Hyperbolic Secant Subsidence Prediction Model under Thick Loose Layer Mining Area

Abstract

:1. Introduction

2. Materials and Methods

2.1. Overview of the Study Area and Acquisition of Subsidence Data

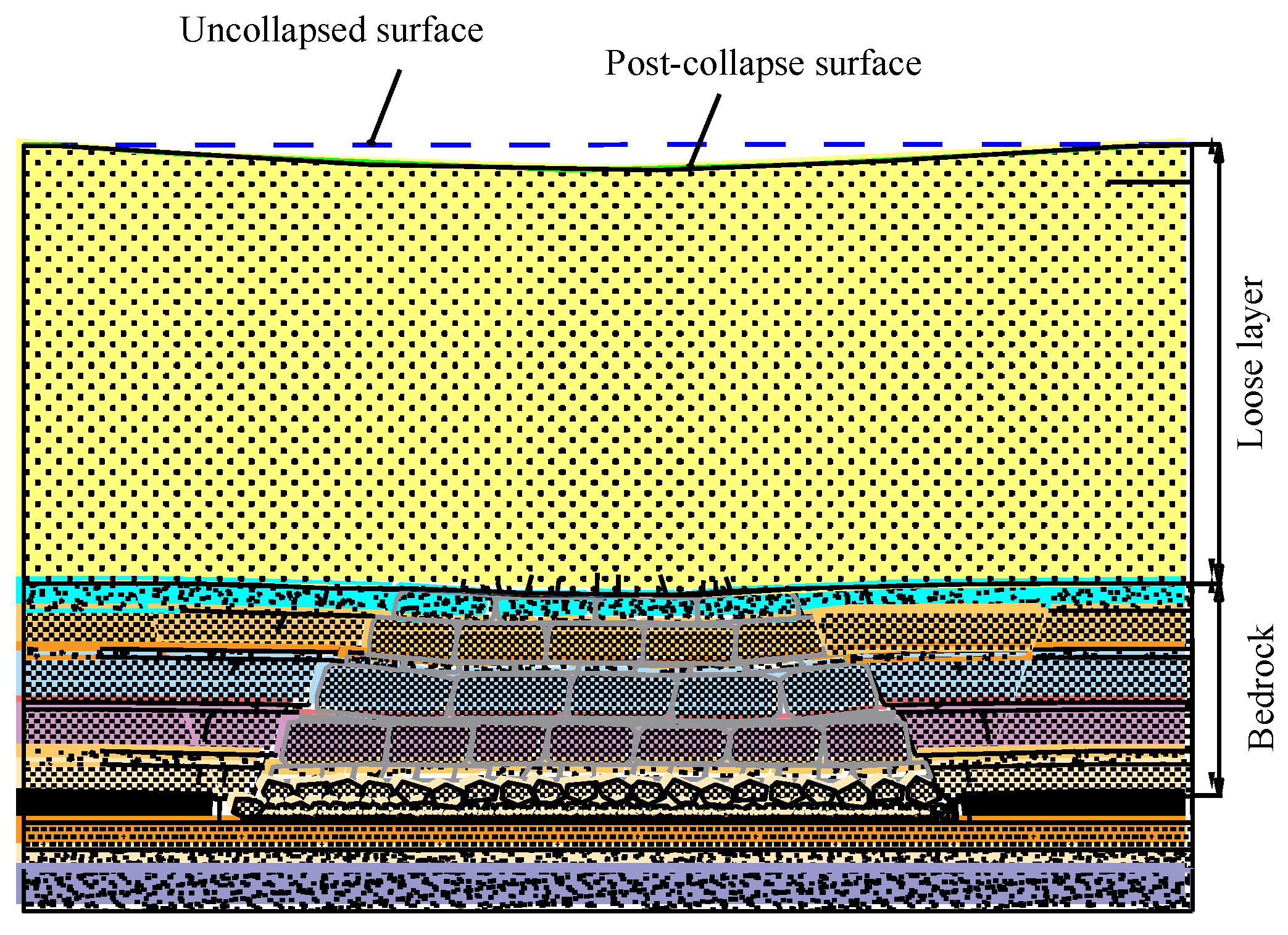

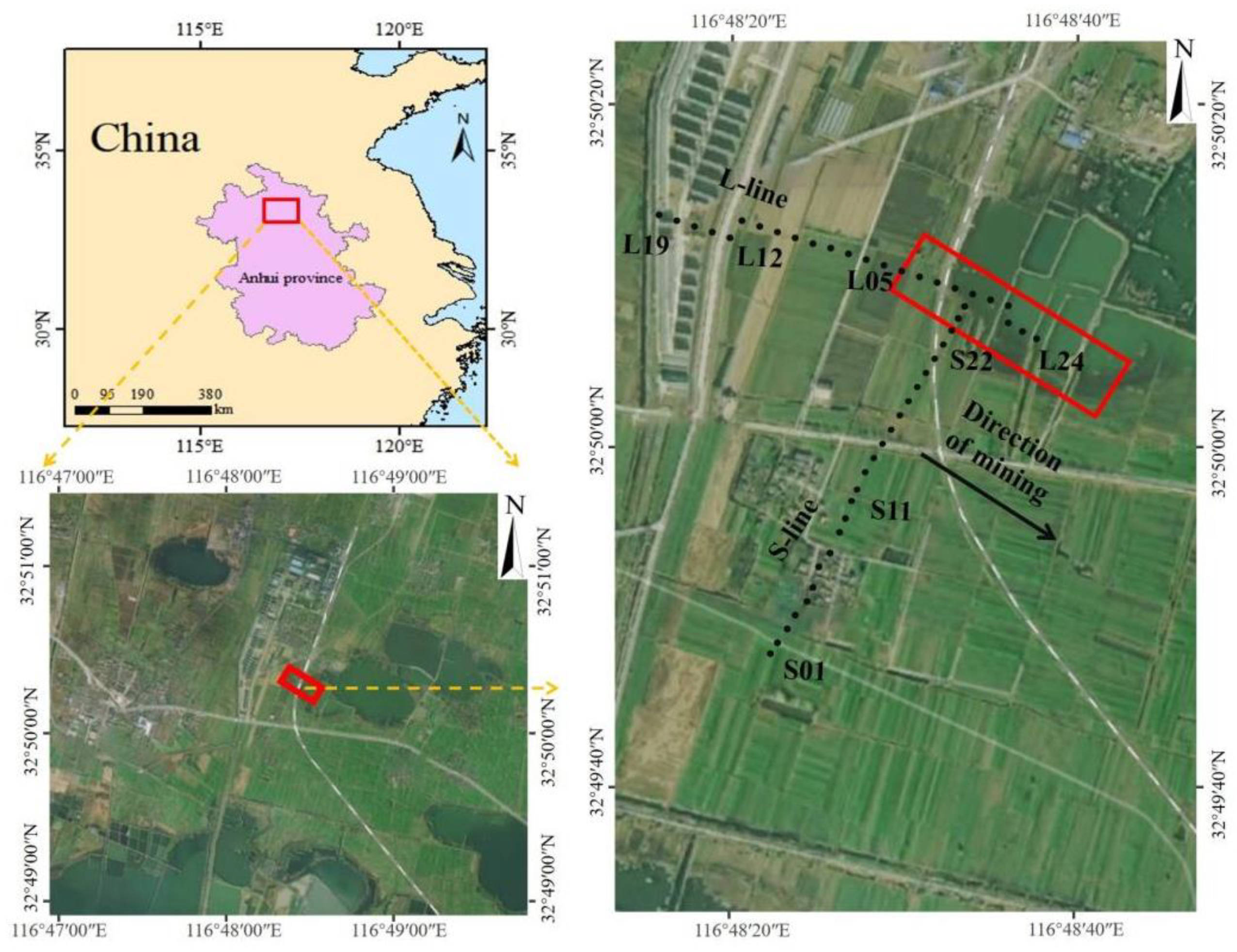

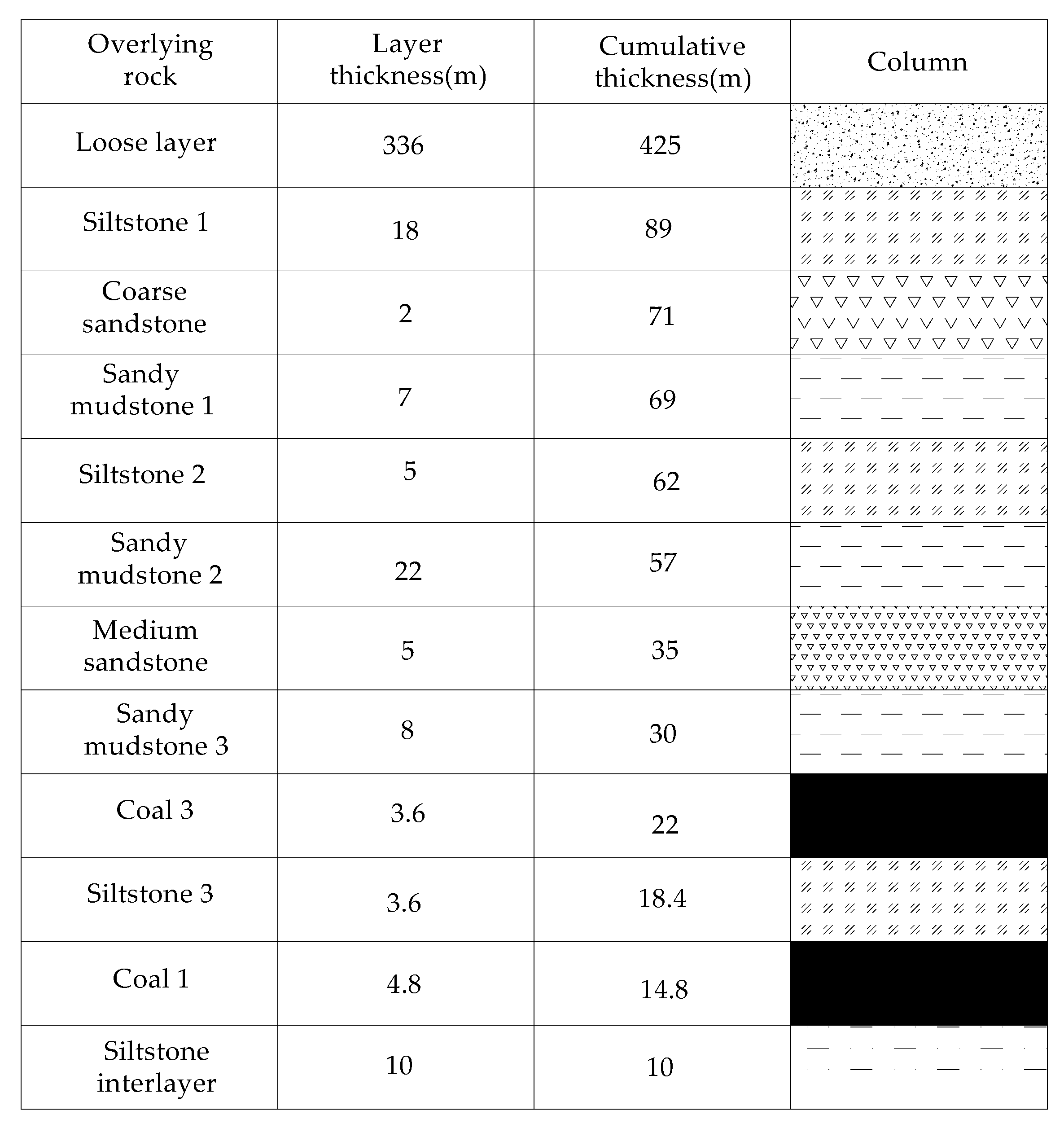

2.1.1. Overview of the Study Area

2.1.2. Acquisition of Subsidence Data

2.2. Hyperbolic Secant Subsidence Prediction Model Construction

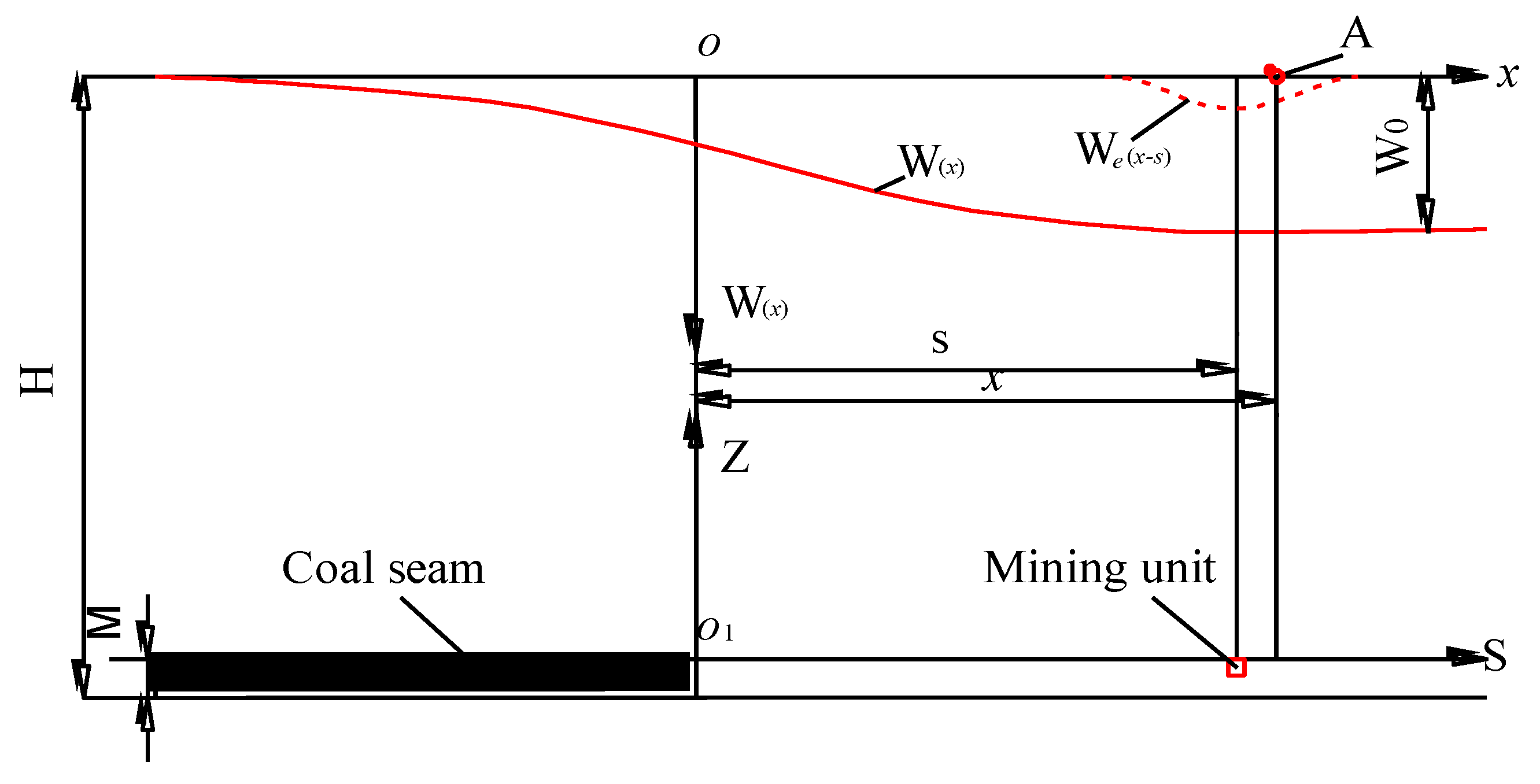

2.2.1. Surface Subsidence during Mining Unit

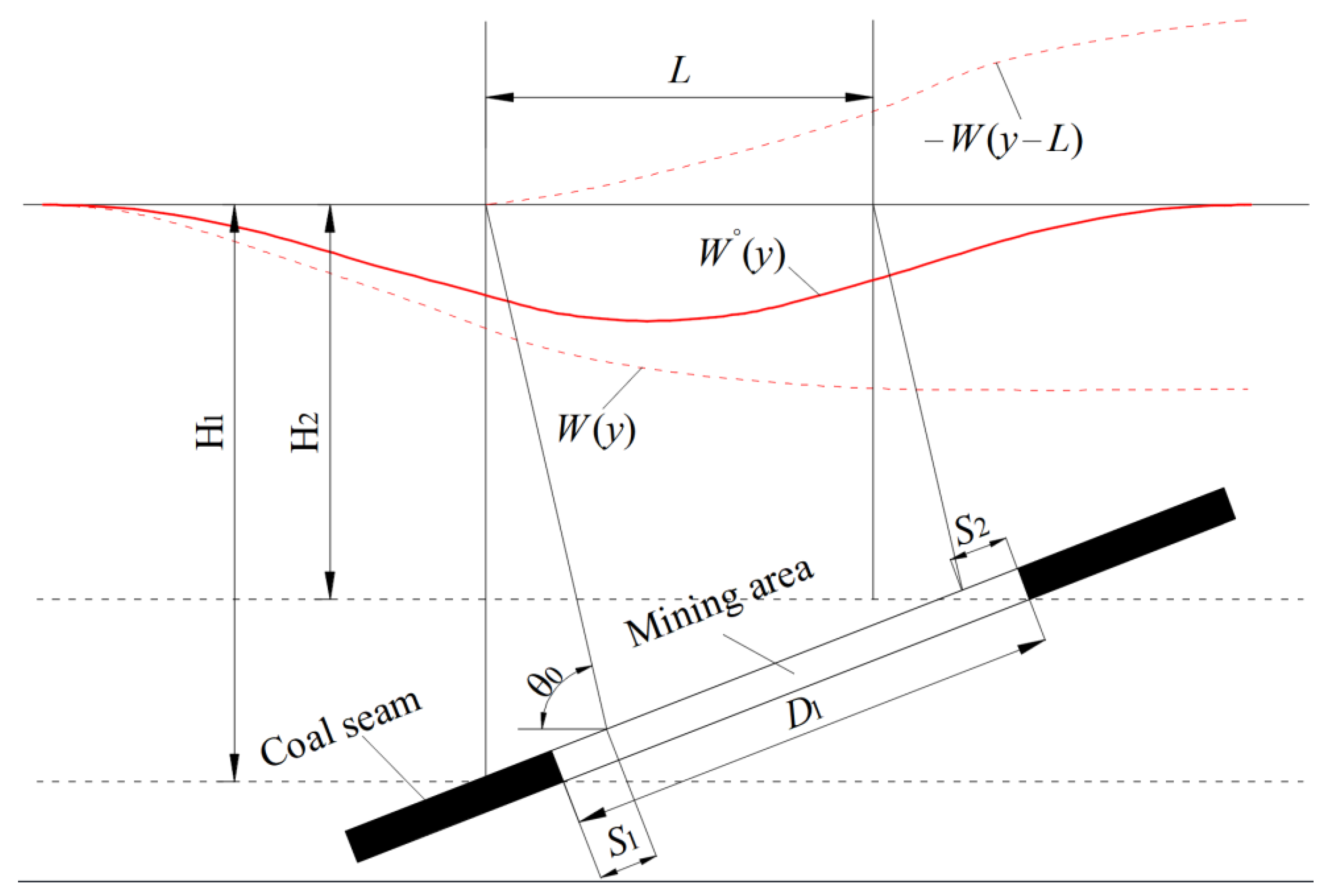

2.2.2. Surface Subsidence during Semi-Infinite Mining

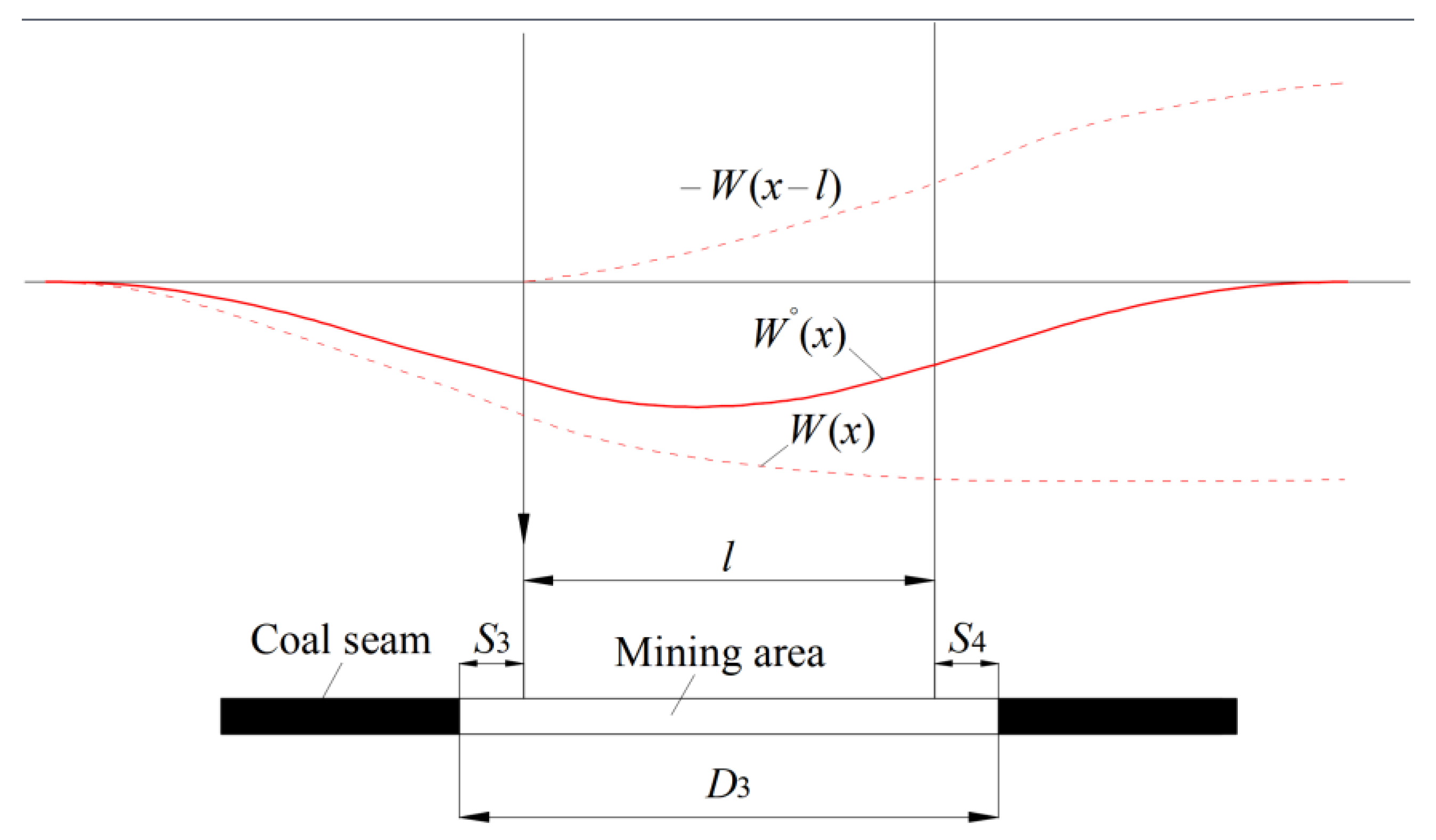

2.2.3. Surface Subsidence during Limited Mining

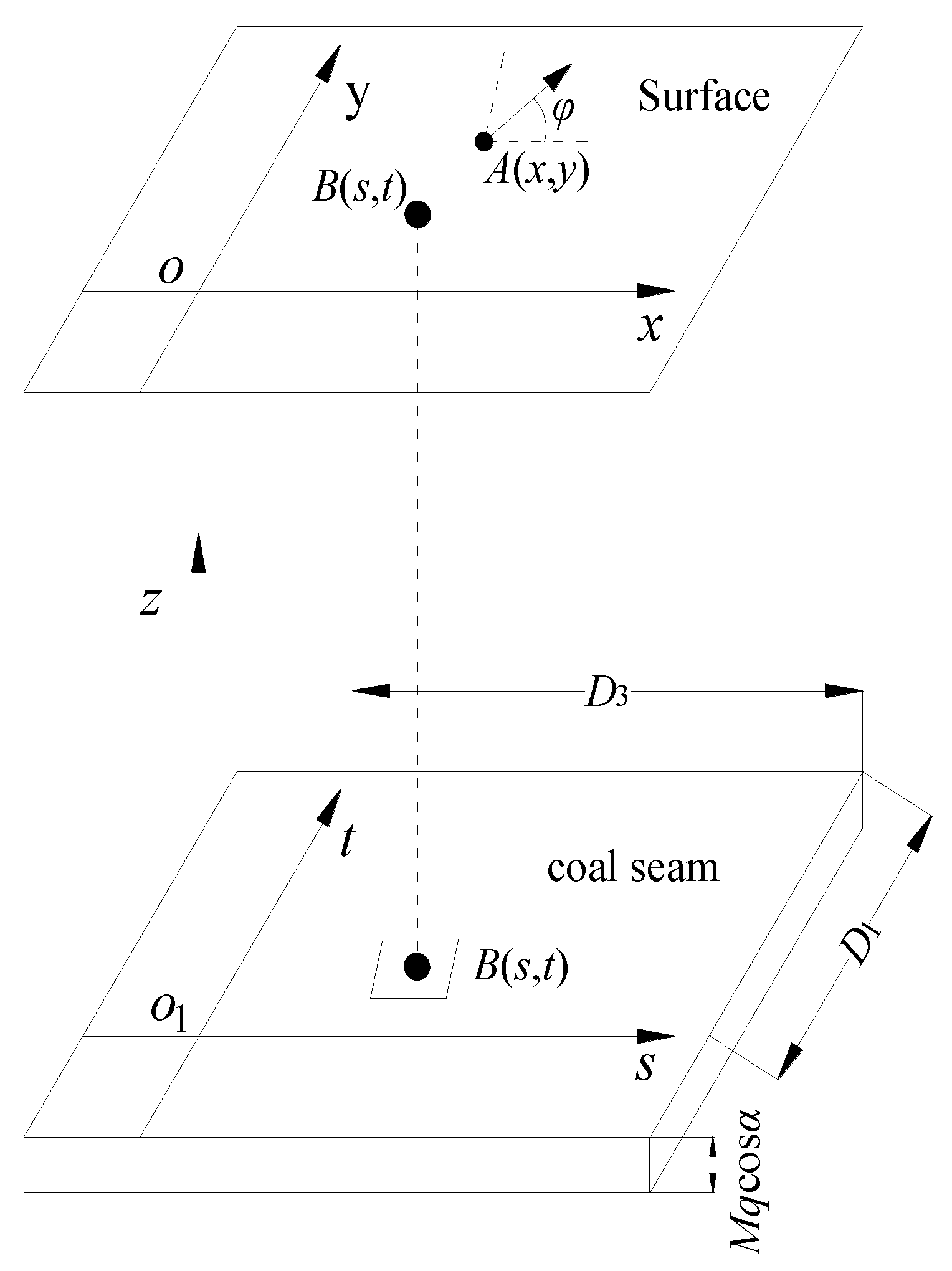

2.2.4. Surface Subsidence at Any Point

2.3. Numerical Simulation

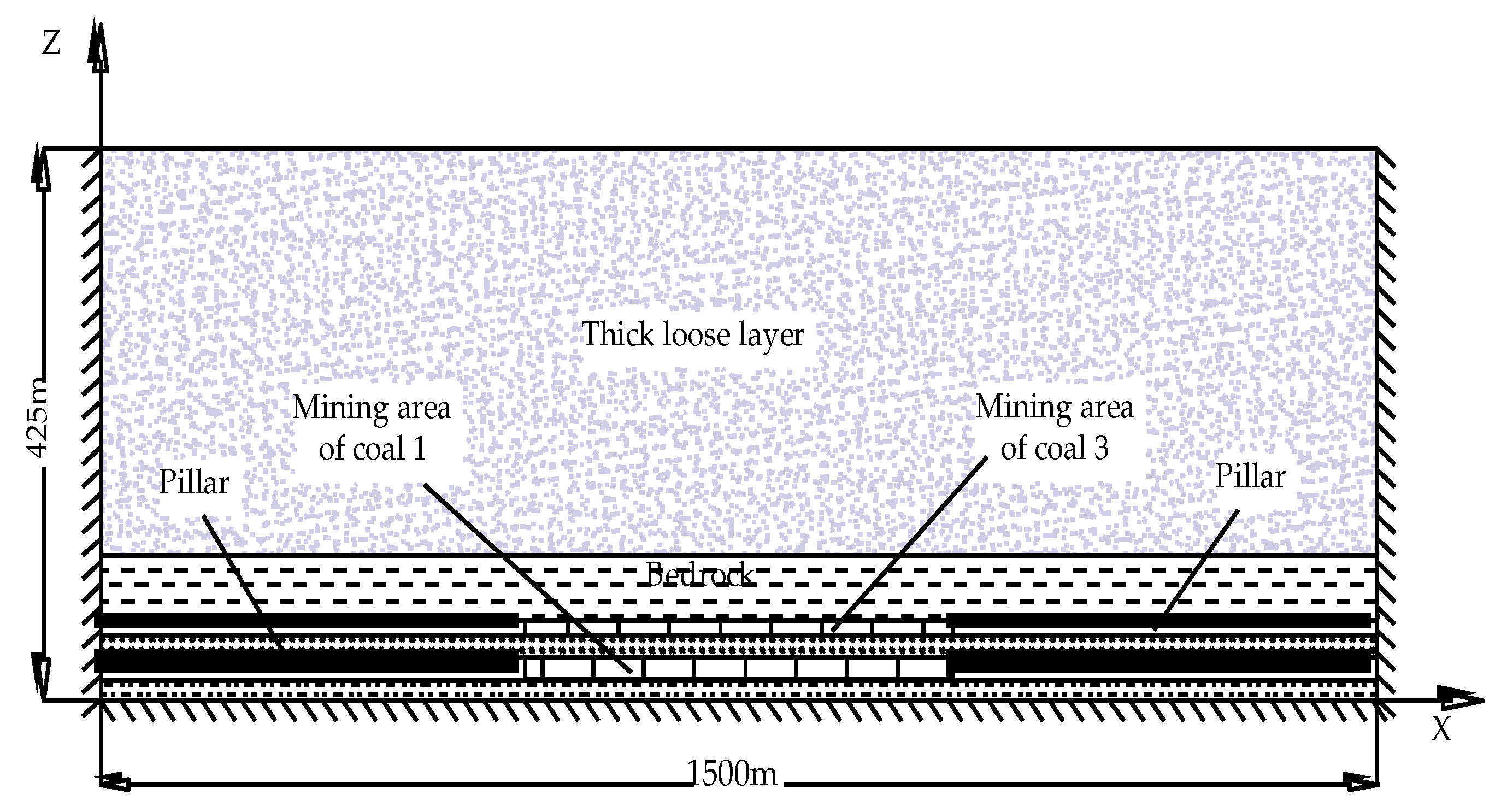

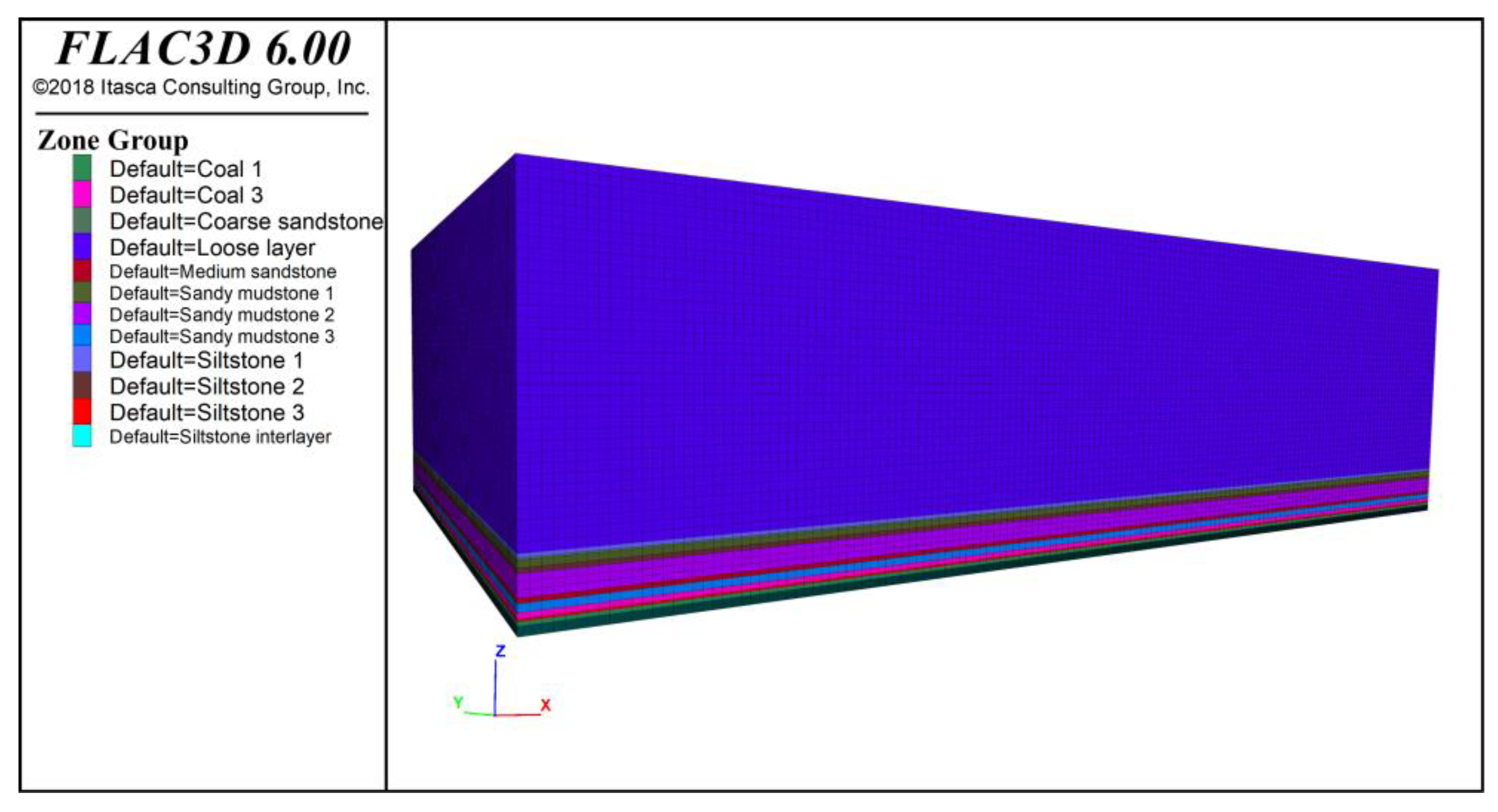

2.3.1. Model Building

2.3.2. Parameters Determination

3. Results

3.1. Surface Subsidence Measurement Data

3.2. Surface Subsidence Prediction

3.3. Numerical Simulation of Surface Subsidence

4. Discussion

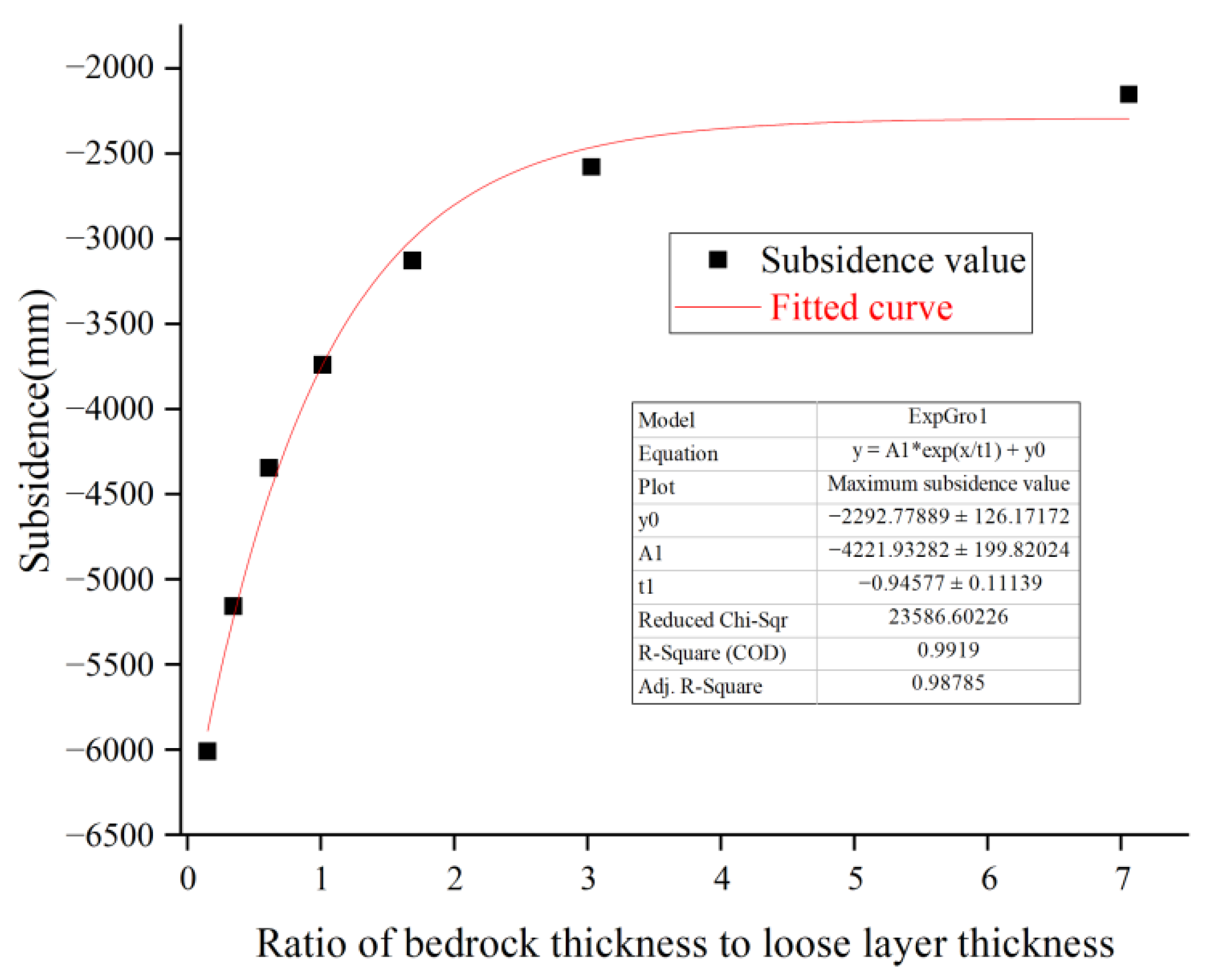

4.1. Relationship between Surface Subsidence Values and Thick Loose Layer

4.2. The Shortcomings of Hyperbolic Secant Subsidence Prediction Model

- (1)

- Multi-layered aquifers are distributed in thick loose layer mines in East China. The derivation of the hyperbolic secant subsidence prediction model in the paper does not consider the additional subsidence values caused by water loss consolidation settlement of the aquifer. The additional subsidence caused by water loss in the aquifer can be taken into account in the subsequent study.

- (2)

- Faulting is a geological formation frequently encountered in mining activities. The presence of a fault makes the surface subsidence of the upper and lower pans show variability. The additional subsidence caused by the slip of the fault surface is not considered in the derivation of the hyperbolic secant subsidence prediction model in the paper. The additional subsidence caused by a fault slip can be taken into account in the subsequent study.

5. Conclusions

- (1)

- According to the measured data from the surface monitoring point of the 11111 working face, it is known that the angle parameter of the surface subsidence basin is small and the subsidence range is large. According to the numerical simulation results, it can be seen that the subsidence value and subsidence range increase with the increase in the thickness of the loose layer. The surface subsidence value is proportional to the thickness of the loose layer, and the surface subsidence value and the ratio of bedrock to the loose layer are exponentially related.

- (2)

- The hyperbolic secant function is used as the mining unit influence function to derive the mining unit surface subsidence estimation formula. Firstly, the surface subsidence estimation formula for semi-infinite mining is derived on the basis of unit mining, and then the surface subsidence estimation formula for the main section of finite mining is derived on the basis of semi-infinite mining. Finally, the formula for surface subsidence at any point of the surface is derived.

- (3)

- The hyperbolic secant subsidence prediction model constructed in this paper and the conventional probabilistic integral method are used for the subsidence prediction of the 11111 working face. The predicted values of the hyperbolic secant subsidence prediction model are closer to the measured values at the subsidence boundary and near the maximum value. The MAE and RMSE values of the hyperbolic secant subsidence prediction model are smaller than those of the conventional probability integral method. The RMSE values of the predicted values from the hyperbolic secant subsidence prediction model were improved by 38% and 37% at all monitoring points and the subsidence boundary monitoring points, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, J.B.; Yin, D.W.; Jiang, N.; Wang, S.; Yao, D.H. Application of a superposition model to evaluate surface asymmetric settlement in a mining area with thick bedrock and thin loose layer. J. Clean. Prod. 2021, 9, 128075. [Google Scholar] [CrossRef]

- Hou, D.F.; Li, D.H.; Xu, G.S.; Zhang, Y.B. Superposition model for analyzing the dynamic ground subsidence in mining area of thick loose layer. Int. J. Min. Sci. Technol. 2018, 4, 663–668. [Google Scholar] [CrossRef]

- Zhou, D.W.; Wu, K.; Li, L.; Diao, X.M. A new methodology for studying the spreading process of mining subsidence in rock mass and alluvial soil: An example from the Huainan coal mine, China. Bull. Eng. Geol. Environ. 2016, 75, 1067–1087. [Google Scholar] [CrossRef]

- Zhang, J.M. Study on Overburden Movement and Surface Movement under Water Loss Mining in Thick Loose Aquifer. Master’s Thesis, Anhui University of Science and Technology, Huainan, China, 2019. [Google Scholar]

- Chang, Q.L.; Yao, X.J.; Leng, Q.; Cheng, H.; Wu, F.F.; Zhou, H.Q.; Sun, Y.T. Strata movement of the thick loose layer under strip-filling mining method: A case study. Appl. Sci. 2021, 11, 11717. [Google Scholar] [CrossRef]

- Chi, S.S.; Wang, L.; Yu, X.X.; Lv, W.C.; Fang, X.J. Research on dynamic prediction model of surface subsidence in mining areas with thick unconsolidated layers. Energy Explor. Exploit. 2021, 39, 927–943. [Google Scholar] [CrossRef]

- Xu, Z.H.; Li, Q.S.; Li, X.B. Overburden migration and failure characteristics in mining shallow buried coal seam with thick loose layer. Adv. Mater. Sci. Eng. 2020, 8, 9024751. [Google Scholar] [CrossRef]

- Shi, W.P.; Li, K.X.; Yu, S.W.; Zhang, C.Z.; Li, J.K. Analysis on subsidence law of bedrock and ultrathick loose layer caused by coal mining. Geofluids 2021, 8, 8849955. [Google Scholar] [CrossRef]

- Cui, X.M.; Zhao, Y.L.; Wang, G.R.; Zhang, B.; Li, C.Y. Calculation of residual surface subsidence above abandoned longwall coal mining. Sustainability 2020, 12, 1528. [Google Scholar] [CrossRef]

- Guzy, A.; Witkowski, W.T. Land subsidence estimation for aquifer drainage induced by underground mining. Energies 2021, 14, 4658. [Google Scholar] [CrossRef]

- Yu, X.Y.; Li, B.B.; Li, R.B.; Duan, W.S.; Liu, P.L. Analysis of mining damage in huge thick collapsible loess of western china. J. China Univ. Min. Technol. 2008, 37, 43–47. [Google Scholar]

- Nakamura, N.; Akita, S.; Suzuki, T.; Koba, M.; Nakamura, S.; Nakano, T. Study of ultimate seismic response and fragility evaluation of nuclear power building using nonlinear three-dimensional finite element model. Nucl. Eng. Des. 2010, 1, 166–180. [Google Scholar] [CrossRef]

- He, G.Q.; Yang, L.; Li, G.D.; Jia, F.C.; Hou, D. Mining Subsidence Science, 1st ed.; China University of Mining and Technology Press: Xuzhou, China, 1991; pp. 116–187. [Google Scholar]

- Tzampoglou, P.; Loupasakis, C. Numerical simulation of the factors causing land subsidence due to overexploitation of the aquifer in the Amyntaio open coal mine, Greece. HydroResearch 2019, 3, 8–24. [Google Scholar] [CrossRef]

- Marino, G.; Osouli, A.; Elgendy, M.; Karimpour, M. Utilization of historical subsidence data for prediction of adverse subsidence conditions over trona mine. Int. J. Geomech. 2017, 2, 2017. [Google Scholar] [CrossRef]

- Dudek, M.; Tajdus, K. FEM for prediction of surface deformations induced by flooding of steeply inclined mining seams. Geomech. Energy Environ. 2021, 11, 100254. [Google Scholar] [CrossRef]

- Li, C.Y.; Ding, L.Z.; Cui, X.M.; Zhao, Y.L.; He, Y.H.; Zhang, W.Z.; Bai, Z.H. Calculation model for progressive residual surface subsidence above mined-out areas based on logistic time function. Energies 2022, 15, 5024. [Google Scholar] [CrossRef]

- Sun, Y.J.; Zuo, J.P.; Karakus, M.; Liu, L.; Zhou, H.W.; Yu, M.L. A new theoretical method to predict strata movement and surface subsidence due to inclined coal seam mining. Rock Mech. Rock Eng. 2021, 54, 2723–2740. [Google Scholar] [CrossRef]

- Liu, B.C. Stochastic medium theory and its application to excavation-induced ground subsidence problems. Chin. J. Nonferrous Met. 1992, 9, 8–14. [Google Scholar] [CrossRef]

- Liu, B.C.; Dai, H.Y. Research development and origin of probability integral method. Coal Min. Technol. 2016, 21, 1–3. [Google Scholar] [CrossRef]

- Ghabraie, B.; Ren, G.; Barbato, J.; Smith, J.V. A predictive methodology for multi-seam mining induced subsidence. Int. J. Rock Mech. Min. Sci. 2017, 3, 280–294. [Google Scholar] [CrossRef]

- He, G.Q. The Weber-distribution method for calculating mining subsidence. J. China Univ. Min. Technol. 1988, 17, 8–15. [Google Scholar]

- Guo, G.L.; Zhu, X.J.; Zha, J.F.; Wang, Q. Subsidence prediction method based on equivalent mining height theory for solid backilling mining. Trans. Nonferrous Met. Soc. China 2014, 24, 3302–3308. [Google Scholar] [CrossRef]

- Yan, W.T.; Chen, J.J.; Yan, Y.G. A new model for predicting surface mining subsidence: The improved lognormal function model. Geosci. J. 2019, 23, 165–174. [Google Scholar] [CrossRef]

- Yan, Y.G.; Yan, W.T.; Liu, J.B.; Guo, J.T. The prediction model of super large subsidence in high water table coal mining areas covered with thick unconsolidated layer. Geofluids 2021, 3, 5520548. [Google Scholar] [CrossRef]

- Dai, H.Y.; Lian, X.G.; Liu, J.Y.; Liu, Y.X.; Zhou, Y.M.; Deng, W.N.; Cai, Y.F. Model study of deformation induced by fully mechanized caving below a thick loess layer. Int. J. Rock Mech. Min. Sci. 2010, 47, 1027–1033. [Google Scholar] [CrossRef]

- Zhao, B.C.; Guo, Y.X.; Mao, X.W.; Zhai, D.; Zhu, D.F.; Huo, Y.M.; Sun, Z.D.; Wang, J.B. Prediction method for surface subsidence of coal seam mining in loess donga based on the probability integration model. Energies 2022, 15, 2282. [Google Scholar] [CrossRef]

- Perzylo, D. A new model for forecasting of land surface subsidence caused by underground extraction of deposits. Int. J. Environ. Sci. Technol. 2022, 5, 2022. [Google Scholar] [CrossRef]

- Yang, B.C.; Chen, Q. A half-discrete hardy-hilbert-type inequality related to hyperbolic secant function. J. Inequal. Appl. 2015, 12, 405. [Google Scholar] [CrossRef]

- Zhang, X.D.; Zhao, Y.H.; Liu, S.J. A new method of calculating surface subsidence and deformations under thick alluvial soil. Chin. J. Nonferrous Met. 1999, 9, 435–440. [Google Scholar] [CrossRef]

- He, P.; Wang, D.P.; Gao, B.B. Applying hyperbolic function to predict the surface movement and deformation in the conditionof thick alluvium. Coal Min. Technol. 2005, 10, 3–5. [Google Scholar]

- Li, P.X.; Tan, Z.X.; Yan, L.L. A shaft pillar mining subsidence calculation using both probability integral method and numerical simulation. CMES-Comput. Model. Eng. Sci. 2018, 117, 231–250. [Google Scholar] [CrossRef]

- Wang, G.R.; Li, P.X.; Wu, Q.; Cui, X.M.; Tan, Z.X. Numerical simulation of mining-induced damage in adjacent tunnels based on FLAC3D. Adv. Civ. Eng. 2021, 1, 9855067. [Google Scholar] [CrossRef]

| Overlying Rocks | Tensile Strength (Mpa) | Elastic Modulus (Gpa) | Poisson's Ratio | Cohesion | Internal Friction Angle (°) | Weight Capacity (kN/m3) |

|---|---|---|---|---|---|---|

| Loose layer | 0.25 | 0.045 | 0.25 | 0.01 | 18 | 18.24 |

| Siltstone 1 | 0.81 | 12.9 | 0.25 | 3.2 | 28 | 26.98 |

| Coarse sandstone | 1.5 | 5.1 | 0.22 | 3.8 | 33 | 25.6 |

| Sandy mudstone 1 | 0.79 | 12.5 | 0.26 | 1.7 | 25 | 26.88 |

| Siltstone 2 | 0.81 | 12.9 | 0.25 | 3.2 | 28 | 26.98 |

| Sandy mudstone 2 | 0.79 | 12.5 | 0.26 | 1.7 | 25 | 26.88 |

| Medium sandstone | 1.3 | 12.9 | 0.26 | 1.2 | 33 | 25.8 |

| Sandy mudstone 3 | 0.79 | 12.5 | 0.26 | 1.7 | 25 | 26.88 |

| Coal 3 | 0.03 | 1 | 0.3 | 1.05 | 27 | 14.6 |

| Siltstone 3 | 0.81 | 12.9 | 0.25 | 3.2 | 28 | 26.98 |

| Coal 1 | 0.03 | 1 | 0.3 | 1.05 | 27 | 14.6 |

| Siltstone interlayer | 2.81 | 5.2 | 0.25 | 5.2 | 34 | 27.21 |

| Models | All Points | L-Line | S-Line | |||

|---|---|---|---|---|---|---|

| MAE (mm) | RMSE (mm) | MAE (mm) | RMSE (mm) | MAE (mm) | RMSE (mm) | |

| Probability integral method | 116.768 | 220.179 | 178.061 | 302.943 | 60.191 | 92.270 |

| Hyperbolic secant subsidence prediction model | 68.900 | 135.856 | 118.847 | 189.995 | 22.795 | 46.609 |

| Accuracy improvement rate | 41% | 38% | 33% | 37% | 62% | 49% |

| Models | Boundary of All Points | Boundary of L-Line | Boundary of S-Line | |||

|---|---|---|---|---|---|---|

| MAE (mm) | RMSE (mm) | MAE (mm) | RMSE (mm) | MAE (mm) | RMSE (mm) | |

| Probability integral method | 150.226 | 194.623 | 163.875 | 230.148 | 136.576 | 150.955 |

| Hyperbolic secant subsidence prediction model | 73.237 | 122.770 | 107.334 | 157.570 | 39.140 | 72.914 |

| Accuracy improvement rate | 51% | 37% | 35% | 32% | 71% | 52% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Yan, Y.; Dai, H.; Xu, L.; Li, J.; Xu, R. Hyperbolic Secant Subsidence Prediction Model under Thick Loose Layer Mining Area. Minerals 2022, 12, 1023. https://doi.org/10.3390/min12081023

Zhang J, Yan Y, Dai H, Xu L, Li J, Xu R. Hyperbolic Secant Subsidence Prediction Model under Thick Loose Layer Mining Area. Minerals. 2022; 12(8):1023. https://doi.org/10.3390/min12081023

Chicago/Turabian StyleZhang, Jinman, Yueguan Yan, Huayang Dai, Liangji Xu, Jiewei Li, and Ruirui Xu. 2022. "Hyperbolic Secant Subsidence Prediction Model under Thick Loose Layer Mining Area" Minerals 12, no. 8: 1023. https://doi.org/10.3390/min12081023

APA StyleZhang, J., Yan, Y., Dai, H., Xu, L., Li, J., & Xu, R. (2022). Hyperbolic Secant Subsidence Prediction Model under Thick Loose Layer Mining Area. Minerals, 12(8), 1023. https://doi.org/10.3390/min12081023