The water–rock response mechanism of coal mines is an important research topic in the field of coal mining [

1]. Water-rich roadways generally refer to a type of roadway that contains water in the surrounding rock, and instability of the surrounding rock is easily caused under the action of mine water. Such roadways are mostly distributed in Jurassic coal seams in western China mining areas, and their roofs mainly constitute soft and water-bearing rock layers. Among them, weak rock layers are generally coal-measure sedimentary rock layers with an argillization tendency and exhibit engineering characteristics such as nonlinear large deformation and significant rheology after encountering water [

2,

3]. From a microscopic point of view, changes in the external environment caused by the roadway during excavation and mining alter the migration state of the hydraulic field of the surrounding rock, resulting in complex physical, chemical, and mechanical effects which in turn change the microstructure and mechanical properties of the rock [

4]. Hence, engineering accidents are likely to occur, and it is extremely difficult to maintain the surrounding rock stability of water-rich roadways, which is the primary scientific problem to be solved urgently in such mines.

In order to solve the above problems, related scholars have carried out a series of research and industrial tests on the water–rock interaction mechanism and stability control technology for water-rich coal measures roadways surrounding rock and achieved a series of useful results. Generally, a rock sample that has been immersed in water for a longer period of time possesses a higher water content, and consequently, its mechanical parameters—such as uniaxial compressive strength, elastic modulus, and tensile strength—decrease more significantly compared to that of a sample that has not been immersed in water [

5,

6,

7]. Water intrusion into coal and rock increases the pore water pressure, reduces the effective stress, weakens the elastic energy storage and release ability, and alters the stress state and microstructure of coal and rock [

8,

9]. Chen et al. [

10] found that the water–rock interaction was complicated by increasing the discreteness of the rock surface height and the enhanced deviation and roughness of the reference surface. Laska-Ripour et al. [

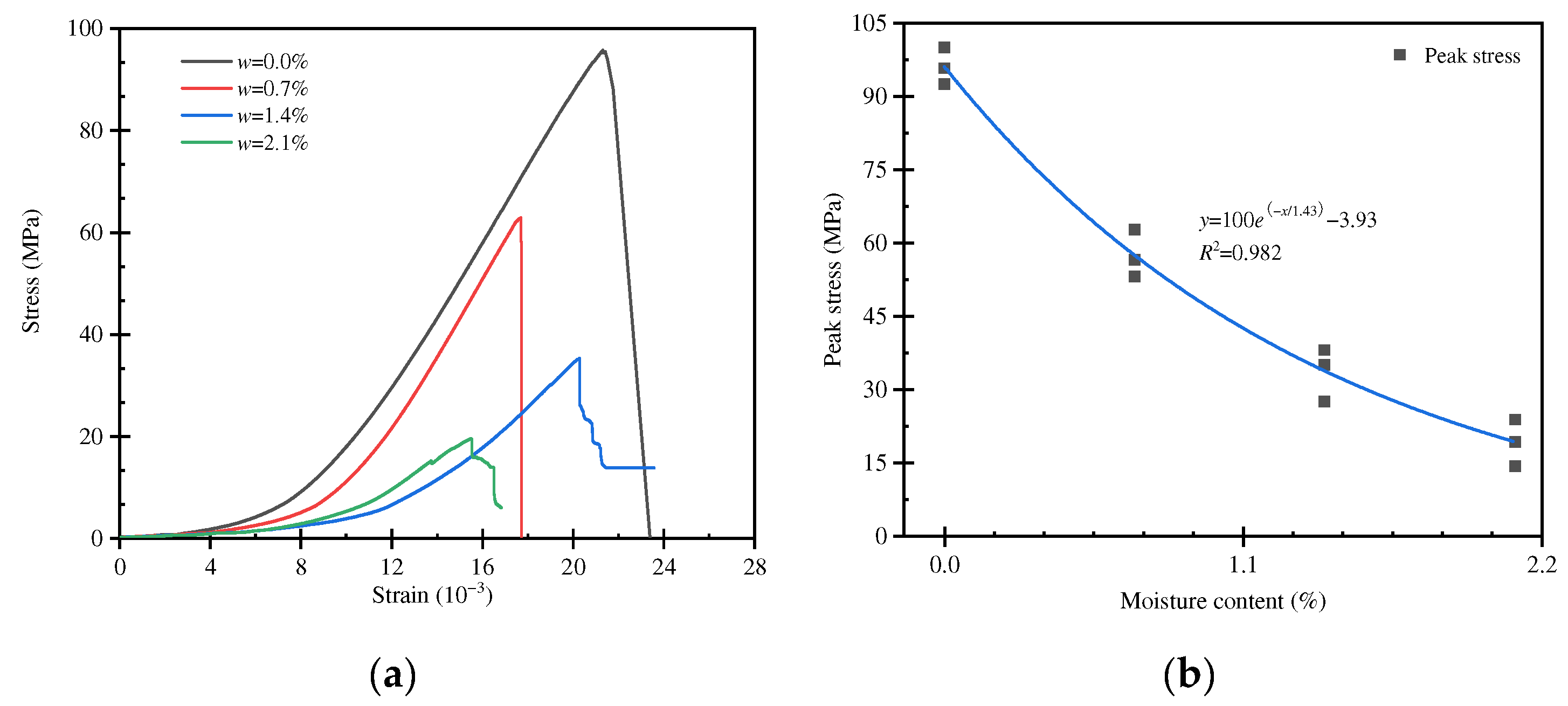

11] studied the rock strength damage law by changing the water content of test blocks and concluded that the uniaxial compressive strength of mud shale decreases negatively exponentially with the increase of water content. Daraei et al. [

12,

13] looked into the role of moisture content on the critical and breaking strains of rocks by uniaxial compression tests, and the rocks used in the tests included eight types of sandstone, conglomerate, mudstone, limestone, siltstone, schist, sillimanite, and amphibolite, and they found that the critical strain increased after most of the rocks reached saturation, and as the moisture content increased, the maximum value of rock-breaking strain became 2.14 times the critical strain. Deng et al. [

14,

15,

16] studied the damage caused by the interaction between water and sandstone under dry and wet cycles and proposed the strength weakening law of sandstone and its constitutive equation, which provided a theoretical basis for realistic engineering problems. Li et al. [

17] established the creep constitutive model of coal–rock combination considering the influence of moisture content based on the Burgers creep model. According to the experimental results of triaxial creep of rock, the relationship between the moisture content and the parameter of the Burgers creep model was derived, and the correctness of the constitutive model in this study was verified. Under the same stress state, with the increased of moisture content, the strain rate of the coal–rock combination exhibited a nonlinear rapid increase in the constant velocity creep stage The limit creep deformation, the instantaneous elastic deformation increased, and the viscosity coefficient significantly decreased. Dong et al. [

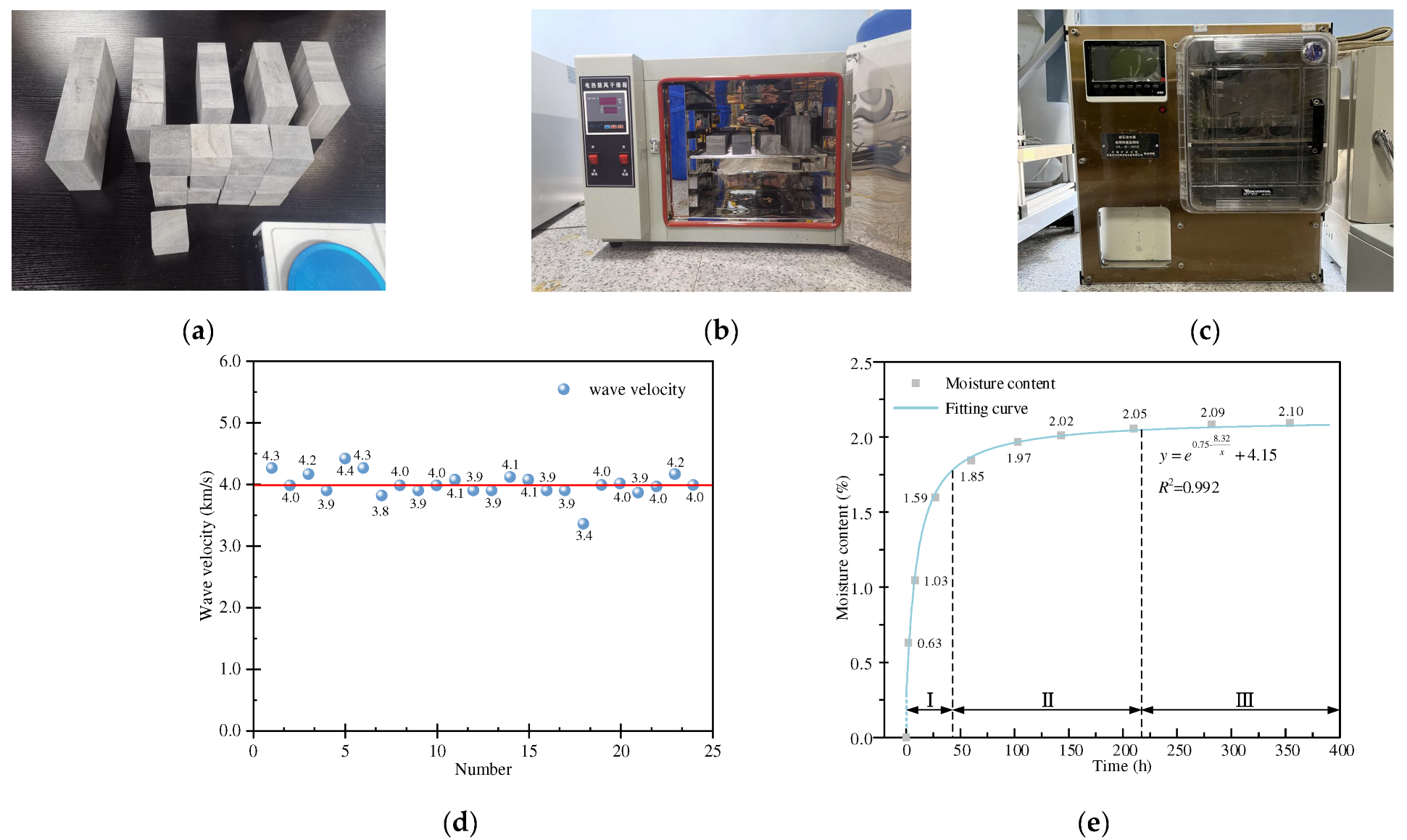

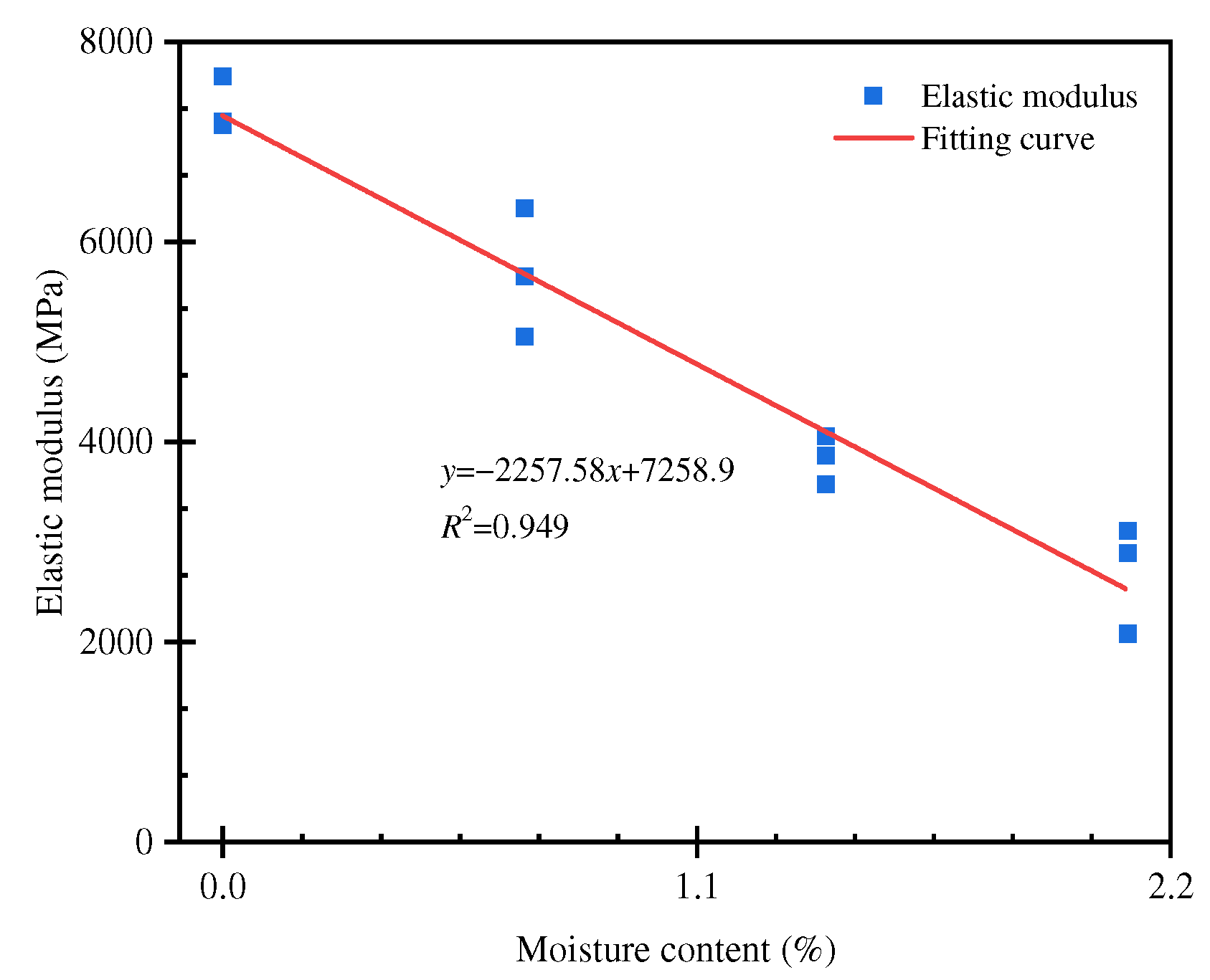

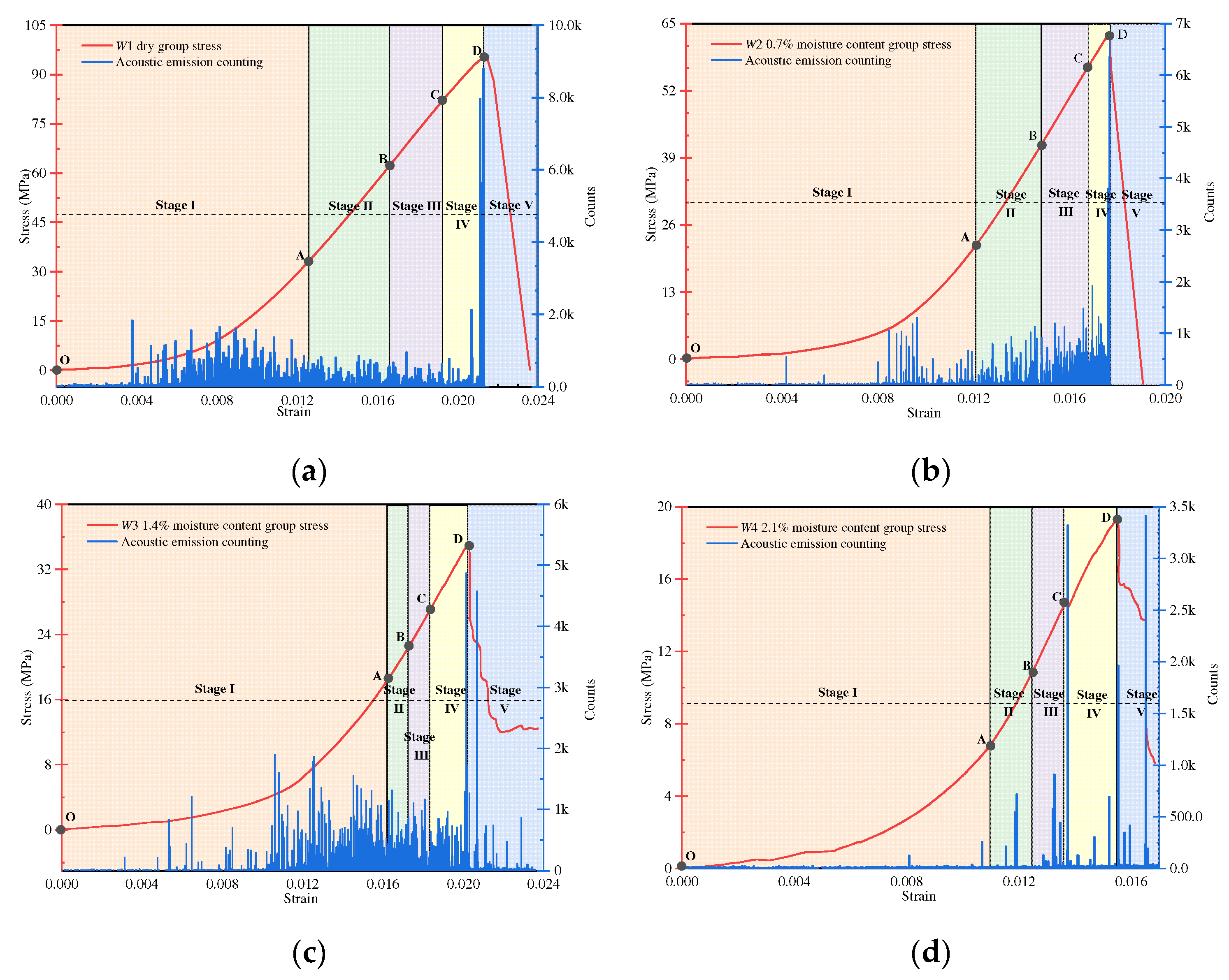

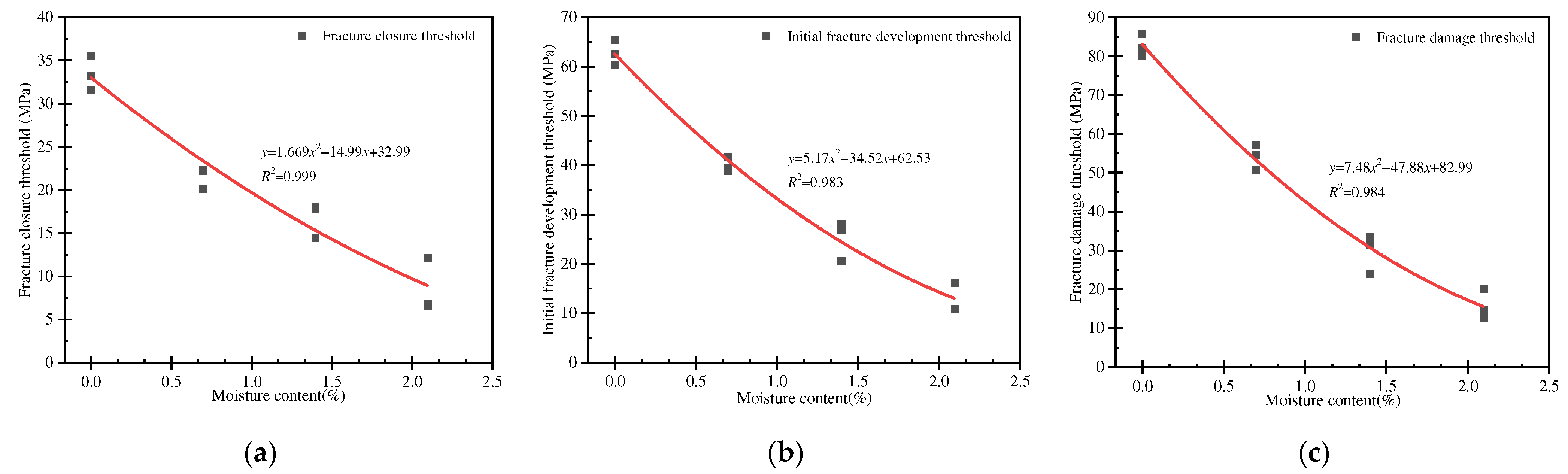

18] studied the moisture content variation of tuff in water absorption tests, and the mechanical and failure characteristics of tuff under different moisture contents were studied through uniaxial compression tests with a Micro-II acoustic emission (AE) control acquisition system. The results showed that the moisture content of tuff increases rapidly at the initial stage of water absorption tests and stabilizes after 180 h of immersion. According to the results of uniaxial compression tests, both uniaxial compressive strength and elasticity modulus decreased with the increase in moisture content. The AE parameters analyses showed that when the moisture content increased, the accumulated AE counts and energy gradually decreased, and the “quiet period” at the initial stage of uniaxial compression tests lasted longer. At present, the maintenance of water-rich coal measures roadways often adopts a combination of control techniques, and many scholars have conducted considerable amounts of field research. Xu et al. [

2] studied the deformation law of muddied soft rock roadway under the action of water and proposed the dynamic process control technology of muddied soft rock roadway. Li et al. [

19,

20] revealed the destabilization mechanism of weakly bonded roof and proposed the long anchor cable and short anchor cable roof control techniques. Zhang et al. [

21,

22] studied the destabilization and collapse of the roadway due to weakly interbedded rock masses and revealed the mechanism of roof destabilization under the influence of dynamic pressure via roof muddification and weakly interbedded layers. Tang et al. [

23] simulated the floor heave processes of a swelling rock tunnel under high humidity through simulation with RFPA. González-Nicieza et al. [

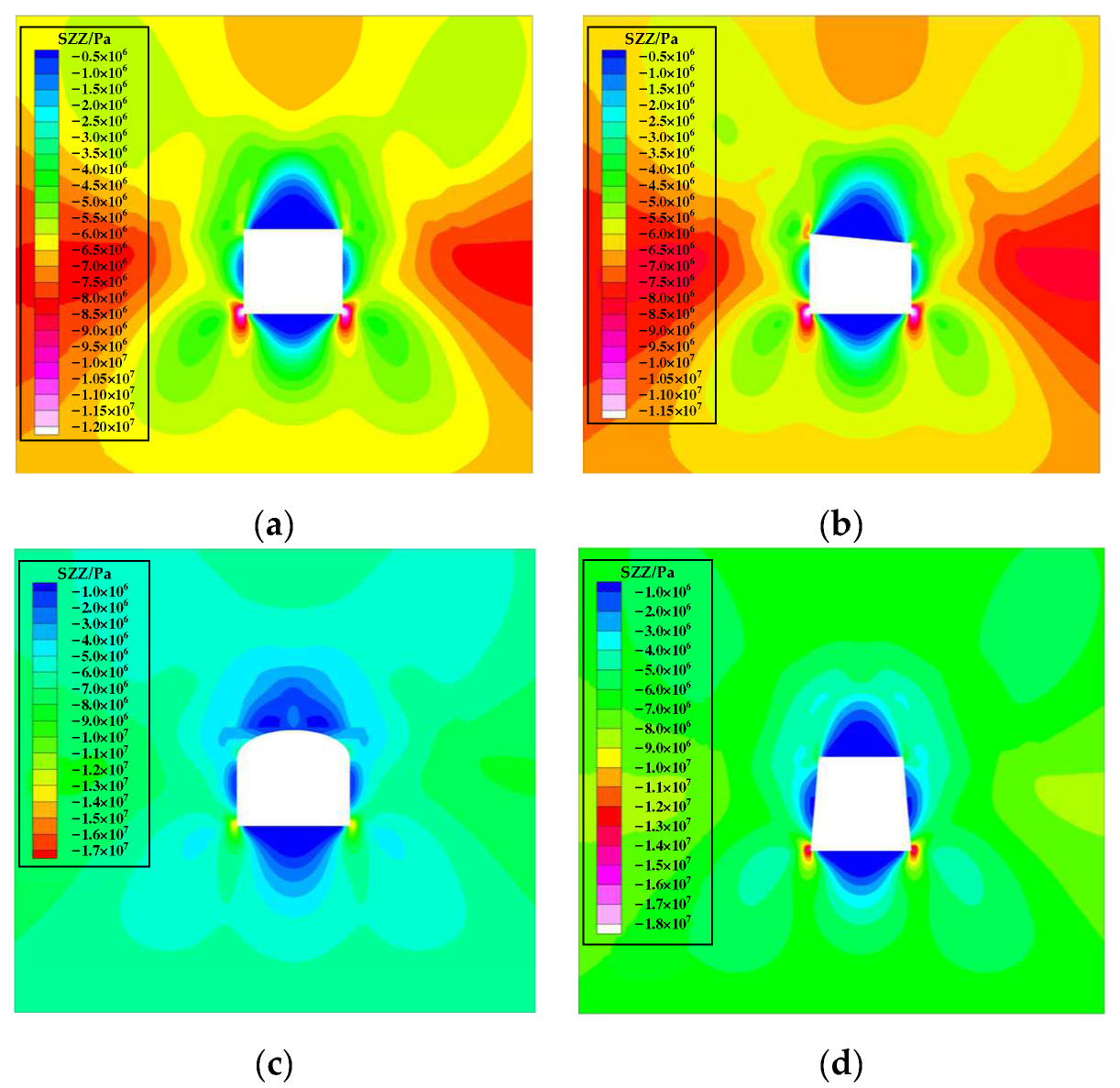

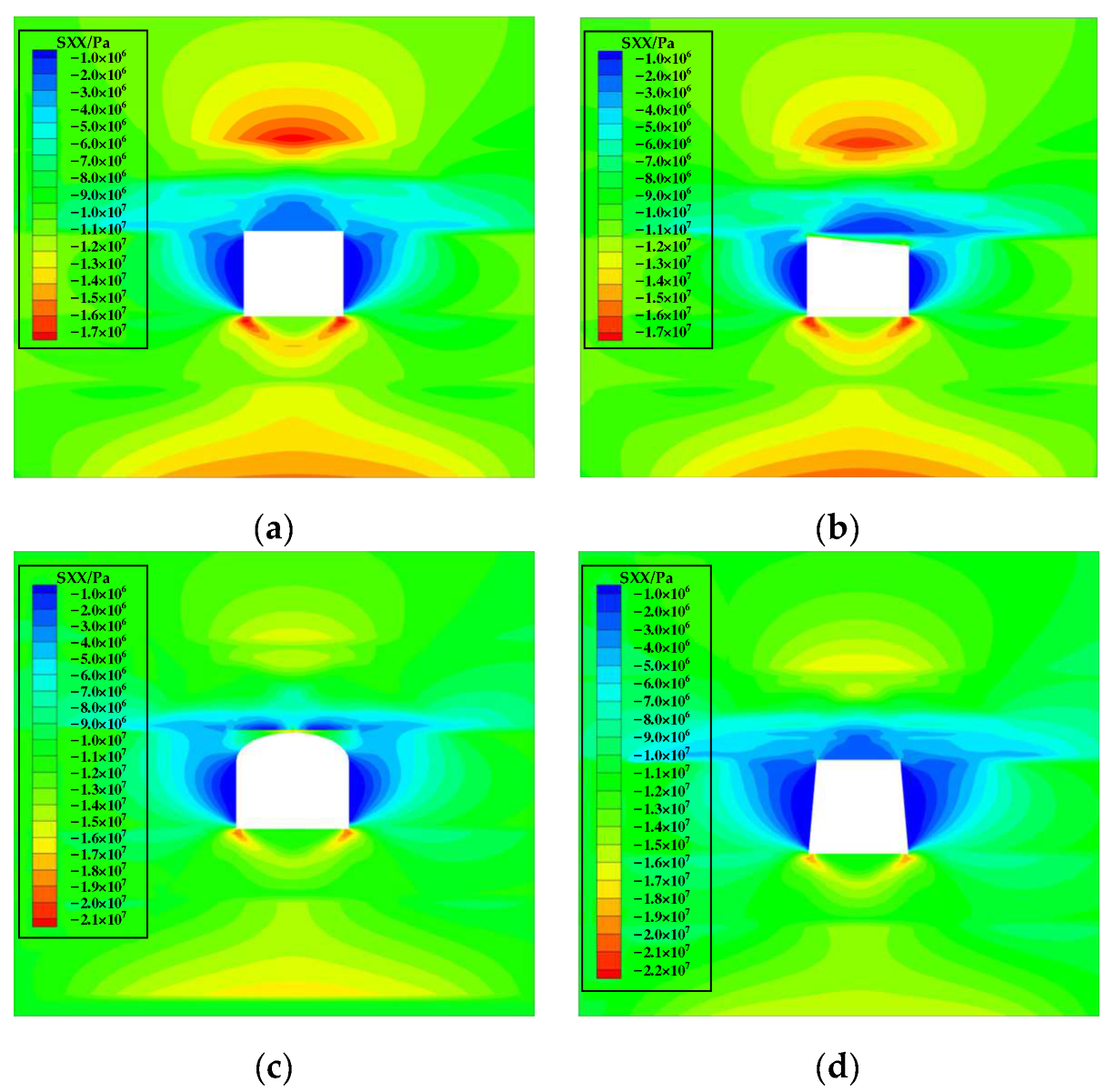

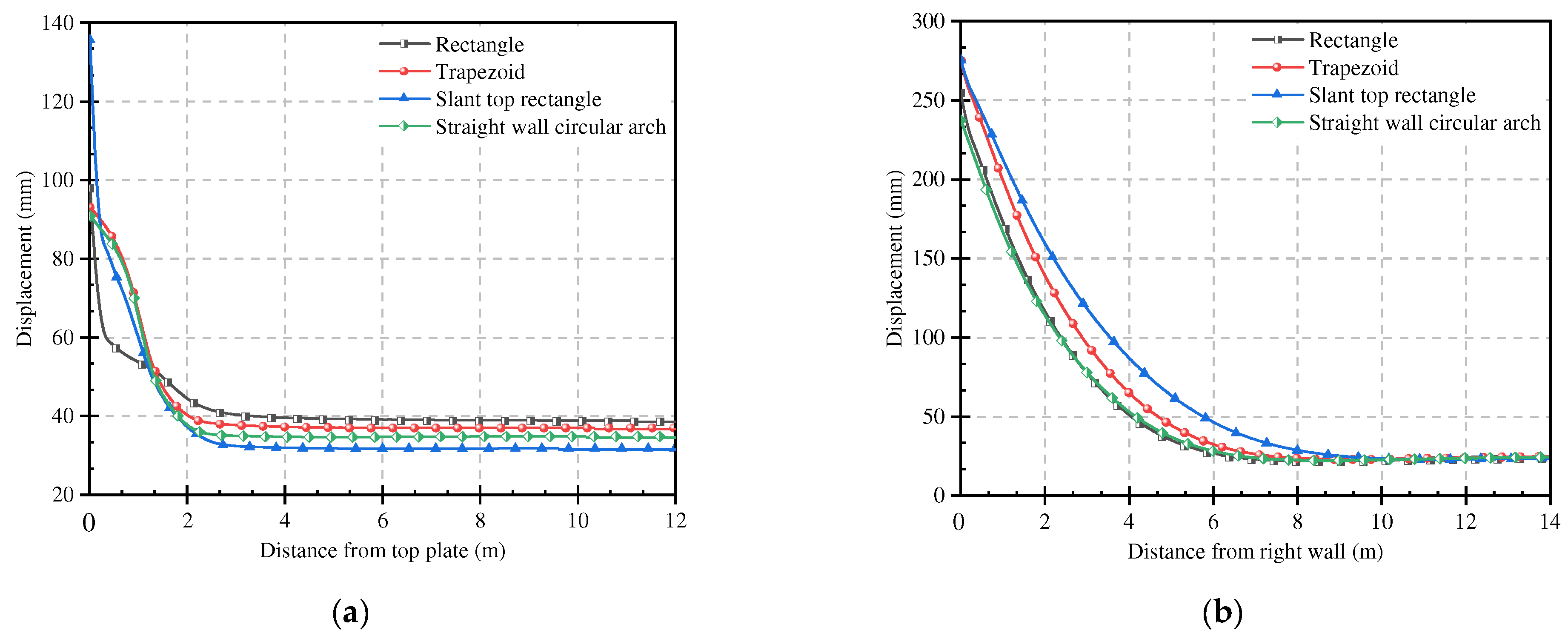

24] investigated the influence of the depth and cross section of the tunnel on the radial displacement via the convergence–confinement method.

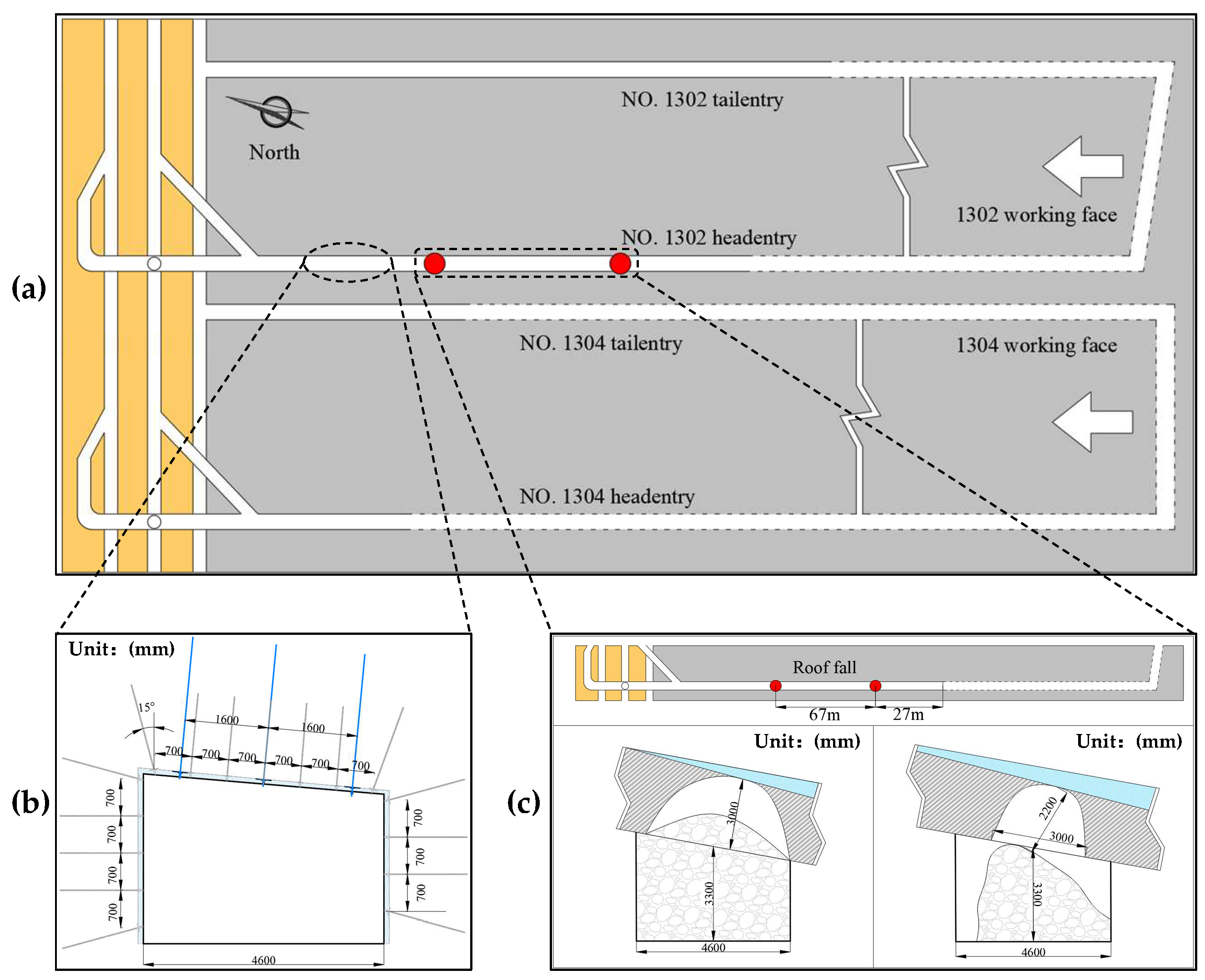

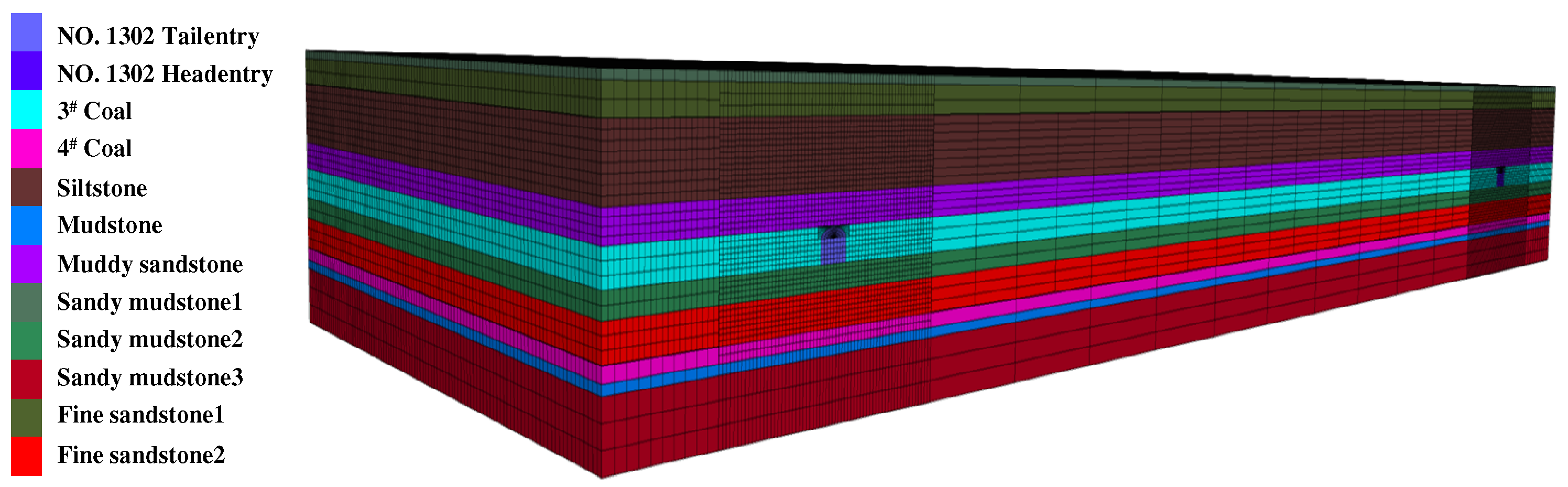

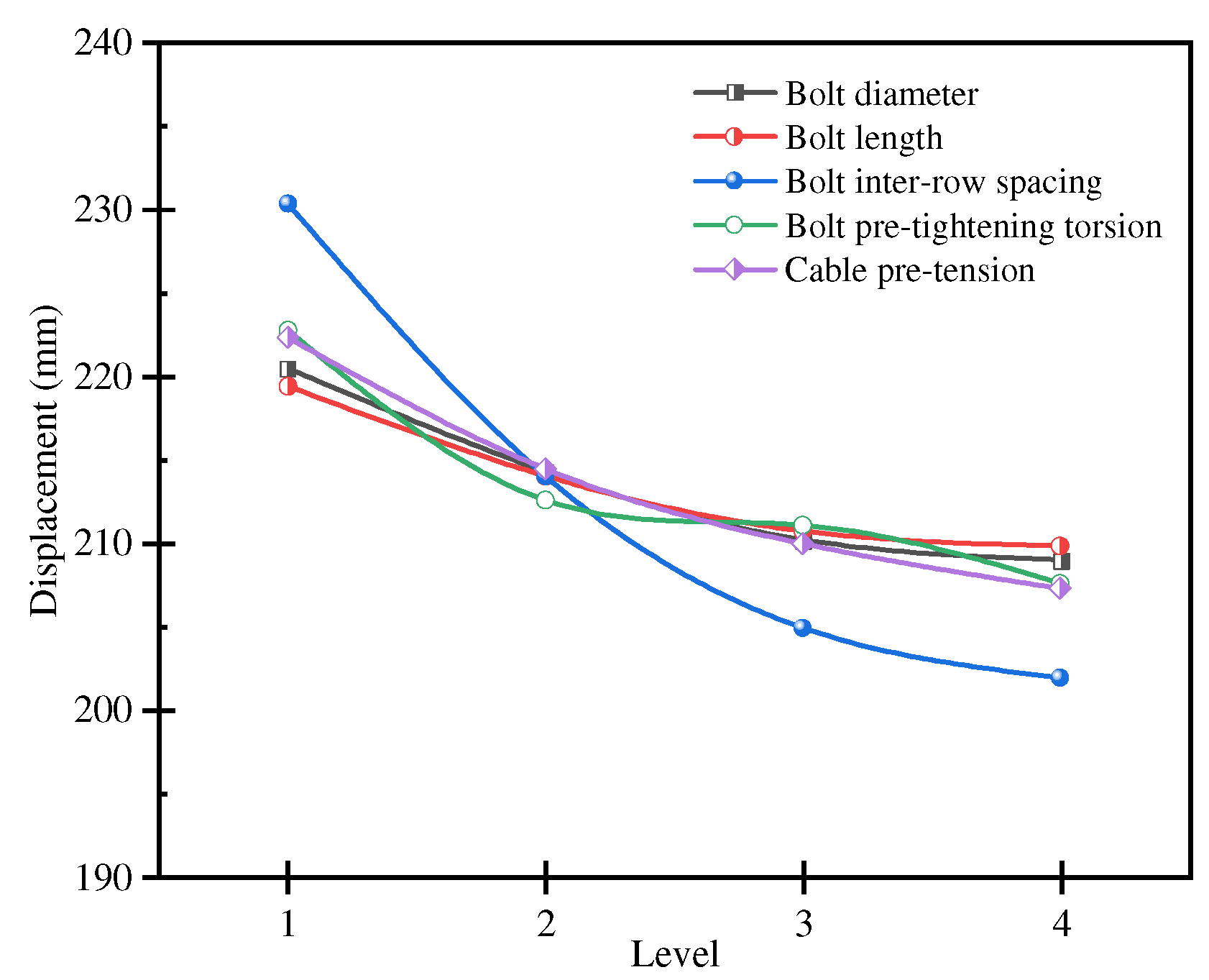

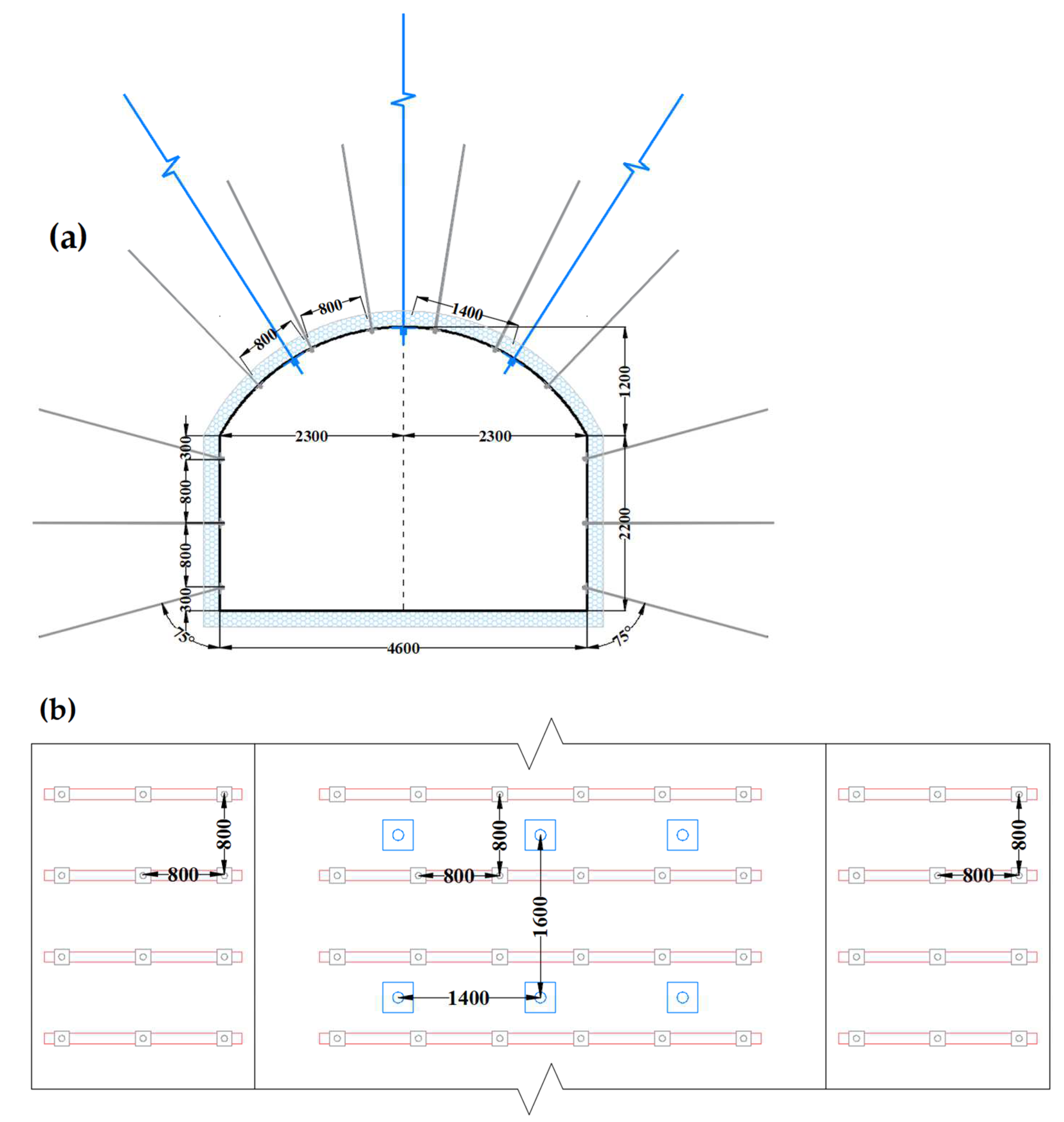

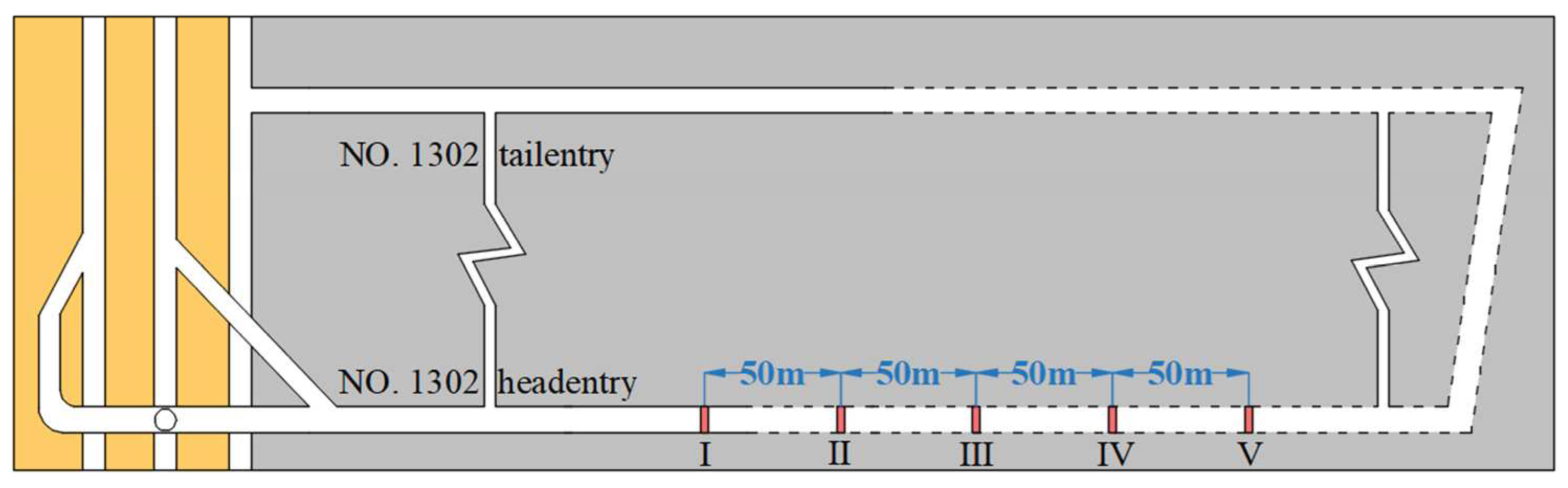

Considering the engineering background of a water-rich roadway in a coal mine in the Qingyang mining area in western China, this study proposed a scheme for controlling the stability of the surrounding rock of the roof of the water-rich roadway by systematically investigating the mechanical property damage law and strength-weakening mechanism of the roof under water–rock interaction. Accordingly, the developed scheme was applied in a coal mine. Through field measurements, the space–time evolution characteristics of the deformation and failure of the surrounding rock of the water-rich roadway were determined. The research results can provide reference for controlling the surrounding rock of the mine and even the same type of roadway and thus have practical significance.