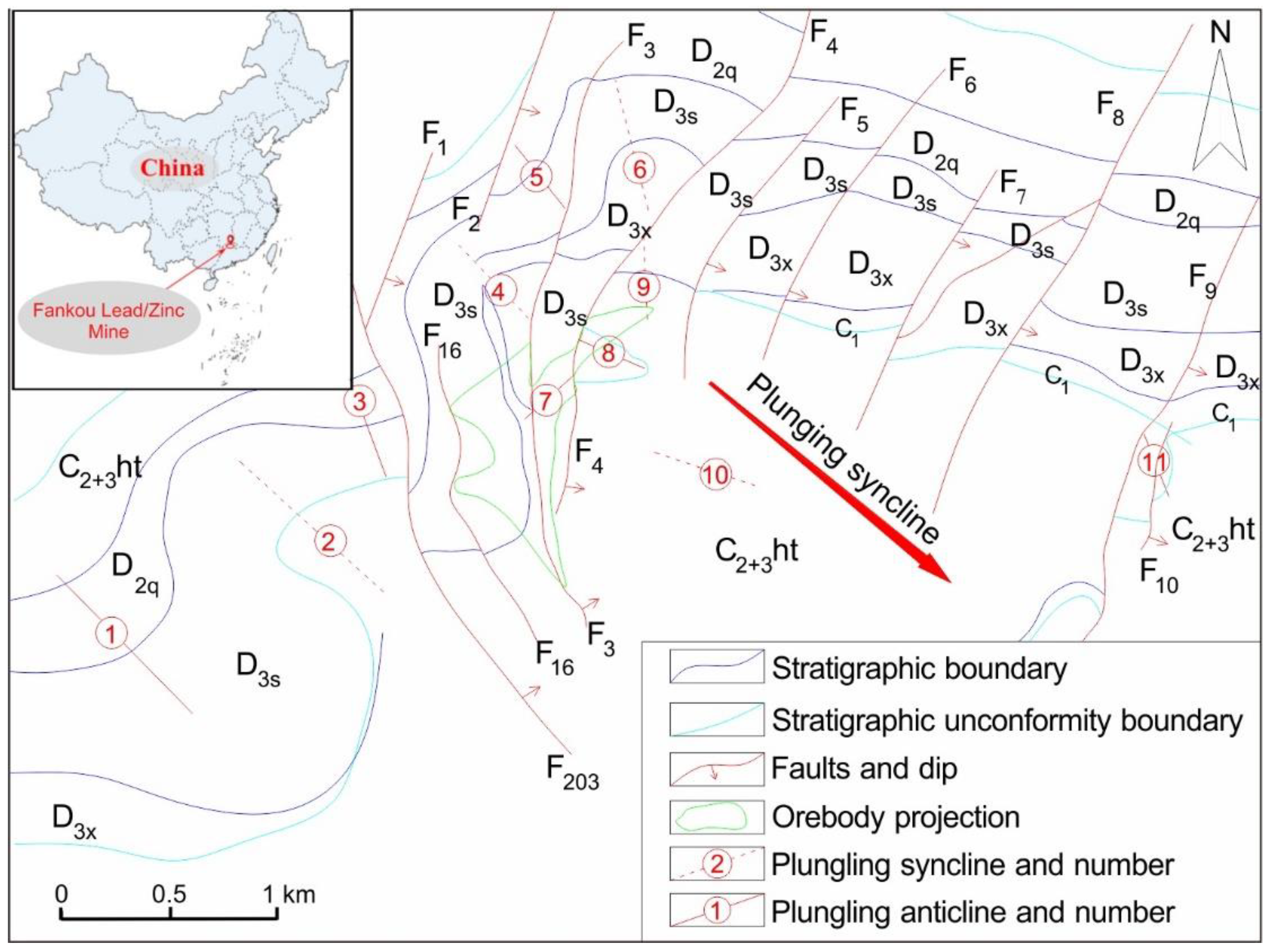

3.1. Microseismic Monitoring System Configuration

The research of Lynch [

41] indicates that geophones are more sensitive than accelerometers to microseismic events of a lower frequency range, as well as more reliable. The microseismic monitoring system must follow certain installation principles, such as meeting the requirements of the mine monitoring range, costing a reasonable amount, creating low surrounding noise and requiring a relatively stable rock mass [

42]. According to the above principles and requirements, the developed microseismic monitoring system for the Fankou Lead/Zinc Mine consists of 32 microseismic sensors, which are spread over the five mining levels. The microseismic sensor array is composed of 32 geophones and five microseismic stations located at five different mining levels of this underground mine. The microseismic stations are separately set at the −280 m, −360 m, −455 m, −550 m and −650 m levels, named from no. 1 to no. 5. The microseismic workstation consists of a 32-bit high-precision eight-channel data collector (netADC8), waveform processor (net SP), intelligent UPS, single-port modulation communication MODEM and other auxiliary equipment. Two eight-channel data collectors are installed at the −455 m mining level workstation and the rest of the mining levels are equipped with only one collector on each (details are shown in

supplementary materials Figures S1 and S2). All the geophones are connected to the eight-channel data collector so that the detected waveform signal can be sent to the waveform processor for processing after analog-to-digital conversion.

The Underground Data Communication Center (UDCC), which is installed at the −455 m level, comprises clock synchronization equipment, a four-port Digital Subscriber Line Access Multiplexer (DSLAM), serial port equipment and photoelectric conversion equipment. The main task of the UDCC is to distribute the control signal and clock synchronization signal from the server and collector and transfer the cache data in the underground data center. Finally, these data are transmitted to the microseismic server on the ground so that the microseismic data can be further processed by professional software. The system’s network of the microseismic monitoring system and the specifications of the instrument used are shown in

supplementary materials Figure S2 and Tables S2 and S3.

In our research, the microseismic monitoring system utilized the average wave velocity determined in the test to infer the source distance. The calculation of the average wave velocity in the Fankou Lead/Zinc Mine was based on the assumption that the microseismic wave propagates in uniform media. Based on this assumption, seven groups of fixed-point blasting tests were carried out over the study period. According to the seven sets of data recorded by the 32 geophones, the weighted average velocity of the wave in the whole mine was obtained. The final calculation results showed that the average longitudinal wave velocity in the blasting tests was VP = 5645 ± 214 m/s and the average shear wave velocity in the blasting tests was VS = 3147 ± 106 m/s. Besides this, the simulation results for the positioning accuracy of microseismic events in the Fankou Lead/Zinc mine showed that the weighted average velocities of waves were reasonable. According to the data of more than three microseismic sensors and the average wave velocity, the microseismic source could be spatially located. The other parameters of the microseismic source could be obtained from spectral analysis of the microseismic waveform through the analysis software in the microseismic monitoring system.

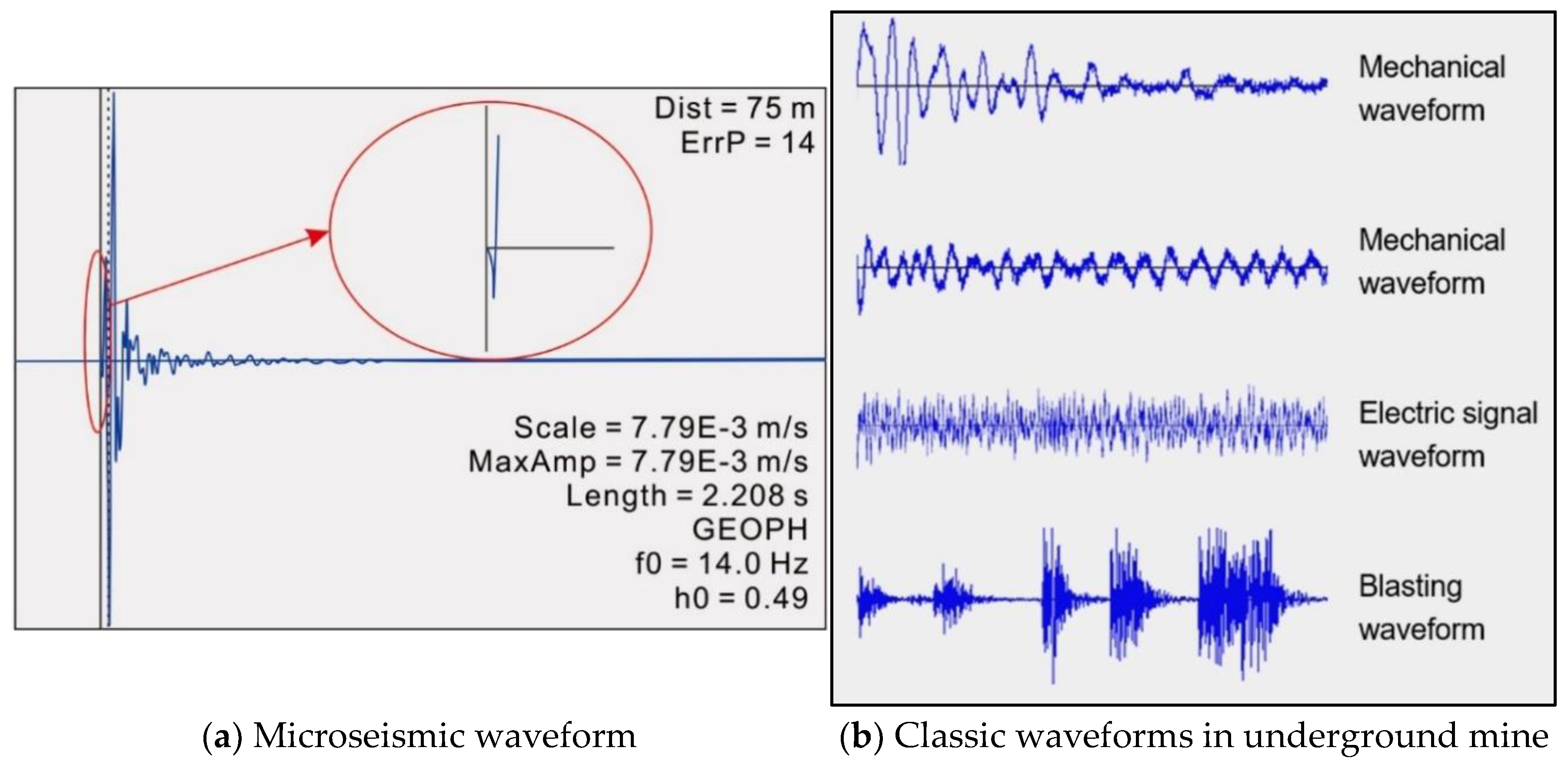

The velocity geophone, data acquisition instrument and waveform processor in the microseismic monitoring system of the Fankou Mine are all from the Institute of Mine Seismology (IMS). The frequency range of microseismic waves monitored by the geophones in the microseismic monitoring system in the Fankou Mine is 8−2000 Hz. The microseismic waveform signals are picked up by the geophones and transmitted to the ground service station through a transmission cable. After a series of processing steps and analyses of the waveform signals in the software Trace, some source parameters such as the microseismic event time, location, intensity and radiation energy are obtained. Then, the parameters are stored in a database of the system and can be viewed in real-time through the software Ticker3D developed by IMS. In our work, the positioning accuracy of the microseismic monitoring system in the Fankou Lead-Zinc Mine reached 10 m according to the simulation analysis results. The sensitivity (magnitude of completeness, Mc) of the system reached the Richter magnitude −3, which met the actual needs of the mine.

3.2. Correlation between Rock Mass Stability and Microseismic Activity Parameters

Before a rock failure event, the rock mass might go through different development processes and its stability has corresponding changes, too. The microseismic sensor can record the elastic wave generated by the rock mass that is deforming, which is the basic correlation between the rock mass and the microseismic monitoring technique. The specific correlation of the two is shown below.

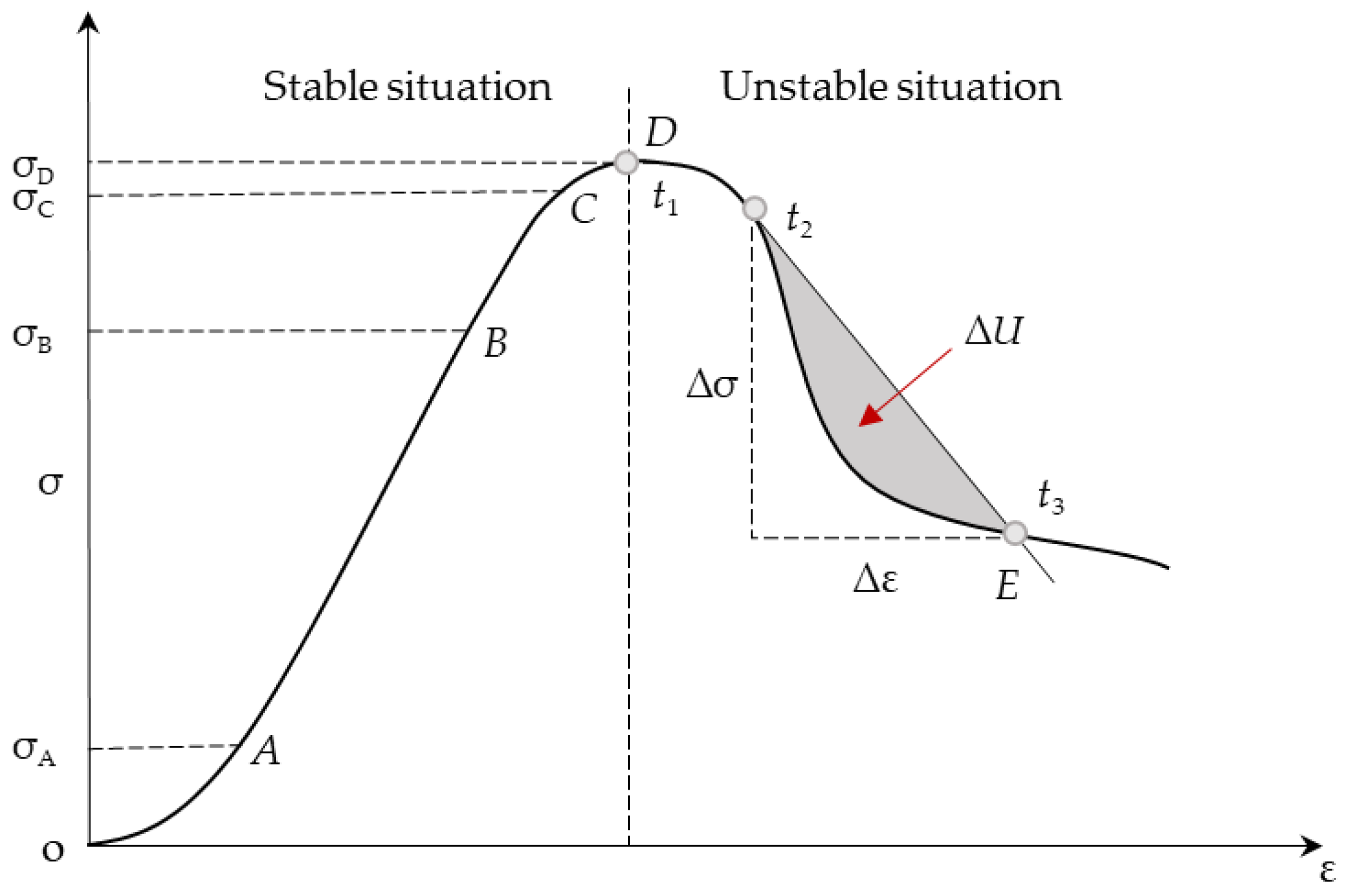

The stress-strain curve can show the basic situation of rock, from a complete one to a broken one [

43,

44,

45,

46,

47]. A classic stress-strain curve of the rock uniaxial compression test is shown in

Figure 2. The curve in

Figure 2 consists of five sections namely OA, AB, BC, CD and DE, corresponding to the different periods in the process of rock failure.

The OA section is the micro-fracture compaction stage. In this stage, the rock specimen will be compacted, which reflects that the internal microfractures of the rock specimen are compressed to close at the initial stage of loading. During this period, there are few elastic waveform signals.

The AB section is the elastic deformation stage of the rock. At this stage, the stress-strain curve continues to vary linearly and obeys Hooke’s law [

48]. The curve keeps a single linear variation until point B. The strength at point B is called the elastic limit of the rock, and the rock specimen terminates the single elastic deformation at point B. During this period, the elastic waveform signals increase at relatively low amplitudes.

After point B, new micro-cracks begin to generate inside the rock specimen in the BC section, which is called the generation and expansion stage of fracture. During this period, the growth of the micro-cracks is subjected to the loading and will stop once the loading is stopped. This characteristic ends at point C, the strength at which is called the yield limit of the rock. During this period, the increase of the elastic waveform signals obviously quickens.

After point C, the development of the cracks inside the rock specimen is no longer fully subjected to loading. Even if the loading is stopped, the micro-cracks will not immediately stop expanding, and the elastic waveform signals increase at high amplitudes. The rock specimen enters the unstable development stage of fracture. The internal micro-cracks will expand and join the sliding surface but the rock is not fully broken until point D. The corresponding stress at point D is called the peak strength.

After point D, in the DE section, the internal cracks inside the rock continue to develop and form macroscopic fracture surfaces. The rock specimen still possesses a certain strength even at point E. ∆U is the elastic energy released during rock failure. During this period, the elastic waveform signals will decrease quickly.

It can be seen from

Figure 2 that the rock has strong deformation resistance before the peak strength. Before the external load reaches the peak strength, the development of microcracks in the rock mass does not reach the scale of macro-failure. After reaching the peak strength, the rock begins to take macroscopic damage until there is a break. Therefore, from the perspective of rock mass stability, the AD section is classed as the stable situation and the DE section is classed as the unstable situation.

Rock masses will release energy in the form of elastic waves when they are deformed or generate microcracks under loading, and those waves are generally of a low frequency from 50–1500 Hz. These elastic waves can radiate a certain amount of energy and often cause a vibration effect, so they are defined as microseismic events. Therefore, microseismic events can reflect the state of rock masses and thus indicate their degree of stability. In other words, the stable state of the rock mass can be inferred by analyzing the corresponding microseismic data. That is why microseismic monitoring technology is considered as a kind of means to understanding the stability of the rock mass in the target area by monitoring, collecting and storing the information on microseismic events.

Microseismic events can be detected by a geophone and then various parameters can be obtained with the analysis software in the microseismic monitoring system. The energy index, cumulative apparent volume and Schmidt number are three of those parameters that can effectively reflect the stability information of the rock mass to some degree; hence, they are often used as indicators to estimate the stability of surrounding rock.

The energy index

EI [

49] is the ratio of the energy

E released by a microseismic event to the average energy

E (

M) released by an event with the same magnitude in a region.

In Equation (1),

M is the magnitude of a microseismic event,

d is the rigidity of the system,

c is the stress level and

c and

d are constants in the region. Therefore, the energy index can reflect the stress level of the rock mass in its region. The larger the energy index, the more energy there is, which means the driving stress of the source will be greater when an event occurs during this period. The apparent volume

VA [

50] is a parameter calculated by the seismic moment

M0 and static stress drop

σA.

The cumulative apparent volume ∑VA is the cumulative value of the apparent volume. The slope of cumulative apparent volume can reflect the strain rate of the rock mass. When the change of cumulative apparent volume is accelerated, it indicates that the deformation rate of the rock mass is also accelerated.

The Schmidt number [

51]

Sc is defined as the ratio of the kinematic viscosity coefficient

ν to the diffusion coefficient

D. The Schmidt number can be used to measure the spatiotemporal complexity of rock rheology. Additionally, it is a unique parameter reflecting potential instability. The stability of rock mass deformation increases with a decreasing Schmidt number.

It can be seen from

Figure 2 that the growth of the strain accelerates slightly and the growth of the stress slows down obviously before reaching the peak strength. Correspondingly, the growth of cumulative apparent volume accelerates, the energy index increases slowly and the Schmidt number decreases slightly. After the peak strength, the rock deformation increases rapidly and the stress decreases rapidly. Accordingly, the cumulative apparent volume increases more rapidly and the energy index decreases more rapidly but the Schmidt number decreases rapidly. That is the reason why rock instability can be warned of early on by monitoring the cumulative apparent volume, energy index and Schmidt number with the microseismic monitoring system.

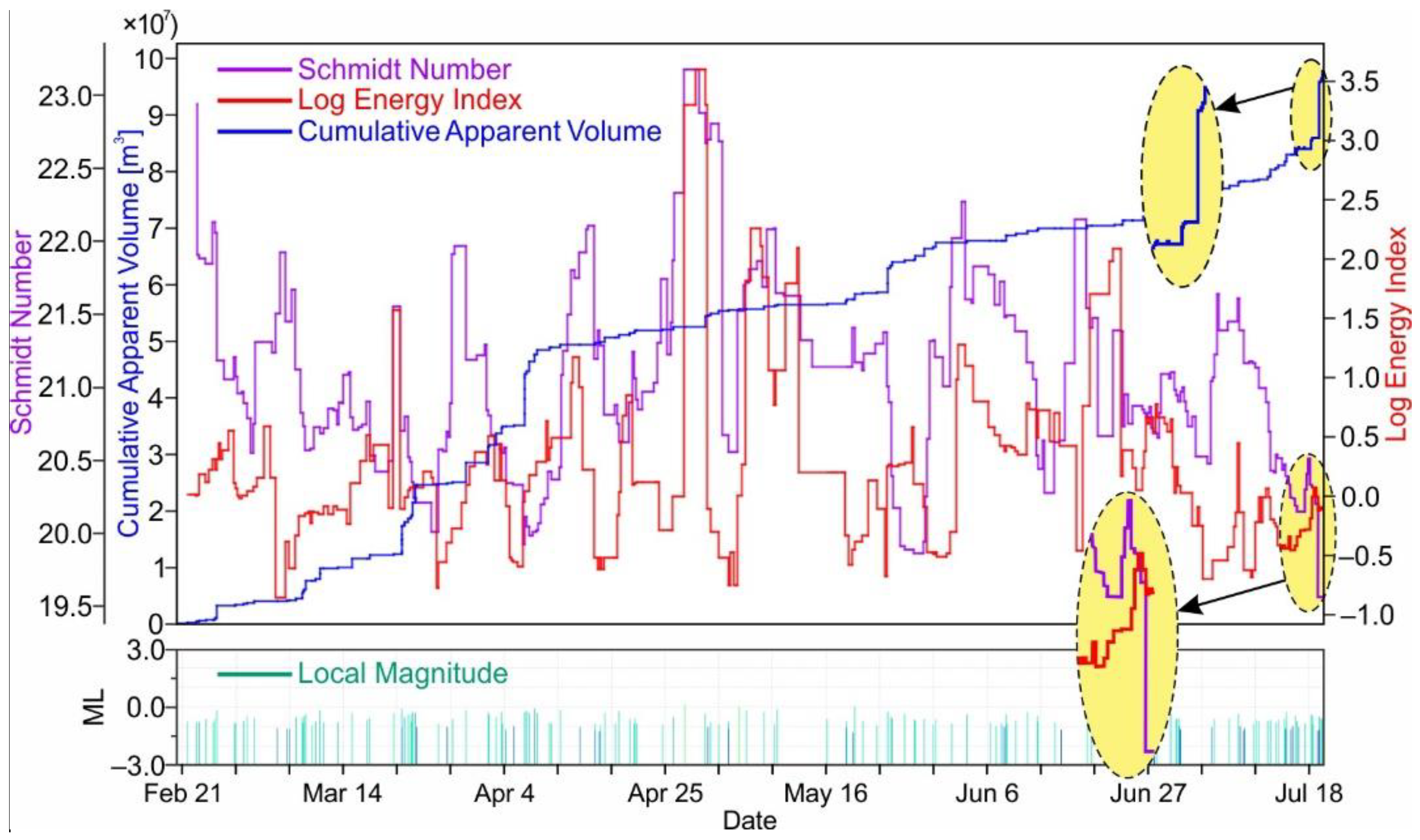

The calculations of

EI,

∑VA and

Sc were completed by the Trace software in the microseismic monitoring system, and the dynamics of

EI,

∑VA, and

Sc were recorded in the form of a curve, as shown in

Figure 3. The evolution of the energy index, Schmidt number and cumulative apparent volume of the microseismic event accumulation area over time are shown in

Figure 3. As can be seen in

Figure 3, the red line represents the variation of the energy index with time, the purple line represents the variation of the Schmidt number with time and the blue line represents the development of the cumulative apparent volume with time.