Solidification/Stabilization of MSWI Fly Ash Using a Novel Metallurgical Slag-Based Cementitious Material

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Binder-MSWI Fly Ash Blocks

2.3. Leaching Tests and the Characterization

3. Results and Discussion

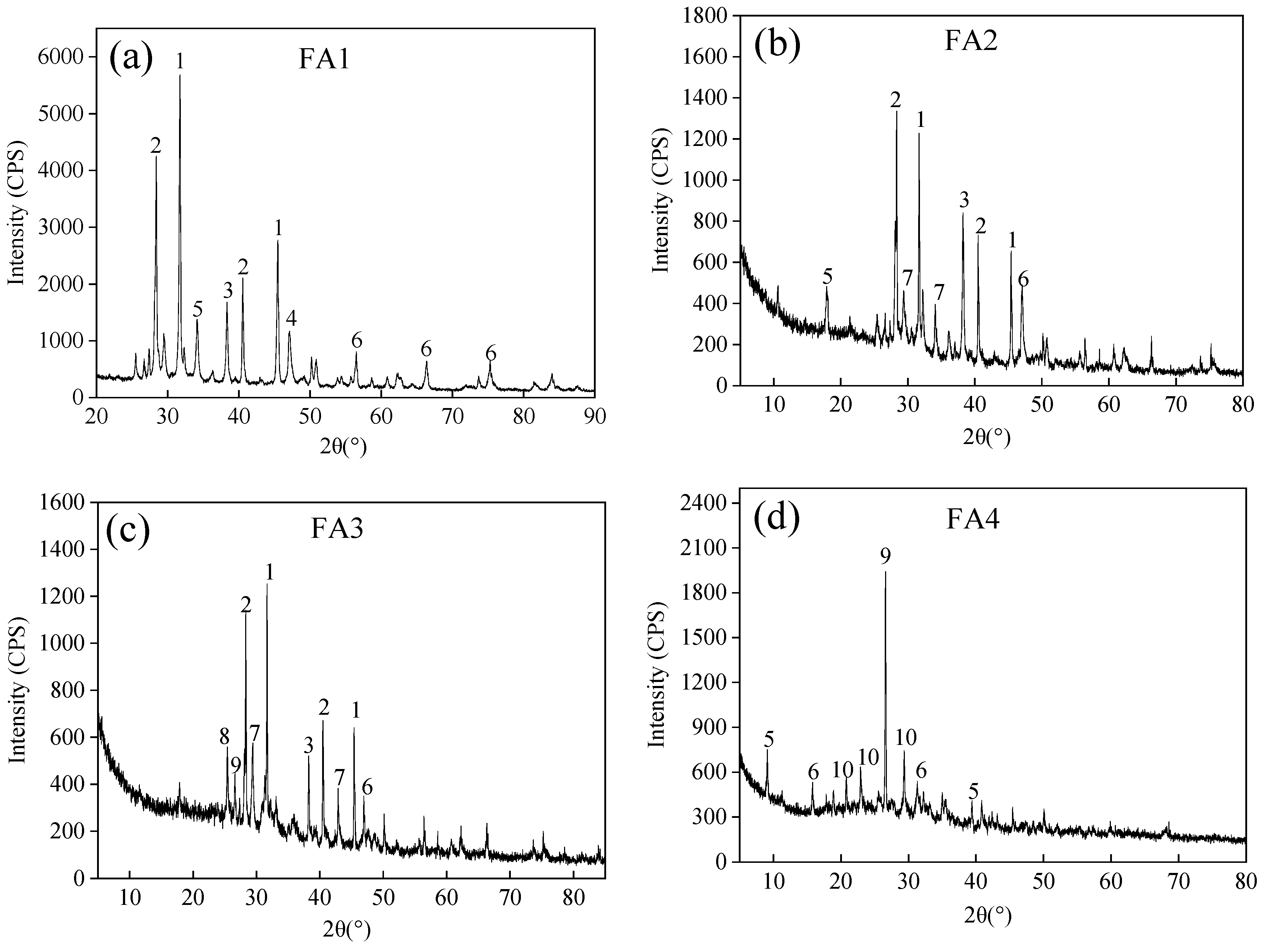

3.1. Characterization of MSWI Fly Ashes

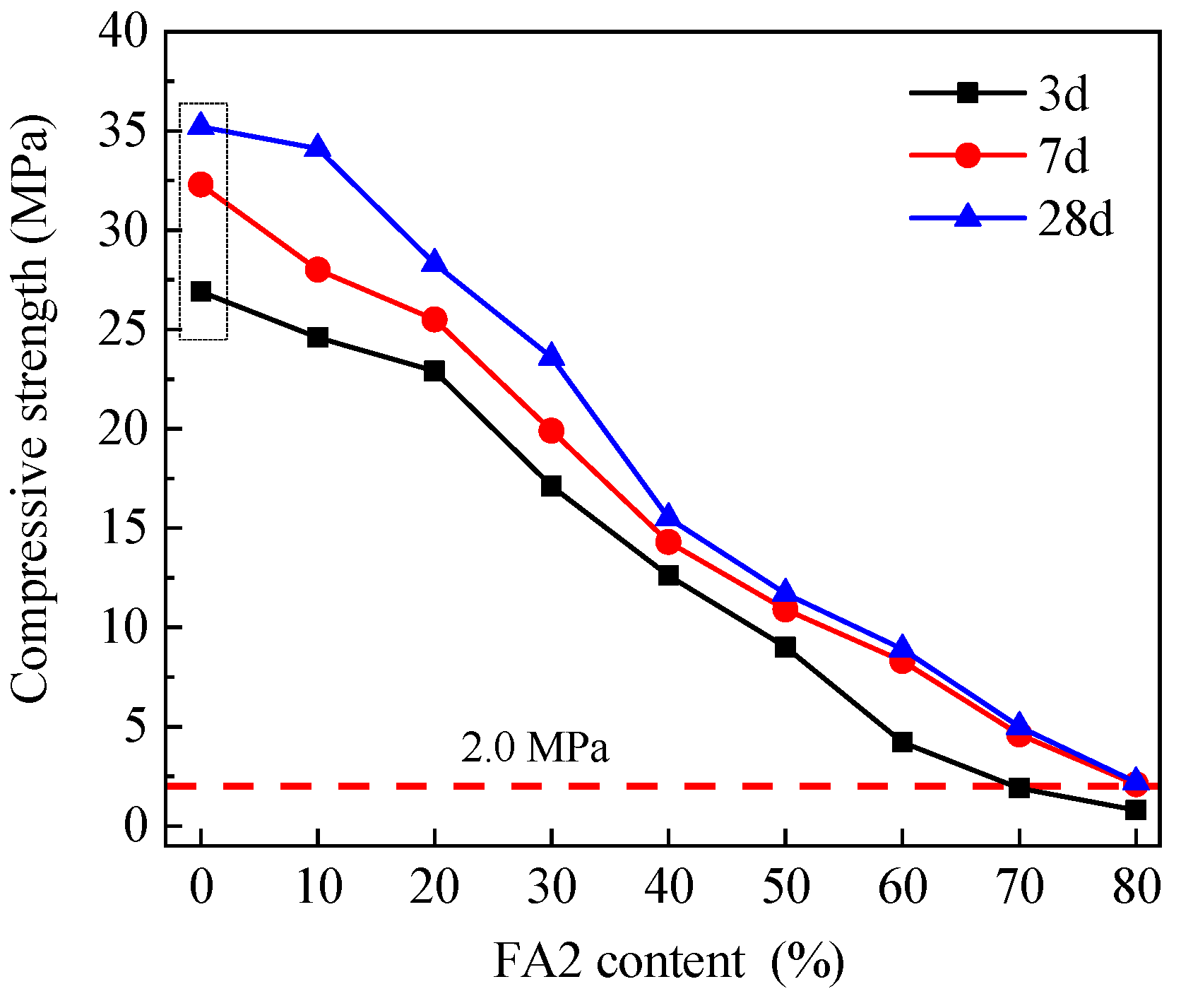

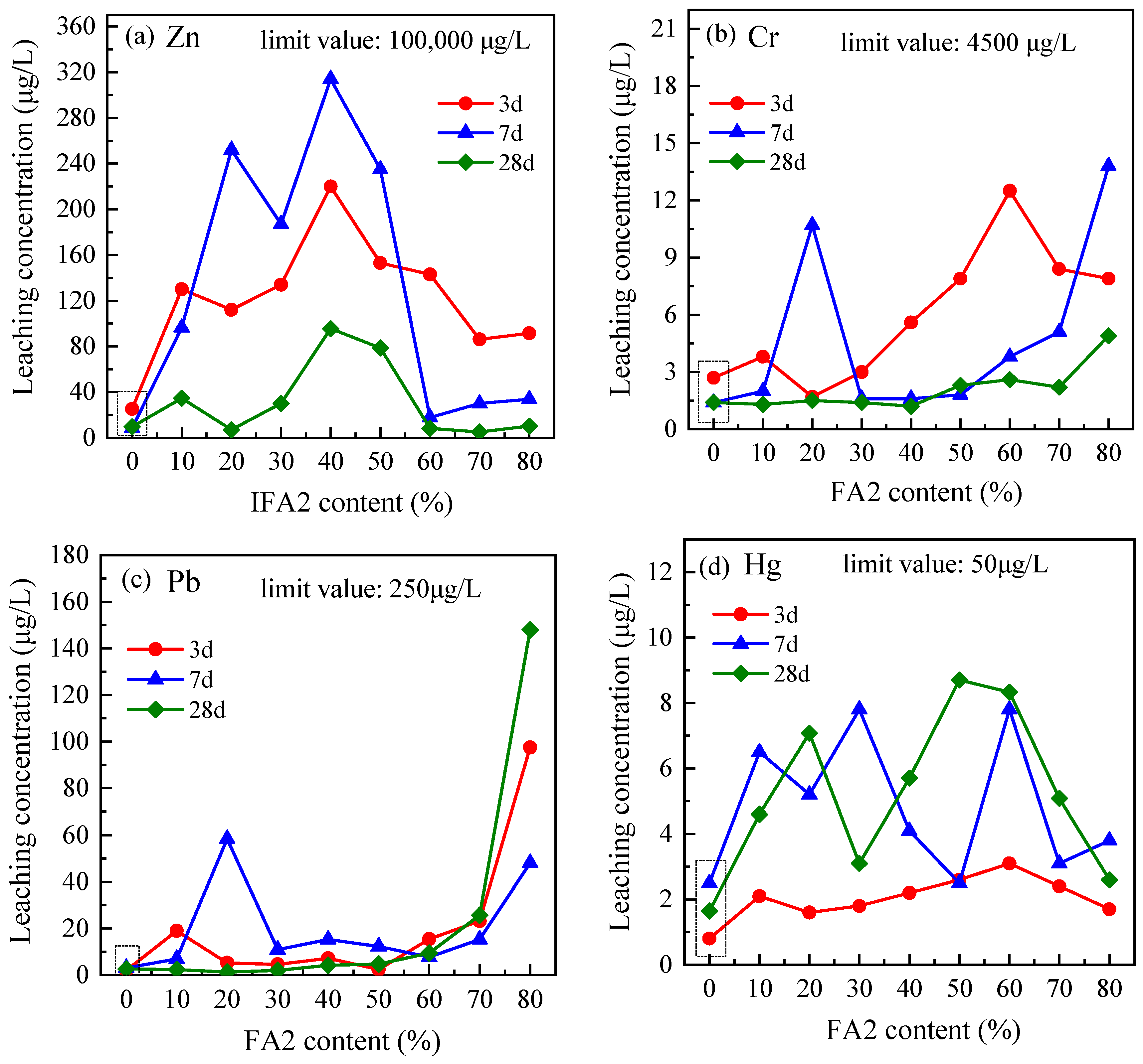

3.2. Solidification of MSWI Fly Ash with Different Proportions

3.3. Solidification of Four Kinds of MSWI Fly Ashes

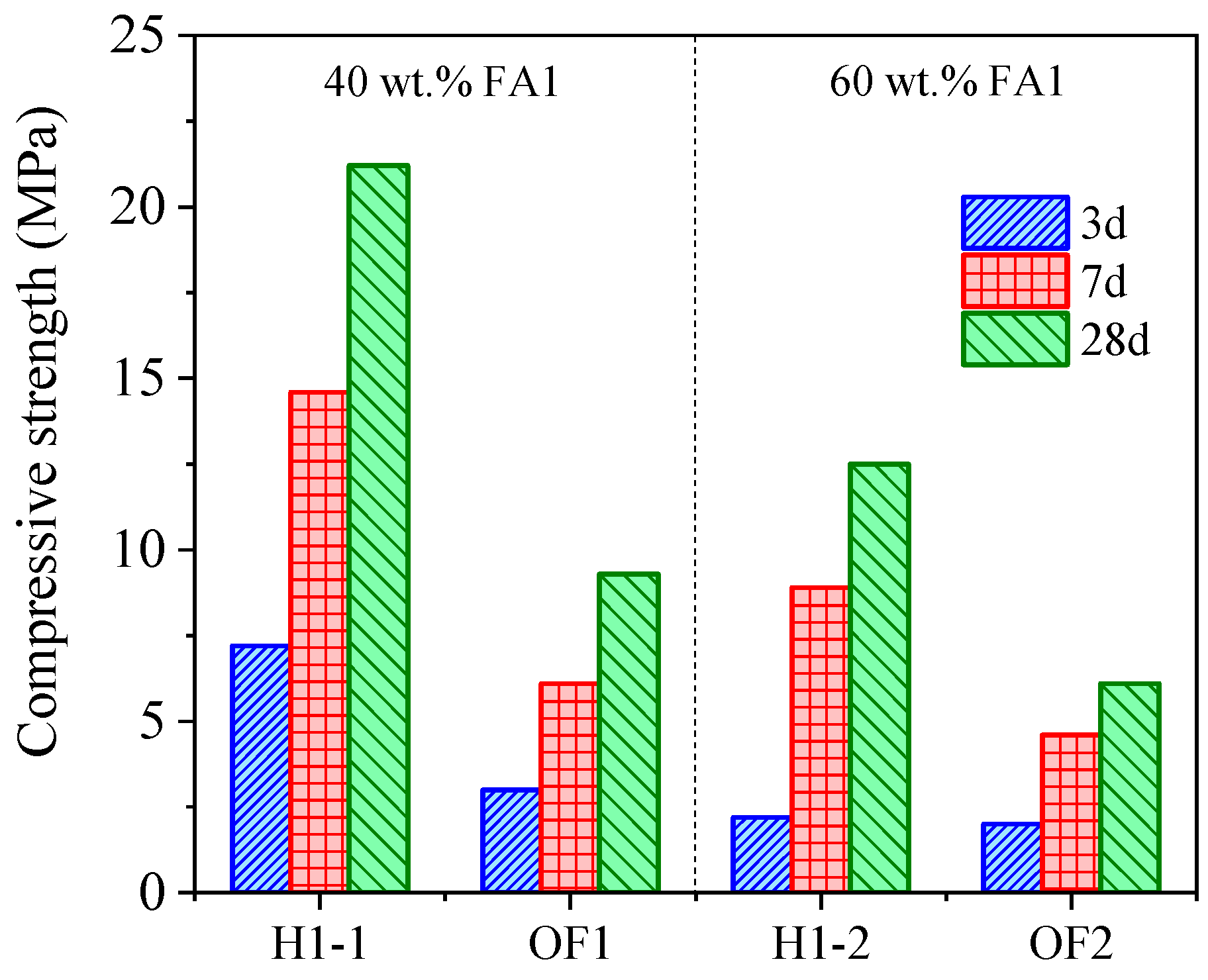

3.4. Comparison of MSWI Fly Ash Solidification by MSCM and OPC

3.5. Solidification Mechanisms of MSWI Fly Ash

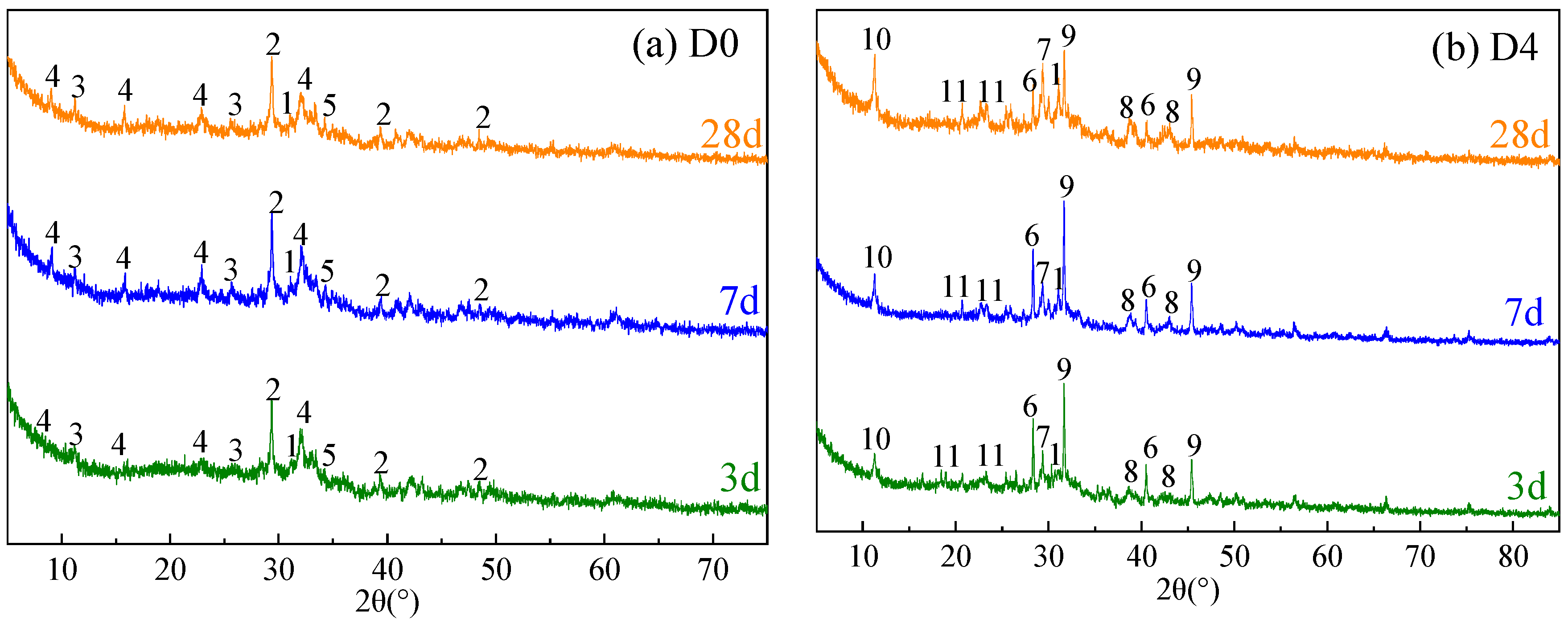

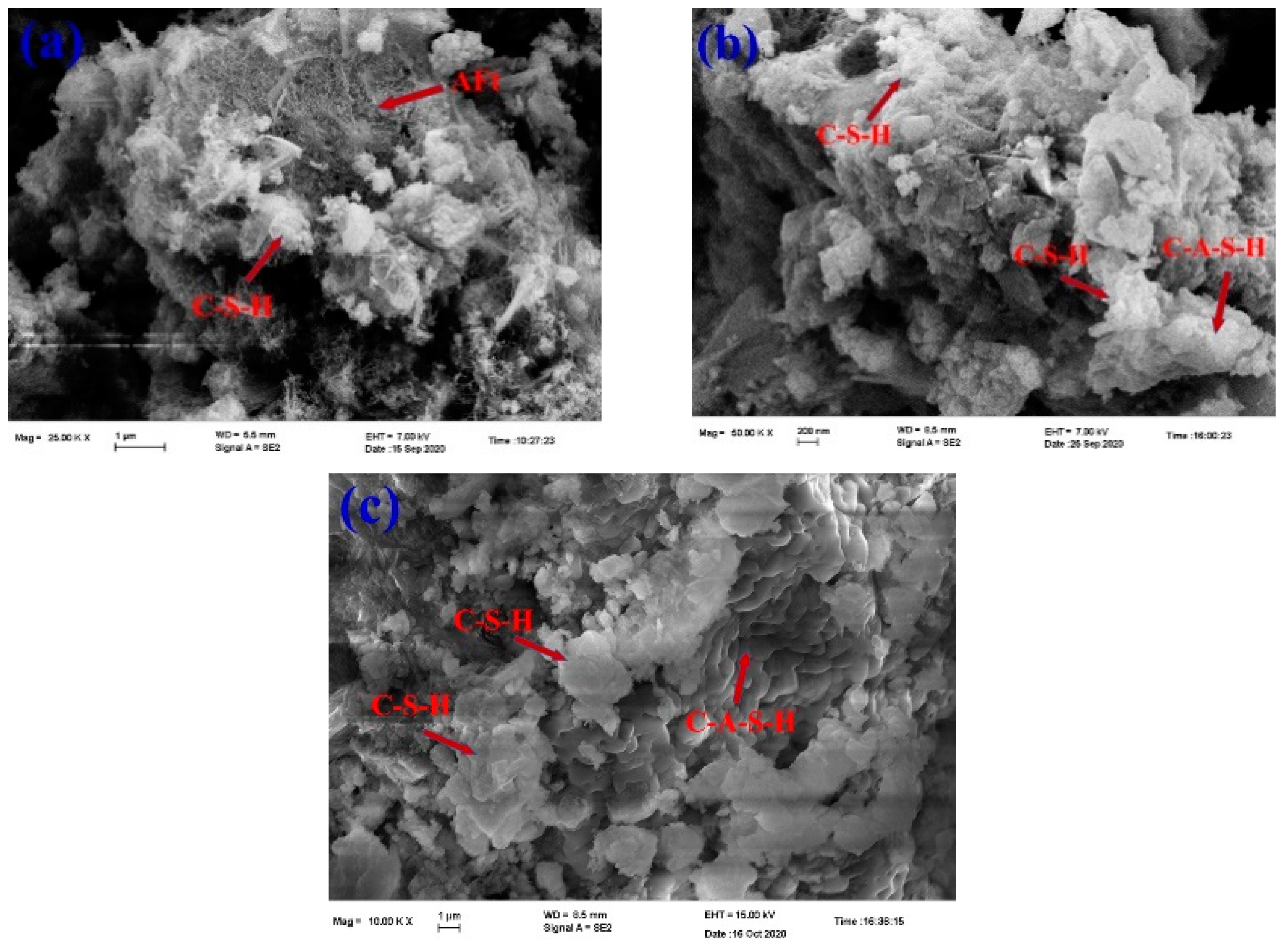

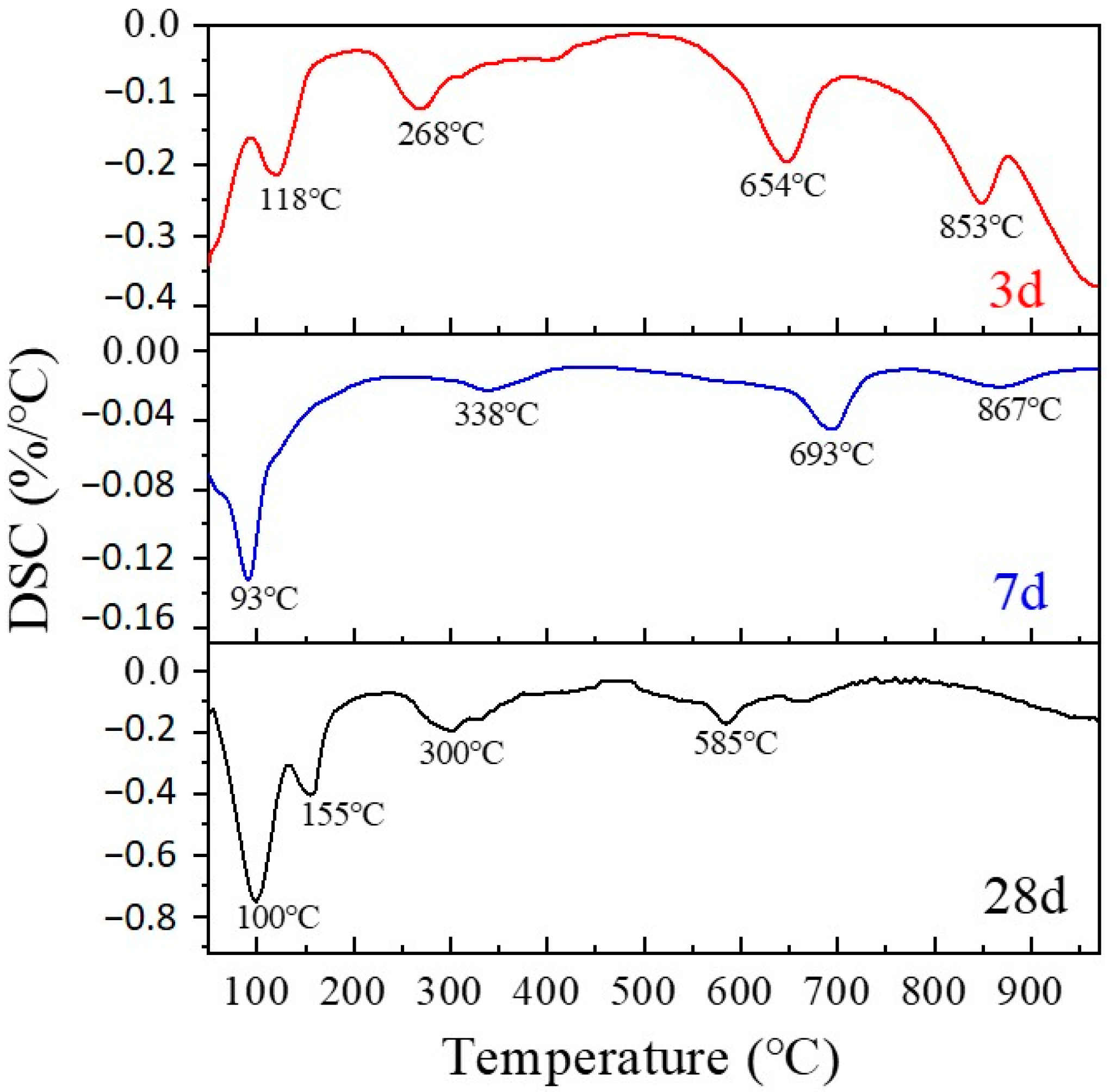

3.5.1. Formation of Hydration Products

3.5.2. Immobilization Mechanisms of Heavy Metals

4. Conclusions

- (1)

- The MSCM exhibited high-hydration reactivity, achieving 3-day and 28-day strengths of 26.9 and 35.2 MPa for pure MSCM pastes, respectively. While the FA2 content was as high as 80 wt.%, the 28-day strength of MSCM-FA2 blocks reached 2.2 MPa, and the leaching concentrations of Zn, Cr, Hg, and Pb were far below the limit values of the Chinese landfill standard (GB 16889-2008). The immobilization rates of Zn, Cr, and Pb were above 99.90%, and that of Hg was above 98.70% for tour kinds of MSWI fly ashes.

- (2)

- The 28-day strength of MSCM-fly ash blocks reached 8.9–13.0 MPa at fly ash content of 60 wt.%. The 28-day strength of binder-FA1 blocks had an increase of 104.92–127.96% by using MSCM to replace OPC. Additionally, the MSCM-FA1 blocks could achieve much lower leaching concentrations of heavy metals than OPC-FA1 blocks. Compared to widely used OPC, the MSCM had the merits of lower cost, lower CO2 emission, and higher efficiency in the solidification/stabilization of MSWI fly ash.

- (3)

- The XRD, SEM, and TG-DSC analysis confirmed the formation of numerous hydrates, e.g., C-S-H gel, AFt, Ca(OH)2, C-A-S-H, and Friedel’s salt, in the hydration process. Heavy metals in MSWI fly ash could be effectively immobilized via adsorption, cation exchange, precipitation, and physical encapsulation.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, Y.; Glad, T.; Zhong, Z.Z.; He, R.N.; Tian, J.P.; Chen, L.J. Environmental life-cycle assessment of municipal solid waste incineration stocks in Chinese industrial parks. Resour. Conserv. Recycl. 2018, 139, 387–395. [Google Scholar] [CrossRef]

- Istrate, I.R.; Galvez-Martos, J.L.; Dufour, J. The impact of incineration phase-out on municipal solid waste landfilling and life cycle environmental performance: Case study of Madrid, Spain. Sci. Total Environ. 2021, 755, 142537. [Google Scholar] [CrossRef] [PubMed]

- Carignan, J.; Libourel, G.; Cloquet, C.; Le Forestier, L. Lead isotopic composition of fly ash and flue gas residues from municipal solid waste combustors in France: Implications for atmospheric lead source tracing. Environ. Sci. Technol. 2005, 39, 2018–2024. [Google Scholar] [CrossRef] [Green Version]

- Bie, R.S.; Chen, P.; Song, X.F.; Ji, X.Y. Characteristics of municipal solid waste incineration fly ash with cement solidification treatment. J. Energy Inst. 2016, 89, 704–712. [Google Scholar] [CrossRef]

- Pedersen, A.J.; Frandsen, F.J.; Riber, C.; Astrup, T.; Thomsen, S.N.; Lundtorp, K.; Mortensen, L.F. A full-scale study on the partitioning of trace elements in municipal solid waste incineration-effects of firing different waste types. Energy Fuels 2009, 23, 3475–3489. [Google Scholar] [CrossRef]

- Polettini, A.; Pomi, R.; Sirini, P.; Testa, F. Properties of Portland cement-stabilised MSWI fly ashes. J. Hazard. Mater. 2001, 88, 123–138. [Google Scholar] [CrossRef]

- Li, J.T.; Zeng, M.; Ji, W.X. Characteristics of the cement-solidified municipal solid waste incineration fly ash. Environ. Sci. Pollut. Res. 2018, 25, 36736–36744. [Google Scholar] [CrossRef]

- Suzuki, K.; Ono, Y. Leaching characteristics of stabilized/solidified fly ash generated from ash-melting plant. Chemosphere 2008, 71, 922–932. [Google Scholar] [CrossRef]

- Gineys, N.; Aouad, G.; Damidot, D. Managing trace elements in Portland cement—Part I: Interactions between cement paste and heavy metals added during mixing as soluble salts. Cem. Concr. Compos. 2010, 32, 563–570. [Google Scholar] [CrossRef]

- Tang, Q.; Liu, Y.; Gu, F.; Zhou, T. Solidification/stabilization of fly ash from a municipal solid waste incineration facility using portland cement. Adv. Mater. Sci. Eng. 2016, 2016, 7101243. [Google Scholar] [CrossRef] [Green Version]

- Dutre, V.; Vandecasteele, C. Immobilization mechanism of arsenic in waste solidified by using cement and lime. Environ. Sci. Technol. 1998, 32, 2782–2787. [Google Scholar] [CrossRef]

- Du, B.; Li, J.T.; Fang, W.; Liu, Y.L.; Yu, S.Y.; Li, Y.; Liu, J.G. Characterization of naturally aged cement-solidified MSWI fly ash. Waste Manag. 2018, 80, 101–111. [Google Scholar] [CrossRef] [PubMed]

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Lynn, C.J.; Dhir, R.K. Use of municipal solid waste incineration bottom ashes in alkali activated materials, ceramics and granular applications: A review. Waste Manag. 2017, 68, 207–220. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Zhang, S.Q.; Ni, W.; Yan, Q.H.; Gao, W.; Li, Y.Y. Immobilisation of high-arsenic-containing tailings by using metallurgical slag-cementing materials. Chemosphere 2019, 223, 117–123. [Google Scholar] [CrossRef]

- Huang, X.; Zhuang, R.L.; Muhammad, F.; Yu, L.; Shiau, Y.C.; Li, D.W. Solidification/stabilization of chromite ore processing residue using alkali-activated composite cementitious materials. Chemosphere 2017, 168, 300–308. [Google Scholar] [CrossRef]

- Zhang, M.T.; Yang, C.H.; Zhao, M.; Yang, K.; Shen, R.; Zheng, Y.J. Immobilization potential of Cr(VI) in sodium hydroxide activated slag pastes. J. Hazard. Mater. 2017, 321, 281–289. [Google Scholar] [CrossRef]

- Lee, T.C.; Li, Z.S. Conditioned MSWI ash-slag-mix as a replacement for cement in cement mortar. Constr. Build. Mater. 2010, 24, 970–979. [Google Scholar] [CrossRef]

- Marjanovic, N.; Komljenovic, M.; Bascarevic, Z.; Nikolic, V. Comparison of two alkali-activated systems: Mechanically activated fly ash and fly ash-blast furnace slag blends. Procedia Eng. 2015, 108, 231–238. [Google Scholar] [CrossRef] [Green Version]

- Jang, G.G.; Ladshaw, A.; Keum, J.K.; Zhang, P.; Tsouris, C. Continuous-flow centrifugal solid/liquid separation for the recovery of rare-earth elements containing particles from phosphoric acid sludge. Ind. Eng. Chem. Res. 2020, 59, 21901–21913. [Google Scholar] [CrossRef]

- Sugiyama, S.; Imanishi, K.; Shimoda, N.; Liu, J.C.; Satou, H.; Yamamoto, T. Recovery of phosphoric acid and calcium phosphate from dephosphorization slag. J. Chem. Eng. Jpn. 2021, 54, 467–471. [Google Scholar] [CrossRef]

- Xia, Z.R.; Lin, J.; Chi, Y.W.; Wang, J.D. Hydrothermal solidification mechanism of calcareous materials and resource utilization of desulfurization ash. Glass Phys. Chem. 2020, 46, 53–63. [Google Scholar]

- Wang, C.Q.; Tan, K.F.; Xu, X.X.; Wang, P.X. Effect of activators, admixtures and temperature on the early hydration performance of desulfurization ash. Constr. Build. Mater. 2014, 70, 322–331. [Google Scholar] [CrossRef]

- Du, Y.J.; Wei, M.L.; Reddy, K.R.; Jin, F.; Wu, H.L.; Liu, Z.B. New phosphate-based binder for stabilization of soils contaminated with heavy metals: Leaching, strength and microstructure characterization. J. Environ. Manag. 2014, 146, 179–188. [Google Scholar] [CrossRef] [PubMed]

- Remond, S.; Pimienta, P.; Bentz, D.P. Effects of the incorporation of municipal solid waste incineration fly ash in cement pastes and mortars: I. Experimental study. Cem. Concr. Res. 2002, 32, 303–311. [Google Scholar] [CrossRef]

- Ma, W.C.; Chen, D.M.; Pan, M.H.; Gu, T.B.; Zhong, L.; Chen, G.Y.; Yan, B.B.; Cheng, Z.J. Performance of chemical chelating agent stabilization and cement solidification on heavy metals in MSWI fly ash: A comparative study. J. Environ. Manag. 2019, 247, 169–177. [Google Scholar] [CrossRef]

- Tang, P.; Chen, W.; Xuan, D.X.; Cheng, H.; Poon, C.S.; Tsang, D.C.W. Immobilization of hazardous municipal solid waste incineration fly ash by novel alternative binders derived from cementitious waste. J. Hazard. Mater. 2020, 393, 122386. [Google Scholar] [CrossRef]

- Shi, Z.; Geiker, M.R.; Lothenbach, B.; De Weerdt, K.; Garzon, S.F.; Enemark-Rasmussen, K.; Skibsted, J. Friedel’s salt profiles from thermogravimetric analysis and thermodynamic modelling of Portland cement-based mortars exposed to sodium chloride solution. Cem. Concr. Compos. 2017, 78, 73–83. [Google Scholar] [CrossRef]

- Li, X.Y.; Chen, Q.Y.; Zhou, Y.S.; Tyrer, M.; Yu, Y. Stabilization of heavy metals in MSWI fly ash using silica fume. Waste Manag. 2014, 34, 2494–2504. [Google Scholar] [CrossRef]

- Saikia, N.; Kato, S.; Kojima, T. Production of cement clinkers from municipal solid waste incineration (MSWI) fly ash. Waste Manag. 2007, 27, 1178–1189. [Google Scholar] [CrossRef]

- Coleman, N.J.; Li, Q.; Raza, A. Synthesis, structure and performance of calcium silicate ion exchangers from recycled container glass. Physicochem. Probl. Miner. Process. 2014, 50, 5–16. [Google Scholar]

- Rozumova, L.; Motyka, O.; Cabanova, K.; Seidlerova, J. Stabilization of waste bottom ash generated from hazardous waste incinerators. J. Environ. Chem. Eng. 2014, 3, 1–9. [Google Scholar] [CrossRef]

- Lilkov, V.; Rostovsky, I.; Petrov, O.; Tzvetanova, Y.; Savoy, P. Long term study of hardened cement pastes containing silica fume and fly ash. Constr. Build. Mater. 2014, 60, 48–56. [Google Scholar] [CrossRef]

- Fan, C.C.; Wang, B.M.; Zhang, T.T. Review on cement stabilization/solidification of municipal solid waste incineration fly ash. Adv. Mater. Sci. Eng. 2018, 2018, 5120649. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.Y.; Wang, L.; Chen, L.; Ma, B.; Zhang, Y.K.; Ni, W.; Tsang, D.C.W. Treatment of municipal solid waste incineration fly ash: State-of-the-art technologies and future perspectives. J. Hazard. Mater. 2021, 411, 125132. [Google Scholar] [CrossRef]

- Billen, P.; Verbinnen, B.; De Smet, M.; Dockx, G.; Ronsse, S.; Villani, K.; De Greef, J.; Van Caneghem, J.; Vandecasteele, C. Comparison of solidification/stabilization of fly ash and air pollution control residues from municipal solid waste incinerators with and without cement addition. J. Mater. Cycles Waste Manag. 2015, 17, 229–236. [Google Scholar] [CrossRef]

- Wang, B.M.; Fan, C.C. Hydration behavior and immobilization mechanism of MgO-SiO2-H2O cementitious system blended with MSWI fly ash. Chemosphere 2020, 250, 126269. [Google Scholar] [CrossRef]

- Wang, C.P.; Li, F.Z.; Zhou, M.K.; Chen, Y.; Chen, X. Effect of cement-MSWI fly ash hydration on the stabilisation/solidification of Pb and Cd. Mater. Res. Innov. 2015, 19, S5-1161–S5-1166. [Google Scholar] [CrossRef]

- Qian, G.R.; Shi, J.; Cao, Y.L.; Xu, Y.F.; Chui, P.C. Properties of MSW fly ash-calcium sulfoaluminate cement matrix and stabilization/solidification on heavy metals. J. Hazard. Mater. 2008, 152, 196–203. [Google Scholar] [CrossRef]

- Sugiyama, S.; Shimizu, Y.; Manabe, T.; Nakagawa, K.; Sotowa, K.I. Preparation of a hydroxyapatite film and its application in the removal and regeneration of aqueous cations. J. Colloid Interface Sci. 2009, 332, 439–443. [Google Scholar] [CrossRef]

- Nag, M.; Saffarzadeh, A.; Nomichi, T.; Shimaoka, T.; Nakayama, H. Enhanced Pb and Zn stabilization in municipal solid waste incineration fly ash using waste fishbone hydroxyapatite. Waste Manag. 2020, 118, 281–290. [Google Scholar] [CrossRef] [PubMed]

| Raw Materials | Components (%) | Heavy Metal Contents (mg/kg) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fe2O3 | Al2O3 | SiO2 | CaO | MgO | K2O | P2O5 | SO3 | F | Zn | Cr | Pb | Hg | |

| Blast furnace slag (BFS) | 1.07 | 15.73 | 35.03 | 36.61 | 8.59 | 0.01 | 0.36 | 0.09 | -- | 16.67 | 36.91 | 0.06 | 0.32 |

| Steel slag (SS) | 26.32 | 4.3 | 14.17 | 38.96 | 8.22 | 0.01 | 1.29 | 0.18 | -- | 39.75 | 442.30 | 1.26 | 0.17 |

| Desulfurization ash (DA) | 5.65 | 0.83 | 2.12 | 32.23 | 0.83 | 3.2 | 0.83 | 17.44 | -- | 192.20 | 27.45 | 2412.81 | 2.35 |

| Phosphoric acid sludge (PAS) | 0.48 | 1.14 | 4.73 | 44.52 | 1.56 | 0.32 | 21.76 | 0.39 | 14.67 | 50.95 | 3.84 | 4.22 | 0.01 |

| Fly Ash Blocks | Binder | Mswi Fly Ash | Proportion of Binder (wt.%) | Proportion of Mswi Fly Ash (wt.%) |

|---|---|---|---|---|

| D0 | MSCM | FA2 | 100 | 0 |

| D1 | MSCM | FA2 | 90 | 10 |

| D2 | MSCM | FA2 | 80 | 20 |

| D3 | MSCM | FA2 | 70 | 30 |

| D4 | MSCM | FA2 | 60 | 40 |

| D5 | MSCM | FA2 | 50 | 50 |

| D6 | MSCM | FA2 | 40 | 60 |

| D7 | MSCM | FA2 | 30 | 70 |

| D8 | MSCM | FA2 | 20 | 80 |

| H1-1 | MSCM | FA1 | 60 | 40 |

| H1-2 | MSCM | FA1 | 40 | 60 |

| H2-1 | MSCM | FA2 | 60 | 40 |

| H2-2 | MSCM | FA2 | 40 | 60 |

| H3-1 | MSCM | FA3 | 60 | 40 |

| H3-2 | MSCM | FA3 | 40 | 60 |

| H4-1 | MSCM | FA4 | 60 | 40 |

| H4-2 | MSCM | FA4 | 40 | 60 |

| OF-1 | OPC | FA1 | 60 | 40 |

| OF-2 | OPC | FA1 | 40 | 60 |

| MSWI Fly Ash | Heavy Metal Content (mg/kg) | Heavy Metal Leaching Concentrations (μg/L) | ||||||

|---|---|---|---|---|---|---|---|---|

| Zn | Cr | Pb | Hg | Zn | Cr | Pb | Hg | |

| FA1 | 10,136.1 | 23.8 | 1323.8 | 34.7 | 5080 | 162 | 46,400 | 37 |

| FA2 | 2526.0 | 42.4 | 1502.0 | 6.46 | 127 | 144 | 8160 | 11 |

| FA3 | 3829.1 | 58.1 | 563.6 | 23.3 | 360 | 107 | 164 | 28 |

| FA4 | 2799.6 | 85.4 | 267.2 | 3.1 | 11,100 | 282 | 108 | 7.8 |

| Limited levels of GB 16889-2008 | 100,000 | 4500 | 250 | 50 | ||||

| FA2 Blocks | Zn | Cr | Pb | Hg |

|---|---|---|---|---|

| D0 | 99.63% | 99.98% | 99.98% | 99.96% |

| D1 | 99.77% | 99.98% | 99.99% | 96.51% |

| D2 | 99.97% | 99.98% | 100.00% | 97.13% |

| D3 | 99.92% | 99.98% | 99.99% | 99.14% |

| D4 | 99.82% | 99.98% | 99.99% | 98.80% |

| D5 | 99.88% | 99.95% | 99.99% | 98.53% |

| D6 | 99.99% | 99.94% | 99.98% | 98.82% |

| D7 | 99.99% | 99.94% | 99.96% | 99.38% |

| D8 | 99.99% | 99.84% | 99.77% | 99.72% |

| Fly Ash Blocks | Compressive Strength (MPa) | Leaching Concentrations (μg/L) | Immobilization Rate (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Zn | Cr | Pb | Hg | Zn | Cr | Pb | Hg | ||

| H1-1 | 21.2 | 2.59 | 2.27 | 18.72 | 1.52 | 99.99 | 99.95 | 99.95 | 99.68 |

| H1-2 | 12.5 | 3.31 | 4.11 | 25.64 | 4.72 | 99.99 | 99.89 | 99.94 | 99.33 |

| H2-1 | 16.4 | 4.95 | 1.17 | 9.78 | 8.54 | 99.99 | 99.93 | 99.97 | 98.21 |

| H2-2 | 8.9 | 7.65 | 3.48 | 23.3 | 4.21 | 99.99 | 99.92 | 99.95 | 99.40 |

| H3-1 | 22.3 | 2.42 | 2.09 | 5.24 | 6.74 | 99.99 | 99.96 | 99.96 | 98.58 |

| H3-2 | 9.6 | 3.18 | 3.47 | 9.15 | 8.79 | 99.99 | 99.93 | 99.96 | 98.75 |

| H4-1 | 24.1 | 2.11 | 2.71 | 5.18 | 7.85 | 99.99 | 99.95 | 99.96 | 98.35 |

| H4-2 | 13.0 | 3.49 | 3.96 | 13.52 | 7.65 | 99.99 | 99.93 | 99.90 | 98.92 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, W.; Fu, P.; Fang, G.; Zhu, W.; Li, S.; Wang, X.; Xue, T.; Chen, Y. Solidification/Stabilization of MSWI Fly Ash Using a Novel Metallurgical Slag-Based Cementitious Material. Minerals 2022, 12, 599. https://doi.org/10.3390/min12050599

Deng W, Fu P, Fang G, Zhu W, Li S, Wang X, Xue T, Chen Y. Solidification/Stabilization of MSWI Fly Ash Using a Novel Metallurgical Slag-Based Cementitious Material. Minerals. 2022; 12(5):599. https://doi.org/10.3390/min12050599

Chicago/Turabian StyleDeng, Wei, Pingfeng Fu, Guiwen Fang, Wan Zhu, Shan Li, Xiaofei Wang, Tianli Xue, and Yuqi Chen. 2022. "Solidification/Stabilization of MSWI Fly Ash Using a Novel Metallurgical Slag-Based Cementitious Material" Minerals 12, no. 5: 599. https://doi.org/10.3390/min12050599

APA StyleDeng, W., Fu, P., Fang, G., Zhu, W., Li, S., Wang, X., Xue, T., & Chen, Y. (2022). Solidification/Stabilization of MSWI Fly Ash Using a Novel Metallurgical Slag-Based Cementitious Material. Minerals, 12(5), 599. https://doi.org/10.3390/min12050599