1. Introduction

Phyllite is widely distributed in southern China, covering provinces including Yunnan, Sichuan, Chongqing, Guizhou, Guangxi, Hunan, and Jiangxi. In Jiangxi, it is often found in association with red clay. Phyllite is a low-grade metamorphic rock. It consists of siltstone, mudstone, and medium-acid tuffaceous rock. It is formed through regional low-temperature dynamic metamorphism or dynamic thermal flow metamorphism. Phyllite has distinct phyllite foliation, and its peak strength and elastic modulus are significantly correlated with the bedding angle’s weathering degree [

1]. Xu et al. [

2] found that water content and a weak plane-loading angle can significantly affect the creep deformation of phyllite. Liu et al. [

3] found that moderately and slightly weathered phyllite could be used as subgrade filling, and a weathered phyllite filling with 55% rock had a wider particle distribution and experienced the least breakage, making it suitable for filling subgrade. After full weathering, the fragmentation of debris increases significantly, which will make phyllite have the following characteristics: a high liquid limit, difficult compaction, low bearing capacity of rolled subgrade, low cohesion, high dispersion, and a high no loading swelling ratio [

4,

5,

6]. Particularly, the no loading swelling ratio of phyllite soil can reach 19%–22% [

7], exceeding the no loading swelling ratio of ordinary expansive soil [

8,

9]. Therefore, filling the subgrade directly will cause large expansion deformation. Moreover, phyllite contains hydrophilic minerals, such as smillonite, chlorite, and illite [

10], which results in fully weathered phyllite that easily collapses after water immersion, and the compacted subgrade is prone to large deformation [

11]. Therefore, fully weathered phyllite is not suitable for directly filling subgrade and is typically regarded as waste and disposed of in open areas outside the construction site, when the land occupied could be used for more beneficial purposes, such as agriculture, forestry, wetlands, or natural reserves. Additionally, it may disrupt soil structure, leading to reduced soil fertility and negatively impacting plant growth and soil ecosystems, thereby endangering the ecological environment. Therefore, it needs to be improved.

To use partially or completely weathered phyllite, it is necessary to improve its properties. Studies often use the California bearing ratio (CBR), the unconfined compressive strength, the resilience modulus, and other important parameters to evaluate the performance of improved soil roads. To use weathered phyllite as subgrade filling, Garzon et al. [

12,

13] used lime and cement for improvement and concluded that the engineering property indicators of weathered phyllite could be significantly improved with lime and cement after a 7-day curing. The optimal lime content was 3%, and its CBR was 11.7–16.8 times that of the original soil. The optimal cement content was 9%, and the unconfined compressive strength of the improved soil was 2.0 times that of the original soil. Therefore, improved phyllite could be applied to fill highway subgrade. Li et al. [

14] found that the CBR of improved phyllite increases with cement content. The CBR of phyllite with 6% cement content is about twice that with 3% cement content, and when the cement content is greater than 3% it can meet the requirements of subgrade specifications. Jiang et al. [

15] found that for every 1% increase in cement content, the unconfined compressive strength of phyllite increased by at least 15%, and the modulus of resilience increased by at least 17%. When the cement content was 2%, the modulus of resilience of the subgrade was 64 MPa, which could meet the requirement of the “Class I Highway subgrade”. Mao et al. [

16] found that with an increase in cement content, the modulus of resilience of improved phyllite subgrade approximately linearly increased according to the field test. When the cement content was 3%, the modulus of resilience of the subgrade was 66 MPa, which could meet the requirement of the “Class I Highway subgrade”. In these two studies, the required modulus of resilience of the “Class I Highway subgrade” was 30 MPa. In addition, Morales et al. [

17] filled the pores of phyllite material by precipitating calcium carbonate from bacteria, thus forming a denser structure and increasing its internal friction angle by 16.5%.

In Jiangxi, China, red clay and phyllite often accompany each other and are difficult to separate, as shown in

Figure 1a. Focusing only on the single improvement of red clay or phyllite does not have much reference significance for actual engineering. Therefore, it is necessary to improve red clay and phyllite at the same time. Red clay has high water sensitivity [

18] and strongly shrinks and cracks [

19,

20] after water loss. However, it possesses intricate engineering properties, such as high cohesion and favorable compaction behavior under low moisture content conditions [

21]. Tan et al. [

22] found that the agglomeration of red clay formed a “hard shell” on the surface of particles, so it had high cohesion. Tang et al. [

23] used lime for the improvement of red clay, and the research findings indicated that the addition of lime resulted in a decrease in the liquid limit, the plasticity index, and the maximum dry density of the improved soil, while concurrently enhancing the plastic limit and the optimum moisture content. Chen et al. [

24] used lime to modify red clay, and triaxial test results showed that as the lime content increased, the strength of the modified soil increased, showing an enhancement of 282% under a confining pressure of 200 kPa. Scanning electron microscopy (SEM) observations showed that the addition of lime caused the aggregation of particles in the soil and changed the pore structure of the red clay.

The above mentioned studies focused on using amendments to improve phyllite and red clay alone; however, there are few studies on the mutual improvement of phyllite and red clay as well as the composite improvement of phyllite soil with other amendments and red clay. Previous research by this research group found that when red clay and cement are used to improve phyllite soil, red clay can rapidly increase the bearing capacity of the improved soil in a short period, while cement enhances soil strength and water stability through a hardening reaction, thereby reducing settlement. In the improvement reaction of lime and cement, both form gelling products between soil particles, thereby enhancing soil strength. Their improvement mechanisms are similar. Additionally, lime can be obtained by heating limestone to a temperature between 800 °C and 1000 °C. Compared with cement, lime is easier to obtain and cheaper. Based on this, lime is more widely used than cement in actual projects. Therefore, this study used lime to modify the mixed soil.

In summary, both phyllite and red clay have unique engineering properties. According to the “Code for Design of Railway Earth Structure” (TB 10001-2016) [

25], different types of soils should not be blended for filling, especially special soils, which may lead to the cumulative occurrence of subgrade distresses. Therefore, current research primarily focuses on individual soil improvement using stabilizers, either for red clay or phyllite soil. In order to simultaneously utilize red clay and phyllite soil to promote waste utilization, this study employs an unconventional approach. The approach of mutual improvement of red clay and phyllite soil fills the knowledge gap in which different soils cannot be mixed and filled, especially special soils like red clay and phyllite soil. Building on this approach, a method using red clay and lime to improve phyllite is proposed in this paper. It is a physical–chemical combined improvement method, which can significantly reduce the no loading swelling ratio and swelling pressure and significantly increase shear strength and the compression modulus. According to the results from the comparison of the data of the combined improvement and single improvement methods, the synergic improvement effect of red clay and lime on phyllite is analyzed as follows.

3. Analysis of the Improvement Effect

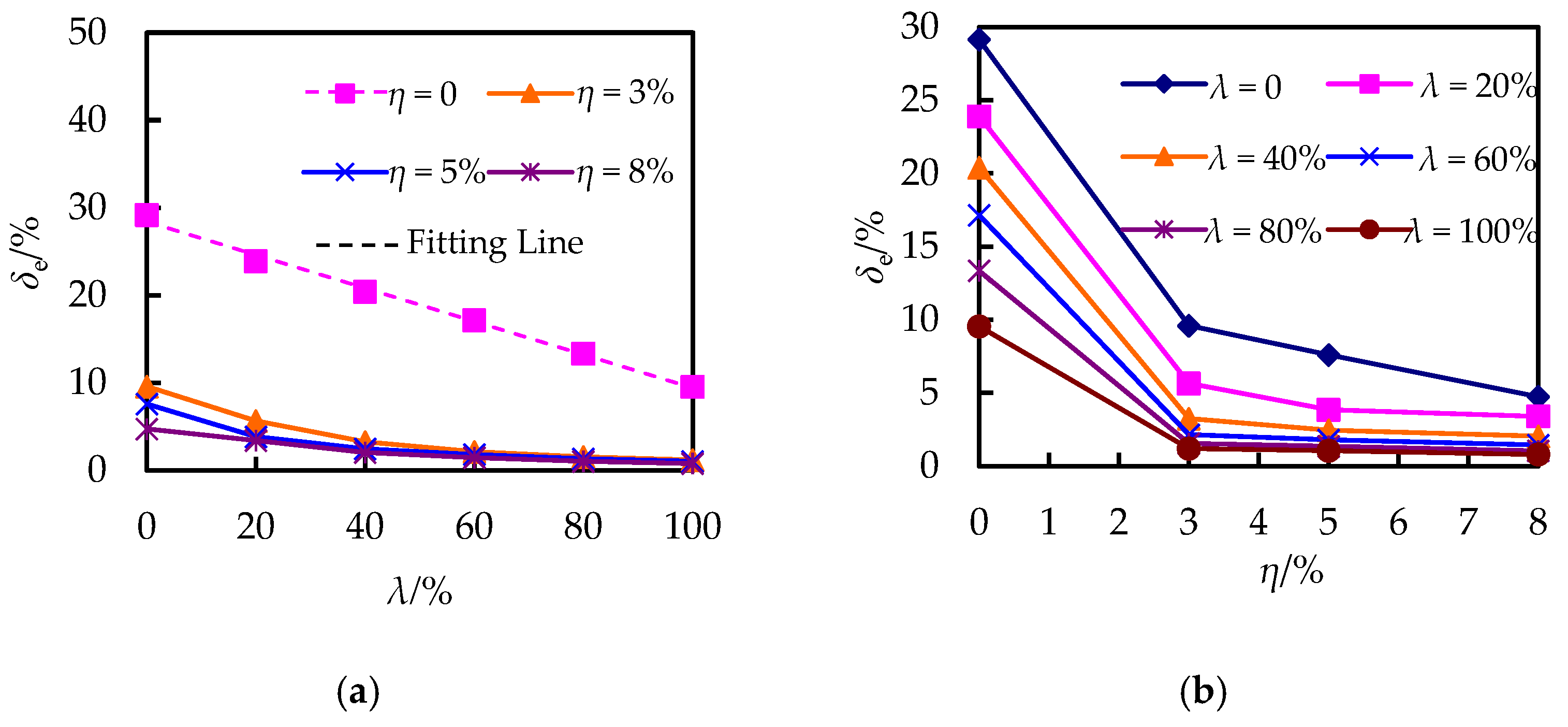

3.1. Analysis of the Improvement Effect on the No Loading Swelling Ratio

The larger the no loading swelling ratio, the larger the expansion potentiality of the soil, so the more likely it is that it will cause expansion deformation of the high-speed railway subgrade and the more unfavorable it is to the engineering project. The free swell ratio of phyllite soil is 32%, which is lower than 40%. According to the “Technical Code for Buildings in Expansive Soil Regions” (GB 50112-2013) [

28], it cannot be defined as expansive soil. Chu et al. [

8,

9] found that the no loading swelling ratio of weak and medium expansive soils lies between 14% and 18%. However, the no loading swelling ratio of phyllite soil reached 29%, which exceeded the no loading swelling ratio of weak and medium expansive soils. If it is directly used as subgrade filling, it may cause a large expansion of the subgrade, resulting in subgrade distress. Therefore, the no loading swelling ratio of phyllite soil must be reduced. The variations in the no loading swelling ratio (

δe) of the improved soil with the blending ratio of red clay and lime content are shown in

Figure 3.

In

Figure 3a, when lime content is 0, the

δe of the improved soil decreases approximately linearly with the additional ratio of red clay. The

δe and

λ are linearly correlated, as shown in Equation (3), and the correlation coefficient

R2 is 0.9950. Upon the addition of lime, a significant reduction in

δe can be observed; however, at

λ > 40%, there is no noticeable effect on the reduction in

δe.

The variation in

δe with

η is shown in

Figure 2. Taking

λ = 0 as an example, the

δe at contents of 3%, 5%, and 8% is 67%, 74%, and 84% lower than that of phyllite soil. Increasing

η from 0% to 3% has the most significant effect on the decrease in

δe, and continuously increasing

η has no significant effect on the decrease in

δe, so the economic lime content is 3%.

For the unloaded swelling test, when the λ is 60% and the η is 3%, under this combined improvement, δe is 2%, which is 93% lower than that of pure phyllite soil, and the decrement is more significant than that of a single improvement. The improvement effect is relatively minor when adding more lime or red clay. Compared to phyllite soil, δe is reduced by 94% at λ = 60% + η = 5%, 95% at λ = 80% + η = 3%, and 95% at λ = 80% + η = 5%). Compared with λ = 60% + η = 5%, the decrease is not significant. Therefore, the recommended optimal improvement scheme is λ = 40% + η = 3%.

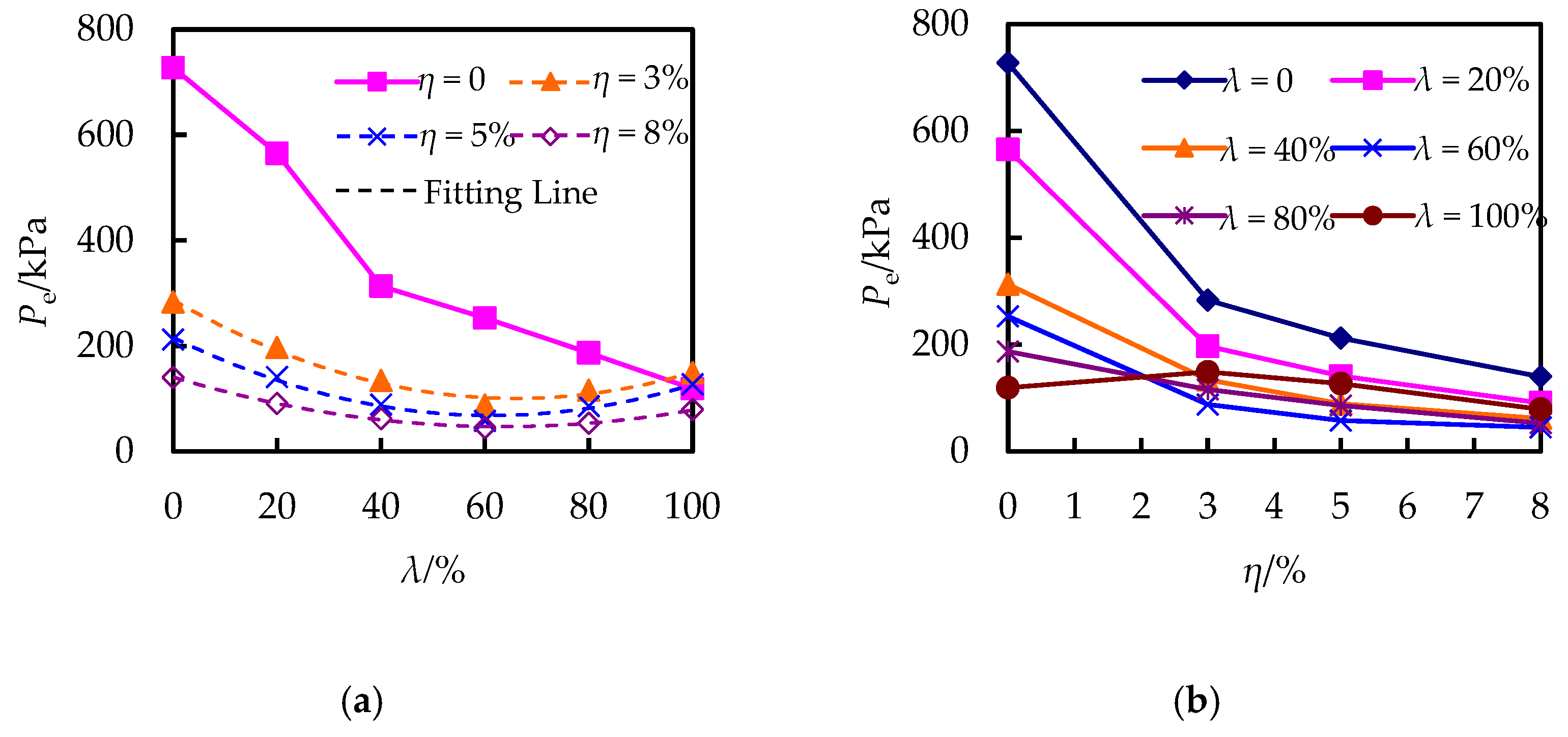

3.2. Analysis of the Improvement Effect on Swelling Pressure

With a higher swelling pressure comes a greater expansive potential. The swelling pressure of the phyllite soil reached 727 kPa, which may cause large expansion deformation of the subgrade. Therefore, an improvement must be made to reduce the swelling pressure. The improvement effect of red clay and lime on the swelling pressure (

Pe) is shown in

Figure 4.

In

Figure 4a, when the blending ratio of red clay increases, the swelling pressure decreases significantly, the rate increases first and then slows down, and there is no optimal blending ratio of red clay. With the addition of lime, the improvement effect of

λ on the swelling pressure presents a quadratic function relation. The swelling pressure reaches its minimum value when

λ = 60%. When

λ = 60% and

η = 8%, the minimum

Pe is 45 kPa. Equations (4)–(6) present the fitting curves of the swelling pressure change with the

λ when

η = 3%, 5%, and 8%, respectively, and the correlation coefficient

R2 is 0.9869, 0.9880, and 0.9981, respectively.

In

Figure 4b, increasing

η from 0% to 3% has the most significant effect on reducing the swelling pressure. Taking

λ = 0% as an example, when

η = 0, 3%, 5%, and 8%, the swelling pressure is reduced by 61%, 71%, and 81%, respectively, when compared with phyllite soil. Under different red clay blending ratios, when the lime content exceeds 3%, the change in the swelling pressure changes significantly slows down. Considering the actual conditions, it is desirable to minimize the use of modification materials as much as possible; therefore, the recommended lime content is 3%.

For the swelling pressure test, the swelling pressure is 88 kPa under a λ = 60% + η = 3% combined improvement, which is 87.9% lower than that of phyllite soil, thus significantly reducing the swelling pressure and the expansive potential of phyllite soil. The improvement effect is relatively minor when adding more lime or red clay. Compared to phyllite soil, Pe is reduced by 92% at λ = 60% + η = 5%, 84% at λ = 80% + η = 3%, and 88% at λ = 80% + η = 5%. When compared with λ = 60% + η = 5%, the decrease is not significant. Therefore, λ = 60% + η = 3% is the recommended optimal improvement scheme.

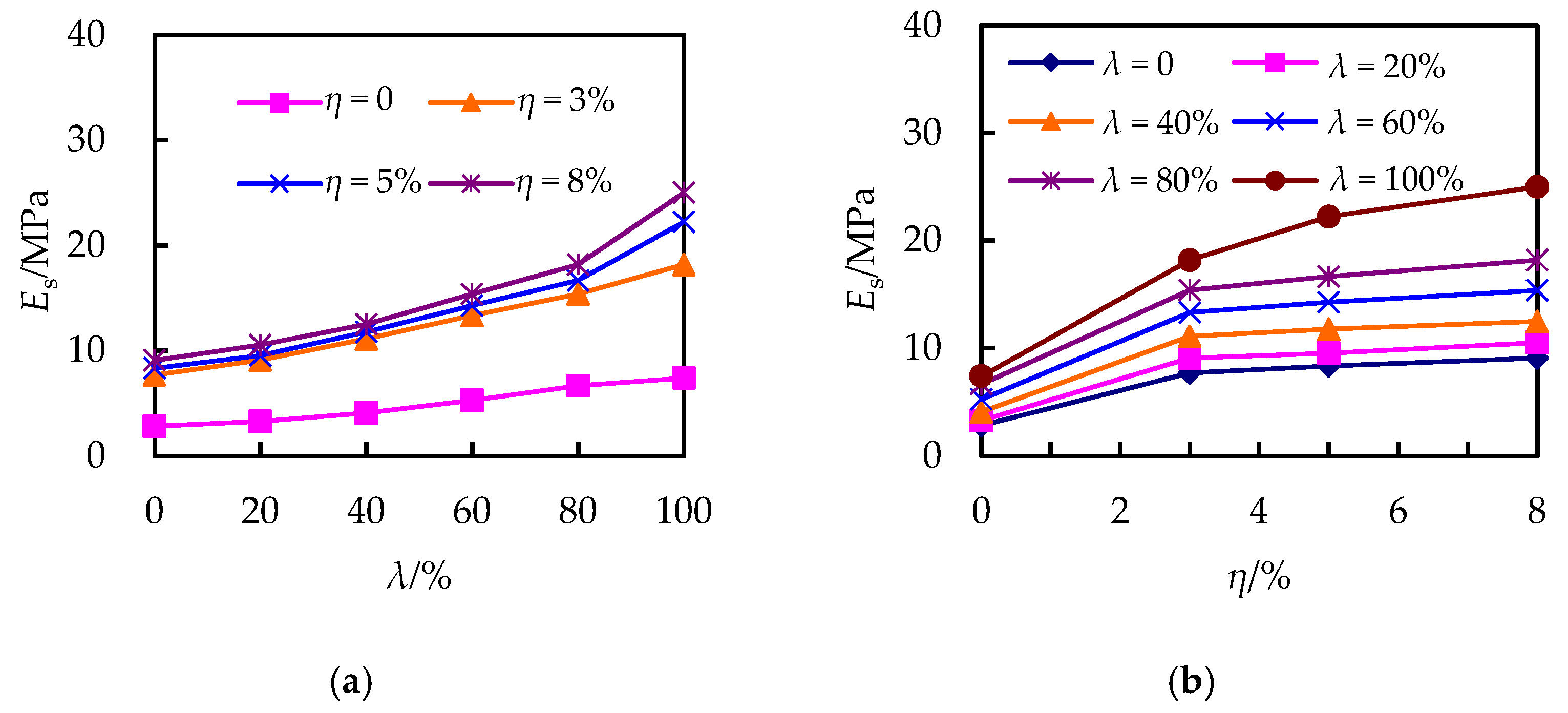

3.3. Analysis of the Improvement Effect on the Compression Modulus

The compression modulus is the ratio of stress to strain between 100 kPa and 200 kPa in the consolidation test. Es is an important index for calculating settlement, which is the key to controlling subgrade settlement. The effect of red clay and lime on the compression modulus (

Es) is shown in

Figure 5.

In

Figure 5a, the compression modulus of the improved soil increases with an increase in the blending ratio of red clay. The larger the blending ratio of red clay, the larger the increment, thus indicating that the addition of red clay can effectively improve the compression modulus. Therefore,

λ = 40% is the optimal blending ratio of red clay.

As

η increases, the

Es of the improved soil in

Figure 5b also increases. The change in

η from 0% to 3% has the most significant improvement effect, and continuously increasing the lime content has no significant effect. Taking

λ = 40% as an example, when

η is 0%, 3%, 5%, and 8%, the

Es increases by 45%, 295%, 319%, and 345%, respectively, when compared with phyllite soil. Therefore,

η > 3% is uneconomic for improving phyllite soil, and the recommended economic lime content is 3%.

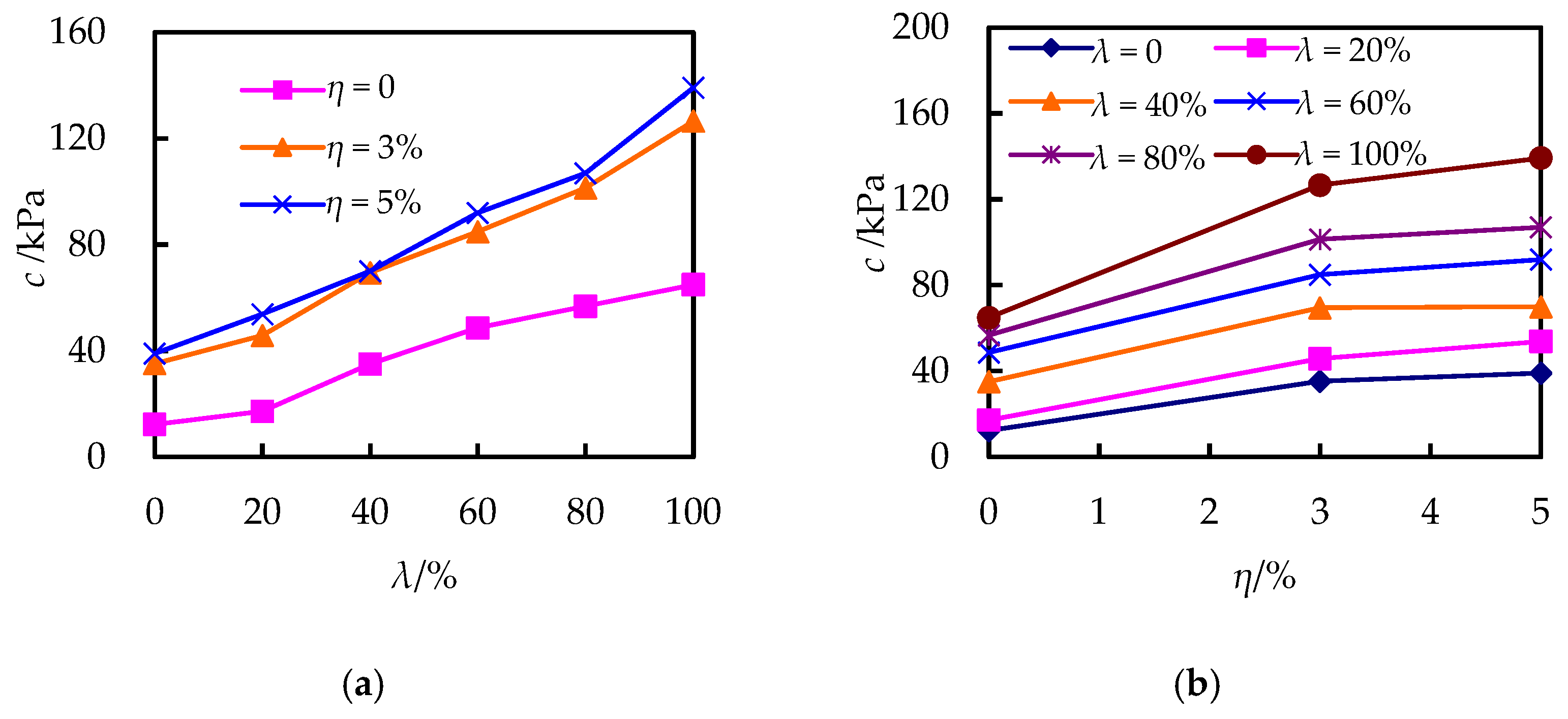

3.4. Analysis of the Improvement Effect on Strength Characteristics

The variations in cohesion (

c) and the internal friction angle (

φ) of the improved soil with the blending ratio of red clay and lime content are shown in

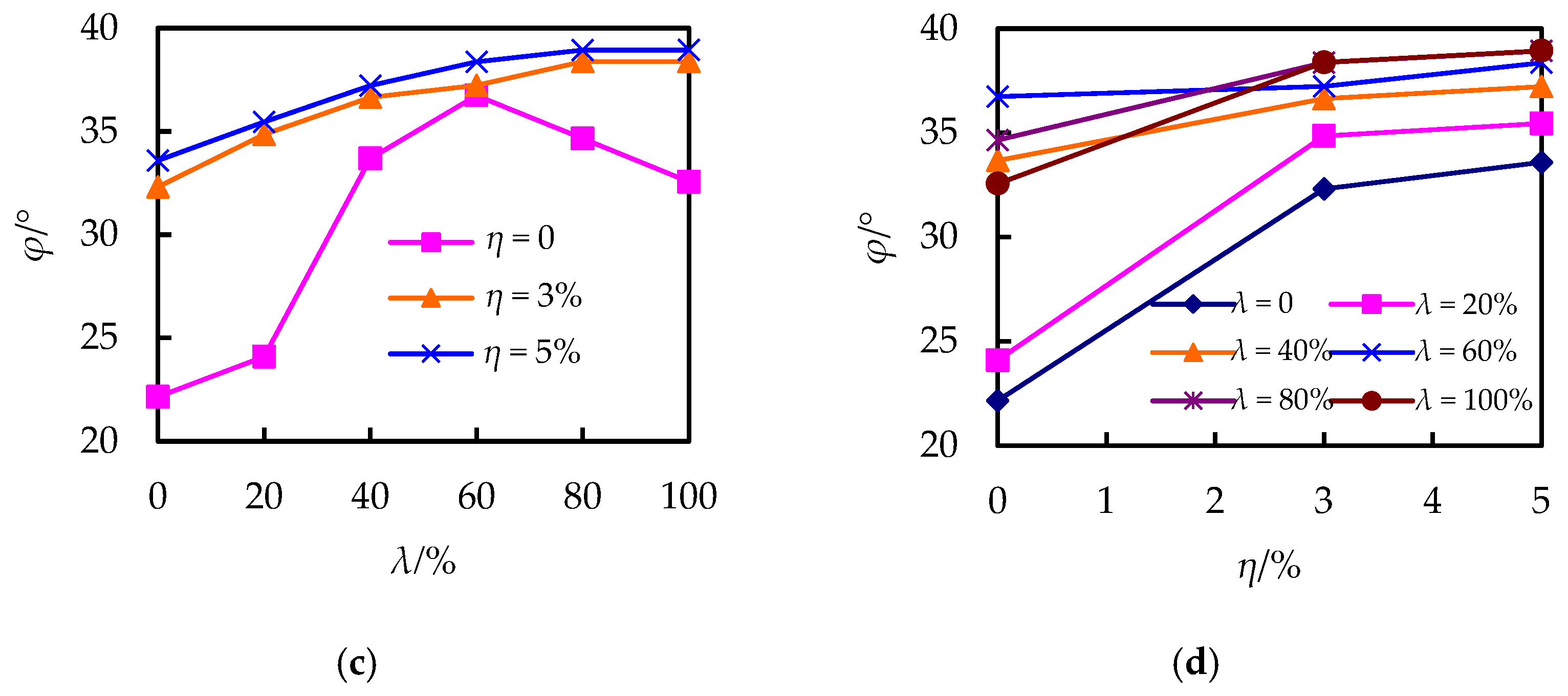

Figure 6.

According to

Figure 6a,b, the cohesion of phyllite soil is 12 kPa, and the cohesion of the improved soil increases with the increase in the blending ratio of red clay or lime content. When

η > 3%, the improvement effect of continuously increasing lime content is not significant. Therefore, the economic lime content is 3%, but there is no optimal blending ratio of red clay.

In

Figure 6c,d, when the lime content is 0%, the

φ of the improved soil first increases and then decreases with the increase in

λ, and

λ = 60% is the optimal blending ratio of red clay. After adding lime, the

φ of the improved soil increases with the increase in

λ, and the improvement effect is relatively minor when

λ is more than 60%. It can be seen from

Figure 5d that

φ increases rapidly first and then slowly with the increase in

η. Except for

λ = 60%, the increase in

η from 0% to 3% has the most significant improvement effect on

φ. Taking

λ = 0% as an example, when

η is 3% and 5%,

φ increases by 46% and 52%, respectively, when compared with phyllite soil. Therefore, the economic lime content is 3%. It is worth noting that when

λ = 60%,

φ under

η = 0% is very close to the values under

η = 3% and

η = 5%. At this point, increasing the dosage of

η has a minimal effect on the enhancement of

φ.

From the above results, it can be seen that when λ = 60% + η = 3%, the no loading swelling ratio, the swelling pressure, the compression modulus, cohesion, and the internal friction angle are 2%, 88 kPa, 13 MPa, 55 kPa, and 37°, respectively. When λ = 0% + η = 8%, the no loading swelling ratio, the swelling pressure, the compression modulus, cohesion, and the internal friction angle are 5%, 140 kPa, 9 MPa, 22 kPa, and 34°, respectively. A comparison shows that the parameters of λ = 60% + η = 3% are stronger than those of λ = 0 + η = 8%. Therefore, adding red clay can effectively reduce the amount of lime, which has a positive effect on environmental protection.

Based on the experimental analysis of the five indexes above, it is concluded that the optimal blending ratio of red clay is 60%, and the optimal lime content is 3%.

4. Evaluation of The Synergistic Effect

Through the analysis of the improvement effects of red clay and lime on phyllite soil in the previous section, it was observed that the composite improvement had superior outcomes as compared to the individual improvements. Therefore, this chapter is dedicated to further researching the synergistic improvement effects of red clay and lime for improving phyllite soil, utilizing the improvement amplitude (%) as a metric for the analysis. The improvement amplitude is calculated as shown in Equations (7)–(9).

where

n0 is the data value measured in a test of pure phyllite soil;

n1, and

n2 are the data values measured in a test of phyllite soil modified by red clay and lime alone; and

n3 are the data values measured in a test of phyllite soil synergistically improved with red clay and lime.

A represents the degree of improvement in the experimentally measured data for improving phyllite soil using only red clay. B is defined as the degree of improvement achieved when lime is used as the sole modifier. C represents the degree of improvement when red clay and lime are used in combination for soil improvement.

For all the engineering property indicators of improved soil, the larger the values of A, B, and C, the better the degree of improvement.

To illustrate the synergistic improvement of red clay and lime, according to the test data, the size relationships among

A,

B, and

C can be grouped into the following three cases:

Equation (10) indicates that the combined improvement degree is lower than two single improvement degrees, which is defined as no synergistic improvement. Equation (11) shows that the combined improvement degree is greater than two single improvement degrees but lower than the sum of two single improvement degrees, which is defined as a weak synergistic improvement. Equation (12) shows that the combined improvement degree is greater than the sum of two single improvement degrees, and the improvement effect is “1 + 1 ≥ 2”, which is defined as a strong synergistic improvement.

4.1. Evaluation of The Synergistic Effect on the Combined Improvement

Based on the results above, taking four kinds of combined improvements with red clay blending ratios of 20%, 40%, 60%, and 80% combined with an economic lime content of 3% as examples, a comparison between the single and combined improvements is analyzed to evaluate the synergistic improvement effect of red clay and lime.

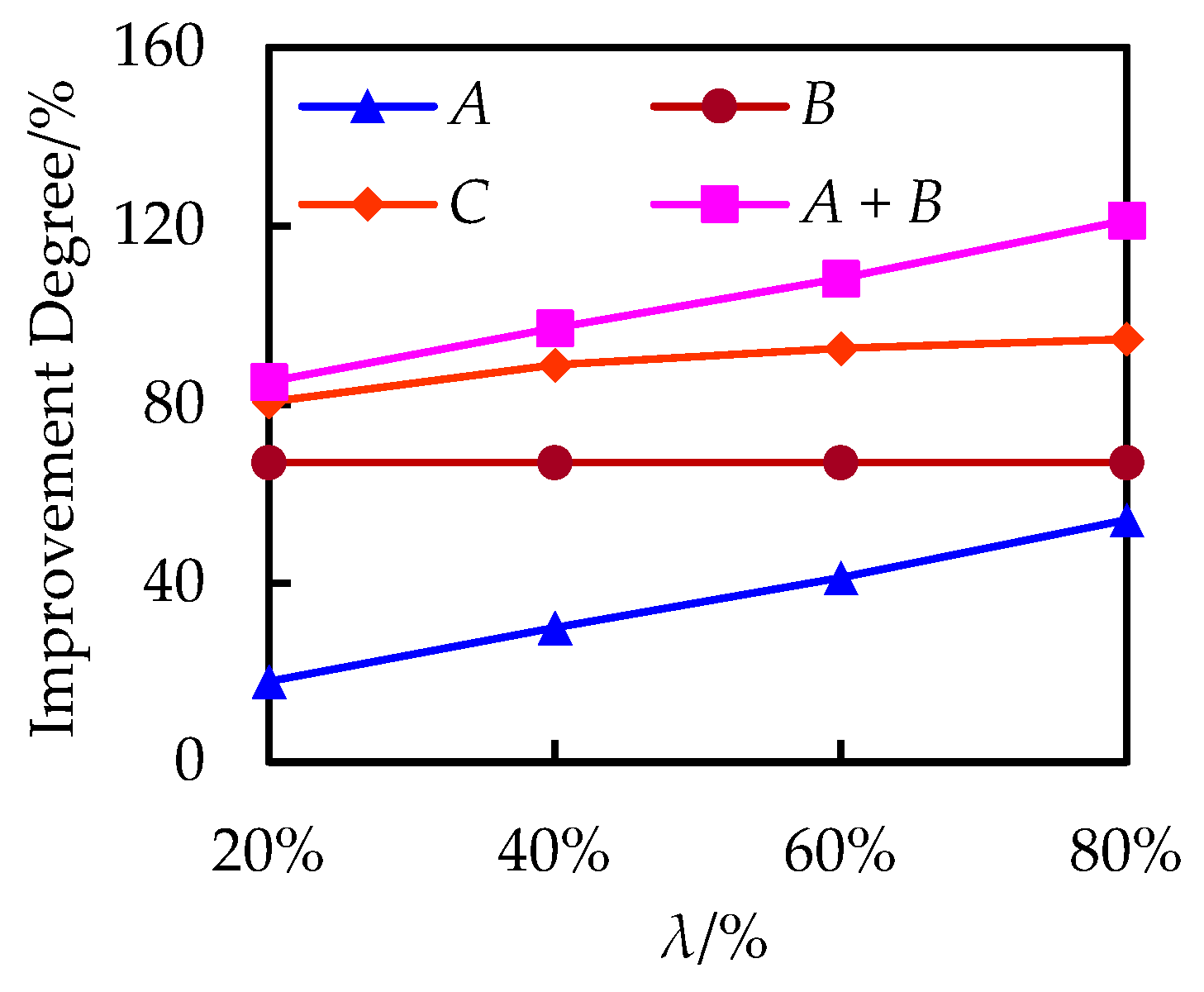

As shown in

Figure 7, in terms of the improvement effect on the no loading swelling ratio,

A +

B >

C under any condition and

C >

A or

B, which agrees with Equation (11). Therefore, there is a weak synergistic improvement effect for red clay and lime. When the red clay blending ratios are 20% and 40%,

C and

A +

B are very close, which approximates a strong synergistic effect. Then, the

C curve tends to be flat, indicating that the synergistic effect depends on the better improvement effect of lime and the linear growth improvement effect of red clay at

λ = 20% and 40%. When

λ > 40%, the improvement effect of red clay on phyllite soil reaches its maximum limit. With the increase in

λ, curve

A increases linearly, but it is still smaller than

B, and the gap is as low as 13%. Therefore, lime is significantly better than red clay for improving the no loading swelling ratio.

Figure 8 shows that

A +

B >

C, illustrating that red clay and lime have a weak synergistic improvement effect on the swelling pressure. When

λ = 20%, the improvement effect trends toward strong synchronization, and the improvement effect of red clay decreases. When

λ = 60%, the improvement effect of red clay on phyllite soil reaches its maximum limit, and the synergistic improvement effect reaches a peak. Then, the inhibiting effect is greater than the lifting effect of red clay; thus, the synergistic improvement effect is reduced, as shown in curve

C in

Figure 7. In terms of individual improvement, when

λ = 20%, the improvement effect of lime is greater than that of red clay. The improvement effect is equivalent when

λ = 40% and 60%. With the increase in

λ, the improvement effect of red clay is greater than that of lime when

λ = 80%.

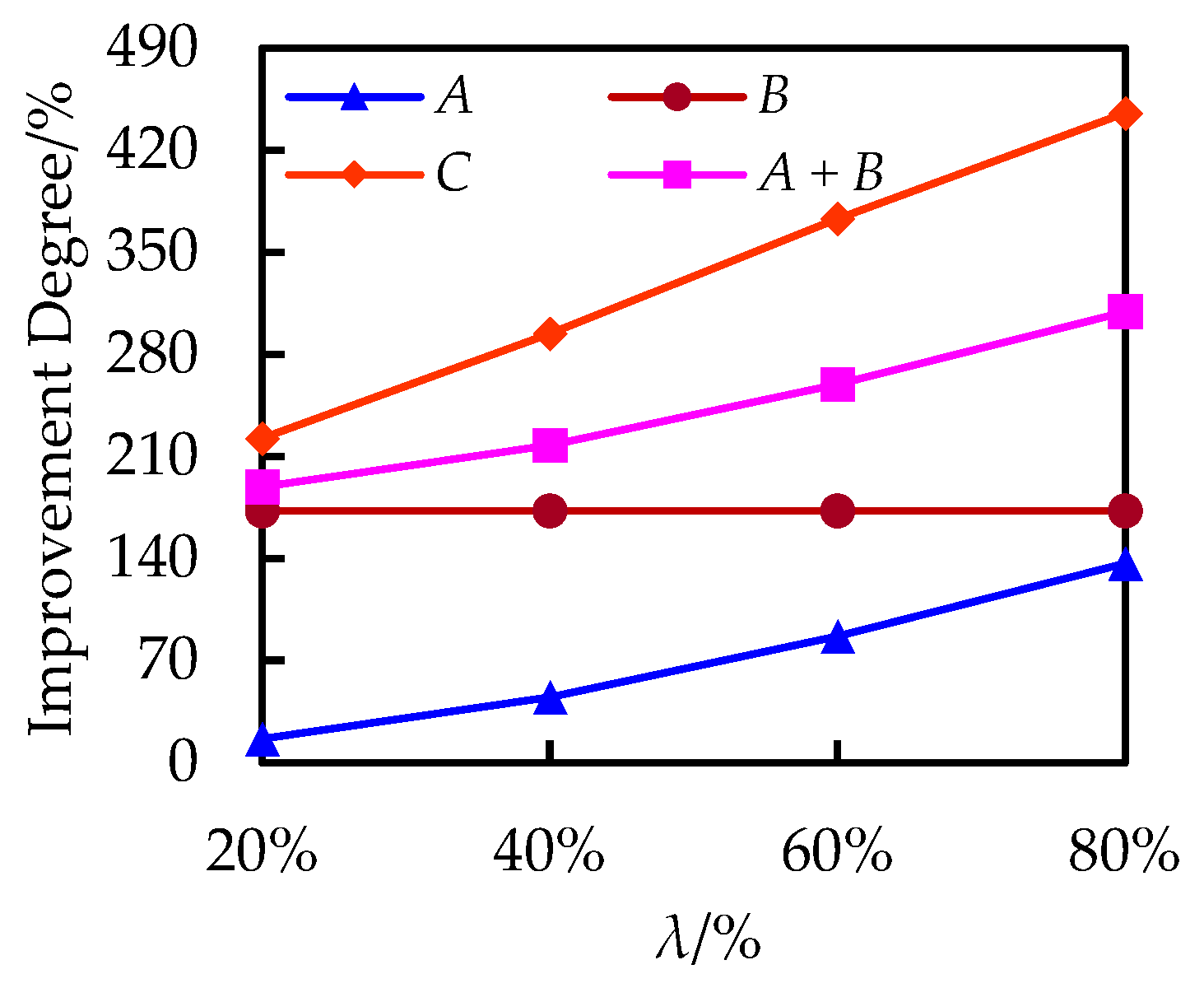

Figure 9 shows that

C ≥

A +

B, illustrating that red clay and lime have a strong synergistic improvement effect on the

Es.

C increases linearly, and its increasing ratio is significantly greater than that of

A +

B, which indicates that the reactions between red clay and lime promote each other. There is no inhibition effect, thus achieving the effect of “1 + 1 ≥ 2”. This is not only beneficial to the application of red clay in engineering but can also further reduce the post-construction settlement of subgrade relative to the individual improvement. In terms of individual improvement, the improvement effect of lime is better than that of red clay: the maximum difference is 156% when

λ = 20%, and the minimum difference is 36.18% when

λ = 80%.

Figure 10a shows that except for

λ = 60%,

C ≥

A +

B, illustrating that red clay and lime have a strong synergistic improvement effect on

c. When

λ ≤ 60%, the growth of

A +

B is faster than that of

C.

C only shows the maximum mutually reinforcing effect when

λ = 20%. With the increase in

λ, the inhibition on the improvement of red clay begins to appear. When

λ = 60%,

A +

B >

C, indicating that the synchronization becomes weak. However, when

λ = 80%, the improvement degree increases rapidly, and the improvement effect transforms into strong synchronization. The reason is that the synergistic improvement of red clay and lime is inhibited when

λ = 60%, and the improvement effect increases slowly. Continuously increasing

λ breaks the inhibitory relationship and stimulates the improvement effect. In terms of individual improvement, in addition to

λ = 20%, the improvement effect of red clay is better than that of lime.

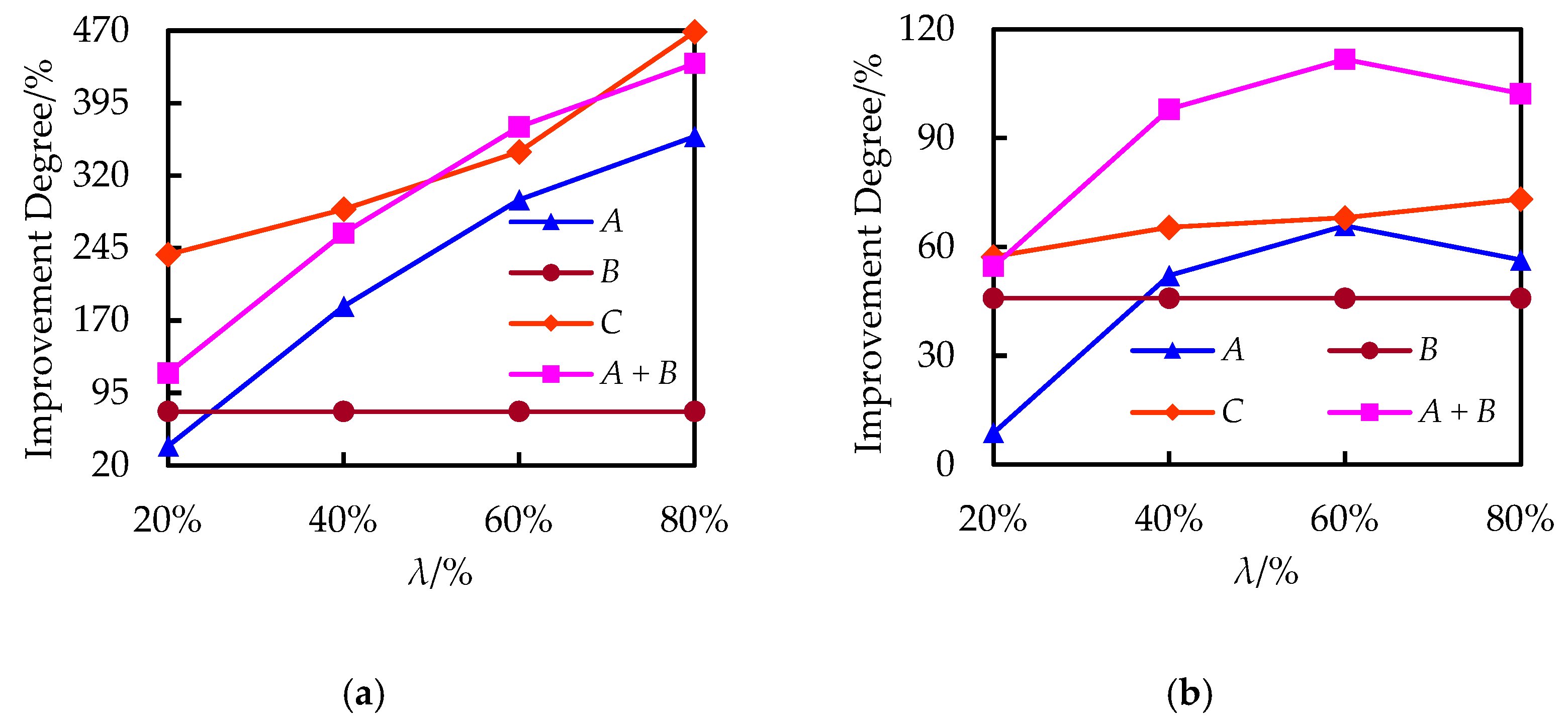

Figure 10b shows the weak synergistic improvement effect of red clay and lime on

φ. After

λ ≥ 40%,

C changes little and does not change with

A, indicating that the synergistic improvement effect has reached saturation. In other words, the promoting and inhibiting effects offset each other. In terms of individual improvement, the improvement effect of lime is better than that of red clay when

λ = 20%. When

λ = 40%, the improvement effect is the same. When

λ > 40%, the improvement effect of red clay is better than that of lime.

4.2. Discussion on the Optimal Blending Ratio for Improvement

Compared with the single improvement schemes, the combined improvement schemes have a strong synergistic effect on the improvement of the compression modulus and cohesion, achieving the effect of “1 + 1 ≥ 2”. The combined improved schemes have a weak synergistic effect on reducing the swelling pressure and the no loading swelling ratio and increasing the internal friction angle. Red clay can rapidly improve cohesion, the internal friction angle, and the compression modulus of the phyllite soil in the compacting process; hence, the instant strength of the improved phyllite soil can meet the requirements of the code after compacting [

29]. However, both red clay and phyllite exhibit a decrease in strength after being saturated with water. Therefore, red clay-improved phyllite soil cannot guarantee the long-term stability of the subgrade. After adding lime, a chemical reaction occurs to generate a hard coagulant substance, greatly improving the water stability of the improved soil. Thus, red clay can temporarily and quickly increase the strength of phyllite soil, and lime solves the problem of long-term weakening after immersion.

According to the test data and the analysis results for synergistic improvement, when lime content exceeds 3%, its effect increases little in reducing the no loading swelling ratio and the swelling pressure and in improving the compression modulus and shear strength. Therefore, the economic and optimal lime content is 3%. When red clay is used for improvement alone, the reduction in the swelling pressure of the improved soil slows down when the blending ratio of red clay is more than 40%. When the blending ratio of red clay is more than 60%, the internal friction angle decreases. Second, in comparison to the quantity of abandoned phyllite soil, red clay is less abundant in Ganjiang New District, Jiangxi Province. Therefore, in order to consume a large amount of phyllite soil, the blending ratio of red clay should be less than 60%.

When lime and red clay are used for composite improvement, the effect on the reduction in the no loading swelling ratio and the swelling pressure and on the improvement in the compression modulus and the shear strength increases slightly when the lime content exceeds 3%. Therefore, the optimal lime content is 3%. The degree of improvement of the combined swelling pressure first increases and then decreases with the increase in the red clay blending ratio. It reaches a maximum when the red clay blending ratio is 60%. When the red clay blending ratio exceeds 60%, the degrees of improvement of the no loading swelling ratio and internal friction angle are small.

To sum up, the recommended ratio of red clay to lime is 60% red clay + 3% cement.