Automatic Cutting Speed Control System of Boom-Type Roadheader Based on Geological Strength Index

Abstract

1. Introduction

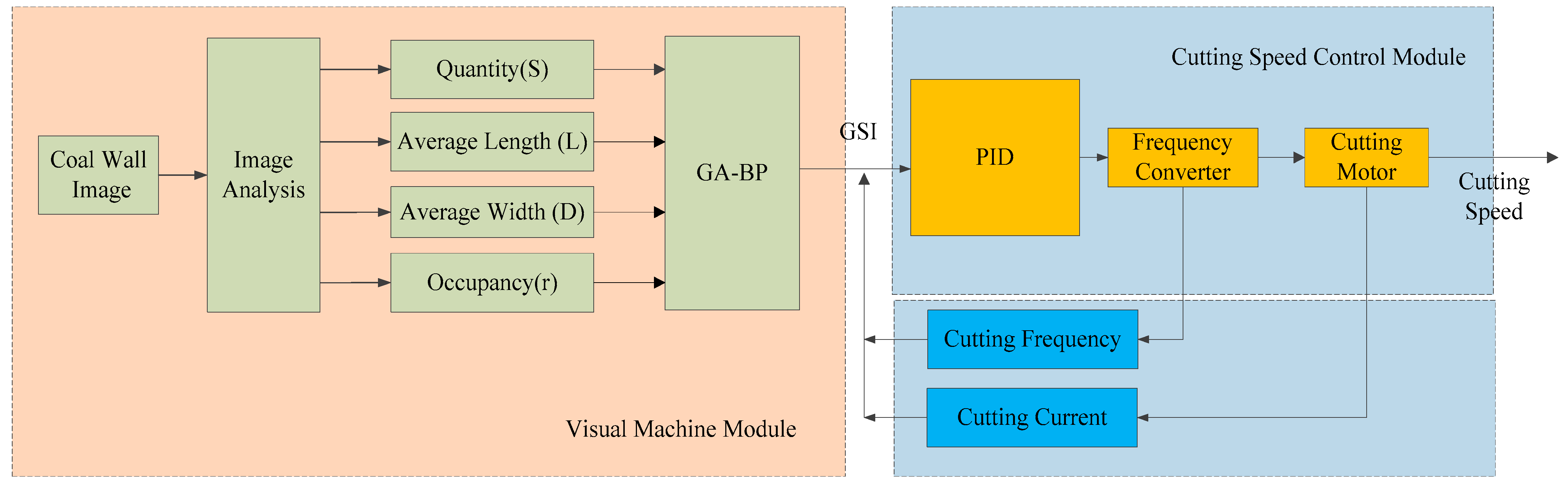

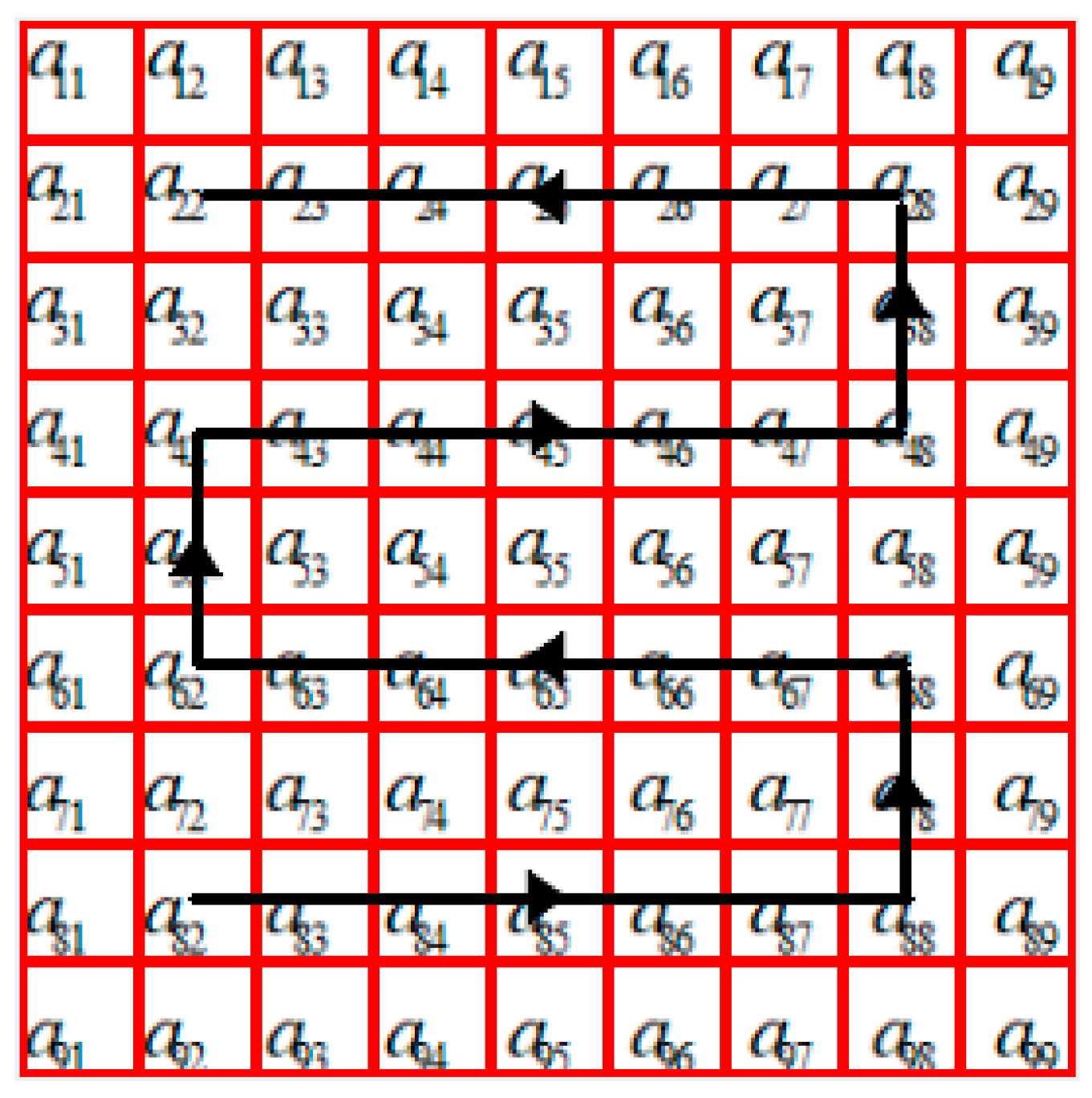

2. Geological Strength Index

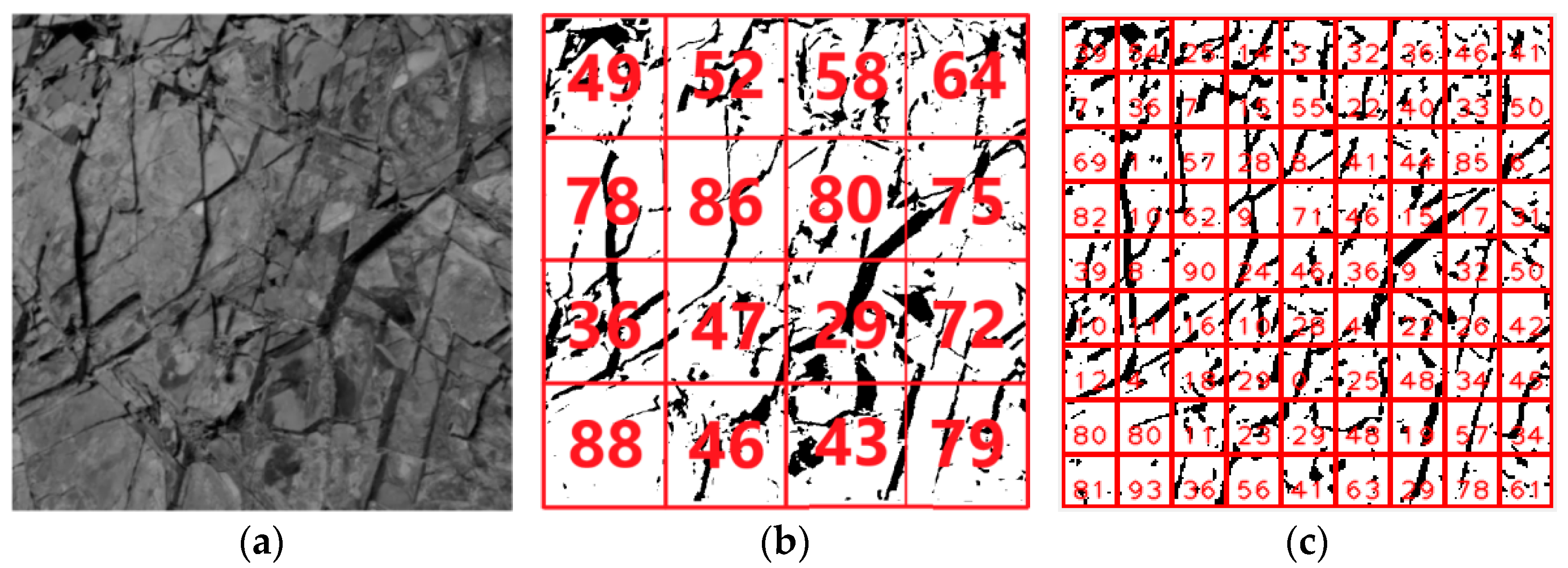

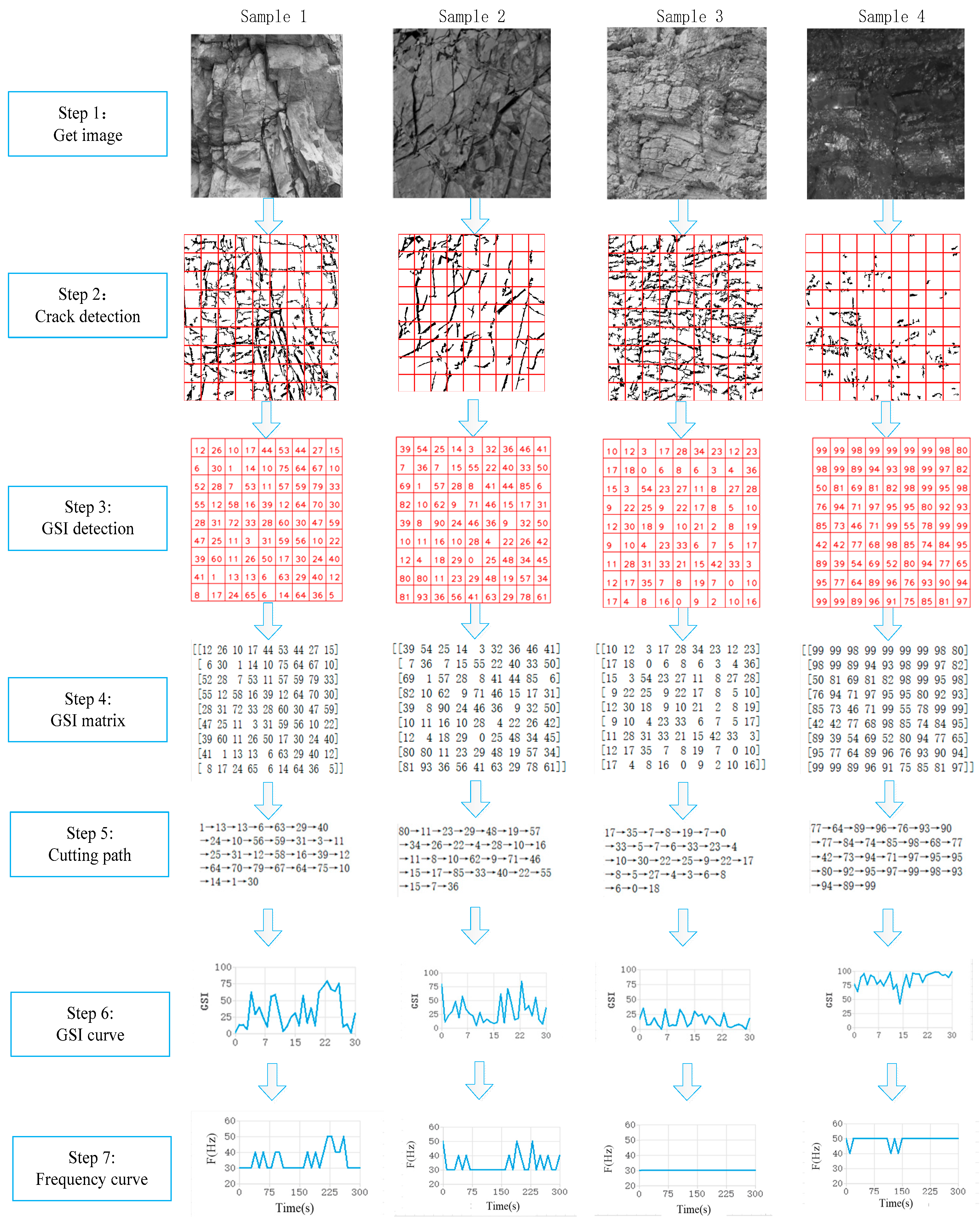

3. Image Detection

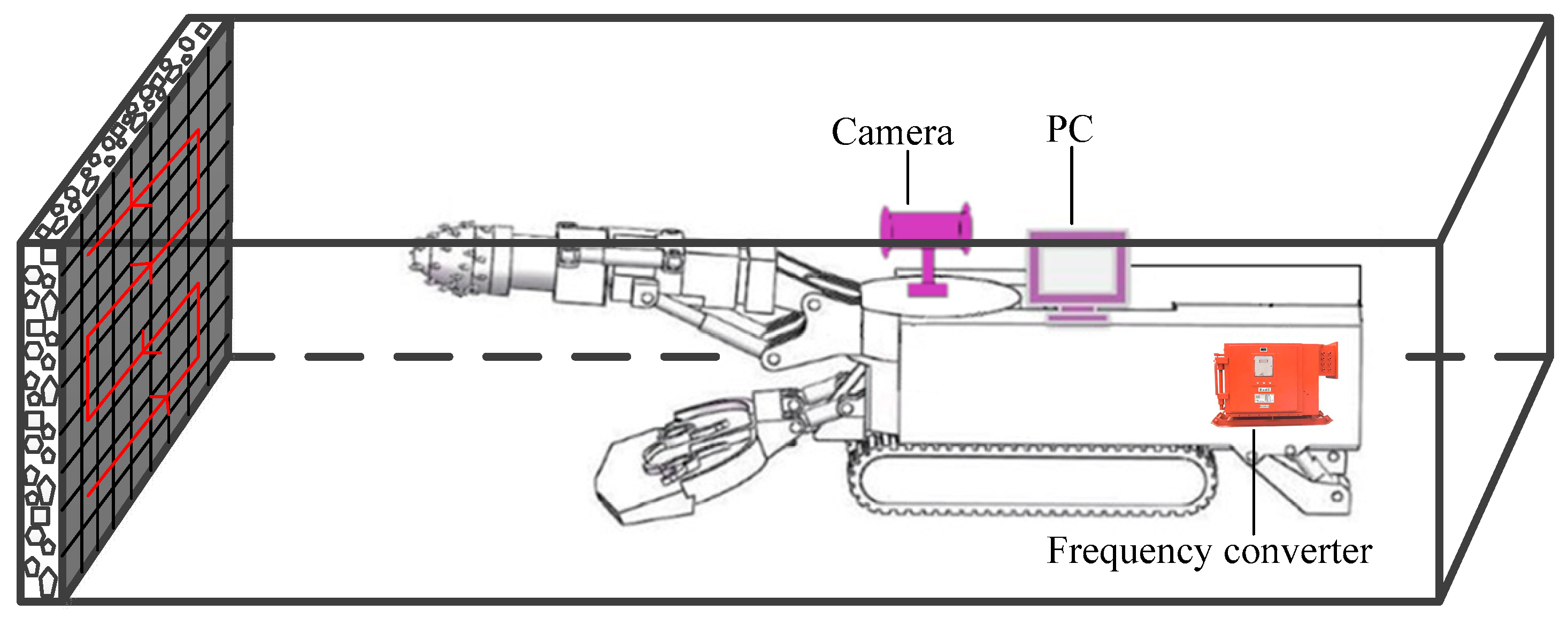

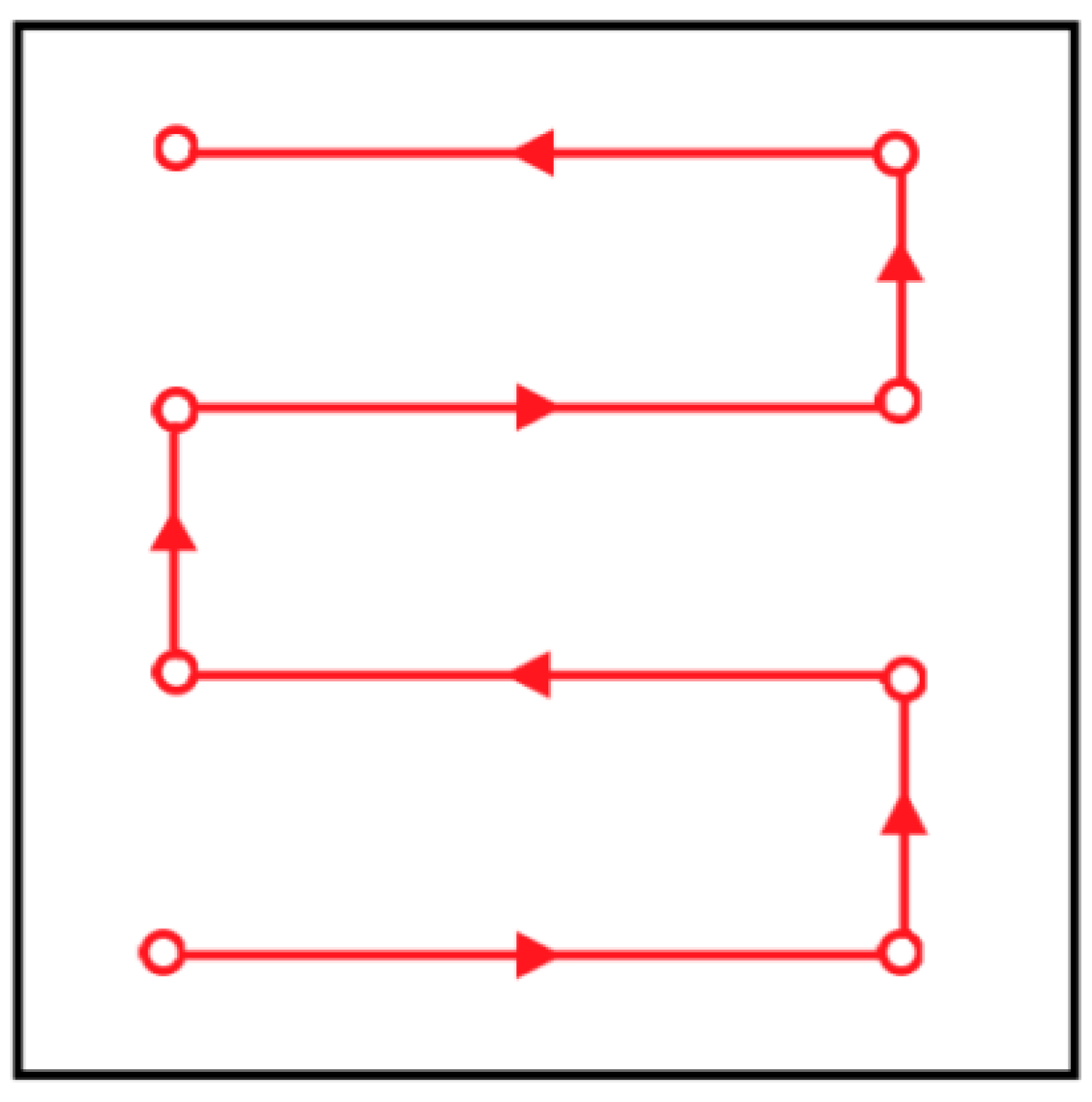

3.1. Acquire Image

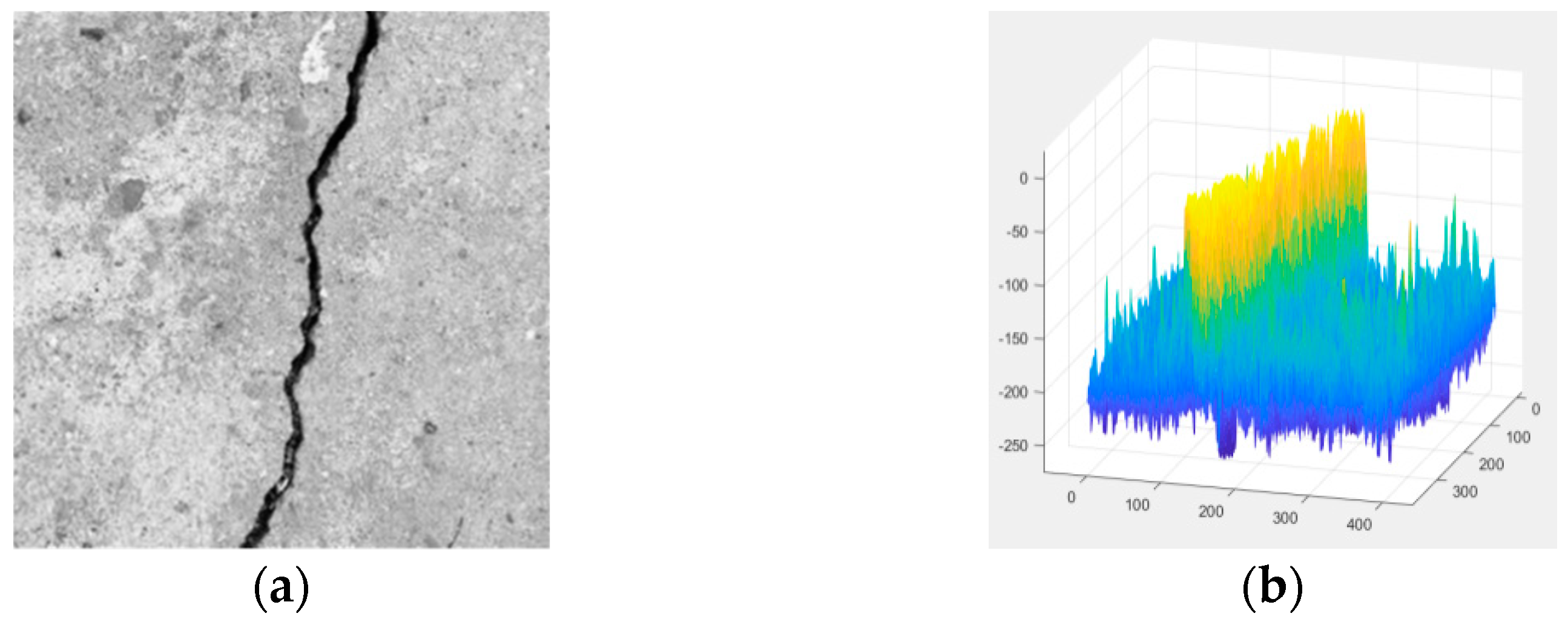

3.2. Crack Detection

- Edge detection:

- 2.

- Binarization:

- 3.

- Noise removal:

- 4.

- Skeleton connection:

3.3. Fracture Characteristic

- Quantity: the quantity of fissure joints in the image is calculated by calculating the lines with continuous gray values, and the line length needs to be greater than the set threshold.

- Length: the length of the image corresponding to each pixel is known. The distance between horizontal or vertical adjacent pixels is 1 pixel interval, and the distance between 45° adjacent pixels is a pixel interval. The crack joint length is the product of the number of central points of the contour skeleton and the length of a single pixel:where L is the crack length, n is the number of horizontally or vertically adjacent pixels on the centerline, m is the number of 45° adjacent pixels on the centerline, and is the length of a single pixel.

- Width: make a vertical line on the skeleton centerline of the fracture joint. The width of the fracture is the product of the number of vertical lines of the skeleton centerline of the contour and the length of a single pixel:where D is the crack width, p is the number of horizontally or vertically adjacent pixels on the vertical line, q is the number of 45° adjacent pixels on the vertical line, and is the length of a single pixel.

- Occupancy: The occupancy rate can reflect the complexity of fissure joints in the image, which is determined by the ratio of the number of pixels of fissure joints to the number of pixels of non-fissure joints in the image.

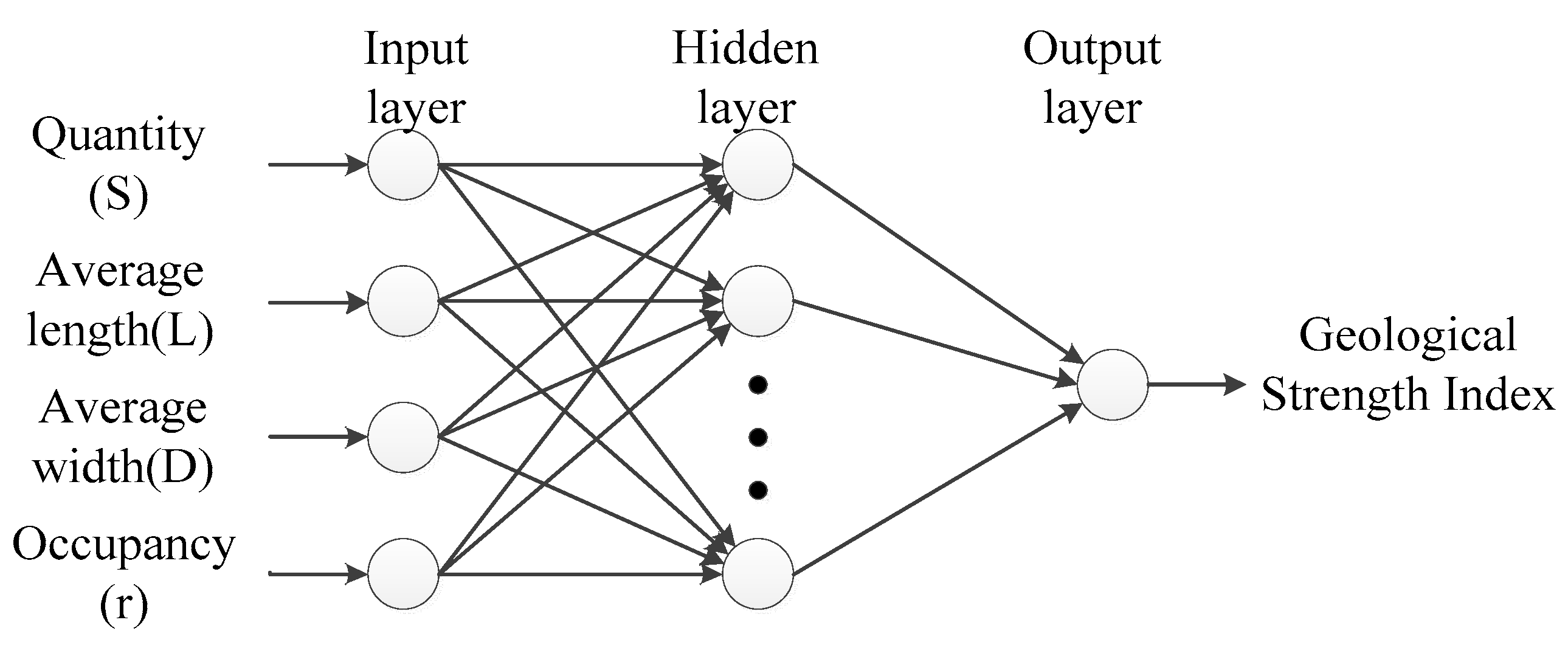

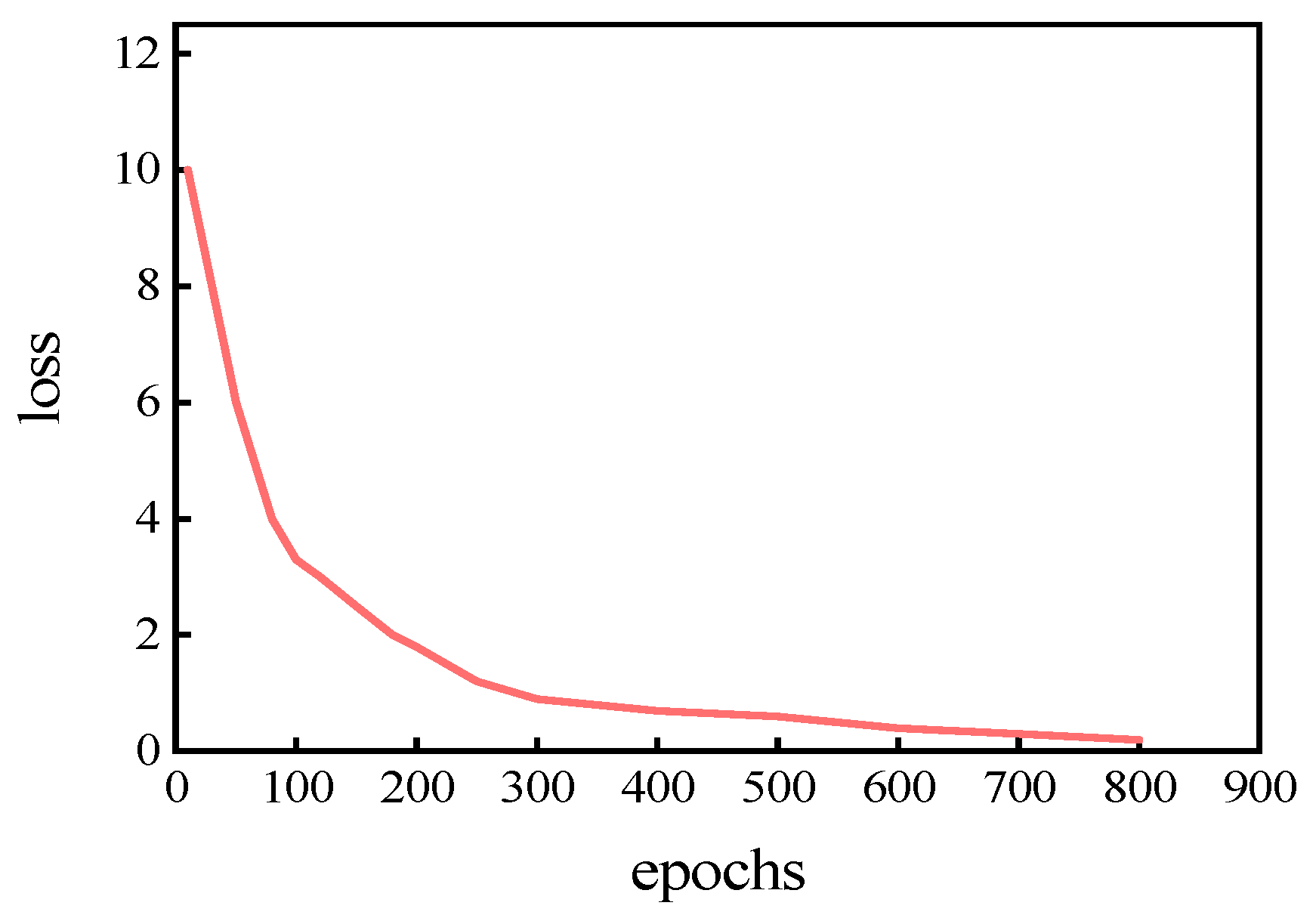

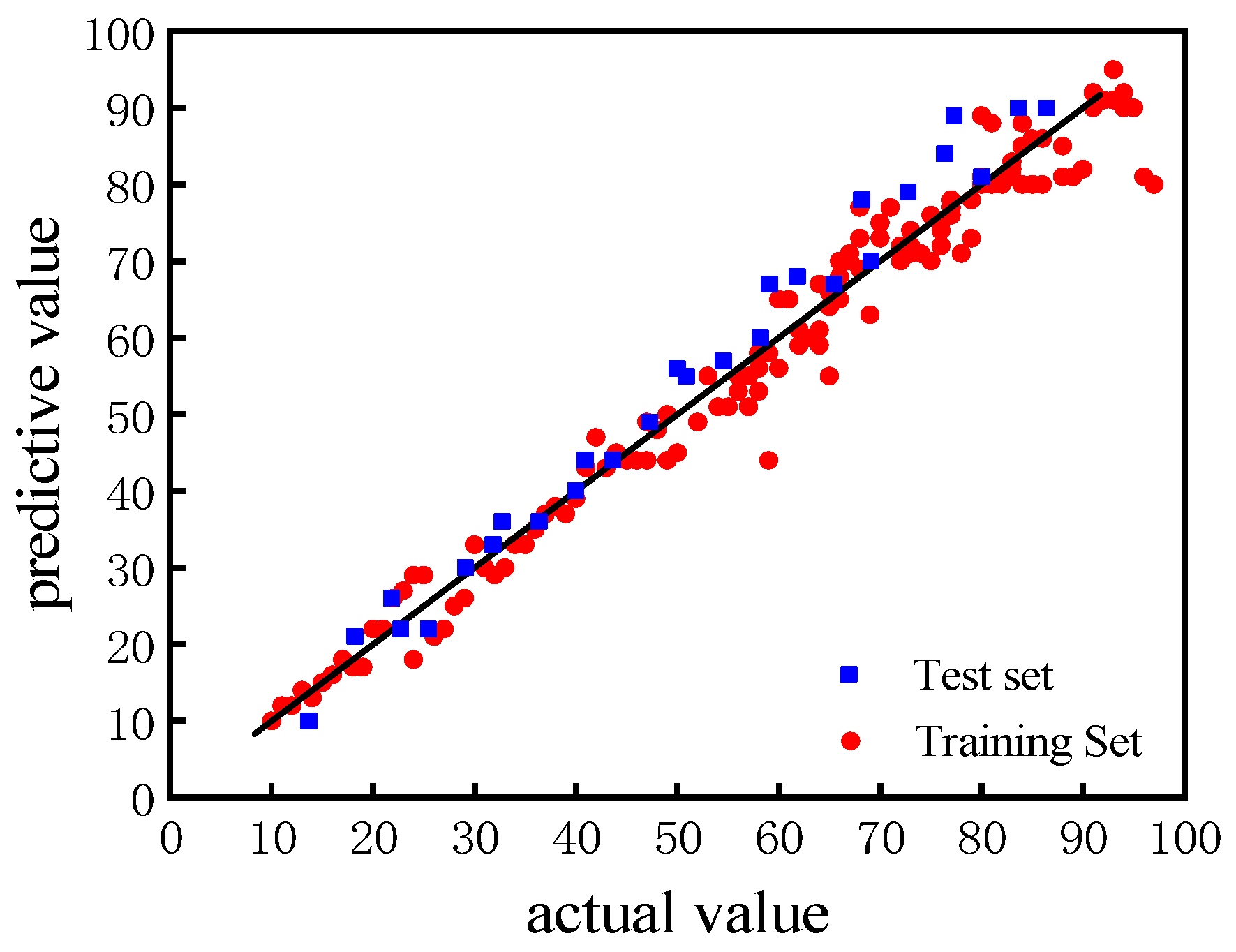

3.4. GA-BP Neural Network

4. Automatic Cutting Control Strategy

4.1. Fractal Dimension

4.2. Control Strategy

5. Experiments and Results

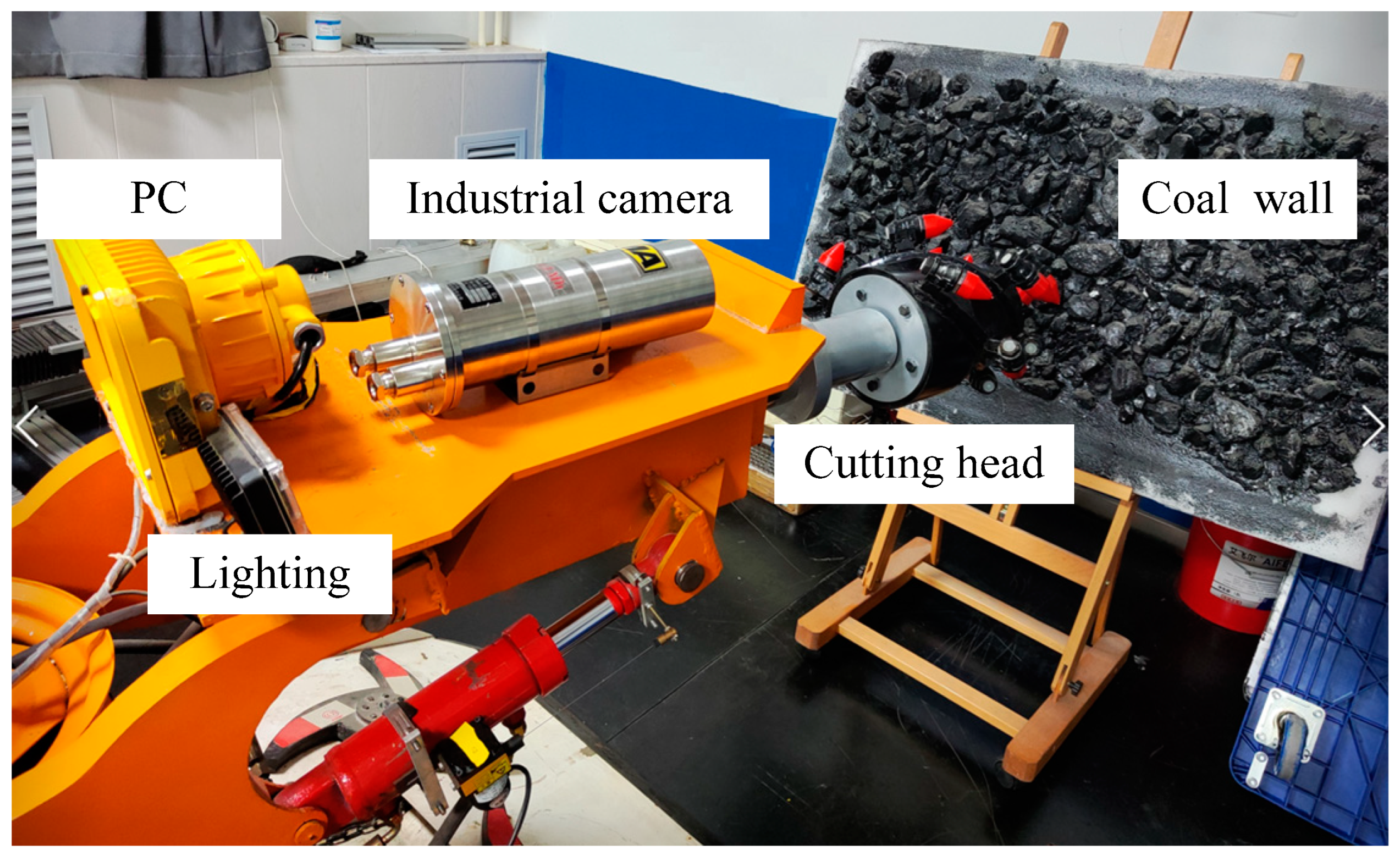

5.1. Establishment of Experimental Platform

5.2. Coal Wall Sample

5.3. Cutting Experiment

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, G.F.; Ren, H.W.; Pang, Y.H. Research and engineering progress of intelligent coal mine technical system in early stages. Coal Sci. Technol. 2020, 48, 1–27. [Google Scholar] [CrossRef]

- Wang, G.F.; Du, Y.B. Development direction of intelligent coal mine and intelligent mining technology. Coal Sci. Technol. 2019, 47, 1–10. [Google Scholar] [CrossRef]

- Wang, H.; Wang, B.K.; Zhang, X.F. Key technology and engineering practice of intelligent rapid heading in coal mine. J. China Coal Soc. 2021, 46, 2068–2083. [Google Scholar] [CrossRef]

- Zhang, Y.B.; Liu, X.R.; Liu, X.; Wang, S.Y.; Ren, F.Y. Numerical characterization for rock mass integrating GSI/Hoek-Brown system and synthetic rock mass method. J. Struct. Geol. 2019, 126, 318–329. [Google Scholar] [CrossRef]

- Bertuzzi, R.; Douglas, K.; Mostyn, G. Improving the GSI Hoek-Brown criterion relationships. Int. J. Rock. Mech. Min. 2016, 89, 185–199. [Google Scholar] [CrossRef]

- Michalowski, R.L.; Park, D. Stability assessment of slopes in rock governed by the Hoek-Brown strength criterion. Int. J. Rock. Mech. Min. 2020, 127, 104217. [Google Scholar] [CrossRef]

- Marinos, P.; Hoek, E.; Marinos, V. Variability of the engineering properties of rock masses quantified by the geological strength index: The case of ophiolites with special emphasis on tunnelling. B. Eng. Geol. Environ. 2006, 65, 129–142. [Google Scholar] [CrossRef]

- Somodi, G.; Bar, N.; Kovács, L.; Arrieta, M.; Török, Á.; Vásárhelyi, B. Study of Rock Mass Rating (RMR) and Geological Strength Index (GSI) Correlations in Granite, Siltstone, Sandstone and Quartzite Rock Masses. Appl. Sci. 2021, 11, 3351. [Google Scholar] [CrossRef]

- Hoek, E.; Wood, D.; Shah, S. A modified Hoek-Brown criterion for jointed rock masses. In Proceedings of the Rock Characterization: ISRM Symposium, Eurock’92, Chester, UK, 14–17 September 1992; Thomas Telford Publishing: London, UK, 1992; pp. 209–214. [Google Scholar]

- Marinos, P.; Hoek, E. Estimating the geotechnical properties of heterogeneous rock masses such as Flysch. Bull. Eng. Geol. Environ. 2001, 60, 85–92. [Google Scholar] [CrossRef]

- Saeidi, A.; Cloutier, C.; Kamalibandpey, A.; Shahbazi, A. Evaluation of the Effect of Geomechanical Parameters and In Situ Stress on Tunnel Response Using Equivalent Mohr-Coulomb and Generalized Hoek-Brown Criteria. Geosciences 2022, 12, 262. [Google Scholar] [CrossRef]

- Chen, C.; Li, T.; Ma, C.; Zhang, H.; Tang, J.; Zhang, Y. Hoek-Brown Failure Criterion-Based Creep Constitutive Model and BP Neural Network Parameter Inversion for Soft Surrounding Rock Mass of Tunnels. Appl. Sci. 2021, 11, 10033. [Google Scholar] [CrossRef]

- Jearsiripongkul, T.; Keawsawasvong, S.; Thongchom, C.; Ngamkhanong, C. Prediction of the Stability of Various Tunnel Shapes Based on Hoek–Brown Failure Criterion Using Artificial Neural Network (ANN). Sustainability 2022, 14, 4533. [Google Scholar] [CrossRef]

- Cai, M.; Kaiser, P.K.; Uno, H.; Tasaka, Y.; Minami, M. Estimation of rock mass deformation modulus and strength of jointed hard rock masses using the GSI system. Int. J. Rock. Mech. Min. 2004, 41, 3–19. [Google Scholar] [CrossRef]

- Zhang, Q.; Huang, X.; Zhu, H.; Li, J. Quantitative assessments of the correlations between rock mass rating (RMR) and geological strength index (GSI). Tunn. Undergr. Space Tech. 2019, 83, 73–81. [Google Scholar] [CrossRef]

- Osgoui, R.R.; Unal, E. An empirical method for design of grouted bolts in rock tunnels based on the geological strength index (GSI). Eng. Geol. 2009, 107, 154–166. [Google Scholar] [CrossRef]

- Wang, P.J.; Yang, Y.; Wang, D.J. Intelligent cutting control system and method of coal and gangue in robotic roadheader. J. China Coal Soc. 2021, 46, 1124–1134. [Google Scholar] [CrossRef]

- Zong, K.; Fu, S.C.; Wu, M. Simulation of control strategy for swing speed of roadheader’s cutting arm based on GA-BP network. J. China Coal Soc. 2021, 46, 511–519. [Google Scholar] [CrossRef]

- Wang, S.Y.; Ma, D.C.; Ren, Z. A multi-objective optimization method for cantilever roadheader section forming trajectory. Chin. J. Sci. Instrum. 2021, 41, 183–192. [Google Scholar] [CrossRef]

- Lei, M.Y.; Zhang, X.H.; Yang, W.J. Current status and trend of research on visual pose detection and control of tunneling equipment in coal mines. J. China Coal Soc. 2021, 1–14. [Google Scholar] [CrossRef]

- Zhang, X.H.; Zhao, J.X.; Zhang, C. Visual servo control system for cutting of boom-type roadheader. Coal Sci. Technol. 2022, 50, 263–270. [Google Scholar]

- Yang, W.J.; Zhang, X.H.; Zhang, C. Research on intelligent cutting control system for roadway forming of boom-type tunneling robot. Ind. Mine Autom. 2019, 45, 40–46. [Google Scholar] [CrossRef]

- Wang, P.; Su, X.B.; Han, Y. Quantitative Characterization of Coal Structure and Its Significance. Saf. Coal Mines 2014, 45, 12–15. [Google Scholar] [CrossRef]

- Guo, H.Y.; Su, X.B.; Xia, D.P. Relationship of the permeability and geological strength index (GSI) of coal reservoir and its significance. J. China Coal Soc. 2010, 35, 1319–1322. [Google Scholar] [CrossRef]

- Wang, T.H.; Dong, Z.; Liu, J.Q.; Guo, H.Y. Design and complete of coal GSI detection system based on mobile image processing. Coal Sci. Technol. 2021, 49, 154–159. [Google Scholar] [CrossRef]

- Hong, K.; Han, E.; Kang, K. Determination of geological strength index of jointed rock mass based on image processing. J. Rock. Mech. Geotech. 2017, 9, 702–708. [Google Scholar] [CrossRef]

- Yang, S.; Liu, S.; Zhang, N. A fully automatic-image-based approach to quantifying the geological strength index of underground rock mass. Int. J. Rock. Mech. Min. 2021, 140, 104585. [Google Scholar] [CrossRef]

- Albuquerque, K.; Silva, H.; Teodoro, E.; Fonseca, A.; Garioli, G.; Lopes, E.; Cota, L.; Euzébio, T. Averaging level control of bulk solid material using a tripper car. IFAC-Pap. 2019, 52, 147–152. [Google Scholar] [CrossRef]

- Brand, H.G.; Vosloo, J.C.; Mathews, E.H. Automated energy efficiency project identification in the gold mining industry. In Proceedings of the 2015 International Conference on the Industrial and Commercial Use of Energy (ICUE) IEEE, Cape Town, South Africa, 18–19 August 2015. [Google Scholar]

- Hoek, E.; Brown, E.T. Practical estimates of rock mass strength. Int. J. Rock. Mech. Min. 1997, 34, 1165–1186. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. How long is the coast of Britain? Statistical self-similarity and fractal dimension. Science 1967, 155, 636–638. [Google Scholar] [CrossRef]

- Mandelbrot, B.B.; Blumen, A. Fractal Geometry: What is it, and What Does it do? [and Discussion]. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1989, 1864, 3–16. [Google Scholar]

| Geological Strength Index | Structure Characteristics | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| VERY GOOD | GOOD | FAIR | POOR | VERY POOR | |||||||

| STRUCTURE | DECREASING SURFACE QUALITY → | ||||||||||

| The rock mass has complete structure, few cracks, high hardness and is not easy to be damaged | N/A | N/A | ||||||||

| 90 | |||||||||||

| The block has relative dislocation, multiple groups of intersecting fissures, and the coal body is hard. | 80 | |||||||||

| 70 | |||||||||||

| The coal seam is curved, the coal joint density is large, and the coal body hardness is low. | 60 | |||||||||

| 50 | |||||||||||

| The coal body is cemented by grains, with many cracks, which are easy to twist into fragmentation. | 40 | |||||||||

| 30 | |||||||||||

| The rock mass is extremely broken and mixed, consisting of angular or rounded fragments | N/A | N/A | 20 | |||||||

| 10 | |||||||||||

| H/Pixel | Percent/% |

|---|---|

| 50 < H < 75 | 0.68 |

| 25 < H < 50 | 3.15 |

| 0 < H < 25 | 90.12 |

| A/Pixel2 | Percent/% |

|---|---|

| 500 < A < 1000 | 0.29 |

| 100 < A < 500 | 4.20 |

| 0 < A < 100 | 91.44 |

| No. | Quantity | Average Length | Average Width | Occupancy |

|---|---|---|---|---|

| 1 | 30 | 90 | 8.32 | 0.24 |

| 2 | 42 | 28 | 3.44 | 0.13 |

| 3 | 27 | 67 | 3.74 | 0.27 |

| 4 | 38 | 52 | 1.35 | 0.17 |

| 5 | 151 | 33 | 2.14 | 0.04 |

| 6 | 12 | 143 | 26.9 | 0.06 |

| 7 | 16 | 67 | 4 | 0.07 |

| 8 | 38 | 136 | 4.6 | 0.09 |

| 9 | 59 | 45 | 2.6 | 0.52 |

| 10 | 78 | 73 | 12 | 0.52 |

| Mode | Speed (r/min) | Frequency (Hz) | Geological Strength Index (GSI) |

|---|---|---|---|

| High speed | 46 | 50 | 70–100 |

| Medium speed | 35 | 40 | 35–70 |

| Low speed | 23 | 30 | 0–35 |

| No. | Estimated Value | Detection Value | Relative Error (%) |

|---|---|---|---|

| 1 | 58 | 58 | 0 |

| 2 | 73 | 72 | 1.4 |

| 3 | 91 | 92 | 1.1 |

| 4 | 62 | 61 | 1.6 |

| 5 | 77 | 76 | 1.3 |

| 6 | 59 | 58 | 1.7 |

| 7 | 68 | 69 | 1.5 |

| 8 | 77 | 78 | 1.3 |

| 9 | 56 | 55 | 1.8 |

| 10 | 65 | 66 | 1.5 |

| 11 | 76 | 74 | 2.6 |

| 12 | 86 | 86 | 0 |

| 13 | 58 | 56 | 3.5 |

| 14 | 76 | 75 | 1.3 |

| 15 | 65 | 64 | 1.5 |

| 16 | 93 | 95 | 2.2 |

| 17 | 83 | 82 | 1.2 |

| 18 | 66 | 68 | 3 |

| 19 | 49 | 50 | 2 |

| 20 | 55 | 56 | 1.8 |

| No. | Time (s) | Uniform Energy Consumption (kW·h) | Eegulation Energy Consumption (kW·h) | Energy Consumption Comparison |

|---|---|---|---|---|

| 1 | 300 | 1.5 | 1.43 | 4.7% |

| 2 | 300 | 1.5 | 1.4 | 6.6% |

| 3 | 300 | 1.5 | 1.45 | 3.3% |

| 4 | 300 | 1.5 | 1.43 | 4.7% |

| 5 | 300 | 1.5 | 1.41 | 6% |

| 6 | 300 | 1.5 | 1.4 | 6.6% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, Z.; Zhang, X.; Yang, W.; Lei, M.; Zhang, C.; Wan, J.; Han, L. Automatic Cutting Speed Control System of Boom-Type Roadheader Based on Geological Strength Index. Minerals 2022, 12, 1582. https://doi.org/10.3390/min12121582

Dong Z, Zhang X, Yang W, Lei M, Zhang C, Wan J, Han L. Automatic Cutting Speed Control System of Boom-Type Roadheader Based on Geological Strength Index. Minerals. 2022; 12(12):1582. https://doi.org/10.3390/min12121582

Chicago/Turabian StyleDong, Zheng, Xuhui Zhang, Wenjuan Yang, Mengyu Lei, Chao Zhang, Jicheng Wan, and Lei Han. 2022. "Automatic Cutting Speed Control System of Boom-Type Roadheader Based on Geological Strength Index" Minerals 12, no. 12: 1582. https://doi.org/10.3390/min12121582

APA StyleDong, Z., Zhang, X., Yang, W., Lei, M., Zhang, C., Wan, J., & Han, L. (2022). Automatic Cutting Speed Control System of Boom-Type Roadheader Based on Geological Strength Index. Minerals, 12(12), 1582. https://doi.org/10.3390/min12121582