Mechanical Properties and Failure Mechanism of the Weakly Cemented Overburden in Deep Mining

Abstract

:1. Introduction

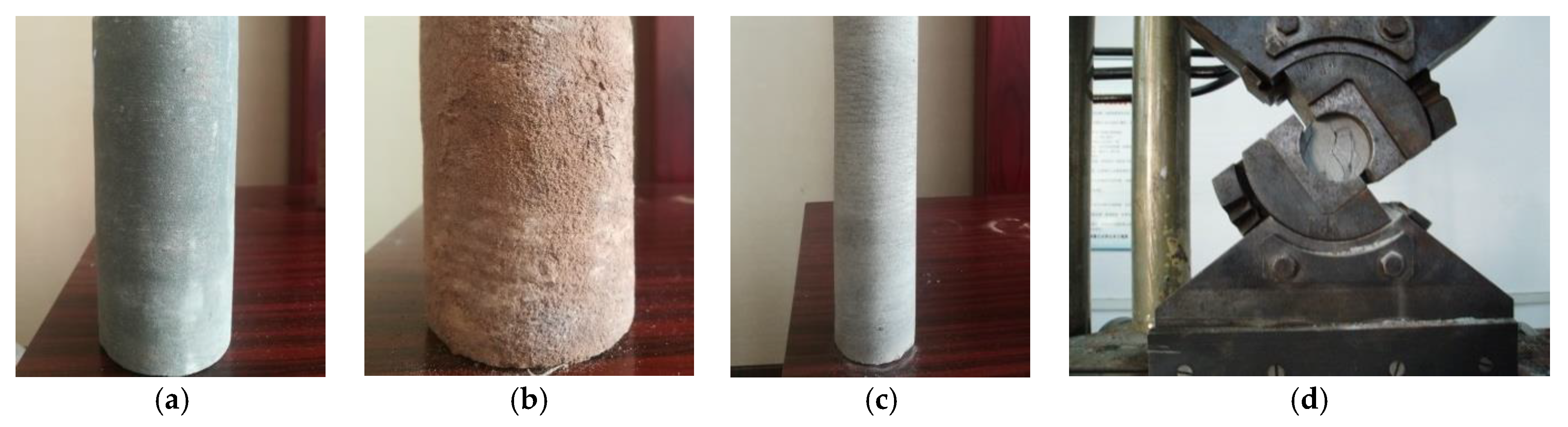

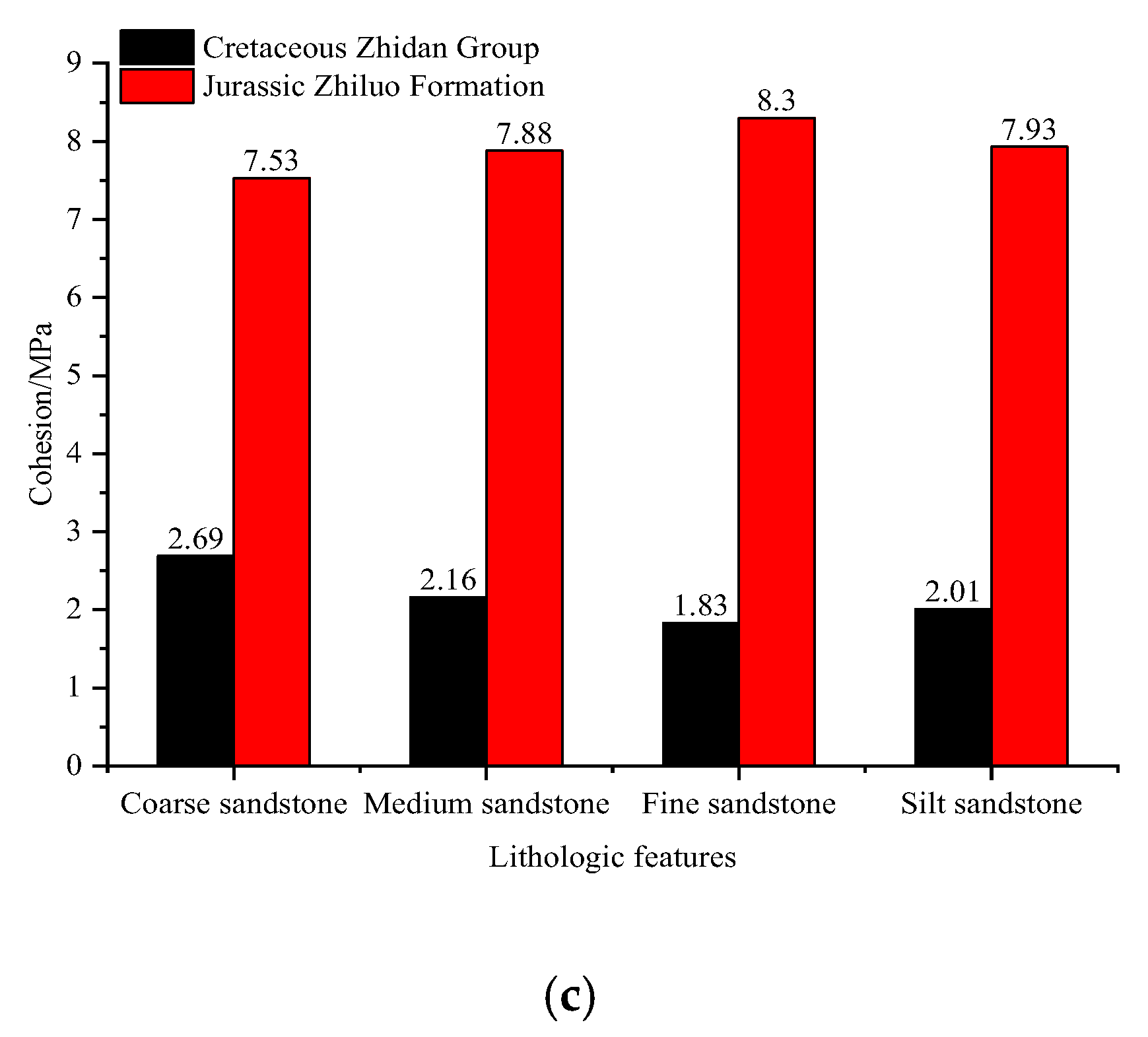

2. Mechanical Properties of Weakly Cemented Sandstone

3. Physical Structural Characteristics of Weakly Cemented Sandstone

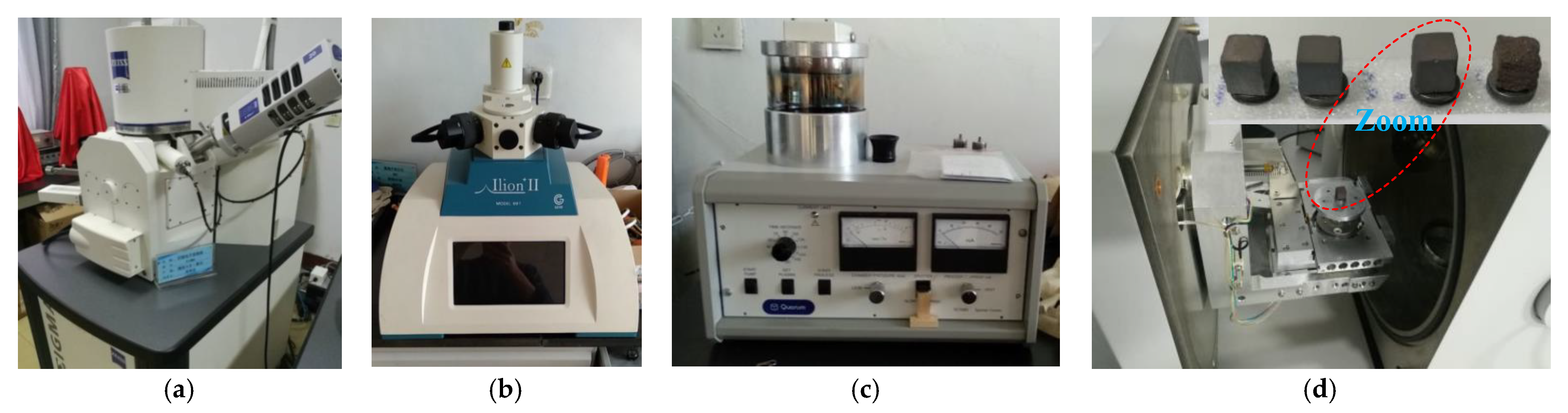

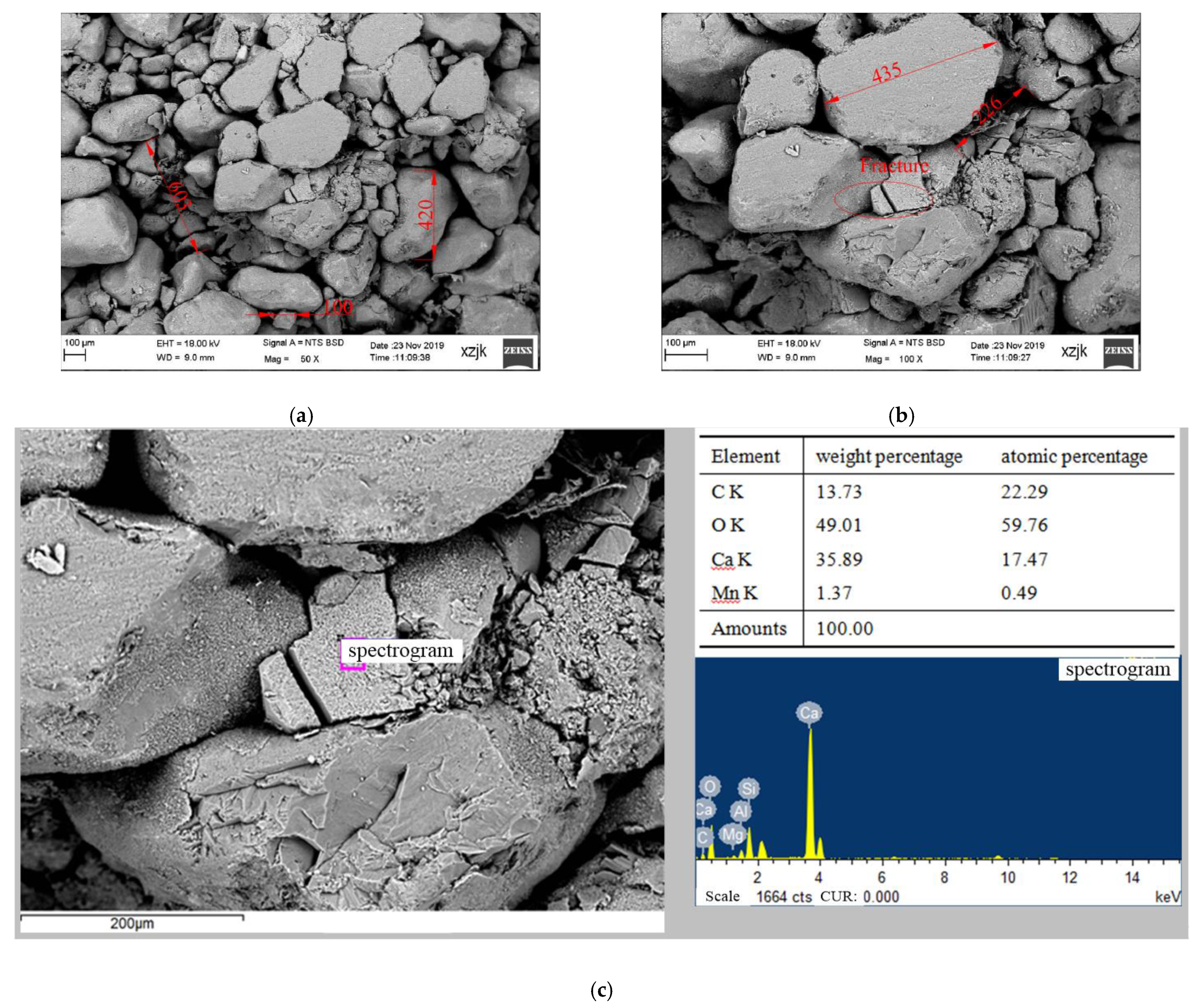

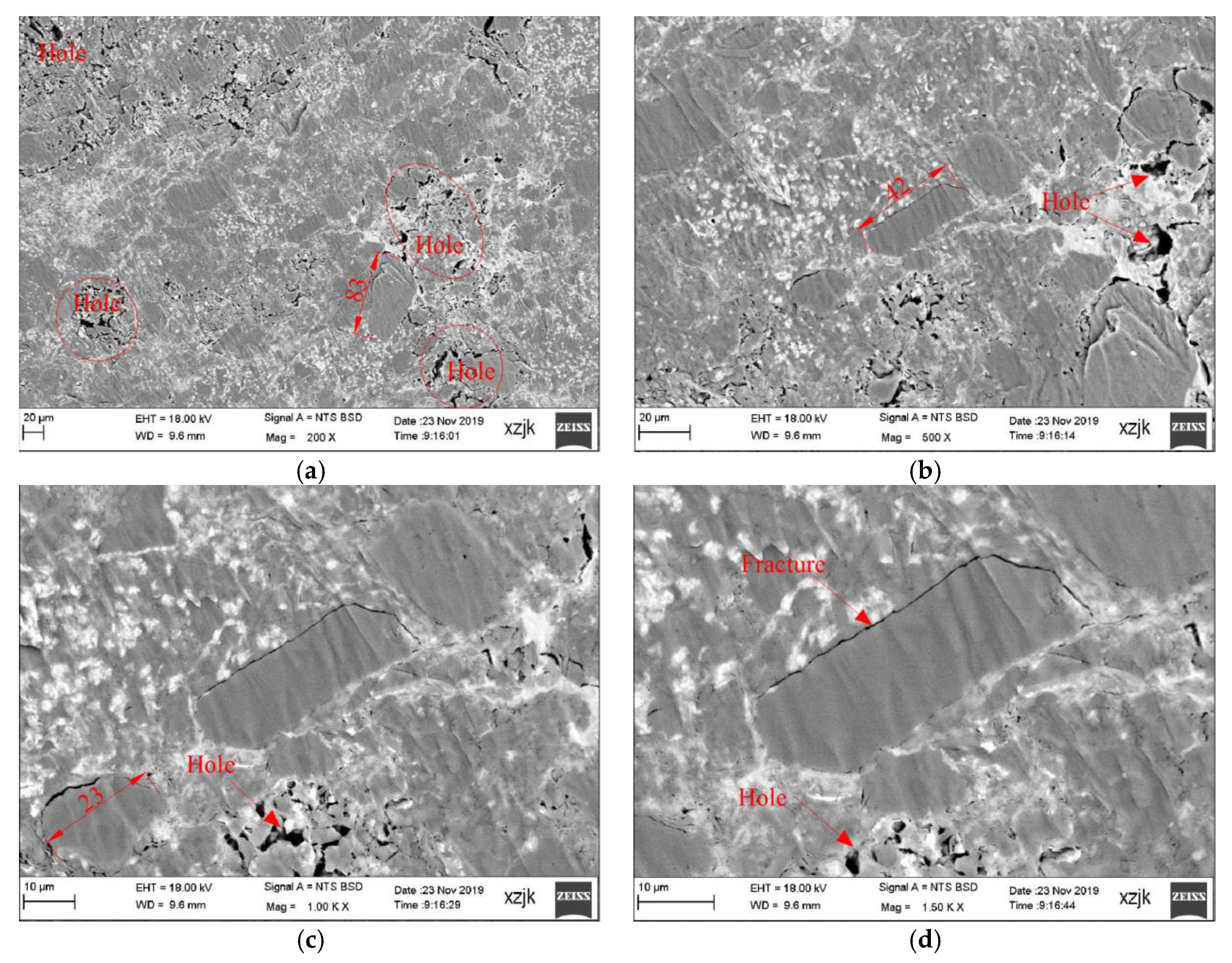

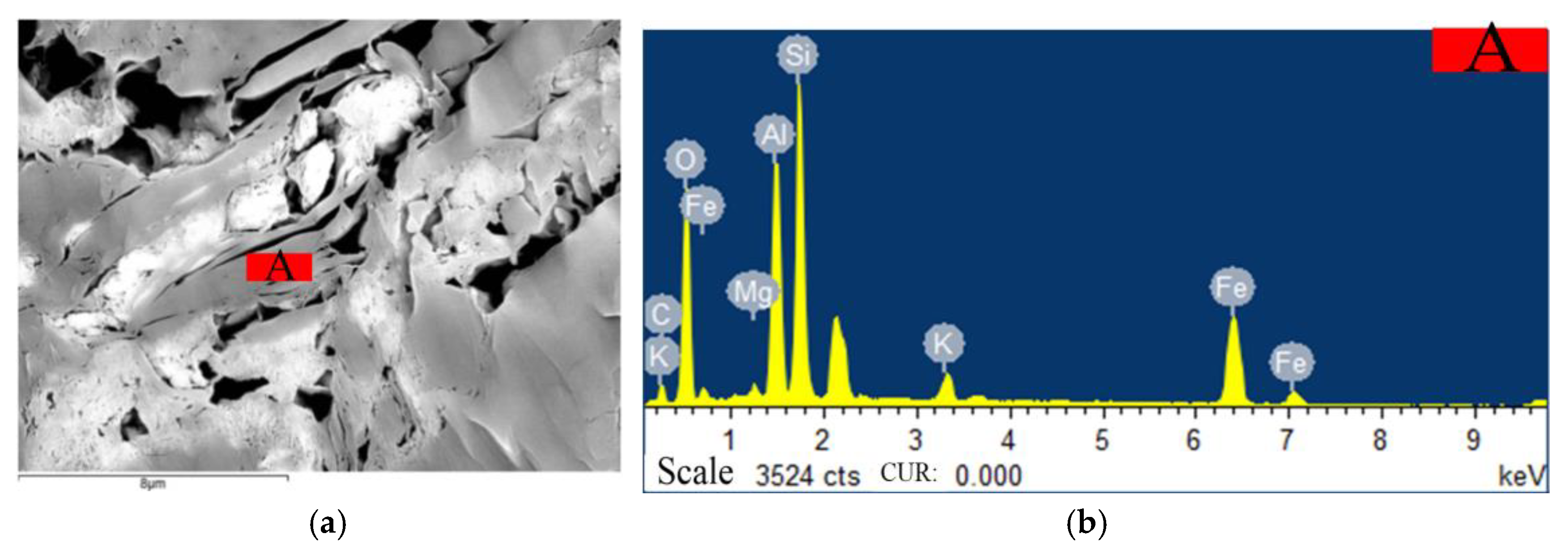

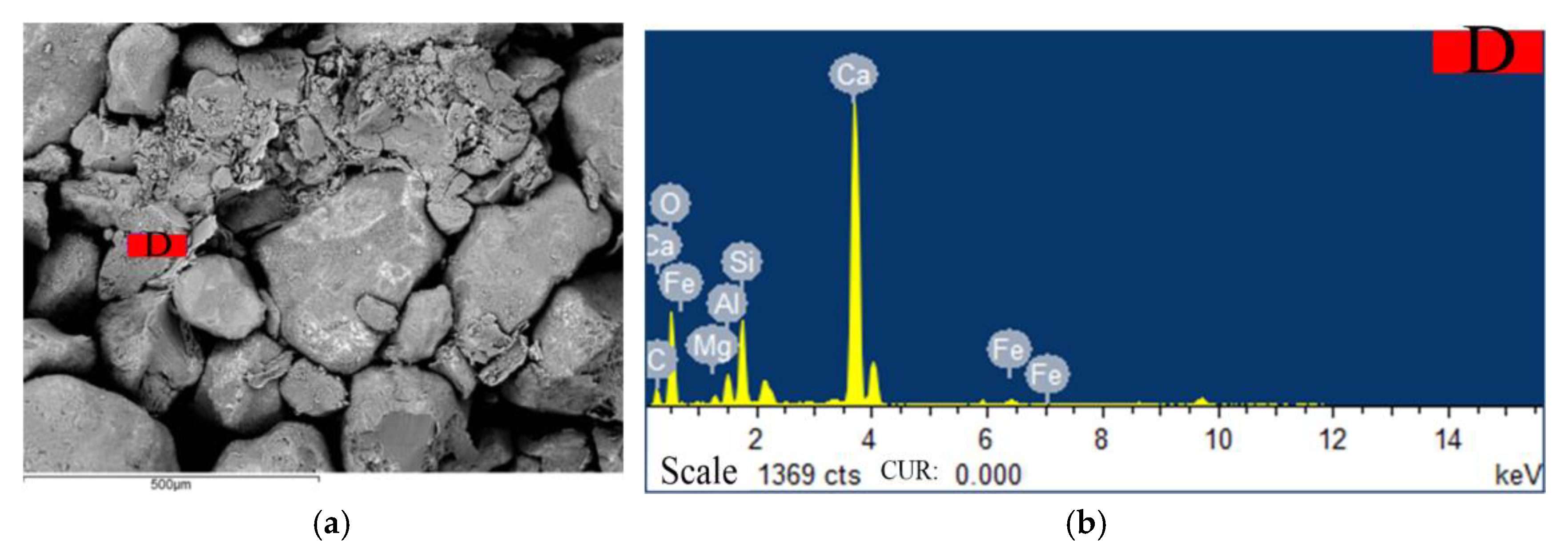

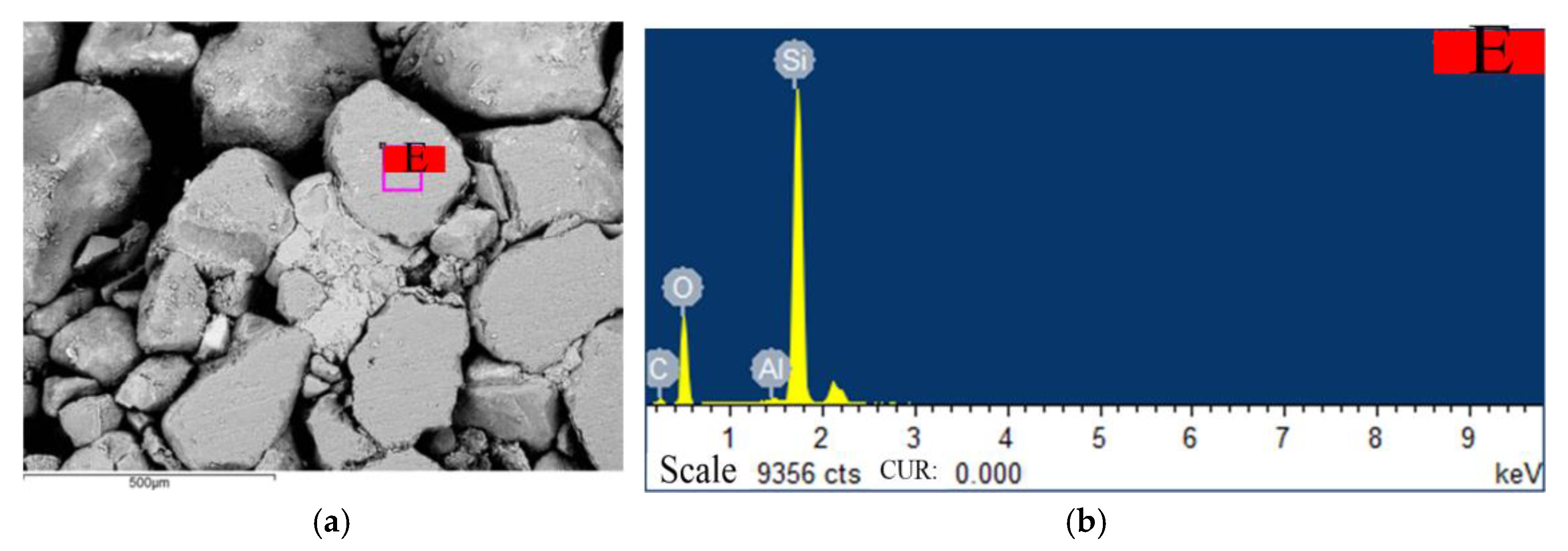

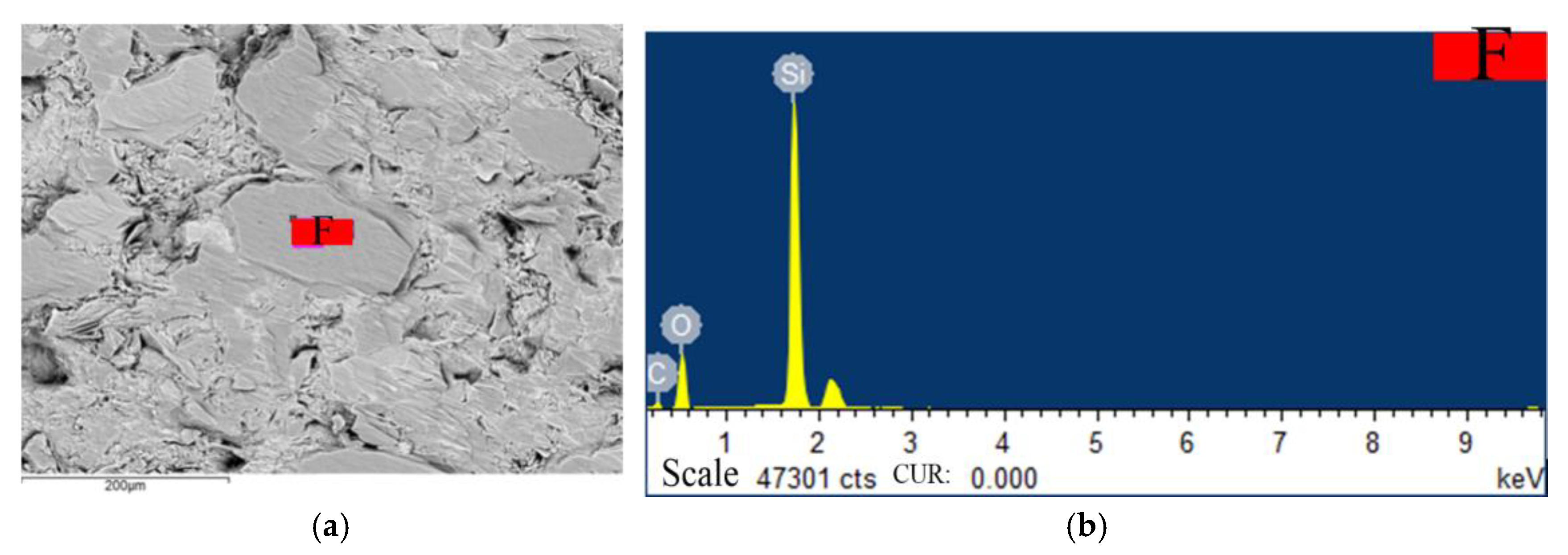

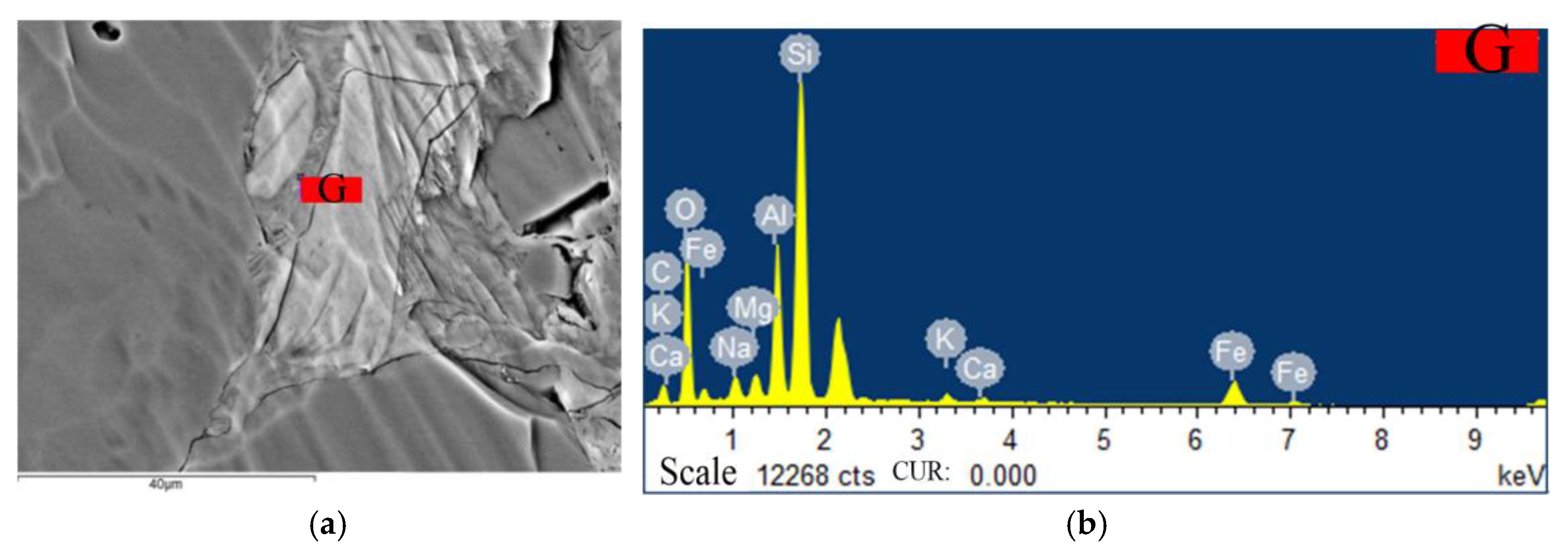

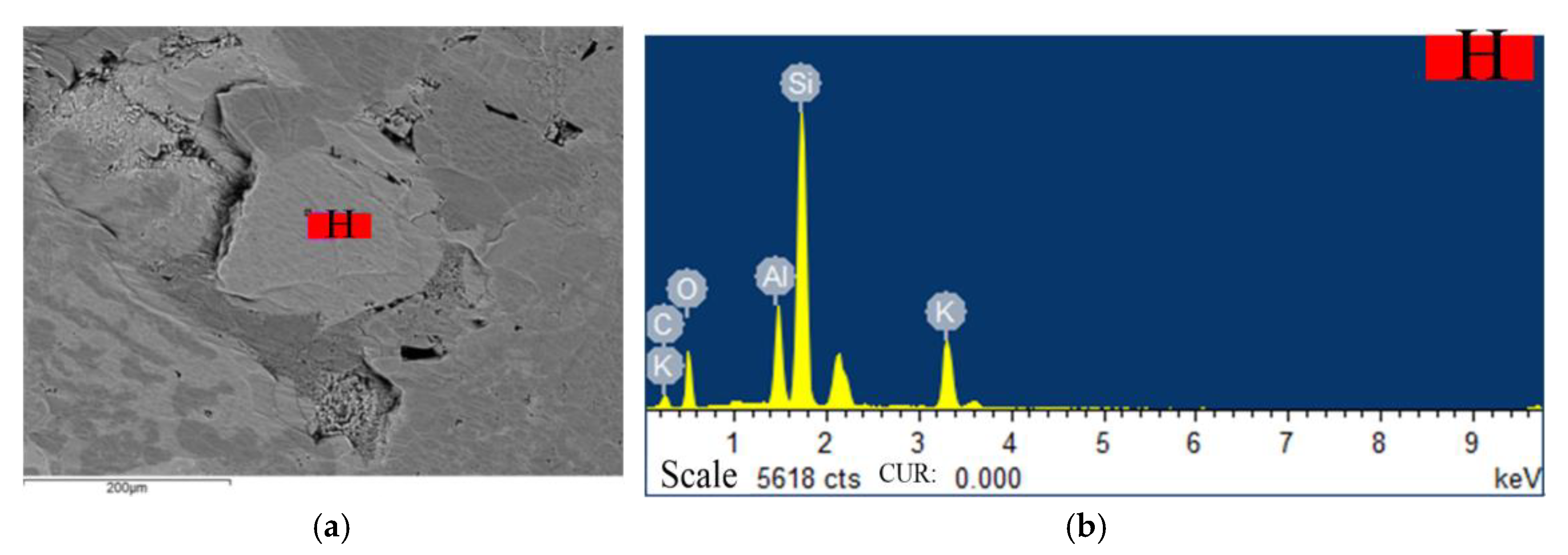

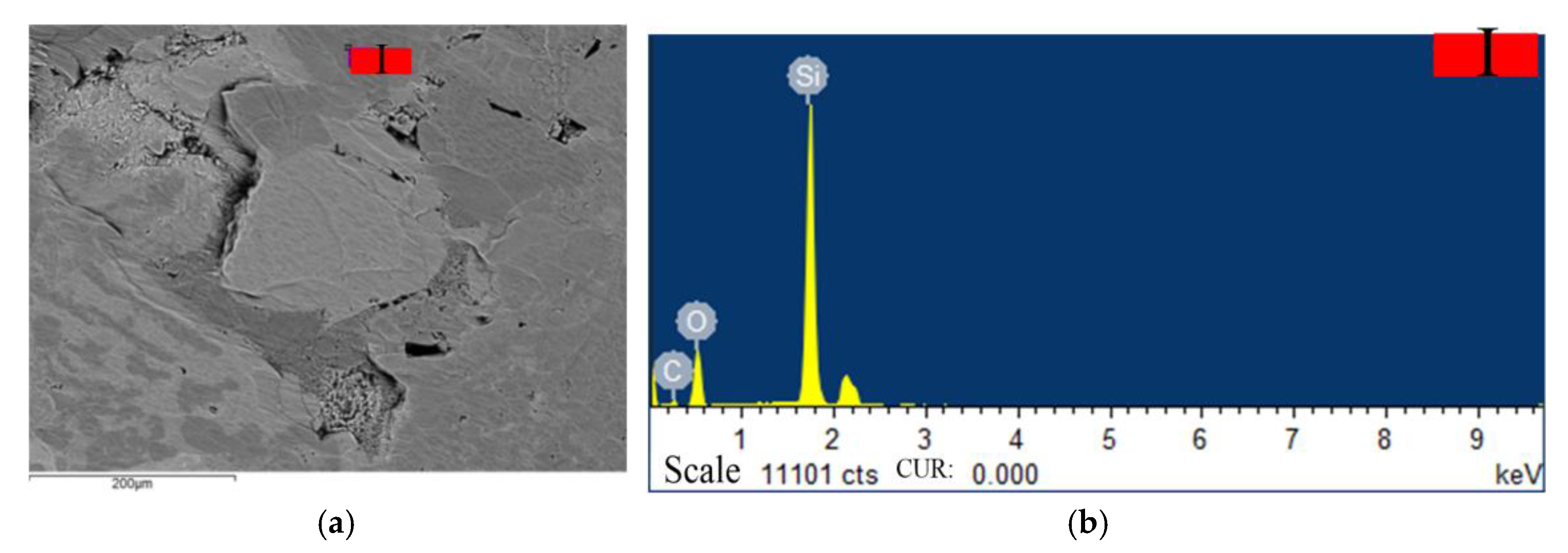

3.1. SEM Tests of Weakly Cemented Sandstone

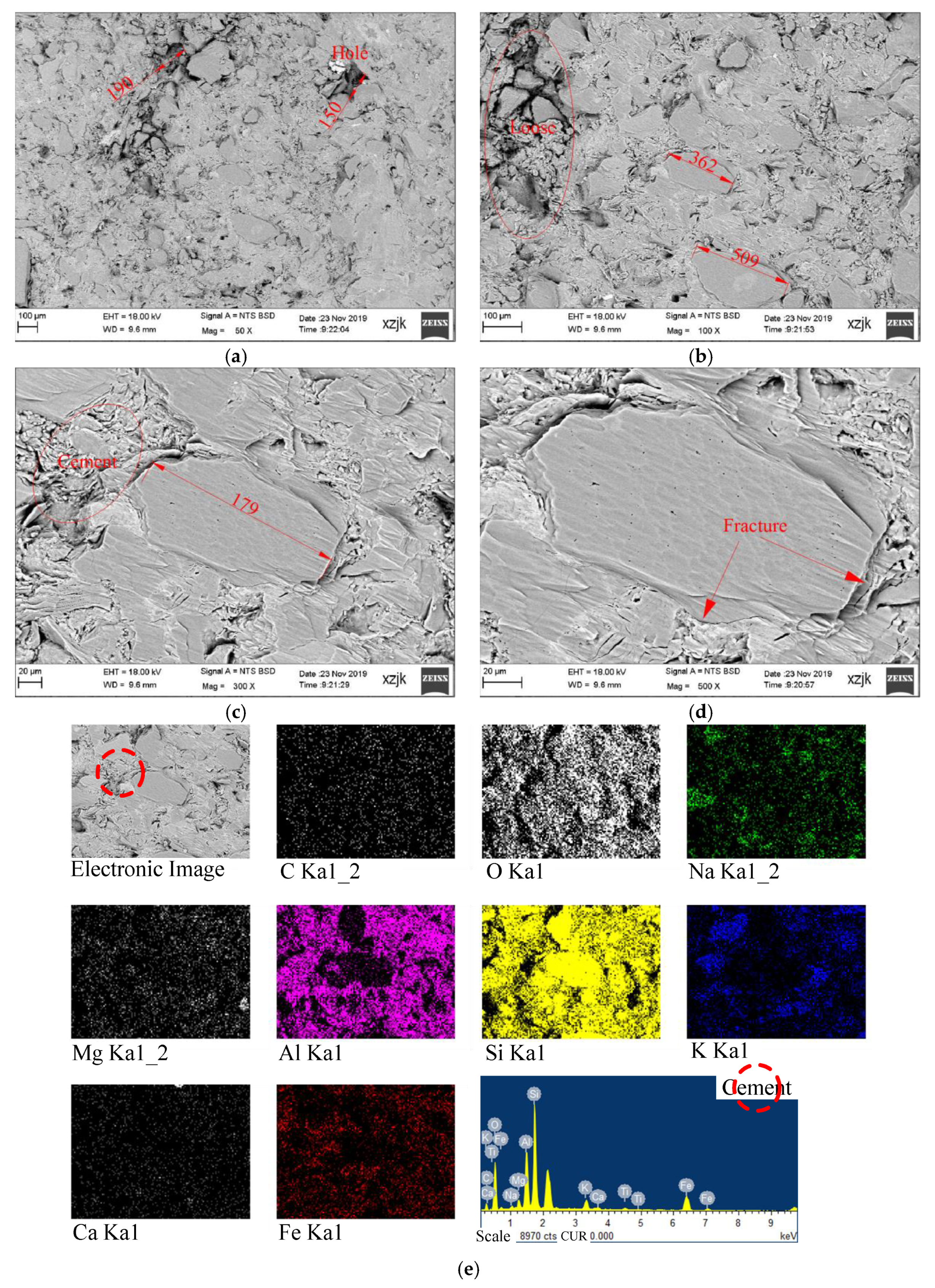

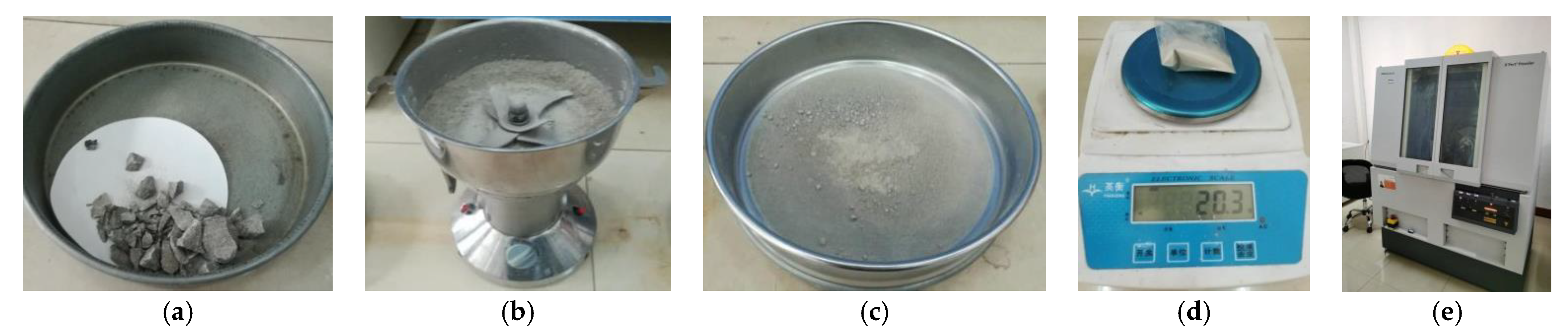

3.2. Cementation Types and Mineral Analysis of Weakly Cemented Sandstone

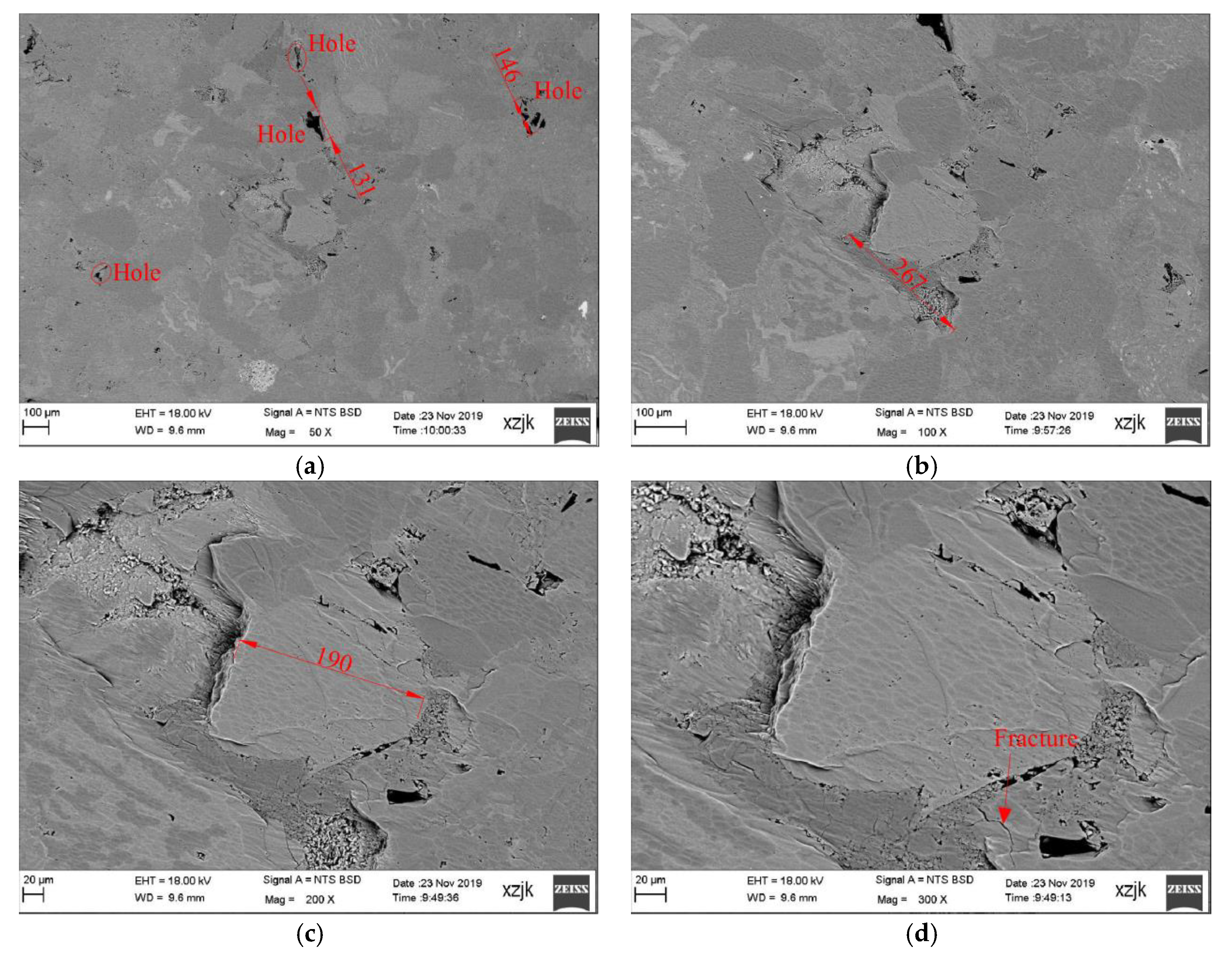

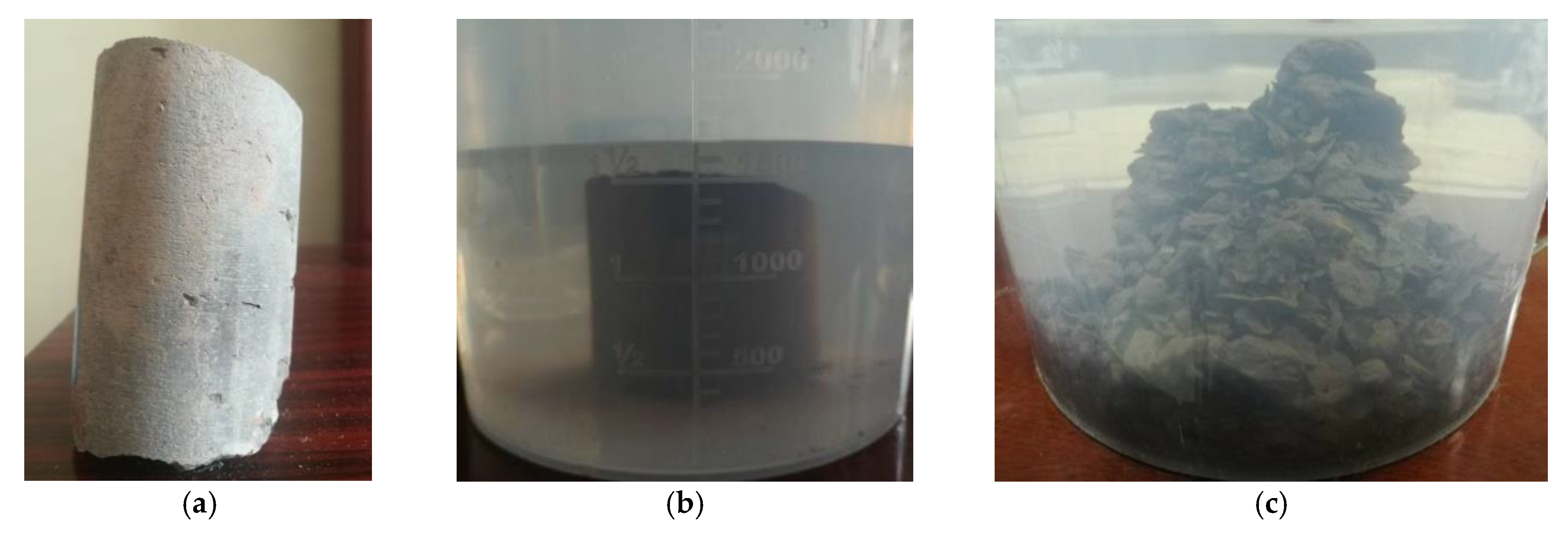

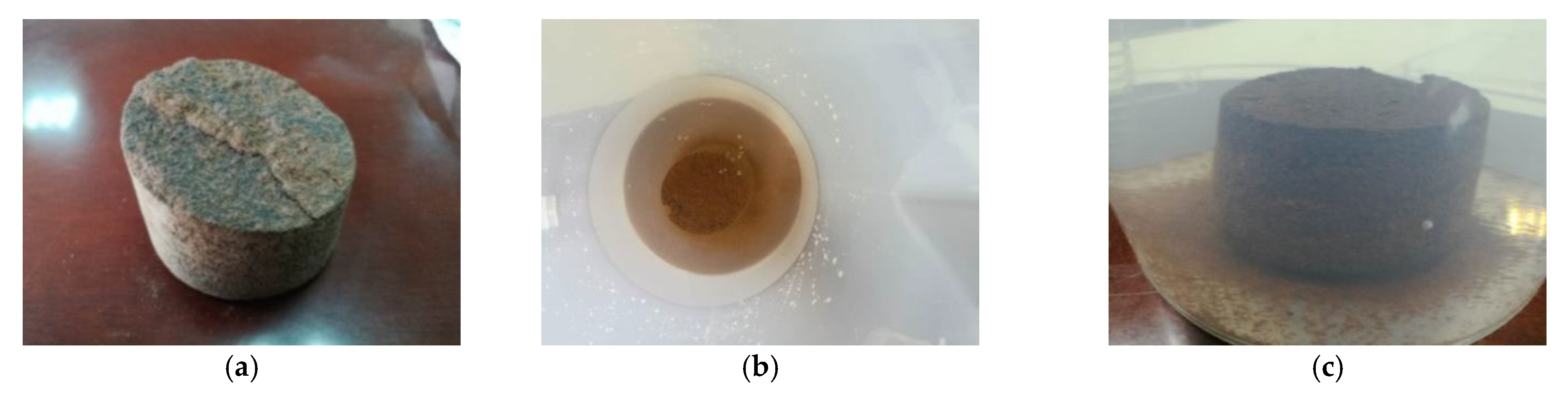

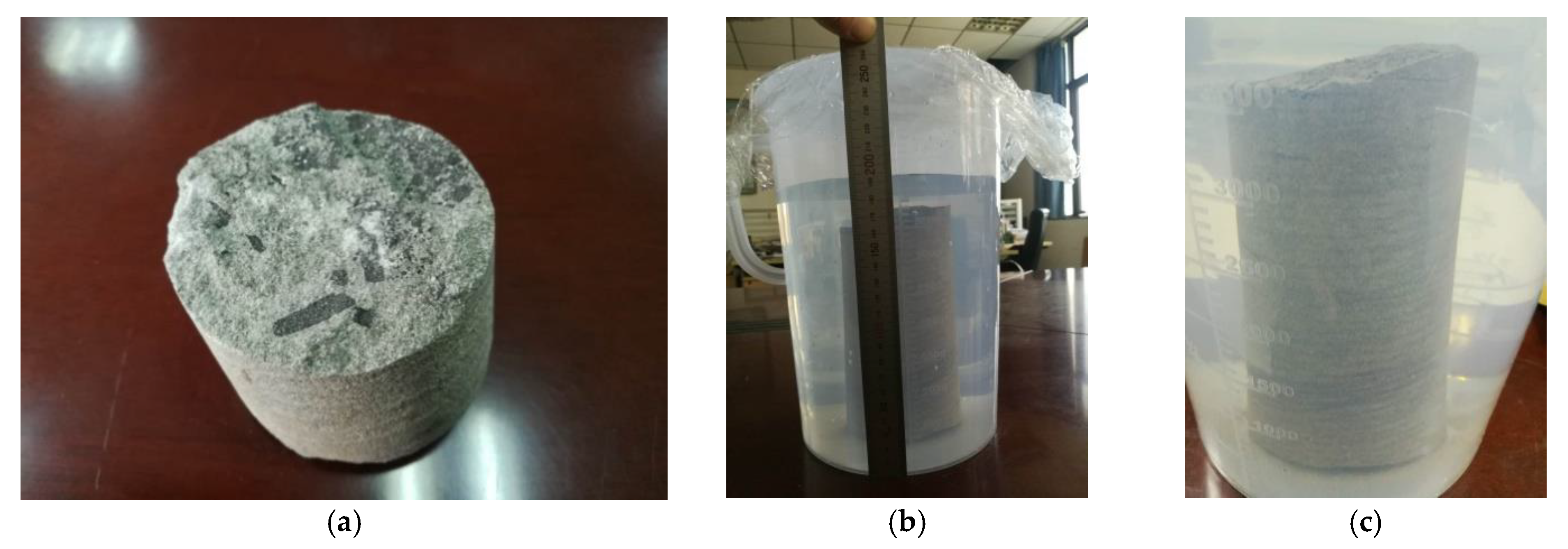

3.3. Hydrolytic Properties of Weakly Cemented Sandstone

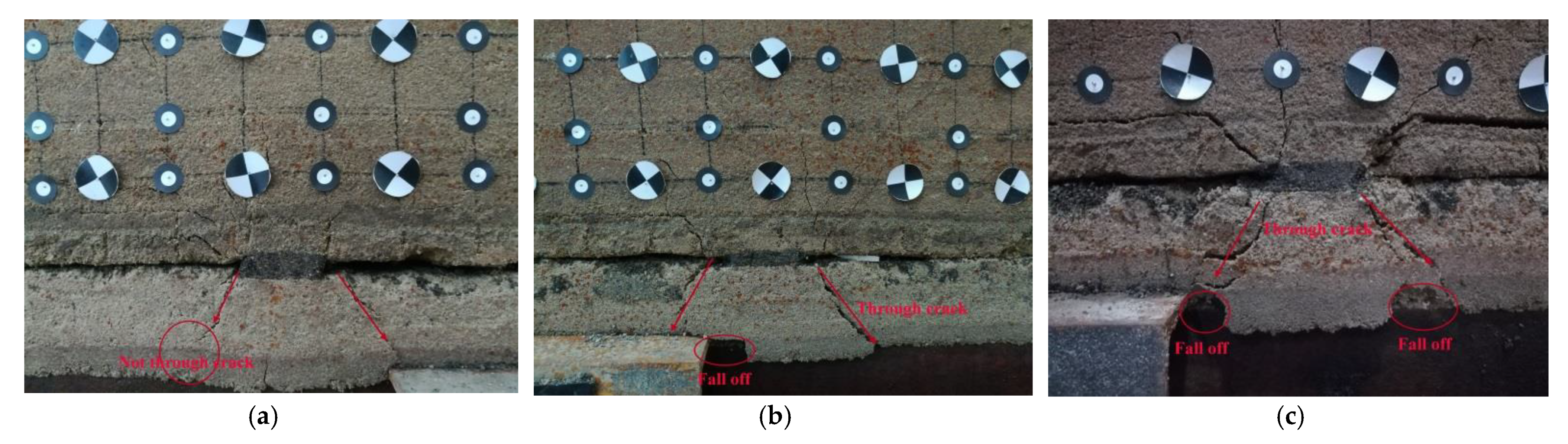

4. Strata Failure Rule of Deep Mining with the Super-Thick and Weakly Cemented Overburden through Numerical Simulation

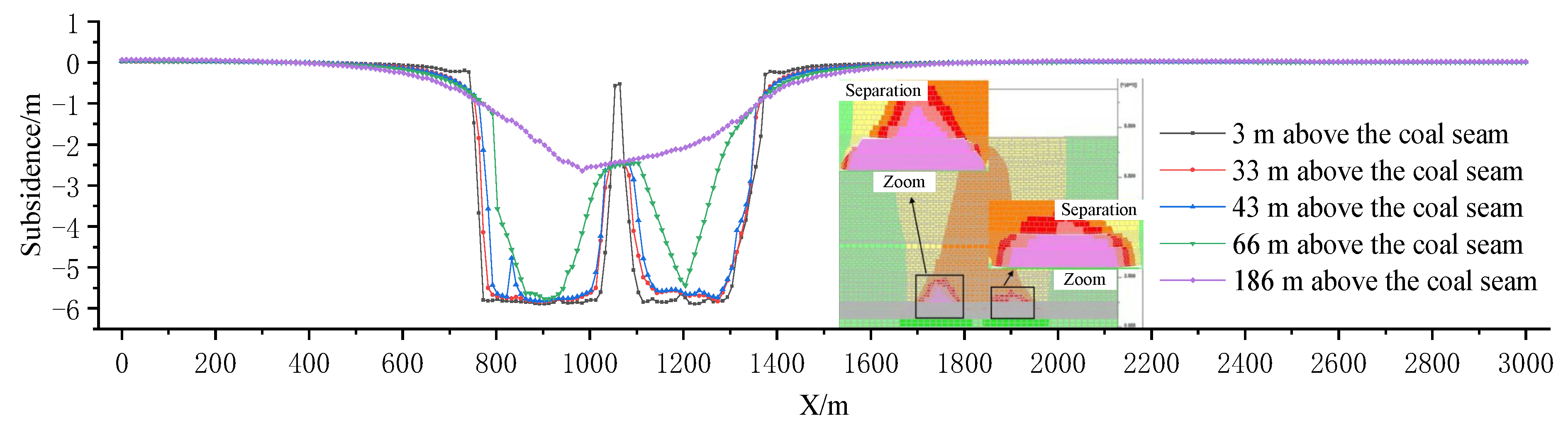

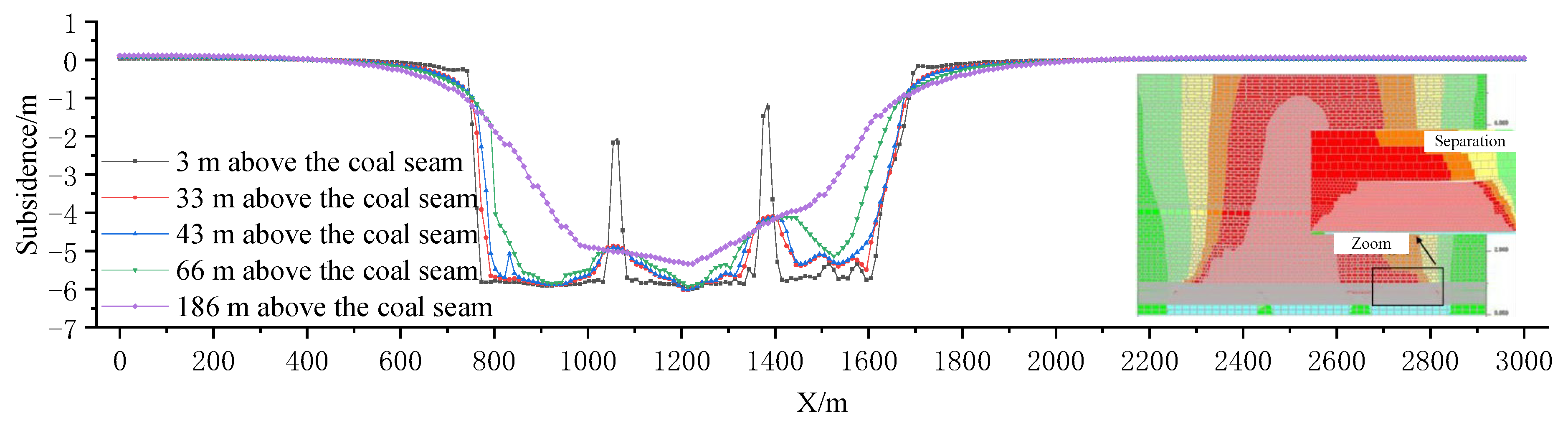

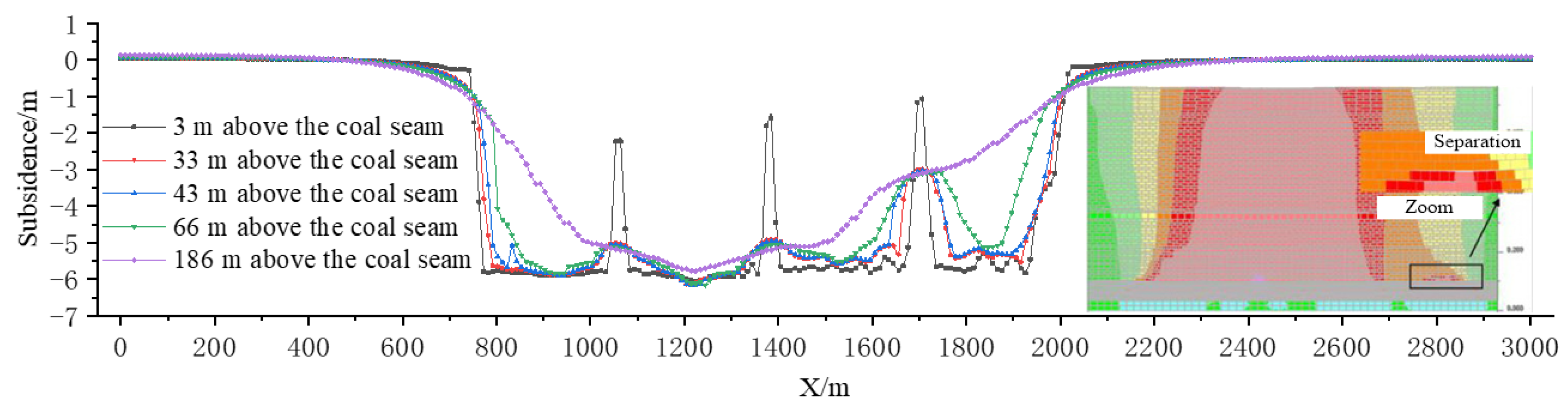

4.1. Displacement Evolution of Overburden Strata

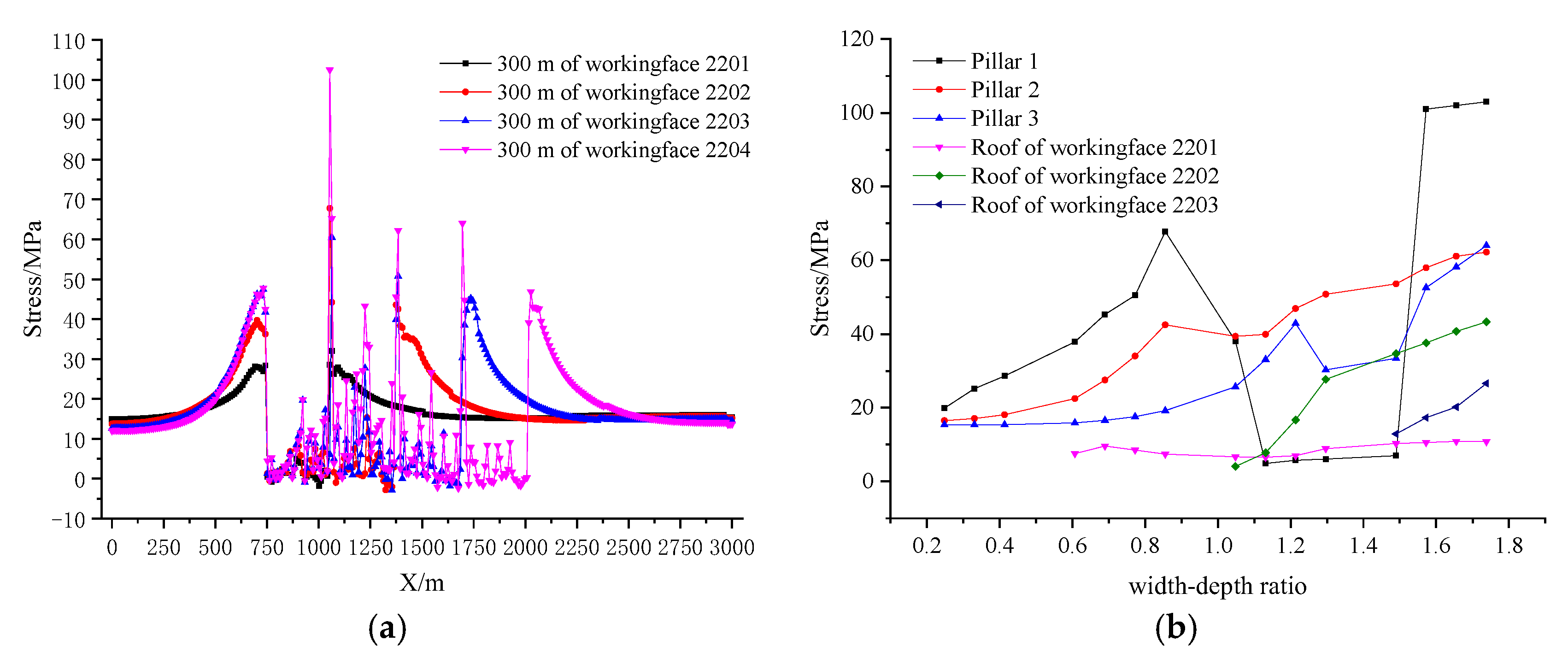

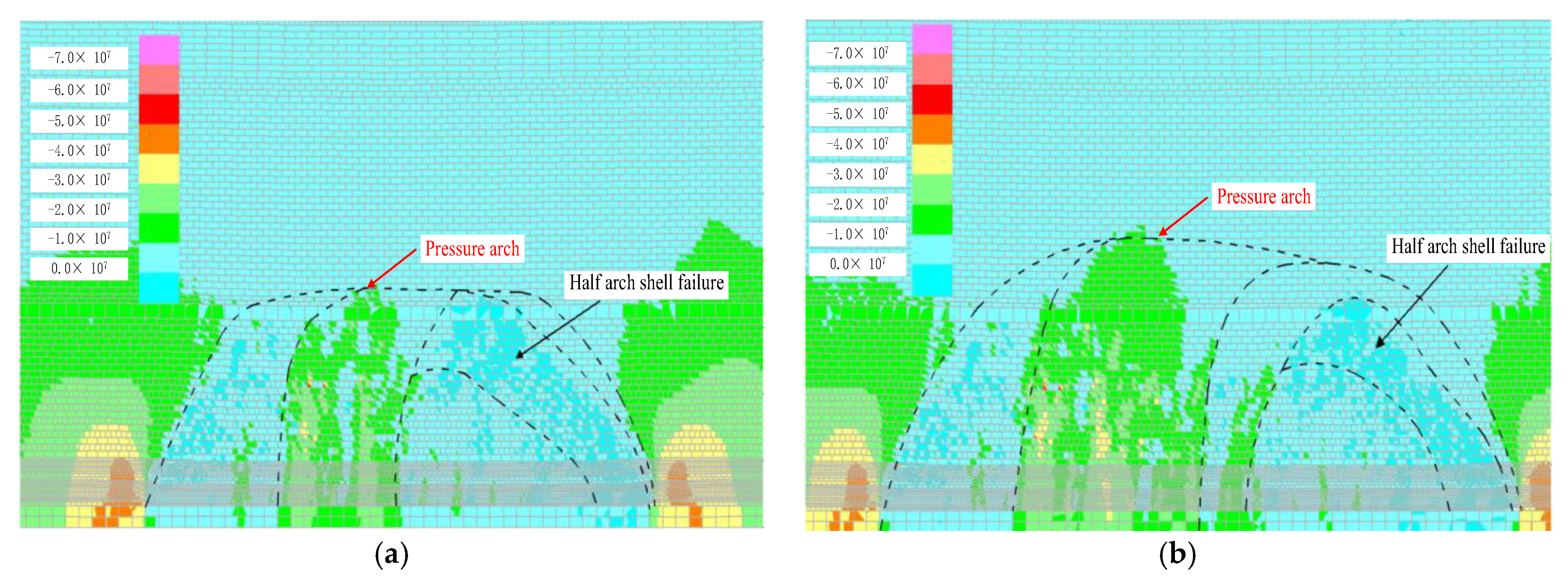

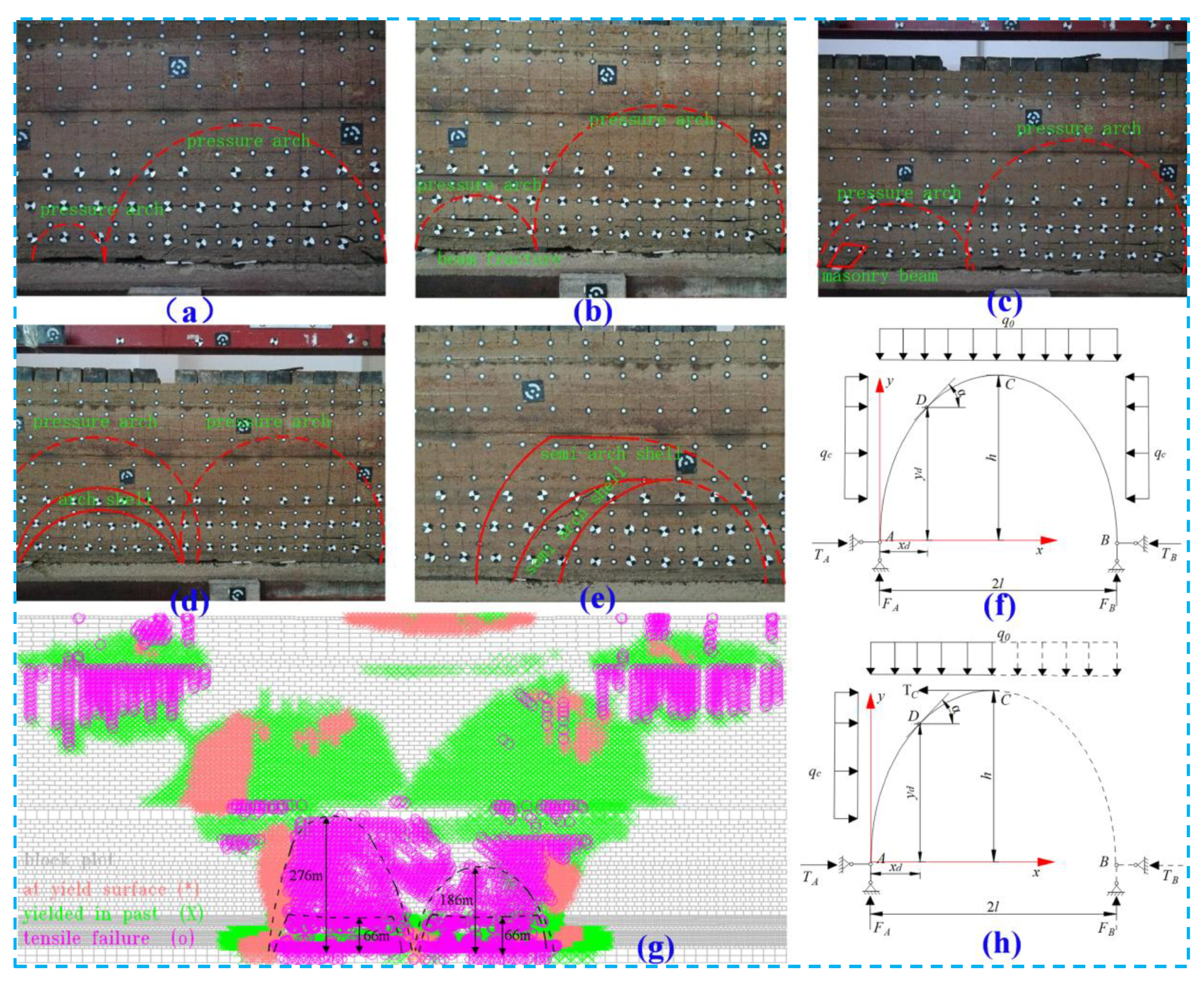

4.2. Evolution Law of the Stress Fields of the Overlying Strata

5. Discussions

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Y.; Xu, W.; Wu, P.; Meng, S. Dissolution versus cementation and its role in determining tight sandstone quality: A case study from the Upper Paleozoic in northeastern Ordos Basin, China. J. Nat. Gas Sci. Eng. 2020, 78, 103324. [Google Scholar] [CrossRef]

- Zhao, P.; Fan, X.; Zhang, Q.; Zhang, M.; Yao, B. Effects of hydration on physical properties and rock microstructure of shale oil reservoir in the Triassic Chang 7 Member of Southern Ordos Basin. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–19. [Google Scholar] [CrossRef]

- Jin, K.; Cheng, Y.; Wang, L.; Dong, J.; Guo, P.; An, F.; Jiang, L. The effect of sedimentary redbeds on coalbed methane occurrence in the Xutuan and Zhaoji Coal Mines, Huaibei Coalfield, China. Int. J. Coal Geol. 2015, 137, 111–123. [Google Scholar] [CrossRef]

- Park, N.; Holder, J.; Olson, J. Discrete Element Modeling of Fracture Toughness Tests in Weakly Cemented Sandstone. In Proceedings of the Gulf Rocks 2004, the 6th North America Rock Mechanics Symposium (NARMS), Houston, TX, USA, 5–10 June 2004. [Google Scholar]

- Li, H.; Wang, K.; Liu, C. Study on mechanical and acoustic emission characteristics of weakly cementation sandstone in Shendong coal field. J. Min. Saf. Eng. 2018, 35, 843–851. [Google Scholar]

- Zhang, Y.; Xu, W.-Y.; Gu, J.-J.; Wang, W. Triaxial creep tests of weak sandstone from fracture zone of high dam foundation. J. Cent. South Univ. 2013, 20, 2528–2536. [Google Scholar] [CrossRef]

- Zheng, W.; Guo, Y.; Zhi, G. Stability Analysis and Control Measures of Large-Span Open-Off Cut with Argillaceous Cemented Sandstone Layered Roof. Math. Probl. Eng. 2021, 2021, 8744081. (In Chinese) [Google Scholar] [CrossRef]

- Sun, L. Structural Evolution and Rock Pressure Activity Regularity of Weakly Cemented Strata of the Large Mining Height Work Face in Western China. Chin. J. Rock Mech. Eng. 2017, 36, 1820. (In Chinese) [Google Scholar]

- Lin, Y. Study on the Surface and Strata Movement Regular of Mining under the Hugely Thick Sand—Illustrated by the Case of Yingpanhao Mine. Master’s Thesis, China University of Mining and Technology, Beijing, China, 2018. (In Chinese). [Google Scholar]

- Gao, S. Study on the Development Law and Hydrogeological Effection of the Water Flowing Fractured Zone in the Western Jurassic Strata. Master’s Thesis, China University of Mining and Technology, Beijing, China, 2018. (In Chinese). [Google Scholar]

- Zhang, W.; Sun, Y.; Zhang, D.; Zhang, L.; Tang, J.; Fan, G.; Liang, S. Three-dimensional Physical Simulation Test for Activity Laws of Mining-induced Overburden by Radon Detection in Yili Mining area of Xinjiang. J. Min. Saf. Eng. 2019, 36, 1102–1108. (In Chinese) [Google Scholar]

- Zhang, G.; Lv, Y.; Guo, G.; Yu, C. Monitoring deep mining similarity material model of super-thick and weak cementation overburden by digital photography. IOP Conf. Ser. Mater. Sci. Eng. 2020, 782, 022028. [Google Scholar] [CrossRef]

- Zhang, G.; Guo, G.; Lv, Y.; Gong, Y. Study on the Strata Movement Rule of the Ultrathick and Weak Cementation Overburden in Deep Mining by Similar Material Simulation: A Case Study in China. Math. Probl. Eng. 2020, 2020, 7356740. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, C.; Wang, W.; Sun, C.; Zhang, B. Height Prediction of Water Flowing Fractured Zone and Thickness Effect of Long Wall Caving in Thick Loose Seam with Weak Cementation. In Proceedings of the 9th China-Russia Symposium “Coal in the 21st Century: Mining, Intelligent Equipment and Environment Protection” (COAL 2018), Qingdao, China, 18–21 October 2018; Atlantis Press: Paris, France, 2018; pp. 1–8. (In Chinese). [Google Scholar]

- Li, Y.; Zhang, S.; Yang, Y.; Chen, H.; Li, Z.; Ma, Q. Study on the water bursting law and spatial distribution of fractures of mining overlying strata in weakly cemented strata in West China. Geomech. Eng. 2022, 28, 613–624. [Google Scholar]

- Du, Q.; Guo, G.; Li, H.; Gong, Y. Spatio-Temporal Evolution Law of Surface Subsidence Basin with Insufficient Exploitation of Deep Coal Resources in Aeolian Sand Area of Western China. Remote Sens. 2022, 14, 2536. [Google Scholar] [CrossRef]

- Gong, Y.; Guo, G.; Wang, L.; Zhang, G.; Zhang, G.; Fang, Z. Numerical Study on the Surface Movement Regularity of Deep Mining Underlying the Super-Thick and Weak Cementation Overburden: A Case Study in Western China. Sustainability 2022, 14, 1855. [Google Scholar] [CrossRef]

- Gong, Y.; Guo, G.; Zhang, G.; Guo, K.; Du, Q.; Wang, L. A Vertical Joint Spacing Calculation Method for UDEC Modeling of Large-Scale Strata and Its Influence on Mining-Induced Surface Subsidence. Sustainability 2021, 13, 13313. [Google Scholar] [CrossRef]

- Zhang, G.; Guo, G.; Shen, S.; Guo, Q.; Zhang, S.; Wu, J. Numerical Simulation Study of the Strata Movement Rule of Deep Mining with the Super-Thick and Weak Cementation Overburden: A Case Study in China. Math. Probl. Eng. 2021, 2021, 6806703. [Google Scholar] [CrossRef]

- Zhang, G.; Guo, G.; Gong, Y.; Xiao, A.; Zhao, T.; Li, H. Failure Mechanism of Giant-Thick Strata Characterized by Weak Cementation Based on Superimposed Similar Material Simulation. KSCE J. Civ. Eng. 2022, 26, 3355–3369. [Google Scholar] [CrossRef]

| Hole | Lithology | R/Mpa | E/Mpa | C/Mpa | /° | (g/cm3) | |

|---|---|---|---|---|---|---|---|

| Hole 1 | coarse sandstone | 14.20 | 1835.75 | 0.34 | 2.19 | 26 | 2.36 |

| medium sandstone | 10.10 | 1338.44 | 0.30 | 2.02 | 26 | 2.23 | |

| fine sandstone | 12.30 | 1748.47 | 0.28 | 2.43 | 27 | 2.26 | |

| silt sandstone | 12.20 | 1573.43 | 0.30 | 2.57 | 27 | 2.22 | |

| Hole 2 | coarse sandstone | 11.96 | 3173.11 | 0.31 | 2.21 | 25 | 2.18 |

| medium sandstone | 15.00 | 1950.14 | 0.31 | 2.16 | 26 | 2.09 | |

| fine sandstone | 11.67 | 1639.94 | 0.30 | 1.31 | 25 | 2.18 | |

| silt sandstone | 10.42 | 777.77 | 0.32 | 1.45 | 28 | 1.93 | |

| Hole 3 | coarse sandstone | 16.36 | 2692.51 | 0.29 | 3.66 | 22 | 2.23 |

| medium sandstone | 15.11 | 2159.67 | 0.30 | 2.31 | 25 | 2.26 | |

| fine sandstone | 14.33 | 1523.21 | 0.31 | 1.76 | 23 | 2.22 | |

| Average | coarse sandstone | 14.17 | 2567.12 | 0.31 | 2.69 | 25 | 2.26 |

| medium sandstone | 13.40 | 1816.08 | 0.30 | 2.16 | 26 | 2.19 | |

| fine sandstone | 12.77 | 1637.20 | 0.30 | 1.83 | 25 | 2.22 | |

| silt sandstone | 11.31 | 1175.60 | 0.31 | 2.01 | 28 | 2.08 |

| Rock | Mineral Content (%) | ||||||

|---|---|---|---|---|---|---|---|

| Quartz | Potash Feldspar | Plagioclase | Calcite | Dolomite | Hematite | TCCM | |

| Anding formation sandstone | 26.3 | 7.2 | 21.1 | 0 | 0 | 4.3 | 41.3 |

| Zhidan group sandstone | 54.1 | 11.5 | 18.4 | 5.1 | 2.4 | 0 | 8.5 |

| Zhiluo formation sandstone | 35.0 | 13.8 | 18.4 | 0 | 0 | 0 | 32.8 |

| Yan’an formation sandstone | 17.3 | 6.6 | 17.1 | 0 | 42.9 | 0 | 16.3 |

| Parameters | Coal | Zhiluo Formation Sandstone | Anding-Zhiluo Formation Sandstone | Anding Formation Sandstone | Zhidan Group Sandstone | Loose |

|---|---|---|---|---|---|---|

| γ/(KN/m3) | 1.21 × 101 | 2.42 × 101 | 2.38 × 101 | 2.27 × 101 | 2.12 × 101 | 1.98 × 101 |

| K/(Pa) | 1.35 × 109 | 8.28 × 109 | 8.72 × 109 | 8.50 × 109 | 5.34 × 109 | 7.92 × 108 |

| G/(Pa) | 5.87 × 108 | 6.17 × 109 | 6.36 × 109 | 6.23 × 109 | 4.04 × 109 | 4.12 × 108 |

| Friction/(°) | 6 | 2.70 × 101 | 2.80 × 101 | 2.60 × 101 | 2.70 × 101 | 2.00 × 101 |

| Cohesion/(Pa) | 8.89 × 106 | 6.99 × 106 | 7.39 × 106 | 5.23 × 106 | 2.28 × 106 | 6.50 × 105 |

| Tension/(Pa) | 1.35 × 106 | 3.26 × 106 | 3.39 × 106 | 3.03 × 106 | 1.42 × 106 | 5.55 × 105 |

| Jkn/(Pa) | 1.05 × 1011 | 4.98 × 109 | 5.42 × 109 | 5.20 × 109 | 2.04 × 109 | 6.62 × 108 |

| Jks/(Pa) | 5.57 × 1011 | 4.87 × 109 | 3.74 × 109 | 4.93 × 109 | 7.40 × 108 | 2.82 × 108 |

| Jcohesion/(Pa) | 8.59 × 106 | 6.99 × 106 | 7.39 × 106 | 5.23 × 106 | 2.28 × 106 | 6.50 × 105 |

| Jfriction/(°) | 6 | 2.70 × 101 | 2.80 × 101 | 2.60 × 101 | 2.70 × 101 | 2.00 × 101 |

| Jtension/(Pa) | 1.05 × 106 | 3.96 × 106 | 3.39 × 106 | 3.03 × 106 | 1.42 × 106 | 5.55 × 105 |

| Boundary conditions | Set gravity 0–9.81 Bound x-velocity = 0 range x −0.1,0.1 Bound x-velocity = 0 range x 2999.9,3000.1 Bound y-velocity = 0 range y −0.1,0.1 |

| Size | Block 0,0 0,763 3000,763 3000,0 |

| Others | Round = 0.1, Edge = 24 |

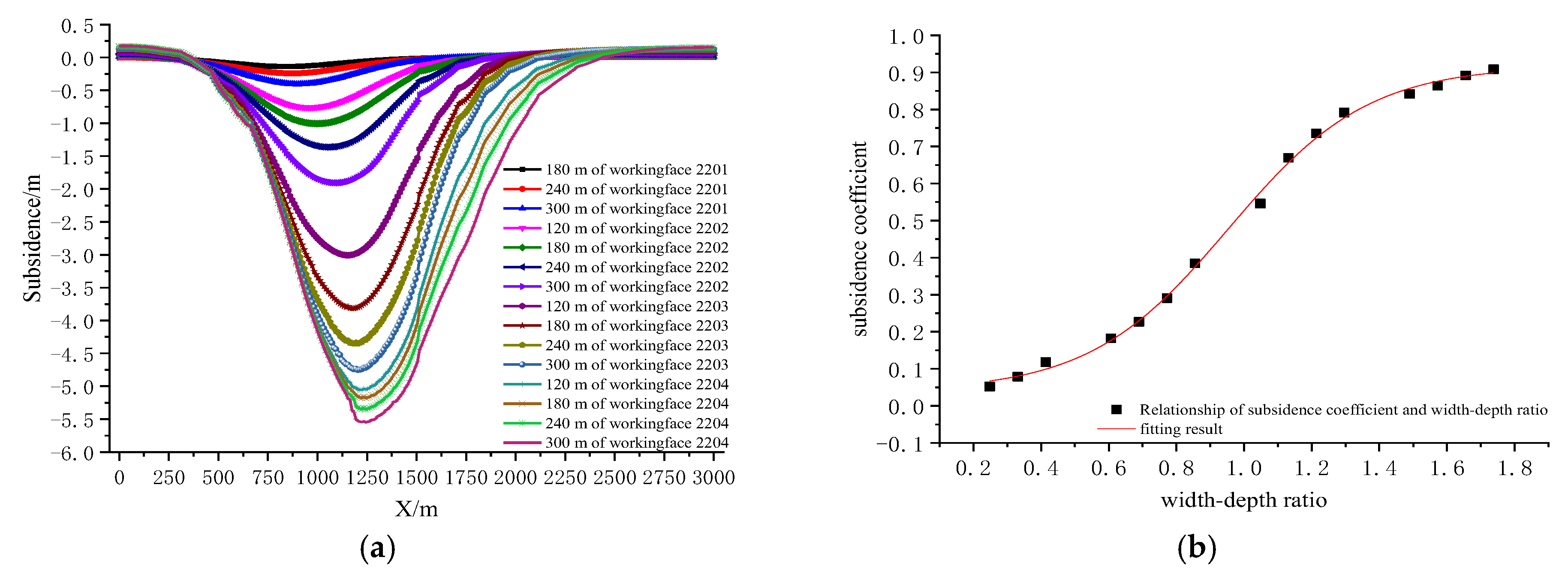

| Mining Process | Mining Width/m | Mining Depth/m | Width-Depth Ratio | Subsidence/mm | q |

|---|---|---|---|---|---|

| Working face 2201-180 m | 180 | 725 | 0.25 | 139 | 0.05 |

| Working face 2201-240 m | 240 | 725 | 0.33 | 242 | 0.08 |

| Working face 2201-300 m | 300 | 725 | 0.41 | 407 | 0.12 |

| Working face 2202-120 m | 440 | 725 | 0.61 | 761 | 0.18 |

| Working face 2202-180 m | 500 | 725 | 0.69 | 1010 | 0.23 |

| Working face 2202-240 m | 560 | 725 | 0.77 | 1370 | 0.29 |

| Working face 2202-300 m | 620 | 725 | 0.86 | 1910 | 0.38 |

| Working face 2203-120 m | 760 | 725 | 1.05 | 3000 | 0.55 |

| Working face 2203-180 m | 820 | 725 | 1.13 | 3820 | 0.67 |

| Working face 2203-240 m | 880 | 725 | 1.21 | 4350 | 0.74 |

| Working face 2203-300 m | 940 | 725 | 1.30 | 4750 | 0.79 |

| Working face 2204-120 m | 1080 | 725 | 1.49 | 5050 | 0.84 |

| Working face 2204-180 m | 1140 | 725 | 1.57 | 5180 | 0.86 |

| Working face 2204-240 m | 1200 | 725 | 1.66 | 5350 | 0.89 |

| Working face 2204-300 m | 1260 | 725 | 1.74 | 5450 | 0.91 |

| Height above the Coal/m | Subsidence Value of the Overlying Strata at Different Buried Depths/mm | |||

|---|---|---|---|---|

| Working Face 2201-300 m | Working Face 2202-300 m | Working Face 2203-300 m | Working Face 2204-300 m | |

| 3 | 5880 | 5890 | 6000 | 6060 |

| 33 | 5820 | 5840 | 6020 | 6160 |

| 43 | 5800 | 5820 | 6020 | 6170 |

| 66 | 5390 | 5760 | 5920 | 6120 |

| 186 | 682 | 2640 | 5340 | 5790 |

| 236 | 625 | 2390 | 5180 | 5670 |

| 276 | 587 | 2300 | 5160 | 5660 |

| 312 | 562 | 2220 | 5130 | 5660 |

| 612 | 440 | 2030 | 5030 | 5520 |

| 725 | 407 | 1910 | 4750 | 5450 |

| Height above the Coal/m | Distance of the Subsidence Influence Boundary to Goaf Boundary/m | |||

|---|---|---|---|---|

| Working Face 2201-300 m | Working Face 2202-300 m | Working Face 2203-300 m | Working Face 2204-300 m | |

| 3 | 340 | 370 | 340 | 340 |

| 33 | 400 | 410 | 370 | 370 |

| 43 | 410 | 410 | 380 | 370 |

| 66 | 430 | 420 | 380 | 380 |

| 186 | 450 | 430 | 390 | 380 |

| 236 | 470 | 430 | 380 | 380 |

| 276 | 470 | 440 | 380 | 380 |

| 312 | 480 | 450 | 390 | 390 |

| 612 | 550 | 470 | 410 | 410 |

| 725 | 600 | 520 | 420 | 420 |

| Mining Order | Width Depth Ratio | Immediate Roof of Working Face 2201 | Pillar 1 | Immediate Roof of Working Face 2202 | Pillar 2 | Immediate Roof of Working Face 2203 | Pillar 3 |

|---|---|---|---|---|---|---|---|

| Working face 2201-180 m | 0.25 | no | 19.90 | no | 16.50 | no | 15.40 |

| Working face 2201-240 m | 0.33 | no | 25.20 | no | 17.10 | no | 15.40 |

| Working face 2201-300 m | 0.41 | no | 28.60 | no | 18.10 | no | 15.40 |

| Working face 2202-120 m | 0.61 | 7.56 | 37.90 | no | 22.50 | no | 15.90 |

| Working face 2202-180 m | 0.69 | 9.63 | 45.30 | no | 27.50 | no | 16.60 |

| Working face 2202-240 m | 0.77 | 8.52 | 50.50 | no | 34.00 | no | 17.60 |

| Working face 2202-300 m | 0.86 | 7.41 | 67.80 | no | 42.50 | no | 19.20 |

| Working face 2203-120 m | 1.05 | 6.71 | 38.10 | 4.08 | 39.40 | no | 25.70 |

| Working face 2203-180 m | 1.13 | 6.57 | 4.90 | 7.81 | 39.90 | no | 33.10 |

| Working face 2203-240 m | 1.21 | 6.99 | 5.74 | 16.70 | 46.90 | no | 42.90 |

| Working face 2203-300 m | 1.30 | 8.91 | 6.10 | 27.70 | 50.80 | no | 30.30 |

| Working face 2204-120 m | 1.49 | 10.30 | 7.01 | 34.70 | 53.60 | 12.90 | 33.40 |

| Working face 2204-180 m | 1.57 | 10.60 | 101.00 | 37.60 | 58.00 | 17.30 | 52.60 |

| Working face 2204-240 m | 1.66 | 10.90 | 102.00 | 40.70 | 61.10 | 20.20 | 58.20 |

| Working face 2204-300 m | 1.74 | 10.80 | 103.00 | 43.30 | 62.20 | 26.60 | 64.00 |

| Strata | Proportion (Sand:Micas:Cement) | Cement (Gypsum:CaCO3) | Saw Dust | Water |

|---|---|---|---|---|

| Coarse sandstone | 80:17:3 | 3:7 | 0 | 10% |

| Sandy mudstone 4 | 80:18:2 | 5:5 | 0 | 10% |

| Anding formation sandstone 4 | 73:23:4 | 3:7 | 0 | 10% |

| Anding-zhiluo formation sandstone | 80:18:2 | 5:5 | 0 | 10% |

| Zhiluo formation sandstone | 80:18:2 | 5:5 | 0 | 10% |

| Sandy mudstone 3 | 73:23:4 | 3:7 | 0 | 10% |

| Medium sandstone 1 | 80:18:2 | 7:3 | 0 | 10% |

| Sandy mudstone 2 | 80:17:3 | 5:5 | 0 | 10% |

| Coal | 80:17:3 | 3:7 | 0 | 10% |

| Sandy mudstone 1 | 73:23:4 | 5:5 | 0 | 10% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Guo, G.; Wei, W.; Wang, J.; Li, H.; Du, Q. Mechanical Properties and Failure Mechanism of the Weakly Cemented Overburden in Deep Mining. Minerals 2022, 12, 1276. https://doi.org/10.3390/min12101276

Zhang G, Guo G, Wei W, Wang J, Li H, Du Q. Mechanical Properties and Failure Mechanism of the Weakly Cemented Overburden in Deep Mining. Minerals. 2022; 12(10):1276. https://doi.org/10.3390/min12101276

Chicago/Turabian StyleZhang, Guojian, Guangli Guo, Wei Wei, Jun Wang, Huaizhan Li, and Qiu Du. 2022. "Mechanical Properties and Failure Mechanism of the Weakly Cemented Overburden in Deep Mining" Minerals 12, no. 10: 1276. https://doi.org/10.3390/min12101276

APA StyleZhang, G., Guo, G., Wei, W., Wang, J., Li, H., & Du, Q. (2022). Mechanical Properties and Failure Mechanism of the Weakly Cemented Overburden in Deep Mining. Minerals, 12(10), 1276. https://doi.org/10.3390/min12101276