mancini, L.; Rustichelli, A.; Baud, P.; Vinciguerra, S. The effects of rock heterogeneity on compaction localization in porous carbonates. J. Struct. Geol. 2014, 67, 75–93. [Google Scholar] [CrossRef]

- Cavailhes, T.; Rotevatn, A. Deformation bands in volcaniclastic rocks—Insights from the Shihtiping tuffs, Coastal Range of Taiwan. J. Struct. Geol. 2018, 113, 155–175. [Google Scholar] [CrossRef]

- Klein, E.; Baud, P.; Reuschlé, T.; Wong, T.F. Mechanical behaviour and failure mode of bentheim sandstone under triaxial compression. Phys. Chem. Earth Part A 2001, 26, 21–25. [Google Scholar] [CrossRef]

- Heap, M.J.; Kennedy, B.M.; Pernin, N.; Jacquemard, L.; Baud, P.; Farquharson, J.I.; Scheu, B.; Lavallee, Y.; Gilg, H.A.; Letham-Brake, M.; et al. Mechanical behaviour and failure modes in the Whakaari (White Island volcano) hydrothermal system, New Zealand. J. Volcanol. Geotherm. Res. 2015, 295, 26–42. [Google Scholar] [CrossRef]

- Heap, M.J.; Baud, P.; Mcbeck, J.A.; Renard, F.; Carbillet, L.; Hall, S.A. Imaging strain localisation in porous andesite using digital volume correlation. J. Volcanol. Geotherm. Res. 2020, 404, 107038. [Google Scholar] [CrossRef]

- Cho, G.C.; Dodds, J.; Santamarina, J.C. Particle Shape Effects on Packing Density, Stiffness, and Strength: Natural and Crushed Sands. J. Geotech. Geoenviron. Eng. 2006, 132, 591–602. [Google Scholar] [CrossRef]

- Liu, Q.B.; Xiang, W.; Budhu, M.; Cui, D.S. Quantification of sandy soil particle shape and its influence on mechanical index. Rock Soil Mech. 2011, 32, 190–197. [Google Scholar]

- Wong, T.F.; Baud, P. The brittle-ductile transition in porous rock: A review. J. Struct. Geol 2012, 44, 25–53. [Google Scholar] [CrossRef]

- Xiong, L.F. Study on Deformation Damage Mechanism of Pore Rock and Its Influencing Factors. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2022. [Google Scholar]

- Hatzor, Y.H.; Zur, A.; Mimran, Y. Microstructure effects on microcracking and brittle failure of dolomites. Tectonophysics 1997, 281, 141–161. [Google Scholar] [CrossRef]

- Wu, X.Y.; Baud, P.; Wong, T.F. Micromechanics of compressive failure and spatial evolution of anisotropic damage in Darley Dale sandstone. Int. J. Rock Mech. Min. Sci. 2000, 37, 143–160. [Google Scholar] [CrossRef]

- Lindqvist, J.E.; Åkesson, U.; Malaga, K. Microstructure and functional properties of rock materials. Mater. Charact. 2007, 58, 1183–1188. [Google Scholar] [CrossRef]

- Liu, W.C.; Huang, L.F.; Liu, S.; Guo, J.Y. Study on the factors influencing the crushing characteristics of ore particles. Mod. Min. 2020, 36, 103–105. [Google Scholar]

| Parameter | Symbol | Definition | Geological Implications |

|---|---|---|---|

| Area | S | Particle area | |

| Perimeter | P | Particle perimeter | |

| Image surface porosity | φ | Proportion of pore area under the microscope | |

| Particle diameter | D | Diameter of the circle with the same area as the particle D =2√(S/π) | Particle size |

| Φ | Φ = −log2D | Particle size | |

| Compactness | - | Ratio of the area of a particle profile to the area of a circle with the same perimeter | Degree of rounding |

| Solidity | - | Ratio of the area of the particle profile to its convex area (the convex area is the area of the circumscribed convex polygon of the profile) | Degree of outline regularity |

| Slenderness | - | Slenderness =P2/S Ratio of the square of the perimeter of the particle profile to its area | Degree of outline slenderness |

| Axial Stress (MPa) | Simulation Depth (m) | Compaction Band Thickness (mm) | Compaction Rate (%) | Image Surface Porosity (%) | Effective Porosity (%) | Porosity Reduction (%) | |

|---|---|---|---|---|---|---|---|

| Before Compaction | After Compaction | ||||||

| 10 | 389 | 9.14 | 11.83 | 35.08 | 57.46 | 31.02 | 26.20 |

| 30 | 1167 | 19.26 | 15.21 | 24.64 | 55.63 | 40.13 | 15.50 |

| 50 | 1945 | - | 27.95 | 14.01 | 56.03 | 40.08 | 15.95 |

| 70 | 2724 | - | 42.75 | 11.73 | 55.95 | 37.76 | 18.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, J.; Tang, H.; Hu, J.; Yang, L.; Guo, T.; Zhang, Z. Characteristics and Controlling Factors of Particle Crushing in Volcaniclastic Sediments under Compaction: The Quaternary Pyroclastic Deposits of Hongtu Hill, Changbaishan Area, Northeastern China. Minerals 2023, 13, 1351. https://doi.org/10.3390/min13101351

Bai J, Tang H, Hu J, Yang L, Guo T, Zhang Z. Characteristics and Controlling Factors of Particle Crushing in Volcaniclastic Sediments under Compaction: The Quaternary Pyroclastic Deposits of Hongtu Hill, Changbaishan Area, Northeastern China. Minerals. 2023; 13(10):1351. https://doi.org/10.3390/min13101351

Chicago/Turabian StyleBai, Jiawei, Huafeng Tang, Jia Hu, Liying Yang, Tianchan Guo, and Zhiqiang Zhang. 2023. "Characteristics and Controlling Factors of Particle Crushing in Volcaniclastic Sediments under Compaction: The Quaternary Pyroclastic Deposits of Hongtu Hill, Changbaishan Area, Northeastern China" Minerals 13, no. 10: 1351. https://doi.org/10.3390/min13101351

APA StyleBai, J., Tang, H., Hu, J., Yang, L., Guo, T., & Zhang, Z. (2023). Characteristics and Controlling Factors of Particle Crushing in Volcaniclastic Sediments under Compaction: The Quaternary Pyroclastic Deposits of Hongtu Hill, Changbaishan Area, Northeastern China. Minerals, 13(10), 1351. https://doi.org/10.3390/min13101351