Study on the Grinding Law of Ball Media for Cassiterite–Polymetallic Sulfide Ore

Abstract

:1. Introduction

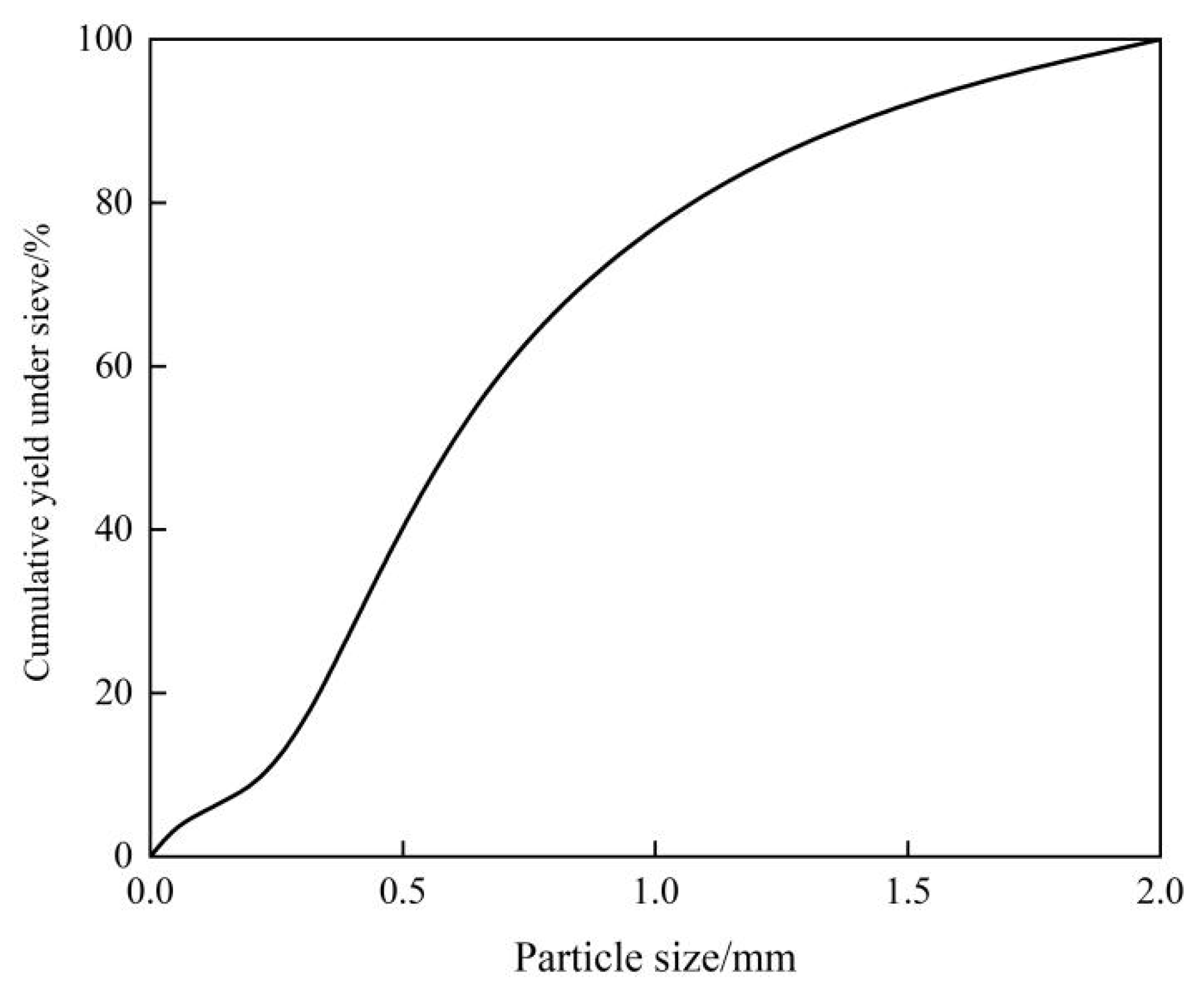

2. Materials and Methods

2.1. Materials

2.2. Methods

2.3. Grinding Evaluation

3. Results and Discussion

3.1. Effects of Grinding Time

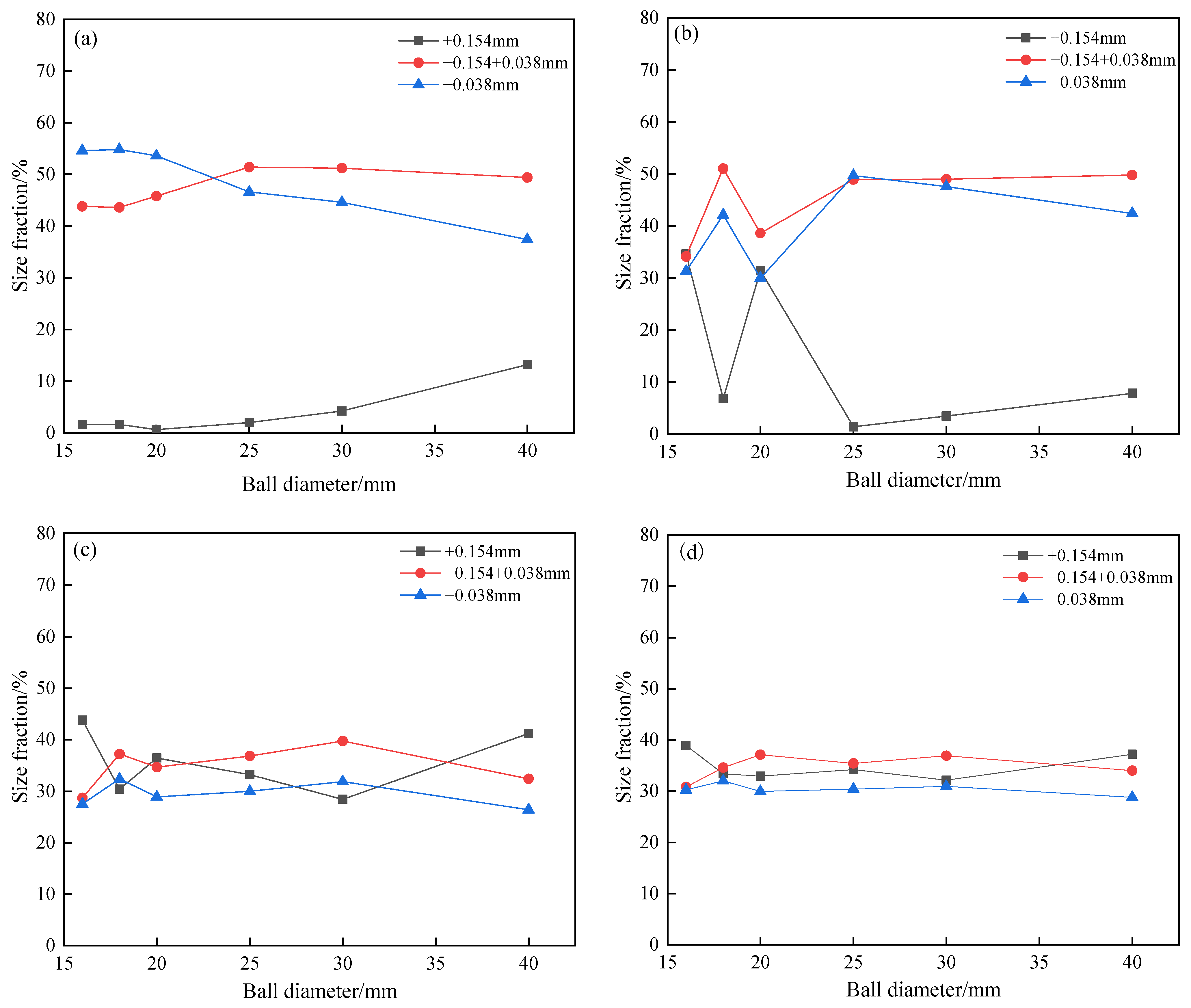

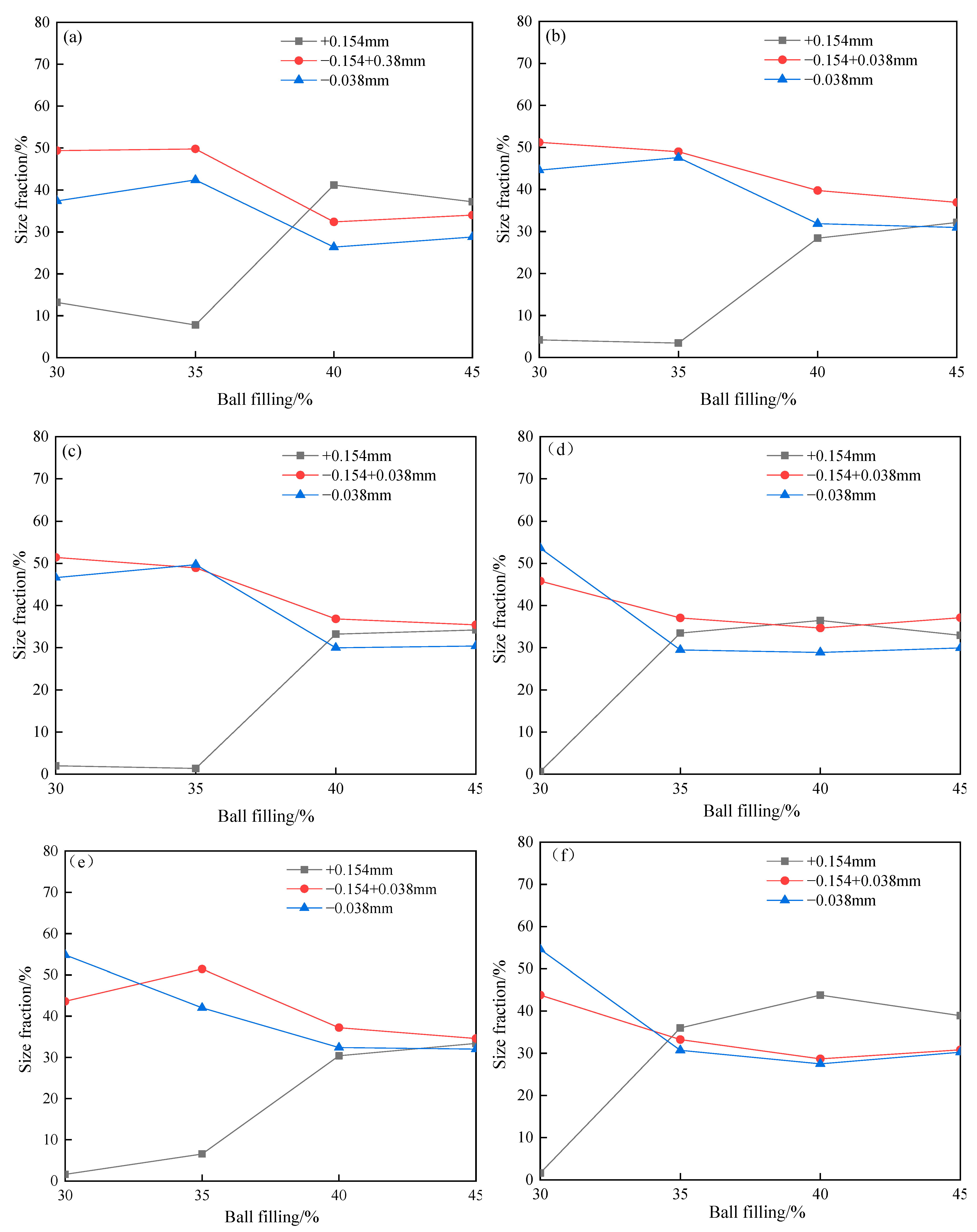

3.2. Effect of Ball Size in Grinding with a Single-Sized Medium

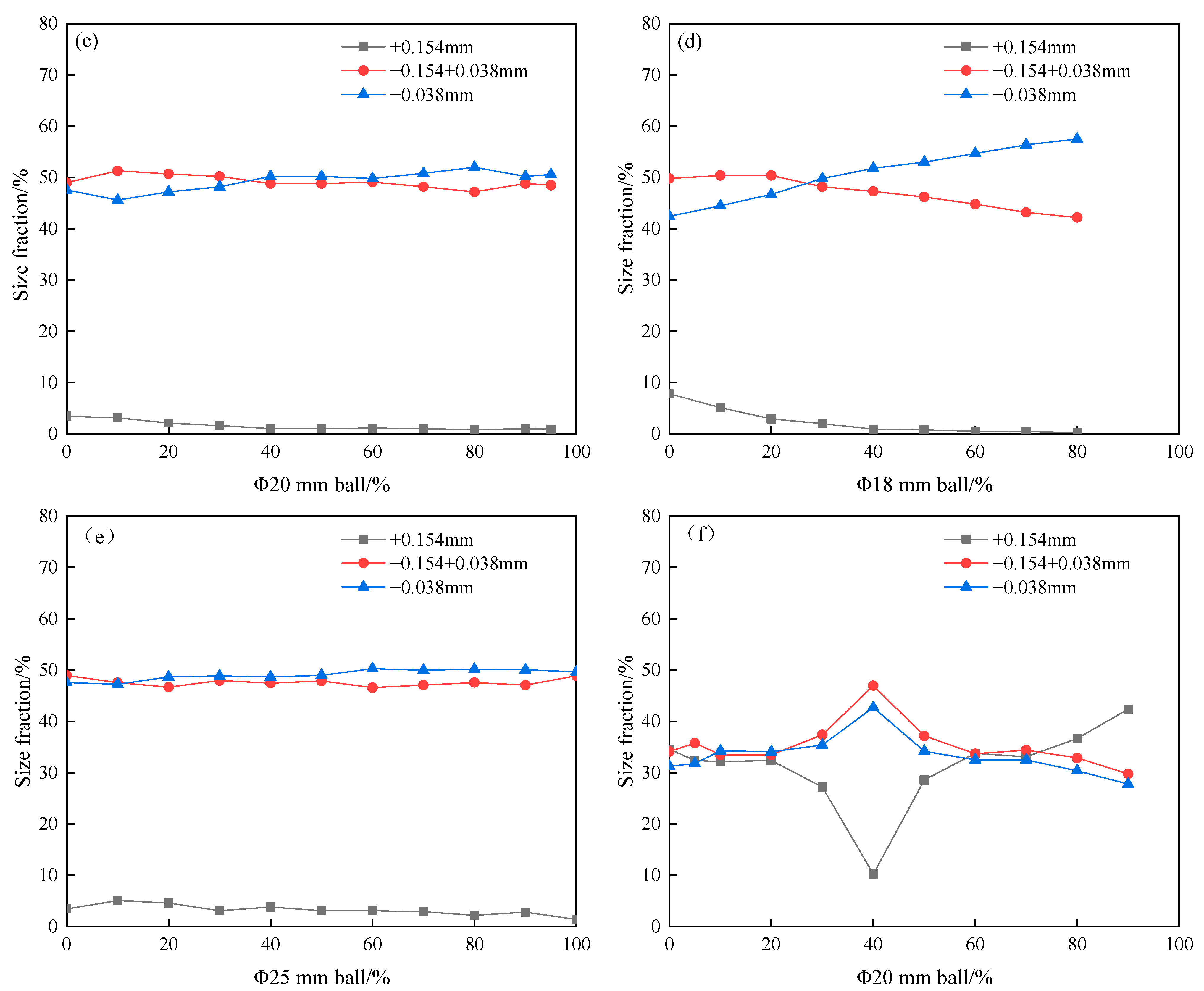

3.3. Effect of Ball Size Composition in Grinding with Multi-Sized Media

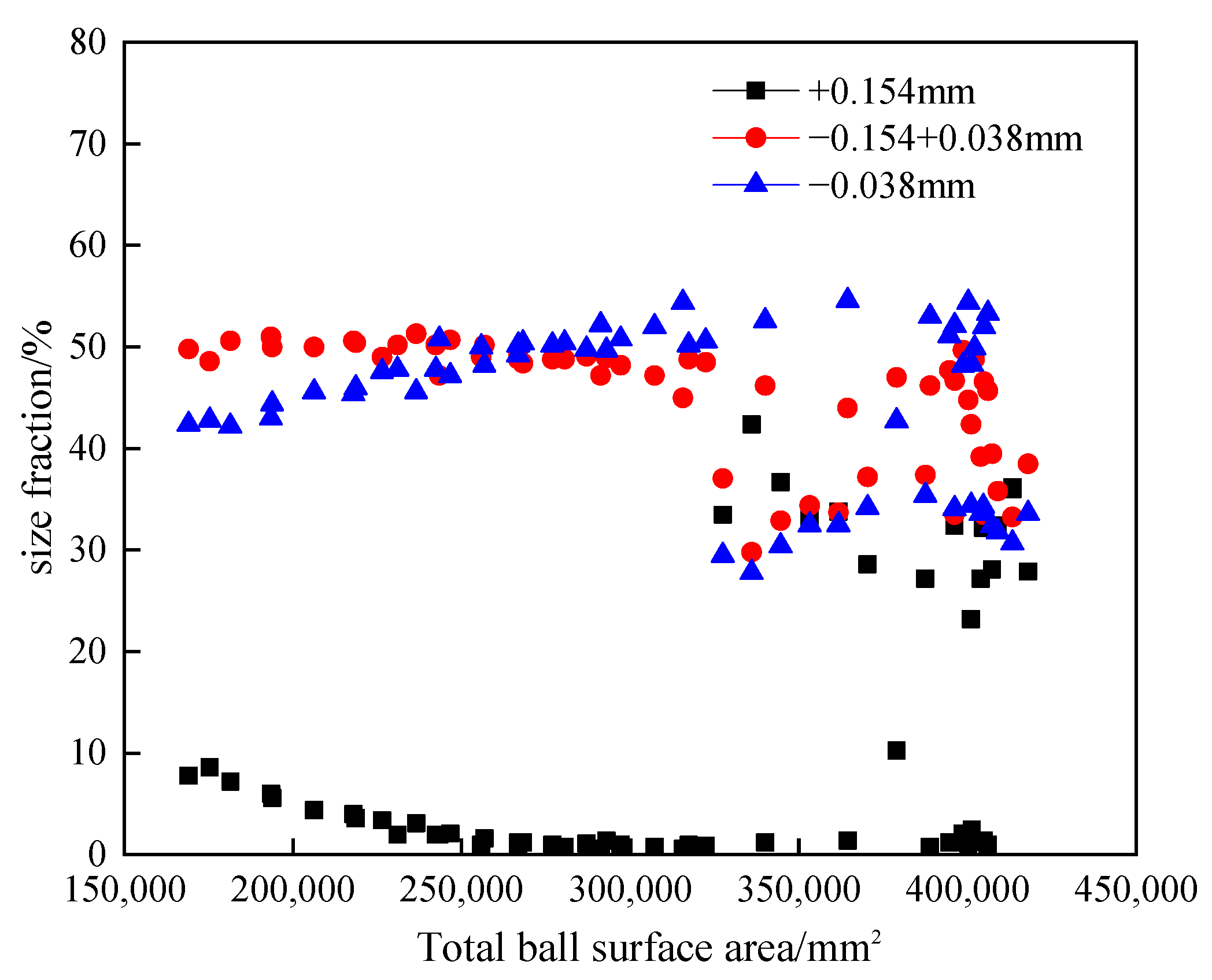

3.4. Effect of the Surface Area of the Grinding Media

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Clarke, A.J.; Wills, B.A. Technical note Enhancement of cassiterite liberation by high pressure roller comminution. Miner. Eng. 1989, 2, 259–262. [Google Scholar] [CrossRef]

- Wills, A.B.; Parker, R.H.; Binns, D.G. Thermally assisted liberation of cassiterite. Miner. Metall. Process. 1987, 5, 94–96. [Google Scholar] [CrossRef]

- Wonnacott, G.; Wills, B.A. Optimisation of thermally assisted liberation of a tin ore with the aid of computer simulation. Miner. Eng. 1990, 3, 187–198. [Google Scholar] [CrossRef]

- Wills, B.A.; Hall, S.T. New methods of reducing losses of fine cassiterite. In Mineral Processing in the United Kingdom; University of Leeds: London, UK, 1989; pp. 143–147. [Google Scholar]

- Veassey, T.J. Thermally assisted liberation of non-sulfide ores. Miner. Eng. 1986, 2, 557. [Google Scholar]

- Veasey, T.J.; Wills, B.A. Review of methods of improving mineral liberation. Miner. Eng. 1991, 4, 747–752. [Google Scholar] [CrossRef]

- Sreenivas, T.; Srinivas, K.; Natarajan, R.; Padmanabhan, N.P.H. An integrated process for the recovery of tungsten and tin from a combined wolframite-scheelite-cassiterite concentrate. Miner. Process. Extr. Metall. Rev. 2004, 25, 193–203. [Google Scholar] [CrossRef]

- Qin, W.Q.; Wang, P.P.; Ren, L.Y.; Wei, Q.; Peng, Z.B.; Gu, Y.L. Effect of matching relationship between particles and bubbles on the flotation of fine cassiterite. J. China Univ. Min. Technol. 2012, 41, 420–424. (In Chinese) [Google Scholar]

- Ye, X.J.; Lu, B.J.; Feng, Z.F.; Chen, J.Q. Test and application of sawtooth wave jigger for recovering fine cassiterite. Met. Mine 2009, 39, 134–136. (In Chinese) [Google Scholar]

- Qin, W.Q.; Ren, L.Y.; Wang, P.P.; Yang, C.R.; Zhang, Y.S. Electro-flotation and collision-attachment mechanism of fine cassiterite. Trans. Nonferrous Met. Soc. China 2012, 22, 917–924. (In Chinese) [Google Scholar] [CrossRef]

- Sreenivas, T.; Padmanabhan, N.P.H. Surface chemistry and flotation of cassiterite with alkyl hydroxamates. Colloids Surf. A Physicochem. Eng. Asp. 2002, 205, 47–59. [Google Scholar] [CrossRef]

- Qin, W.Q.; Xu, Y.B.; Liu, H.; Ren, L.Y.; Yang, C.R. Flotation and surface behavior of cassiterite with salicylhydroxamic acid. Ind. Eng. Chem. Res. 2011, 50, 10778–10783. [Google Scholar] [CrossRef]

- Wu, X.Q.; Zhu, J.G. Selective flotation of cassiterite with benzohydroxamic acid. Miner. Eng. 2006, 19, 1410–1417. [Google Scholar] [CrossRef]

- Zhu, Y.S.; Zhu, D. Adsorption thermodynamics of octyl hydroxamic acid on cassiterite. Nonferrous Met. 1994, 46, 24–28. (In Chinese) [Google Scholar]

- Cheng, J.G. Research on a new collector of fine cassiterite-phosphorous ester. Changsha Cent. South Coll. Min. Metall. 1985, 1985, 72. (In Chinese) [Google Scholar]

- Qin, W.Q.; Ren, L.Y.; Xu, Y.B.; Wang, P.P.; MA, X.H. Adsorption mechanism of mixed salicylhydroxamic acid and tributyl phosphate collectors in fine cassiterite electro-flotation system. J. Cent. South Univ. 2012, 19, 1711–1717. (In Chinese) [Google Scholar] [CrossRef]

- Madrid, I.E.R.; Rodriguez, B.A.; Bustamante, O.; Baena, O.J.R.; Menendez-Aguado, J.M. Ceramic ball wear prediction in tumbling mills as a grinding media selection tool. Powder Technol. 2014, 373–376. [Google Scholar] [CrossRef]

- Amankwah, R.K.; Khan, A.U.; Pickles, C.A.; Yen, W.T. Improved grindability and gold liberation by microwave pretreatment of a free-milling gold ore. Miner. Process. Extr. Metall. 2014, 114, 30–36. [Google Scholar] [CrossRef]

- Zhou, Y.C.; Tong, X.; Song, S.X.; Wang, X.; Deng, Z.B.; Xie, X. Beneficiation of cassiterite fines from a tin tailing slime by froth flotation. Sep. Sci. Technol. 2014, 49, 458–463. [Google Scholar] [CrossRef]

- Gruner, H.; Bilsing, U. Cassiterite flotation using styrene phosphonic acid to produce high-grade concentrates at high recoveries from finely disseminated ores-comparison with other collectors and discussion of effective circuit configurations. Miner. Eng. 1992, 5, 429–434. [Google Scholar] [CrossRef]

- Liu, Y.; Shen, Z.J.; Deng, J.; Jiang, S.Q. Vibration spectra and genetic type of cassiterites. Spectrosc. Spectr. Anal. 2008, 28, 1506–1509. (In Chinese) [Google Scholar]

- Wills, A.B.; Atkinson, K. The development of minerals engineering in the 20th century. Miner. Eng. 1991, 4, 643–652. [Google Scholar] [CrossRef]

- Liddell, K.S.; Moys, M.H. The effects of mill speed and filling on the behaviour of the load in a rotary grinding mill. J. S. Afr. Inst. Min. Metall. 1988, 88, 49–57. [Google Scholar]

- Zeng, Y.; Forssberg, E. Effects of mill feed size on the product fineness and energy consumption in coarse grinding. Miner. Eng. 1991, 4, 599–609. [Google Scholar] [CrossRef]

- Zeng, Y.; Forssberg, E. Effect of mill feed size and rod charges on grinding performance. Powder Technol. 1992, 69, 119–123. [Google Scholar] [CrossRef]

- Chandrasekaran, T. A new approach to the kinetics of size reduction in ball milling. Miner. Eng. 1992, 5, 931–938. [Google Scholar] [CrossRef]

- Salter, J.D. Mill control using particle size monitors. Miner. Eng. 1991, 4, 707–716. [Google Scholar] [CrossRef]

| Grinding Time/min | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 |

|---|---|---|---|---|---|---|---|---|

| Percentage of −0.038 mm particles | 29.84 | 40.62 | 49.75 | 56.61 | 59.72 | 62.65 | 66.00 | 69.32 |

| Sn grade/% | 0.52 | 0.55 | 0.55 | 0.55 | 0.56 | 0.58 | 0.64 | 0.55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Deng, X.; Xu, W.; Li, H.; Ma, S. Study on the Grinding Law of Ball Media for Cassiterite–Polymetallic Sulfide Ore. Minerals 2022, 12, 270. https://doi.org/10.3390/min12020270

Yang J, Deng X, Xu W, Li H, Ma S. Study on the Grinding Law of Ball Media for Cassiterite–Polymetallic Sulfide Ore. Minerals. 2022; 12(2):270. https://doi.org/10.3390/min12020270

Chicago/Turabian StyleYang, Jinlin, Xingjian Deng, Wenzhe Xu, Hengjun Li, and Shaojian Ma. 2022. "Study on the Grinding Law of Ball Media for Cassiterite–Polymetallic Sulfide Ore" Minerals 12, no. 2: 270. https://doi.org/10.3390/min12020270

APA StyleYang, J., Deng, X., Xu, W., Li, H., & Ma, S. (2022). Study on the Grinding Law of Ball Media for Cassiterite–Polymetallic Sulfide Ore. Minerals, 12(2), 270. https://doi.org/10.3390/min12020270