Selective Leaching of Vanadium from Calcification-Roasted Pellets of Vanadium–Titanium–Iron Concentrate by a Cyclic Two-Stage Sulfuric Acid Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

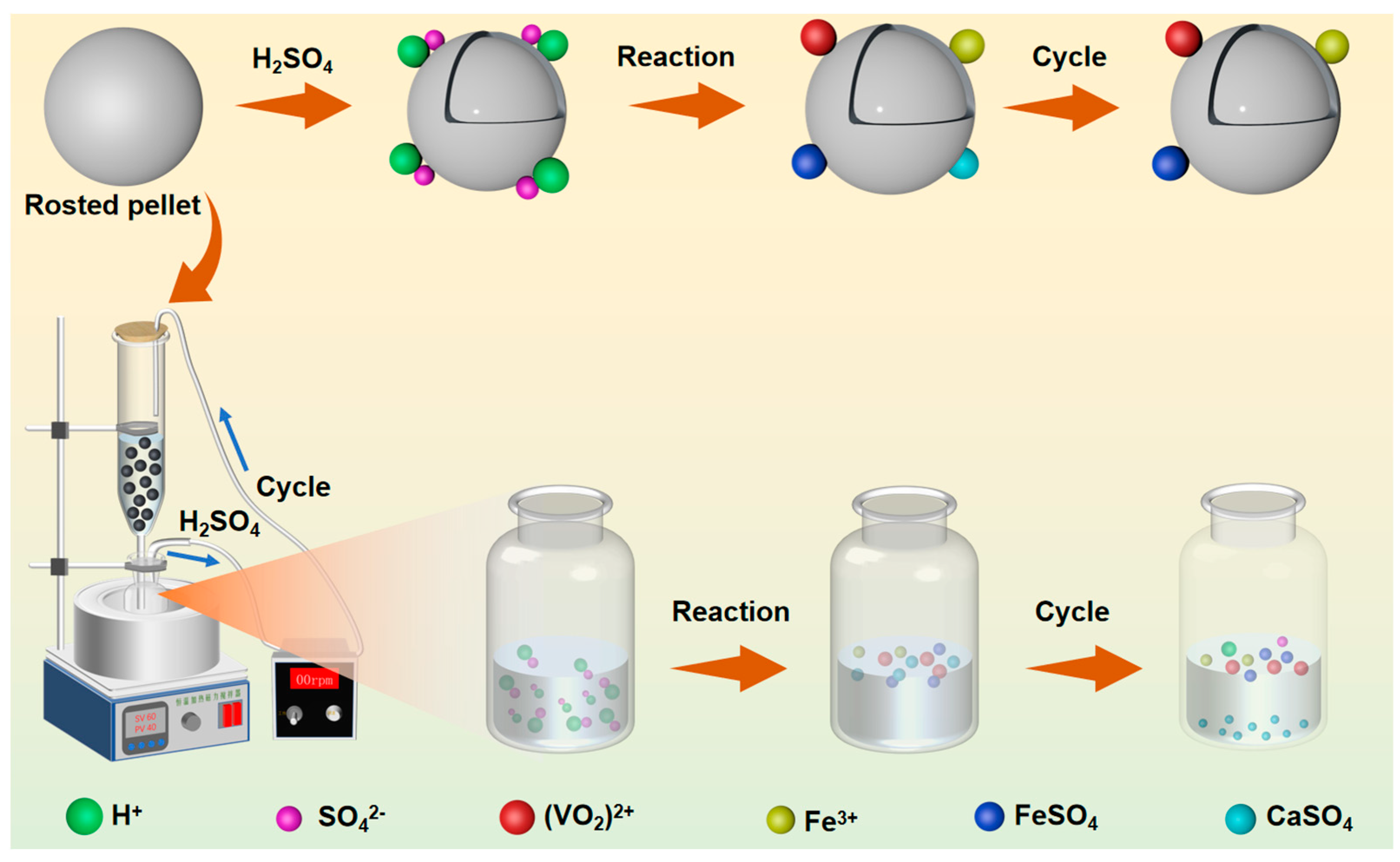

2.2. Experimental Procedure

2.3. Characterization and Analysis

3. Eh-pH Diagrams

4. Results

4.1. First Stage Leaching

4.1.1. Effect of Acid Concentration on Pellet Silicon Removal

4.1.2. Effect of Solid–Liquid Ratio on Silicon Removal from Pellets

4.1.3. Effect of Acid Concentration on Silicon Removal from the Leachate

4.1.4. Effect of Standing Time on Silicon Removal from the Leachate

4.2. Second-Stage Leaching

4.2.1. Effect of Acid Concentration on the Leaching Rate of Vanadium and Iron

4.2.2. Effect of Temperature on the Leaching Rate of Vanadium and Iron

4.2.3. Effect of Solid–Liquid Ratio on the Leaching Rate of Vanadium and Iron

4.2.4. Effect of Leaching Time on the Leaching Rate of Vanadium and Iron

5. Discussion

Characterization of Pellets before and after Leaching

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Langeslay, R.; Kaphan, D.; Marshall, C.; Stair, P.; Sattelberger, A.; Delferro, M. Catalytic applications of vanadium: A mechanistic perspective. Chem. Rev. 2019, 119, 2128–2191. [Google Scholar] [CrossRef] [PubMed]

- Kurtz, R.; Abe, K.; Chernov, V.; Hoelzer, D.; Matsui, H.; Muroga, T.; Odette, G. Recent progress on development of vanadium alloys for fusion. J. Nucl. Mater. 2005, 329, 47–55. [Google Scholar] [CrossRef]

- Parasuraman, A.; Lim, T.; Menictas, C. Review of material research and development for vanadium redox flow battery applications. Electrochim. Acta. 2013, 101, 27–40. [Google Scholar] [CrossRef]

- Moskalyk, R.; Alfantazi, A. Processing of vanadium: A review. Miner. Eng. 2003, 16, 793–805. [Google Scholar] [CrossRef]

- Guo, Y.; Li, H.; Huang, J.; Shen, S.; Wang, C.; Wu, Z.; Xie, B. Efficient separation of V (V) and Cr (VI) in aqua by microemulsion extraction. Sep. Purif. Technol. 2020, 238, 116409. [Google Scholar] [CrossRef]

- Wang, G.; Lin, M.M.; Diao, J.; Li, H.Y.; Xie, B.; Li, G. Novel strategy for green comprehensive utilization of vanadium slag with high-content chromium. Acs. Sustain. Chem. Eng. 2019, 7, 18133–18141. [Google Scholar] [CrossRef]

- Bian, Z.; Feng, Y.; Li, H. Efficient separation of vanadium, titanium, and iron from vanadium-bearing titanomagnetite by pressurized pyrolysis of ammonium chloride-acid leaching-solvent extraction process. Sep. Purif. Technol. 2021, 255, 117169. [Google Scholar] [CrossRef]

- Gao, H.; Jiang, T.; Xu, Y.; Wen, J.; Xue, X. Leaching kinetics of vanadium and chromium during sulfuric acid leaching with microwave and conventional calcification-roasted high chromium vanadium slag. Miner. Process. Extr. Metall. 2020, 41, 22–31. [Google Scholar] [CrossRef]

- Li, R.; Liu, T.; Zhang, Y.; Huang, J.; Xu, C. Efficient Extraction of Vanadium from Vanadium-Titanium Magnetite Concentrate by Potassium Salt Roasting Additives. Minerals 2018, 8, 25. [Google Scholar] [CrossRef] [Green Version]

- Zou, K.; Xiao, J.; Liang, G.; Huang, W.; Xiong, W. Effective extraction of vanadium from bauxite-type vanadium ore using roasting and leaching. Metals 2021, 11, 1342. [Google Scholar] [CrossRef]

- Xiang, J.; Huang, Q.; Lv, X.; Bai, C. Extraction of vanadium from converter slag by two-step sulfuric acid leaching process. J. Clean. Prod. 2018, 170, 1089–1101. [Google Scholar] [CrossRef]

- Peng, H. A literature review on leaching and recovery of vanadium (Review). J. Environ. Chem. Eng. 2019, 7, 103313. [Google Scholar] [CrossRef]

- Li, M.; Liu, B.; Zheng, S.; Wang, S.; Du, H.; Dreisinger, D.; Zhang, Y. A cleaner vanadium extraction method featuring non-salt roasting and ammonium bicarbonate leaching. J. Clean. Prod. 2017, 149, 206–217. [Google Scholar] [CrossRef]

- Liu, S.; Ding, E.; Ning, P.; Xie, G.; Yang, N. Vanadium extraction from roasted vanadium-bearing steel slag via pressure acid leaching. J. Environ. Chem. Eng. 2021, 9, 105195. [Google Scholar] [CrossRef]

- Peng, H.; Guo, J.; Zhang, X. Leaching Kinetics of Vanadium from Calcium-Roasting High-Chromium Vanadium Slag Enhanced by Electric Field. Minerals 2020, 5, 17664–17671. [Google Scholar] [CrossRef]

- Vaschetti, V.; Eimer, G.; Cánepa, A.; Casuscelli, S. Catalytic performance of V-MCM-41 nanocomposites in liquid phase limonene oxidation: Vanadium leaching mitigation. Microporous Mesoporous Mater. 2021, 311, 110678. [Google Scholar] [CrossRef]

- Xiang, J.; Wang, X.; Pei, G. Recovery of vanadium from vanadium slag by composite roasting with CaO/MgO and leaching. Trans. Nonferrous Met. Soc. China 2020, 30, 11. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, W.; Xue, Z. An Environment-Friendly Process Featuring Calcified Roasting and Precipitation Purification to Prepare Vanadium Pentoxide from the Converter Vanadium Slag. Metals 2019, 9, 21. [Google Scholar] [CrossRef] [Green Version]

- Wen, J.; Jiang, T.; Wang, J.; Lu, L.; Sun, H. Cleaner extraction of vanadium from vanadium-chromium slag based on MnO2 roasting and manganese recycle. J. Clean. Prod. 2020, 261, 121205. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, T.; Dreisinger, D.; Lv, C.; Lv, G.; Zhang, W. Recovery of vanadium from calcification roasted-acid leaching tailing by enhanced acid leaching. J. Hazard. Mater. 2019, 369, 632–641. [Google Scholar] [CrossRef]

- Wen, J.; Jiang, T.; Zhou, W.; Gao, H.; Xue, X. A cleaner and efficient process for extraction of vanadium from high chromium vanadium slag: Leaching in (NH4)(2)SO4-H2SO4 synergistic system and NH4+ recycle. Sep. Purif. Technol. 2019, 216, 126–135. [Google Scholar] [CrossRef]

- Hu, P.; Zhang, Y.; Huang, J.; Liu, T.; Yuan, Y.; Xue, N. Eco-Friendly Leaching and Separation of Vanadium over Iron Impurity from Vanadium-Bearing Shale Using Oxalic Acid as a Leachant. Acs. Sustain. Chem. Eng. 2018, 6, 1900–1908. [Google Scholar] [CrossRef]

- Luo, Y.; Che, X.; Cui, X.; Zheng, Q.; Wang, L. Selective leaching of vanadium from V-Ti magnetite concentrates by pellet calcification roasting-H2SO4 leaching process. Int. J. Min. Sci. Technol. 2021, 31, 2095–2686. [Google Scholar] [CrossRef]

- Cao, Z.; Ma, B.; Wang, C.; Chen, Y.; Liu, B.; Xing, P.; Zhang, W. E-pH diagrams for the metal-water system at 150 °C: Thermodynamic analysis and application for extraction and separation of target metals from saprolitic laterite(Article). Miner. Eng. 2020, 152, 106365. [Google Scholar] [CrossRef]

- Pesterfield, L.; Maddox, J.; Crocker, M.; Schweitzer, G. Pourbaix (E–pH-M) Diagrams in Three Dimensions. J. Chem. Educ. 2012, 89, 891–899. [Google Scholar] [CrossRef]

- Chen, D.; Zhao, H.; Hu, G.; Qi, T.; Yu, H.; Zhang, G.; Wang, L.; Wang, W. An extraction process to recover vanadium from low-grade vanadium-bearing titanomagnetite. J. Hazard. Mater. 2015, 294, 35–40. [Google Scholar] [CrossRef]

- Deng, S.; Zheng, W. Effect of polymeric flocculants in secondary removal of silicon for high-purity zirconium oxychloride preparation. Chin. J. Appl. Chem. 1999, 16, 85–87. [Google Scholar]

| Element | Fe | Ti | Si | Ca | Mg | Al | Cr | V | Ni | Mn |

|---|---|---|---|---|---|---|---|---|---|---|

| Content/wt% | 45.0 | 8.0 | 2.0 | 2.0 | 1.0 | 1.0 | 0.5 | 0.3 | 0.2 | 0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, Z.; Wang, Z.; Li, Y.; Zhu, Y.; Xie, K. Selective Leaching of Vanadium from Calcification-Roasted Pellets of Vanadium–Titanium–Iron Concentrate by a Cyclic Two-Stage Sulfuric Acid Process. Minerals 2022, 12, 1613. https://doi.org/10.3390/min12121613

Peng Z, Wang Z, Li Y, Zhu Y, Xie K. Selective Leaching of Vanadium from Calcification-Roasted Pellets of Vanadium–Titanium–Iron Concentrate by a Cyclic Two-Stage Sulfuric Acid Process. Minerals. 2022; 12(12):1613. https://doi.org/10.3390/min12121613

Chicago/Turabian StylePeng, Zhonghui, Zhixiang Wang, Yang Li, Yongze Zhu, and Keqiang Xie. 2022. "Selective Leaching of Vanadium from Calcification-Roasted Pellets of Vanadium–Titanium–Iron Concentrate by a Cyclic Two-Stage Sulfuric Acid Process" Minerals 12, no. 12: 1613. https://doi.org/10.3390/min12121613

APA StylePeng, Z., Wang, Z., Li, Y., Zhu, Y., & Xie, K. (2022). Selective Leaching of Vanadium from Calcification-Roasted Pellets of Vanadium–Titanium–Iron Concentrate by a Cyclic Two-Stage Sulfuric Acid Process. Minerals, 12(12), 1613. https://doi.org/10.3390/min12121613